Fermenting method for joint production of alpha-ketoglutaric acid and pyruvic acid

A technology of ketoglutaric acid and fermentation method, applied in the field of fermentation engineering, can solve the problems of adding new impurities to sulfuric acid, low substrate conversion rate, prolonged fermentation period, etc., to promote the accumulation of carboxylic acid, improve economic benefits, shorten the The effect of the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

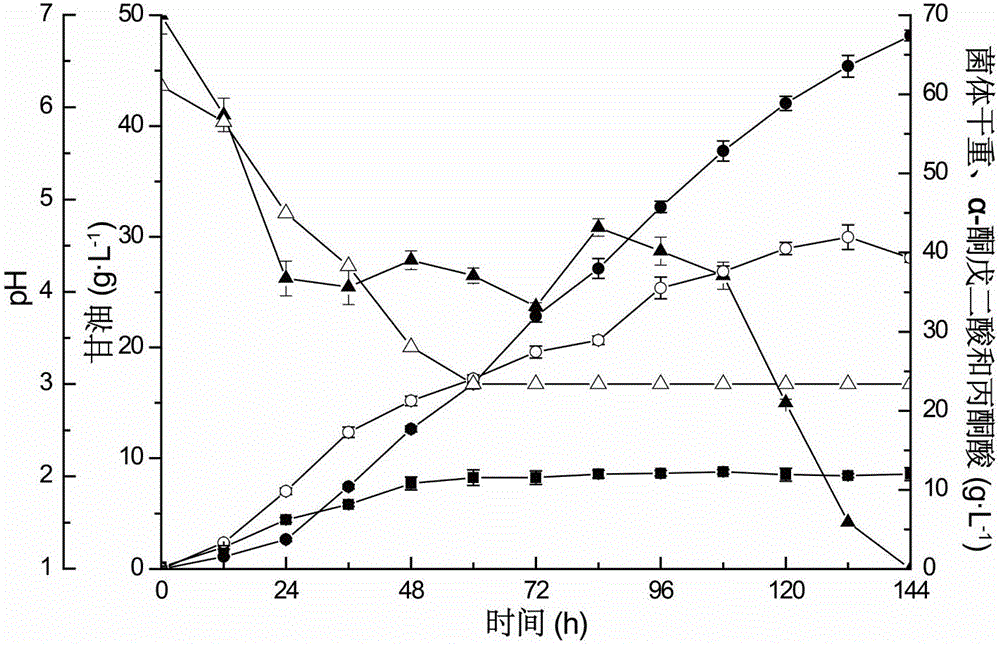

[0023] Carboxylic acid co-production under the condition of initial glycerol concentration 50g / L of embodiment 1 and adding glycerol later stage

[0024] Step 1. Inoculate Yarrowia lipolytica WSH-Z06 from a glycerol tube to the slant of an eggplant bottle for activation. After culturing at 28°C for 24 hours, use an inoculation loop to connect the activated seeds to the first-level seed medium, and incubate at 28°C for 18 hours. Finally, connect the primary seed solution to the secondary seed medium at 0.5% inoculation amount, and after cultivating at 28°C for 18 hours, then transfer the secondary seed liquid to the fermentation medium at 10% inoculation amount, and ferment at 28°C to cultivate. The primary seed cultivation method is: 50mL of liquid in a 500mL Erlenmeyer flask, cultivation temperature of 28°C, rotational speed of 200r / min, cultivation for 17-18h. The secondary seed cultivation method is as follows: 10.5L liquid volume in 15L seed tank, 0.5% inoculum size, 28°C...

Embodiment 2

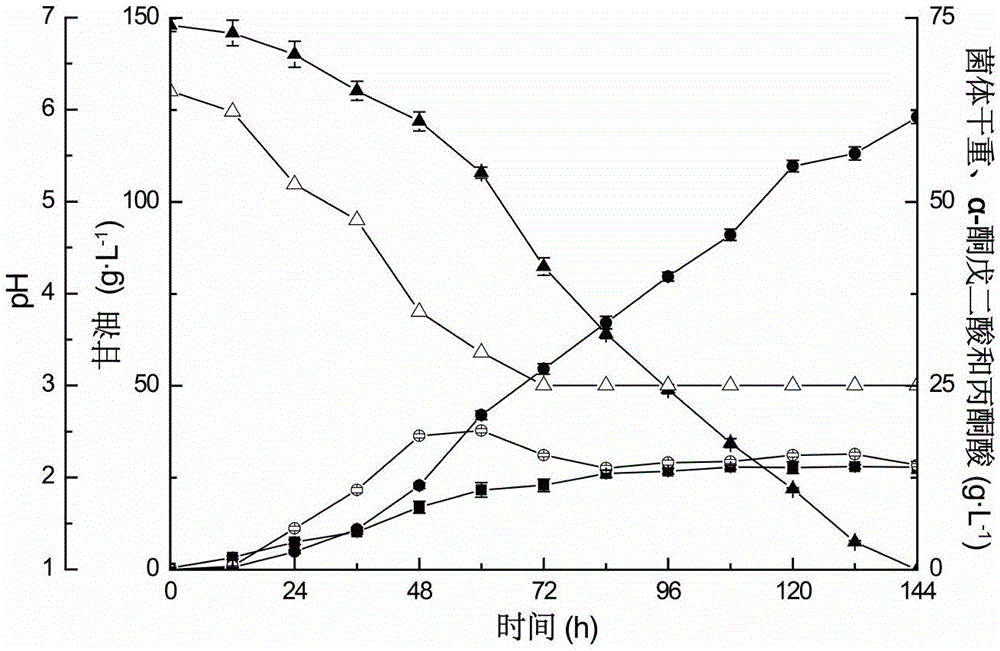

[0028] Carboxylic acid coproduction under the condition of embodiment 2 initial glycerol concentration 150g / L

[0029] Step 1. Inoculate Yarrowia lipolytica WSH-Z06 from a glycerol tube to the slant of an eggplant bottle for activation. After culturing at 28°C for 24 hours, use an inoculation loop to connect the activated seeds to the first-level seed medium, and incubate at 28°C for 18 hours. Finally, connect the primary seed solution to the secondary seed medium at 0.5% inoculation amount, and after cultivating at 28°C for 18 hours, then transfer the secondary seed liquid to the fermentation medium at 10% inoculation amount, and ferment at 28°C to cultivate.

[0030] Step 2, in the early stage of fermentation, rely on the calcium carbonate of 10g / L in the fermentation medium as the pH buffering agent, when the pH naturally drops to 3.0, use 20% Ca(OH) 2 The solution pH was maintained at 3.0.

[0031] During the fermentation process, the initial glycerol concentration was 1...

Embodiment 3

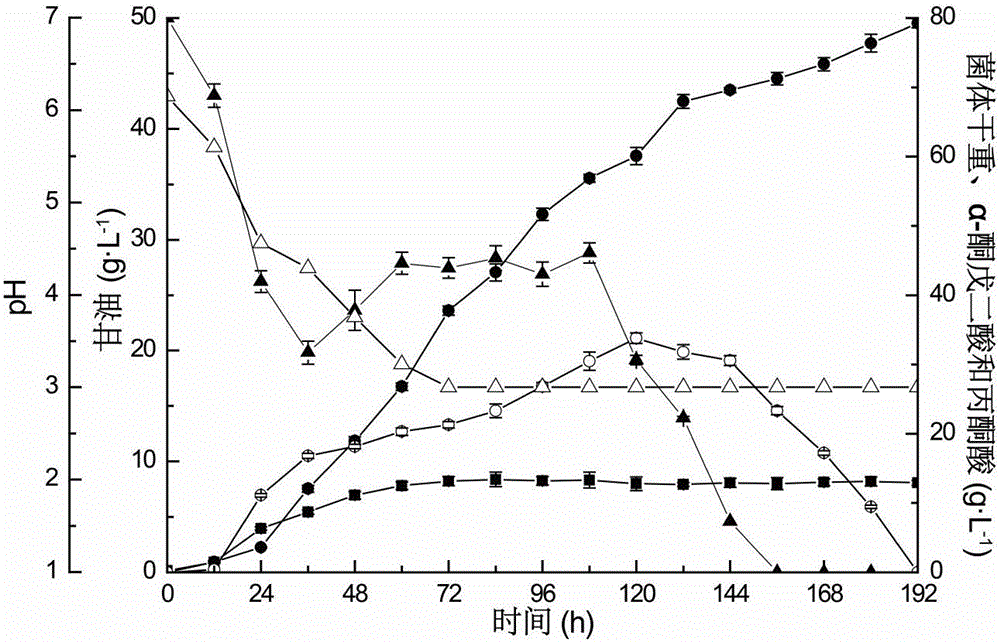

[0033] Example 3 Only α-ketoglutaric acid is produced under the condition of initial glycerol concentration of 50g / L and adding glycerol later

[0034] Step 1. Inoculate the bacteria from the glycerol tube to the slope of the eggplant bottle for activation. After culturing at 28°C for 24 hours, use an inoculation loop to connect the activated seeds to the primary seed medium. After cultivating at 28°C for 18 hours, inoculate the The liquid was received into the secondary seed culture medium at 0.5% inoculation amount, and after culturing at 28°C for 18 hours, the secondary seed liquid was received at 10% inoculum amount in the fermentation medium for fermentation and cultivation, and the fermentation was completed after 144 hours of fermentation at 28°C.

[0035] Step 2, relying on 10g / L calcium carbonate in the fermentation medium as a pH buffer in the early stage of fermentation, when the pH naturally drops to 3.0, use 20% Ca(OH) 2 Control the pH and maintain it at 3.0. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com