Aluminum electrolysis cell region control system and method

A zone control, aluminum electrolytic cell technology, applied in the field of electrolytic cell control system, can solve the problems of unbalanced melt interface fluctuation, severe fluctuation, energy waste, etc., to achieve stable electrolytic cell operation, improve control accuracy, and improve current efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

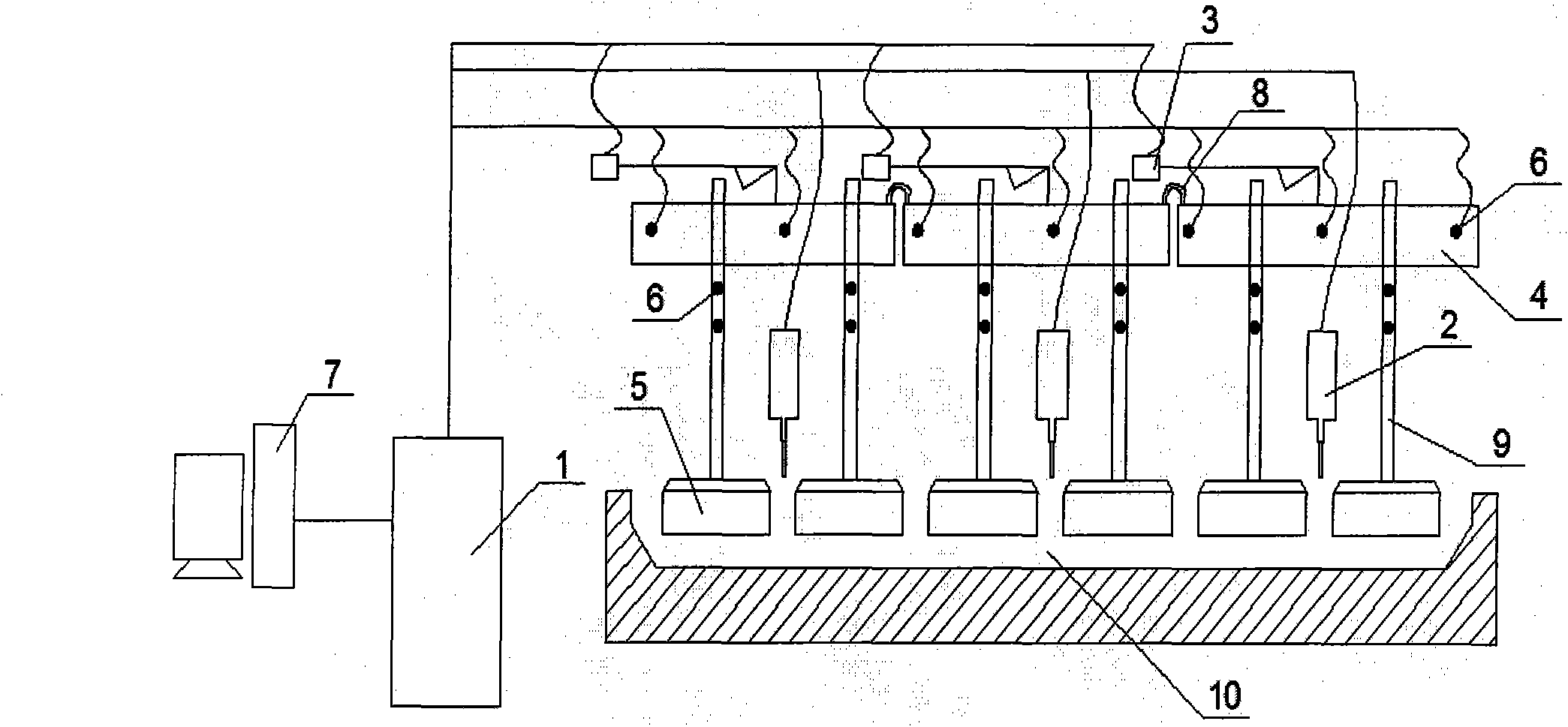

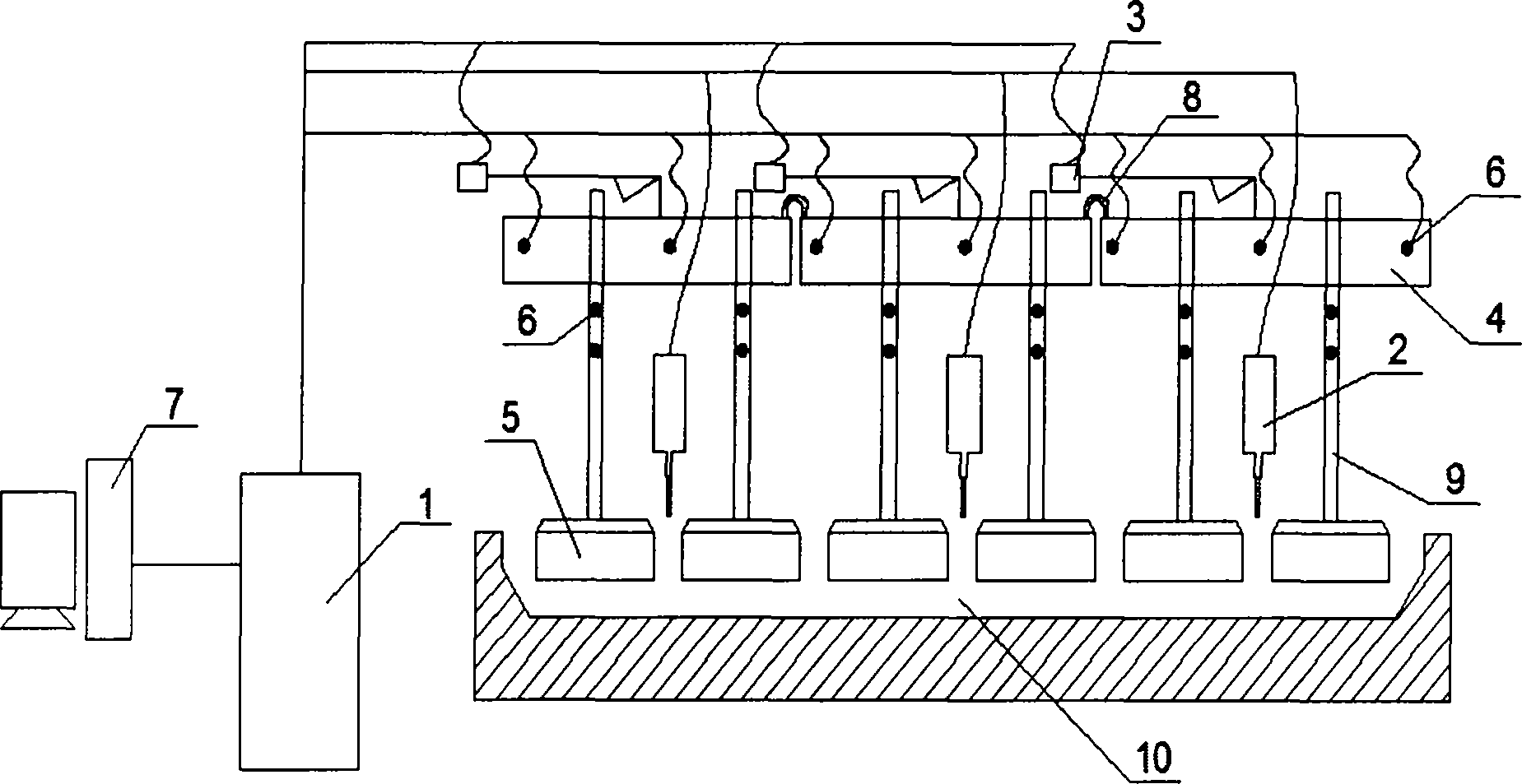

[0028] Such as figure 1 As shown, the regional control system for the aluminum electrolytic cell of the present invention includes the electrolytic cell 10 and the cell control machine 1, divides the electrolytic cell 10 into two control areas, and is provided with a signal acquisition and processing subsystem and a cell condition diagnosis in each control area Subsystem, regional alumina feeding subsystem and regional pole distance control subsystem; the signal acquisition and processing subsystem is a signal acquisition device 6 arranged on the anode guide rod 9 and / or the anode busbar 4, and the signal acquisition device 6 collects voltage or Current signal; the tank condition diagnosis subsystem is composed of the following structure: the tank control machine 1 receives the signal sent by the signal acquisition and processing subsystem, and sends the control signal to the electrolyzer after processing; the host computer 7 receives the signal from the tank control machine 1 ...

Embodiment 2

[0037] The electrolytic cell 10 in Embodiment 1 is divided into three control areas, and two anode lifting mechanisms are arranged in each control area, and two alumina feeding devices are arranged in each control area. other same

[0038] Example 1.

Embodiment 3

[0040] The electrolytic cell 10 in Embodiment 1 is divided into four control areas, three anode lifting mechanisms are arranged in each control area, and four alumina feeding devices are arranged in each control area. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com