Foam glass blank annealing device

The technology of foam glass and annealing device is applied in the field of annealing device for glass products, which can solve the problem of large occupied space, and achieve the effects of reducing floor space, ensuring physical properties and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

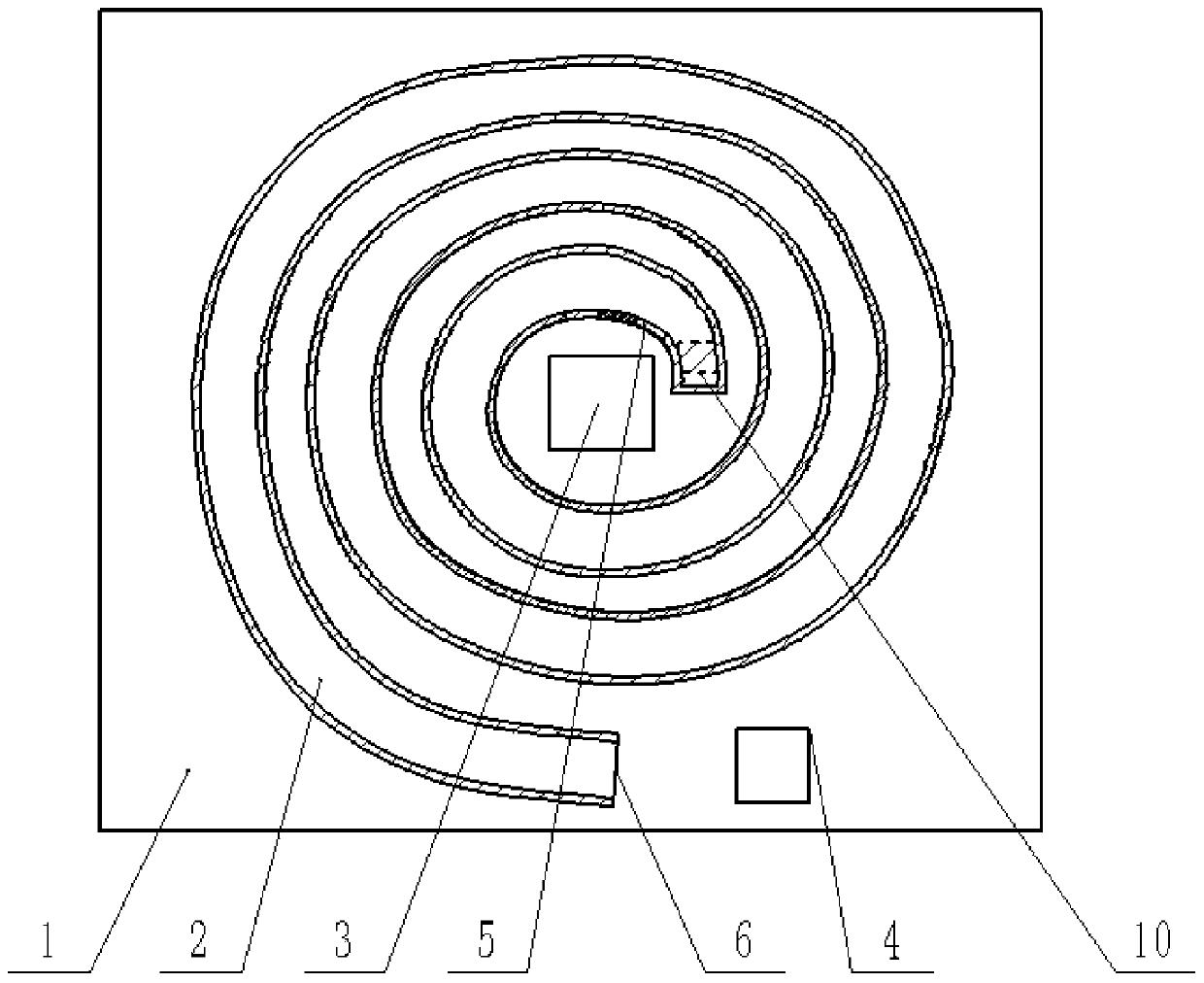

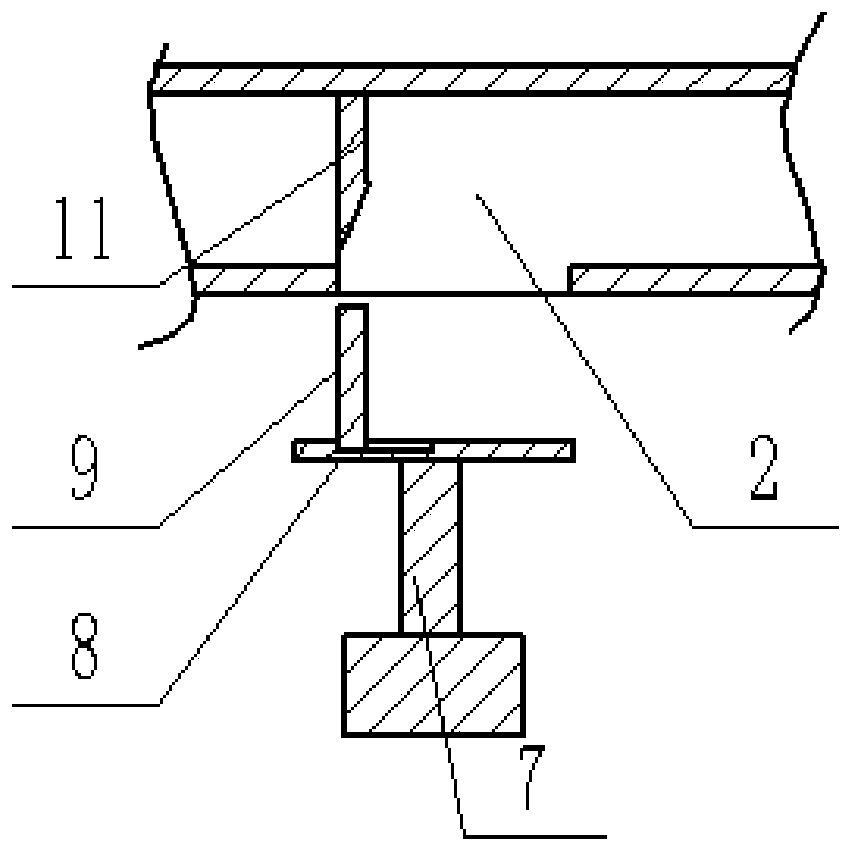

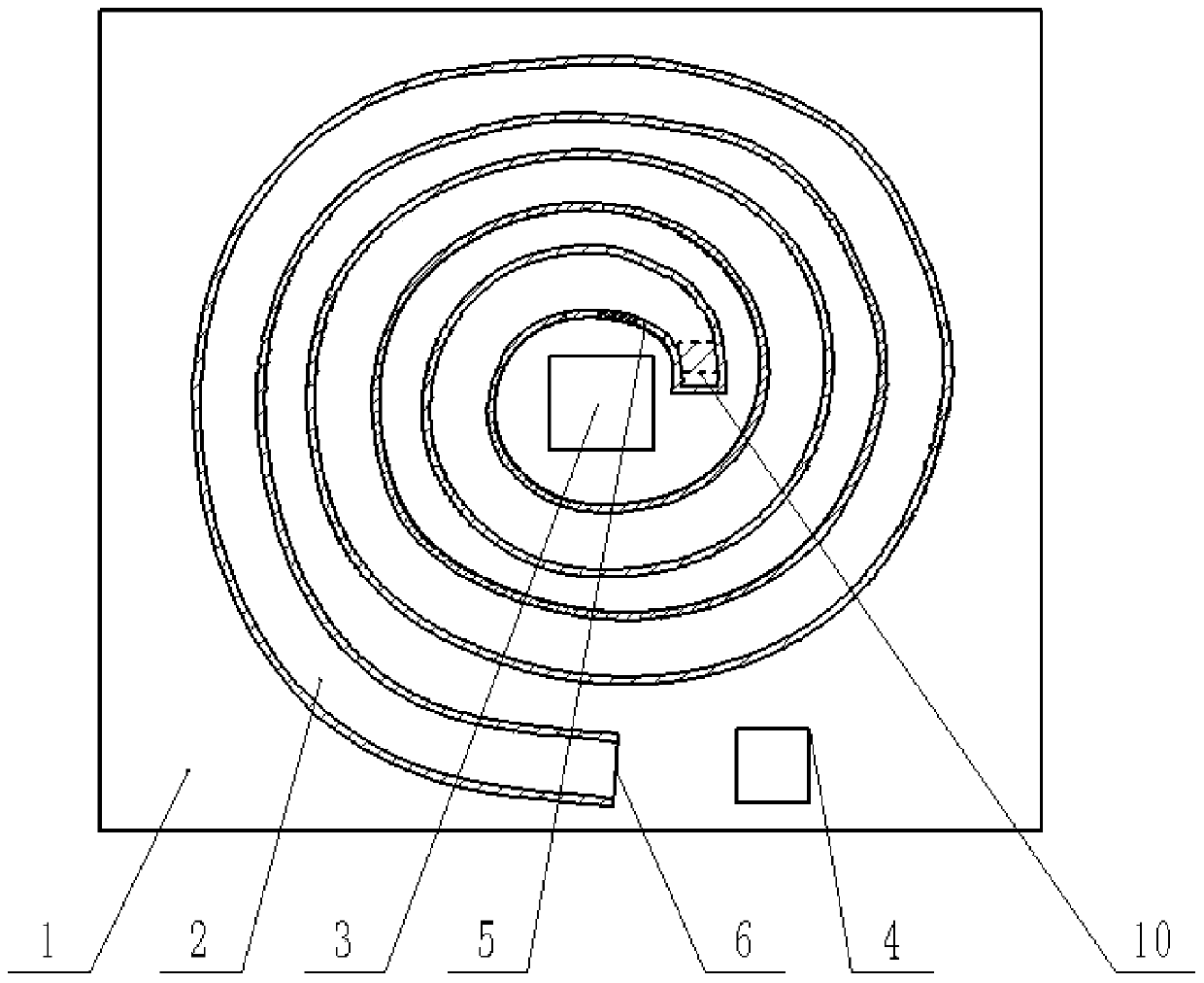

[0022] Foam glass blank annealing device of the present invention, as attached figure 1 and figure 2 As shown, it includes a base plate 1 , a motor for rotating the base plate 1 , an annealing mechanism located on the upper surface of the base plate 1 and a feeding mechanism located below the base plate 1 . The annealing mechanism includes a screw cap 2 , a heating device 3 in the center of the screw cap 2 and an exhaust fan 4 . The heating device 3 is at the same height as the foam glass. Since the heating device 3 is located in the spiral center of the screw cap 2, if the heating device 3 is lower than the foam glass, hot air will act on the lower end of the foam glass, causing the foam glass to be heated at a temperature step. Inhomogeneity affects its annealing effect. The screw cap 2 is a heat insulating material, and the inner wall of the screw cap 2 is bonded with a high temperature resistant rubber pad. The screw cover 2 is fastened to the base plate 1 and forms a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com