Preparation method of magnesium stearate with improved specific volume and whiteness

A technology of magnesium stearate and stearic acid, applied in the preparation of carboxylate, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problem of high energy consumption and water consumption, low production efficiency, decreased reactivity, etc. problems, to achieve the effect of improving efficiency and quality indicators, improving production efficiency, and reducing drying processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

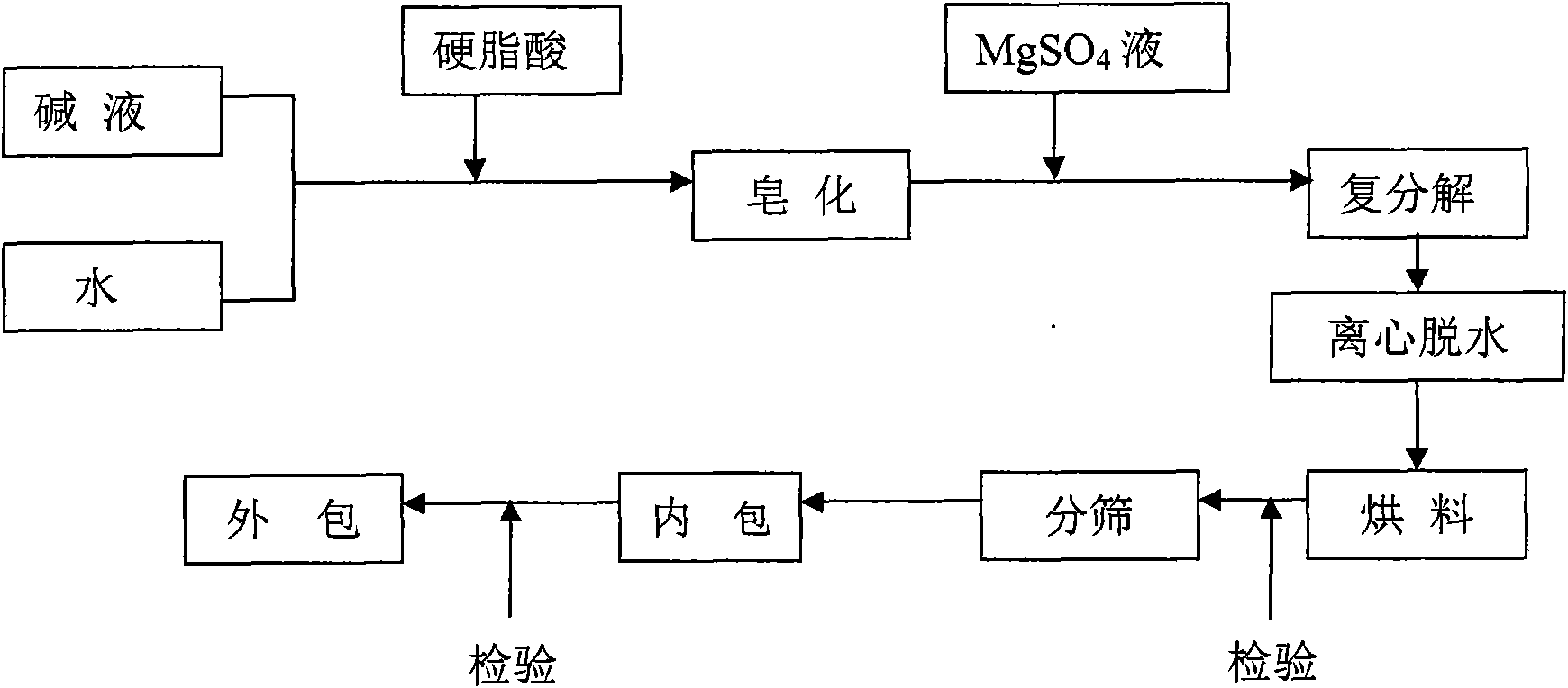

Method used

Image

Examples

Embodiment Construction

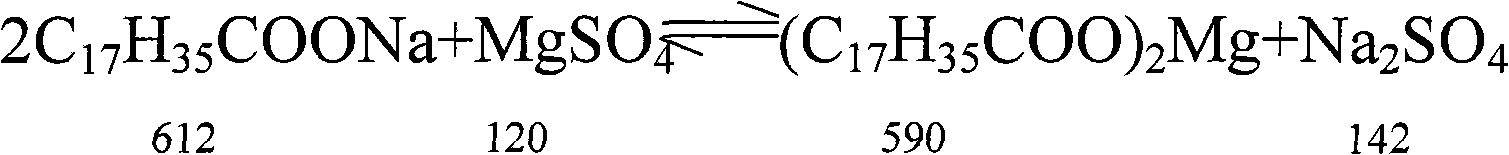

[0030] Describe in detail below in conjunction with specific embodiment:

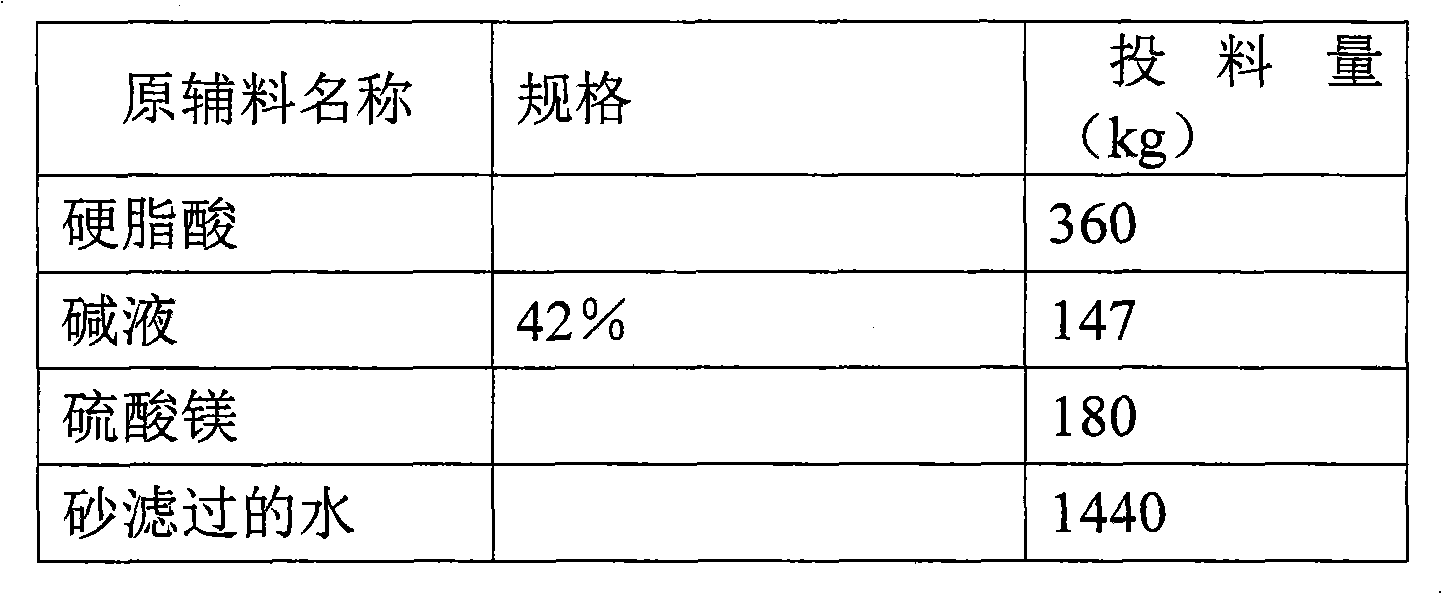

[0031] A kind of magnesium stearate, described raw material is stearic acid, lye, magnesium sulfate, sand filter water, and its mass ratio is: 1.8~2.2: 0.7~0.9: 1: 7.6~8.4, the concentration of described lye 40%. The material of this embodiment is as follows:

[0032] Name of raw material

Specification

Feeding amount (kg)

stearic acid

200

lye

40%

80

magnesium sulfate

50%

100

sand filtered water

800

[0033] The preparation method that magnesium stearate improves its specific volume and whiteness, the steps are as follows:

[0034] Step 1, batching: Pour 32kg of the prepared caustic soda into the alkali tank, add about 660kg of sand-filtered water, open the compressed air valve to blow and dissolve, and adjust the concentration of the lye to 40% after dissolving. Compared with the traditional process, the conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com