Composite type annealing furnace

An annealing furnace and composite technology, applied in the field of metal heat treatment equipment, can solve the problems of deteriorating working environment, excessive heat dissipation, waste of resources, etc., and achieve the effects of improving thermal efficiency, improving economic benefits, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

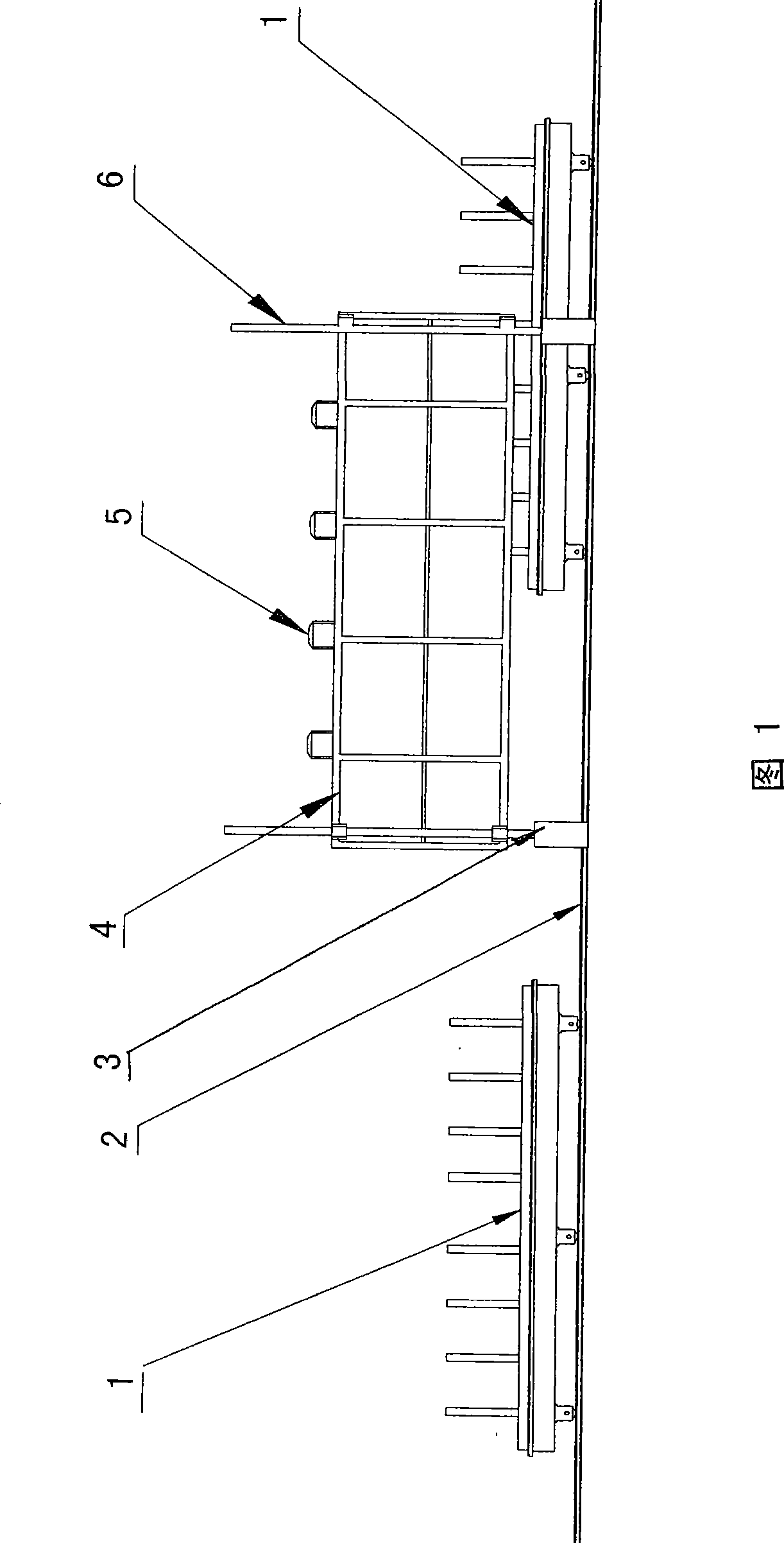

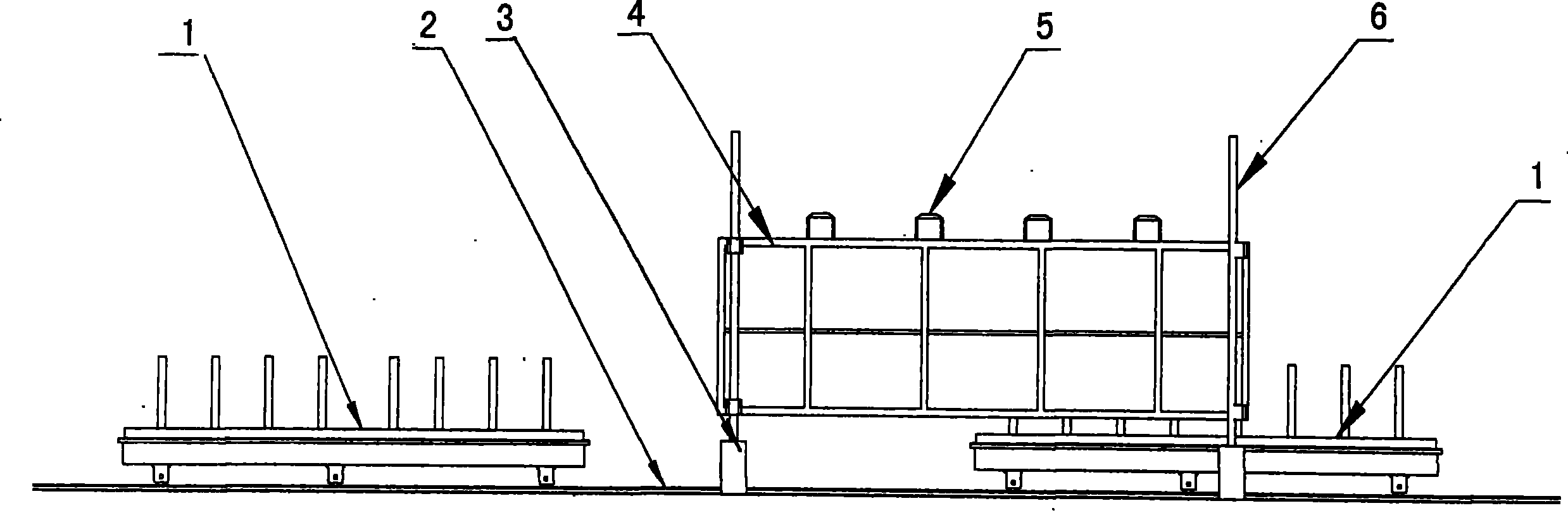

[0014] The annealing furnace shown in Figure 1 has a separate furnace body, consisting of a furnace cover 4, a furnace bottom 1 and a hydraulic lifting device matched with the furnace cover. The furnace cover 4 is equipped with an electric heating system and a hot air circulation system. The air guide cover in the hot air circulation system is made of a stainless steel plate with a thickness of 2 mm, and sheet metal folding and other technological means are used to increase the strength and prevent thermal deformation; The lower double-layer structure realizes the side air inlet and outlet, so that the hot air can pass through the gap between the bar layers, improve the heat exchange efficiency and reduce the temperature difference between the inner and outer layers of the bar.

[0015] Considering factors such as the obstruction of the air flow in the furnace, 4 sets of heat circulation fans 5 are installed on the top of the furnace cover to ensure that the air in the furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com