Patents

Literature

128 results about "Alpha-Ketoglutaric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

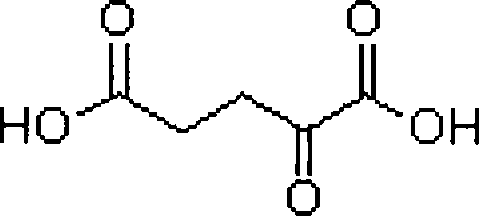

Α-Ketoglutaric acid (2-oxoglutaric acid) is one of two ketone derivatives of glutaric acid. (The term "ketoglutaric acid," when not further qualified, almost always refers to the alpha variant. β-Ketoglutaric acid varies only by the position of the ketone functional group, and is much less common.

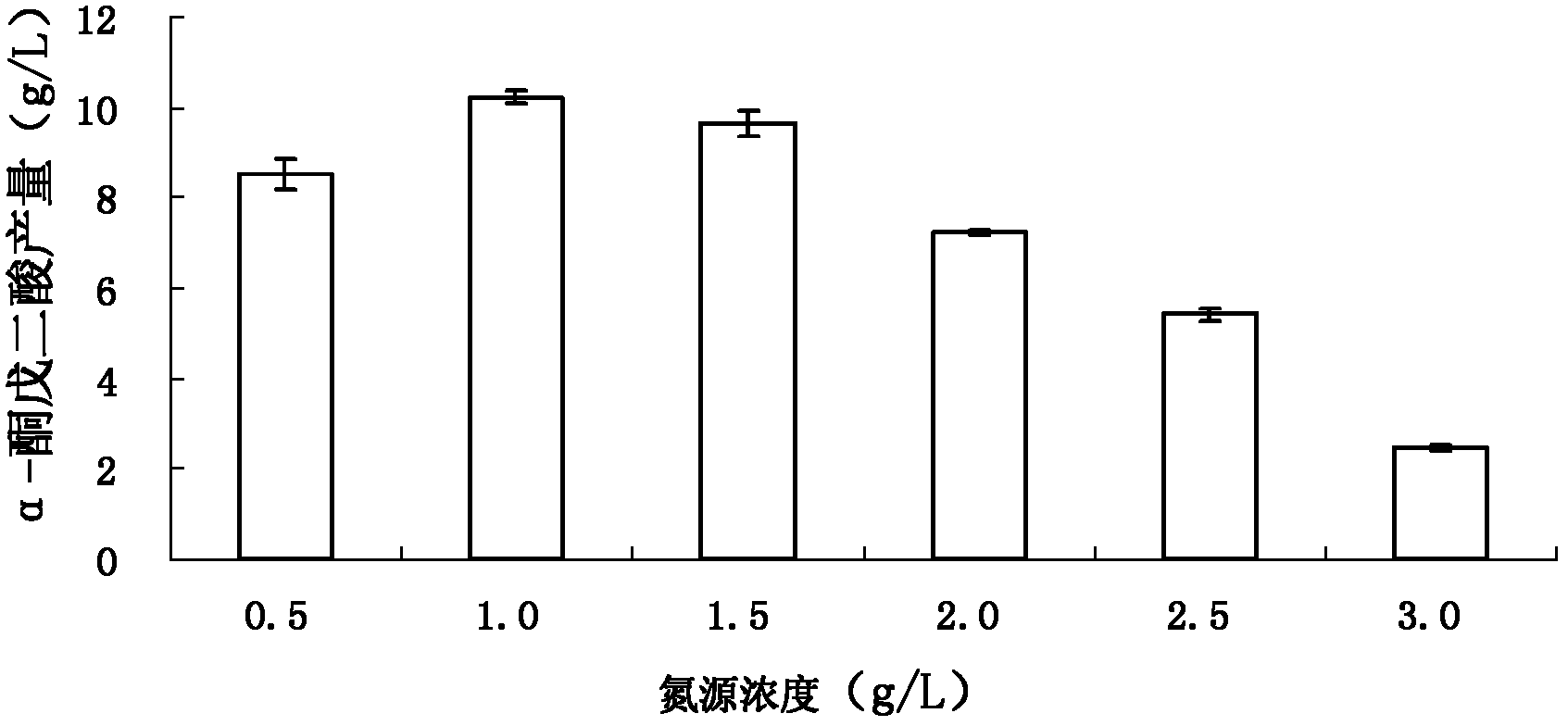

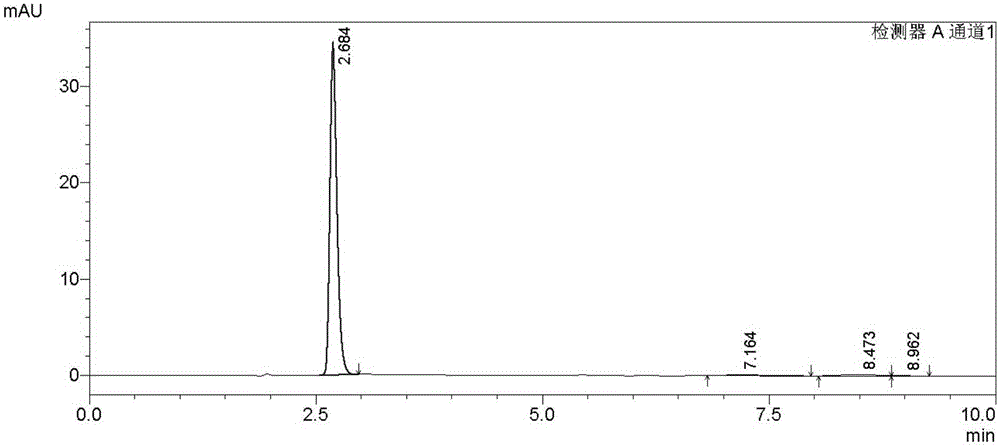

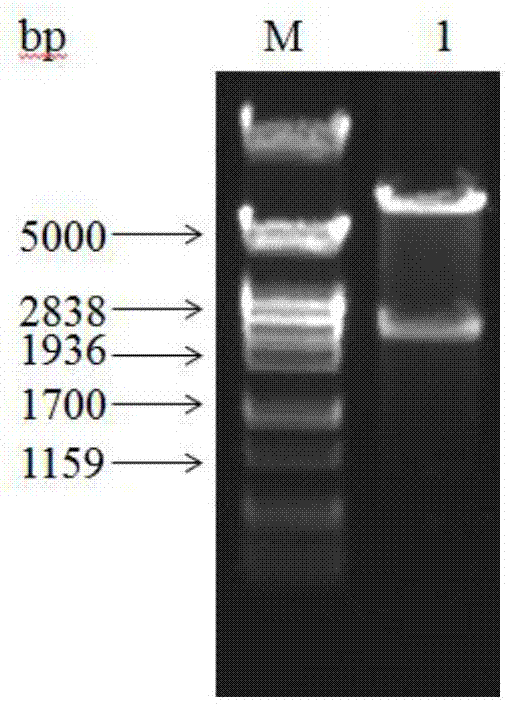

Alpha-ketoglutaric acid high yield bacterium, screening method thereof and production of alpha-ketoglutaric acid from the same by fermentation method

InactiveCN101215529AEfficient accumulationFungiMicrobiological testing/measurementScreening methodMicrobiology

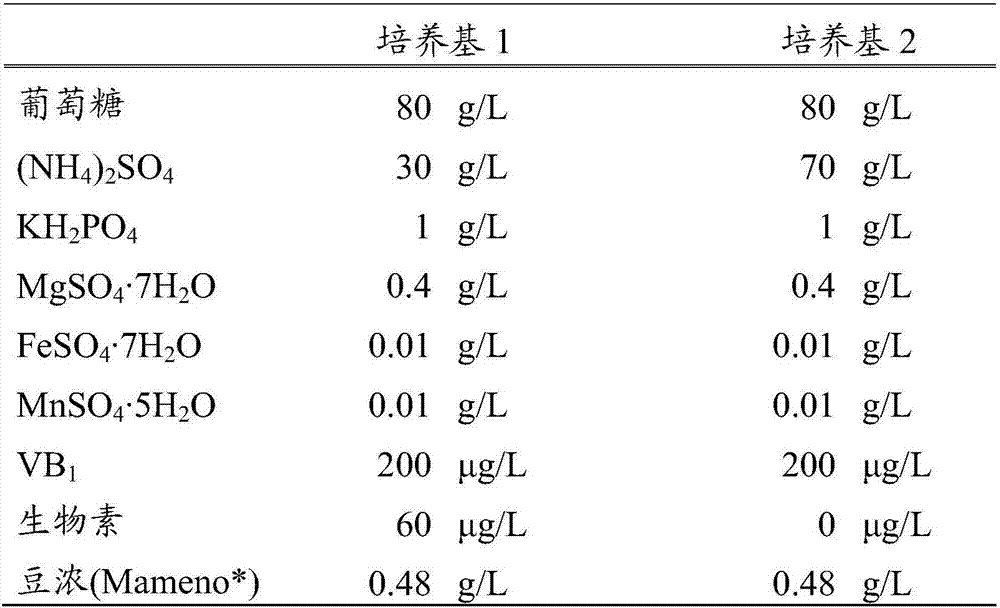

An alpha-ketoglutaric acid high-yield strain and a method for sieving and preparing alpha-ketoglutaric acid through strain by fermenting belong to the chemical engineering technique field. The strain of the invention is Yarrowia lipolytica WSH-Z06 and the preservation number is CCTCC NO: M207143. The strain is aneurine nutriment defect strain which is contrasted and sieved from the soil near the oil refinery according to the colony growth condition on the complete culture medium, basic culture medium and complementary culture medium flats, and then the aneurine nutriment defect strain is adopted by one-grade ferment to do shake flask culture one by one and sieve primarily. The fermentation liquor is analyzed by silica gel chromatography. The strain which keeps alpha-ketoglutaric acid colour development spot is transferred in the shake flask which is loaded with ferment culture medium to do ferment sieve again. The fermentation liquor is tested by high-effective liquid-phase method and produces the high-yield alpha-ketoglutaric acid strain compared with the production of alpha-ketoglutaric acid. The production of alpha-ketoglutaric acid can reach 39.3 g / L through optimizing the important component in the ferment culture medium and fermenting for 6 d.

Owner:JIANGNAN UNIV

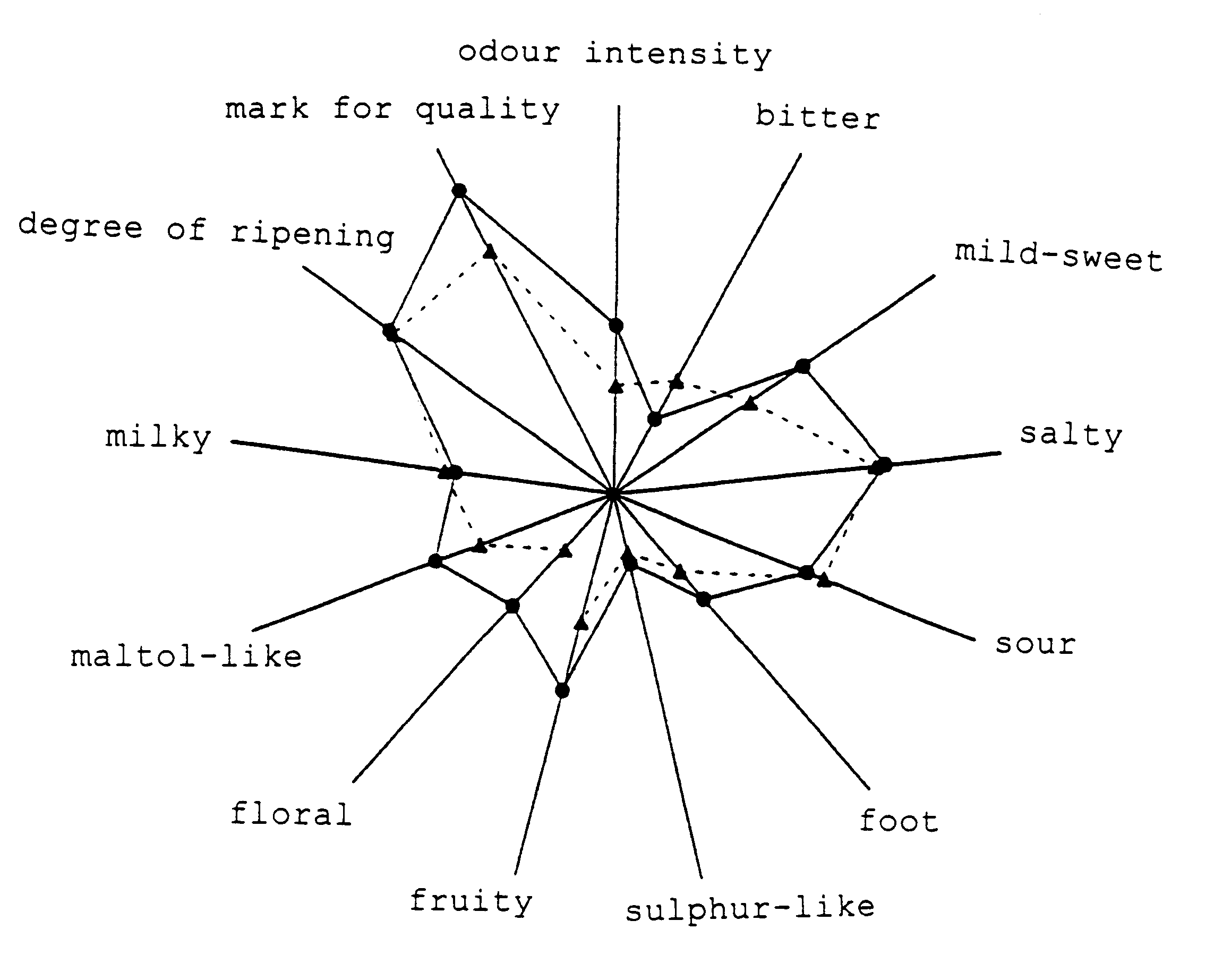

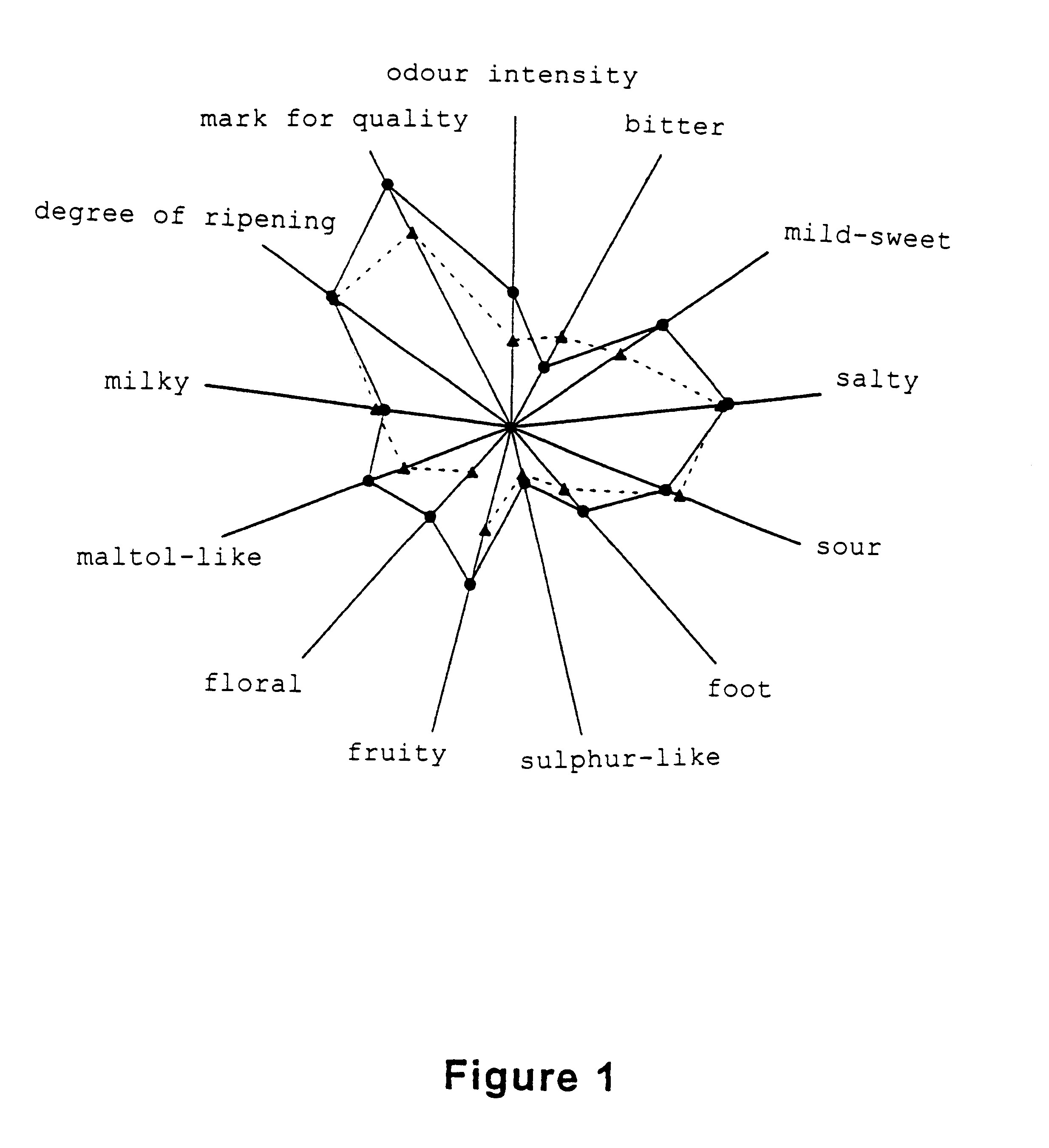

Use of keto acids to enhance the flavor of cheese products

Process for enhancing the flavour of a cheese or of a cheese-flavoured food product whose preparation comprises a maturation step in the presence of lactic acid bacteria, characterized in that a preparation additive comprising at least one keto acid chosen from the group consisting of alpha-ketoglutaric acid, alpha-ketoisocaproic acid ketoisovaleric acid and phenylpyruvic acid is used to increase the catabolism of the amino acids in the cheese or food product by the said bacteria.

Owner:INSTITUT NATIONAL DE LA RECHERCHE AGRONOMIQUE

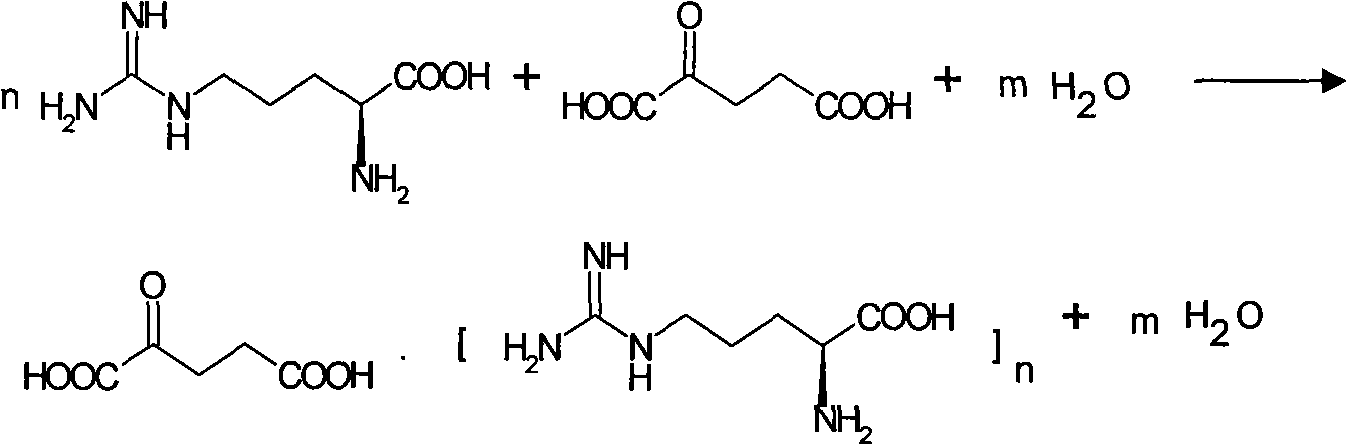

Preparation method of crystal L-arginine alpha-ketoglutarate

InactiveCN101591271AReasonable workmanshipSimple stepsOrganic chemistryFood preparationArginineL-arginine alpha-ketoglutarate

The invention relates to a preparation method of crystal L-arginine alpha-ketoglutarate, comprising the following steps: preparing water solution of L-arginine, and slowly adding alpha-ketoglutaric acid into the water solution, wherein the mol ratio of L-arginine and alpha-ketoglutaric acid is 1:1 or 2:1; reducing pressure and concentrating the alpha-ketoglutaric acid at 50-80 DEG C after complete dissolution, removing water accounting for 20-60 percent of the total volume and cooling to 20-30 DEG C; slowly adding an organic hydrophilic solvent or a mixed solvent of a polar hydrophilic solvent and a non-polar hydrophilic solvent; and carrying out temperature reduction, crystallization, filtering, washing and vacuum drying to obtain the crystal L-arginine alpha-ketoglutarate. Compared with the prior art, the invention has the advantages of reasonable process, simple steps, easy operation, good crystal form of the obtained product, difficult caking, convenient transportation and use, high purity (more than or equal to 98 percent) and high yield (80-86 percent) of the product, and the like, and is suitable for industrialization production.

Owner:上海汉飞生化科技有限公司

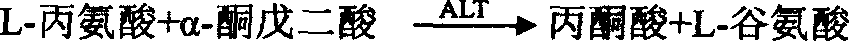

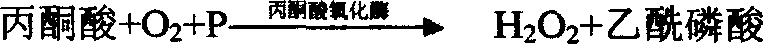

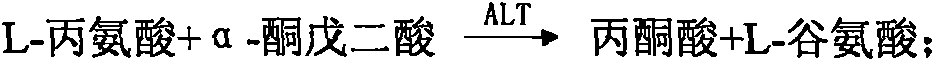

Glutamate-pyruvate transaminase determination method and glutamate-pyruvate transaminase determination reagent kit

ActiveCN1995378AReactivityImprove detection accuracyMicrobiological testing/measurementMaterial analysisAlanine aminotransferaseOxygen

The invention discloses a measuring method of Alanine Aminotransferase (ALT) and agent box in the external diagnostic technical domain, which comprises the following steps: reacting agent 1 and sample; generating hydrogen peroxide through reacting acetonic acid oxidase and endogenous acetonic acid; producing water and oxygen from hydrogen peroxide acted by catalase; reacting with agent 2; utilizing L-Ala and alpha-ketoglutaric acid starting serum ALT to react; detecting the activity of serum ALT of absorbance change of linear reaction.

Owner:BEIJING BGI GBI BIOTECH

Preparing method of alpha-ketoglutaric acid-arginine salt and its use for treating hepatic disease

The invention relates to an alpha-ketoglutaric acid-arginine salt, the preparing process and use thereof, wherein the salt is prepared through combining alpha-ketoglutaric acid and arginine with a preferred ratio of 1:1 and 1:2. Pharmacological experiment shows that, the salt can be used for treating liver damages.

Owner:BEIJING JIASHILIANBO PHARM SCI & TECH

Detection reagent for alanine aminotransferase

ActiveCN103320497AHigh sensitivityImprove accuracyMicrobiological testing/measurementThiamine pyrophosphatePhosphoric acid

The invention discloses a detection reagent for alanine aminotransferase. The detection reagent comprises a diluent and a reaction reagent. The diluent comprises a buffer, a surfactant, an antiseptic, a bilirubin-interference removing reagent, and an ascorbic oxidase. The reaction reagent comprises a buffer, L-alanine, alpha-ketoglutaric acid, phosphoric acid, pyruvate oxidase, thiamine pyrophosphate, magnesium chloride, peroxidase, 4-aminoantipyrene, a chromogen, an antiseptic, and a freeze-drying protecting agent. The detection reagent has advantages of good sensitivity, accuracy, precision and linearity, and can completely meet the requirements of clinical examination.

Owner:NINGBO MEDICAL SYSTEM BIOTECHNOLOGY CO LTD

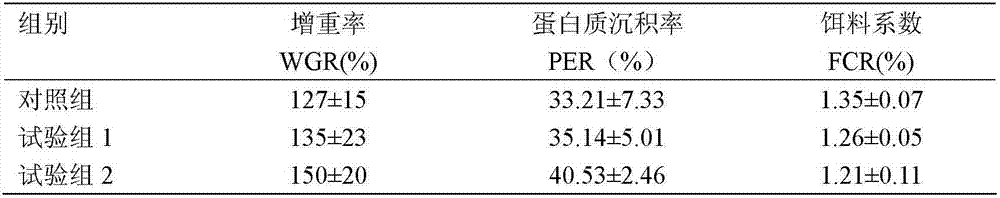

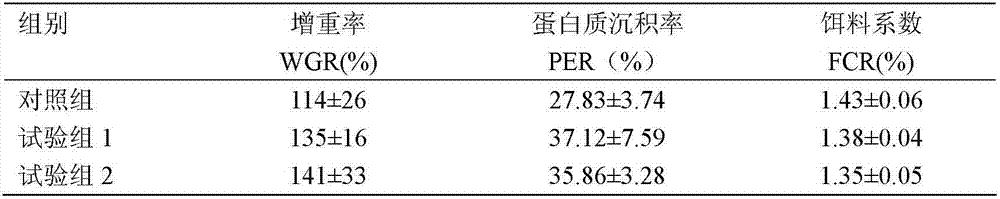

Feed capable of enhancing growth performance and protein deposition of carp

The invention relates to a feed capable of enhancing growth performance and protein deposition of a carp, solving the problem that protein deposition rate of the existing feed is low. The feed capable of enhancing growth performance and protein deposition of carp comprises the following components in parts by weight: 17-19 parts of fish meal, 29-40 parts of soybean meal, 32-45 parts of middlings, 0.8-1.1 parts of soybean lecithin, 2-3 parts of fish oil, 1-2 parts of soybean oil, 1.5-2.5 parts of monocalcium phosphate, 0.4-0.6 part of choline, 0.2-0.5 part of lysine, 0.1-0.25 part of sulfur-containing amino acid, 0.4-0.6 part of premix and 0.7-1.6 parts of alpha-ketoglutaric acid. The feed provided by the invention is applied to the field of carp cultivation.

Owner:HEILONGJIANG RIVER FISHERY RES INST CHINESE ACADEMY OF FISHERIES SCI

Alanine aminotransferase detection kit

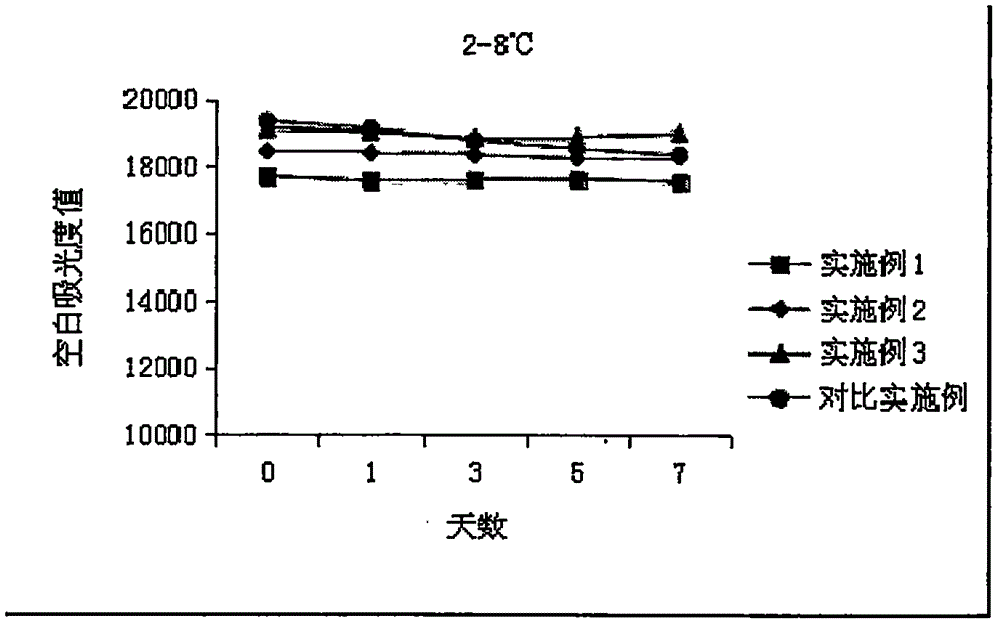

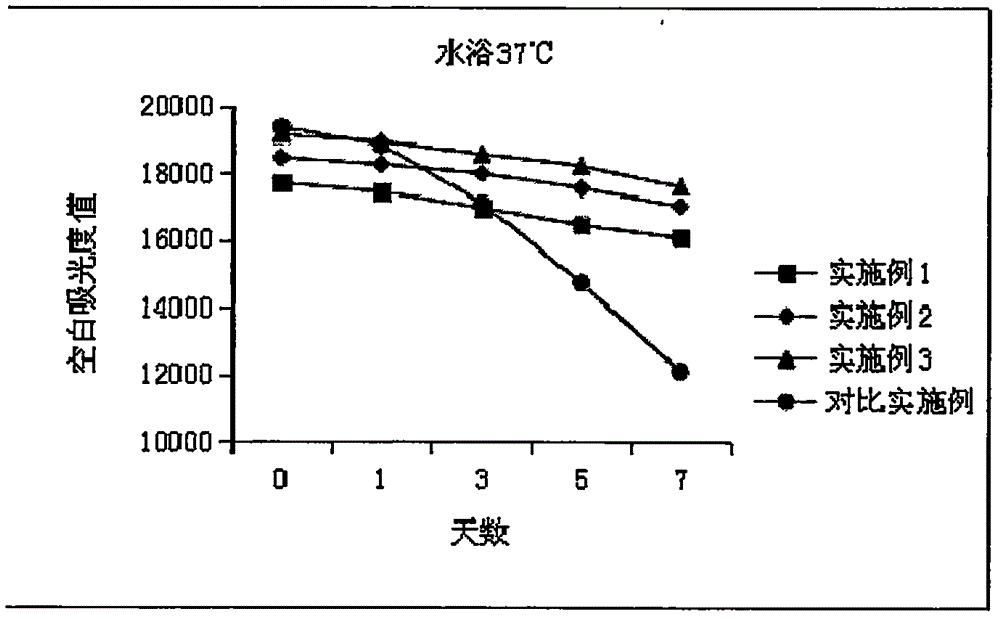

InactiveCN106501514AEliminate distractionsImprove accuracyAnalysis by subjecting material to chemical reactionLactate dehydrogenasePreservative

The invention relates to an alanine aminotransferase (ALT) detection kit, belongs to the technical field of clinical in vitro diagnostic reagents, and aims at being capable of providing an alanine aminotransferase detection kit which can effectively eliminate interference of endogenous alpha-ketoglutaric acid and is good in stability to enable an alanine aminotransferase determination result to be more accurate and reliable. The kit comprises a reagent 1 and a reagent 2, wherein the reagent 1 is prepared from a Tris-HCl buffer solution, L-alanine, a reduced coenzyme (NADH), lactic dehydrogenase (LDH), an enzyme protectant, a stabilizer and a preservative, and the reagent 2 is prepared from a Tris-HCl buffer solution, alpha-ketoglutaric acid, a stabilizer and a preservative. Due to the fact that the enzyme protectant and the stabilizer are added into the ALT detection kit, the stability of the alanine aminotransferase detection kit is improved, and the alanine aminotransferase (ALT) detection kit is suitable for various full-automatic biochemical analyzers, easy to operate, safe in operation and convenient to apply and popularize clinically.

Owner:王贤俊

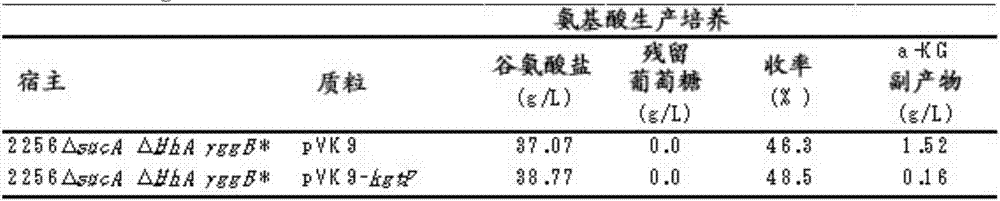

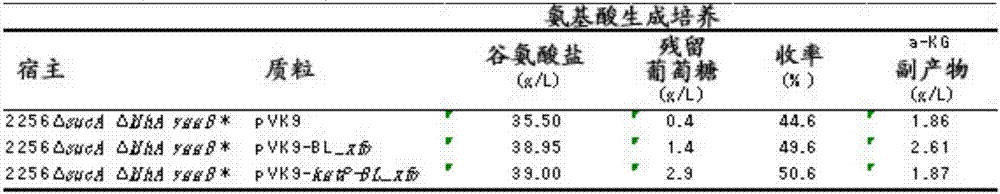

Method for Producing L-Amino Acid of Glutamate Family

ActiveCN107034250AIncrease production capacityEfficient preparationBacteriaTransferasesAlpha-Ketoglutaric acidCoryneform bacterium

A method for producing an L-amino acid of glutamate family such as L-glutamic acid is provided. An L-amino acid of glutamate family is produced by culturing a coryneform bacterium having an ability for producing an L-amino acid of glutamate family, which has been modified so that the activity of an alpha-ketoglutaric acid (alpha-KG) uptake carrier is increased, in a medium, and collecting the L-amino acid of glutamate family from the medium.

Owner:AJINOMOTO CO INC

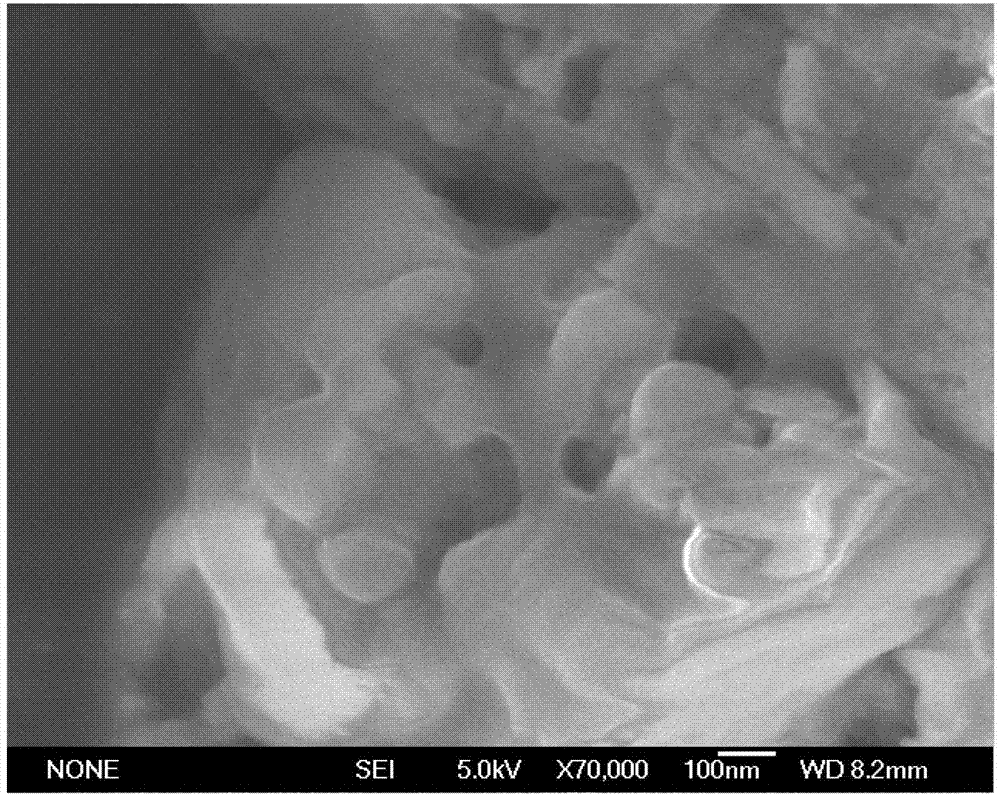

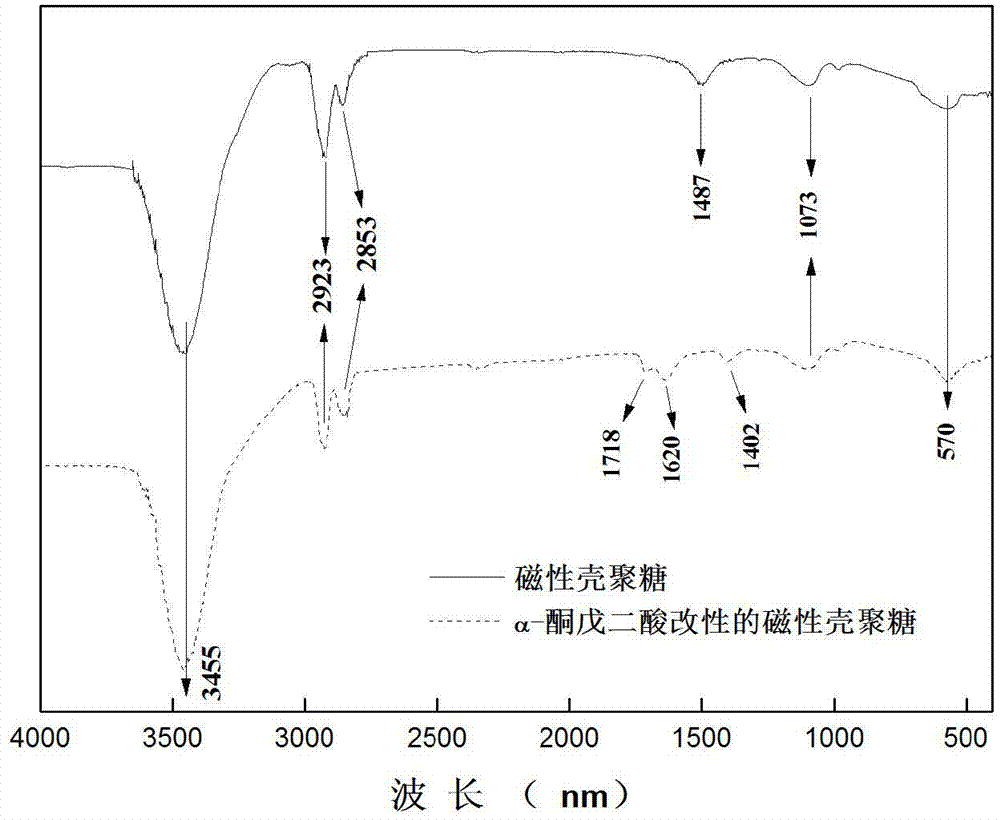

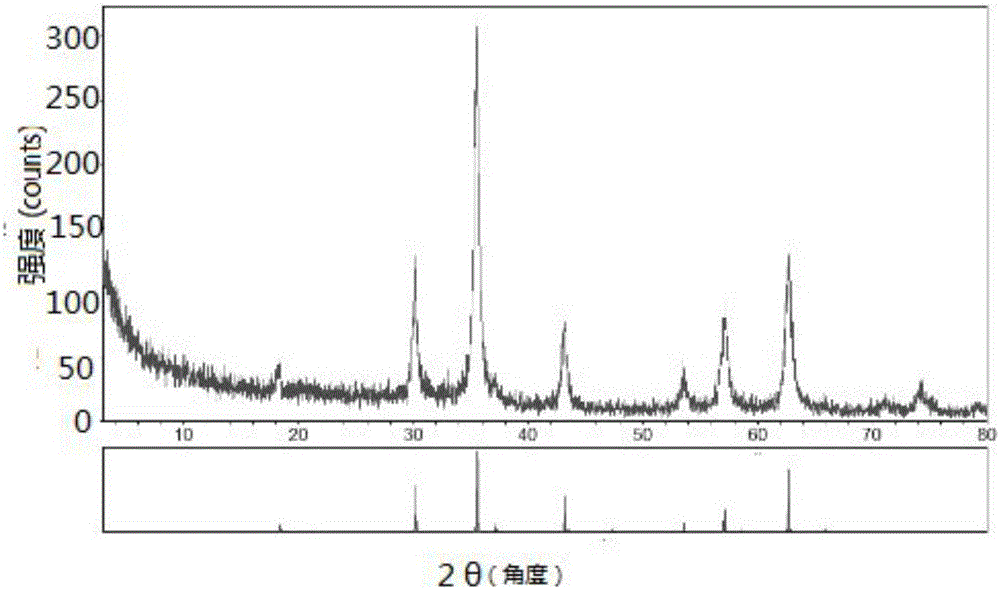

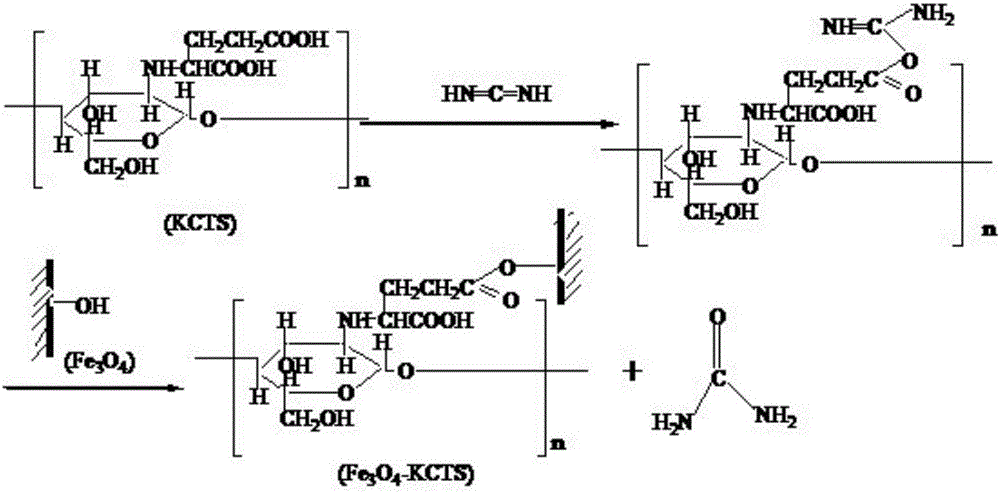

Alpha-ketoglutaric acid modified magnetic chitosan and preparation method and application thereof in field of cadmium-containing wastewater treatment

InactiveCN103611503AStable physical and chemical propertiesStrong magnetismOther chemical processesAlkali metal oxides/hydroxidesCadmium CationKetoglutaric Acid

The invention provides alpha-ketoglutaric acid modified magnetic chitosan. The alpha-ketoglutaric acid modified magnetic chitosan contains ferroferric oxide, chitosan and alpha-ketoglutaric acid and has the saturated magnetization value of 20-25emu / g, wherein magnetic chitosan is prepared from ferroferric oxide and chitosan, modified magnetic chitosan is of a reticular structure, peak values of functional groups, such as Fe-O bonds and the like, appear in an infrared spectrogram, and an agglomeration phenomenon is expressed. A preparation method of the alpha-ketoglutaric acid modified magnetic chitosan comprises the steps of adding an acetic acid solution containing chitosan into a ferroferric oxide suspension, adding a sodium tripolyphosphate solution, reacting and separating, so as to obtain the magnetic chitosan; then, adding alpha-ketoglutaric acid into an acetic acid buffer solution containing the magnetic chitosan, adding a sodium borohydride solution, and separating, thereby obtaining the alpha-ketoglutaric acid modified magnetic chitosan. The alpha-ketoglutaric acid modified magnetic chitosan has stable physical and chemical properties and strong magnetism; during the treatment of wastewater containing cadmium ions, the treatment efficiency is high, and the alpha-ketoglutaric acid modified magnetic chitosan can be repeatedly used and is convenient to recover.

Owner:HUNAN UNIV

Use of alpha-ketoglutaric acid

ActiveCN103340293APromote growthRegulates the immune systemAnimal feeding stuffAlpha-Ketoglutaric acidFodder

The invention discloses a use of alpha-ketoglutaric acid. The alpha-ketoglutaric acid can be used as immune regulating / promoting agent for grass carp and anti-ammonia-nitrogen stress agent additive for the grass carp in the form of additive to be added into grass carp feed, so that the grass carp growth can be promoted and the immune function and anti-ammonia-nitrogen stress capacity of the grass carp can be improved, and therefore, problems that the grass carp feed conversion rate is low, and the anti-ammonia-nitrogen stress capacity of the grass carp is poor can be solved.

Owner:HUNAN AGRICULTURAL UNIV

Blood ammonia reagent kit for enzyme detection

The reagent kit for enzyme detection of blood ammonia consists of tromethamine in 50-150 mmol, Tween-20 in 0.1-2 ml, sodium azide om 0.5-2 g, lactose in 5-50 g, glutamate dehydrogenase in 500-1500 u, alpha-ketoglutaric acid in 2-20 mmol, sodium acetonate in 1-10 mmol, and reducing nicotin-amide-adenine dinuclectide phosphate in 0.1-0.5 mmol. After regulating pH to optimal value of 8.0, the components are dissolved, packed and freeze dried and may be cold stored for two years. After being re-dissolved, the components are stabilized at room temperature for 1 week and cold stored to stabilize for 1 month. The reagent kit has powerful interference resistance, medium hemolysis and chylemia, blood sugar below 20 mmol / L, bilirubin below 0.1 mmol / L, enzyme activity loss less than 5 %, MADPH loss less than 10 %, linearity reaching 0.2 mmol / L, CV inside batch of 3.8 % and CV between batches of 5.1 %, and recovering rate of 96.1 %.

Owner:HARBIN MEDICAL UNIVERSITY

Method for extracting alpha-ketoglutaric acid from fermentation liquor

InactiveCN105198732AEmission reductionEfficient emissionsOrganic compound preparationCarboxylic compound separation/purificationHigh concentrationMycoprotein

The invention discloses a method for extracting alpha-ketoglutaric acid from fermentation liquor. The method comprises the following steps: heating fermentation liquor containing the alpha-ketoglutaric acid for sterilization and decolorization, and drying mycoprotein; adding Ca(OH)2 into a filtration liquid, and performing centrifugal separation to obtain calcium 2-oxoglutarate and Ca(OH)2; adding H2SO4 into the calcium 2-oxoglutarate and Ca(OH)2, and performing centrifugal separation to obtain CaSO4 sediments; enabling the filtration liquid to flow into an ion exchange column for adsorption, and adding activated carbon into eluant for decolorization for 30 min; performing pressure reduction evaporation on the high-concentration alpha-ketoglutaric acid solution to obtain alpha-ketoglutaric acid crystals, and performing centrifugal separation to obtain an alpha-ketoglutaric acid crude product, washing the alpha-ketoglutaric acid crude product with methanol, removing impurities through washing, and performing centrifugation to remove methanol, so as to obtain the alpha-ketoglutaric acid, wherein the volume ratio of the alpha-ketoglutaric acid crude product to the methanol is 5:1. Through the adoption of the method, the problems in the prior art that pyruvic acid as a by-product during the extraction process of the alpha-ketoglutaric acid cannot be effectively separated and the discharge amount of waste liquid is high are solved.

Owner:SHANDONG YANGCHENG BIOLOGY TECH CO LTD

Method and special-purposed strain used for producing alpha-ketoglutaric acid

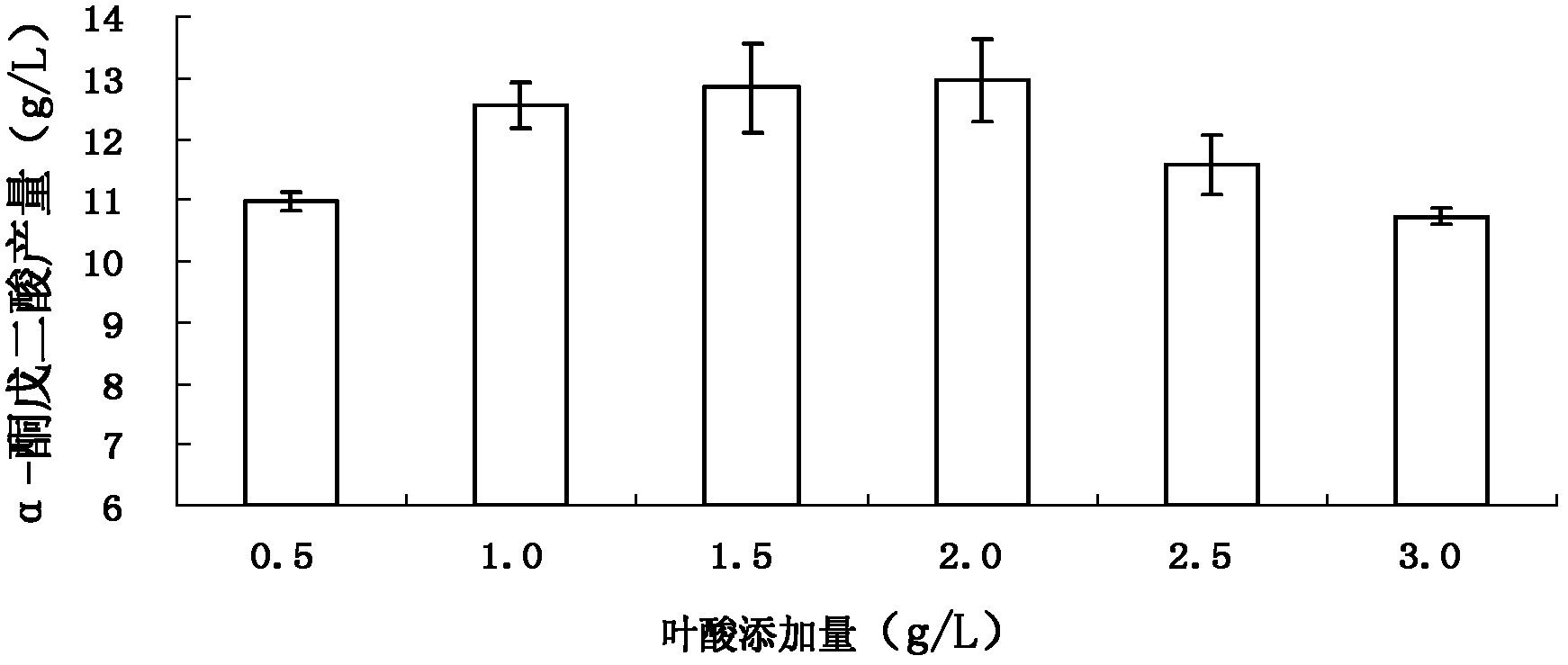

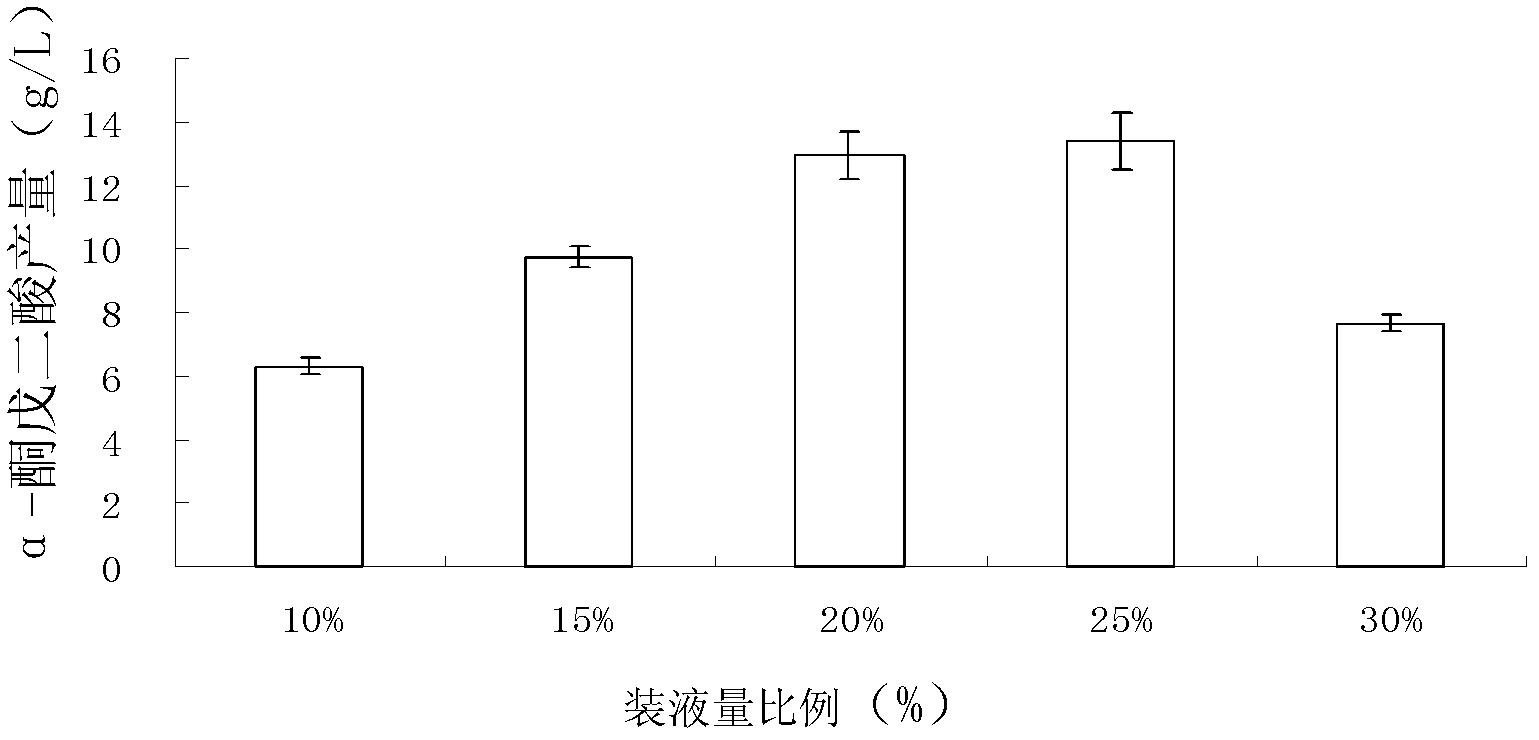

ActiveCN103074232AGood ability to produce α-ketoglutaric acidReduce fermentation costsFungiMicroorganism based processesAlpha-Ketoglutaric acidFermentation condition

The invention provides a method and a special-purposed strain used for producing alpha-ketoglutaric acid. Lichtheimia corymbifera D1 provided by the invention has a collection number of CGMCC NO.4974. The lichtheimia corymbifera D1 provided by the invention has good strain stability, good alpha-ketoglutaric acid production capacity, relatively low fermentation cost (substrates have wide source and low cost), and good industrialized application prospect. The invention also optimizes the fermentation conditions of lichtheimia corymbifera D1. The method provided by the invention is used for producing alpha-ketoglutaric acid, and has good scientific research value and industrial application prospect.

Owner:CHINA AGRI UNIV

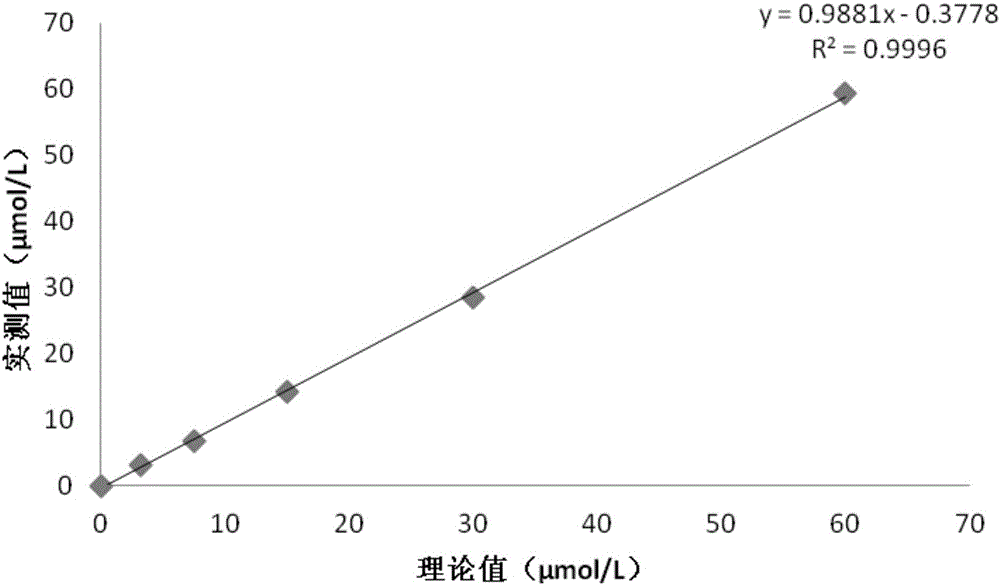

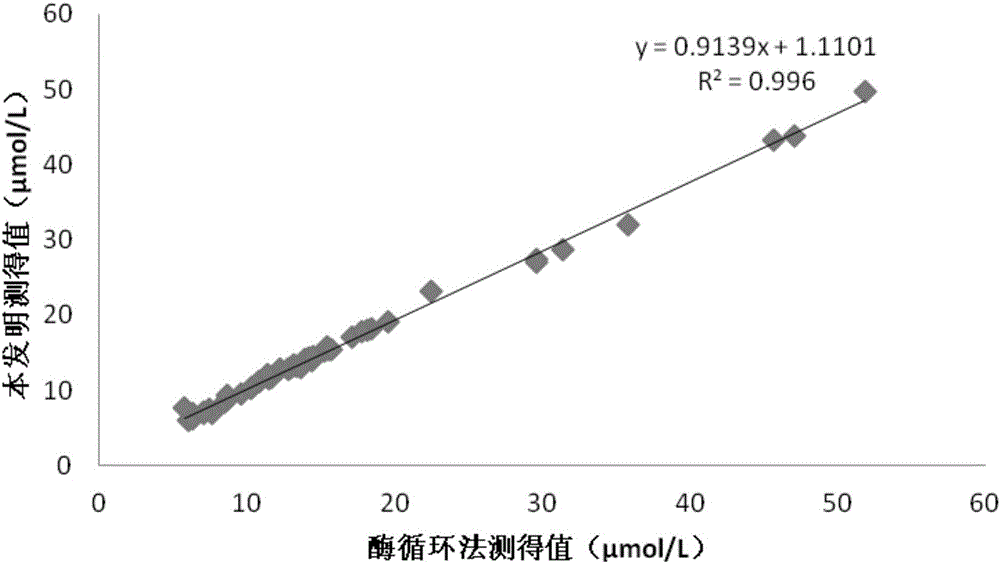

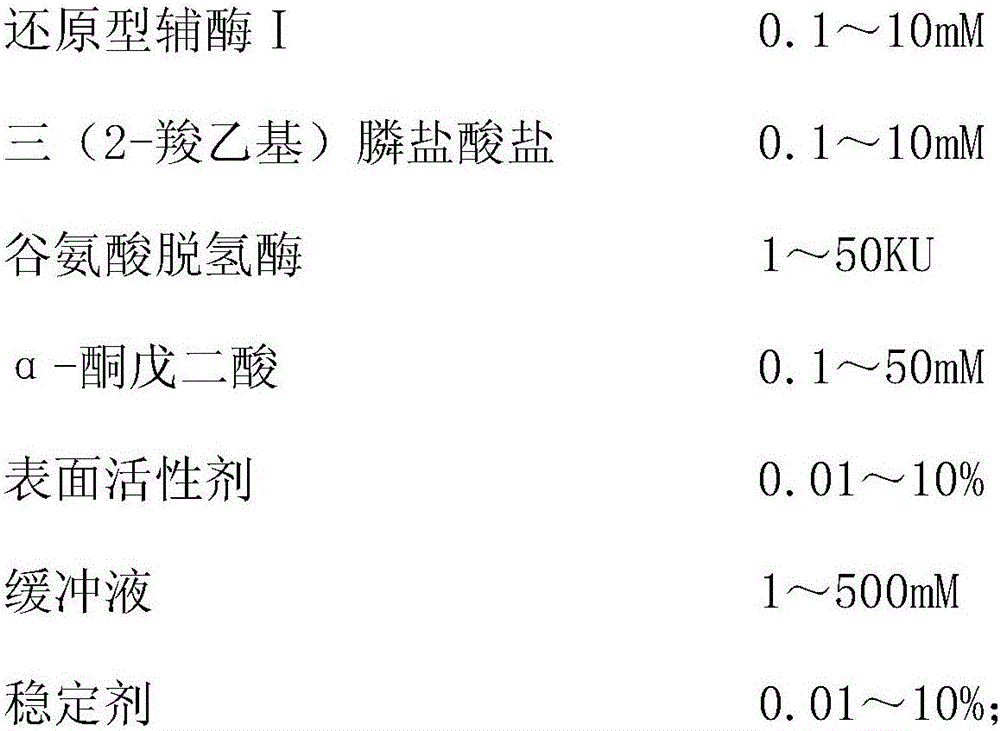

Homocysteine diagnosis kit and homocysteine concentration measuring method

InactiveCN106198995AEasy to detectLow priceColor/spectral properties measurementsBiological testingFluorescencePhosphine

The invention relates to a homocysteine concentration measuring method. The method includes: oxidizing homocysteine to generate alpha-butanone acid, ammonia and hydrogen sulfide; using ammonia to convert NADH into NAD+ under action of glutamate dehydrogenase; quantifying by measuring light absorbance of NADH at a position of 340nm. The homocysteine diagnosis kit comprises a reagent I and a reagent II, the reagent I contains reduced coenzyme I, glutamate dehydrogenase, tri(2-carboxyethyl) phosphine hydrochloride, alpha-ketoglutaric acid, surfactant, buffer solution and stabilizer, and the reagent II contains HCYase, phosphopyridoxal, buffer solution and stabilizer. The homocysteine diagnosis kit and the homocysteine concentration measuring method have the advantages that the kit for detecting homocysteine in human serum through two liquid reagents is built, and an additional fluorescence detector is not needed, so that convenience is brought to detection of plenty of samples; the method is free of interference by pyruvic acid, methionine and cysteine in the samples and lower in cost.

Owner:ENZYMAKER LABCHANGZHOU CO LTD

Specific feed for meat chickens

The present invention discloses a specific feed for meat chickens. The feed comprises the following raw materials: corns, vinegar residues, fermented soybean meal, palm kernel meal, cottonseed meal, fish meal, tenebrio molitor, chicken liver, montmorillonite powder, natural zeolite powder, edible salt, flaxseed oil, corn oil, grape seed oil, plant essential oil, calcium superphosphate, compound vitamins, compound minerals, lysine, methionine, methionine oligopeptides, algal polysaccharides, epimedium polysaccharides, propolis flavones, traditional Chinese medicinal additives, lipoic acid, enzyme preparations, taurine, undaria pinnatifida, and alpha-ketoglutaric acid. The provided special feed for the meat chickens is scientific in formula and comprehensive in nutrition, can meet the growth needs of the meat chickens, improves the immunity of the meat chickens, promotes the growth of the meat chickens, and improves the economic benefits of farmers.

Owner:许孝东

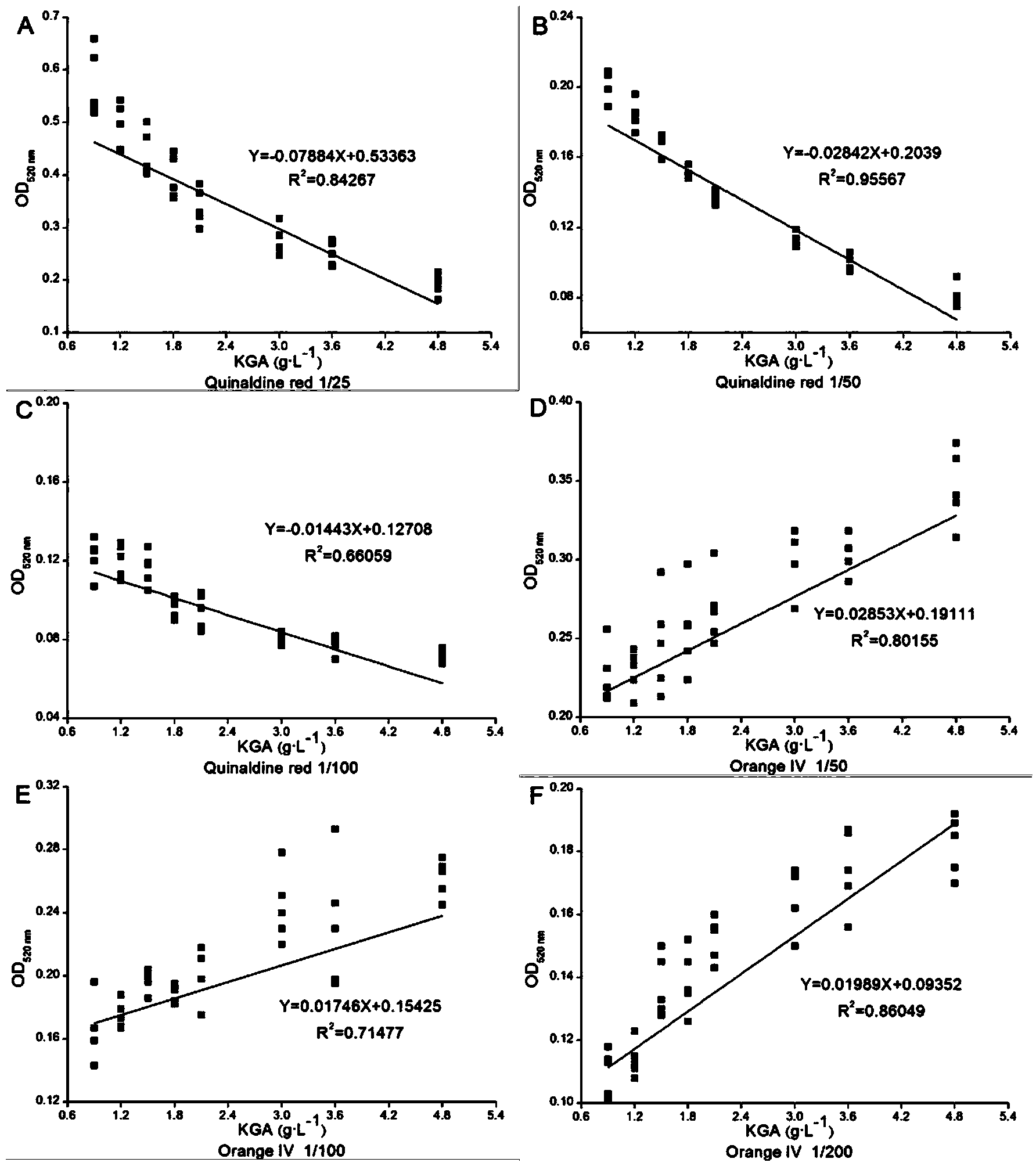

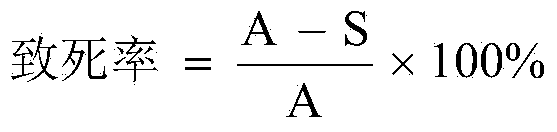

High-throughput screening method for high-organic acid yield strains

ActiveCN104357539AIncrease productionReduce outputMicrobiological testing/measurementMicroorganism based processesOrganic acidMicroorganism

The invention discloses a high-throughput screening method for high-organic acid yield strains, and belongs to the technical field of microbiology. According to the method, a pH indicator is combined with high-throughput screening, so that strains with higher organic acid yield can be screened from a great number of strains, the whole screening process is simplified, and the screening efficiency is improved; high-throughput screening combined with the pH indicator is also combined with a conventional breeding method to obtain a strain with high alpha-ketoglutaric acid yield, and compared with that of an original strain, the yield of the strain is improved by 51.8 percent on a shake flask, and is improved by 45.4 percent on a 3L fermentation tank.

Owner:JIANGNAN UNIV

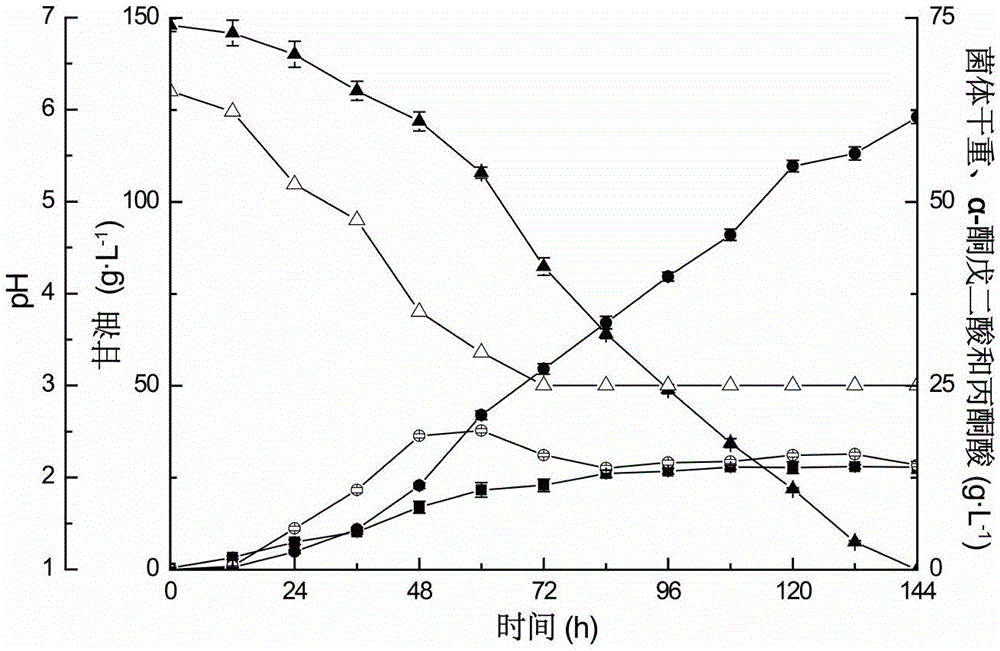

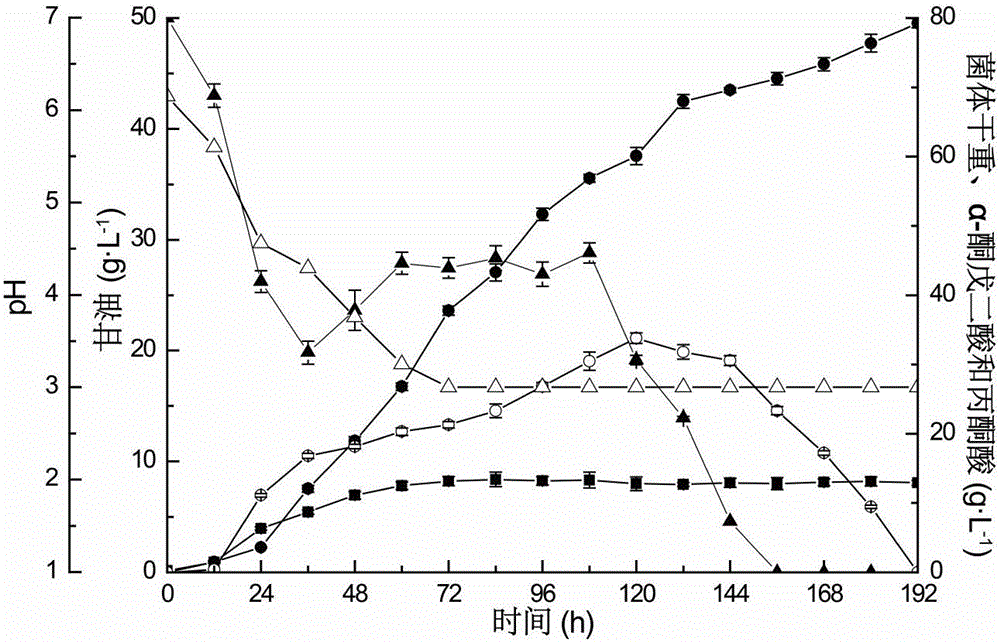

Two-stage pH (Potential Of Hydrogen) control method for high output of alpha-ketoglutaric acid

ActiveCN102586347AIncrease productionMicroorganism based processesFermentationHydrogenLaboratory scale

The invention discloses a two-stage pH (Potential Of Hydrogen) control method for the high output of alpha-ketoglutaric acid, which belongs to the field of fermentation engineering. The method adopts two stages of pH control to control the process of fermentation, and adopts Yarrowia lipolytica CCTCC NO.M207143 as a producing strain, CaCO3 is adopted as a pH buffer in the early stage of fermentation, NaOH is used for keeping the pH at 2.5 in the later stage, a great deal of Alpha-ketoglutaric acid is accumulated, and the output of alpha-ketoglutaric acid on the laboratory scale reaches 53.4g / L; in comparison with constant pH equal to 2.5, the output of alpha-ketoglutaric acid is increased by 142.7 percent; in comparison with only CaCO3 as the pH buffer, the output of alpha-ketoglutaric acid is increased by 32.5 percent; in the later stage of fermentation, the low pH value can decrease the probability of contamination, the dosage of NaOH is reduced, and thereby the extraction of downstream product is benefited; and the method has a broad industrial application prospect.

Owner:JIANGNAN UNIV +1

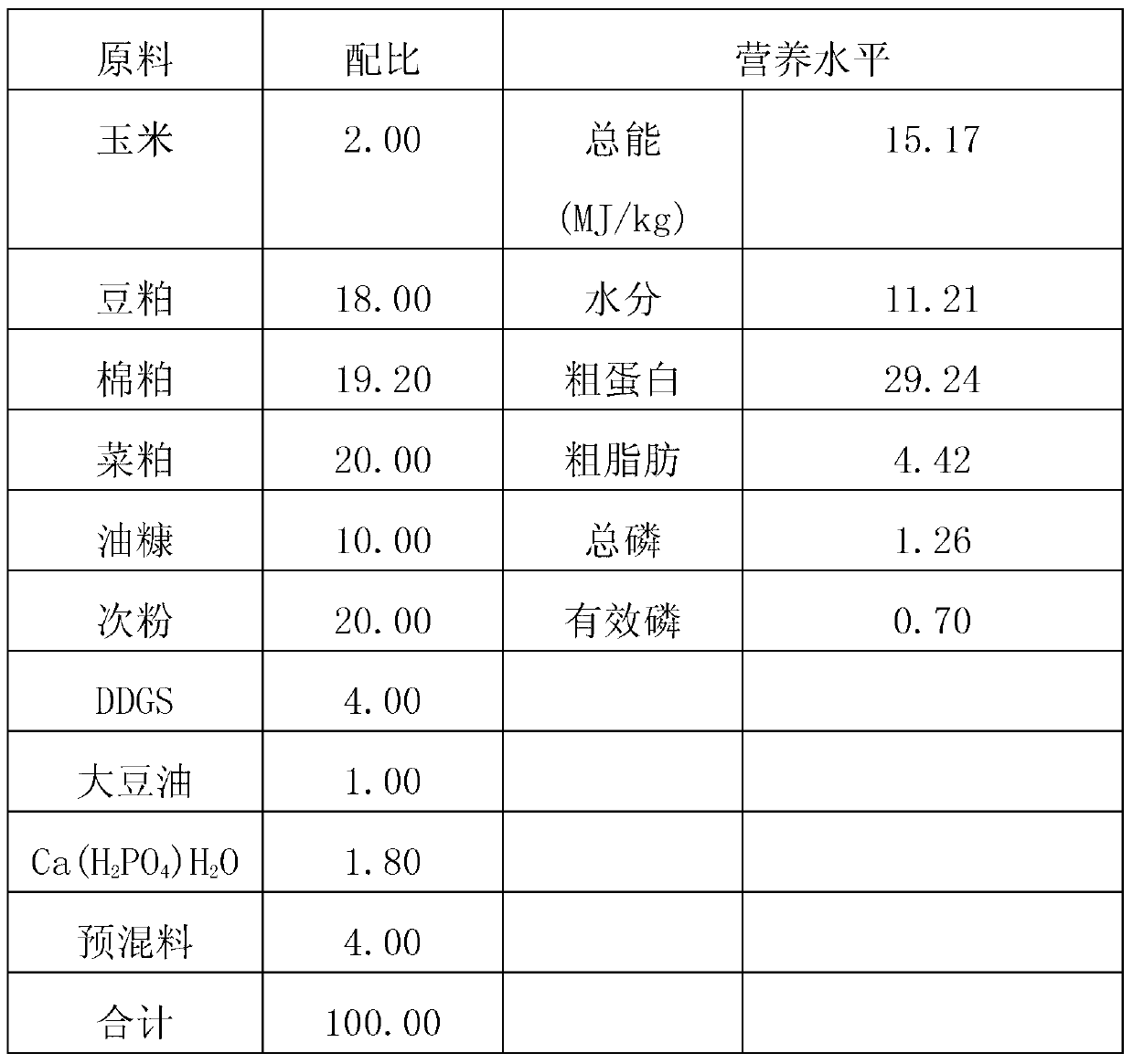

Grass carp feed for resisting stress

InactiveCN106923068AImprove digestion utilizationFully digestedFood processingClimate change adaptationFeed conversion ratioRapeseed

The invention relates to a feed, in particular to a grass carp feed for resisting stress. The grass carp feed consists of the following substances in parts by weight: 15-25 parts of meat and bone meal, 5-10 parts of broad bean protein powder, 15-25 parts of soybean meal, 15-25 parts of rapeseed meal, 15-22 parts of cottonseed meal, 15-25 parts of corn protein powder, 10-15 parts of tapioca, 15-25 parts of malt roots, 8-12 parts of rice bran, 5-10 parts of soybean oil, 3-5 parts of bentonite, 0.5-0.8 part of a fat emulsifying agent, 0.5-0.8 part of choline chloride, 0.5-0.8 part of calcium dihydrogen phosphate, 5-8 parts of a herba artemisiae capillaris extract, 1-3 parts of a vitamin premix, 1-3 parts of a mineral premix, 1-3 parts of zeolite powder, 0.5-0.8 part of alpha-ketoglutaric acid, 0.1-0.5 part of curcumin, 0.05-0.09 part of tea polyphenols and 0.05-0.09 part of taurine. According to the grass carp feed provided by the invention, various green feed additives are added, so that the digestion and utilization rate of the feed by the grass carps is increased, the immunization, the oxidation resistance and the stress resistance of grass carps are strengthened, the usage of drugs for preventing diseases in the breeding process is reduced or avoided, sufficient digestion and quick and high absorption of nutrients are increased, requirements for quick growth of the grass carps are met, and the feed conversion is increased.

Owner:QINGDAO ZHITONG SIHAI FURNITURE DESIGN RES & DEV CO LTD

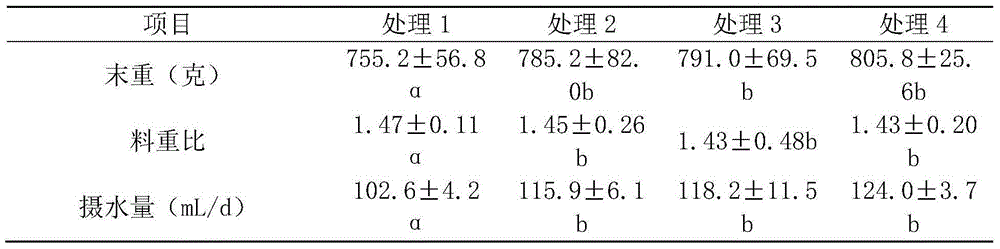

Application of alpha-ketoglutaric acid disodium in preparation of poultry feeds

InactiveCN105076722AGood for drinking waterDrinking Water Adds ReliefAnimal feeding stuffKetoglutaric AcidAlpha-Ketoglutaric acid

The invention discloses application of alpha-ketoglutaric acid disodium in preparation of poultry feeds. Experimental results show that the application of the alpha-ketoglutaric acid disodium in the poultry feeds is capable of evidently relieving stress for broilers, laying hens, meat ducks and laying ducks and evidently improving productivity of the broilers, the laying hens, the meat ducks, the laying ducks and the like.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

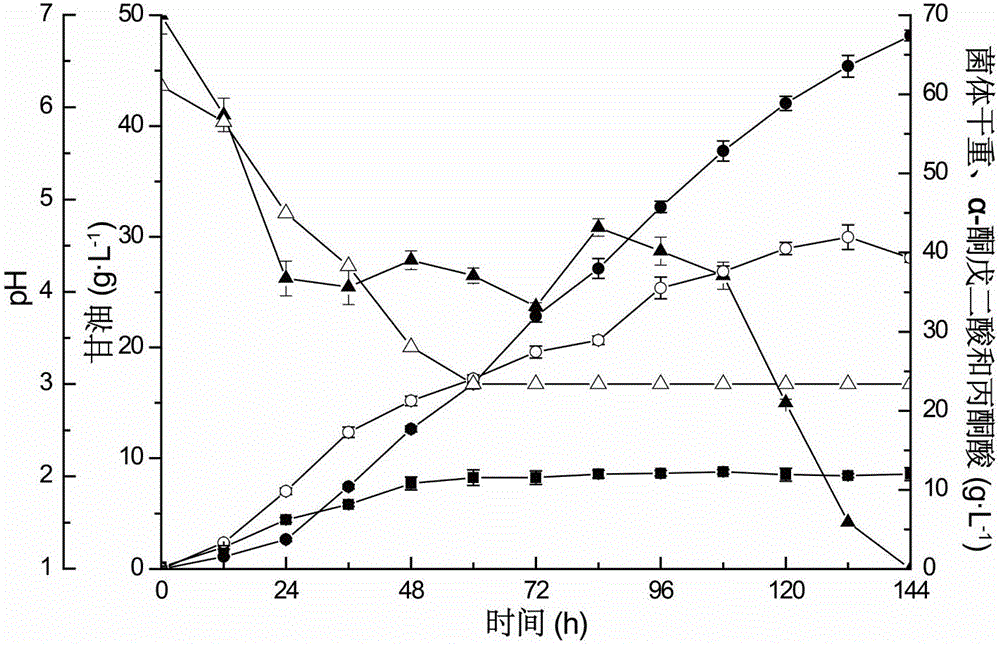

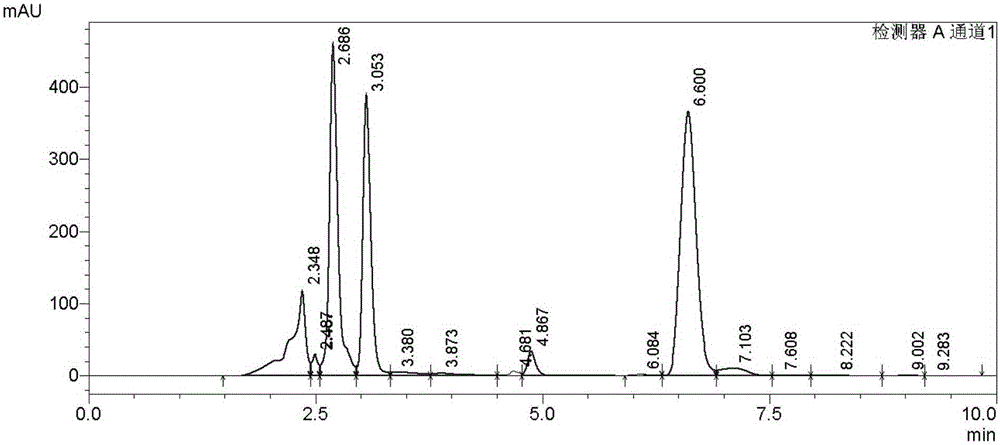

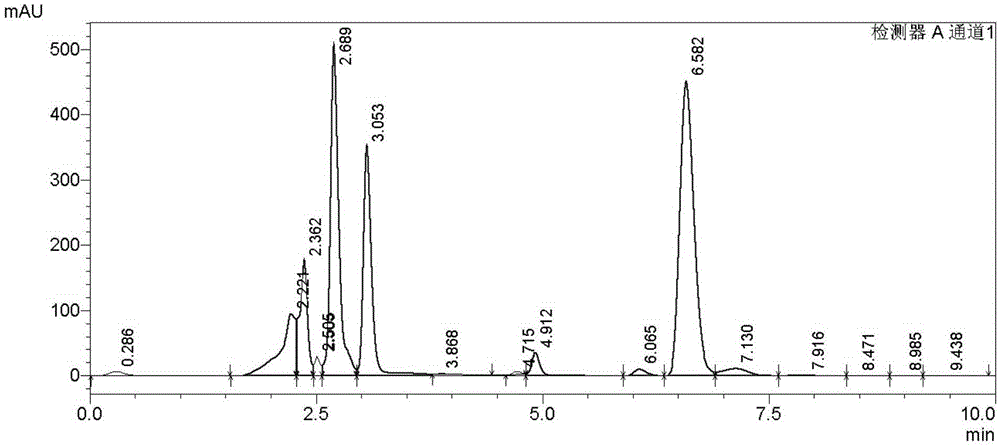

Fermenting method for joint production of alpha-ketoglutaric acid and pyruvic acid

ActiveCN106086092APromote accumulationPromote growthMicroorganism based processesFermentationGlycerolEconomic benefits

The invention discloses a fermenting method for joint production of alpha-ketoglutaric acid and pyruvic acid, and belongs to the technical field of fermenting engineering. The fermenting method is characterized in that because the difference of commercial values of alpha-ketoglutaric acid and pyruvic acid is small, the two types of carboxylic acids are jointly produced; in the fermenting process for joint production of carboxylic acids, the proper initial concentration and flowing accelerated speed of glycerinum are controlled, so as to promote the growth of bacteria and the accumulation of carboxylic acids. The fermenting method has the advantages that the conversion rate of substrate is greatly improved, the output of total acids is increased, and the production intensity is improved; the fermenting cycle is shortened, the energy-saving and consumption-decreasing effects are realized, and the economic benefit is improved.

Owner:JIANGNAN UNIV

Preparation method of hydroxyectoine

InactiveCN105177078ALow costEasy to separate and purifyMicroorganism based processesFermentationEscherichia coliAlpha-Ketoglutaric acid

The invention relates to a preparation method of hydroxyectoine. According to the preparation method, an ectoine-containing feed liquid is adopted as a substrate, Escherichia coli with ectonine hydroxylase activity and alpha-ketoglutaric acid are added, and an enzymatic reaction is performed under conditions that the pH is 7.0-8.0 and the temperature is 37-45 DEG C to synthesize the hydroxyectoine. According to the method, the hydroxyectoine with the higher added value is synthesized with the ectoine-containing feed liquid, prepared with a fermentation method, used as the substrate, and the method has the advantages that the raw material source is wide, the production cost is low and the like.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

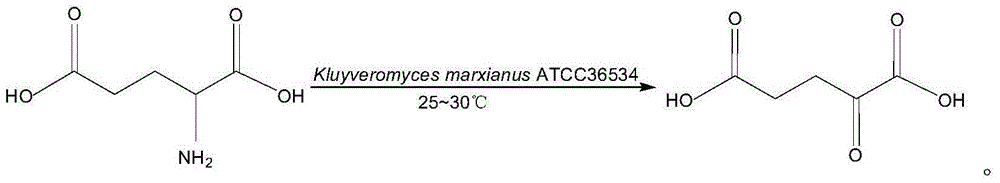

Method for synthesizing alpha-ketoglutaric acid by biological conversion method

ActiveCN105177065AGrow fastLow nutritional requirementsMicroorganism based processesFermentationKetoglutarate dehydrogenaseAlpha-Ketoglutaric acid

The invention aims at providing a method for synthesizing alpha-ketoglutaric acid by a biological conversion method. According to the method, L-glutamic acid is used as a substrate; in a conversion culture solution obtained from kluyveromyces marxianus ATCC36534 through being cultured via a conversion culture substrate, alpha-ketoglutaricdehydrogenase inhibitors are added; the synthesis conversion culture is performed under the oscillation conditions of 25 to 30 DEG C and 200 to 250 r / min; after the synthesis conversion culture is completed, the alpha-ketoglutaric acid is obtained through separating and purifying the synthesis conversion solution; the L-glutamic acid is converted into alpha-ketoglutaric acid by yeast cells in the growth state; the alpha-ketoglutaricdehydrogenase inhibitors are added; the further metabolism consumption is blocked, so that a great amount of alpha-ketoglutaric acid is accumulated in the culture medium; when the feeing concentration of the substrate L-glutamic acid is 50g / L, the mol conversion rate can reach 83.2 percent. The low-value L-glutamic acid is converted into high-value alpha-ketoglutaric acid; the large-scale industrial application can be realized; a production process has the advantages of short period, high conversion rate, small environment pollution and the like.

Owner:ZHEJIANG SHUREN UNIV

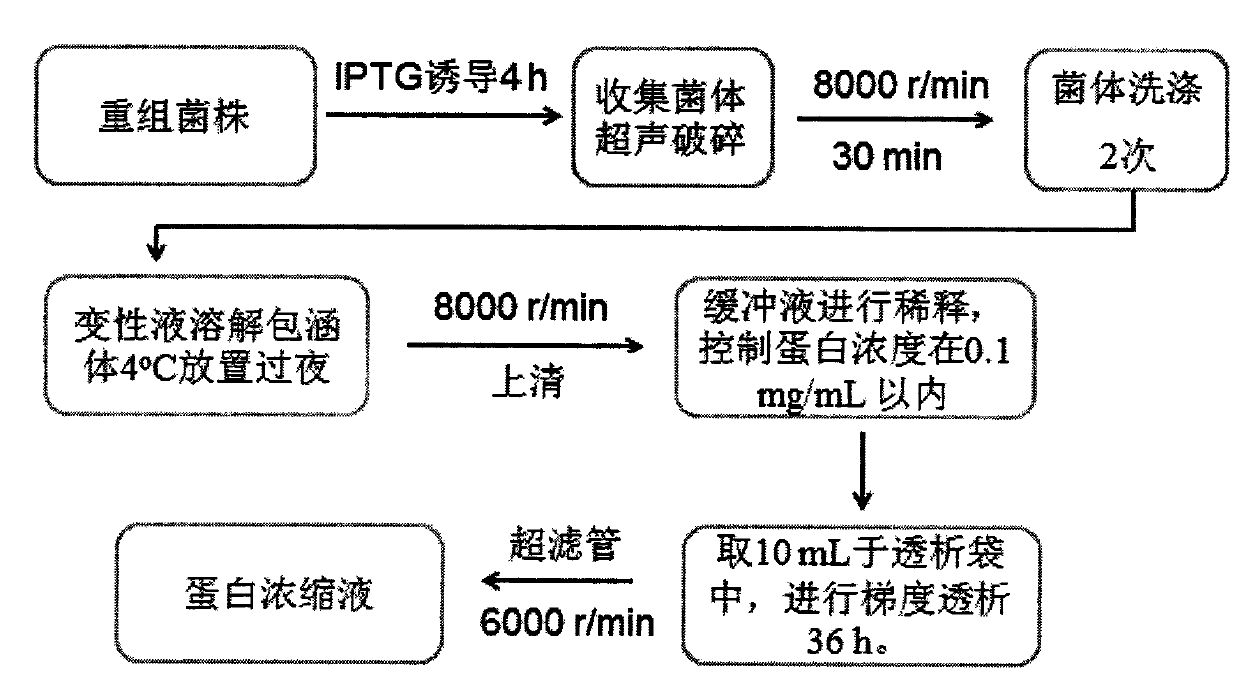

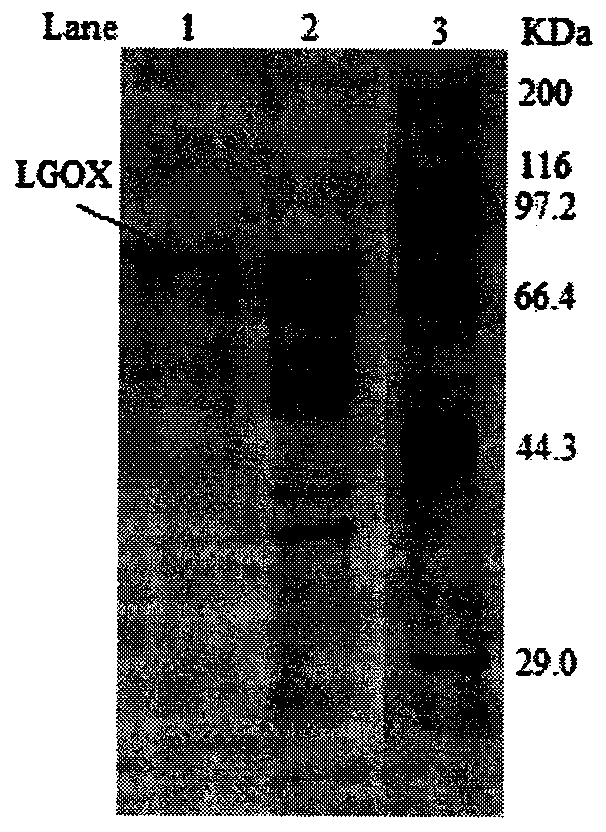

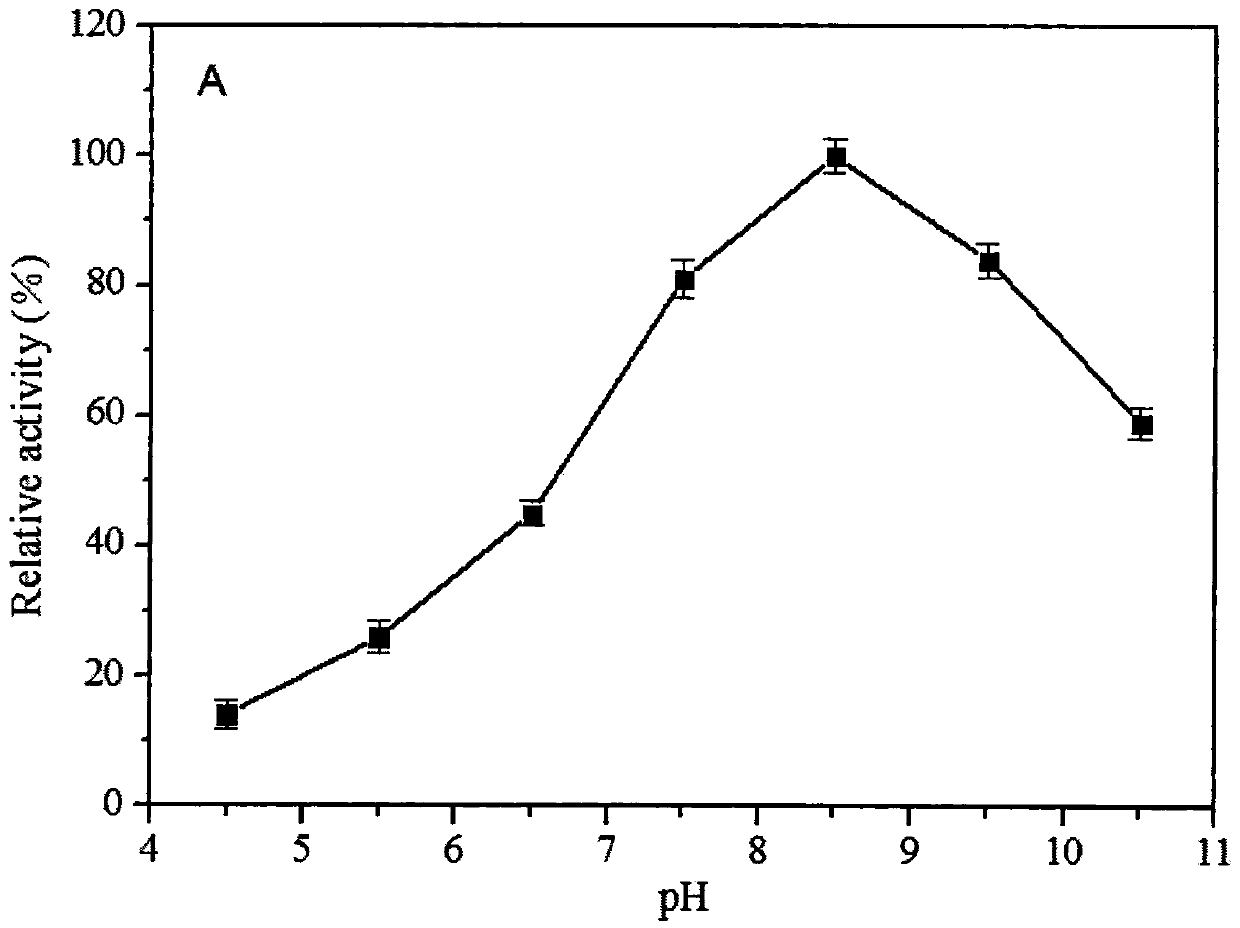

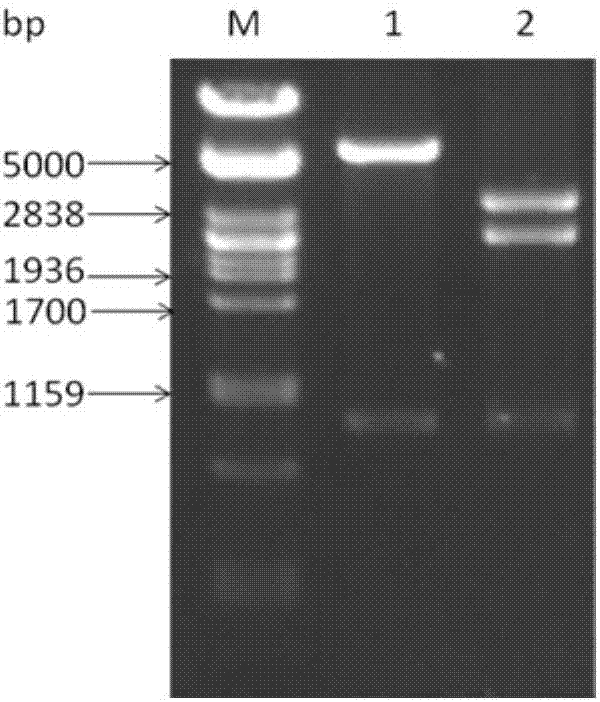

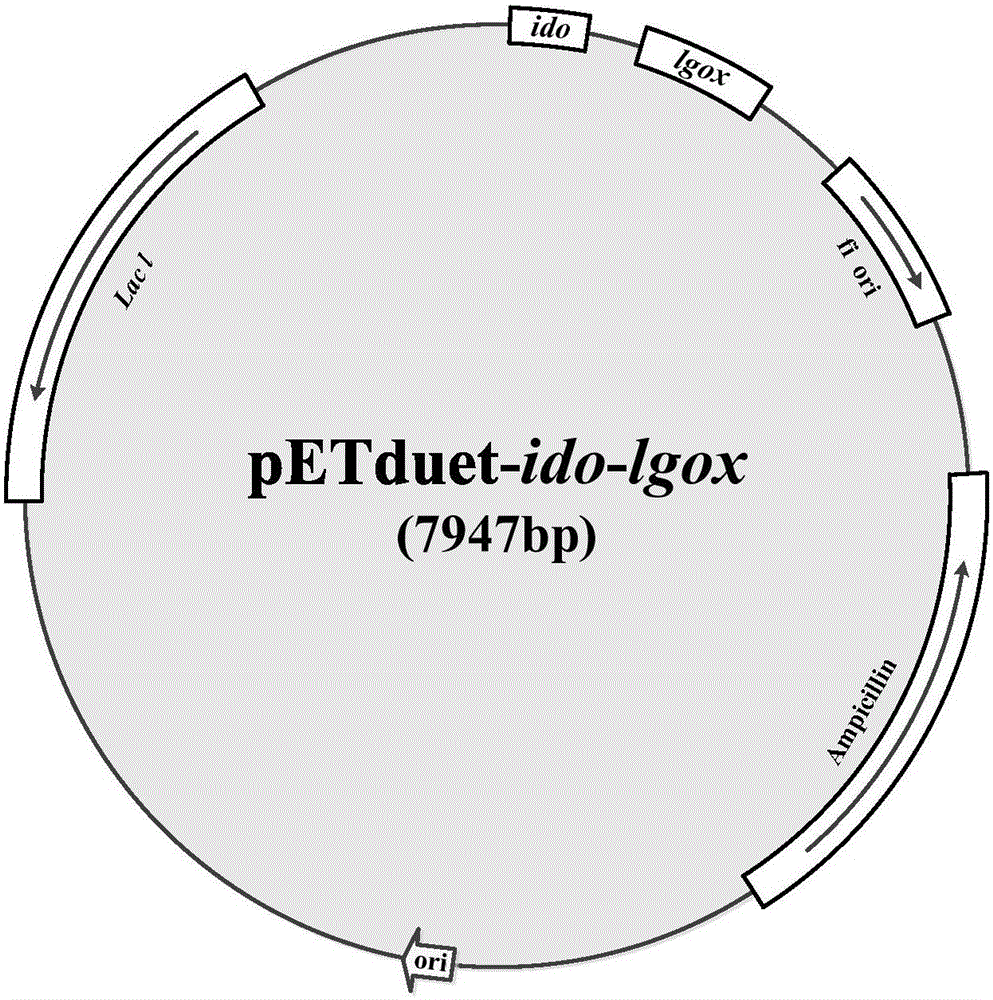

Construction method for recombinant strain producing L-glutamic oxidase and applications of the recombinant strain

The invention discloses a construction method for a recombinant strain producing L-glutamic oxidase and applications of the recombinant strain, and belongs to the fields of genetic engineering and enzyme products. Glutamic oxidase inclusion bodies produced by recombination are subjected to protein denaturation, renaturation and concentration to allow that 30% of the protein inclusion bodies regain activity. Researches on enzymatic properties of a recombinase show that the optimum pH of the recombinase is 8.5, the optimum temperature of the recombinase is 35 DEG C, Mn<2+> can increase the enzyme specific activity by over 20%, and exogenous addition of FAD has no influence on the enzyme activity. By combination of enzymatic characteristics, 8.3 g / L of alpha-ketoglutaric acid can be produced by adding the recombinase into a buffer solution that contains 20 g / L of sodium glutamate and has a pH of 8.5, and converting at 35 DEG C for 12 h.

Owner:JIANGNAN UNIV

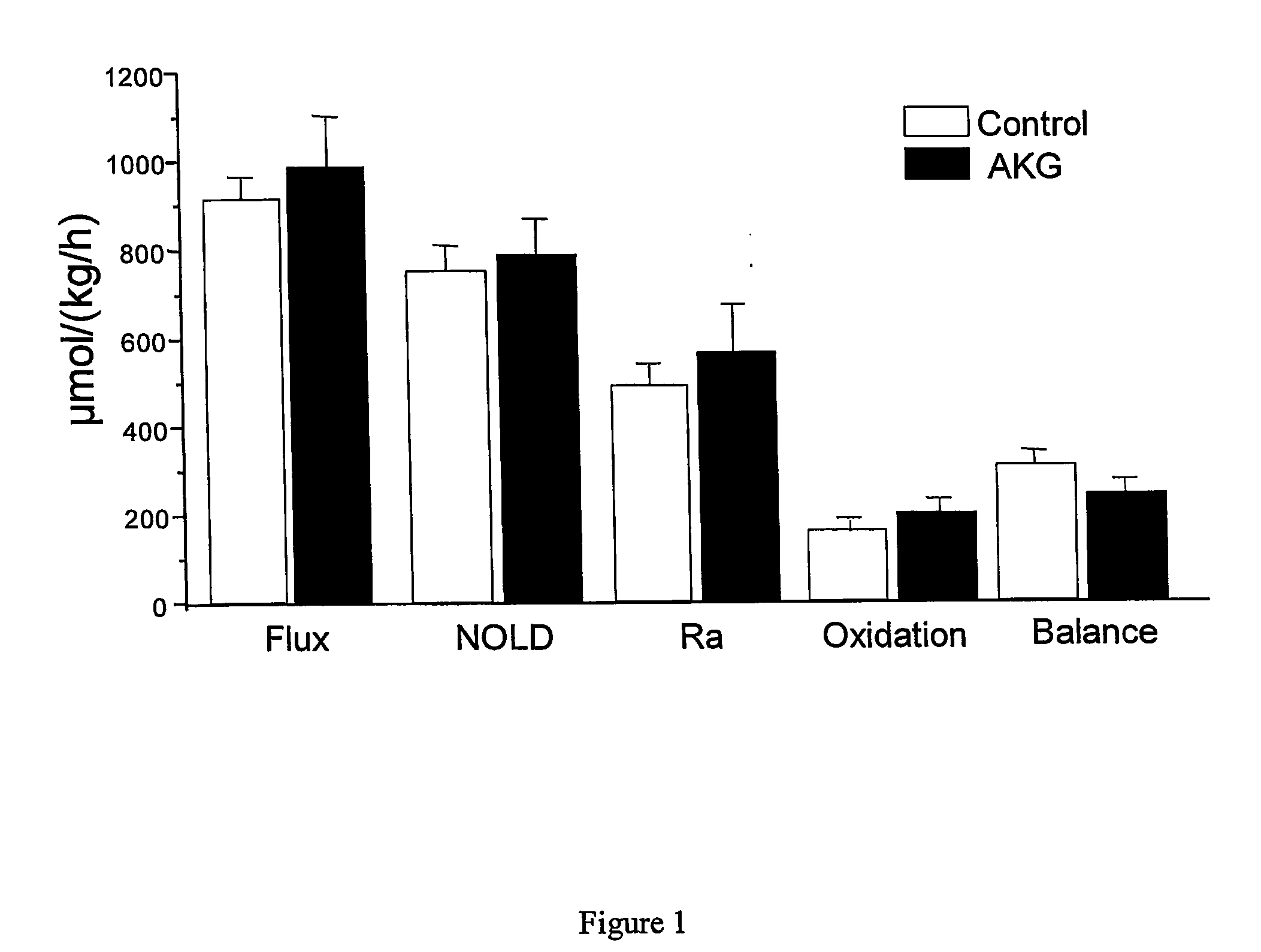

Use of alpha-ketoglutaric acid for the treatment of malnutrition or high plasma glucose condition

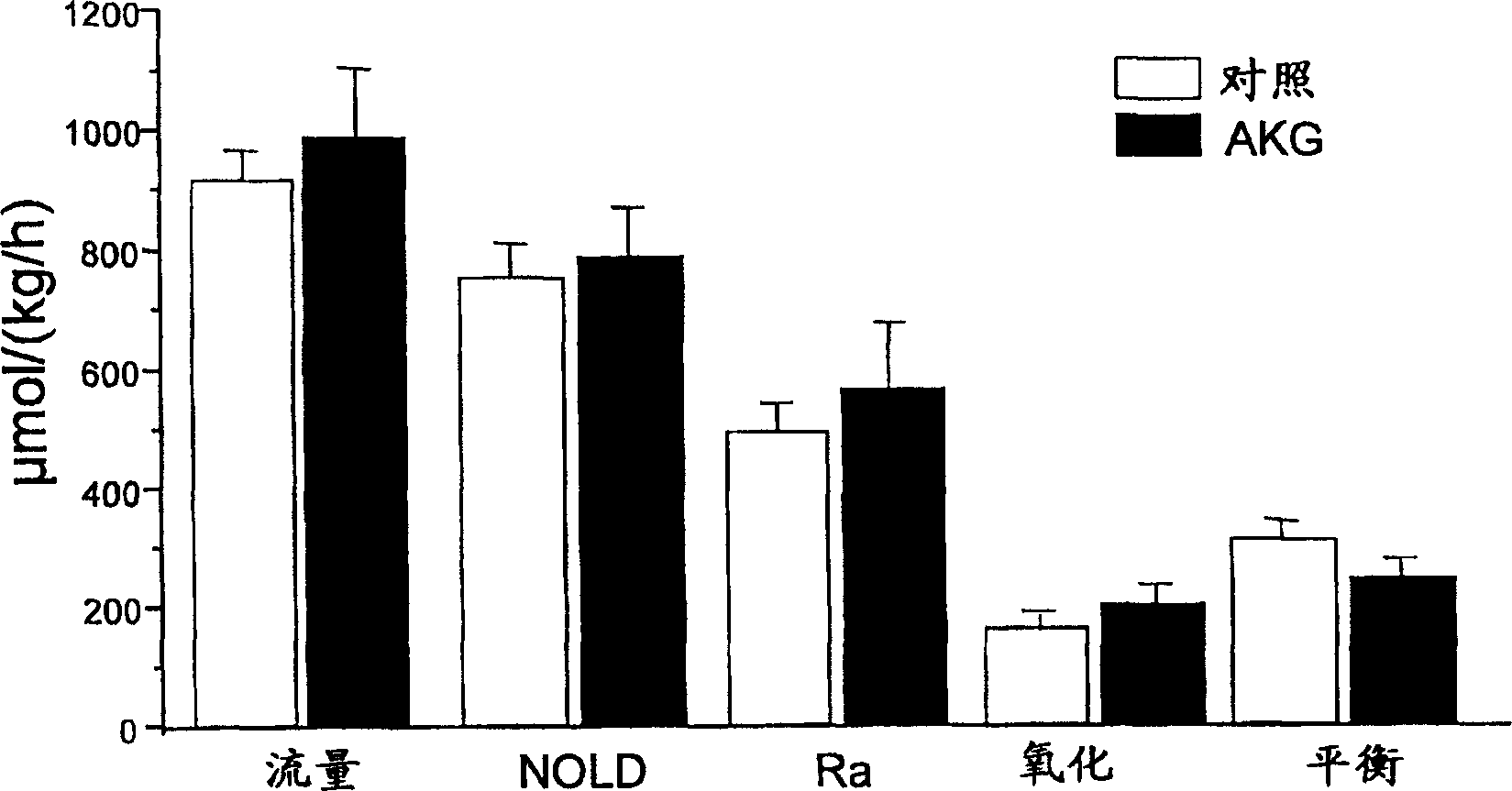

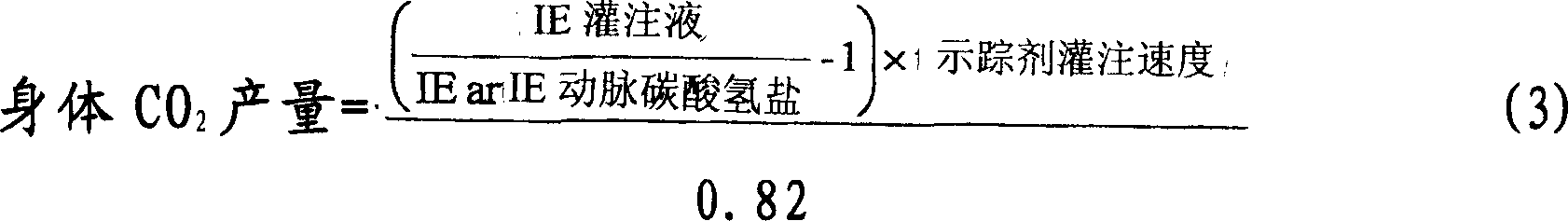

A method for improving adsorption of amino acids in a vertebrate, including mammal and bird, is included. The method comprises administering to a vertebrate, including mammal and bird, in a sufficient amount and / or at a sufficient rate to enable desire effect. AKG, AKG derivatives or metabolites, AKG analogues or mixture thereof. Also conteplated is a method for decreasing adsorption of glucose in a vertebrate, including mammal and bird, in the need thereof, AKG, AKG derivates or metabolites, AKG analogues or mixture thereof, for decreasing glucose adsorption as well as compositions for use in treatment.

Owner:ESSENTYS AB

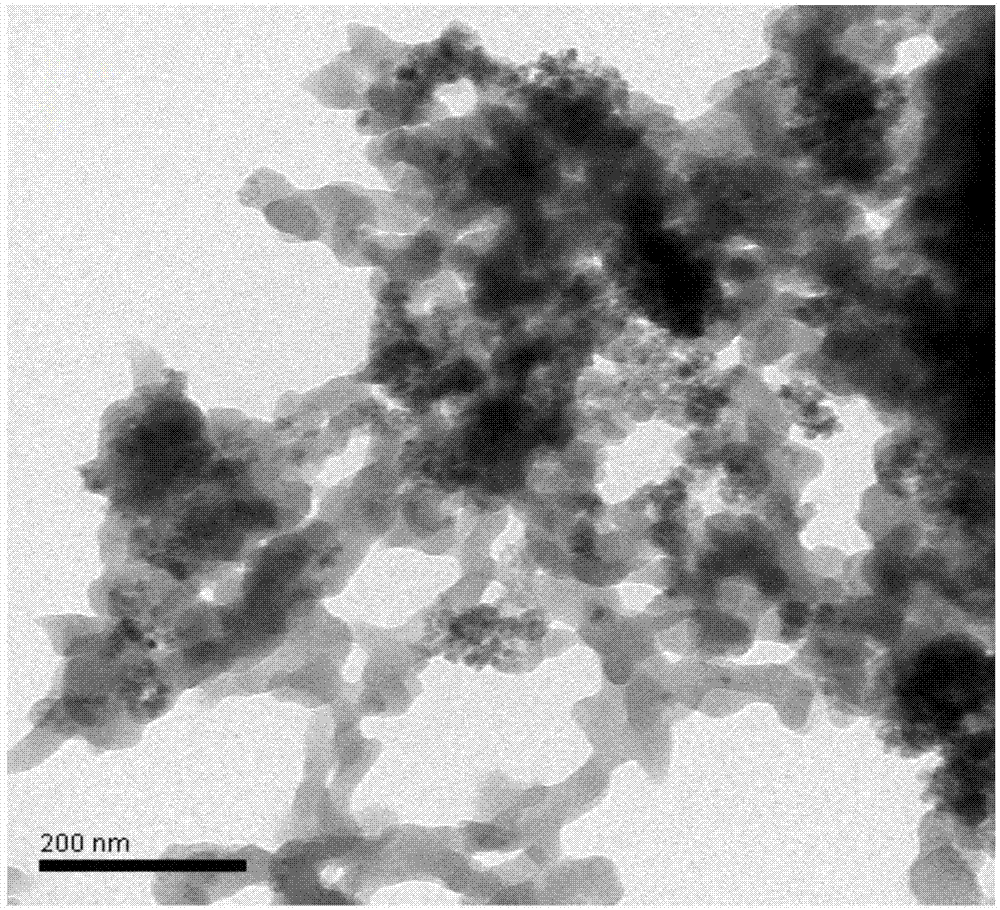

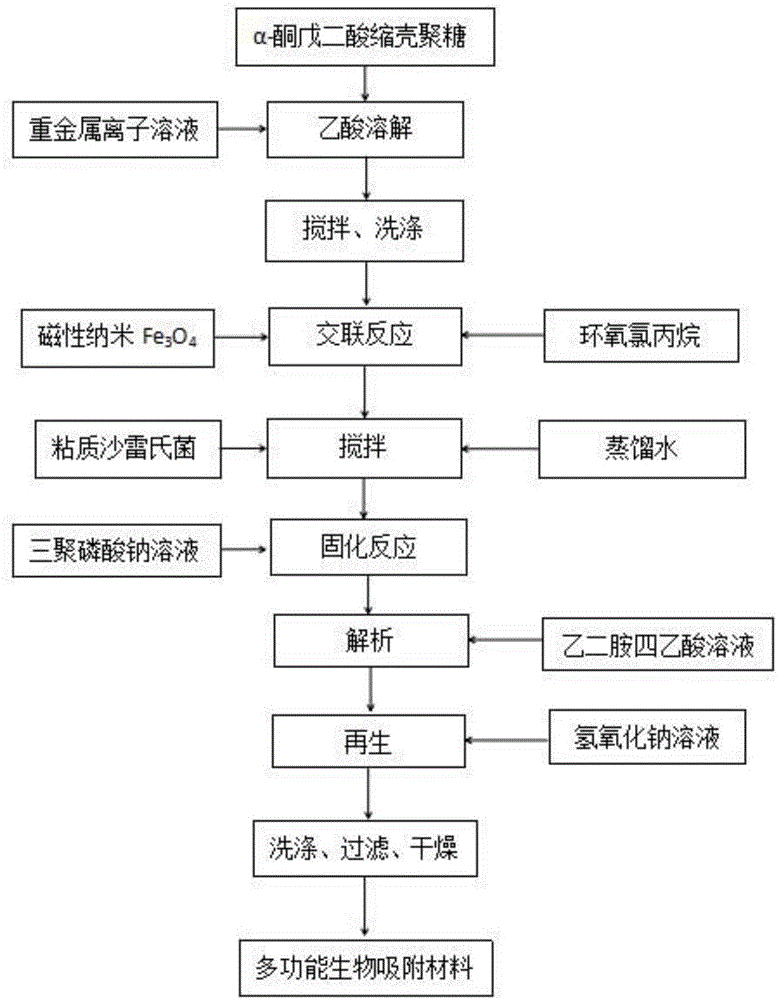

Multifunctional biological adsorbent and preparation method thereof

ActiveCN105771912AImprove adsorption capacityLow costOther chemical processesWater contaminantsWastewaterAlpha-Ketoglutaric acid

The invention provides a multifunctional biological adsorbent, and a preparation method thereof comprises the following steps: chitosan alpha-ketoglutaric acid is taken as a carrier, a heavy metal ion is taken as an imprinted template, an ionic imprinting material is obtained through the ionic imprinting technique, then the ionic imprinting material and magnetic nano-Fe3O4 are subjected to cross-linking reaction, a magnetic ionic imprinting material is obtained, and finally the surface of a Serratia marcescens thallus is coated with the magnetic ionic imprinting material through curing reaction. The obtained biological adsorbent integrates advantages of high adsorption with low cost, high selectivity with low pollution, high separating efficiency with low loss, and the like, also has advantages of magnetic materials and biological adsorbents, and can realize various functions such as magnetic separation, selective recognition, circulative recovery and the like; moreover, the method is simple, the cost is low, and the biological adsorbent is green and environment-friendly, avoids secondary pollution, and can be widely used for treatment of various specific heavy metal industrial wastewater, therefore, a novel material is provided for treatment of industrial wastewater.

Owner:CENT SOUTH UNIV

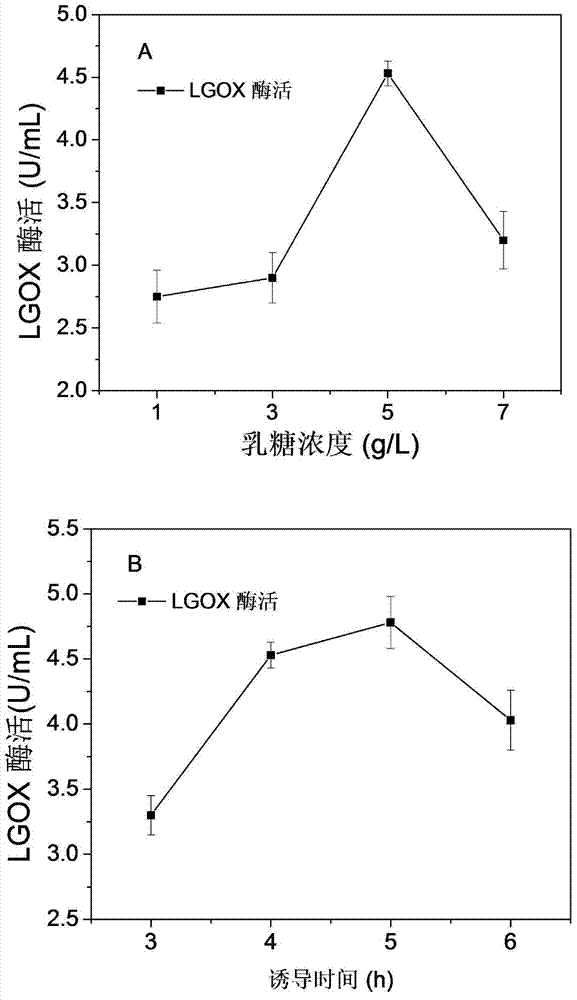

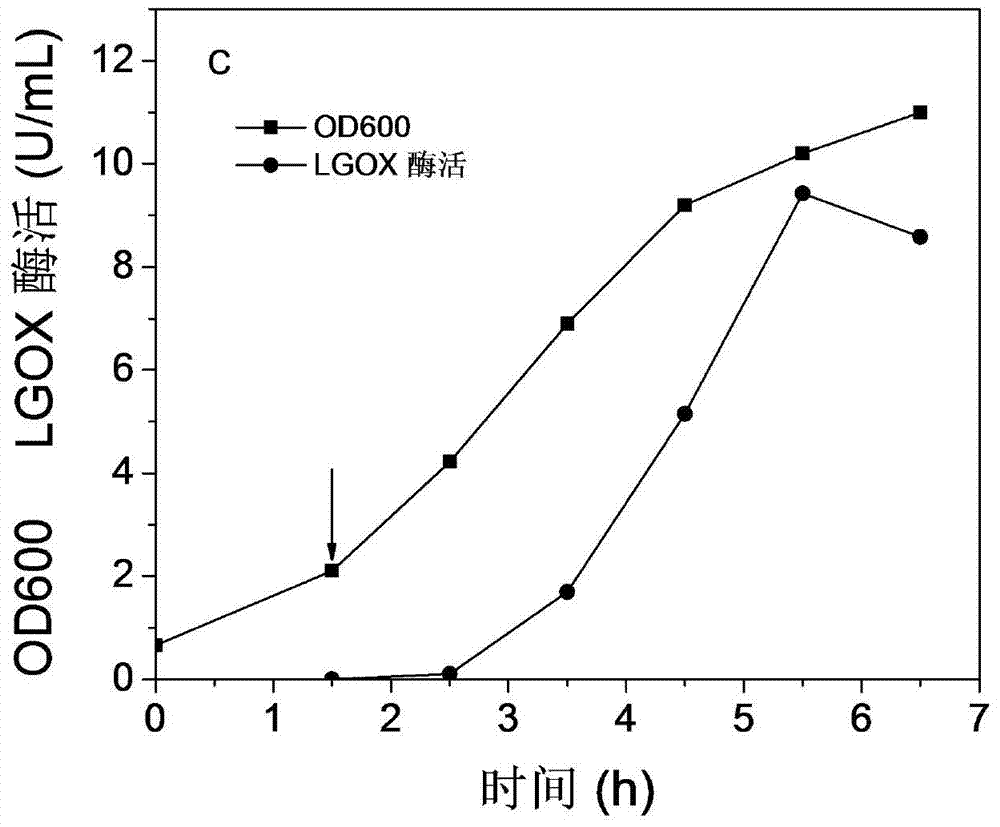

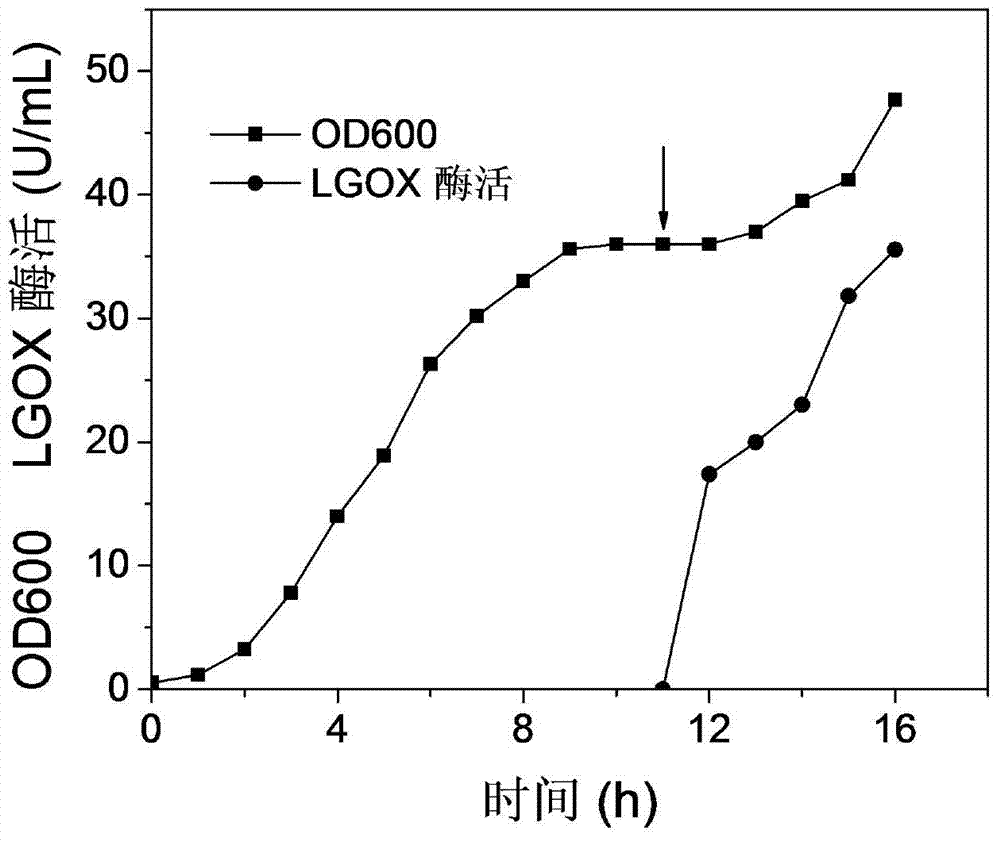

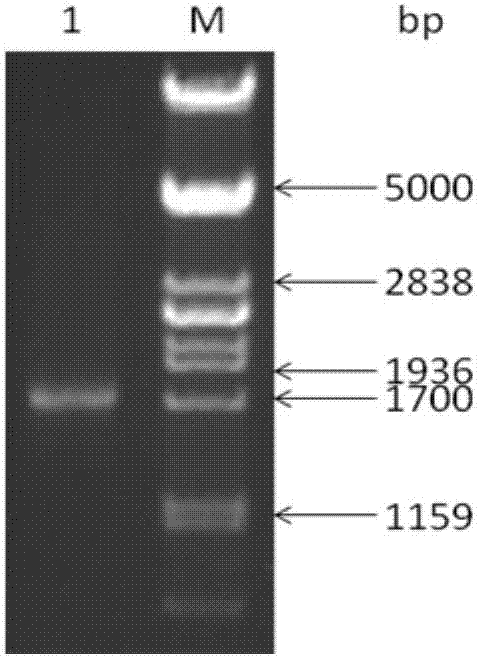

Method for efficiently producing L-glutamate oxidase

ActiveCN104745545AEfficient expressionBacteriaMicroorganism based processesBatch fermentationLactose

The invention discloses a method for efficiently producing L-glutamate oxidase and belongs to the technical fields of fermentation engineering and enzyme engineering. In the method disclosed by the invention, the optimal induction condition for L-glutamate oxidase recombinant bacteria is inducted for 5h in the presence of 5g / L lactose at 25-30 DEG C; through researches on different feeding modes of batch feeding fermentation, a manner of combining index feeding with Do-stat is beneficial to increase for a bacteria density; through optimization for induction condition of batch fermentation, inducing lasts for 12h in the presence of 10g / L lactose under the condition of a logarithmic phase OD600 of 40, and the highest enzyme activity reaches 156.1U / mL; high-expression recombinant wet bacteria are added in buffer solution containing 110g / L of glutamic acid with a pH value of 8.0, and converted for 24h at 37 DEG C to produce 107.9g / L of alpha-ketoglutaric acid, the conversion rate is 90% or above, and the needed bacterium solution amount is only 1 / 50 of that of shake-flask fermentation.

Owner:JIANGNAN UNIV

Metabolism transformation Bacillus subtilis biotransformed cell, preparation method and applications thereof

ActiveCN107287144AImprove effective conversion rateImprove conversion rateBacteriaMicroorganism based processesEndogenous metabolismAlpha-Ketoglutaric acid

The invention discloses a metabolism transformation Bacillus subtilis biotransformed cell. The preparation method comprises: carrying out recombinant over-expression to obtain a L-glutamic acid oxidase, carrying out metabolism engineering transformation on the endogenous glutamic acid decomposition pathway of Bacillus subtilis, and finally transforming the glutamic acid transport pathway of Bacillus subtilis to prepare the Bacillus subtilis biotransformed cell, ie., the recombinant Bacillus subtilis. According to the present invention, the experimental basis is provided for the construction and the improvement of the whole cell transformation system involved in cellular endogenous metabolism, and the reference is provided for the production of alpha-ketoglutaric acid through the efficient whole cell transformation of L-glutamic acid with Bacillus subtilis.

Owner:JIANGNAN UNIV

Use of alpha-ketoglutaric acid for the treatment of malnutrition or high plasma glucose condition

InactiveUS20060247207A1Reduce absorptionBiocidePeptide/protein ingredientsMetaboliteGlucose polymers

A method for improving adsorption of amino acids in a vertebrate, including mammal and bird, is included. The method comprises administering to a vertebrate, including mammal and bird, in a sufficient amount and / or at a sufficient rate to enable desire effect. AKG, AKG derivatives or metabolites, AKG analogues or mixture thereof. Also conteplated is a method for decreasing adsorption of glucose in a vertebrate, including mammal and bird, in the need thereof, AKG, AKG derivates or metabolites, AKG analogues or mixture thereof, for decreasing glucose adsorption as well as compositions for use in treatment.

Owner:ESSENTYS AB

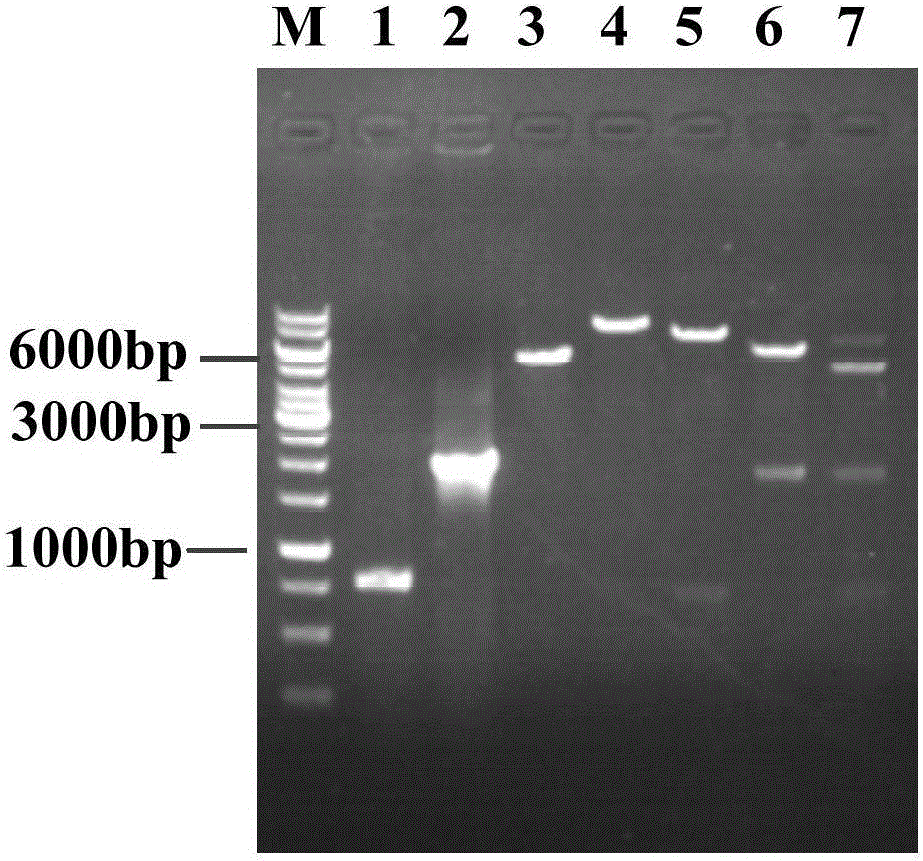

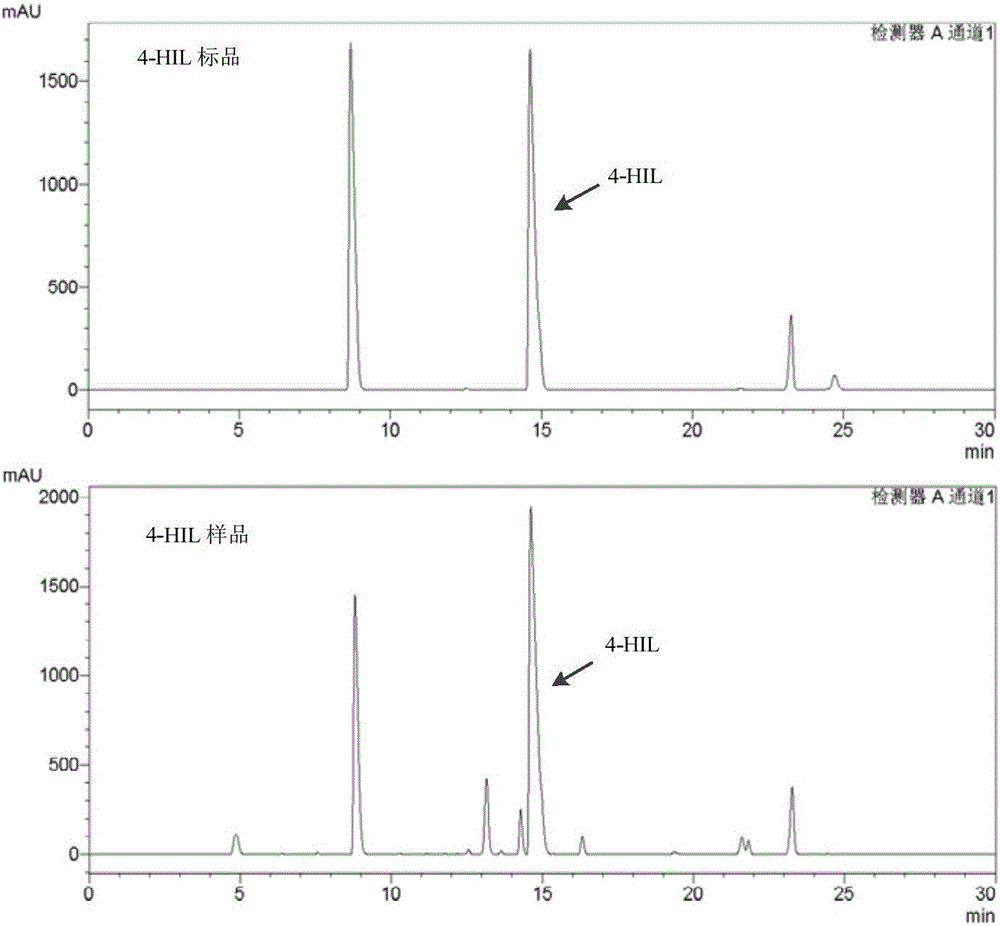

Synthesis method for 4-hydroxyisoleucine

ActiveCN105969785AEasy to operateAchieve high density cultureBacteriaMicroorganism based processesSynthesis methodsL-Isoleucine

The invention relates to a synthesis method for 4-hydroxyisoleucine. The method comprises the following steps: firstly, constructing recombinant expression plasmids for expressing L-isoleucine-4-hydroxylase and L-glutamate oxidase simultaneously; adding two types of substrates including L-glutamic acid and L-isoleucine into a constructed catalytic reaction system; taking the substrates as precursors of a catalytic reaction and synthesizing the 4-hydroxyisoleucine. After the catalytic reaction is performed for 4h, the conversion rates of the L-glutamic acid and the L-isoleucine are 97.01 percent and 98.45 percent respectively. By replacing alpha-ketoglutaric acid with the L-glutamic acid and utilizing the L-glutamic acid as the precursor for synthesizing the 4-hydroxyisoleucine, the 4-hydroxyisoleucine can be efficiently produced, the production cost is low and industrial production is convenient to realize.

Owner:TIANJIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com