Method and special-purposed strain used for producing alpha-ketoglutaric acid

A technology of ketoglutaric acid and pyruvic acid, which is applied in the field of producing α-ketoglutaric acid, can solve the problems such as Absidia codica α-ketoglutarate that has not been seen yet, and achieve good scientific research value and industrial application prospects , high yield and low fermentation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, the isolation and identification of Absidia coliformis D1

[0032] 1. Isolation of Absidia codica D1

[0033] Absidia codica D1 was screened from distiller's yeast samples.

[0034] Primary screening medium: add 1.0g / L sodium deoxycholate and 0.1g / L bromocresol green to PDA medium, natural pH.

[0035] Incline medium (PDA medium): potato 200g / L, glucose 20g / L, agar 20g / L, natural pH.

[0036] Fermentation medium: glucose 80g / L, (NH 4 ) 2 SO 4 1g / L, KH 2 PO 4 1.36g / L, MgSO 4 ·7H 2 O 0.2g / L, FeSO 4 ·7H 2 O 0.01g / L, NaCl 2g / L, corn steep liquor 0.5g / L, CaCO 3 30g / L (sterilized separately), natural pH.

[0037] The distiller's yeast samples were diluted and spread on the separation medium, and cultured in a constant temperature incubator at 37°C. When colonies grow out of the separation medium, inoculate the strains into the primary screening medium, inoculate all the strains that can turn the indicator medium yellow around the colonies into th...

Embodiment 2

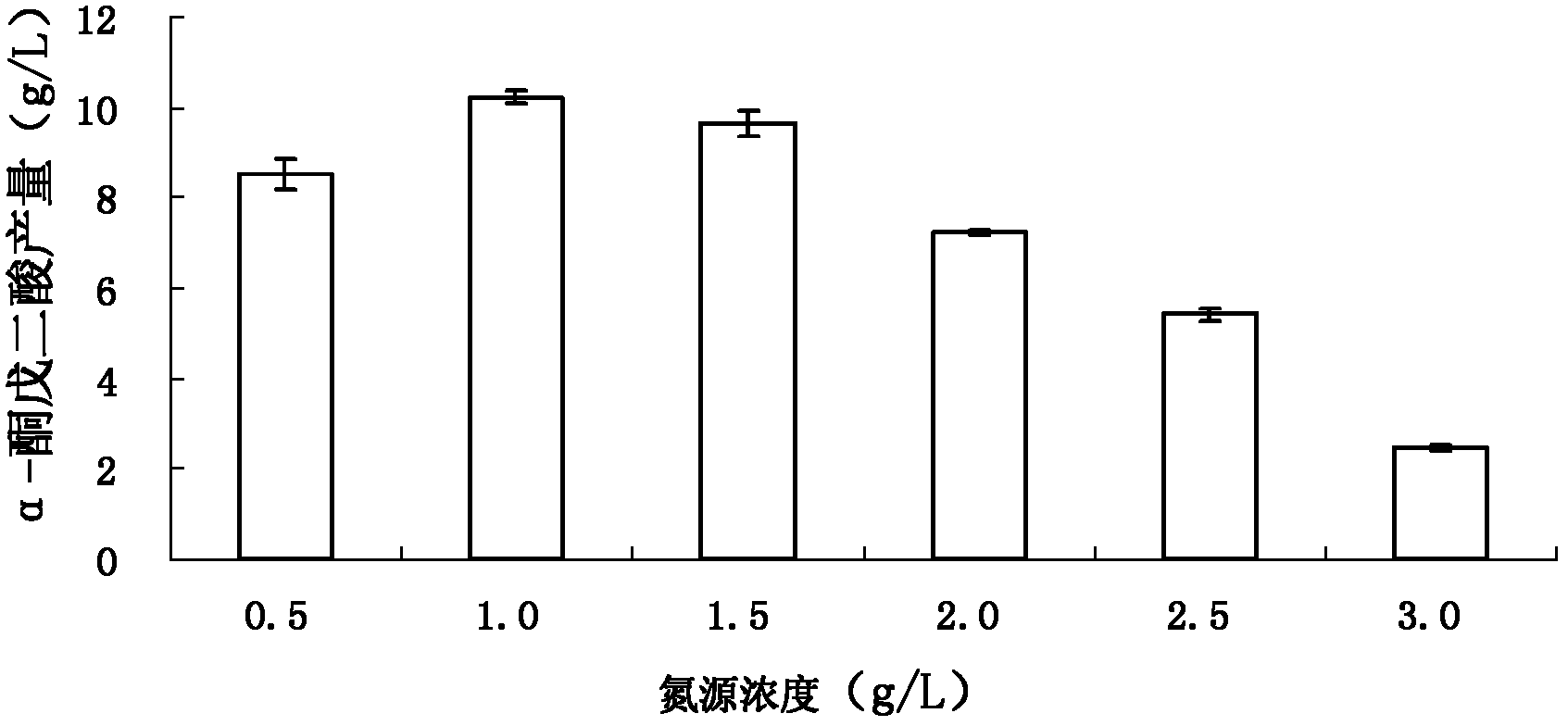

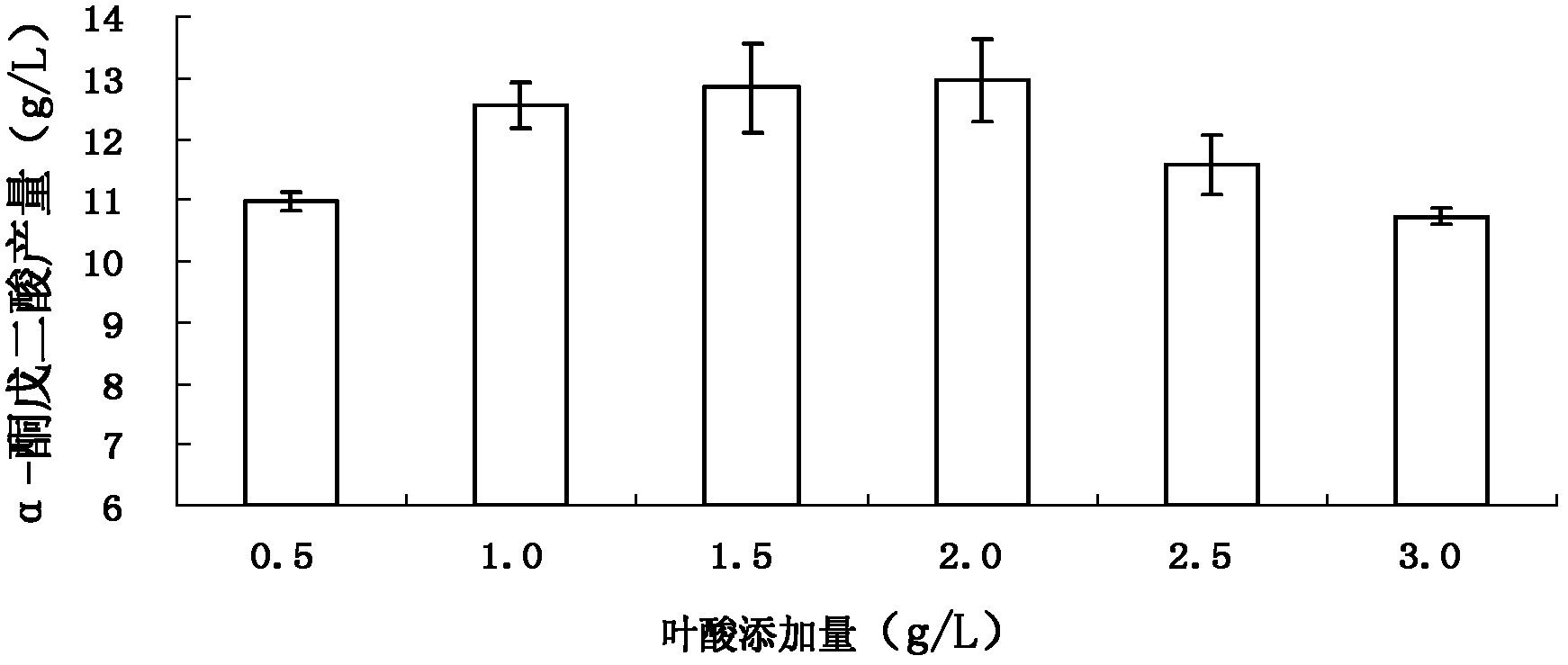

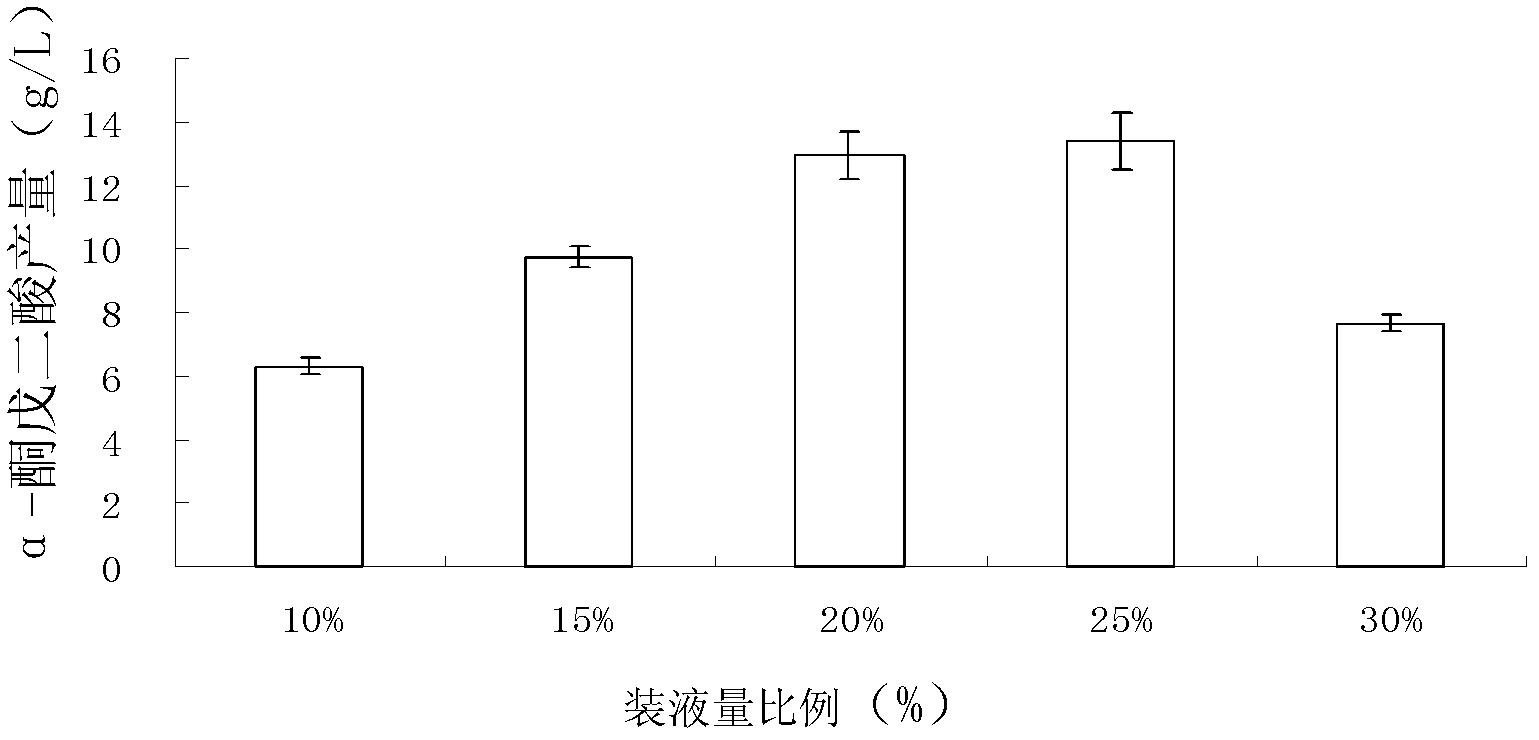

[0043] Example 2. Optimization of conditions for the production of α-ketoglutarate by shake flask fermentation using sucrose as a substrate

[0044] 1. Screening of carbon source in fermentation medium

[0045] 1. Screening of carbon sources

[0046] The fermentation medium is obtained by distilling the following substances to 1L (natural pH): carbon source 60g, (NH 4 ) 2 SO 4 1g, KH 2 PO 4 1.36g, MgSO 4 ·7H 2 O 0.2g, FeSO 4 ·7H 2 O 0.01g, NaCl 2g, corn steep liquor 0.5g, CaCO 3 30g. The following seven carbon sources were used: glucose, sucrose, maltose, raffinose, glutinous rice starch, corn starch, and soluble starch.

[0047] Experimental method: in 250mL Erlenmeyer flask, pack 50mL fermentation medium, inoculate 200 μ L of the spore liquid of Absidia codica D1 (the concentration of spores in the spore liquid is 1×10 8 spores / mL), cultured on a reciprocating shaker in a constant temperature air bath at 37°C at 200r / min for 72h; take the fermentation broth, c...

Embodiment 3

[0100] Example 3. Optimization of conditions for the production of α-ketoglutarate by shake flask fermentation using pyruvate as a substrate

[0101] 1. Screening of the amount of pyruvate added in the fermentation medium

[0102] The fermentation medium is obtained by distilling the following substances to 1L (natural pH): pyruvate, (NH 4 ) 2 SO 4 1g, KH 2 PO 4 1.36g, MgSO 4 ·7H 2 O 0.2g, FeSO 4 ·7H 2 O 0.01g, NaCl 2g, corn steep liquor 0.5g, CaCO 3 60g. The following 8 adding amounts of pyruvic acid were adopted respectively: 10g, 20g, 30g, 40g, 50g, 60g, 70g, 80g.

[0103] Experimental method: in 250mL Erlenmeyer flask, pack 50mL fermentation medium, inoculate 200 μ L of the spore liquid of Absidia codica D1 (the concentration of spores in the spore liquid is 1×10 8 spores / mL), cultured on a reciprocating shaker in a constant temperature air bath at 37°C at 200r / min for 72h; take the fermentation broth, centrifuge at 12000r / min for 10min, absorb the supernatan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com