Patents

Literature

143results about How to "Achieve energy saving and consumption reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

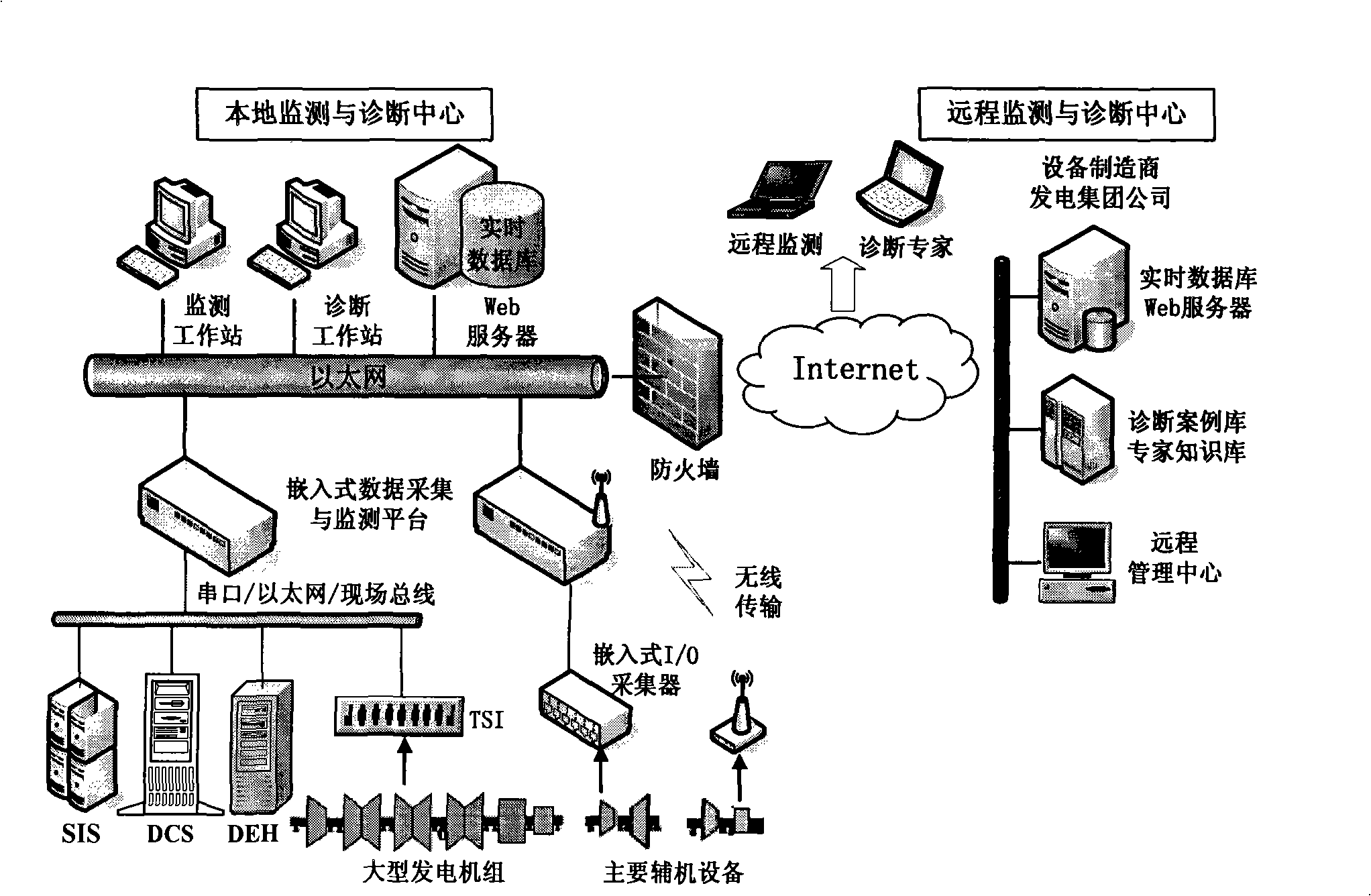

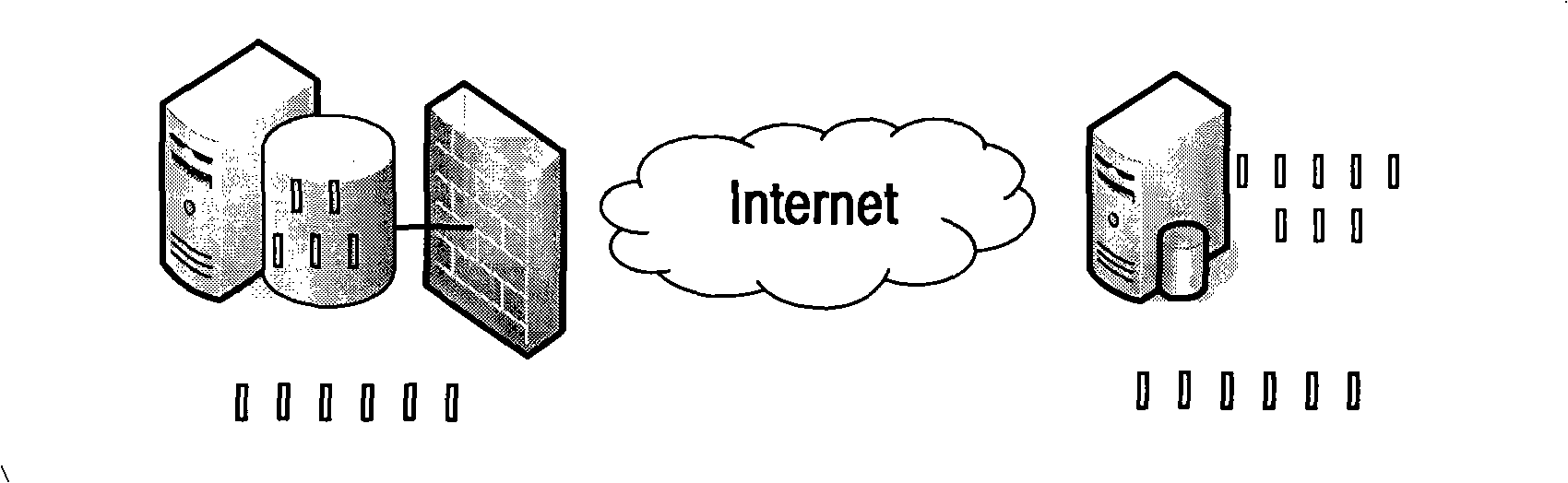

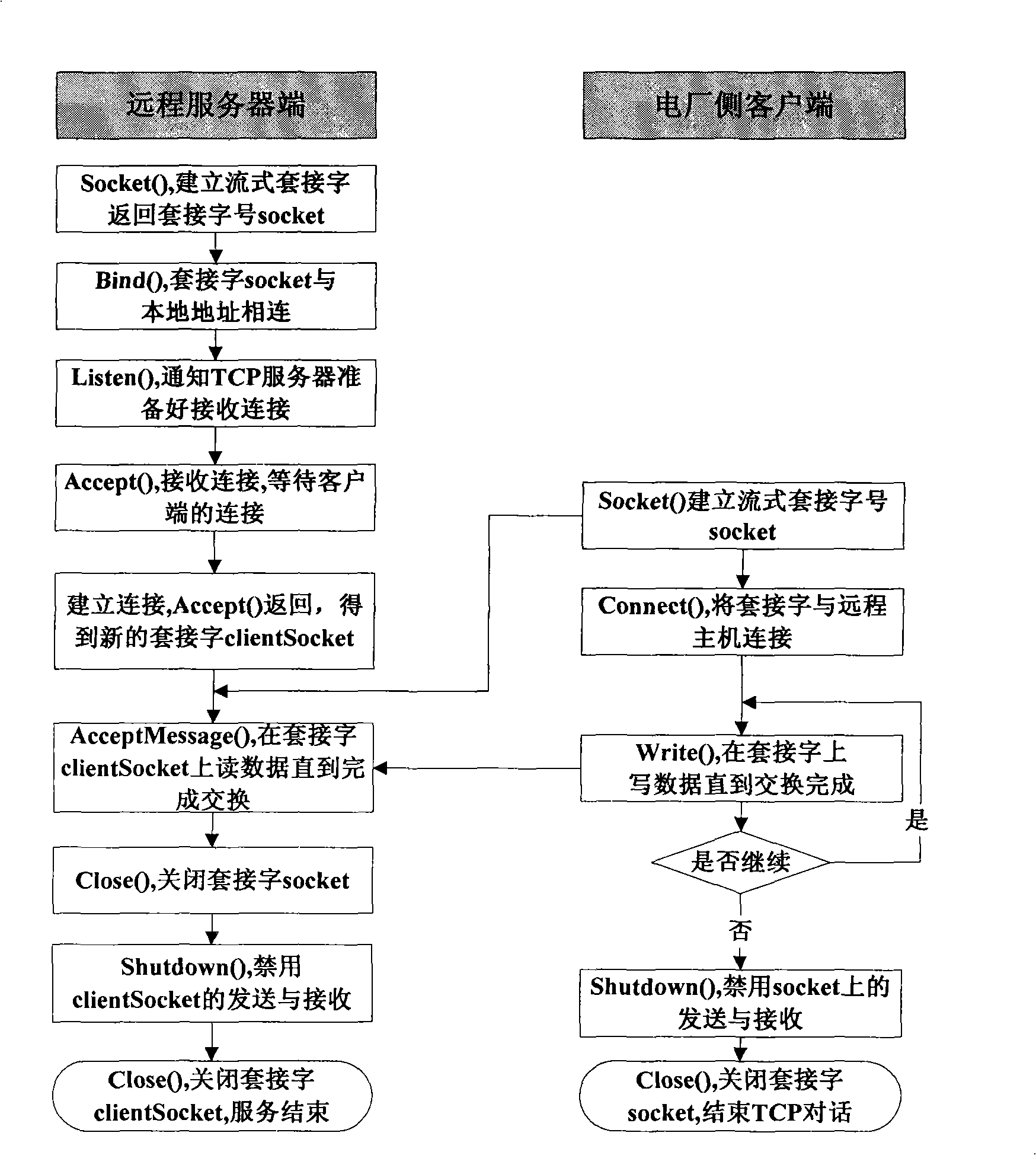

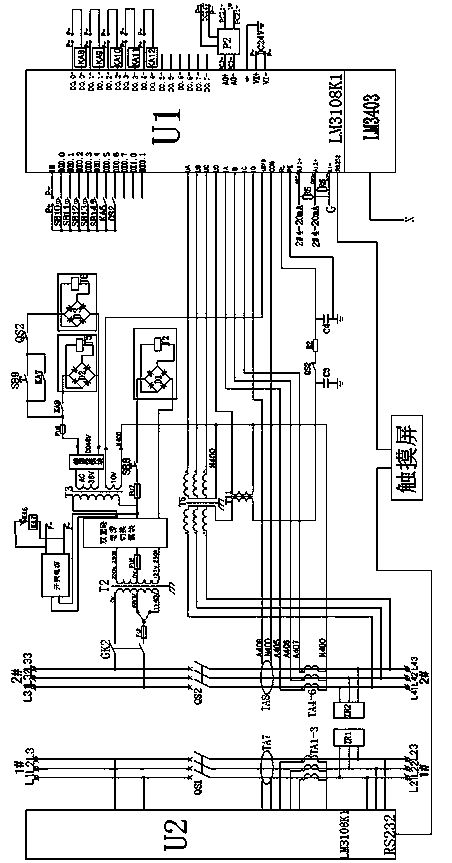

Embedded remote state monitoring system of generating unit

InactiveCN101526586AImprove economyImproving the level of modern scientific managementDynamo-electric machine testingInternet networkWeb server

The invention relates to an embedded remote state monitoring system of a generating unit. The system comprises a local monitoring and diagnosis center and a remote monitoring and diagnosis center which are connected with respective real-time databases and Web servers by Internet network, and a remote monitoring user and a diagnostician can obtain real-time data of the unit from the server of the monitoring and diagnosis center by the network to perform real-time remote state monitoring and diagnosis analysis. The embedded remote state monitoring system can help fully master running state of the generating unit, improve economical efficiency, reliability and operating efficiency of a large generating unit, enhance modernized scientific management level of power enterprises so as to realize energy-saving and consumption reduction of the power enterprises.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

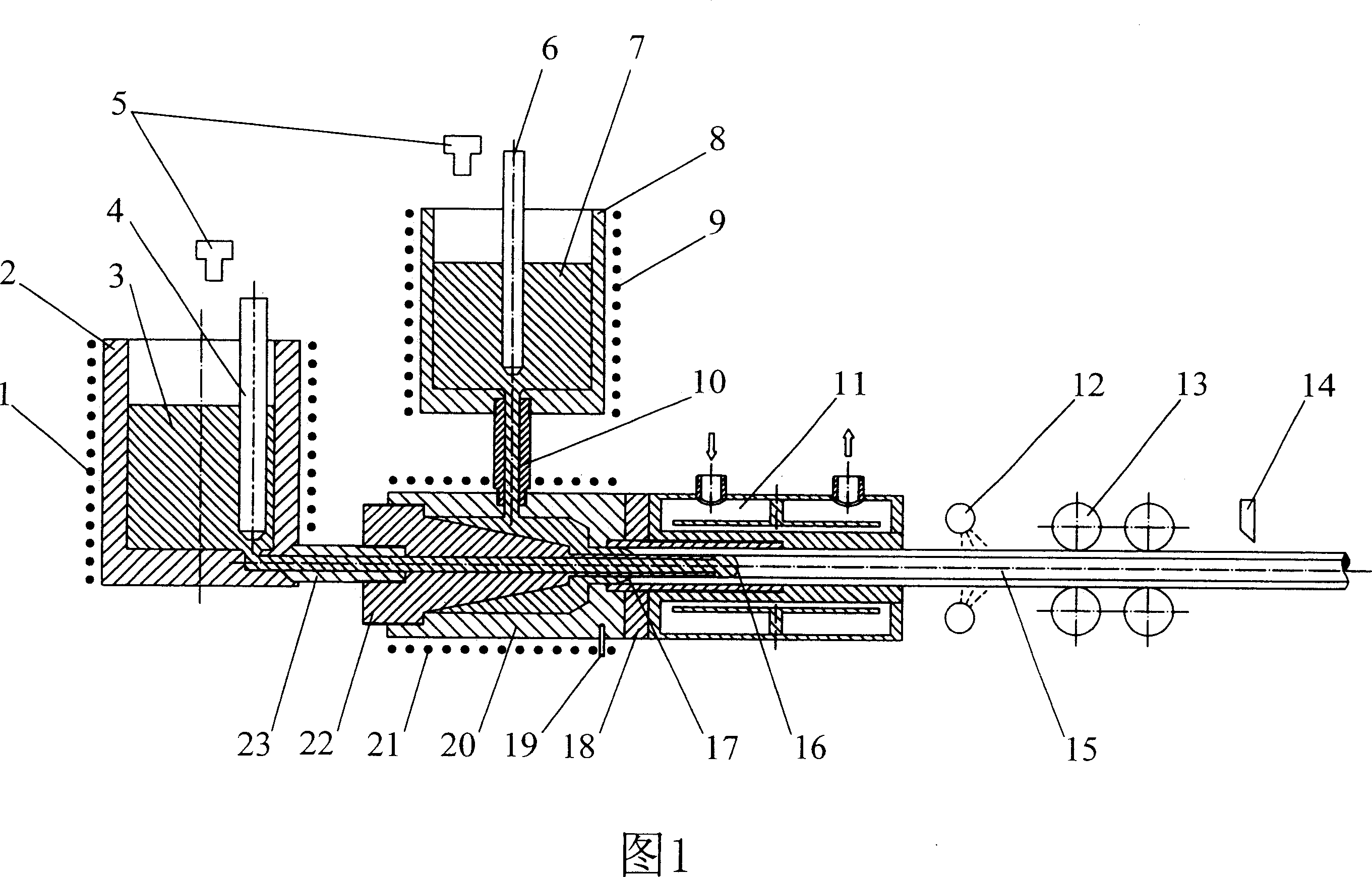

Coating material horizontal continuous casting direct recombination forming apparatus and technology

ActiveCN1927504AAchieve energy saving and consumption reductionContinuous pullHeating elementCrucible

The invention relates to a package material horizontal casting shaping device. Wherein, it comprises core metal temperature-control pot, package metal temperature-control pot, core metal liquid irrigate tube, package metal crystallizer, drawing device, temperature tester, heating element and secondary cooler; and the producing method comprises the temperature of package metal is kept by the package metal temperature-control pot, passing through the package metal thermal-insulated chamber, irrigates into the casting mould formed by crystallizer and irrigate tube to be solidified into package metal tube; the core metal is solidified in the solidified package metal tube, with he package metal tube to form composite cast ingot; the cast ingot via second cooler is cooled and drawn by the drawing device, to be cut by cutter at certain length. The invention has simple process and lower cost, while the interface between package metal and core metal has non oxidization and non pollution.

Owner:UNIV OF SCI & TECH BEIJING

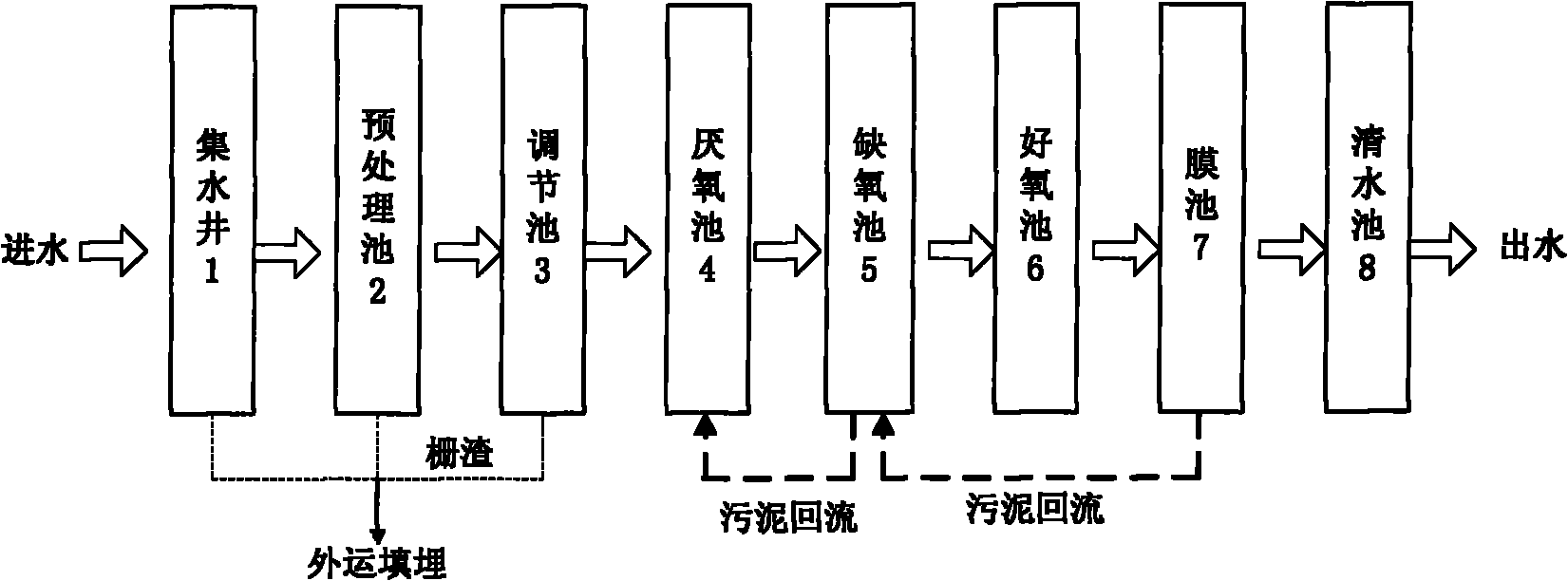

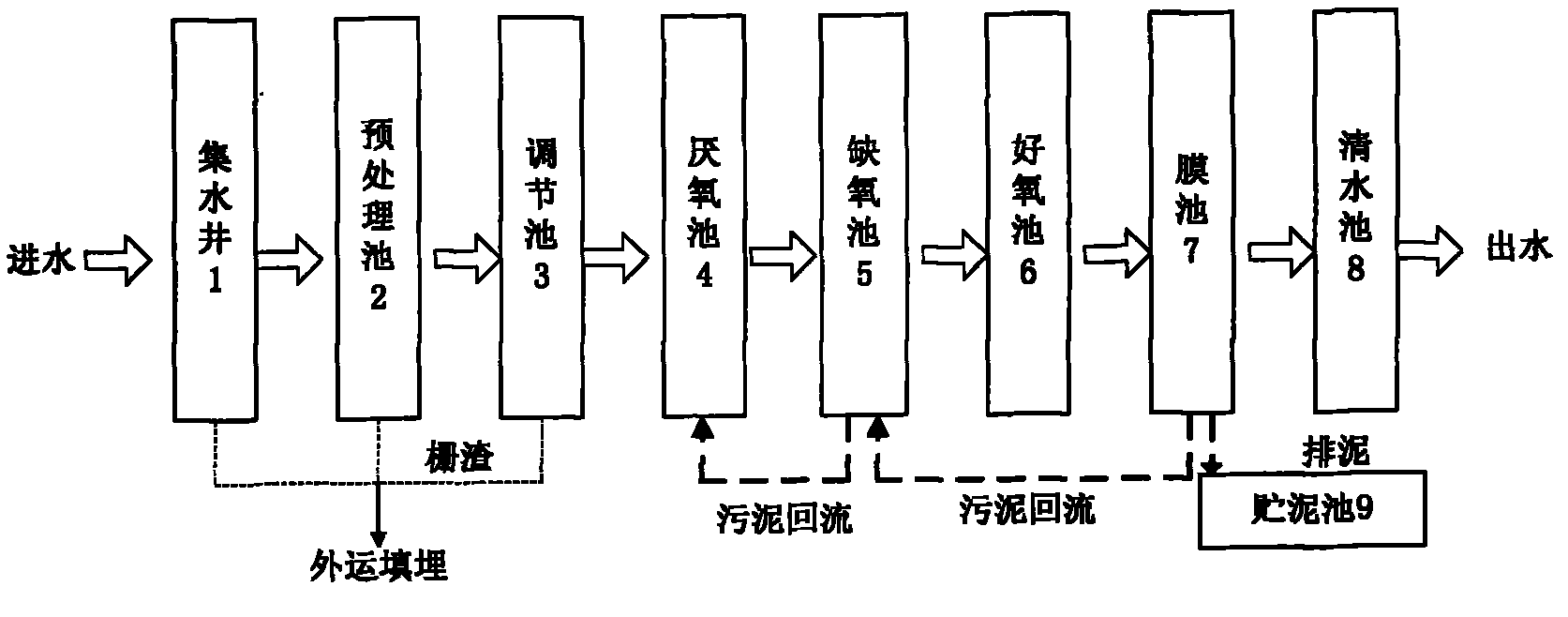

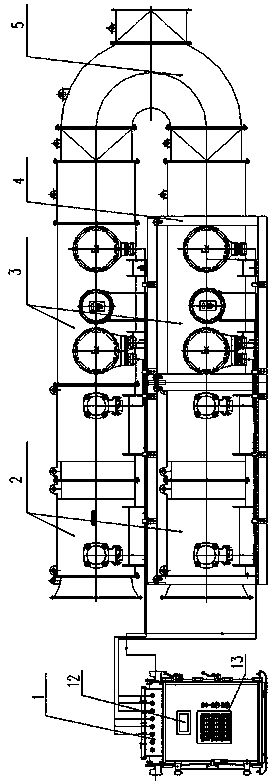

Sewage treatment method and system in ecological sensitive areas

InactiveCN101928096AEfficient removalReach protectionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentVegetable oilWater source

The invention discloses a sewage treatment method and a system in ecological sensitive areas. The method comprises the following steps: larger suspended matters in sewage are removed by using a collecting well the inlet of which is provided with a mechanical coarse screen, the treated sewage enters a pretreatment tank, the suspended matters are further removed by the coarse screen, animal and vegetable oils and mineral oils are removed by an oil separator, and the retreated sewage enters a regulating reservoir to equalize the water quantity and water quality; the pretreated sewage enters an anaerobic tank to be mixed with backflow mixed liquor from an anoxic tank; effluent from the anaerobic tank and the backflow mixed liquor from a membrane pool are mixed to enter the anoxic tank, and effluent from the anoxic tank enters an aerobic tank; effluent from the aerobic tank enters the membrane pool to be biodegraded; and the effluent is filtered by membranes. By adopting an anaerobic-anoxic-aerobic-MBR mode, the invention has higher treatment efficiency and stability and can effectively remove COD, BOD, TN, TP and oils in the sewage; and the effluent meets first grade A emission requirements, and can be used as a reuse water source, thereby protecting the environment and saving the water resources. The invention is especially suitable for treating rural domestic sewage and catering wastewater in the ecological sensitive areas.

Owner:TSINGHUA UNIV

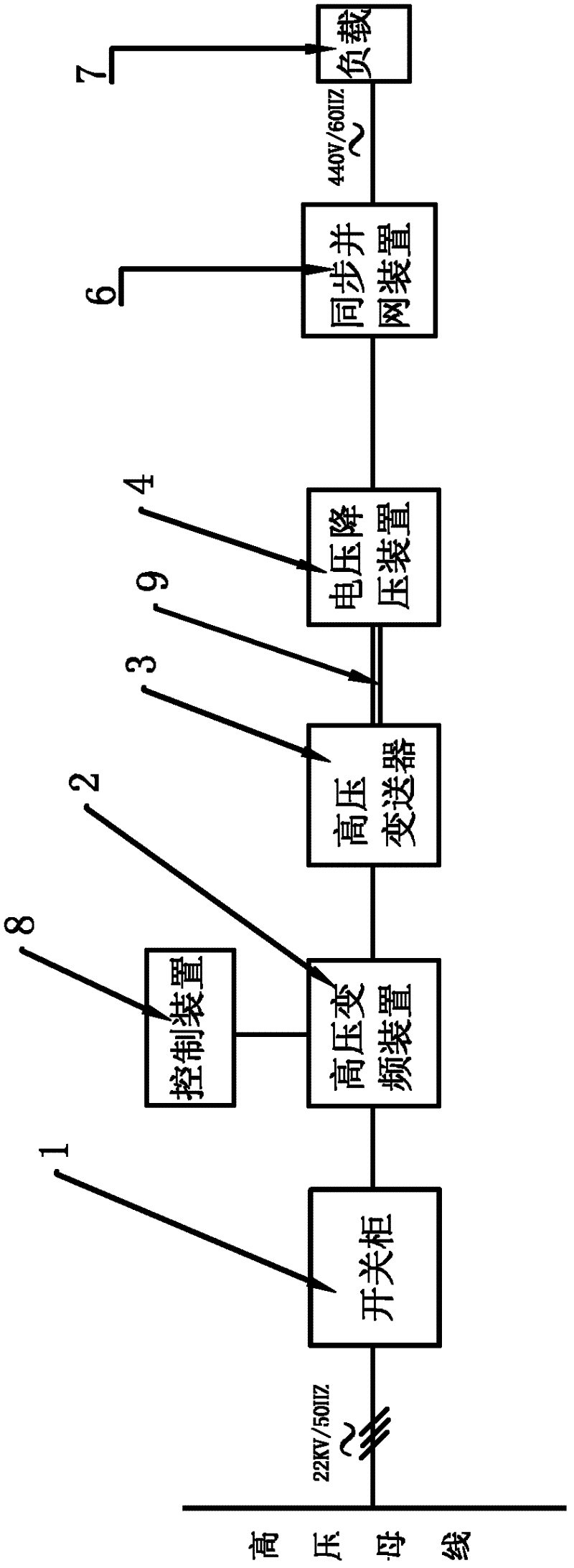

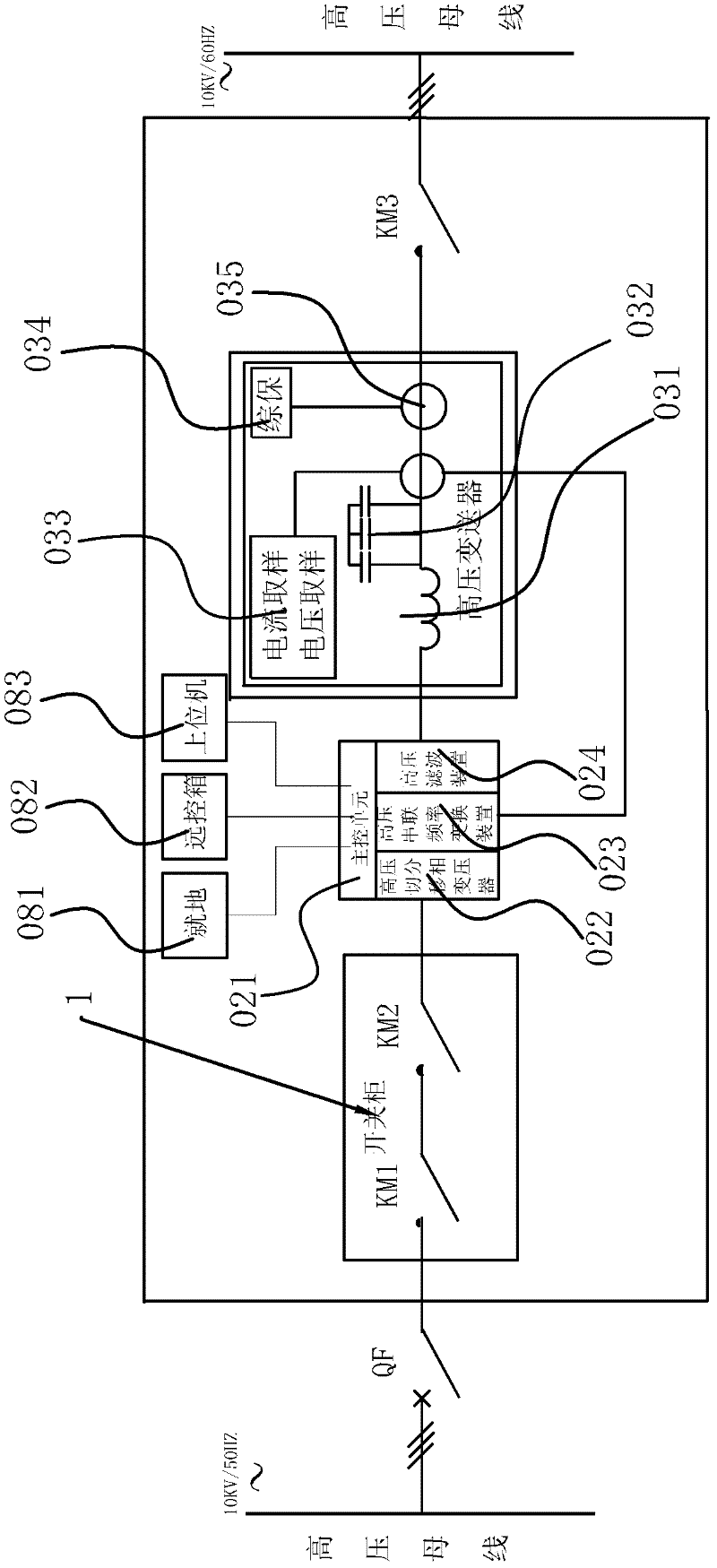

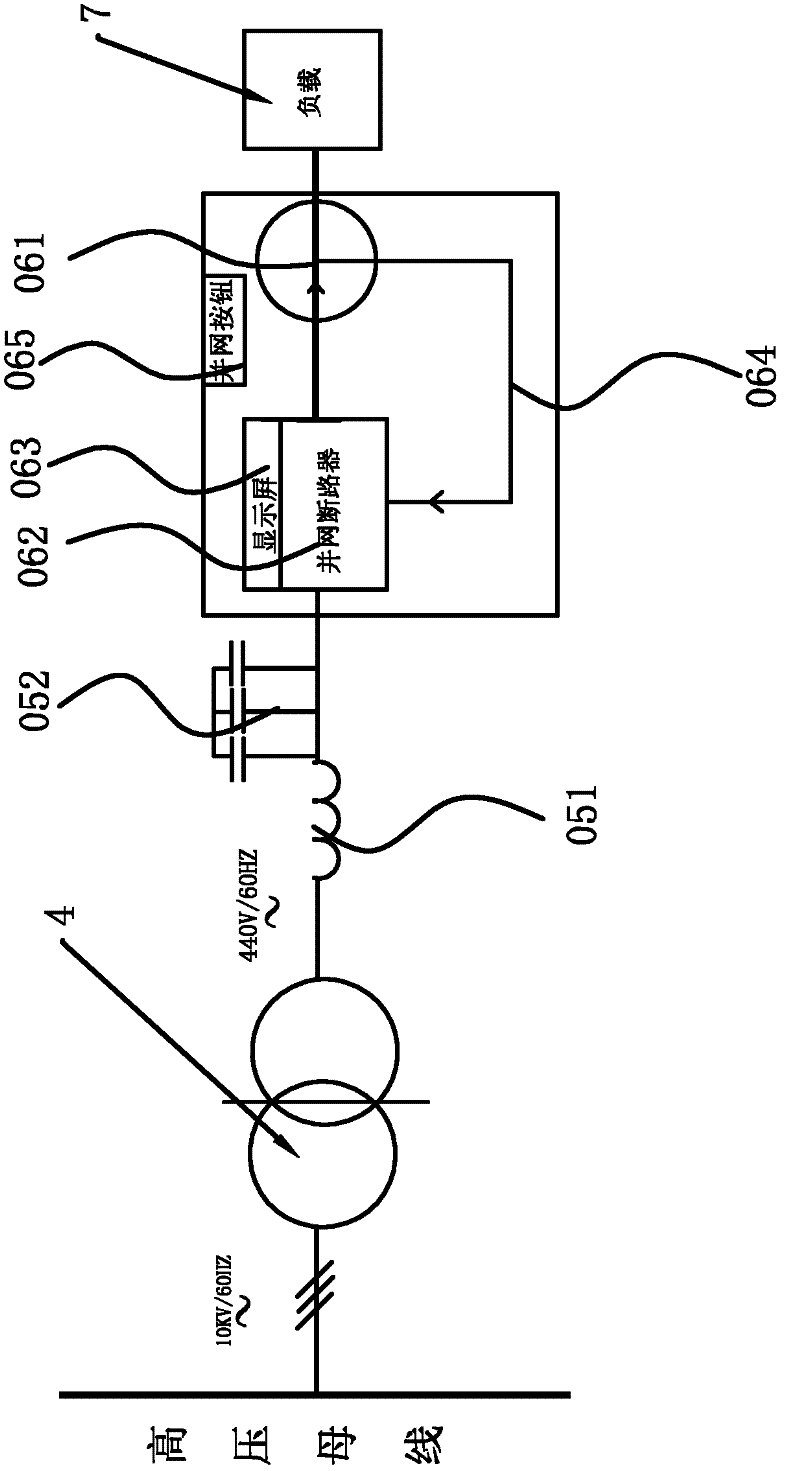

Shore power supply for ship

InactiveCN102255517AReduce the numberReduce noiseFlexible AC transmissionConversion with intermediate conversion to dcLow voltageAlternating current

The invention provides a shore power supply for a ship, which belongs to the technical field of ship power supplies and is used for solving the problems that power cannot be supplied remotely or supplied to large-sized ships, uninterrupted parallel running of chips cannot be realized and the like. The shore power supply for the ship comprises a switch cabinet, a shoreside high-voltage frequency conversion device, an onboard voltage reducing device and a synchronous grid-connected device, wherein the shoreside high-voltage frequency conversion device is connected with the switch cabinet; the high-voltage side of the high-voltage frequency conversion device is connected with the high-voltage side of the voltage reducing device through a high-voltage cable; the low-voltage side of the voltage reducing device is connected with the synchronous grid-connected device; three-phase high-voltage alternating current can be subjected to cutting, phase shifting, rectifying and inverting by using the high-voltage frequency conversion device to obtain needed frequency; and three-phase alternating current which is subjected to frequency conversion and voltage reduction can be seamlessly combined into a power grid of the ship, and the power supply of the ship can be switched off by using the synchronous grid-connected device. By adopting the shore power supply, remote power supply or power supply for large-sized ships can be realized, automatic grid-connected operation can be realized, the ship runs unremittingly, and normal production operation is not influenced.

Owner:ZHEJIANG NEW FOLINN ELECTRIC

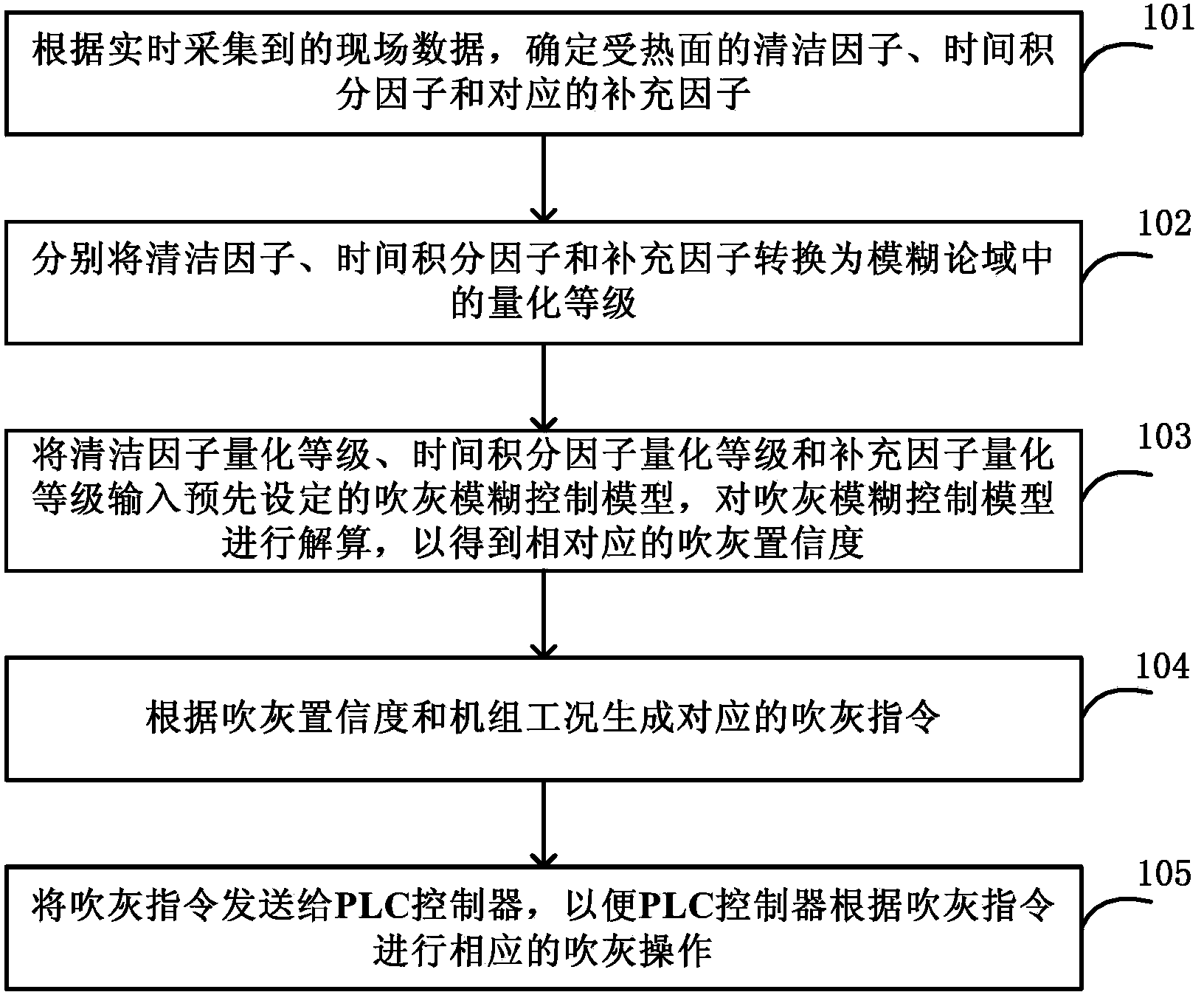

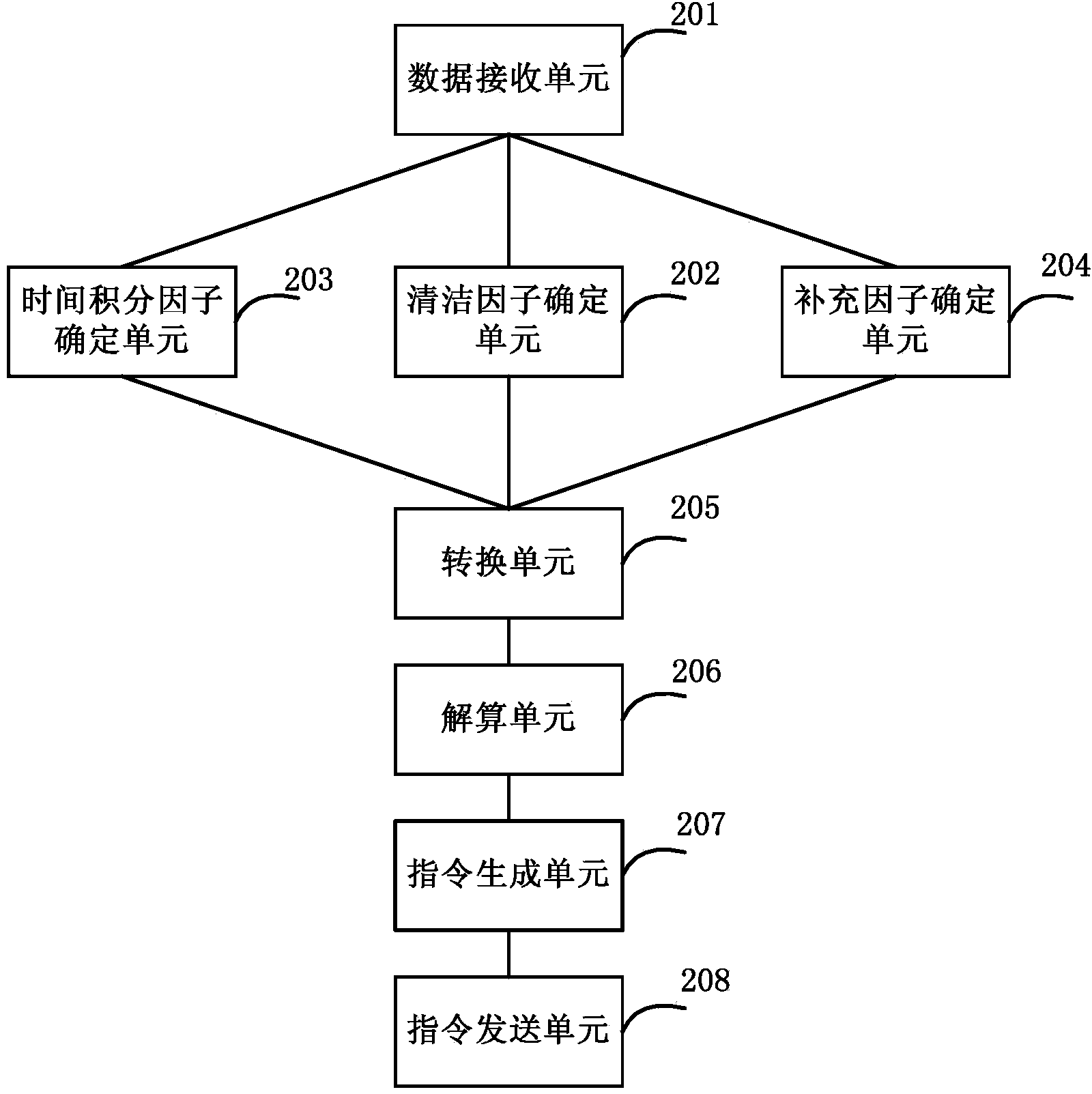

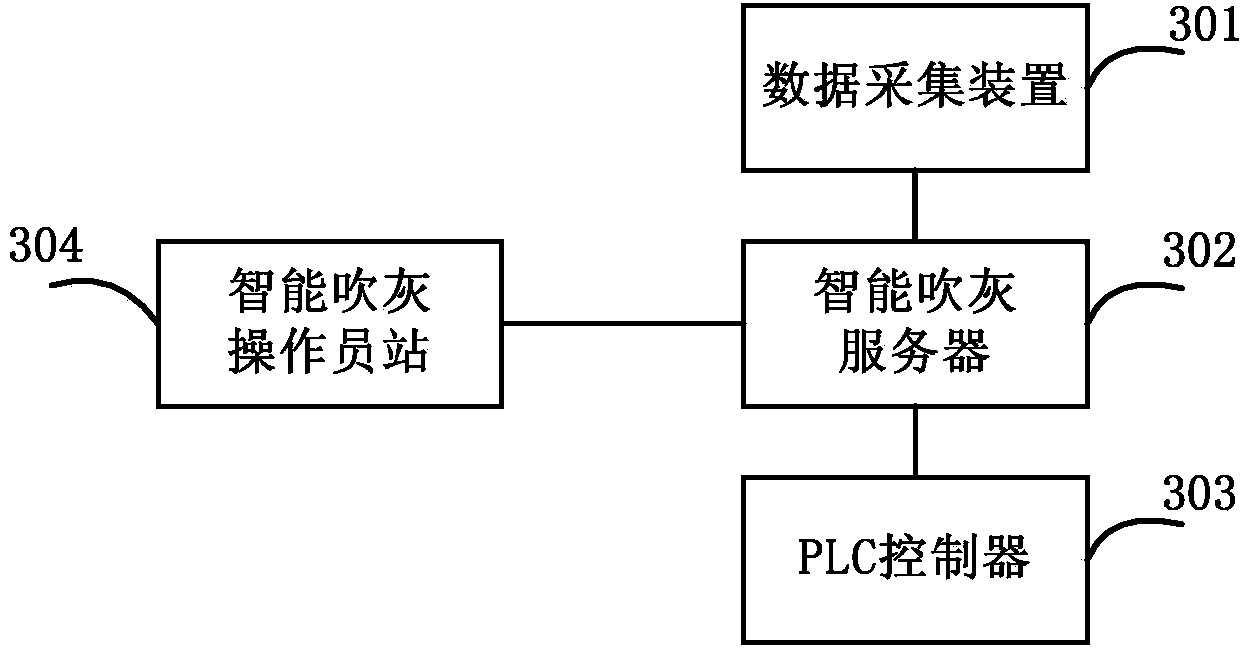

Intelligent soot blowing closed-loop control method, device and system for coal-fired power station boiler

The invention discloses an intelligent soot blowing closed-loop control method, device and system for a coal-fired power station boiler. The method includes the steps that a cleaning factor, a time integral factor and a corresponding supplement factor of a heating surface are determined according to field data collected in real time and are converted into quantization levels respectively in the fuzzy field; the cleaning factor quantization level, the time integral factor quantization level and the supplement factor quantization level are input into a preset soot blowing fuzzy control model, and the soot blowing fuzzy control model is resolved to obtain a corresponding soot blowing confidence coefficient; a corresponding soot blowing instruction is generated according to the soot blowing confidence coefficient and working conditions of a unit and is then sent to a PLC so that the PLC can carry out corresponding soot blowing operation according to the soot blowing instruction. Closed-loop control over a soot blowing system is achieved by comprehensively considering operation factors affecting soot blowing, soot blowing frequency is reduced to the minimum under the condition that heat transfer characteristics of the heating surface are guaranteed, and the purposes of saving energy, reducing consumption and improving the operation economy and safety of the unit are achieved.

Owner:YANTAI LONGYUAN POWER TECH +1

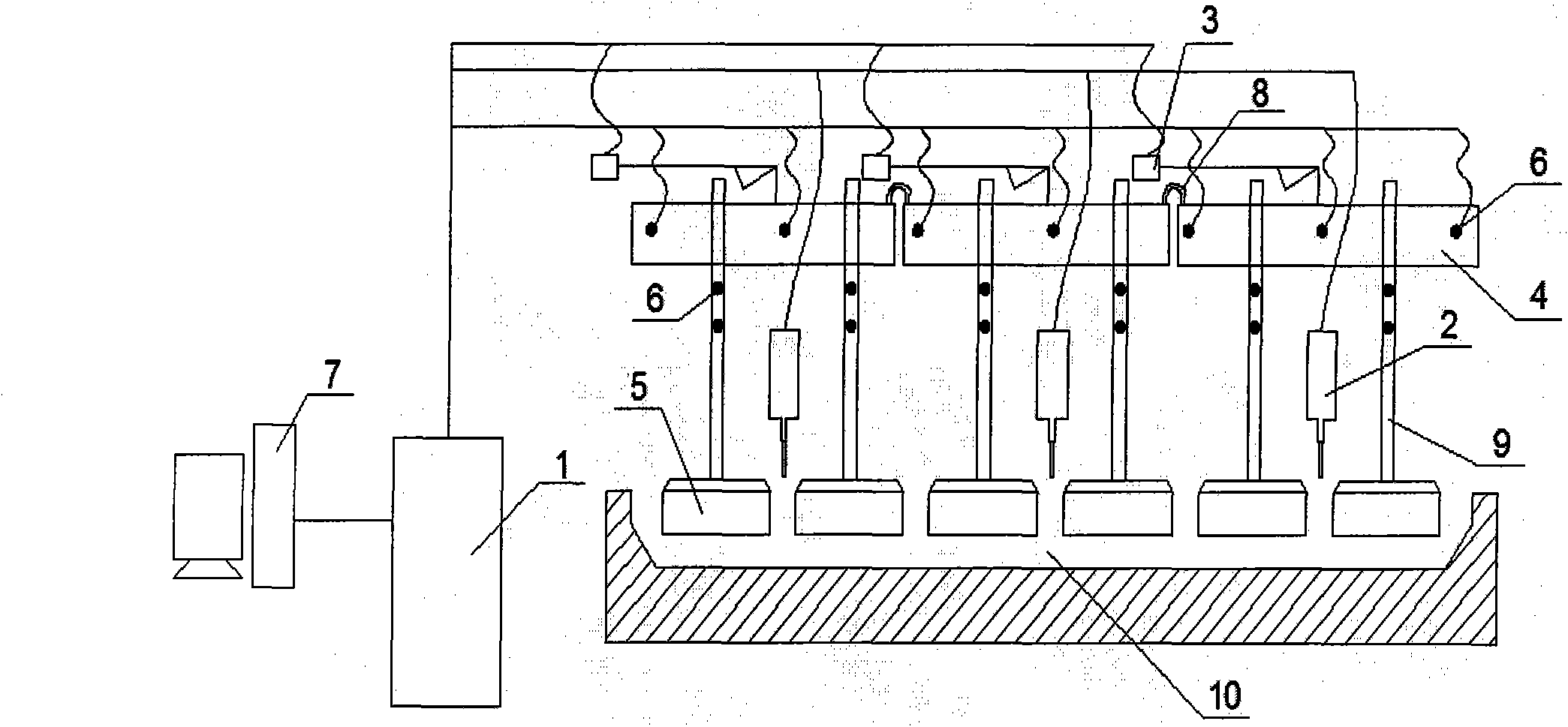

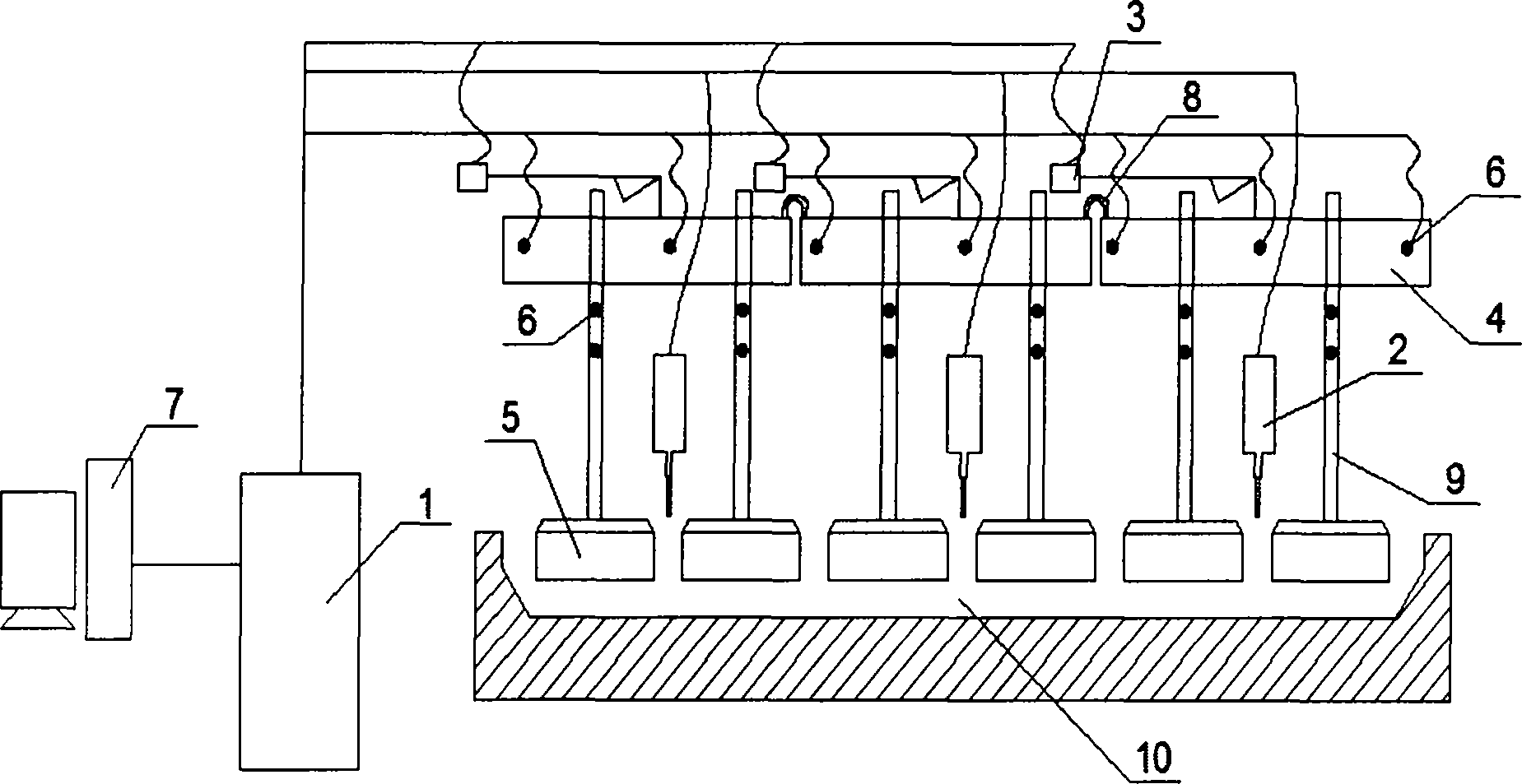

Aluminum electrolysis cell region control system and method

The invention discloses a control system for an electrolysis cell, and particularly relates to an aluminum electrolysis cell region control system for regionally controlling material balance, anode current distribution and aluminum electrolyte interface stability of a pre-baked anode aluminum electrolysis cell by using a region control method and an aluminum electrolysis cell region control method. The system comprises the electrolysis cell and a cell control machine; the electrolysis cell is divided into two or more control regions; and a signal acquisition and processing subsystem, a cell condition diagnosis subsystem, a regional alumina feeding subsystem and a regional polar distance control subsystem are arranged in each control region. The system and the method have the advantages of controlling each control region of the electrolysis cell with pertinence, improving the control precision, performing effective monitoring and separate region control on the abnormal regions, preventing the integral operation from destroying the state of the electrolysis cell, particularly heat balance, facilitating stable electrolysis cell operation, and achieving the effects of saving energy, reducing consumption and improving current efficiency.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

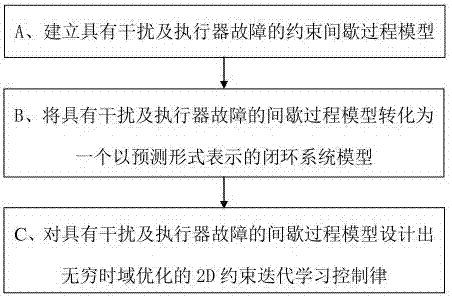

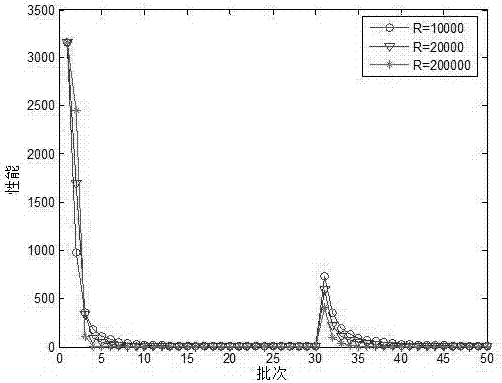

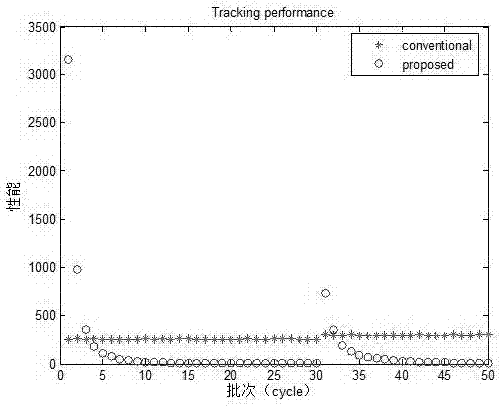

Batch process 2D constraint fault-tolerance control method through infinite time domain optimization

ActiveCN107976942ARealize energy saving and consumption reductionAchieve energy saving and consumption reductionProgramme controlComputer controlLyapunov stabilityFault tolerance

The present invention belongs to the field of automation technology advanced control, and especially relates to a batch process 2D constraint fault-tolerance control method through infinite time domain optimization. An iteration learning control law is designed for a constraint fault control system model with interference, state errors and output errors are introduced, a Roesser model is employedto convert a dynamic model of an original system to a closed-loop system model expressed by a prediction mode, and the designed iteration learning control law is converted to a determined constraint update law; and according to the designed infinite optimization performance index and a 2D system Lyapunov stability theory, giving an update law real-time online design which can ensure the asymptotically stable closed loop system robustness in a linear matrix inequality (LMI) mode. The problem is solved that the control performance cannot be improved with the batch progressive increasing and theproblem of initial value indetermination batch process is solved, and finally, energy saving and consumption reduction are achieved, the cost is reduced, and the generation probability of accidents being harmful for personal safety.

Owner:HAINAN NORMAL UNIV

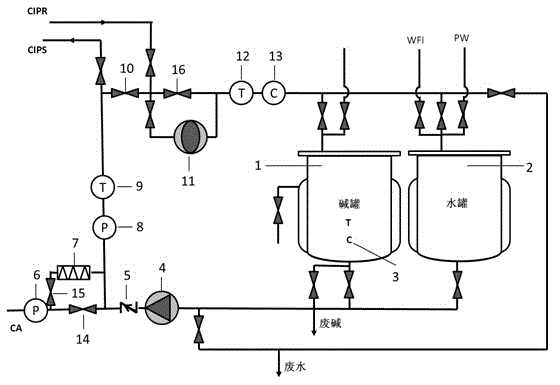

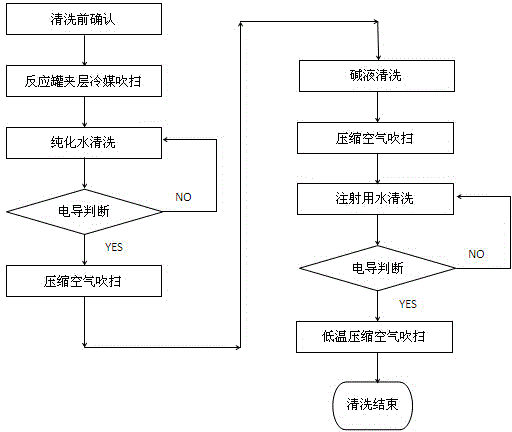

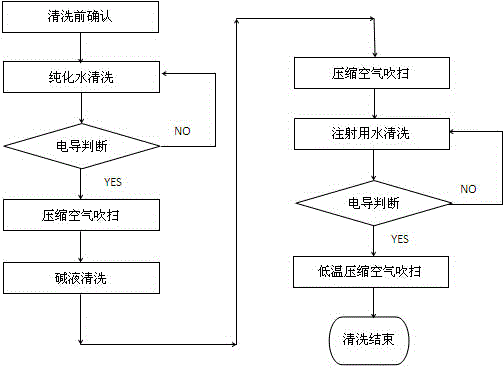

Water-saving cooling type online washing method

The invention belongs to an online washing method used for the field of biological pharmacy, and particularly relates to a water-saving cooling type online washing method. The online washing method is used for cleaning and cooling of reaction tanks and pipes in the field of biological pharmacy. The water-saving cooling type online washing method is a full-automatic online washing method for the reaction tanks and the pipes. The water-saving cooling type online washing method includes the following steps: 1, affirming that washing conditions are met before washing is carried out; 2, carrying out washing through purified water; 3, carrying out blowing through compressed air; 4, carrying out washing through alkali liquor; 5, carrying out blowing through compressed air; 6, carrying out washing through water for injection; 7, carrying out blowing through low-temperature compressed air; 9, finishing. The defects of an existing online washing method are overcome; on the basis that the washing effect is guaranteed, the cooling time after washing is shortened, and meanwhile the aims of saving energy, reducing consumption and saving water can be achieved.

Owner:SHANDONG TAIBANG BIOLOGICAL PROD CO LTD

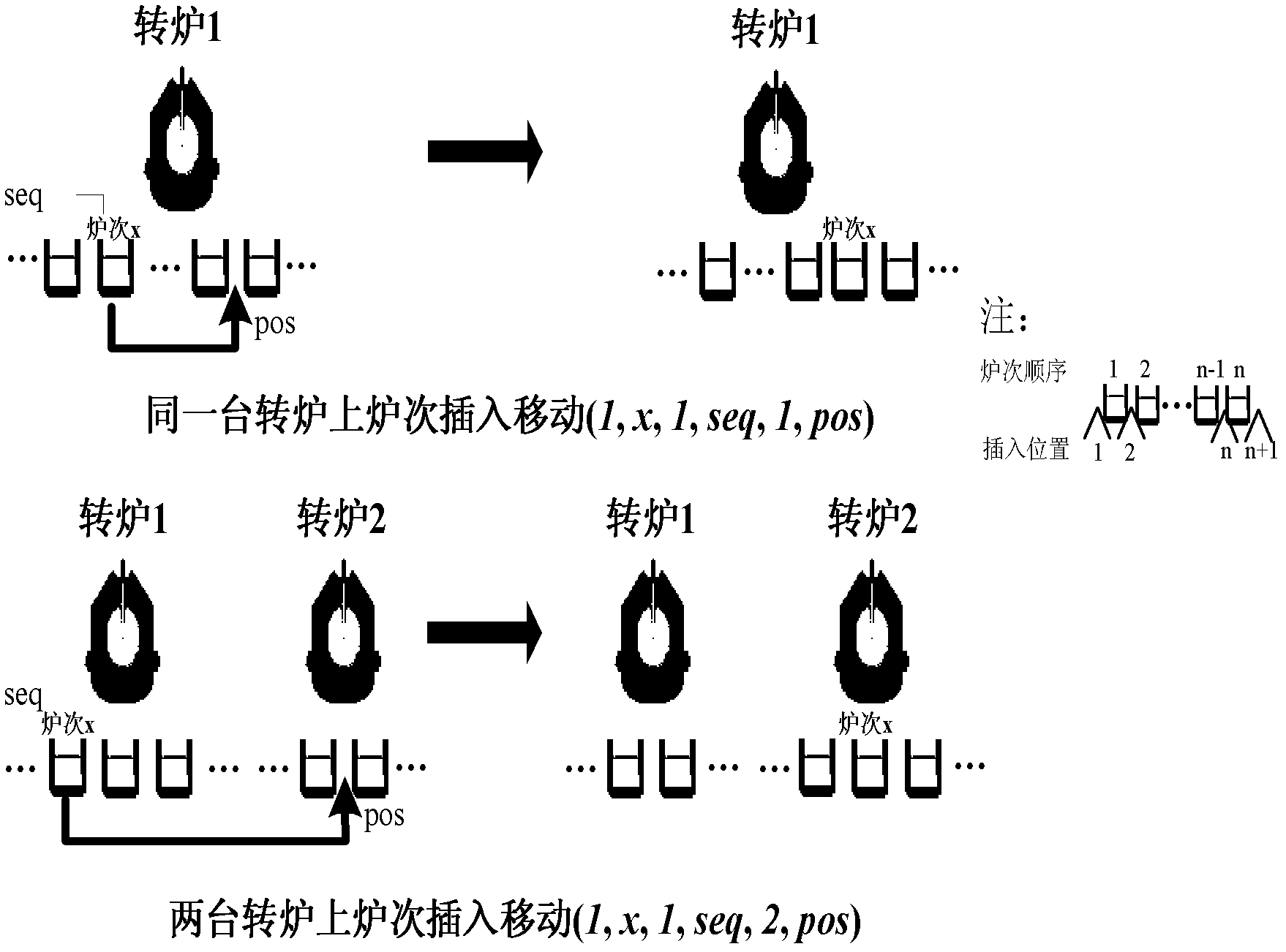

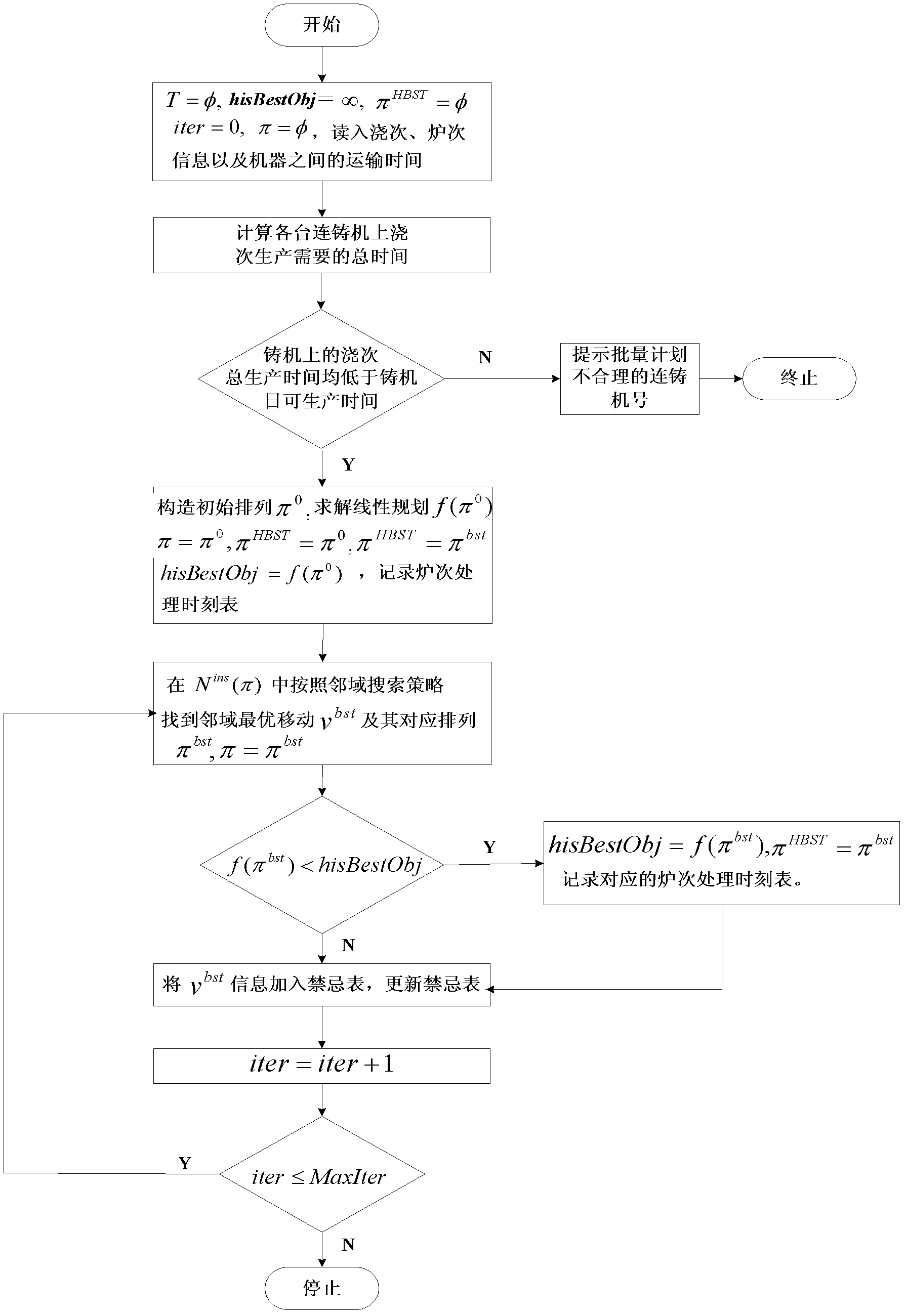

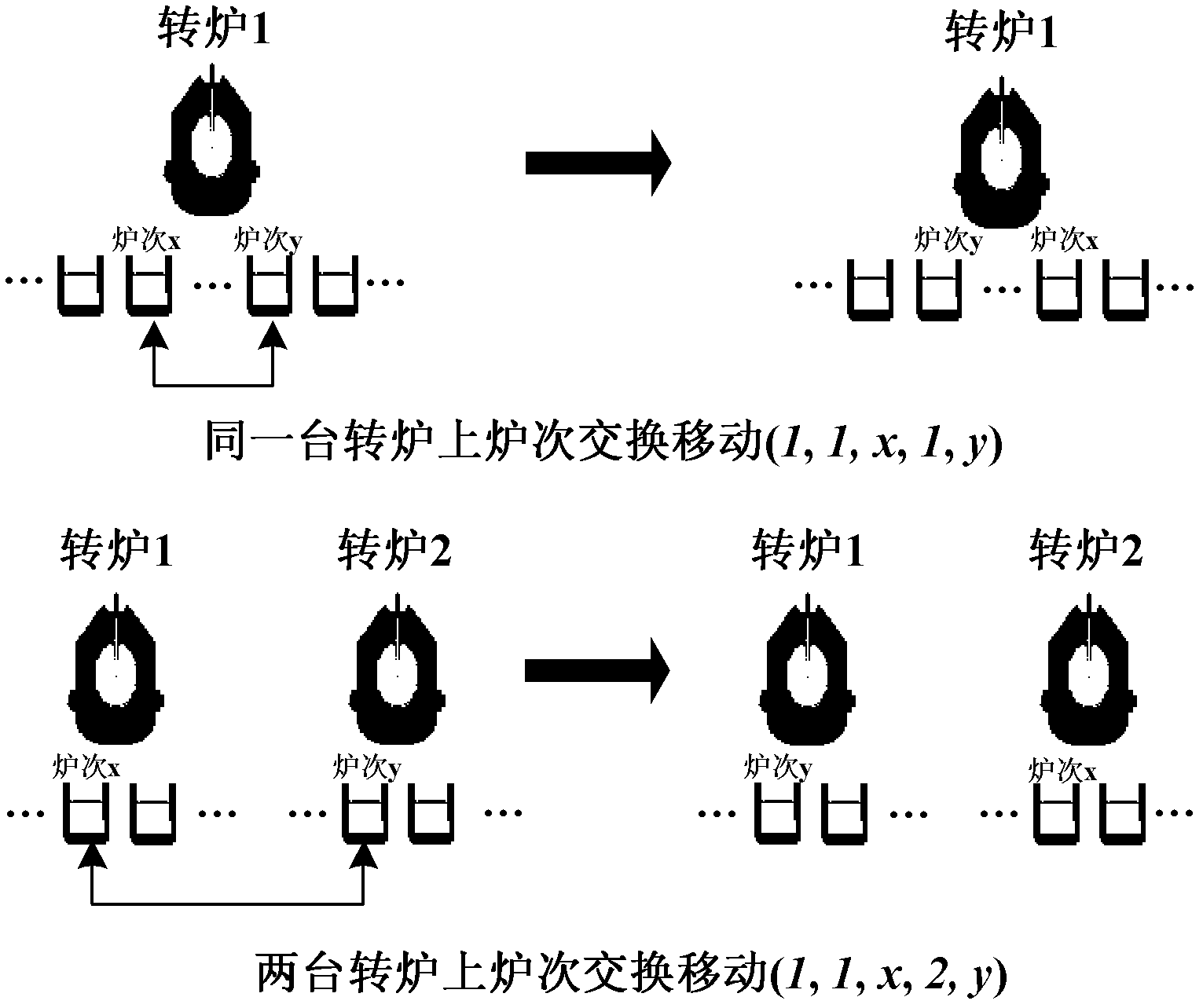

Method for controlling molten steel processing of steelmaking workshop

The invention relates to a method for controlling molten steel processing of a steelmaking workshop. Process constraints in actual production are taken into account to reduce heat losses of molten steel and obtain a process for controlling the molten steel processing of the steelmaking workshop. By adopting the method, prompt production can be achieved, the times of interruption to casting can bereduced, the rate of utilization of production equipment can be increased, the production of a steelmaking plant can be carried out according to the processing startup time of heat on each machine, and the heat can be promptly delivered to a continuous casting machine to ensure continuous casting. Meanwhile, the load on each refining device is uniform, the failure rate is low, and the productivity of the continuous casting machine and the steelmaking workshop can be improved. By adopting the method, new production schemes can be prepared in a short term according to new production environments so as to deal with unavoidable equipment faults and other unexpected accidents. Due to the reasonable and efficient control of the molten steel processing progress, the heat can be utilized on the reasonable machine, excessive heat delivery can be reduced, energy can be saved, the logistic cost can be decreased, the waiting time of molten steel in different procedures and heat losses of the molten steel can be reduced, and the effects of energy conservation and consumption reduction can be achieved.

Owner:NORTHEASTERN UNIV

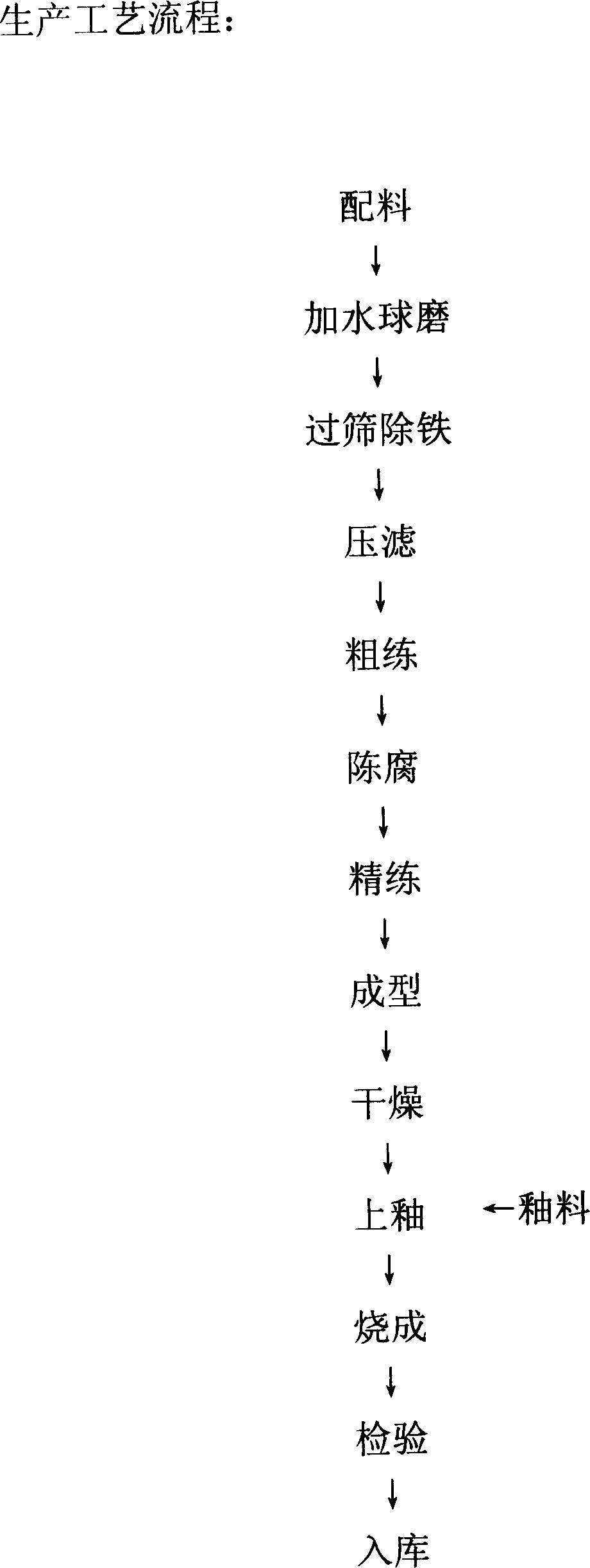

Middle-temperature high-aluminum reinforced porcelain and process for producing same

The invention discloses a middle temperature high-alumina intensification ceramic and manufacturing technique, which comprises the following parts: big-same-sand, wind-transmission potash feldspar, alumina, hunan-wash-mud, Jiangxi lithium chinastone powder, Hunan blach feldspar, calcinations talcum, boundary board soil, and quartz and Guizhou soil. The manufacturing technique comprises the following steps: batching; adding in water and abrading-ball; riddling and deironing; filter-pressing; pugging; ageing scouring; forming; drying; glazing; firing by kiln oven. The veintion has high transverse strength and good heat endurance.

Owner:林伟河

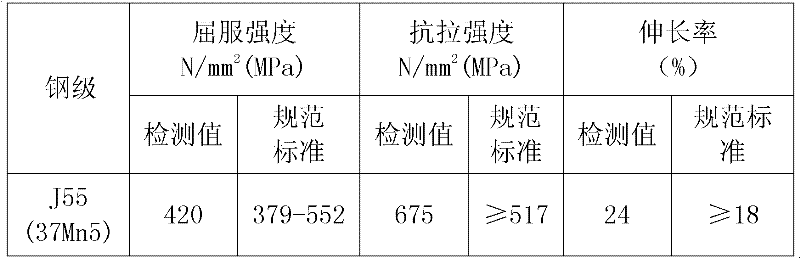

Waste and old oil well pipe performance recovery process

ActiveCN102581542ADense tissueAchieve energy saving and consumption reductionPulp and paper industryPerformance recovery

The invention discloses a waste and old oil well pipe performance recovery process which comprises the following steps: (1) heating; (2) sorting; (3) carrying out constant-diameter wall reducing; (4) carrying out heat diffusion; (5) carrying out negative-tension diameter reducing; (6) sorting and dimensioning; (7) stretching and carrying out a hydraulic test: stretching the sorted and dimensioned waste and old oil well pipes, and carrying out the hydraulic test; and (8) packaging: packaging the detected and qualified waste and old oil well pipes, and putting into service. The waste and old oil well pipe performance recovery process has the advantages that the waste and old oil well pipes are reforged, so that the repaired oil well pipes are more compact in internal structures, higher in corrosion resistance and higher in wear resistance, the waste and old oil well pipes are subjected to same-specification regenerative repair to meet the specification and the API (American Petroleum Institute) standard requirements, and the purposes of saving energy, reducing consumption and changing waste materials into valuable materials are achieved.

Owner:梅河口市弘业无缝钢管有限公司

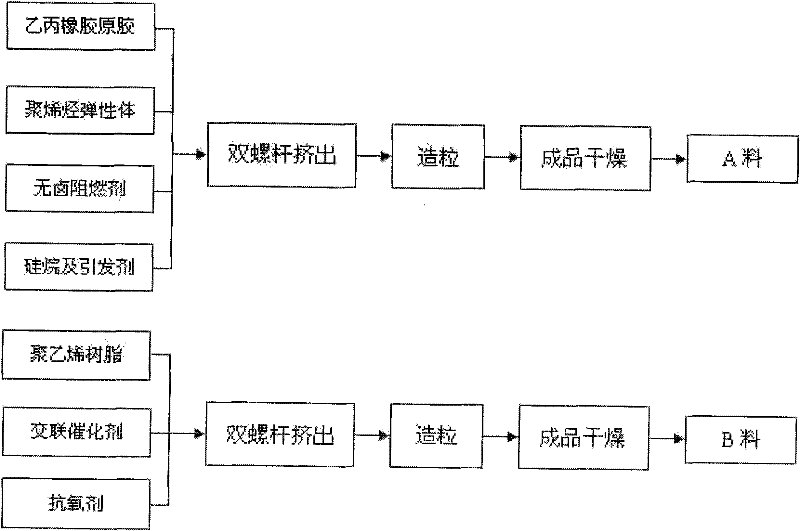

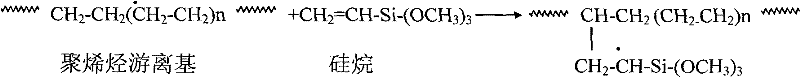

Silane crosslinked halogen-free flame-retardant ethylene-propylene insulating material and preparation method thereof

ActiveCN102295809AImprove insulation performanceGood chemical stabilityPlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention discloses a silane crosslinking halogen-free antiflaming ethyl-propylene insulating material. The material consists of a material A and a material B in a weight ratio of 95:5, wherein the material A comprises the following components in parts by weight: 87-92 parts of ethyl-propylene rubber, 8-13 parts of polyolefin elastomer, 1.4-1.8 parts of silane, 0.1-0.15 part of initiator, 110-130 parts of halogen-free fire retardant and 5-10 parts of lubricant; and the material B comprises the following components in parts by weight: 100 parts of polyethylene resin, 5-10 parts of antioxidant and 1.0-1.5 parts of crosslinking catalyst. The silane crosslinking halogen-free antiflaming ethyl-propylene insulating material provided by the invention not only has good electric insulating property and chemical stability like those of the ethyl-propylene rubber but also has high breaking elongation, and can be used as the substitute of the ethyl-propylene rubber to be used for insulation and sheathing of soft electric wires and cables.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

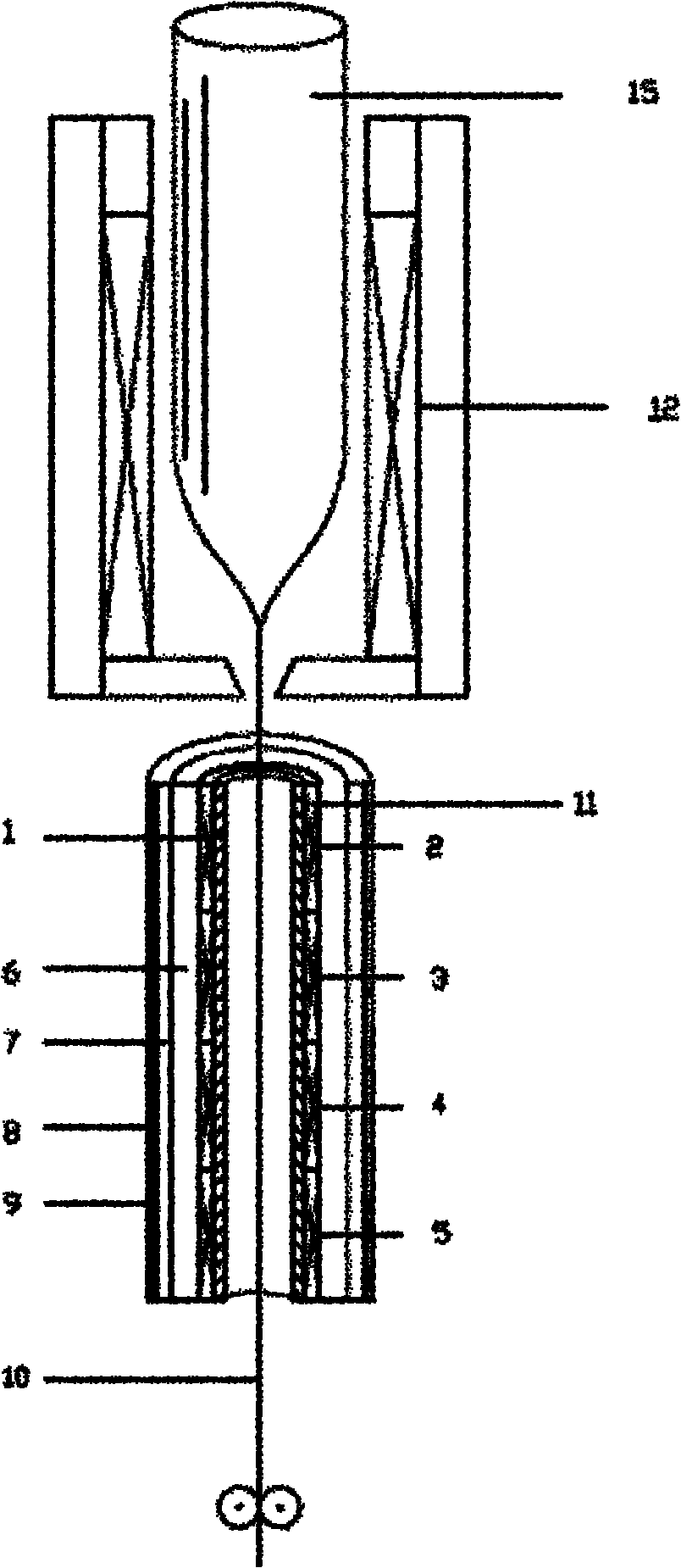

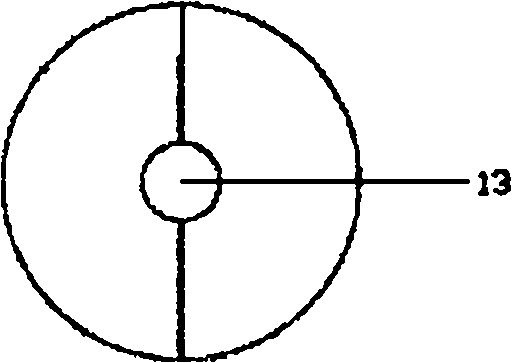

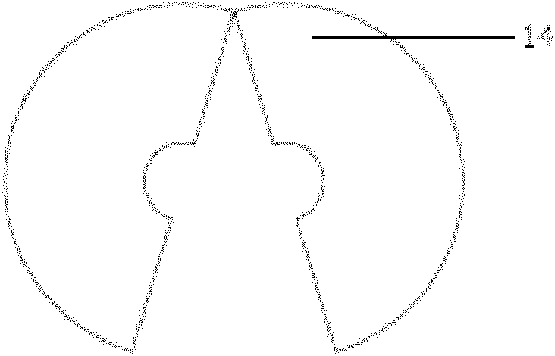

Optical fiber eat treatment method and device

ActiveCN102010123AReduce small density changesReduced Rayleigh backscatter lossGlass making apparatusGlass productionScattering lossStaying time

The invention relates to optical fiber heat treatment method and device. In the method, a maintaining furnace for thrilling the optical fibers is set to perform temperature-preservation heat treatment on optical fibers which are drawn from a fiber drawing furnace and in a high temperature and uncooled state; the temperatures of the optical fibers entering and removing from the maintaining furnace are respectively controlled to be 1400 DEG C-1800 DEG C and 1145 DEG C-1170 DEG C; the optical fibers thrill through the maintaining furnace for 0.08s-0.24s; and the temperature of the chamber of the maintaining furnace is controlled between 600 DEG C and 1300 DEG C. The maintaining furnace has a heat preservation effect on the cores of the optical fibers, the stay time of the optical fibers in an annealing temperature range is prolonged, the internal stress of the optical fibers is relieved, and the Rayleigh back scatter loss is reduced. The maintaining furnace has the advantages of simple structure and reliable performance; the inner chamber of the furnace is directly communicated with ambient air, which avoids the disturbance of protective gas in a drawing channel to the optical fibers, and thus, the stability of high-speed drawing is improved; and the equipment is simplified, and the cost is saved.

Owner:长飞光纤潜江有限公司

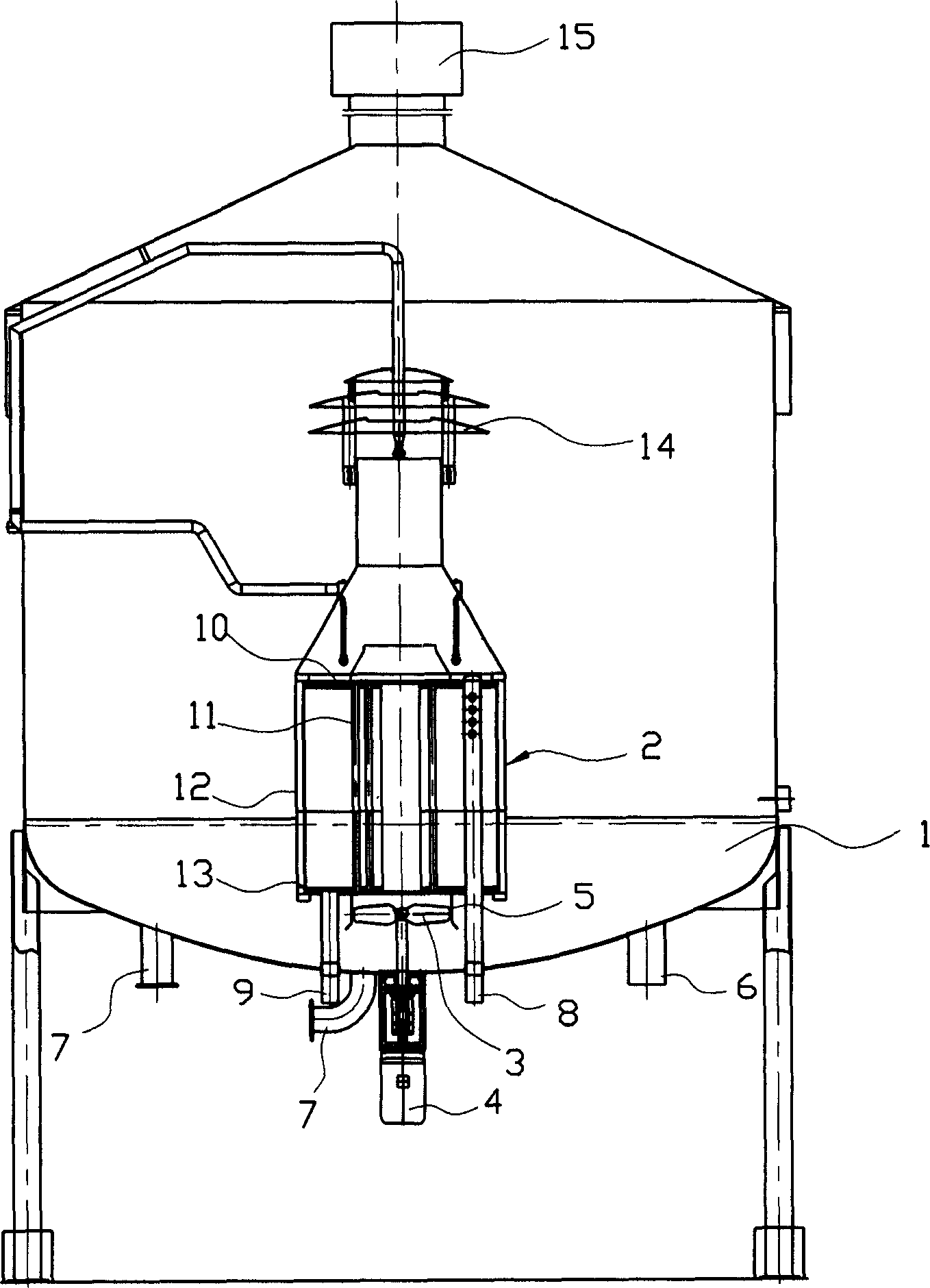

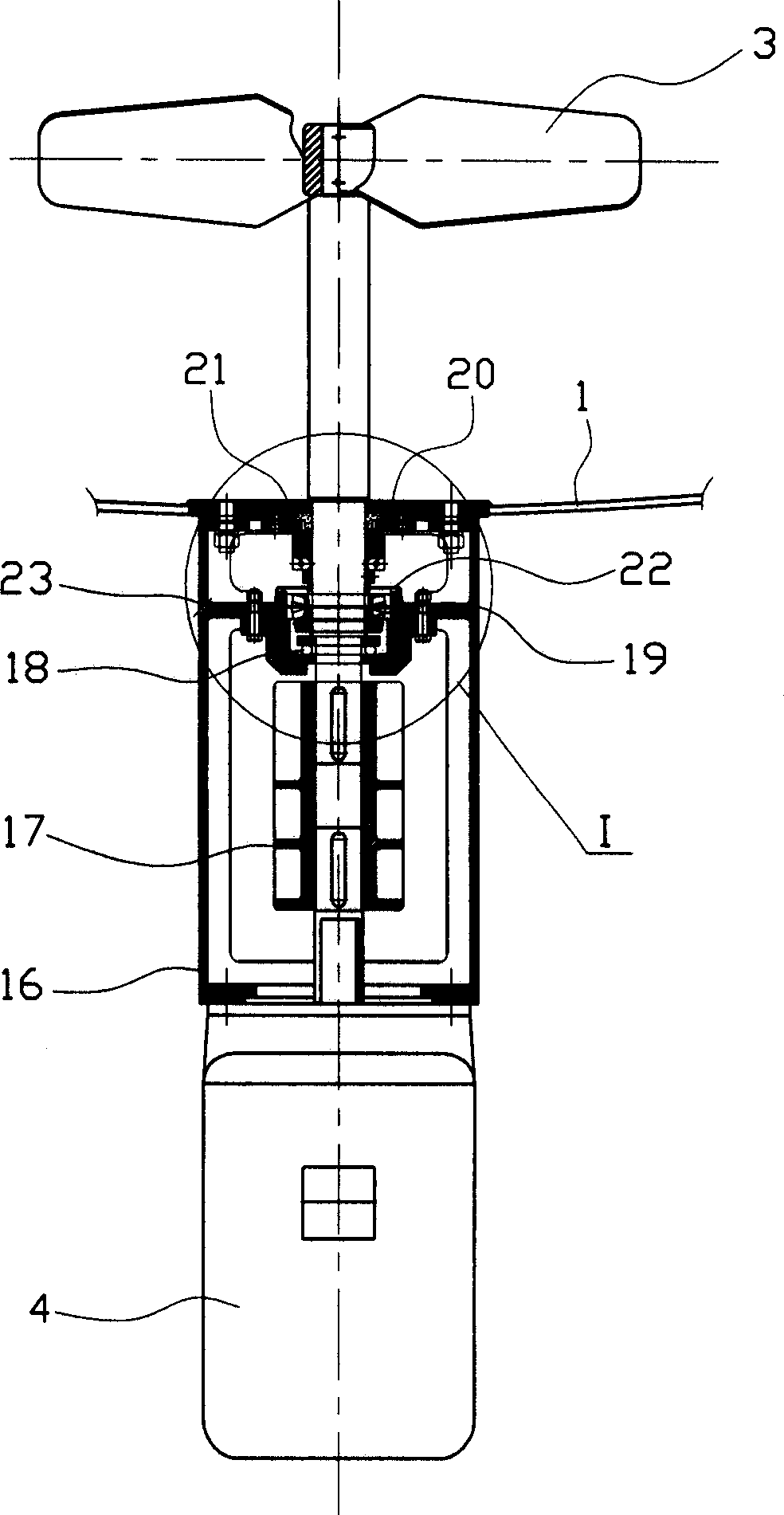

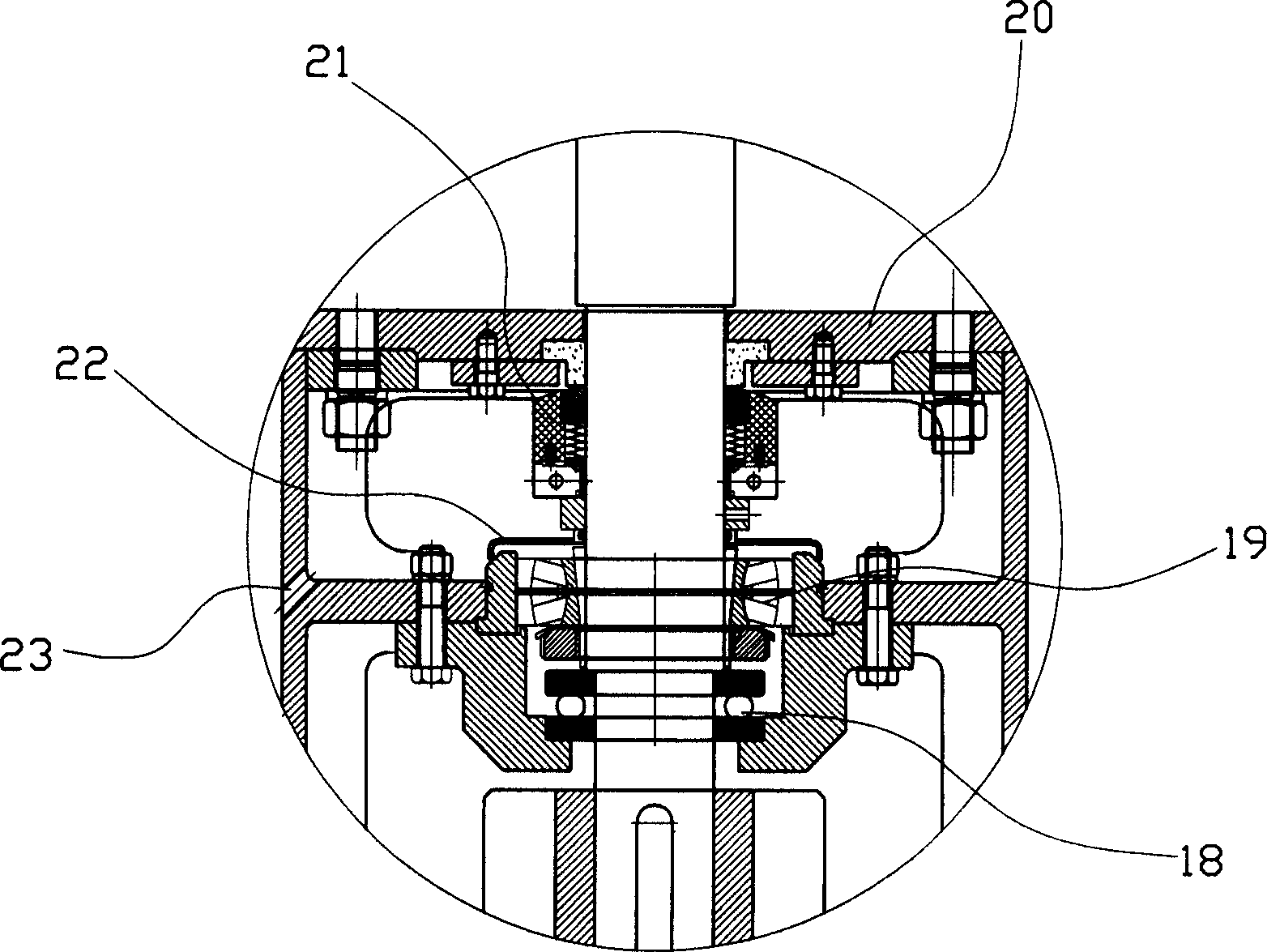

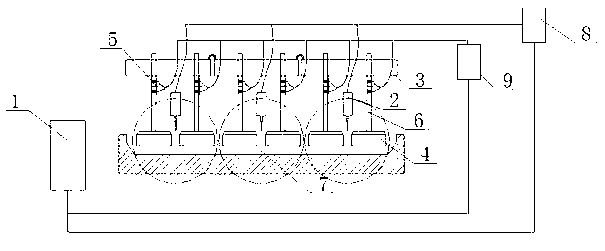

Internal circulation boiling pot

The invention relates to an internal circulation-boiling kettle. It includes kettle body, tube and shell heat exchanger, and allocation cover. The tube and shell heat exchanger includes shell body and many exchange tubes. Its feature is that kettle body is set helical runner linked to electric machinery. After adopting the upper structure, wheat juice is forced to flow to the upper around the center tube of the heat exchanger by the helical runner. This can prevent fouling and blinding, and increase í‹thermosiphoníŒ action; and at the same time the wheat juice is only need to keep boiling to realize its circulation. So this can increase boiling efficiency, economize energy sources, and reduce consumption.

Owner:NINGBO LEHUI INT ENG EQUIP CO LTD

Corrugated roller surface reinforcement modifying method and manufacturing process

InactiveCN1891847AImprove wear resistanceAccelerated corrosionSolid state diffusion coatingCorrosion resistantQuality of work

The invention discloses a surface intensifying modification method for alloy corrugated roller that includes the following steps: taking nitrogen-carbon salt bath co-infiltrating to enrich nitrogen on metal surface to form epsilon phase iron-nitrogen compound layer and nitrogen diffused layer, taking washing and polishing to the component; and taking salt bath oxidation to make the infiltrated nitrogen cover oxide layer on organize layer surface. It also discloses the manufacture technology for the corrugated roller and the raw material. After taking surface intensifying modification process to the surface, the corrugated roller would have superior abrasion resistant, corrosion proof and high temperature resistant ability; it obviously prolongs the useful life and quality of corrugated roller. The cost is lowered, and the energy consumption is saved.

Owner:翟兰

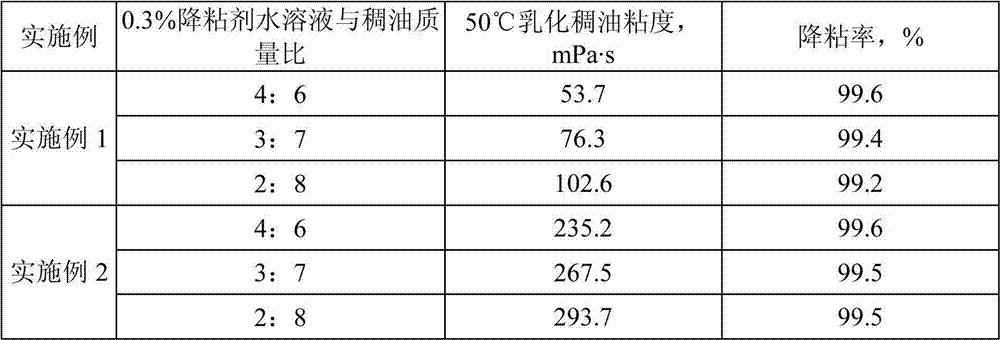

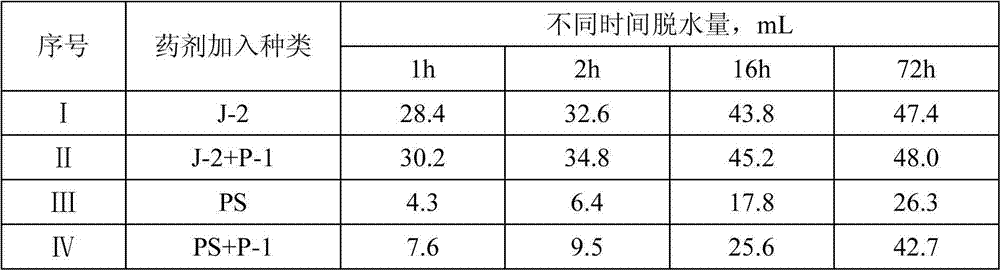

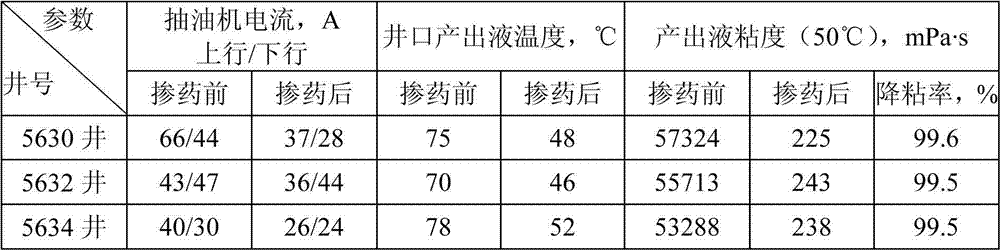

Easily-degradable alkali-free viscosity reducer for thick oil and preparation method thereof

ActiveCN102732241AEasy to degradeImprove surface activityFluid removalPipeline systemsAlkali freeReducer

The invention relates to an easily-degradable alkali-free viscosity reducer for thick oil and a preparation method thereof. The viscosity reducer consists of propylene glycol block polyether, fatty alcohol ammonium sulfate, fatty alcohol, a penetrating agent and water; and in terms of the total mass of the viscosity reducer, the sum of mass percent of propylene glycol block polyether, fatty alcohol ammonium sulfate, fatty alcohol and the penetrating agent is 45 to 60 wt%. The invention also provides the preparation method for the viscosity reducer, and the method comprises the following steps: successively adding propylene glycol block polyether, fatty alcohol ammonium sulfate, fatty alcohol and the penetrating agent into water at a temperature of 50 to 80 DEG C under normal pressure, wherein a mass ratio of the four above-mentioned raw materials to water is 15: 15: 5: 10: 55 to 25: 25: 4: 6: 40; and carrying out continuous stirring for 60 to 90 min at a rotating speed of 60 to 120 r / min while adding the four raw materials so as to obtain the easily-degradable alkali-free viscosity reducer for thick oil. Surfactant used in the viscosity reducer is nonionic and anionic surfactant, the structure of benzene rings is not included in a molecule, and therefore, the characteristics of easy degradability, no toxicity, greenness and environment friendliness are obtained.

Owner:PETROCHINA CO LTD

Single-point feeding control method of feeder of aluminum electrolytic cell

ActiveCN102851704AImprove blanking control accuracyAvoid precipitation or frequent effectsAluminum electrolysisEngineering

The invention relates to a single-point feeding control method of a feeder of an aluminum electrolytic cell. The method includes dividing a feeding port into different regions, acquiring equidistant voltage drop signals from anode rods in the different regions, calculating anode current according to the equidistant voltage drop signals, comparing alumina concentrations in each region of the feeding port with one another according to the change trend of the anode current, and carrying out different feeding control in relation to the states of each region of the feeding port. The inventive method can carry out pertinent control on the alumina concentration of each region of the electrolytic cell 7, improves the feeding control accuracy, avoids precipitation or frequent occurrence of effects, and as a result, facilitates stable operation of the electrolytic cell, reduces the energy consumption and improves the current efficiency.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

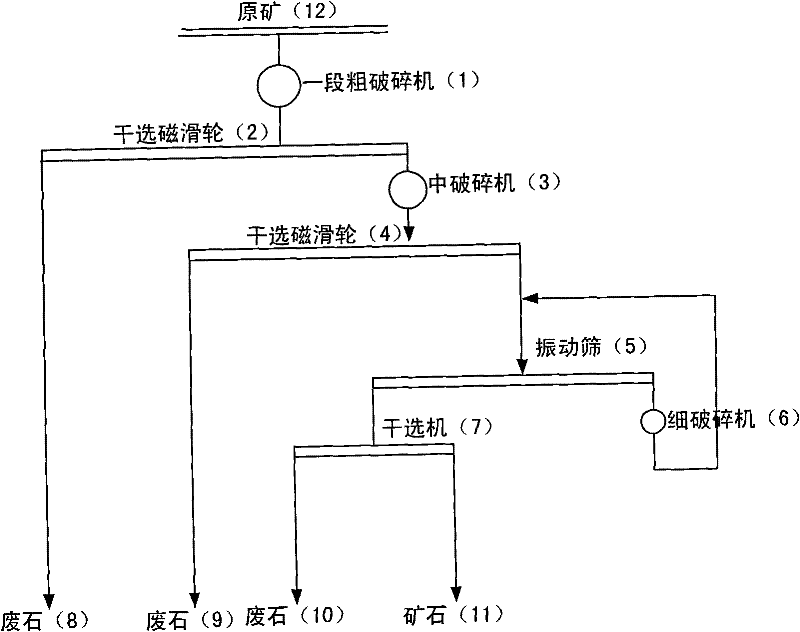

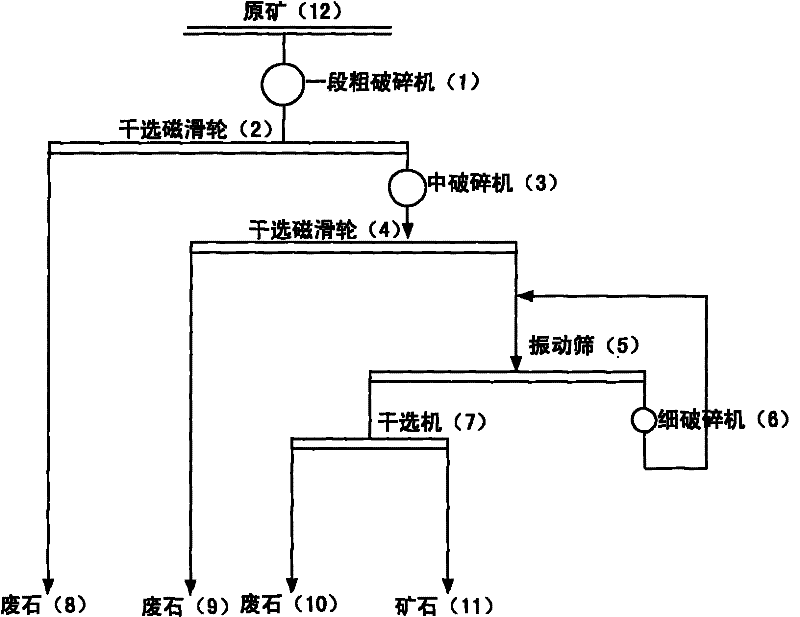

Novel three-stage pre-dressing and crushing process for low-grade magnetite

The invention belongs to the technical field of ore dressing in metallurgy and mining industry, in particular relates to a three-stage pre-dressing and crushing process for low-grade magnetite. The process comprises the following steps of: feeding magnetite into a coarse crushing machine, transferring the material discharged from the coarse crushing machine to a first-stage dry-type magnetic pulley by using a rubber belt machine, delivering first-stage ore concentrate products to a middle crushing machine by using the rubber belt machine via a middle crushing machine ore bin, delivering middle crushing machine products to a second-stage magnetic pulley by using the rubber belt machine, screening ore concentrate products by a sieving machine to obtain on-sieve products and under-sieve products, crushing the on-sieve products by a fine crushing machine and mixing the crushed on-sieve products with the products crushed by the middle crushing machine, and then transferring the mixedcrushed products to the sieving machine, delivering the under-sieve products to a third-stage dry-type magnetic separation machine by a belt conveyer, wherein ore concentrates discharged from the from the third-stage dry-type magnetic separation machine are taken as the crushed final products, and waste stone from the magnetic separation machine is stored in a waste stone bin. According to the invention, the dry-type magnetic pulley operation is performed after the coarse crushing operation and the dry-type magnetic separation machine operation is performed after the fine crushing operation, the tailing rejection is performed in advance, therefore the milling grade can be improved and the ore grinding load can be reduced, and further, the purposes of reducing the energy consumption and increasing the economic benefits of ore dressing plants can be achieved.

Owner:ANSTEEL GRP MINING CO LTD

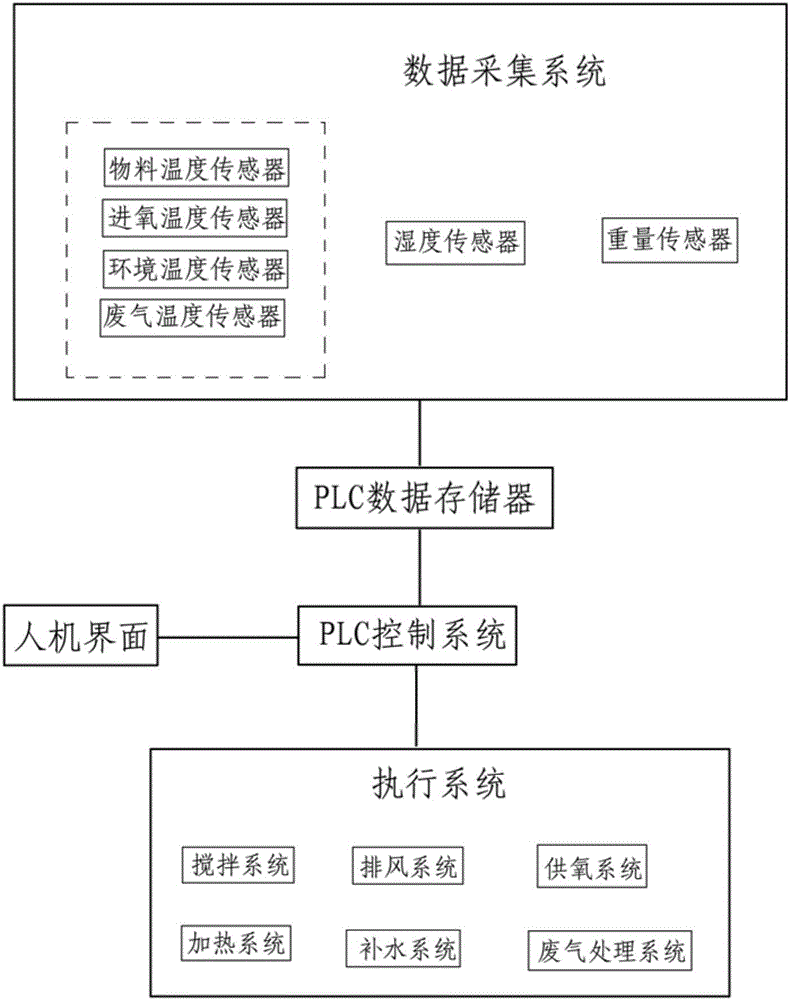

Intelligent control method and system for microbial decomposition process of organic matters

InactiveCN106431540AIncrease temperatureEasy to breedBio-organic fraction processingFertiliser treatment controlWeight changeDecomposition

The invention relates to an intelligent control method and system for a microbial decomposition process of organic matters. The invention aims to provide the intelligent control method and the intelligent control system for the microbial decomposition process of the organic matters; the temperature, humidity and weight changes of a material during microbial decomposition can be fully utilized, the temperature, humidity and oxygen supply quantity in the decomposition process can be intelligently controlled, and the decomposition efficiency of the organic matters is improved. According to the method, through acquisition of the temperature data, weight data and humidity data in the process of microbial decomposition of the organic matters, and with combination of predetermined ideal state temperature-time change data, ideal state humidity-time change data and ideal state decomposition rate-time change data of microbial flora in the organic matter decomposition process, the temperature, humidity, oxygen supply and decomposition rate in the organic matter decomposition process are adjusted.

Owner:SHANGHAI YIKE ENVIRONMENT TECH CO LTD

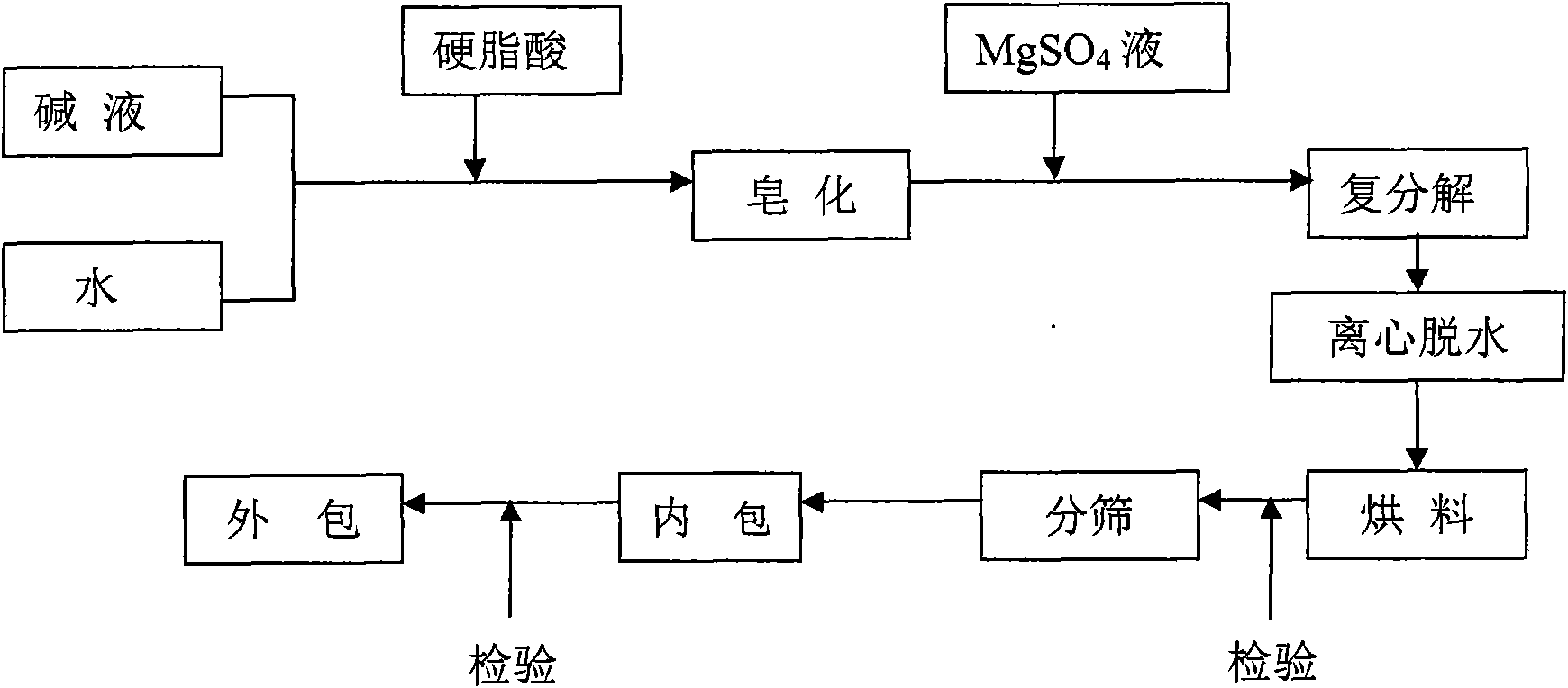

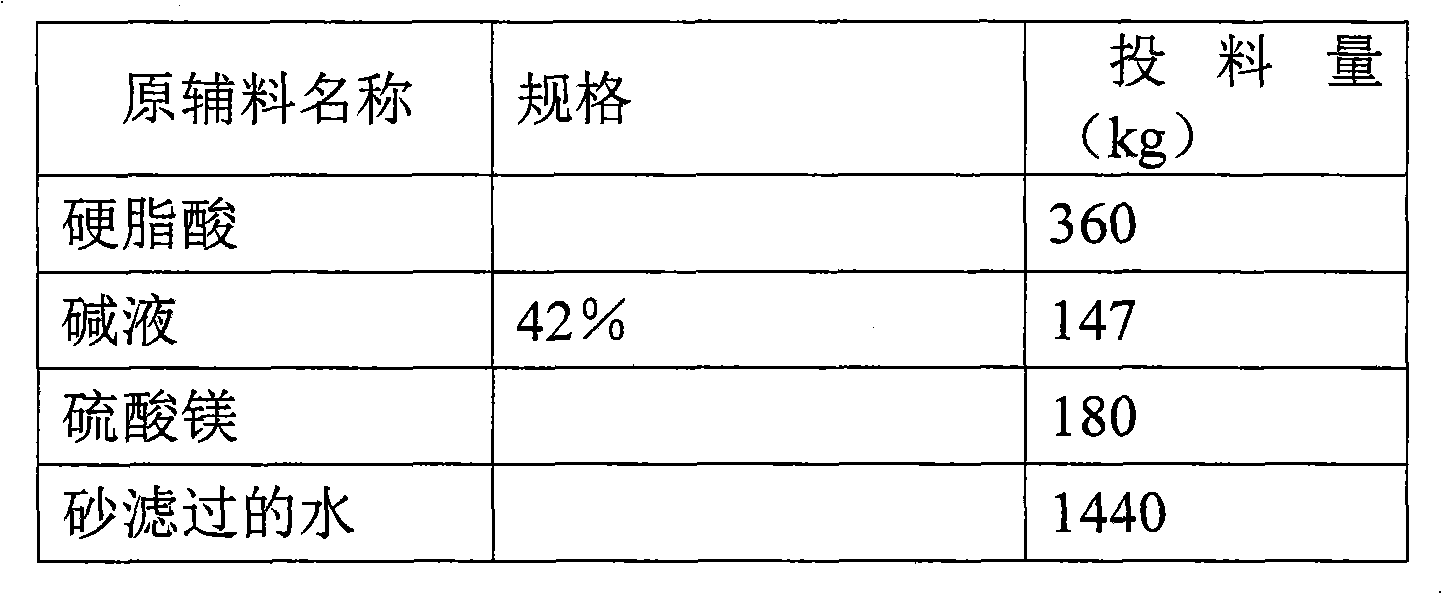

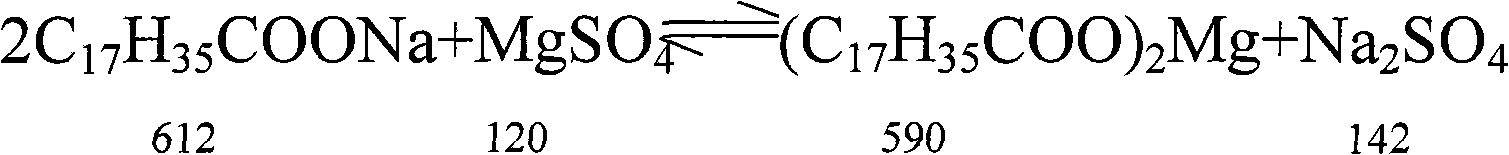

Preparation method of magnesium stearate with improved specific volume and whiteness

ActiveCN102372620AIncrease specific volumeHigh whitenessCarboxylic acid salt preparationCarboxylic compound separation/purificationDecompositionFiltration

The invention relates to a preparation method of magnesium stearate with improved specific volume and whiteness. According to the invention, a mass ratio of stearic acid to lye to magnesium sulfate to sand-filtered water is 1.8-2.2:0.7-0.9:1:7.6-8.4. The concentration of lye is 40%. The invention provides a preparation method of magnesium stearate with the components. The method provided by the invention is advantaged in that: (1) according to the novel technology, during an alkalization process, 40% of lye is used for replacing 42% of lye; the replacement is beneficial for purification in a filtration process, and for removing impurities. Under the controlling of optimal temperature, time, and rotary rate, saponification and double decomposition reactions are fully carried out, a reaction period is shortened, efficiency and quality indexes are improved, and property advantages of magnesium stearate such as specific volume and whiteness are improved; (2) according to the novel technology, a plurality of washing processes are eliminated; a one-step method is adopted in the drying process, such that the drying processes are reduced. Therefore, purposes of energy saving, energy consumption reducing, and water consumption reducing are achieved; large-area reformation upon equipments is not required; production efficiency can be substantially improved; and product indexes can reach a national first-grade standard. Compared to prior arts, the technology is substantially advanced.

Owner:QUFU TIANLI MEDICAL SUPPLEMENTS CO LTD

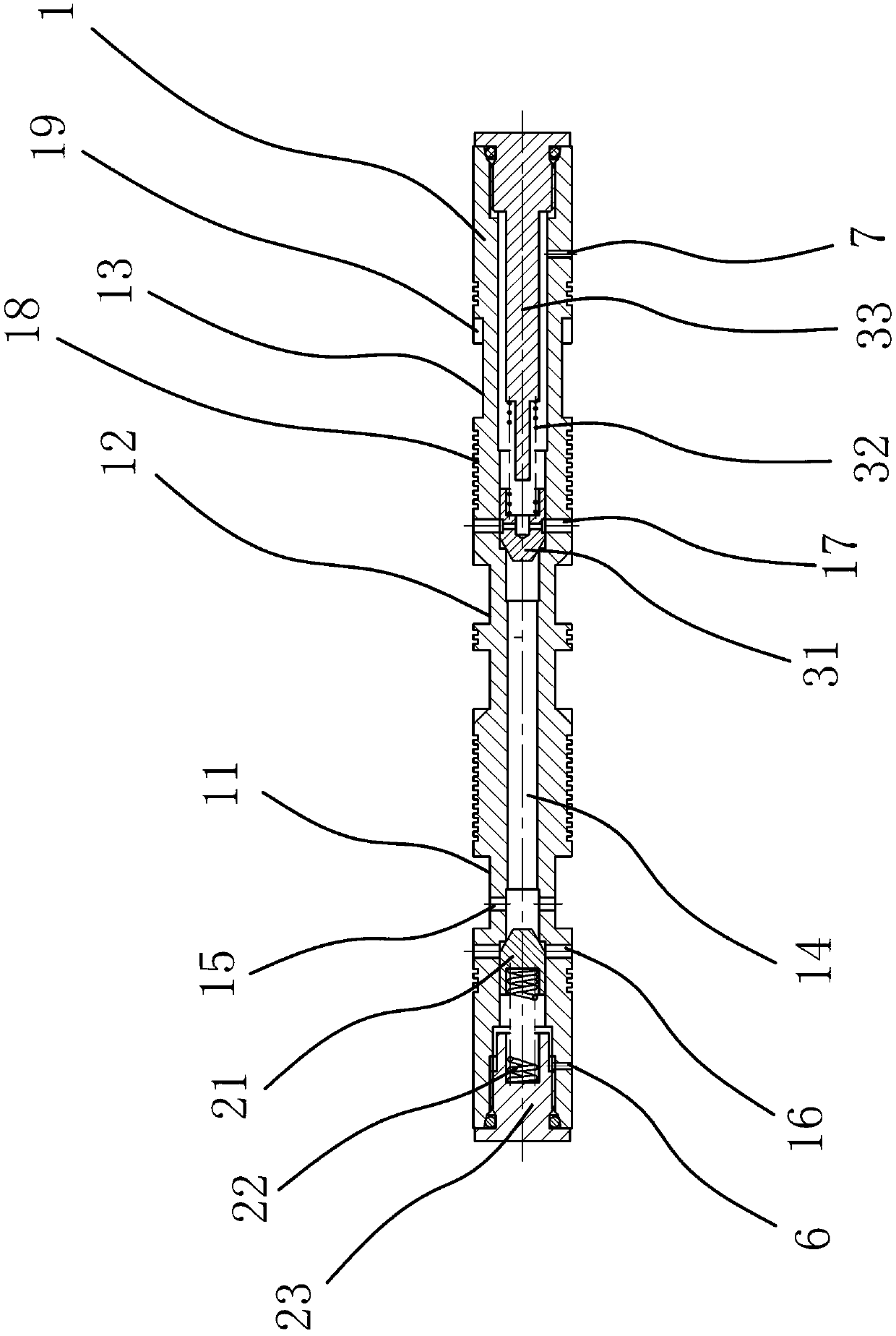

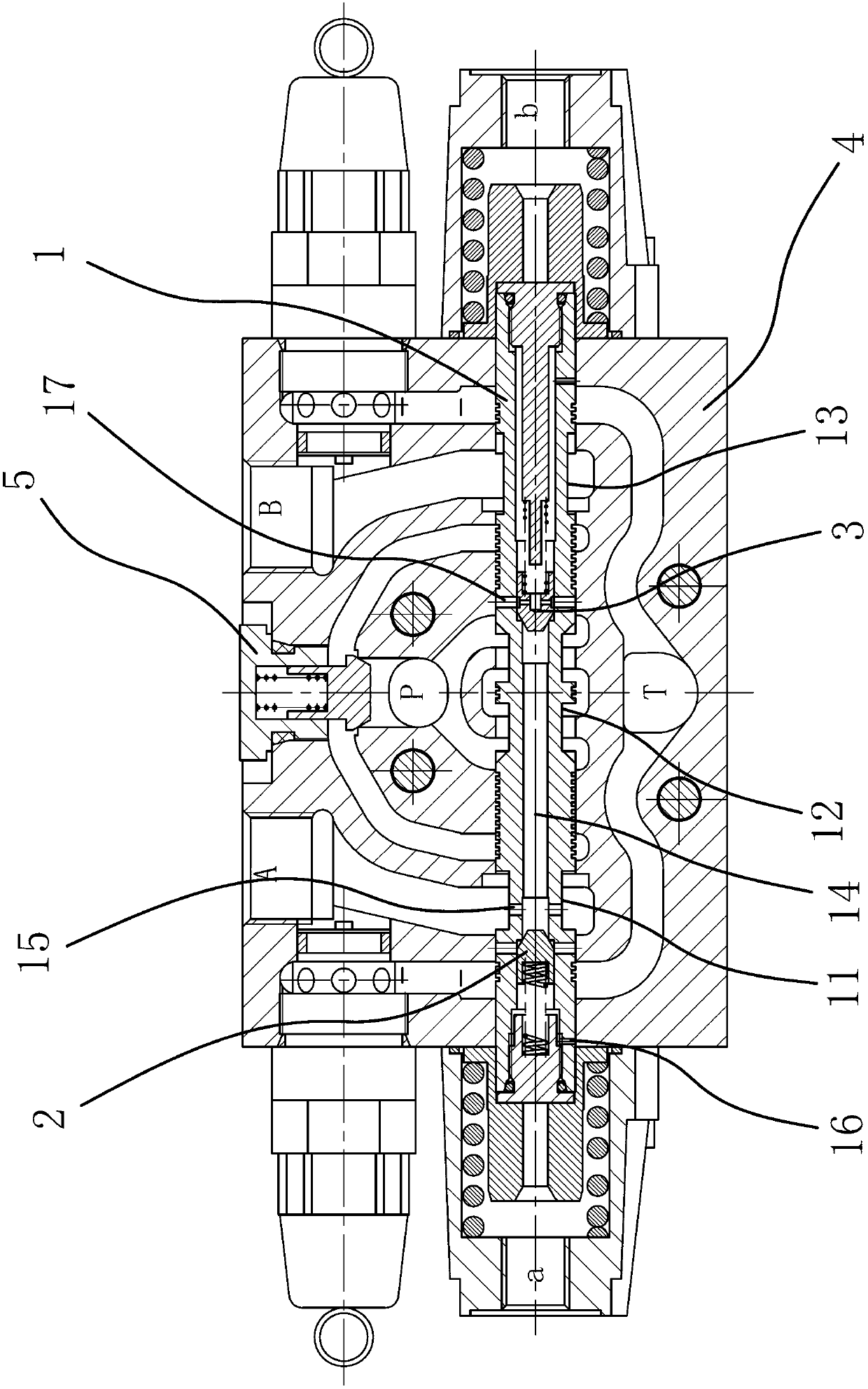

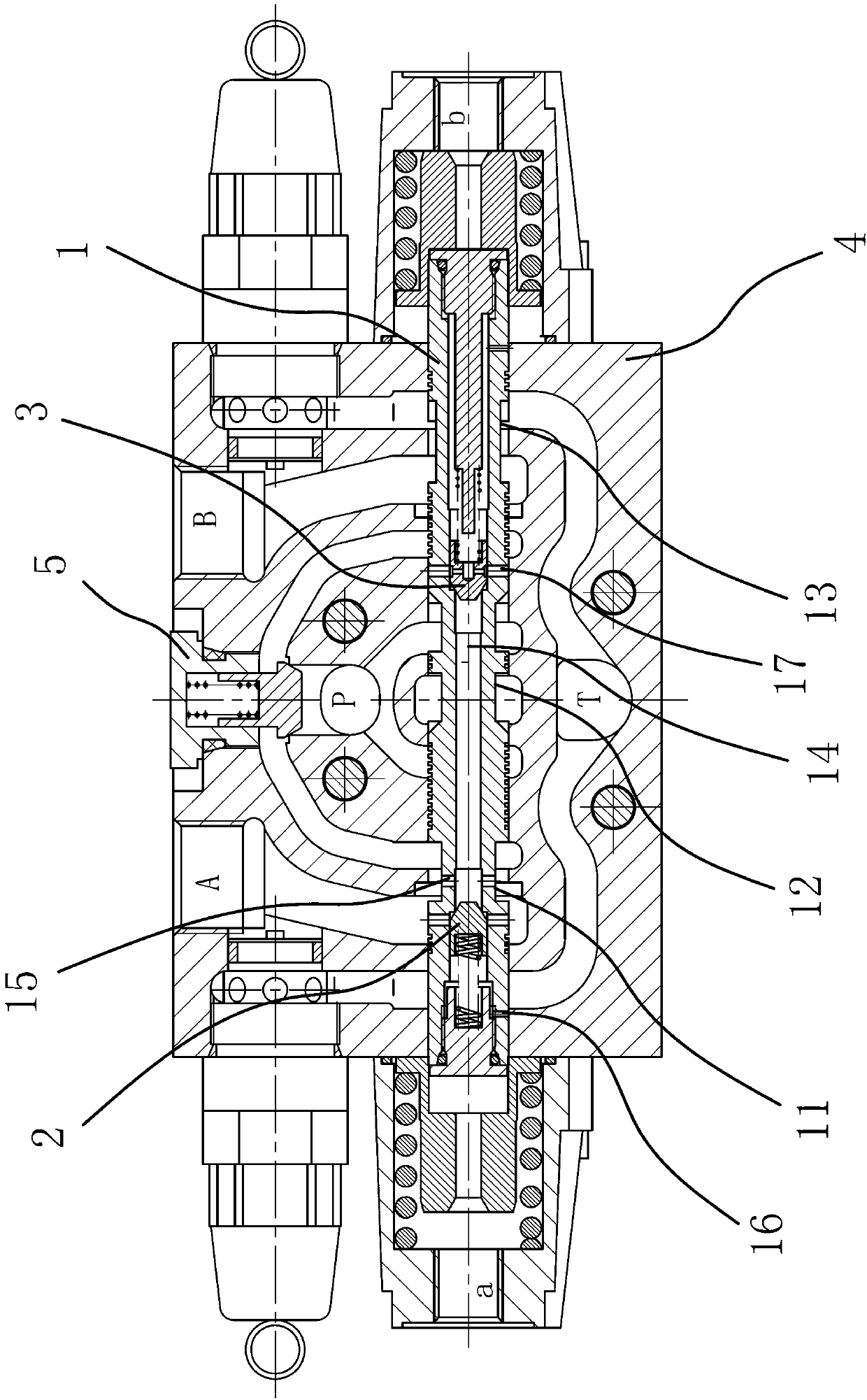

Valve rod of multi-path valve and multi-path valve with valve rod

The invention provides a valve rod of a multi-path valve and the multi-path valve with the valve rod and belongs to the technical field of machinery. The valve rod and the multi-path valve solve the problem that the phenomenon of empty sucking of the existing multi-path cylinder cannot be eliminated, the cylinder is unstable in operation, and service life and integral performance of sealing members are influenced. The multi-path valve comprises a valve body and the valve rod arranged in the valve body, wherein an ascending working cavity, a descending working cavity, an oil inlet cavity and an oil return cavity are arranged in the valve body, a first guide assembly with an ascending guide opening and corresponding to one end of the valve rod is arranged on the valve body, and a second guide assembly with a descending guide opening and corresponding to the other end of the valve rod is arranged on the valve body; and by means of a first communication groove, a second communication groove and a third communication groove on the valve rod, the ascending working cavity can be communicated with the oil inlet cavity, the oil inlet cavity can be communicated with the oil return cavity, and the descending working cavity can be communicated with the oil return cavity or the oil inlet cavity. The multi-path valve can achieve energy recovering during descending of the oil cylinder, avoids the phenomenon of empty sucking of the descending working cavity caused by fast descending of the oil cylinder and prolongs service life of the oil cylinder.

Owner:ZHEJIANG HAIHONG HYDRAULIC TECH

Light weight high strength wood or bamboo base laminated composite precast slab or beam and manufacturing method thereof

ActiveCN101817189AEasy to buildImprove insulation effectWood veneer joiningFlat articlesEnvironmental resistanceThermal insulation

The invention relates to a light weight high strength wood or bamboo base laminated composite precast slab or beam and manufacturing method thereof. The structure thereof is in three layers or five layers, manufacturing method includes the following process steps: (1) broadside splicing is carried out to form a laminated unit with breadth requirement; (2) polishing or sanding is carried out on the laminated unit; (3) glue assembly is coated by adopting polyurethane resin or resorcinol resin, and rate of spreading single face is 125-185g / m2; (4) pressure curing is carried out, curing pressure is generally 0.4-1.25MPa, and moisture content requirement of material is 8-15%. The invention has the advantages that weight is light, strength is high, natural reproduction can be realized, and carbon absorption function is strong; the product is environmentally friendly, shock resistance is strong, price is low, transportation is convenient, house construction is fast and convenient; heat-conducting property of structure slab is only 1 / 9 that of steel bar concrete precast slab (beam) and cast-in-situ beam; thermal insulation property of construction can be improved more than 40%, emission of greenhouse gas is reduced, thus achieving the comprehensive effect of energy conservation and consumption reduction.

Owner:NANJING FORESTRY UNIV

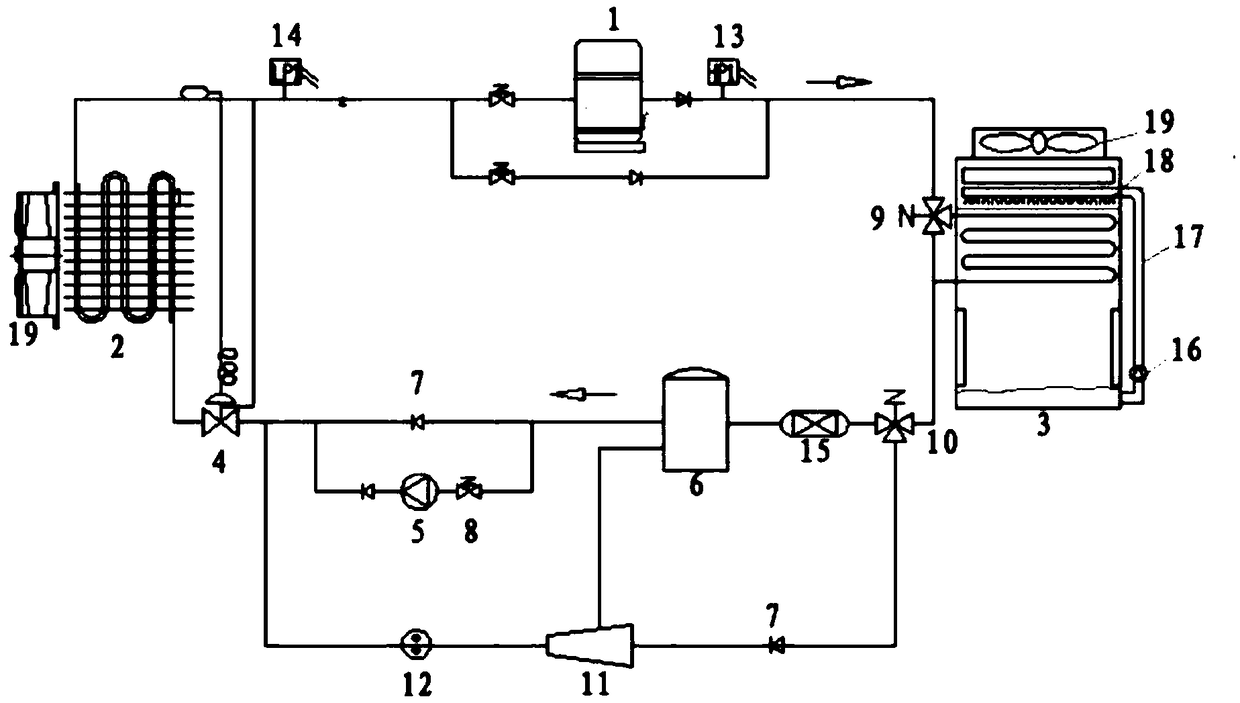

Natural cold source energy-saving refrigerating system

PendingCN108917226AImprove energy efficiencyAchieve energy saving and consumption reductionRefrigeration machinesData centerProcess engineering

The invention provides a natural cold source energy-saving refrigerating system. The natural cold source energy-saving refrigerating system comprises a compressor refrigerating cycle, a fluorine pumprefrigerating cycle and a spray pipe injection refrigerating cycle. Refrigeration is carried out according to a single mode in three different outdoor temperature refrigerating cycle modes or different mode combinations. According to the scheme, by means of evaporative cooling, fluorine pump natural cold sources and the spray pipe injection refrigerating technology, energy saving and consumption reduction can be achieved in the refrigerating system, and the effect of improving the energy efficiency of a unit is achieved. The effects of saving energy, reducing consumption and reducing PUE can be achieved in a data center, and the product competitiveness of the data center is improved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

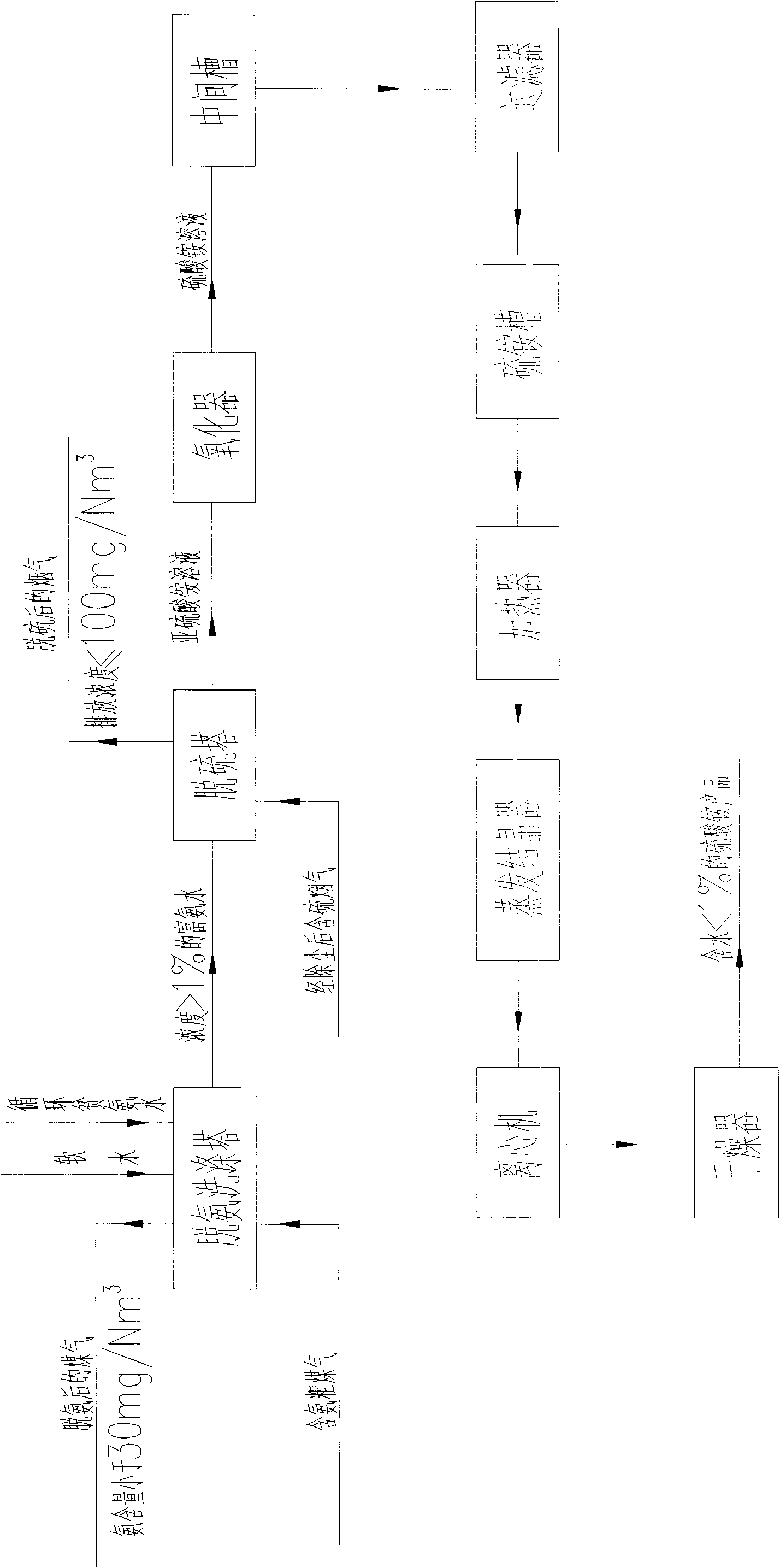

Method for desulphurizing sulfur-containing flue gas with coking crude gas water-washing deaminized ammonia water

InactiveCN101898081AEliminate the ammonia distillation processReduce consumptionChemical industryDispersed particle separationEvaporationCoke oven

The invention relates to a method for desulphurizing sulfur-containing flue gas with coking crude gas water-washing deaminized ammonia water, which comprises the following steps: introducing coke furnace crude gas into a deamination washing tower to obtain ammonia-enriched water after water washing of ammonia, and discharging the ammonia-enriched water out of the tower; introducing sulfur-containing flue gas into a desulfurizing tower from the bottom of the desulfurizing tower, spraying the ammonia-enriched water into the tower from the tower top to absorb SO2 in the flue gas so as to generate an ammonium sulfite solution, discharging the ammonium sulfite solution from the tower bottom, and discharging the desulphurized flue gas from the tower top; and using the ammonium sulfite solution to produce chemical fertilizer ammonium sulfate by the conventional technology. The method for desulphurizing sulfur-containing flue gas combines coking plant crude gas water-washing deamination and sulfur-containing flue gas ammonia desulfurization, and omits the ammonia evaporation procedure in the water-washing deamination. Besides, the ammonia water is wholly and effectively utilized, and can be used by being combined with flue gas desulfurization for producing chemical fertilizer ammonium sulfate without producing new three wastes, thereby achieving the purposes of energy saving, consumption reduction and environmental friendliness.

Owner:山西新唐工程设计股份有限公司

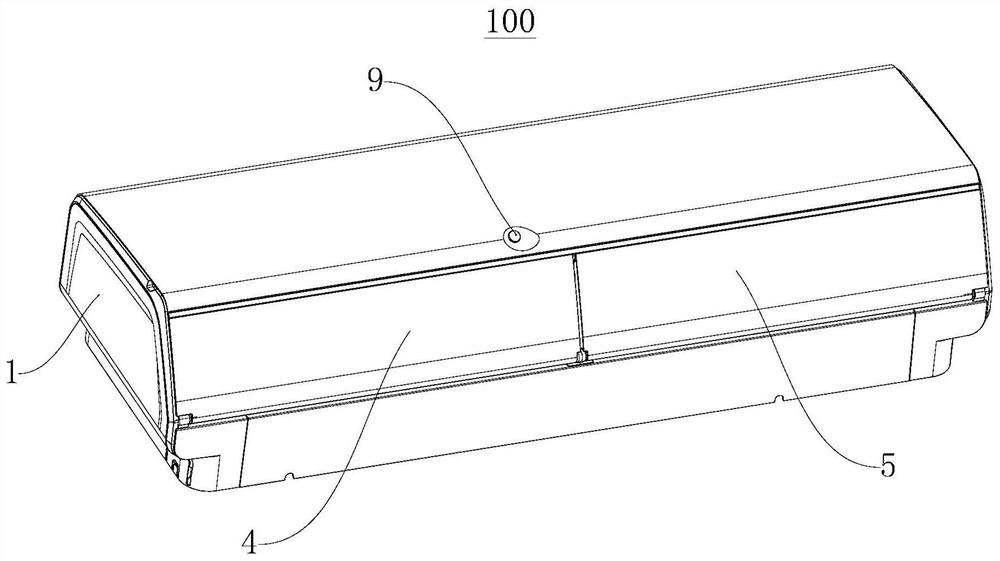

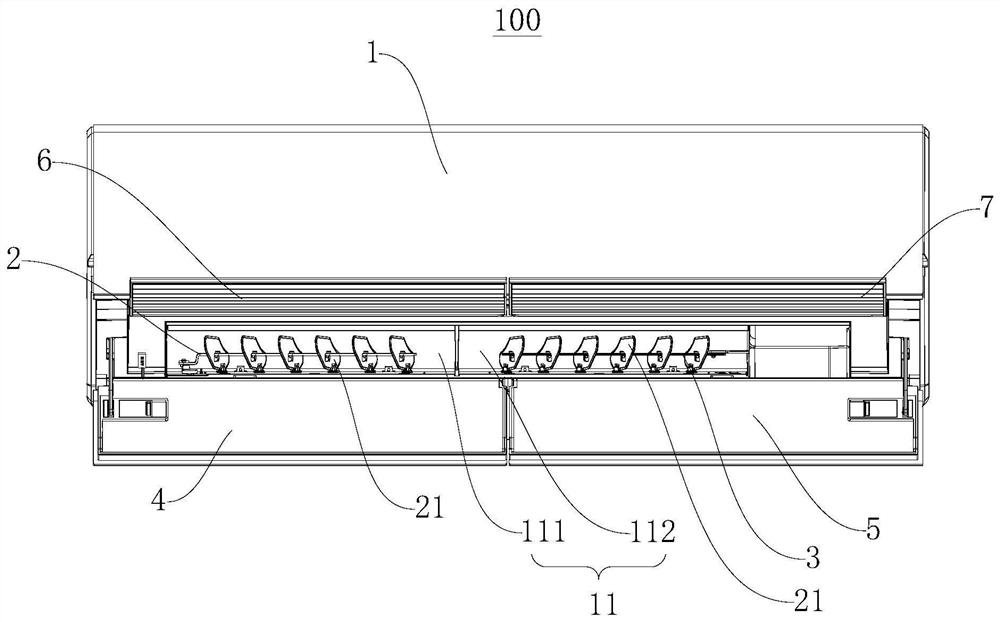

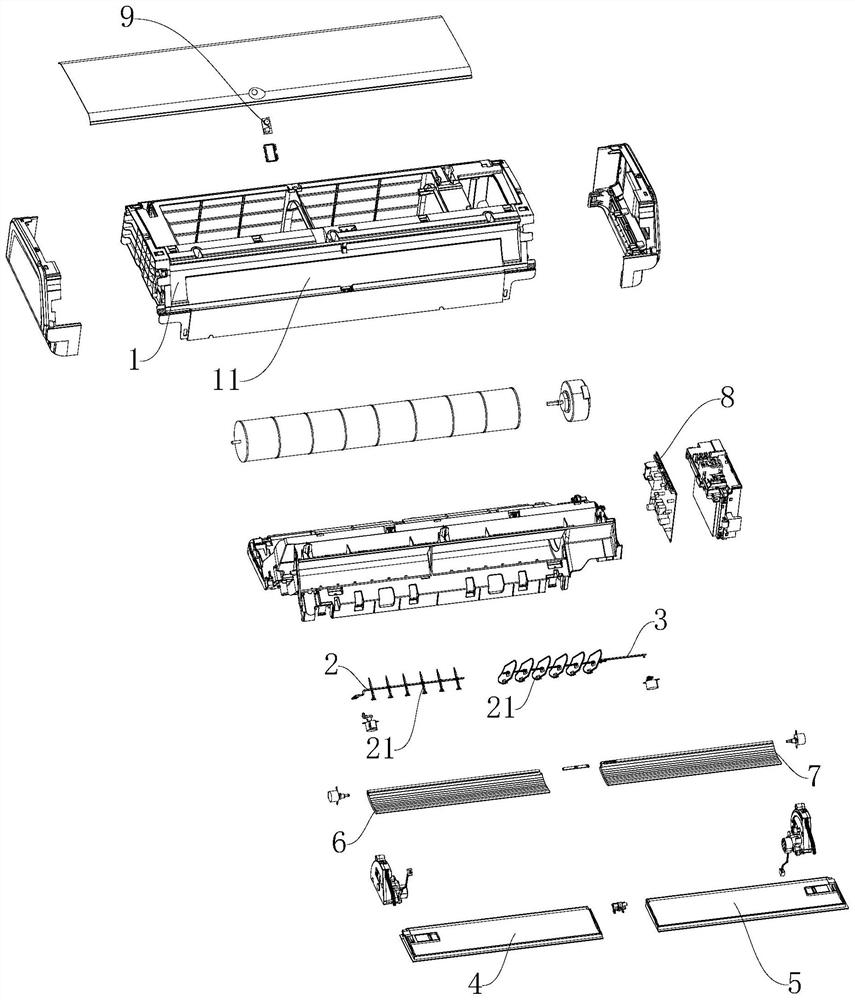

Air conditioner indoor unit

InactiveCN111720888AEasy to controlAchieve precise air supplyMechanical apparatusLighting and heating apparatusEnvironmental engineeringMechanical engineering

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

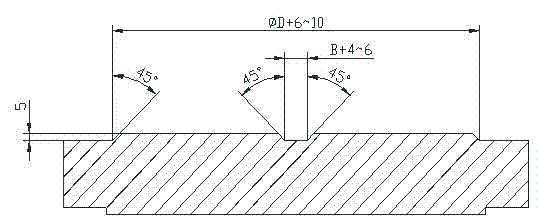

Machining method of heat exchanger tube plate build-up welding

InactiveCN103894838AEasy to operateImprove efficiencyArc welding apparatusOther manufacturing equipments/toolsEngineeringComposite plate

As the number of tube plate build-up welding composite layers of a composite plate heat exchanger increases, a traditional direct build-up welding mode wastes labor and time. The invention provides a machining method of heat exchanger tube plate build-up welding. In the machining method, the method that machining is performed firstly and then build-up welding is conducted is used for machining, therefore, operation is more convenient, and the efficiency is greatly increased; firstly machining is conducted according to the method, the external diameter of a tube plate sealing surface is reduced by 6-10 mm, the depth of the tube plate sealing surface is 5 mm, and 45-degree chamfering is conducted on the tube plate sealing surface, the width of a partition plate groove is increased by 4-6 mm, the depth of the partition plate groove is 5 mm, the two sides of the partition plate groove are chamfered by 30-60 degrees, and a 3-5 mm stainless steel composite layer is formed in a build-up welding mode. According to the method, the purposes of energy conservation, consumption reduction, cost decreasing and efficiency increasing are achieved.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

Intelligent coal mine local ventilation system

ActiveCN103591041AAutomatic speed adjustmentImprove safety and reliabilityTunnel/mines ventillationPump controlAuto regulationComputer module

The invention discloses an intelligent coal mine local ventilation system which comprises a mining flame-proof type two-circuit feeder switch, two passageway type anti-explosion frequency converters and two local ventilation machines. The mining flame-proof type two-circuit feeder switch is connected with an information collecting module under a coal mine, supplies power for the two anti-explosion frequency converters respectively and controls the two anti-explosion frequency converters to work. The two anti-explosion frequency converters are connected with the two local ventilation machines respectively, and air flow automatic switching devices are further arranged at air outlets of the two local ventilation machines. Under the control of the mining flame-proof type intelligent two-circuit feeder switch, rotation speed of a fan is automatically adjusted, air is supplied according to needs, gas is intelligently exhausted, energy is saved, consumption is reduced, disasters are prevented, and safety and reliability of the local ventilation system are improved.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

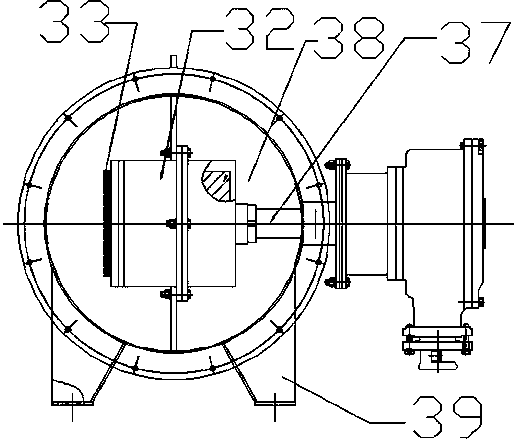

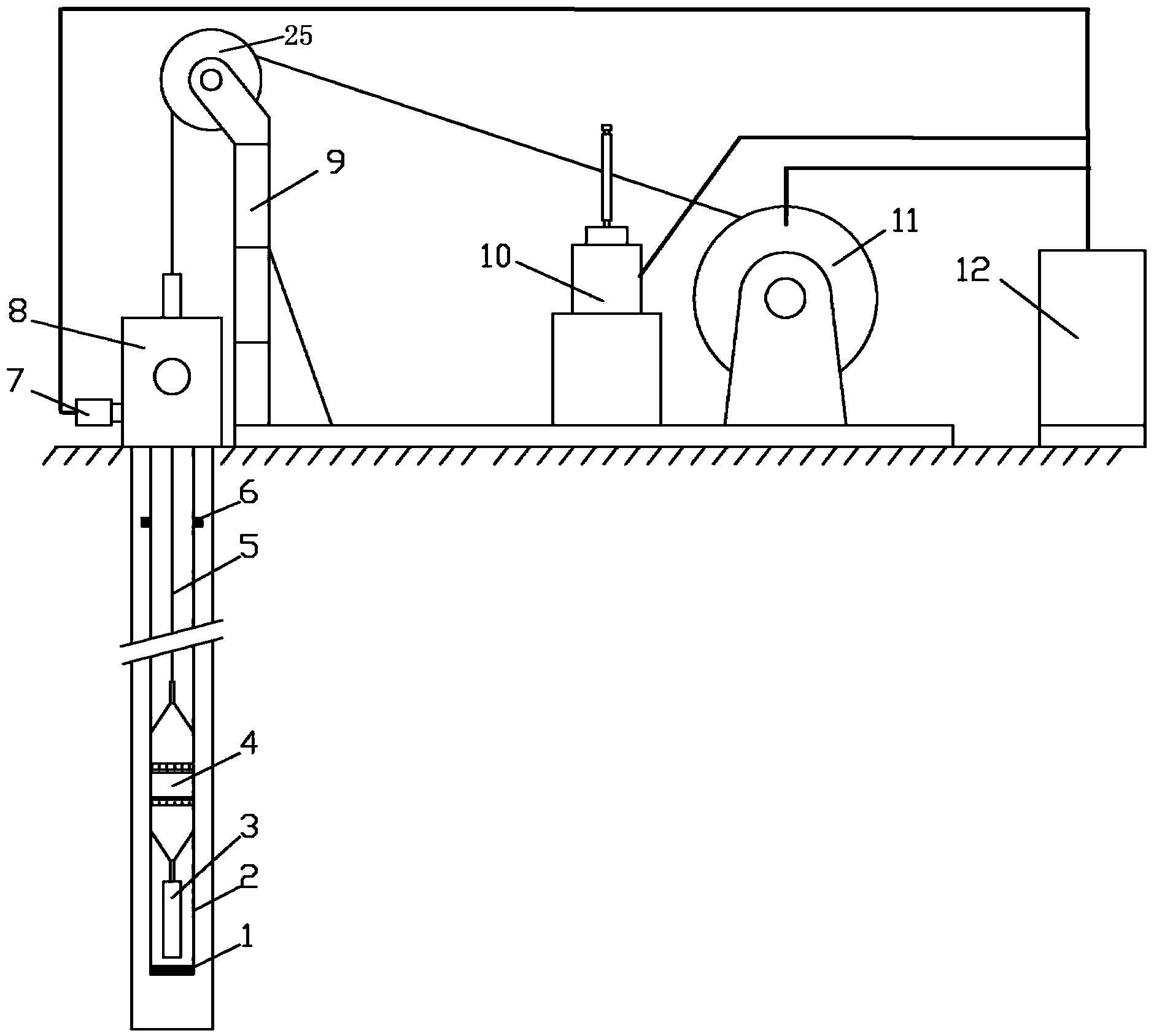

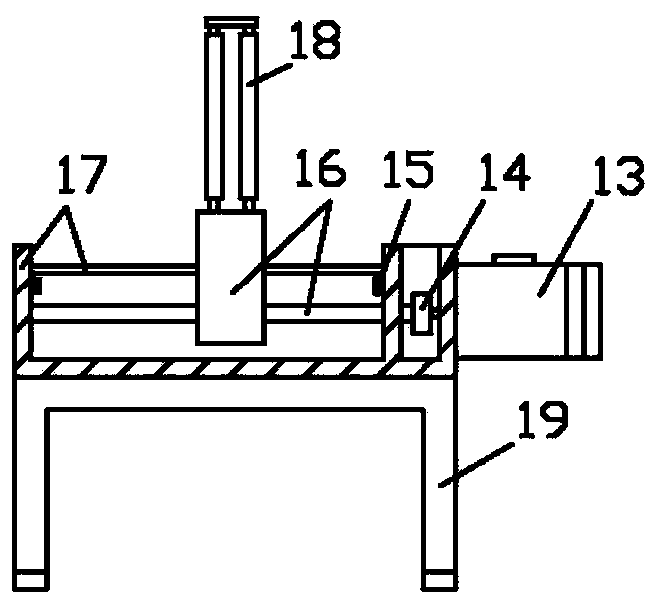

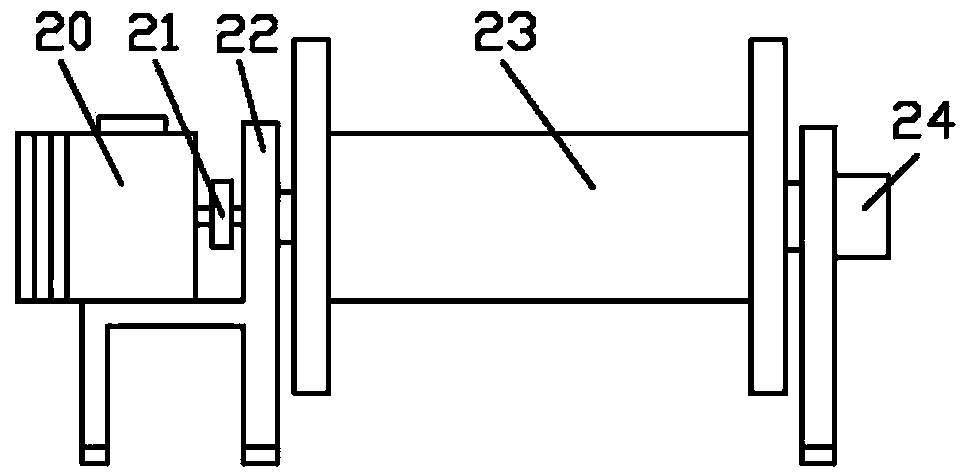

Low-yield well numerically controlled oil pipe oil bailing device and oil bailing method

InactiveCN103615216ARealize intelligent controlAchieve energy saving and consumption reductionFluid removalWorking fluidOil production

The invention discloses a low-yield well numerically controlled oil pipe oil bailing device. The device comprises an oil pipe, a support, a wire arraying device and a wire winding device, wherein the oil pipe, the support, the wire arraying device and the wire winding device are sequentially fixedly arranged on the ground on one side of an oil well. The oil pipe is located inside the oil well. A cross-shaped check block inside the oil pipe is in threaded connection with the bottom end of the oil pipe, a flexible pump is matched with the inner wall of the oil pipe, the lower end of the flexible pump is in threaded connection with a balance weight, the upper end of the flexible pump is fixedly connected with a steel wire rope, a sound symbol is fixedly arranged on the outer wall of the upper portion of the oil pipe, and the upper end of the oil pipe is fixed to a well mouth switching device in a threaded mode. A working fluid level detection device is installed on the well mouth switching device. The invention further discloses an oil bailing method by the utilization of the low-yield well numerically controlled oil pipe oil bailing device. The oil bailing method includes the steps that firstly, the low-yield well numerically controlled oil pipe oil bailing device is installed and tested, trial bailing is conducted after a system is set and initialized, and then automatic oil bailing is started. The device and method can solve the problems that a system of an oil pumping machine, an oil pumping rod and an oil pumping pump is low in efficiency, high in energy consumption and low in utilization rate of the oil well when low permeability and ultra-low permeability reservoirs are exploited and especially when oil production is conducted on a low-yield well.

Owner:YANCHANG OIL FIELD

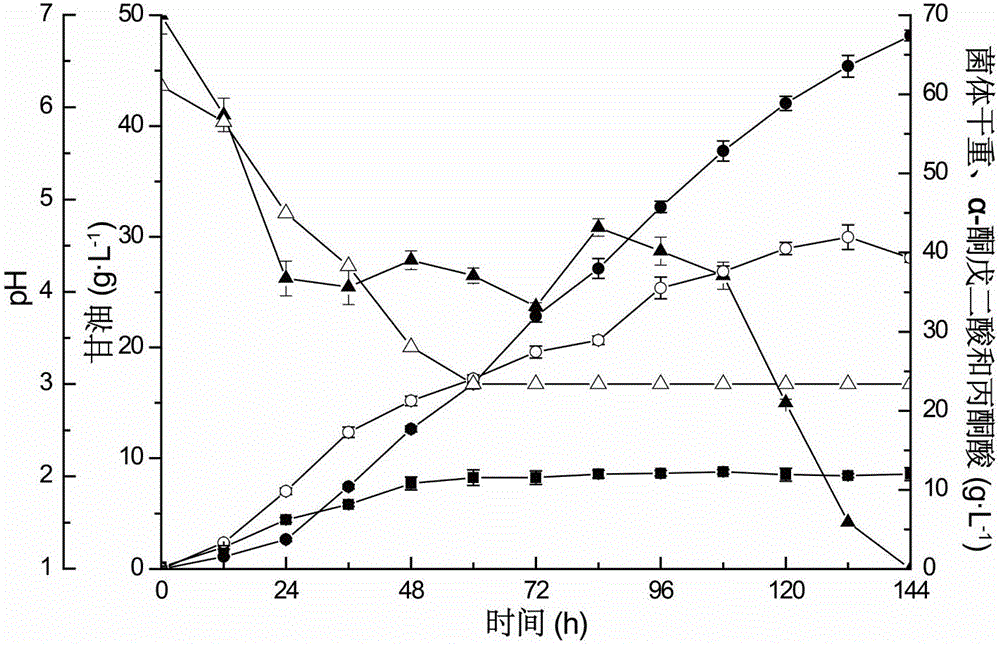

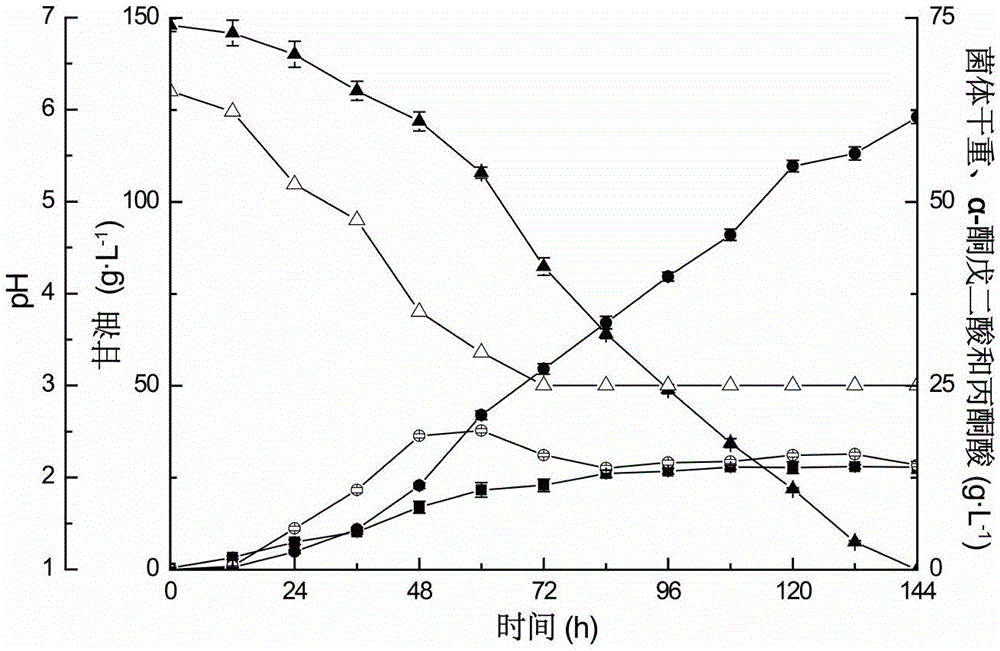

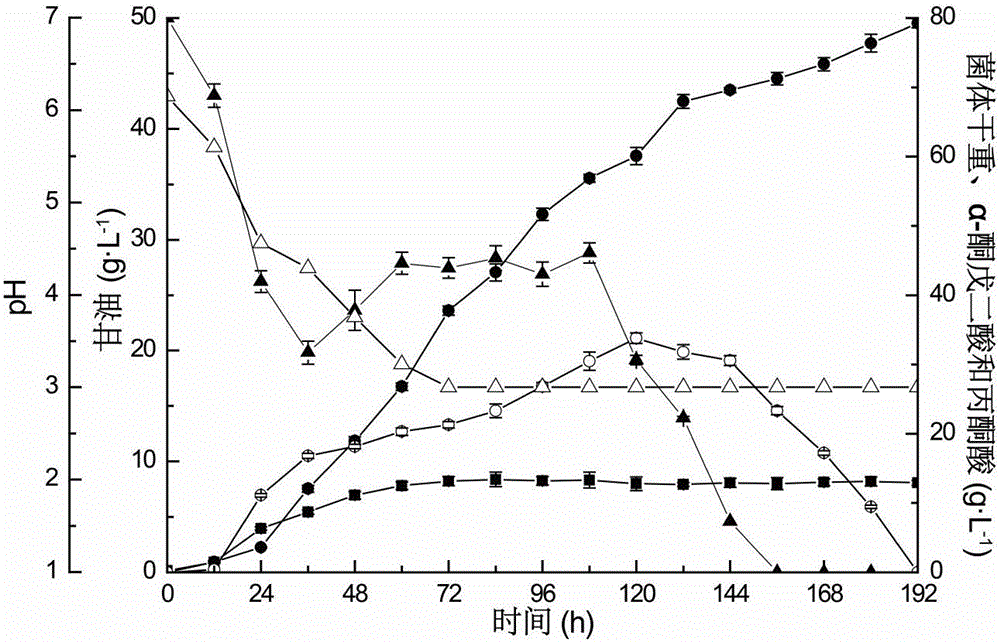

Fermenting method for joint production of alpha-ketoglutaric acid and pyruvic acid

ActiveCN106086092APromote accumulationPromote growthMicroorganism based processesFermentationGlycerolEconomic benefits

The invention discloses a fermenting method for joint production of alpha-ketoglutaric acid and pyruvic acid, and belongs to the technical field of fermenting engineering. The fermenting method is characterized in that because the difference of commercial values of alpha-ketoglutaric acid and pyruvic acid is small, the two types of carboxylic acids are jointly produced; in the fermenting process for joint production of carboxylic acids, the proper initial concentration and flowing accelerated speed of glycerinum are controlled, so as to promote the growth of bacteria and the accumulation of carboxylic acids. The fermenting method has the advantages that the conversion rate of substrate is greatly improved, the output of total acids is increased, and the production intensity is improved; the fermenting cycle is shortened, the energy-saving and consumption-decreasing effects are realized, and the economic benefit is improved.

Owner:JIANGNAN UNIV

Device and method for measuring material quantity of multifunctional self-setting ball mill

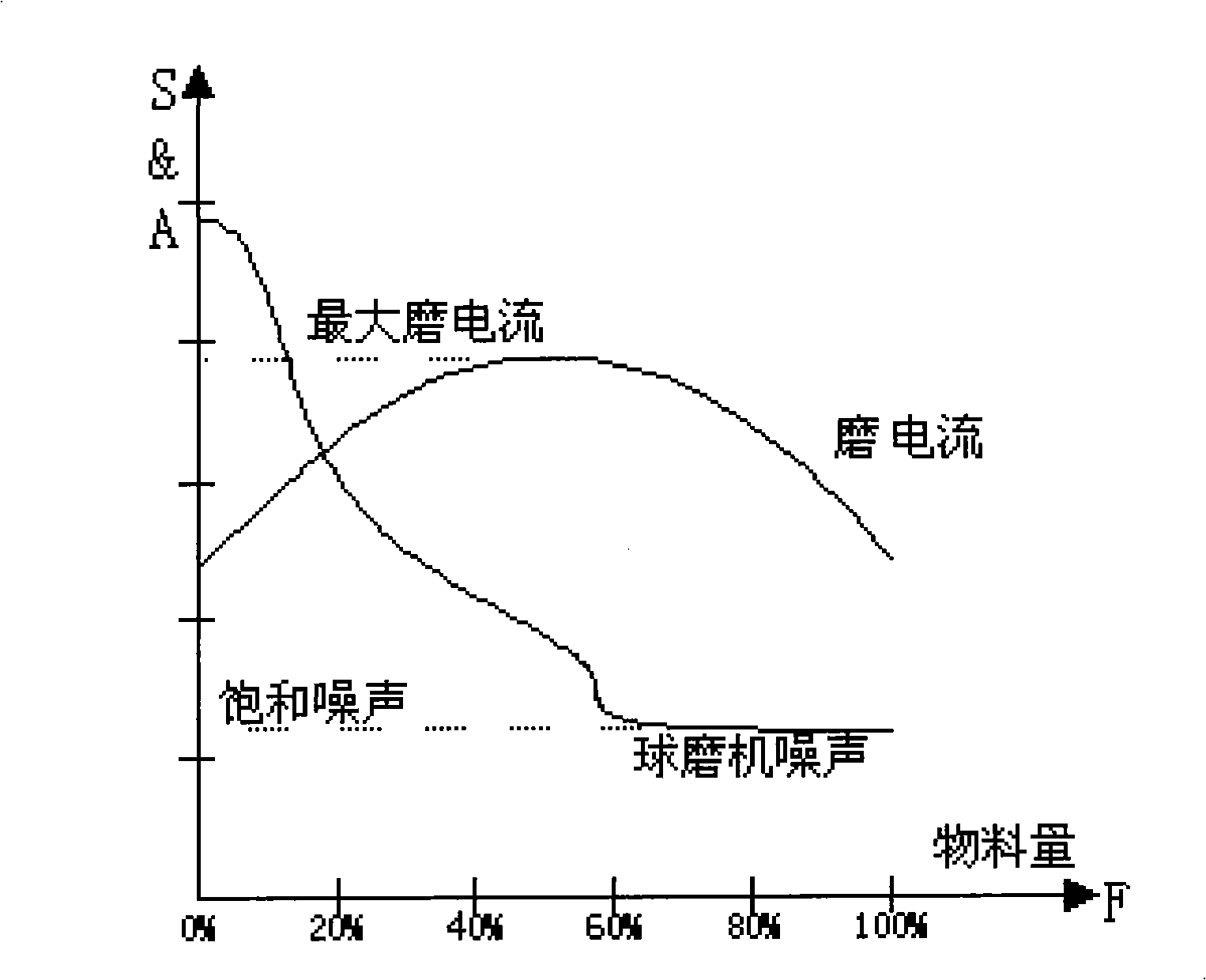

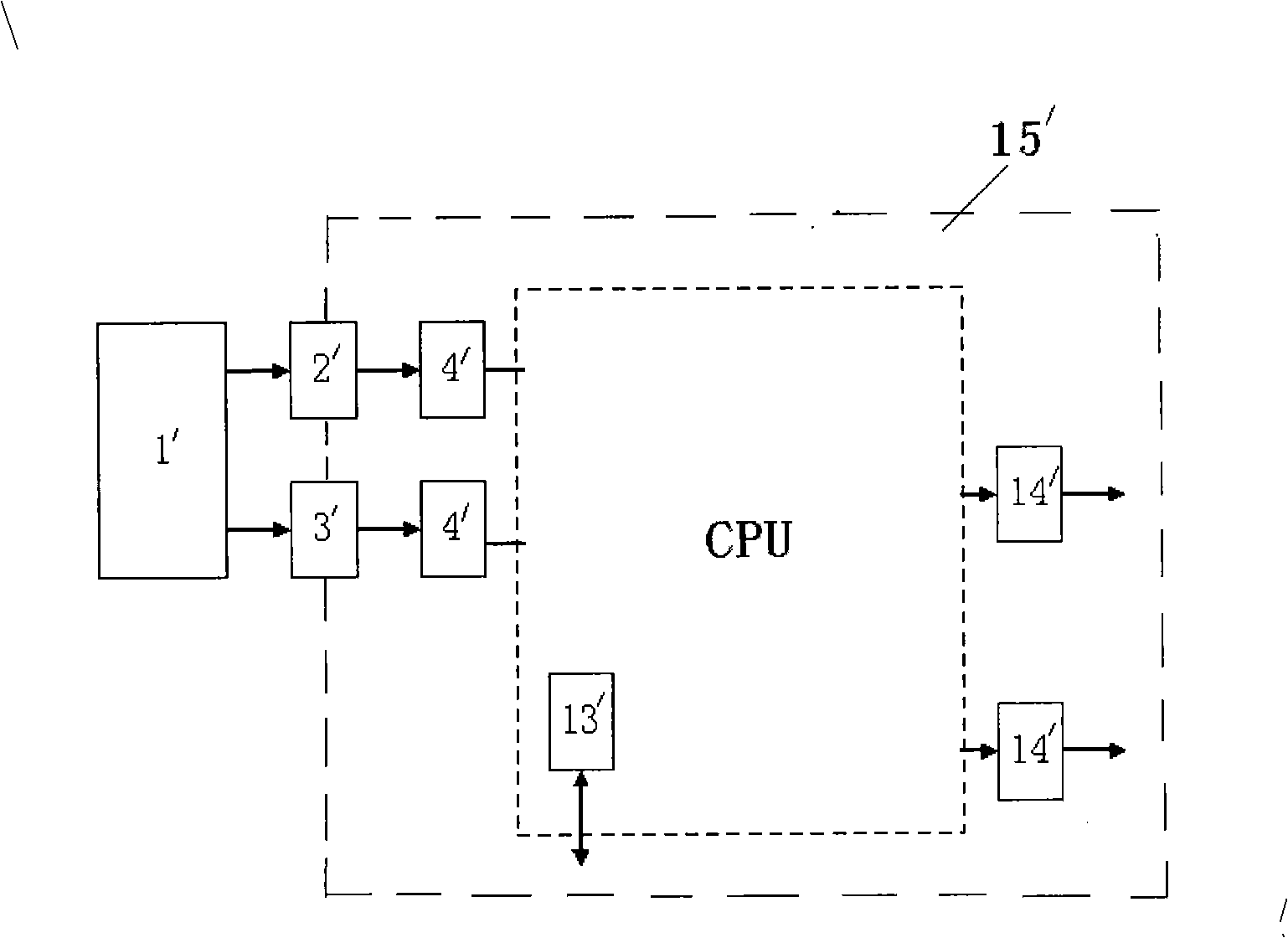

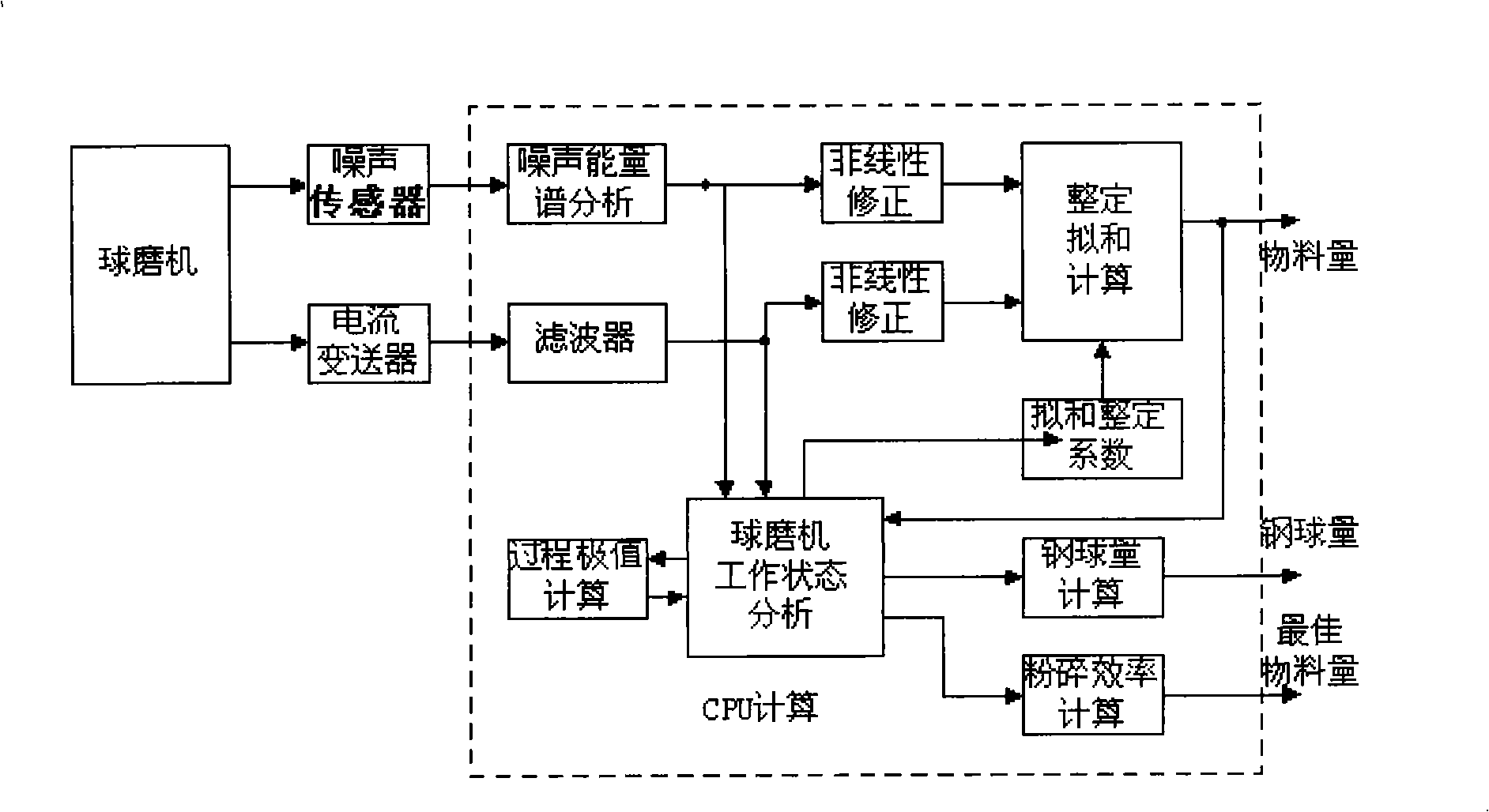

InactiveCN101329193AGuaranteed long-term reliabilityOptimize runMachines/enginesLevel indicatorsFull scaleMeasurement device

The invention relates to a ball grinder and discloses a device and a method for measuring the inventory of a multifunctional, self-rectifying and fixed-ball grinder. The device comprises a noise probe of the ball grinder and an inventory transducer of the self-rectifying and fixed-ball grinder. The method comprises the following steps: (a) noise energy is extracted and noise frequency spectrum is analyzed; (b) the largest grinding current of the ball grinder is calculated and determined; (c) measurement is implemented automatically in real time, and a curve of the relation between grinding current and the inventory of the ball grinder as well as a curve of the relation between grinding noise and the inventory are rectified; (d) the relation between the grinding current and the inventory of the ball grinder and the relation between the grinding noise and the inventory are fitted, and the inventory of the ball grinder is calculated; (e) the quantity of steel balls inside the ball grinder is determined and output according to the largest grinding current and characteristic spectrum change; (f) the optimal inventory of the ball grinder is determined and output according to noise spectrum change when various materials are fed into the ball grinder. The invention is stable, reliable and characterized by full-scale measurement and long-time accurate measurement.

Owner:SHIJIAZHUANG DEV ZONE TIANNENG SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com