Patents

Literature

133 results about "A-Ketoglutaric Acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

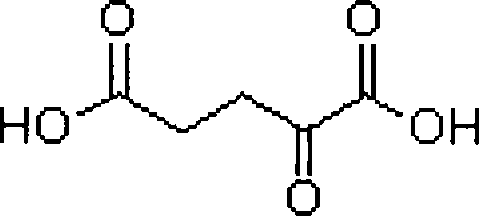

Definition of ketoglutaric acid. : either of two crystalline keto derivatives C5H6O5 of glutaric acid; especially : the alpha keto isomer formed in various metabolic processes (such as the Krebs cycle)

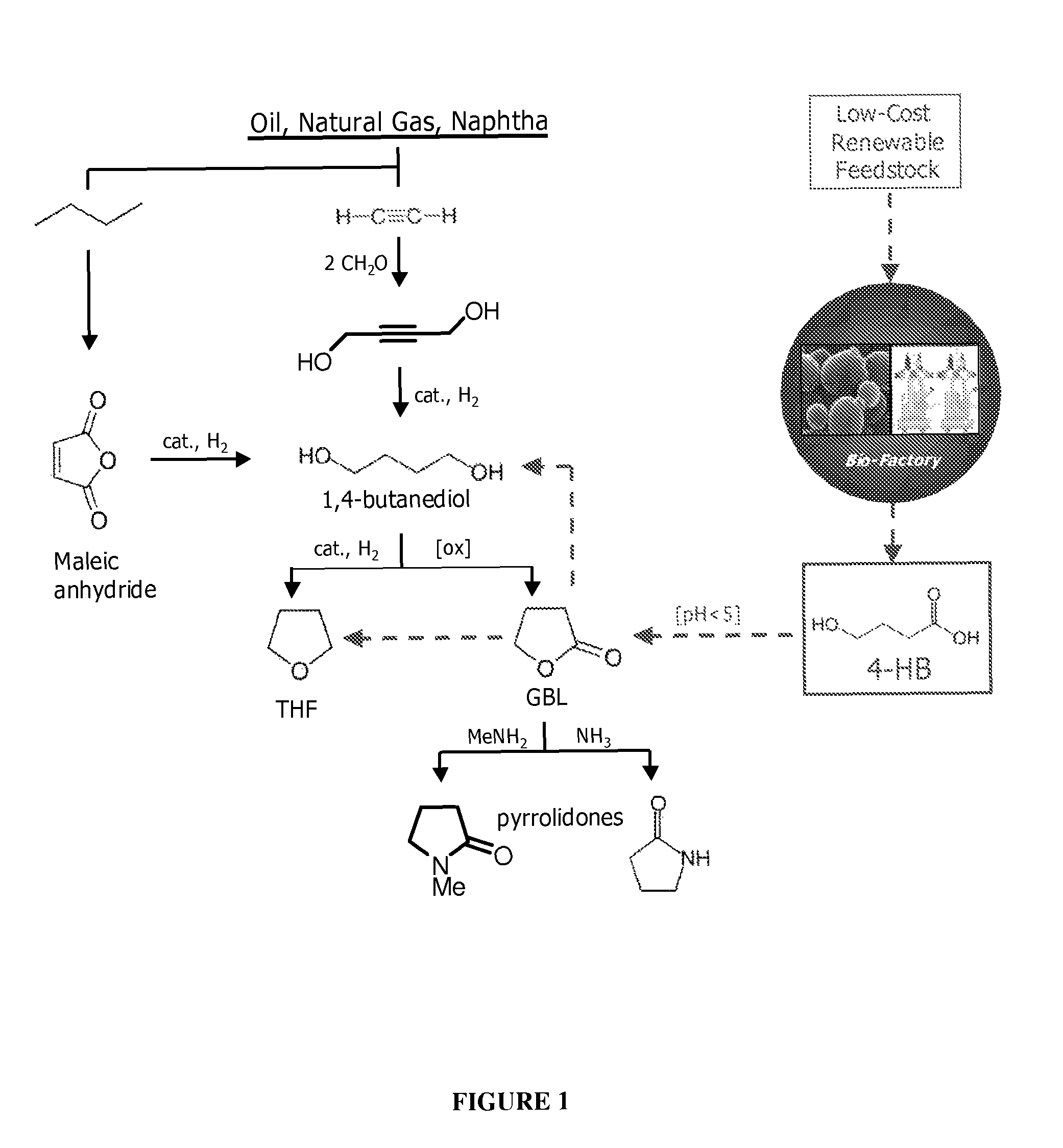

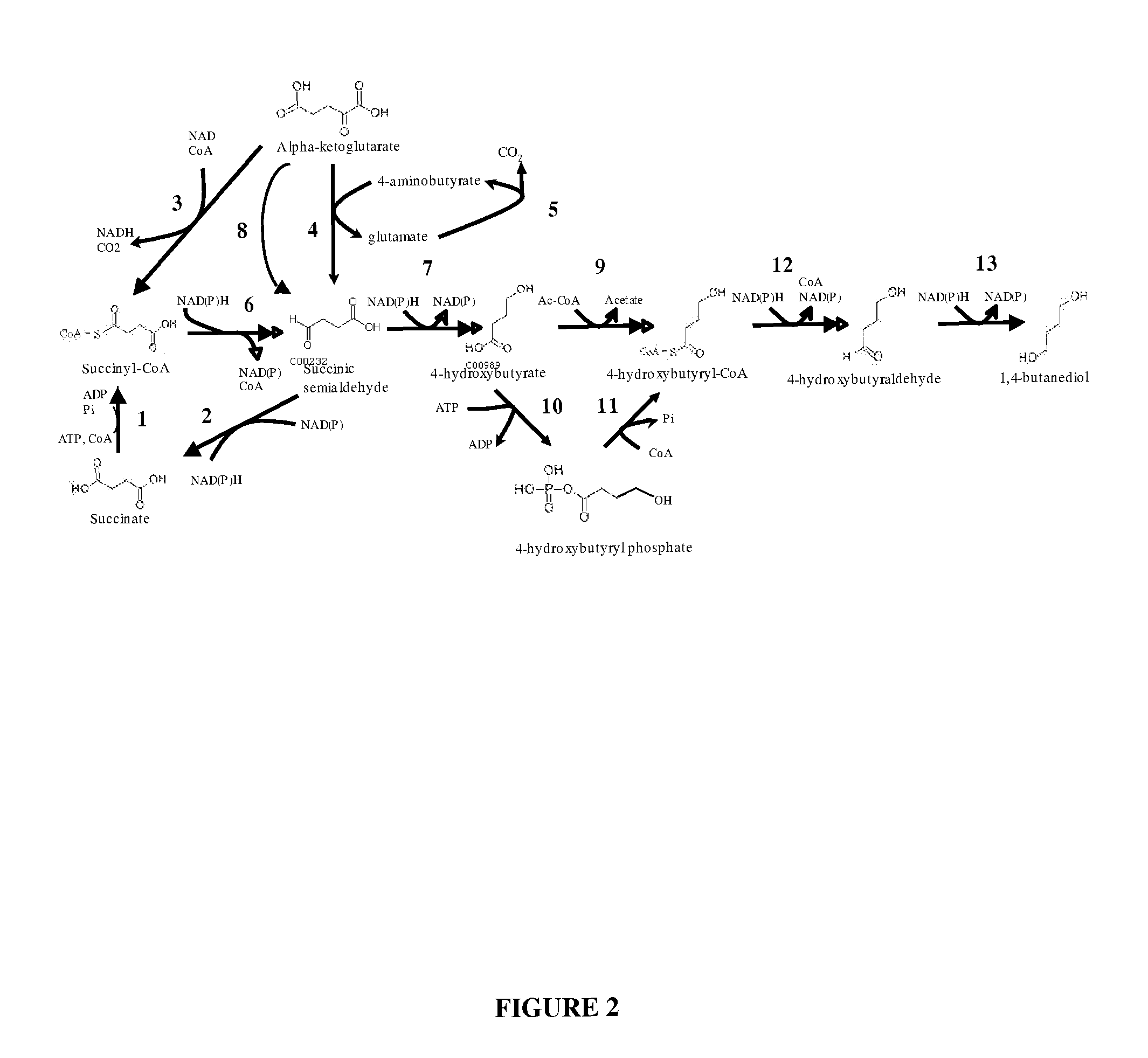

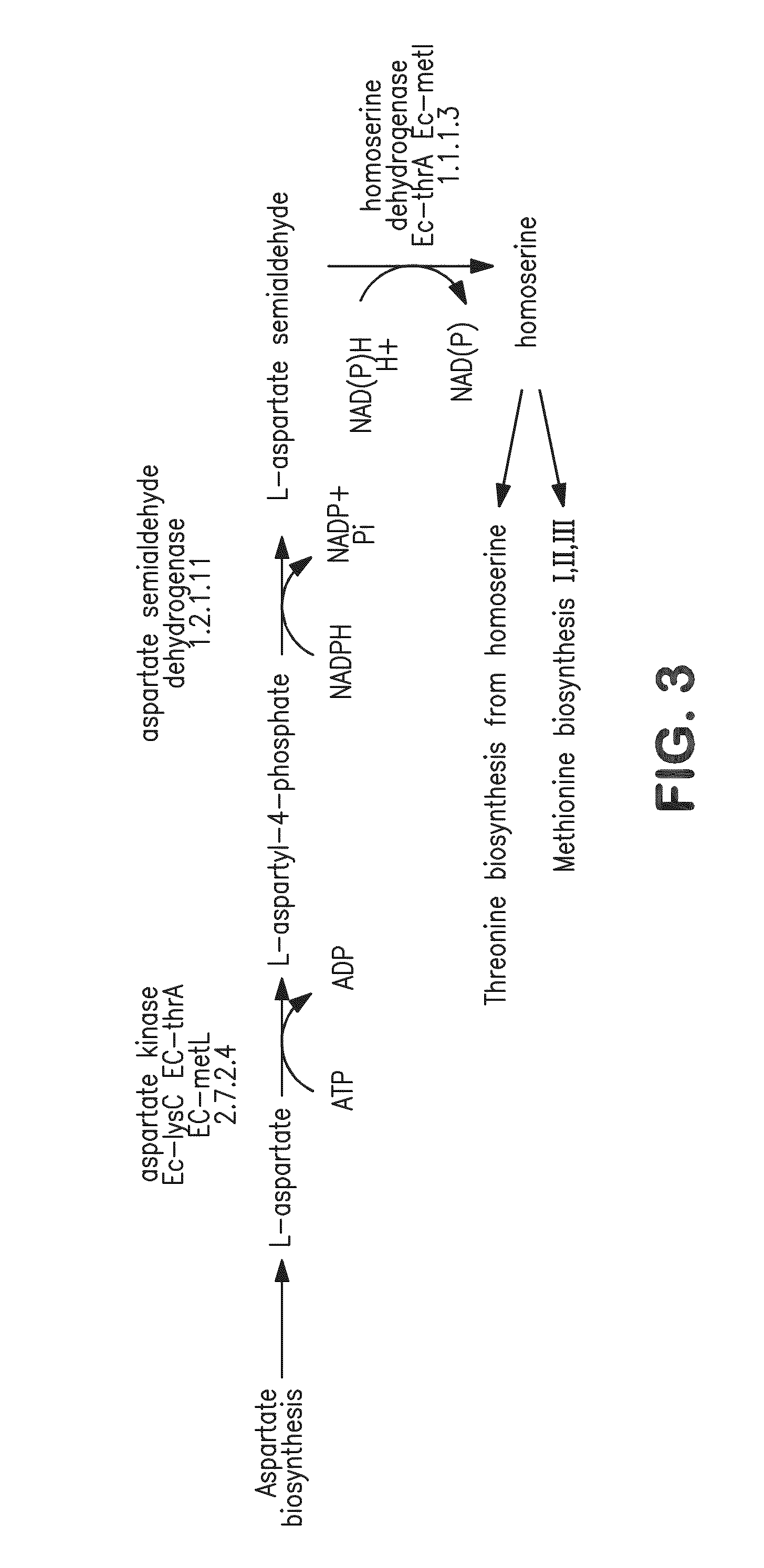

Compositions and methods for the biosynthesis of 1,4-butanediol and its precursors

The invention provides a non-naturally occurring microbial organism having 4-hydroxybutanoic acid (4-HB) and 1,4-butanediol (1,4-BDO) biosynthetic pathways. The pathways include exogenous nucleic acids encoding a) an α-ketoglutarate decarboxylase; b) a 4-hydroxybutanoate dehydrogenase; c) a 4-hydroxybutyryl-CoA:acetyl-CoA transferase or a butyrate kinase and a phosphotransbutyrylase; d) an aldehyde dehydrogenase, and e) an alcohol dehydrogenase, wherein the exogenous nucleic acids are expressed in sufficient amounts to produce 1,4-butanediol (1,4-BDO). Also provide is a method for the production of 1,4-BDO. The method includes culturing the non-naturally occurring microbial organism having 4-HB and 1,4-BDO biosynthetic pathways substantially anaerobic conditions for a sufficient period of time to produce 1,4-BDO.

Owner:GENOMATICA INC

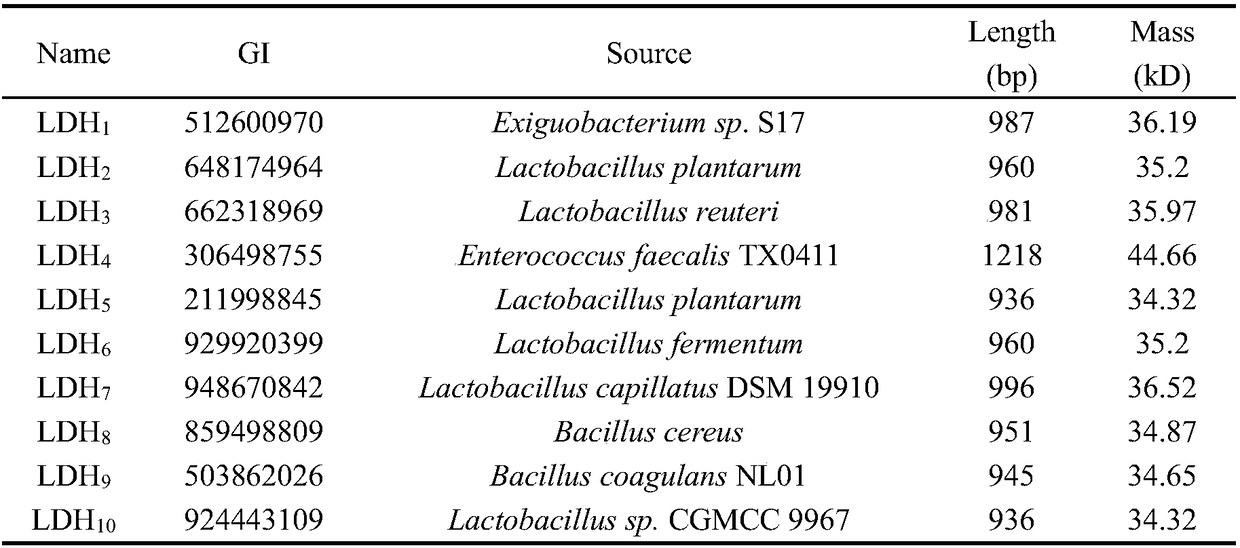

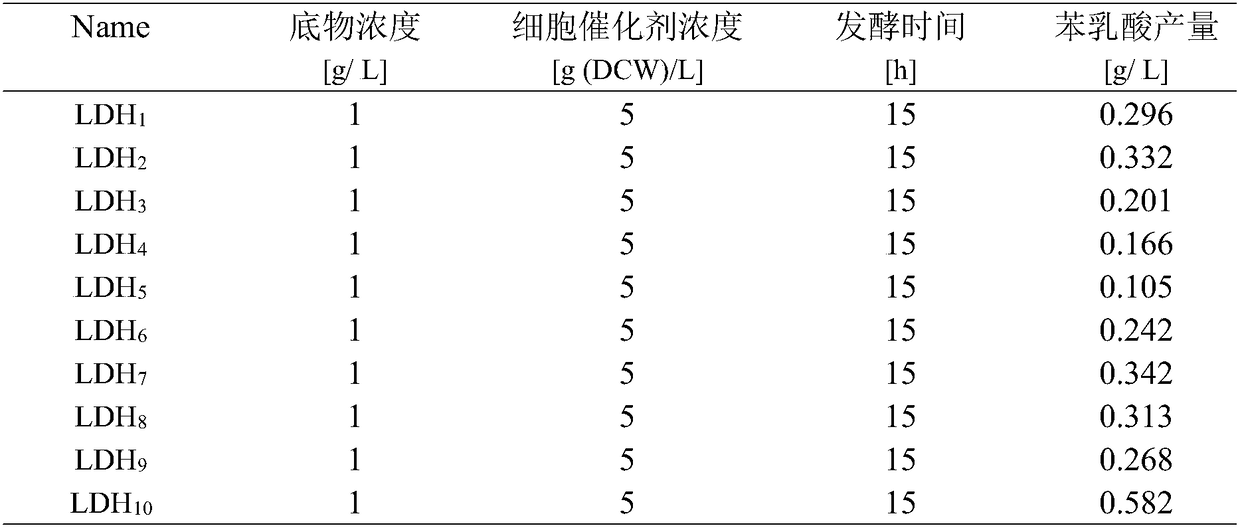

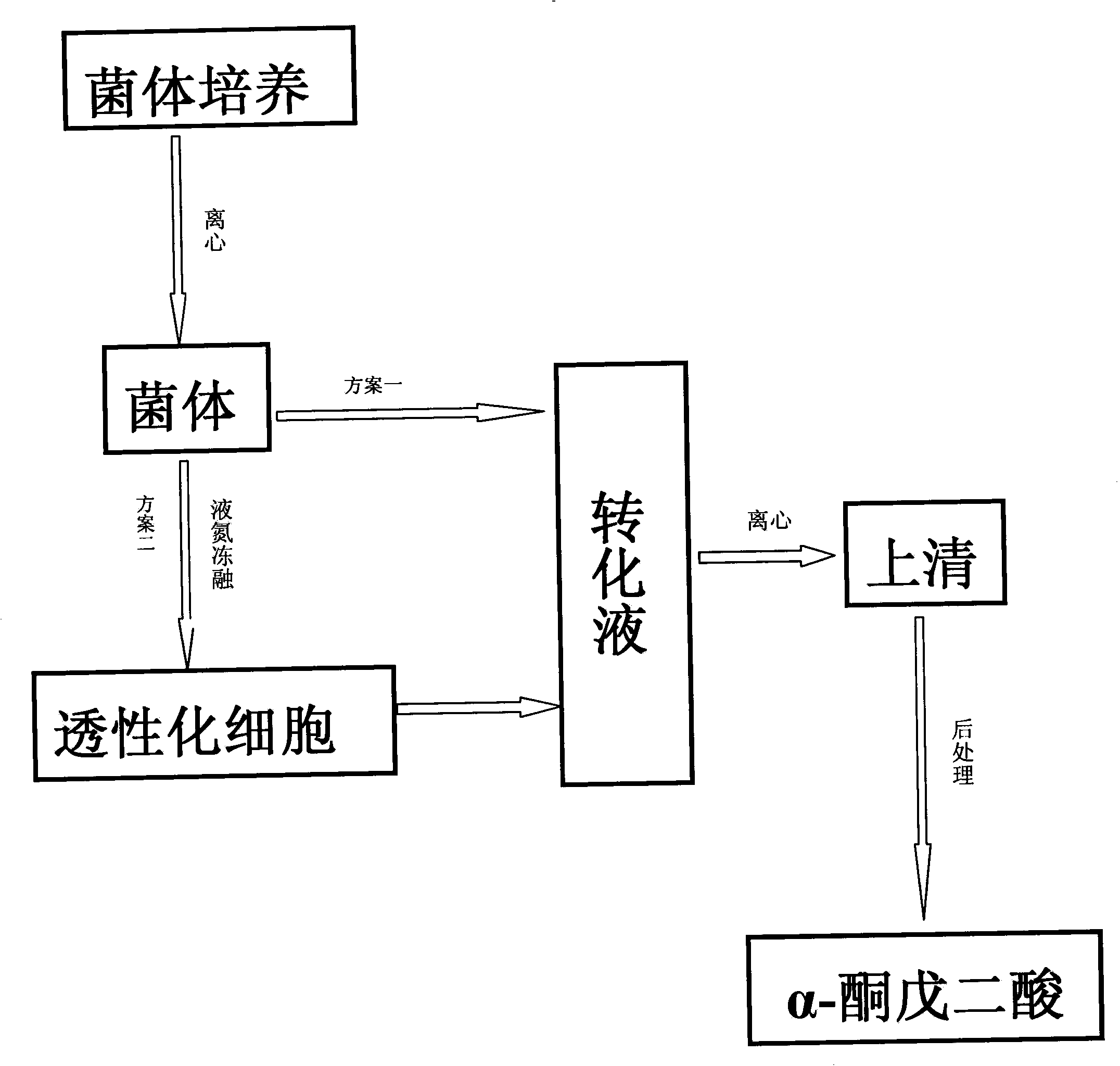

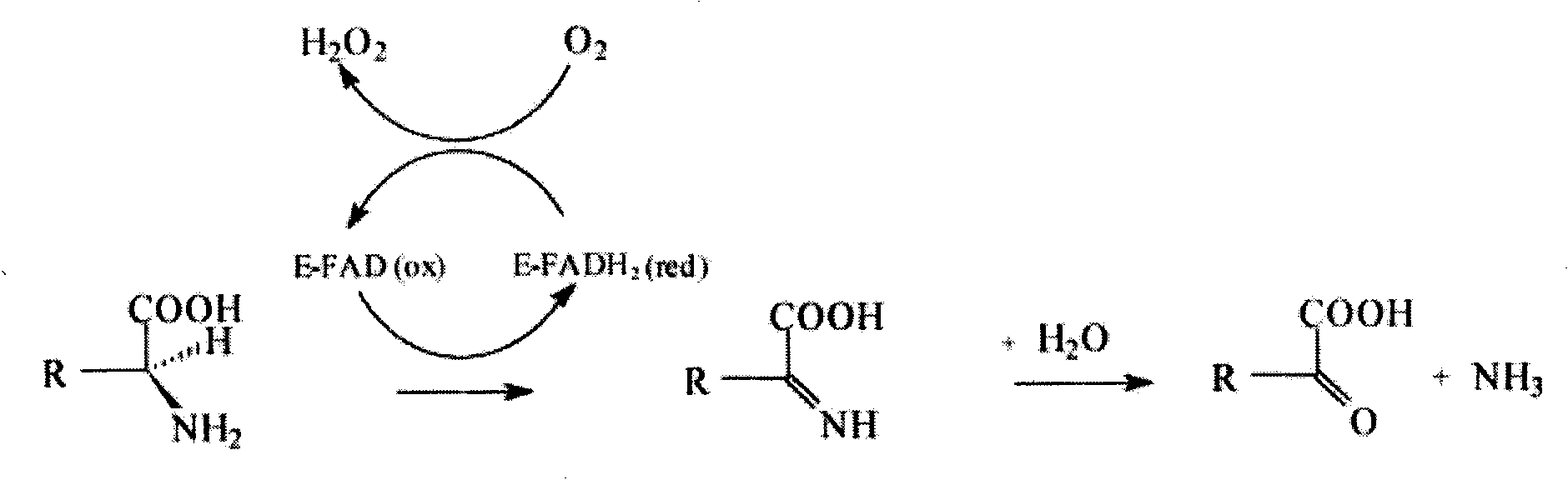

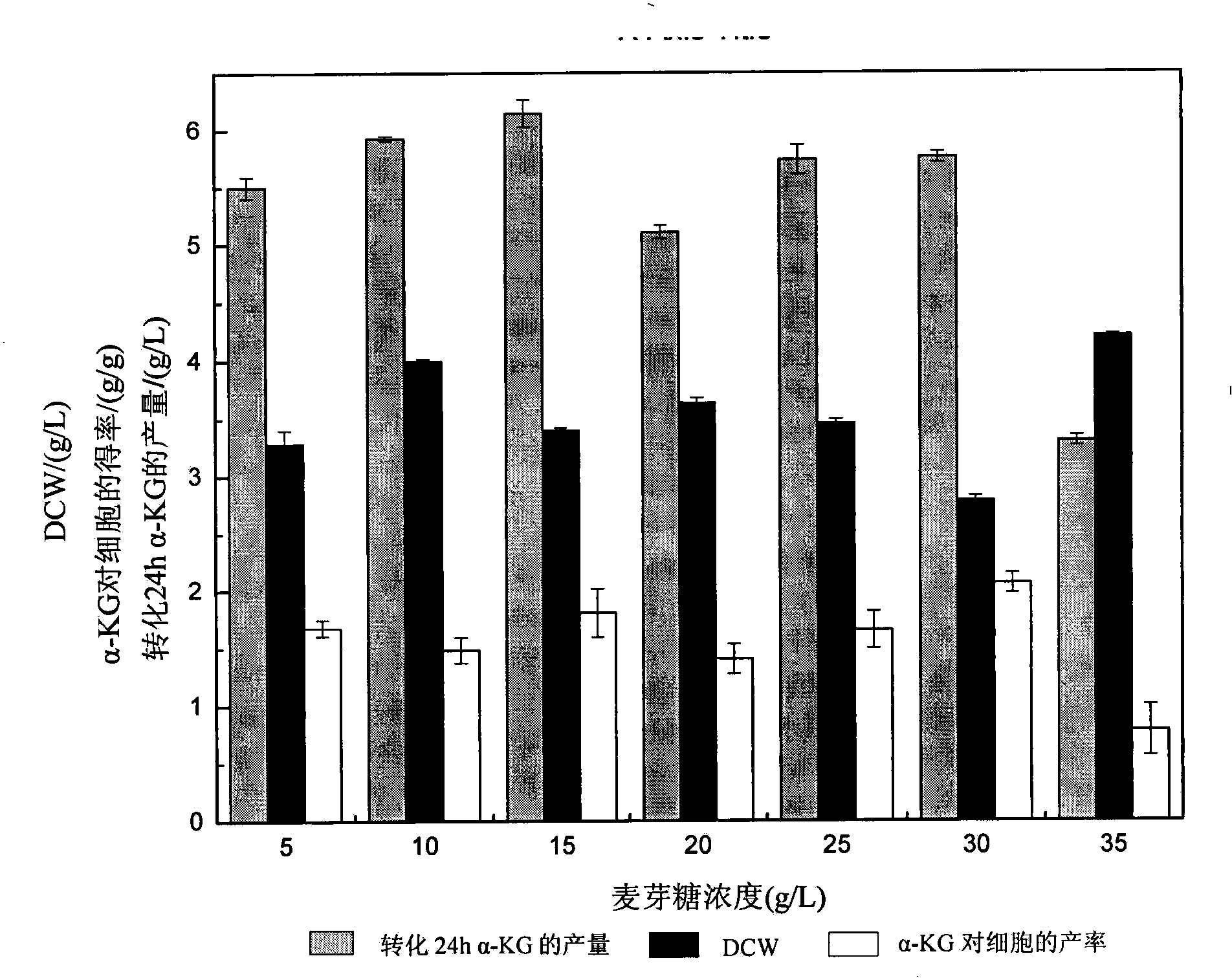

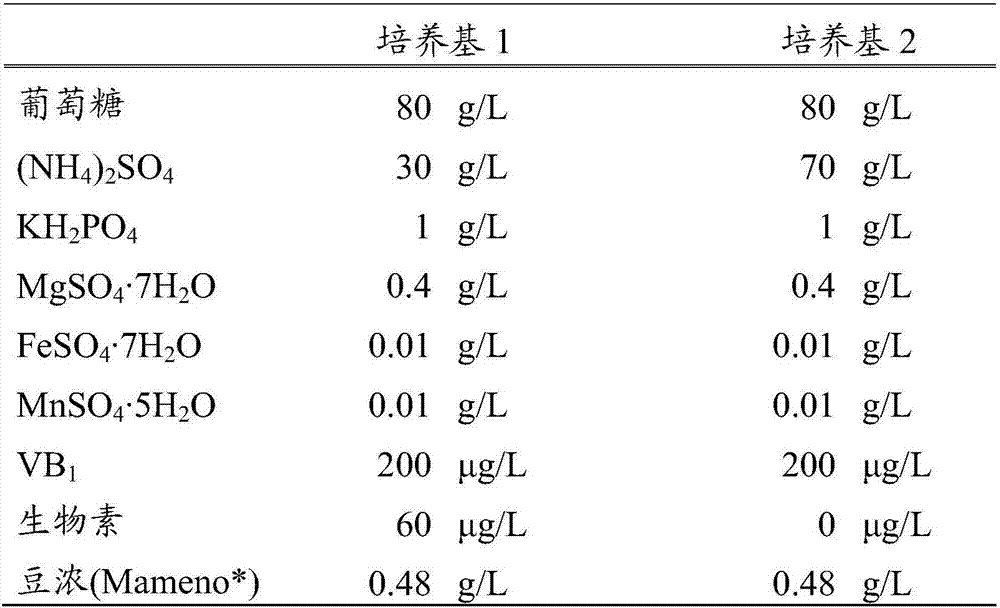

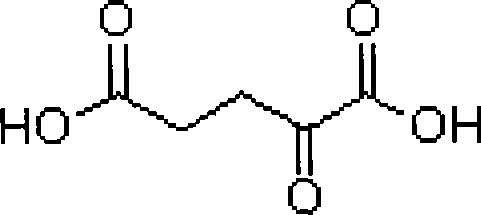

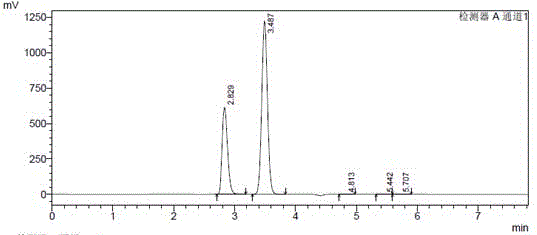

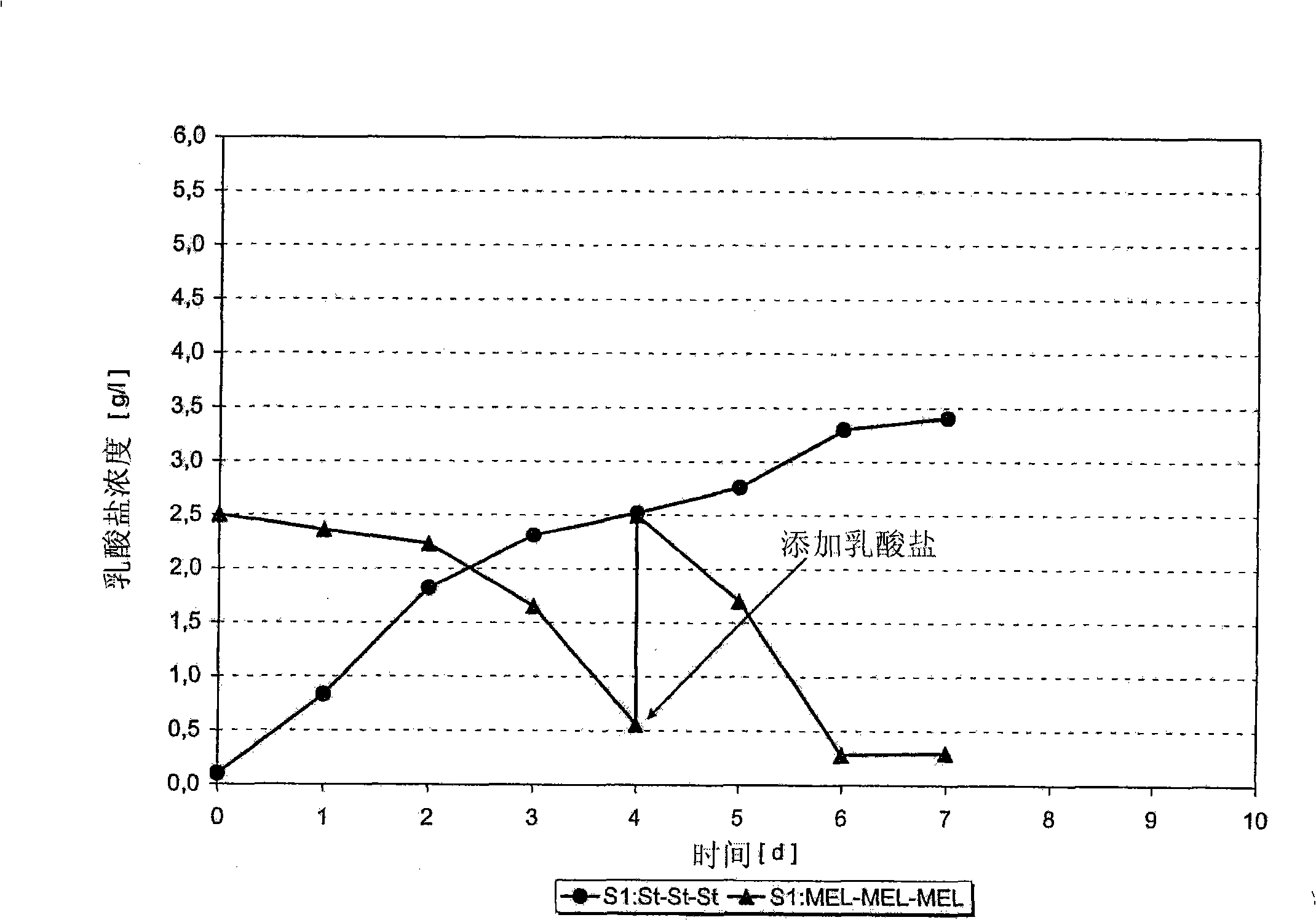

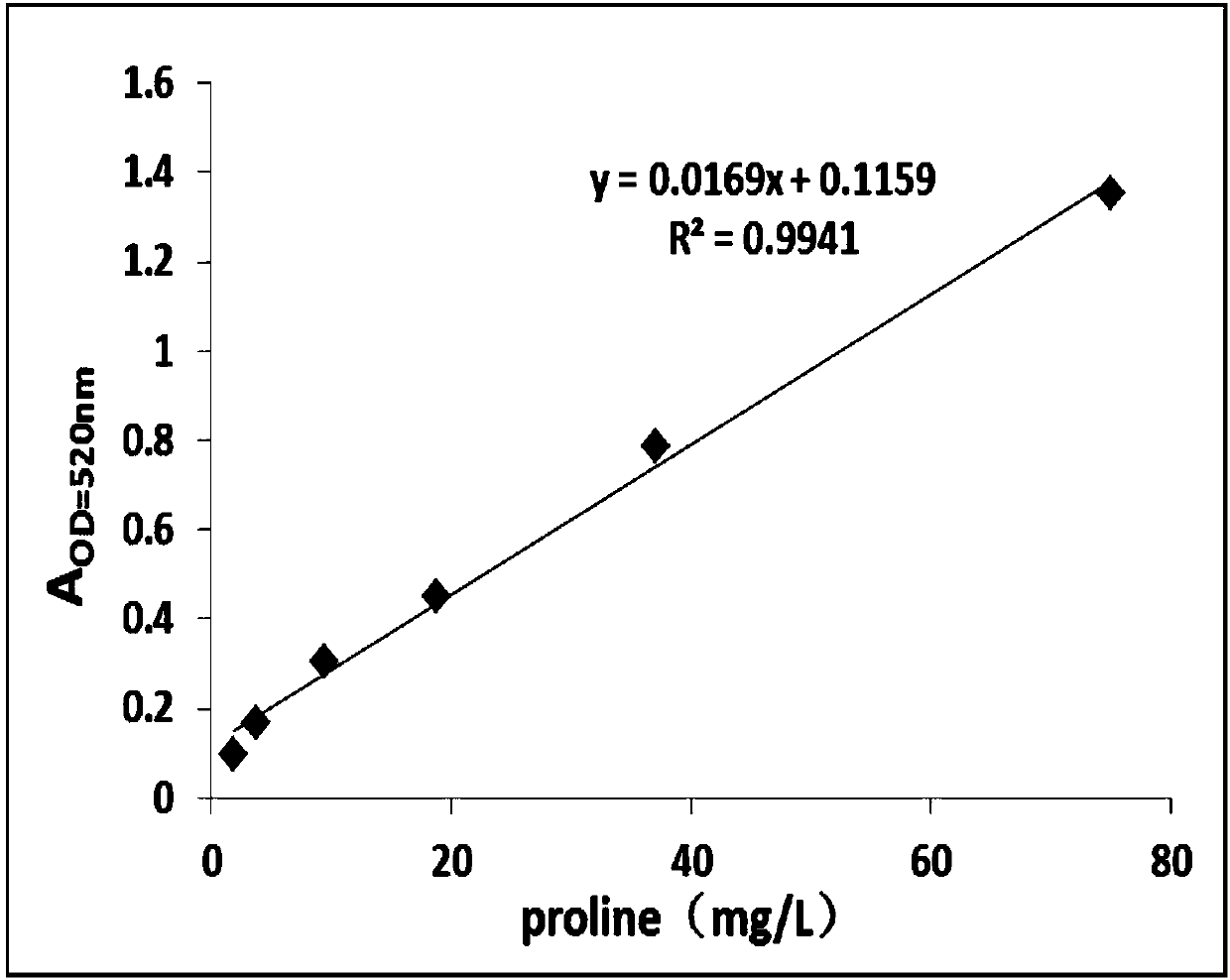

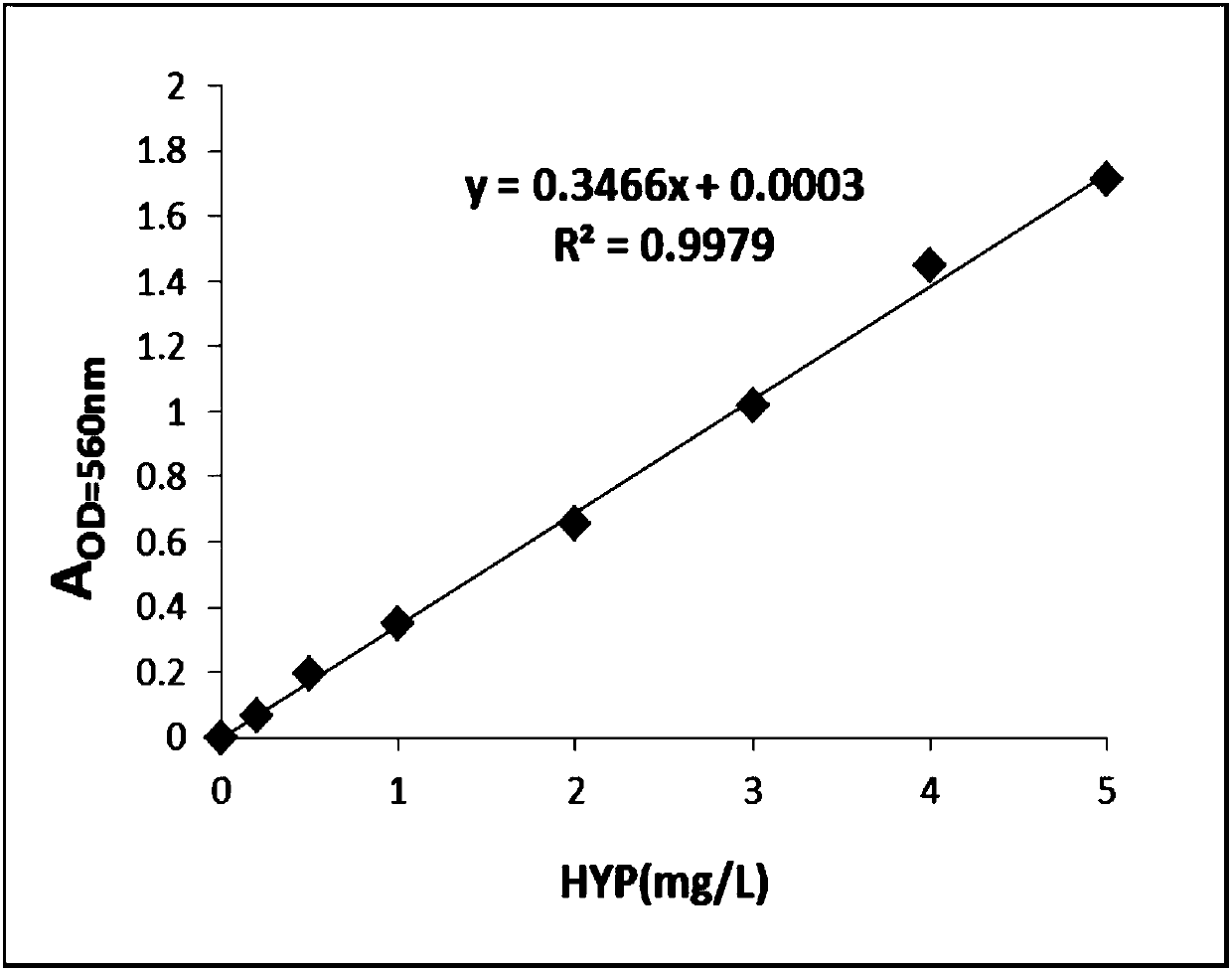

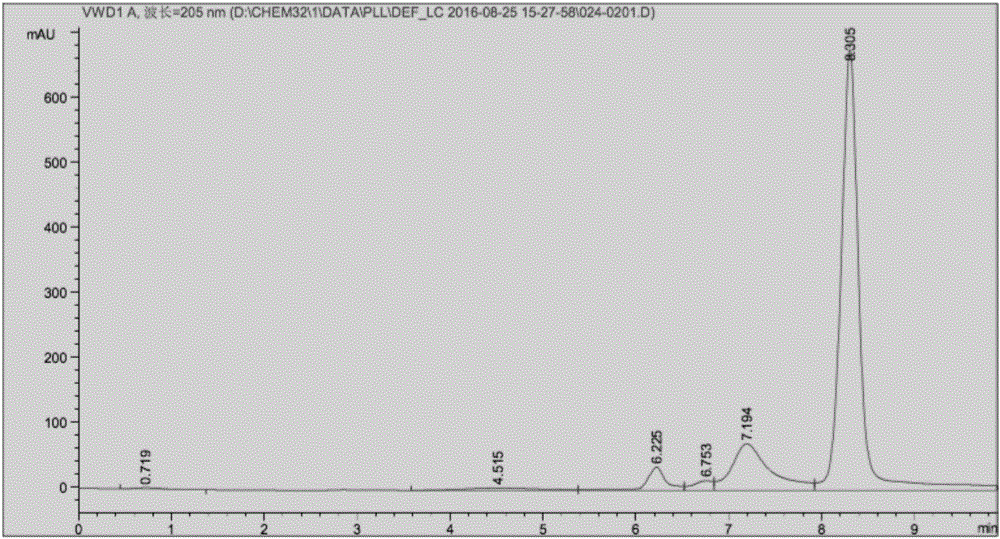

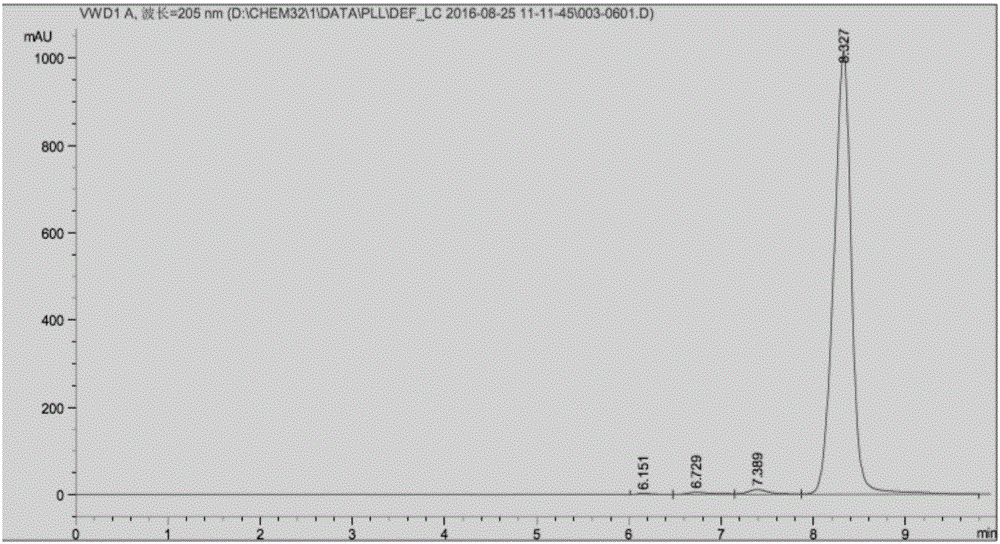

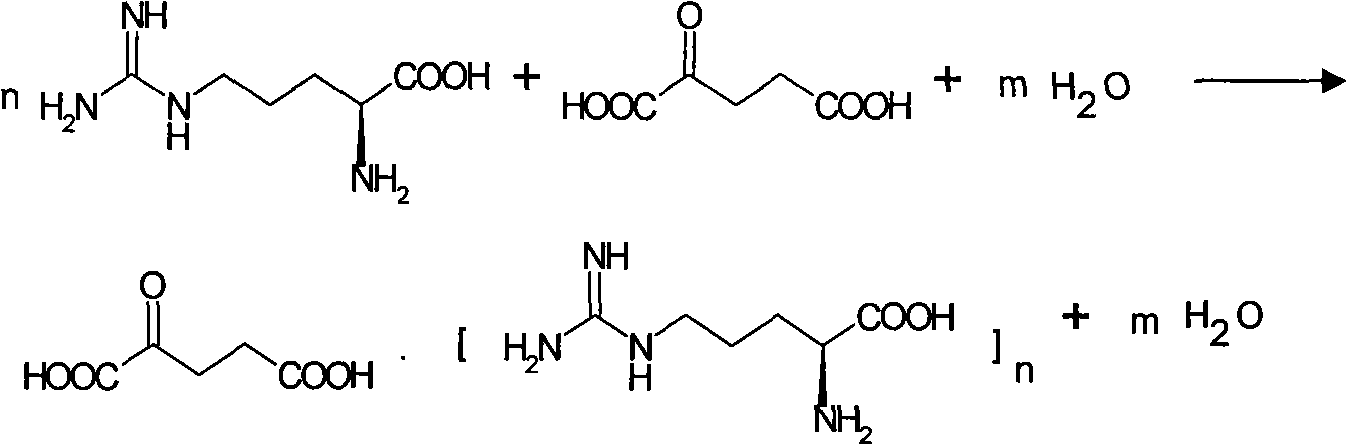

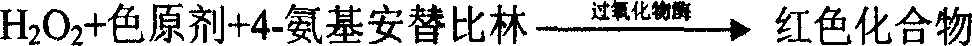

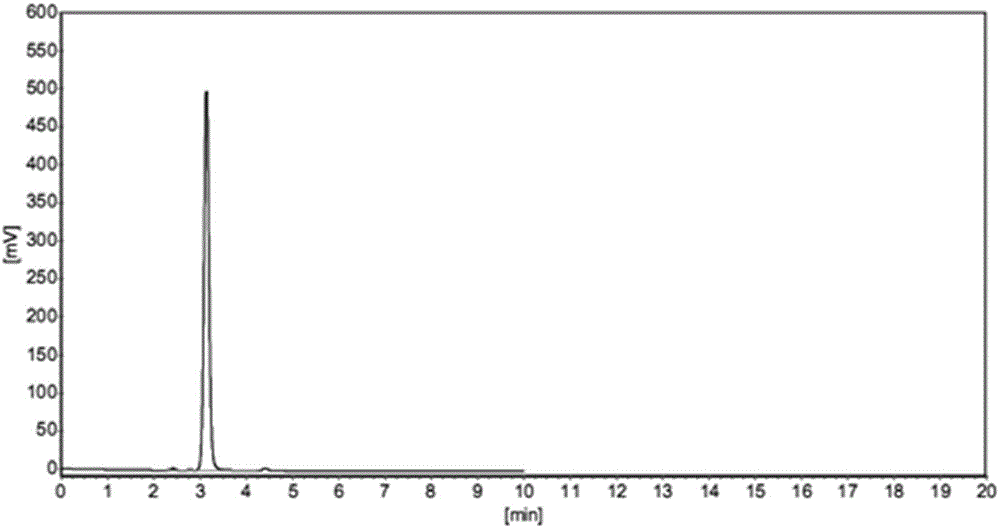

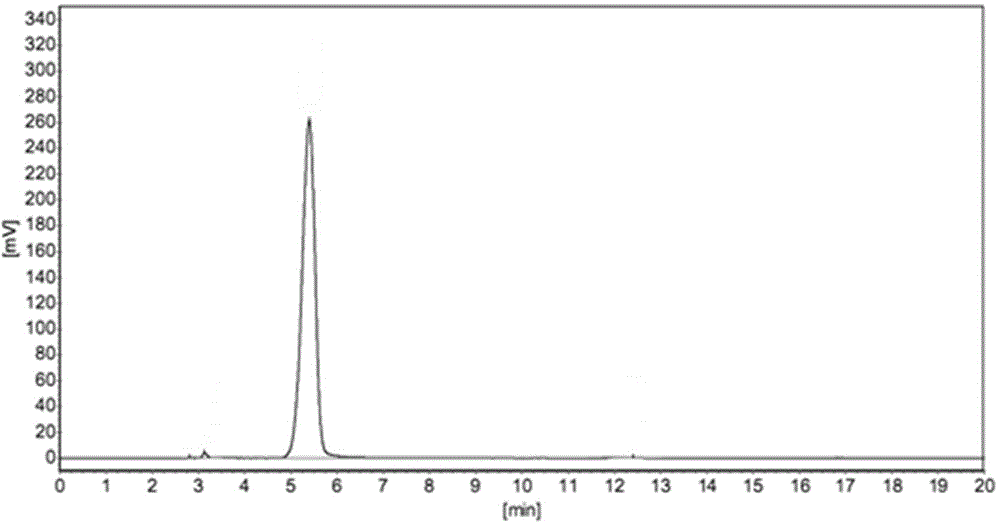

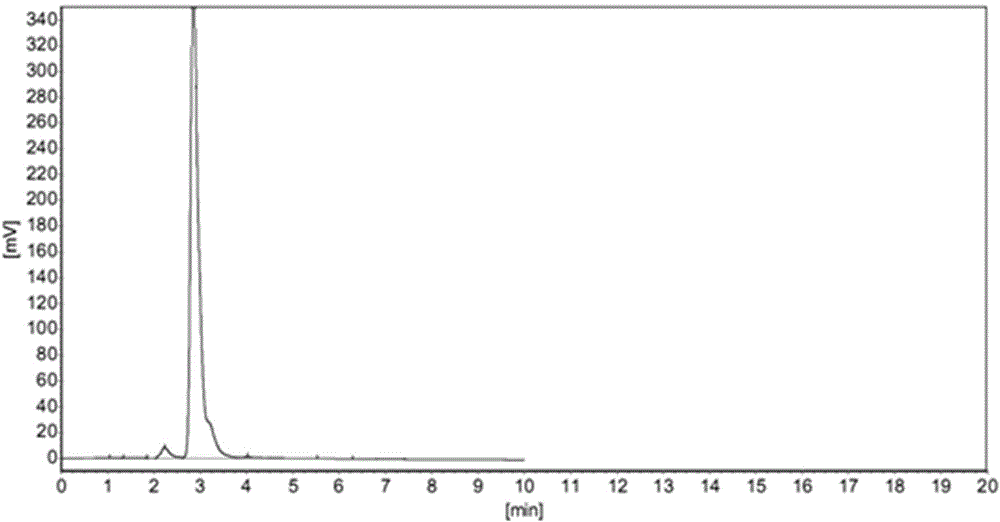

Enzymic method for producing [alpha]-ketoglutaric acid

The invention discloses an enzymic method for producing [alpha]-ketoglutaric acid. The method includes a step of carrying out a catalytic oxidation reaction, catalyzed by L-glutamic oxidase, to L-glutamic or a salt thereof in the presence of a hydrogen peroxide scavenger to obtain [alpha]-ketoglutaric acid. The method is short in production period, is high in product concentration and yield, is low in environment-protective pressure and is suitable for large-scale industrial production.

Owner:SHANGHAI RES & DEV CENT OF INDAL BIOTECH +1

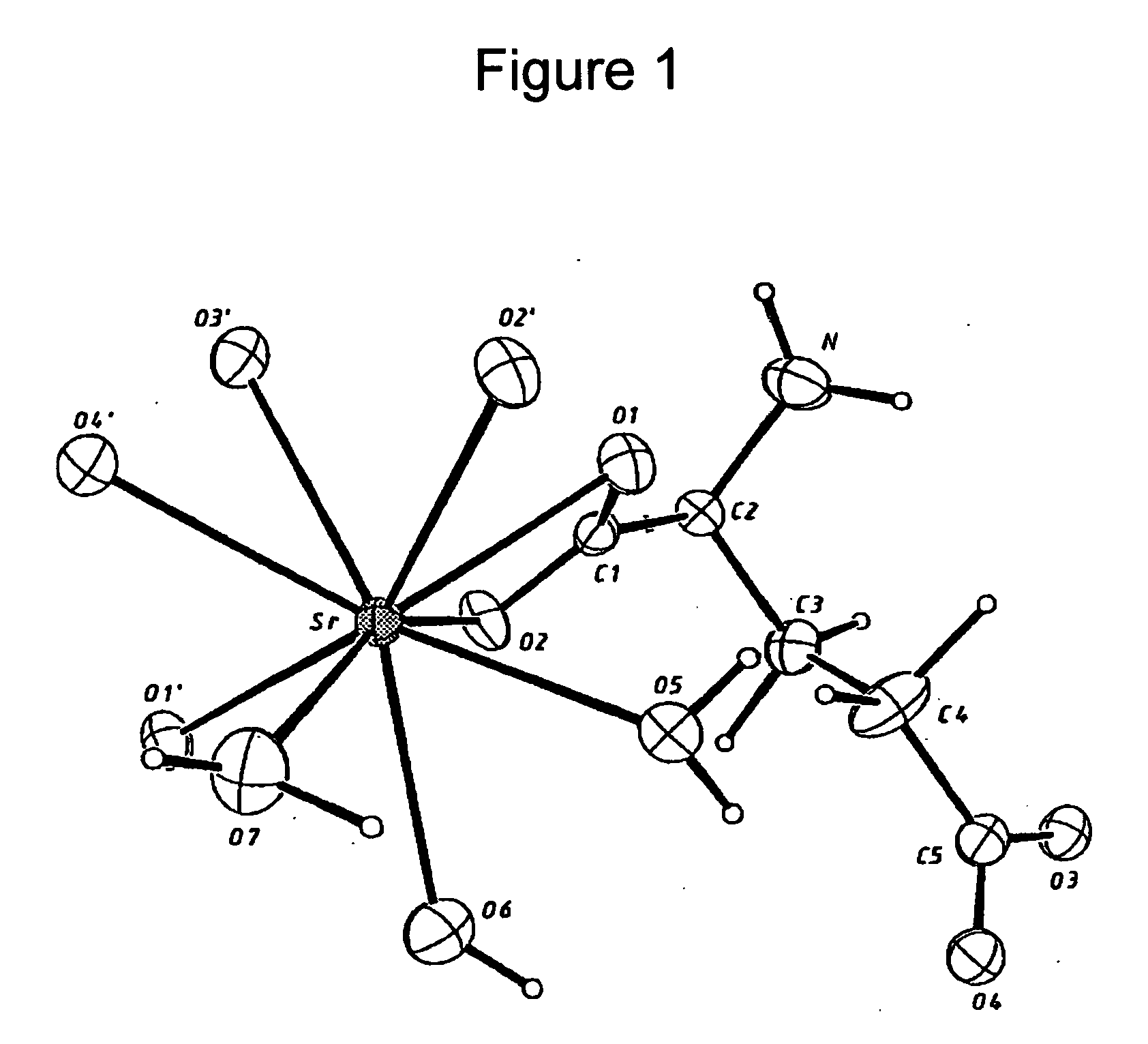

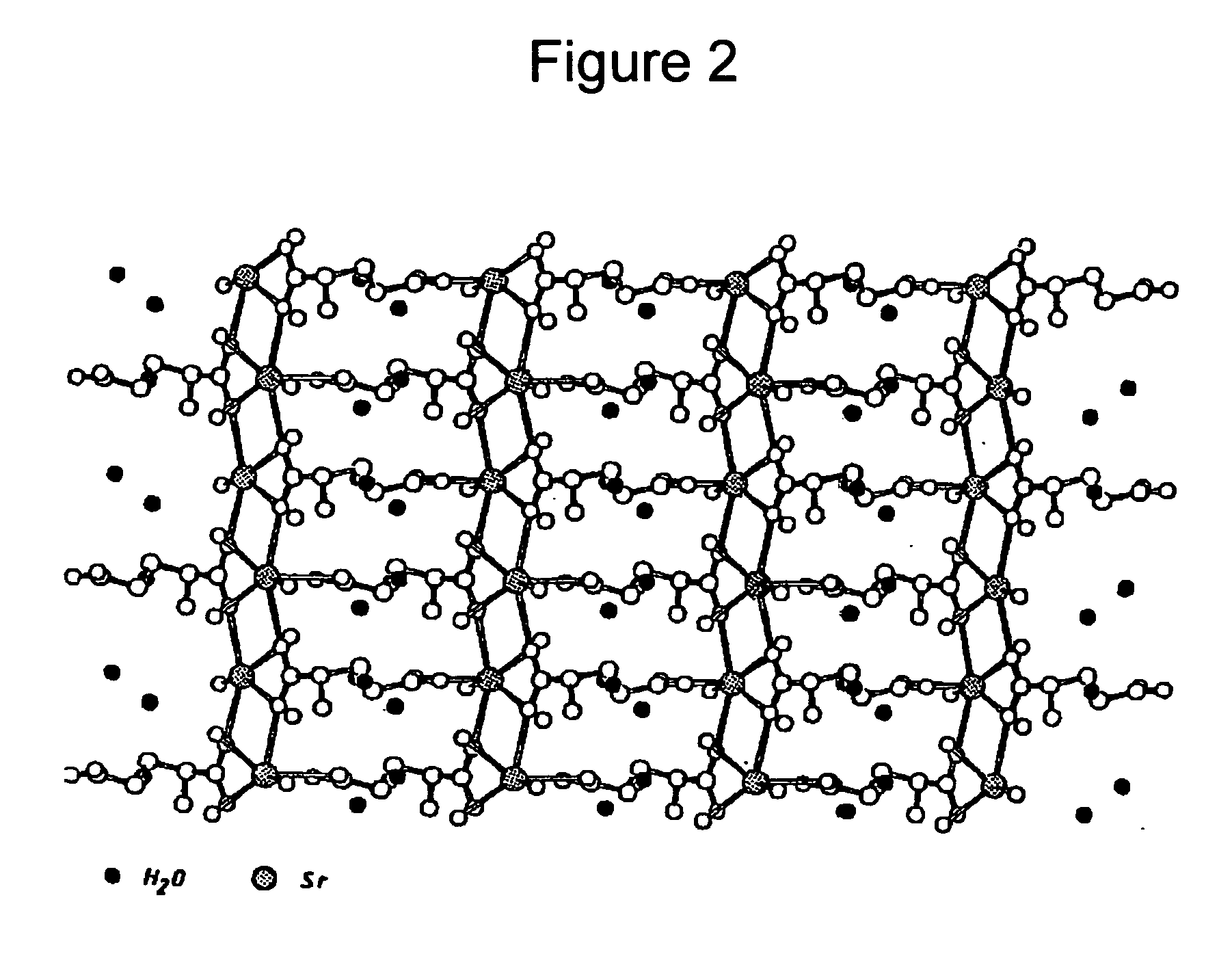

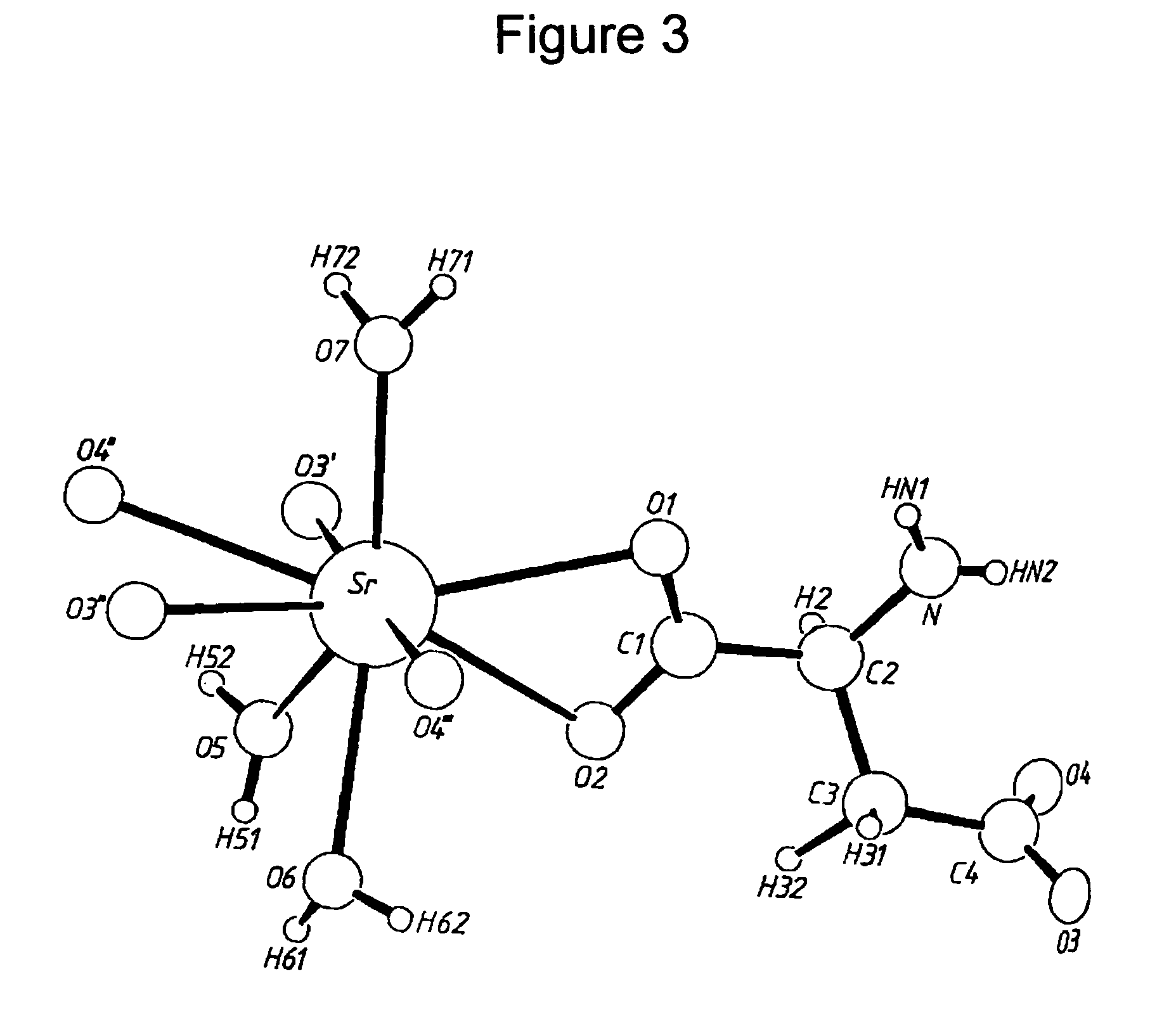

Water-soluble strontium salts for use in treatment of cartilage and/or bone conditions

InactiveUS20060122274A1Weight increaseReduce morbidityBiocideHeavy metal active ingredientsDiseaseSolubility

Compounds and pharmaceutical compositions for use in the treatment and / or prophylaxis of cartilage and / or bone conditions and for methods of treating such condition. The compounds are salts of strontium that have a water-solubility of from about 1 g / l to about 100 g / l at room temperature, especially amino acid salts of strontium or dicarboxylic acid salts of strontium. Examples of novel water-soluble strontium salts are e.g. strontium glutamate and strontium alpha-ketoglutarate. The present invention also relates to an improved method for preparing the strontium salt of glutamic acid.

Owner:OSTEOLOGIX AS

L-d-glutamic oxidase with substrate specificity and alpha-oxoglutarate produced by catalysis of same

InactiveCN102994467ANo pollution in the processSimple production processMicroorganism based processesEnzymesSodium GlutamateIsopropyl alcohol

The invention discloses L-d-glutamic oxidase with substrate specificity and alpha-oxoglutarate produced by catalysis of the same, and belongs to the field of enzyme-method catalytic production of fine chemicals. The invention has the advantages that the L-d-glutamic oxidase which only has the substrate specificity to L-glutamic acid, L-sodium glutamate and glutamine is utilized, 20g / L L-sodium glutamate solution is added in fermented liquid which is fermented for 60 hours and contains the L-d-glutamic oxidase, carrying out conversion for 12 hours under the ventilating condition and the conditions that the temperature is 30 DEG C, the pH is 8.5 and the 5% (v / v) isopropyl alcohol, and measured by a high-performance liquid chromatography, the content of alpha-oxoglutarate reaches 14.5g / L.

Owner:JIANGNAN UNIV

Alpha-ketoglutaric acid high yield bacterium, screening method thereof and production of alpha-ketoglutaric acid from the same by fermentation method

InactiveCN101215529AEfficient accumulationFungiMicrobiological testing/measurementScreening methodMicrobiology

An alpha-ketoglutaric acid high-yield strain and a method for sieving and preparing alpha-ketoglutaric acid through strain by fermenting belong to the chemical engineering technique field. The strain of the invention is Yarrowia lipolytica WSH-Z06 and the preservation number is CCTCC NO: M207143. The strain is aneurine nutriment defect strain which is contrasted and sieved from the soil near the oil refinery according to the colony growth condition on the complete culture medium, basic culture medium and complementary culture medium flats, and then the aneurine nutriment defect strain is adopted by one-grade ferment to do shake flask culture one by one and sieve primarily. The fermentation liquor is analyzed by silica gel chromatography. The strain which keeps alpha-ketoglutaric acid colour development spot is transferred in the shake flask which is loaded with ferment culture medium to do ferment sieve again. The fermentation liquor is tested by high-effective liquid-phase method and produces the high-yield alpha-ketoglutaric acid strain compared with the production of alpha-ketoglutaric acid. The production of alpha-ketoglutaric acid can reach 39.3 g / L through optimizing the important component in the ferment culture medium and fermenting for 6 d.

Owner:JIANGNAN UNIV

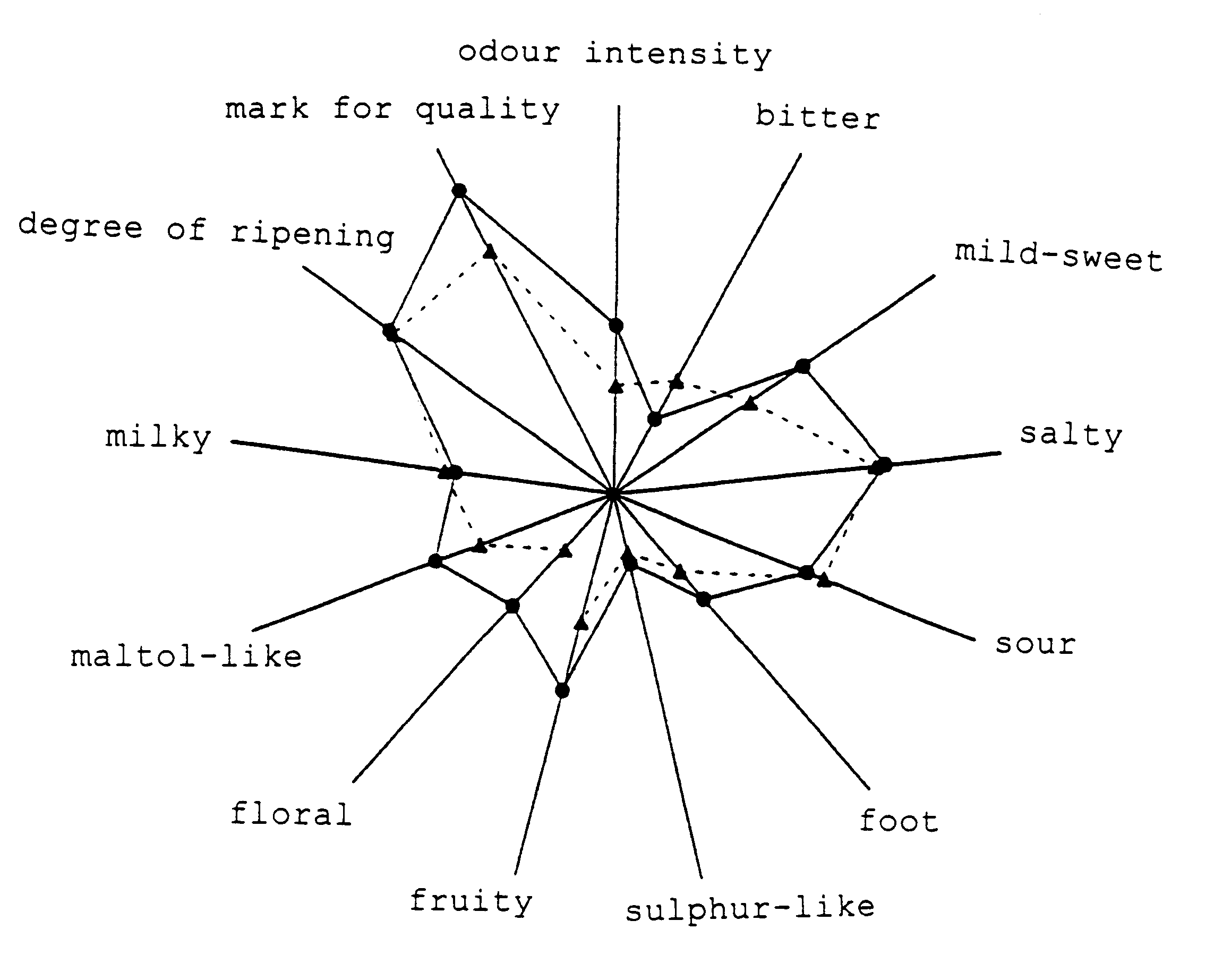

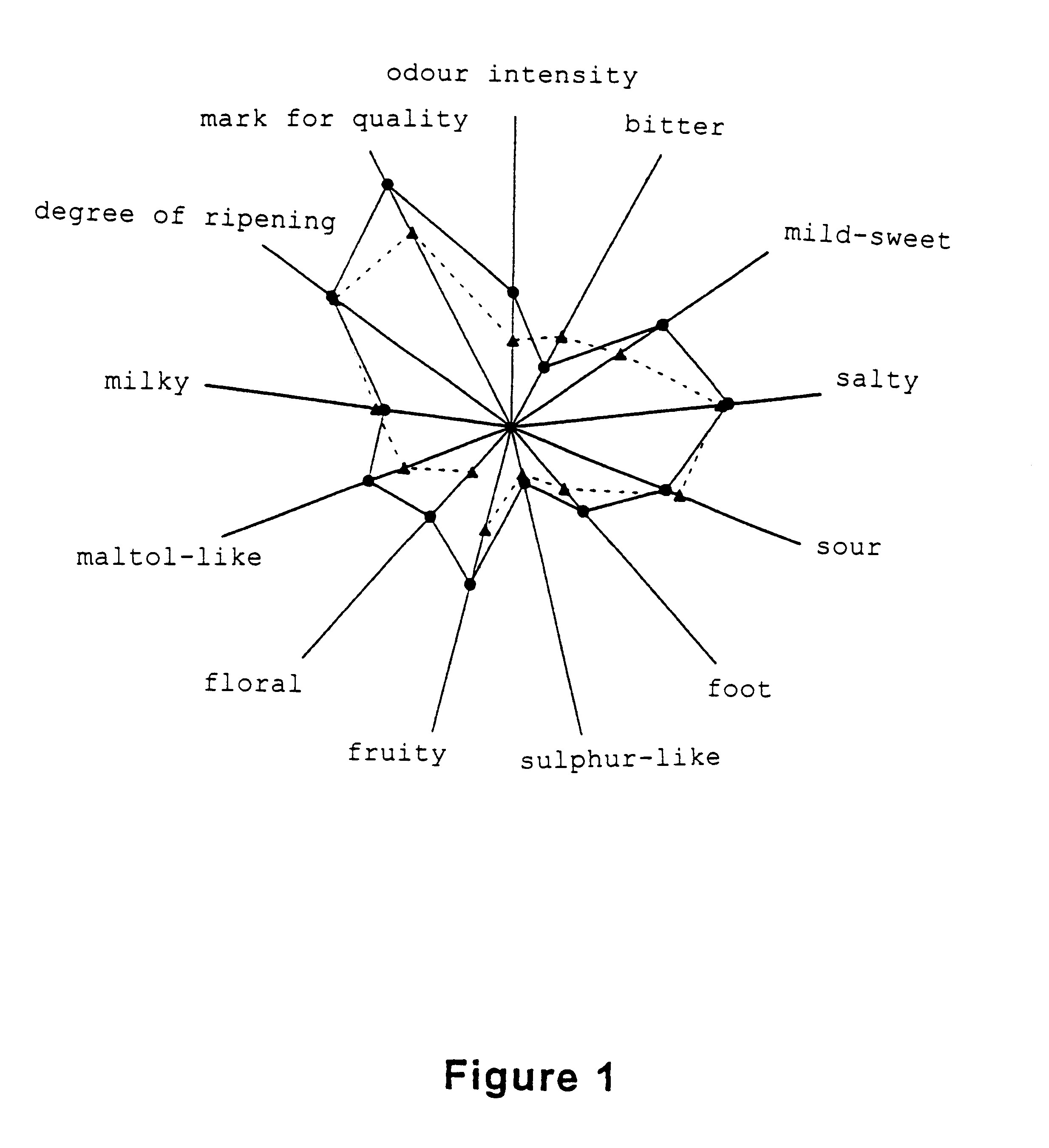

Use of keto acids to enhance the flavor of cheese products

Process for enhancing the flavour of a cheese or of a cheese-flavoured food product whose preparation comprises a maturation step in the presence of lactic acid bacteria, characterized in that a preparation additive comprising at least one keto acid chosen from the group consisting of alpha-ketoglutaric acid, alpha-ketoisocaproic acid ketoisovaleric acid and phenylpyruvic acid is used to increase the catabolism of the amino acids in the cheese or food product by the said bacteria.

Owner:INSTITUT NATIONAL DE LA RECHERCHE AGRONOMIQUE

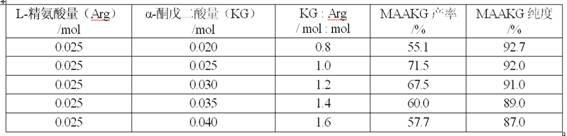

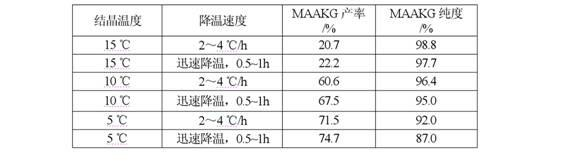

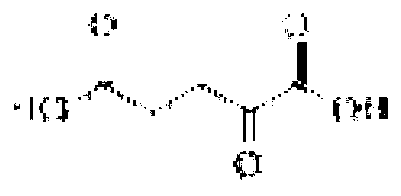

Preparation method of crystal L-arginine alpha-ketoglutarate

InactiveCN101591271AReasonable workmanshipSimple stepsOrganic chemistryFood preparationArginineL-arginine alpha-ketoglutarate

The invention relates to a preparation method of crystal L-arginine alpha-ketoglutarate, comprising the following steps: preparing water solution of L-arginine, and slowly adding alpha-ketoglutaric acid into the water solution, wherein the mol ratio of L-arginine and alpha-ketoglutaric acid is 1:1 or 2:1; reducing pressure and concentrating the alpha-ketoglutaric acid at 50-80 DEG C after complete dissolution, removing water accounting for 20-60 percent of the total volume and cooling to 20-30 DEG C; slowly adding an organic hydrophilic solvent or a mixed solvent of a polar hydrophilic solvent and a non-polar hydrophilic solvent; and carrying out temperature reduction, crystallization, filtering, washing and vacuum drying to obtain the crystal L-arginine alpha-ketoglutarate. Compared with the prior art, the invention has the advantages of reasonable process, simple steps, easy operation, good crystal form of the obtained product, difficult caking, convenient transportation and use, high purity (more than or equal to 98 percent) and high yield (80-86 percent) of the product, and the like, and is suitable for industrialization production.

Owner:上海汉飞生化科技有限公司

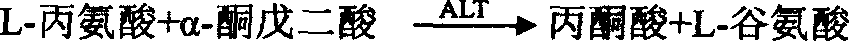

Glutamate-pyruvate transaminase determination method and glutamate-pyruvate transaminase determination reagent kit

ActiveCN1995378AReactivityImprove detection accuracyMicrobiological testing/measurementMaterial analysisAlanine aminotransferaseOxygen

The invention discloses a measuring method of Alanine Aminotransferase (ALT) and agent box in the external diagnostic technical domain, which comprises the following steps: reacting agent 1 and sample; generating hydrogen peroxide through reacting acetonic acid oxidase and endogenous acetonic acid; producing water and oxygen from hydrogen peroxide acted by catalase; reacting with agent 2; utilizing L-Ala and alpha-ketoglutaric acid starting serum ALT to react; detecting the activity of serum ALT of absorbance change of linear reaction.

Owner:BEIJING BGI GBI BIOTECH

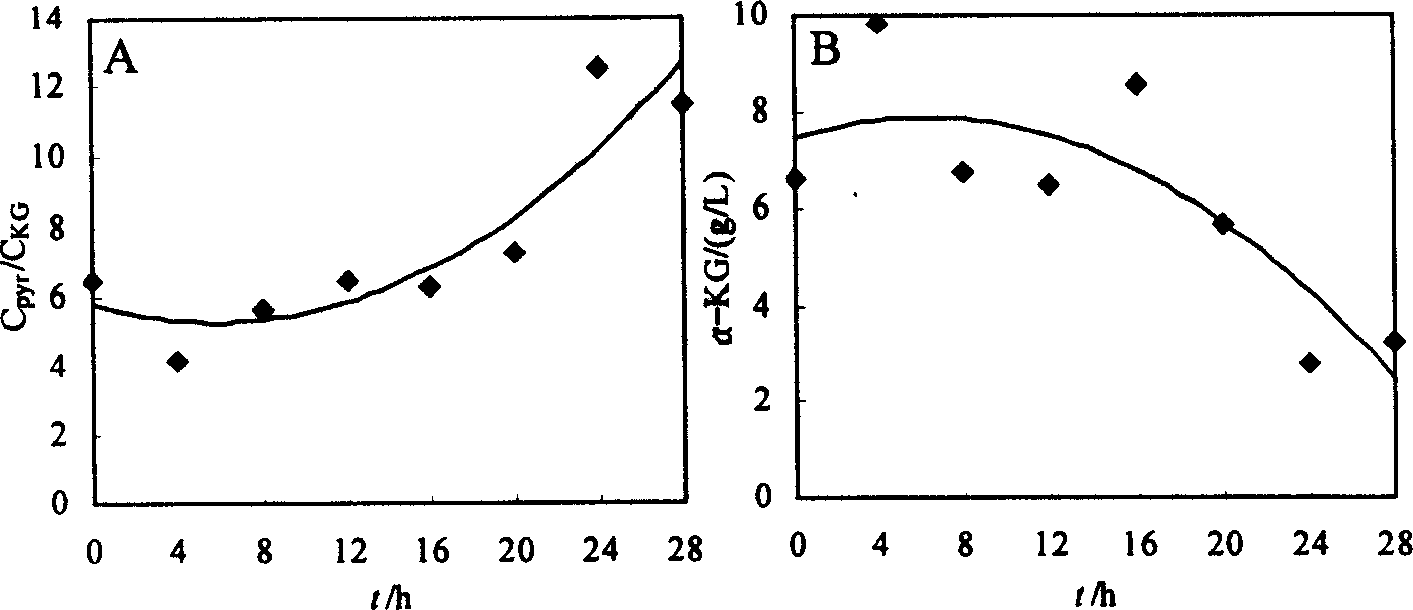

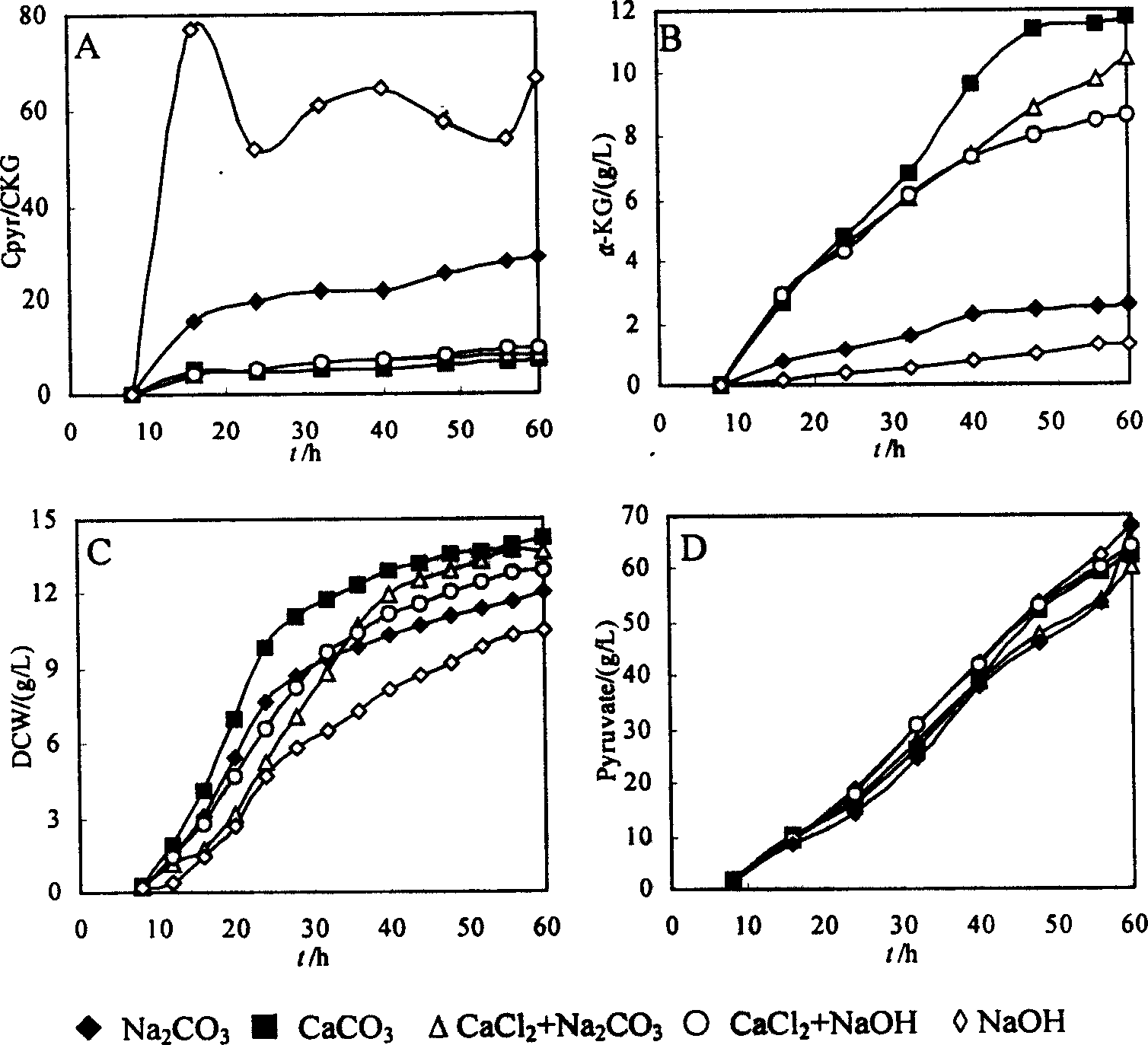

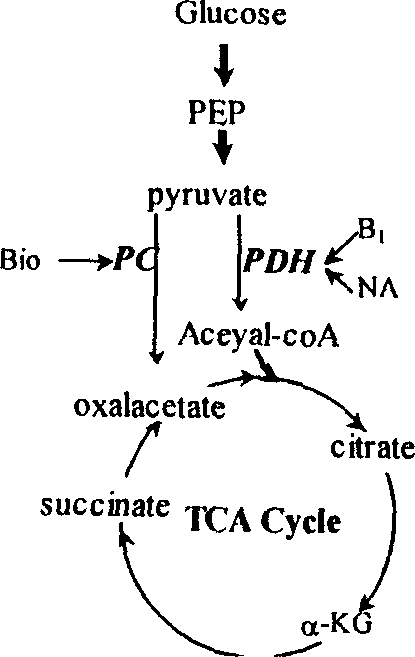

Method for microbial fermentation synthesis of ª‡- ketoglutaric acid

InactiveCN1544642AIncrease carbon molar ratioIncrease concentrationFermentationHigh concentrationIncreased biotin

The invention is a method of synthesizing alpha-ketoglutarate by fermenting microbes, promoting to produce a large amount of alpha-ketoglutarate in fermenting course by adding CaCO3 to the culture medium and increasing biotin concentration. in the course of fermenting candida glabrata CCTCC M202019 to producing pyruvic acid, the delay of time of adding CaCO3 will inhibit the generation of alpha-ketoglutarate and increase the carbon mole ratio of pyruvic acid to alpha-ketoglutarate (CPYR / CKG), and increase of CaCO3 concentration in the culture medium will promote accumulation of a large amount of alpha-ketoglutarate, when the CaCO3 concentration is 40g / L, it is most beneficial to alpha-ketoglutarate generation. Keeping the CaCO3 concentration in the culture medium but increasing biotin concentration in the culture medium so as to promote the continuous increase of the alpha-ketoglutarate concentration but continuous decrease of CPYR / CKG value, and when biotin concentration is 60mum g / L, accumulated quantity of alpha- ketoglutarate is 23.5g / L. when Ca2+ exists, in-cell phosphoenolpyruvate carboxylase activity can be increased by 40%, and the activity of pyruvic acid dehydrogenase system does not change obviously. The increase of the Ca2+ and biotin concentration can remarkably the activity of enhance pyruvic acid dehydrogenase, thus making T.glabrata transfer from production of pyruvic acid by fermenting to synthesis of high-concentration alpha-ketoglutarate.

Owner:JIANGNAN UNIV

Preparing method of alpha-ketoglutaric acid-arginine salt and its use for treating hepatic disease

The invention relates to an alpha-ketoglutaric acid-arginine salt, the preparing process and use thereof, wherein the salt is prepared through combining alpha-ketoglutaric acid and arginine with a preferred ratio of 1:1 and 1:2. Pharmacological experiment shows that, the salt can be used for treating liver damages.

Owner:BEIJING JIASHILIANBO PHARM SCI & TECH

Method for separating alpha-ketoglutaric acid from conversion solution

ActiveCN104529755ARealize multiple recyclingAchieve recyclingOrganic compound preparationChemical industryUltrafiltrationSulfate

The invention discloses a method for separating alpha-ketoglutaric acid from a conversion solution, which comprises the following steps: sequentially carrying out ceramic filtration, ultrafiltration and reverse osmosis on the conversion solution to obtain an alpha-ketoglutaric acid concentrated solution; reacting the obtained concentrated solution with calcium superchloride, and filtering to obtain alpha-ketoglutarate; adding the alpha-ketoglutarate and ethanol into a reaction kettle, slowly and dropwisely adding sulfuric acid, stopping adding the acid when the pH value of the ethanol solution is 1.3-1.5, stirring to react to generate a calcium sulfate precipitate, filtering, and collecting the filtrate which is a ketoglutaric acid ethanol solution; eluting the residual alpha-ketoglutaric acid from the calcium sulfate with ethanol, and collecting the eluting solution; and mixing the filtrate and eluting solution, and heating and concentrating under reduced pressure to precipitate the alpha-ketoglutaric acid crystal. The membrane filtration technique is adopted to avoid abundant water evaporation; and thus, the method has the advantages of energy saving, high production yield, favorable crystal form, light color of the crystal grain, and stable product quality, and can easily implement industrialized large-scale production.

Owner:JING JING PHARMA

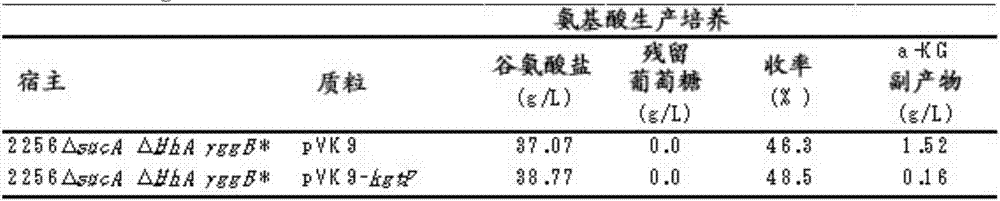

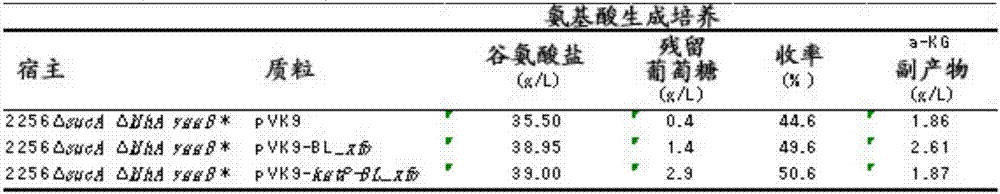

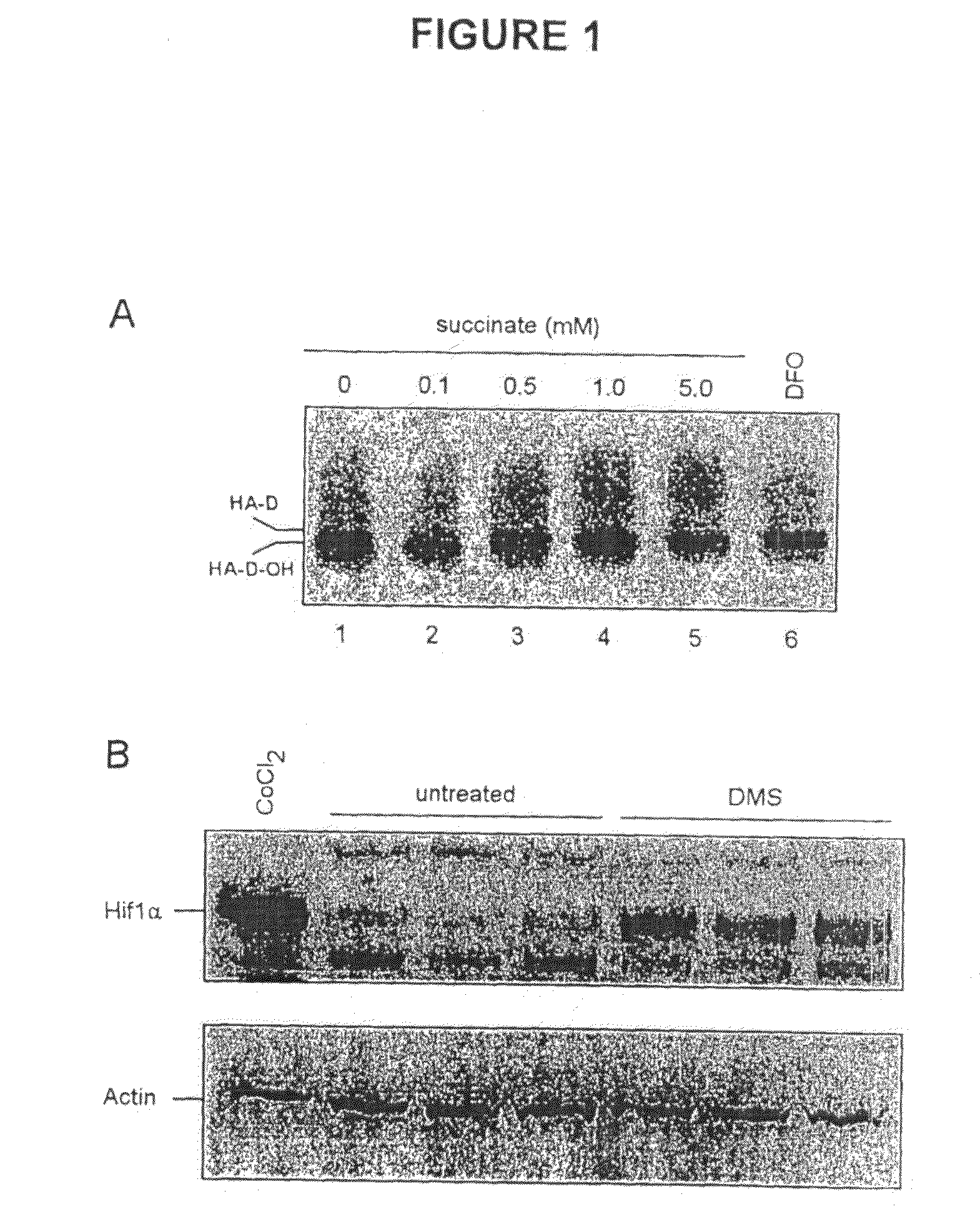

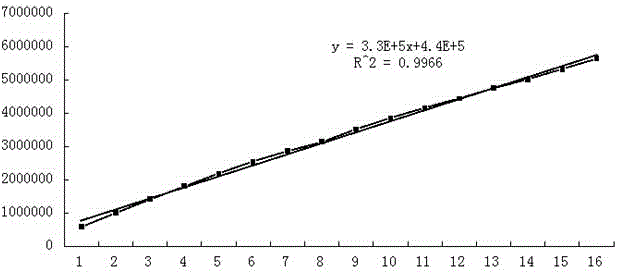

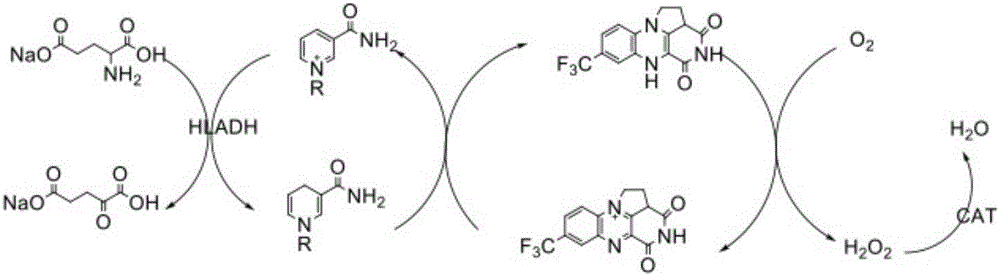

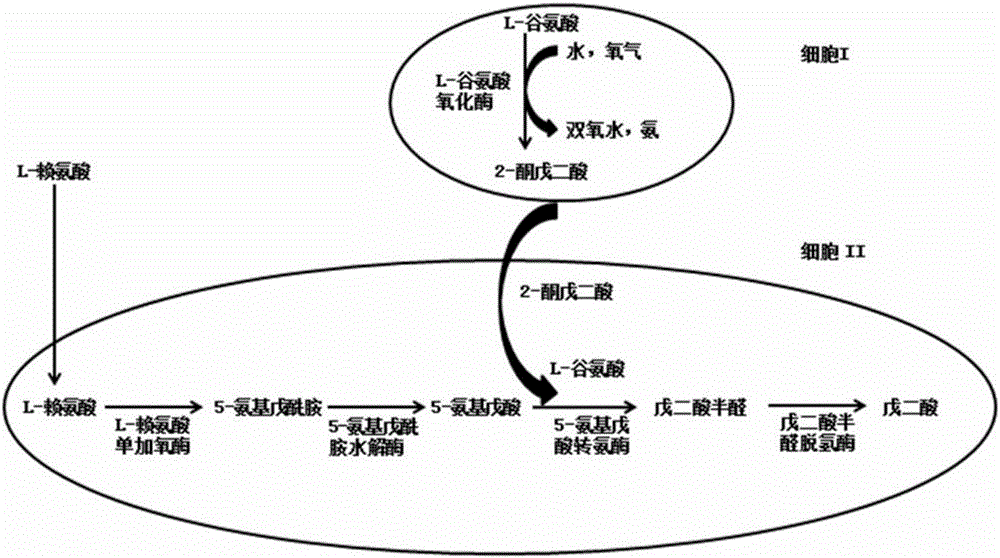

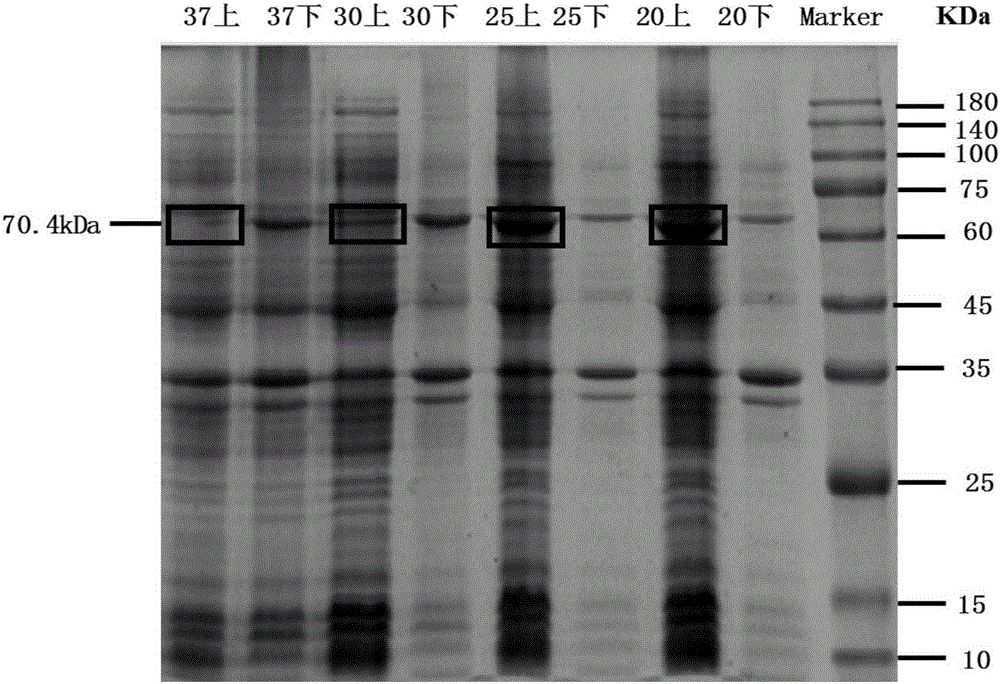

Construction method of dual-enzyme co-expression strains for producing [alpha]-ketoglutarate

ActiveCN106047913AEfficient expressionReasonable realization of expression rangeBacteriaOxidoreductasesMicrobiologyFermentation

The invention discloses a construction method of dual-enzyme co-expression strains for producing [alpha]-ketoglutarate, and belongs to the technical fields of fermentation engineering and enzyme engineering. According to the construction method, on the basis of analyzing the production of the [alpha]-ketoglutarate from L-glutamic acid, a KatG dosage required by a transformation system is analyzed; and then, the co-enzyme co-expression strains, which are different in expression level, are constructed at a transcription level and a translation level, and the performances of the co-expression strains are evaluated by the production of the [alpha]-ketoglutarate through whole-cell transformation of L-glutamic acid at a shaker level, wherein transformation conditions are as follows: 110g / L of the L-glutamic acid, 2-2.5g / L of bacteria, a phosphate buffer system with pH value at 6.5, 30 DEG C, and 18-24h at 200rpm. The yield of the [alpha]-ketoglutarate from the optimum strain F006 can reach 107.2g / L or above, with a transformation rate of 98.4%, completely replacing exogenous catalase; bacterium concentration is increased, the yield of the [alpha]-ketoglutarate under the condition of 132g / L of a substrate can reach 127.1g / L and a transformation rate is 96.9%.

Owner:JIANGNAN UNIV

Method for producing phenyllactic acid through whole-cell transformation of phenylalanine

InactiveCN108277190AThe solution steps are cumbersomeLow resolutionBacteriaMicroorganism based processesChemical synthesisPhenylalanine

The invention discloses a method for producing a phenyllactic acid through whole-cell transformation of phenylalanine, and belongs to the technical field of enzyme engineering. The method successfullyconstructs an L-amino acid deaminase, L-lactic dehydrogenase and formate dehydrogenase co-expressed strain. Phenyllactic acid of 30 g / L is produced through the whole-cell transformation of phenylalanine, and the transformation rate is 100%. The establishment of a whole-cell transformation system solves the problems of complicated steps, low yield and environment pollution in the chemical synthesis of the phenyllactic acid as well as the problem of low transformation rate in the production of the alpha-oxoglutarate through the enzymatic conversion, the phenyllactic acid is produced through a one-step method at high yield without pollution, and a certain theoretical foundation is laid for the subsequent industrial production.

Owner:JIANGNAN UNIV

Biocatalysis method for preparing Alpha ketoglutarate from L-soda glutamate

ActiveCN103352058AImprove conversion rateMicroorganism based processesFermentationL-amino-acid oxidaseSodium Glutamate

The invention expounds a biocatalysis method for preparing Alpha ketoglutarate from L-soda glutamate, and belongs to the biotechnological field. The method comprises the following steps: utilizing strains (Rhodococcus opacus) producing L-amino acid oxidase, performing fermentation for 48 hours, collecting thallus, weighing and pouring 12 g / L (calculating by dry weight) thallus into a 10 g / L L-soda glutamate contained conversion solution, performing conversion at the temperature of 35 DEG C and the pH of 8.4 for 10 hours, adding 4.3 g / L L-soda glutamate into a reaction system every 6 hours, and performing continuous conversion for 24 hours, where the output of Alpha-ketoglutarate reaches 16.8 g / L, and the conversion rate reaches more than 90 percent.

Owner:JIANGNAN UNIV +1

Method for Producing L-Amino Acid of Glutamate Family

ActiveCN107034250AIncrease production capacityEfficient preparationBacteriaTransferasesAlpha-Ketoglutaric acidCoryneform bacterium

A method for producing an L-amino acid of glutamate family such as L-glutamic acid is provided. An L-amino acid of glutamate family is produced by culturing a coryneform bacterium having an ability for producing an L-amino acid of glutamate family, which has been modified so that the activity of an alpha-ketoglutaric acid (alpha-KG) uptake carrier is increased, in a medium, and collecting the L-amino acid of glutamate family from the medium.

Owner:AJINOMOTO CO INC

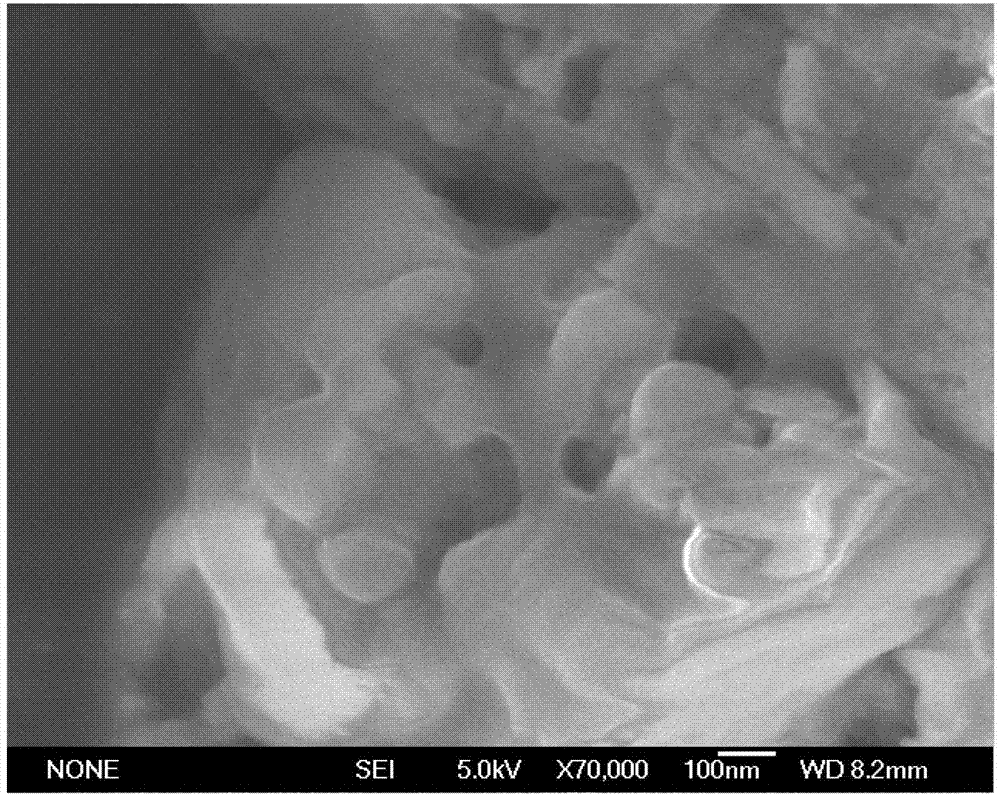

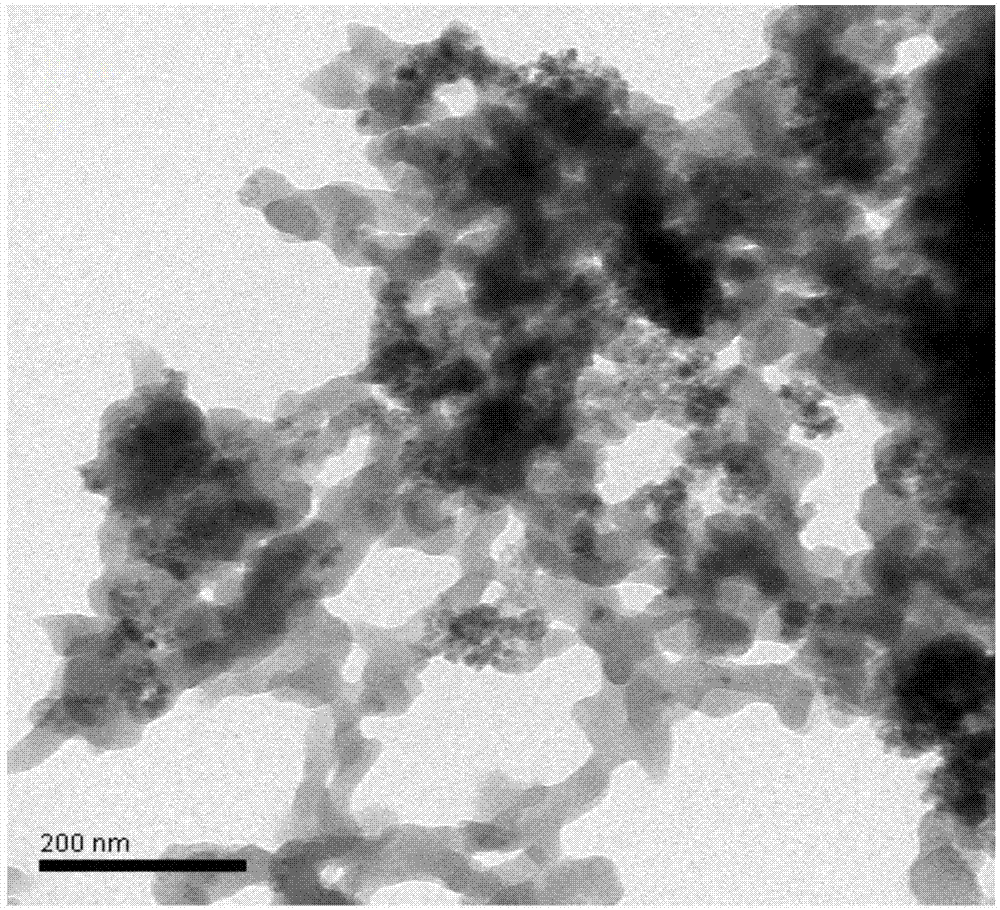

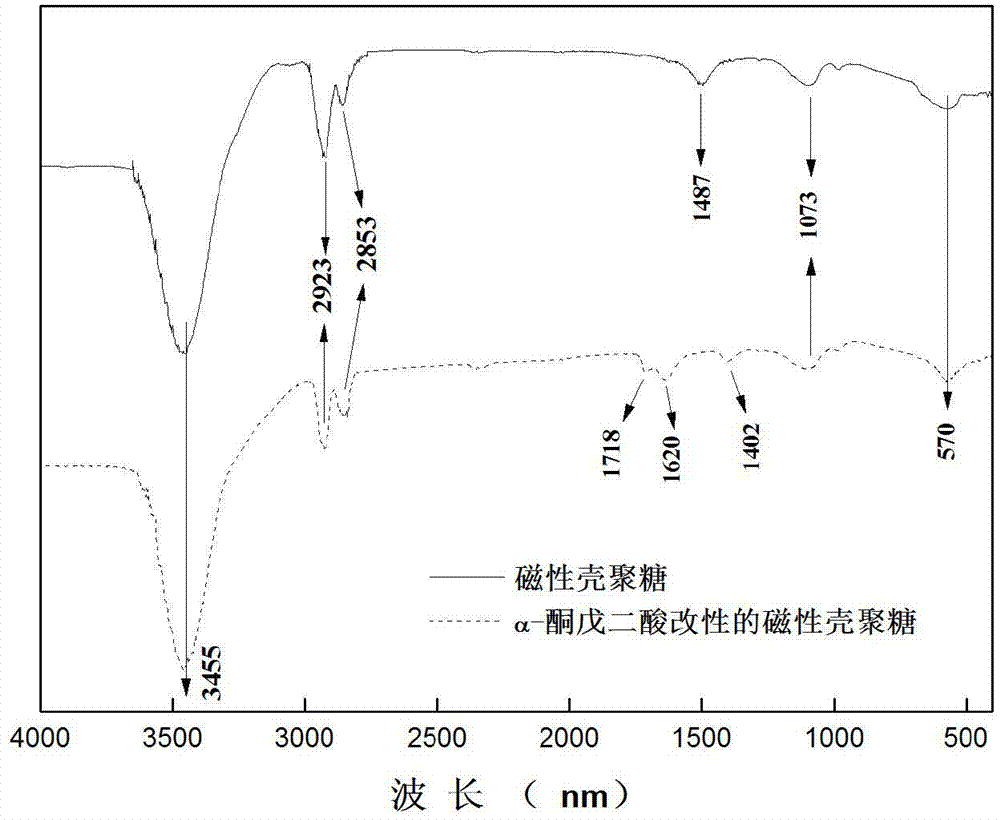

Alpha-ketoglutaric acid modified magnetic chitosan and preparation method and application thereof in field of cadmium-containing wastewater treatment

InactiveCN103611503AStable physical and chemical propertiesStrong magnetismOther chemical processesAlkali metal oxides/hydroxidesCadmium CationKetoglutaric Acid

The invention provides alpha-ketoglutaric acid modified magnetic chitosan. The alpha-ketoglutaric acid modified magnetic chitosan contains ferroferric oxide, chitosan and alpha-ketoglutaric acid and has the saturated magnetization value of 20-25emu / g, wherein magnetic chitosan is prepared from ferroferric oxide and chitosan, modified magnetic chitosan is of a reticular structure, peak values of functional groups, such as Fe-O bonds and the like, appear in an infrared spectrogram, and an agglomeration phenomenon is expressed. A preparation method of the alpha-ketoglutaric acid modified magnetic chitosan comprises the steps of adding an acetic acid solution containing chitosan into a ferroferric oxide suspension, adding a sodium tripolyphosphate solution, reacting and separating, so as to obtain the magnetic chitosan; then, adding alpha-ketoglutaric acid into an acetic acid buffer solution containing the magnetic chitosan, adding a sodium borohydride solution, and separating, thereby obtaining the alpha-ketoglutaric acid modified magnetic chitosan. The alpha-ketoglutaric acid modified magnetic chitosan has stable physical and chemical properties and strong magnetism; during the treatment of wastewater containing cadmium ions, the treatment efficiency is high, and the alpha-ketoglutaric acid modified magnetic chitosan can be repeatedly used and is convenient to recover.

Owner:HUNAN UNIV

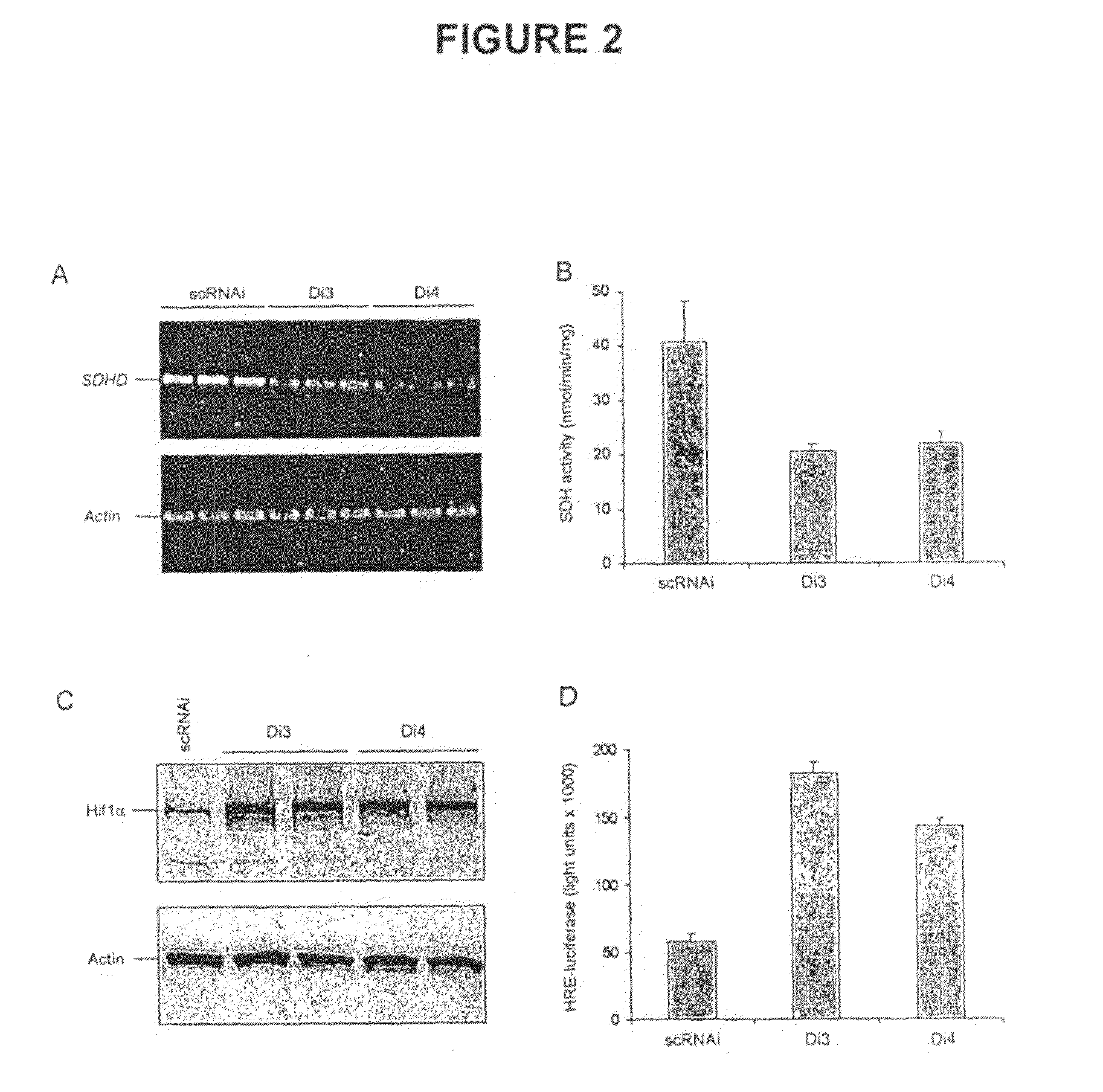

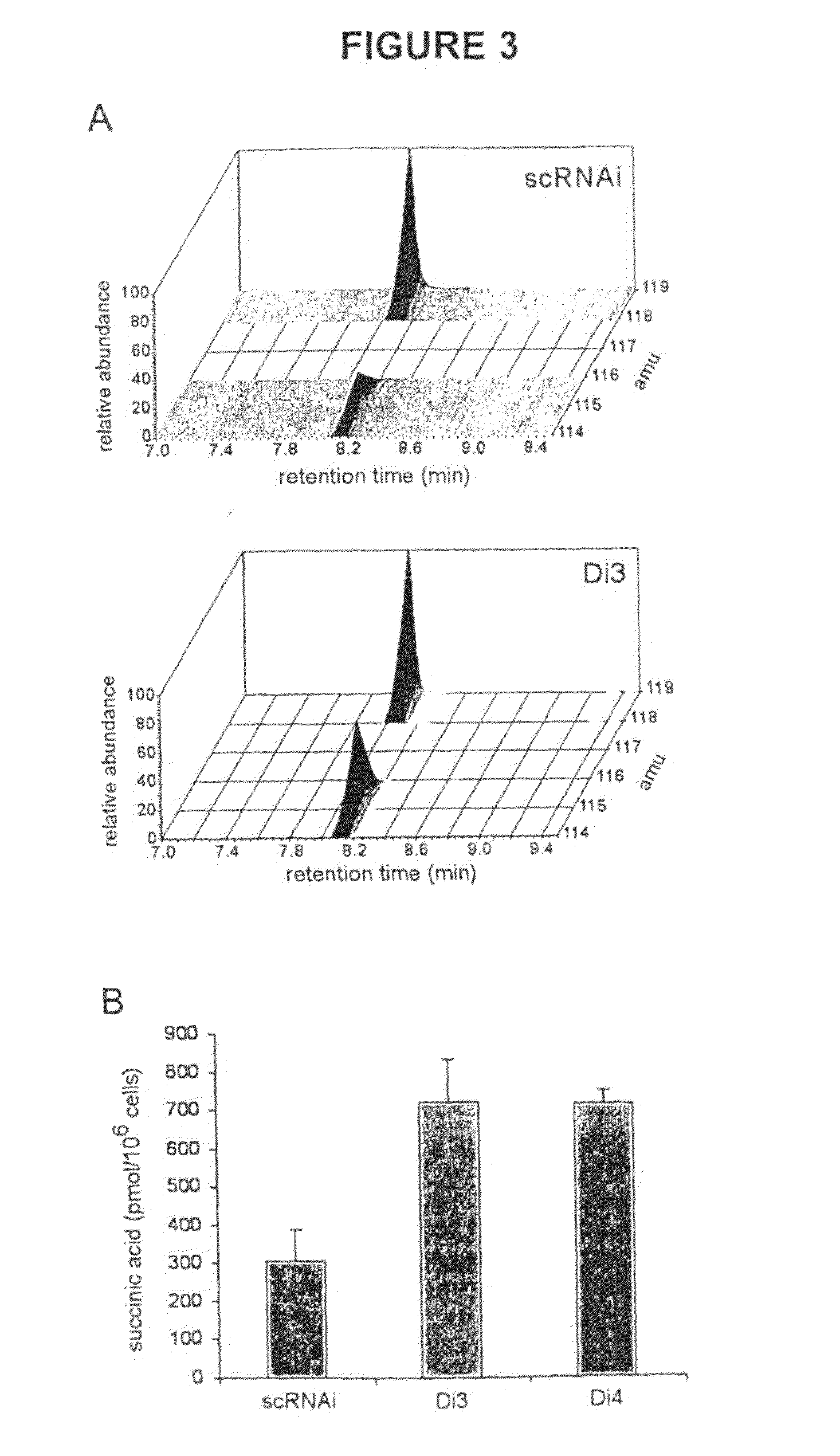

Alpha-Ketoglutarates and Their Use as Therapeutic Agents

InactiveUS20090005437A1Inhibit and prevent stabilizationImprove the level ofOrganic active ingredientsBiocideTricarboxylic acidAcid group

The present invention relates generally to the field of pharmaceuticals and medicine. More particularly, the present invention relates to certain compounds (e.g., α-ketoglutarate compounds; compounds that activate HIFα hydroxylase; compounds that increases the level of α-ketoglutarate, etc.) and their use in medicine, for example, in the treatment of cancer (e.g., cancer in which the activity of one of the enzymes in the tricarboxylic acid (TCA) cycle is down regulated), in the treatment of angiogenesis (e.g., hypoxia-induced angiogenesis). One preferred class of compounds are α-ketoglutarate compounds having a hydrophobic moiety that is, or is part of, an ester group formed from one of the acid groups of α-ketogluartic acid; and pharmaceutically acceptable salts, solvates, amides, esters, ethers, N-oxides, chemically protected forms, and prodrugs thereof.

Owner:CANCER RES TECH LTD

Method for realizing excessive accumulation of alpha-ketoglutarate acid by adding alpha-ketoglutarate acid dehydrogenase inhibitor

InactiveCN101250563AImproved compared to the controlMicroorganism based processesFermentationTorulopsis glabrataCarbon metabolism

The invention relates to a method for adding alpha-ketoglutarate dehydrogenase inhibitor to realize excessive accumulation of alpha-ketoglutaric acid, which belongs to the technical field of the metabolic regulation optimized fermentation process of the protein level. The method of the invention comprises following steps: utilizing multi - vitamin - auxotrophic yeast of Torulopsis glabrata CCTCC M202019 as producing strains, regulating the activity of alpha-ketoglutarate dehydrogenase through adding the alpha-ketoglutarate dehydrogenase inhibitor: hydrogen peroxide, methotrexate, sodium hypochlorite or hydroxyamino in culture medium, purposively lowing the activity of the alpha-ketoglutarate dehydrogenase, reducing the degradation of the alpha-ketoglutaric acid in the metabolic process, and achieving the aim of the excessive accumulation of the alpha-ketoglutaric acid. The method of the invention cuts off carbon metabolism flow on a node of the alpha-ketoglutaric acid through regulating the stream distribution of carbon metabolism and the carbon metabolism flow, wherein the maximum output of the alpha-ketoglutaric acid reaches 23.2g / L, which is increased by 12.2% compared with the control. The invention provides a new thought for the fermentation research of TCA cycle intermediate metabolite.

Owner:GUANGDONG HUANXI BIOLOGICAL TECH

Process for preparing L-arginine-alpha-ketoglutarate (AAKG) from fermentation liquor through direct crystallization

ActiveCN102020593AHigh purityQuality improvementOrganic compound preparationCarboxylic acid salt preparationLiver functionsArginine

The invention belongs to the technical field of biopharmaceuticals and relates to a method for preparing L-arginine-alpha-ketoglutarate (AAKG) from raw materials comprising L-arginine and alpha-ketoglutarate obtained by fermentation. In the method, the L-arginine and alpha-ketoglutarate in the fermentation liquor are directly used as the raw materials for AAKG rather than being used for extracting the refined crystalline products. The process mainly comprises the following technical steps: fermentation liquor pretreatment, chelation, concentration, crystallization, dissolution for decolorization, recrystallization, drying and the like. The process is characterized by comprising the following steps: pretreating the fermentation liquor with L-arginine, adding a certain amount of fermentation filtrate with alpha-ketoglutarate to the pretreated fermentation liquor to be chelated, carrying out vacuum evaporation concentration and then cooling the crystal to obtain the coarse product; and recrystallizing the coarse product by utilizing an organic solvent to obtain the high-purity product. The process has the advantages of high product purity, short flow, obvious emission reduction effect and the like, and is easy for quality control. The AAKG is mainly used as a physique enhancer and has the functions of promoting the muscles to grow and recover rapidly, promoting liver cells to absorb the nutrients and energy, maintaining normal liver functions and the like.

Owner:FUJIAN GUTIAN PHARMA

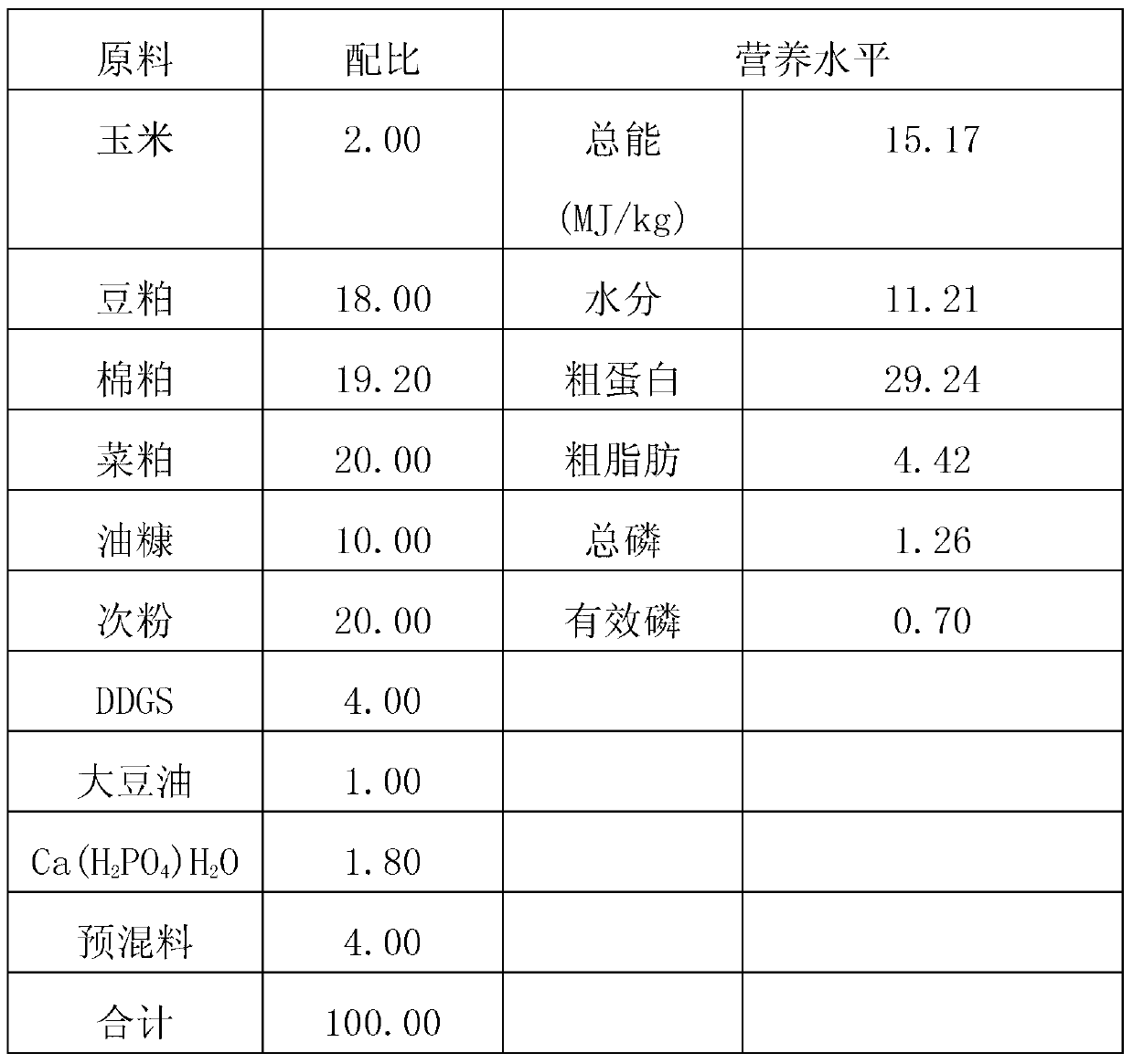

Use of alpha-ketoglutaric acid

ActiveCN103340293APromote growthRegulates the immune systemAnimal feeding stuffAlpha-Ketoglutaric acidFodder

The invention discloses a use of alpha-ketoglutaric acid. The alpha-ketoglutaric acid can be used as immune regulating / promoting agent for grass carp and anti-ammonia-nitrogen stress agent additive for the grass carp in the form of additive to be added into grass carp feed, so that the grass carp growth can be promoted and the immune function and anti-ammonia-nitrogen stress capacity of the grass carp can be improved, and therefore, problems that the grass carp feed conversion rate is low, and the anti-ammonia-nitrogen stress capacity of the grass carp is poor can be solved.

Owner:HUNAN AGRICULTURAL UNIV

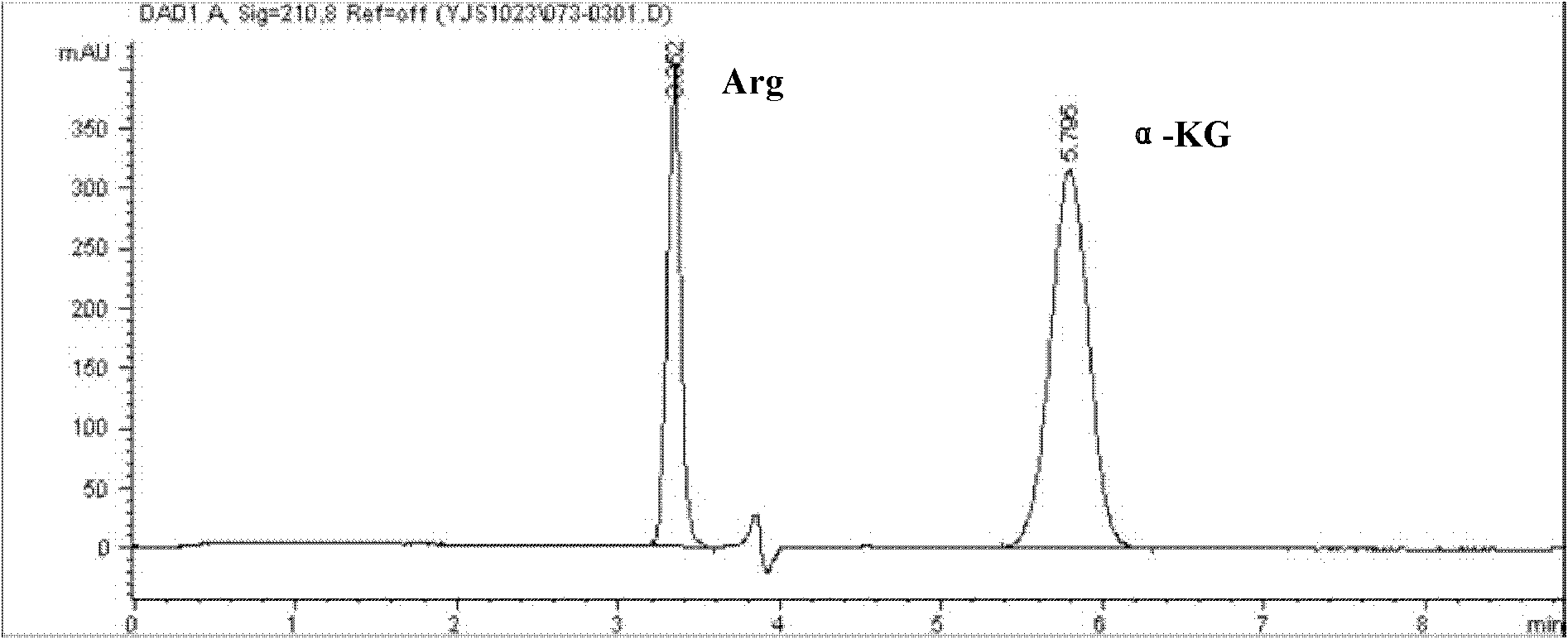

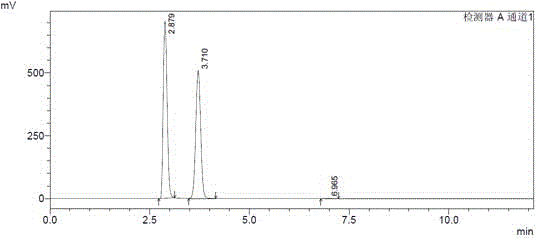

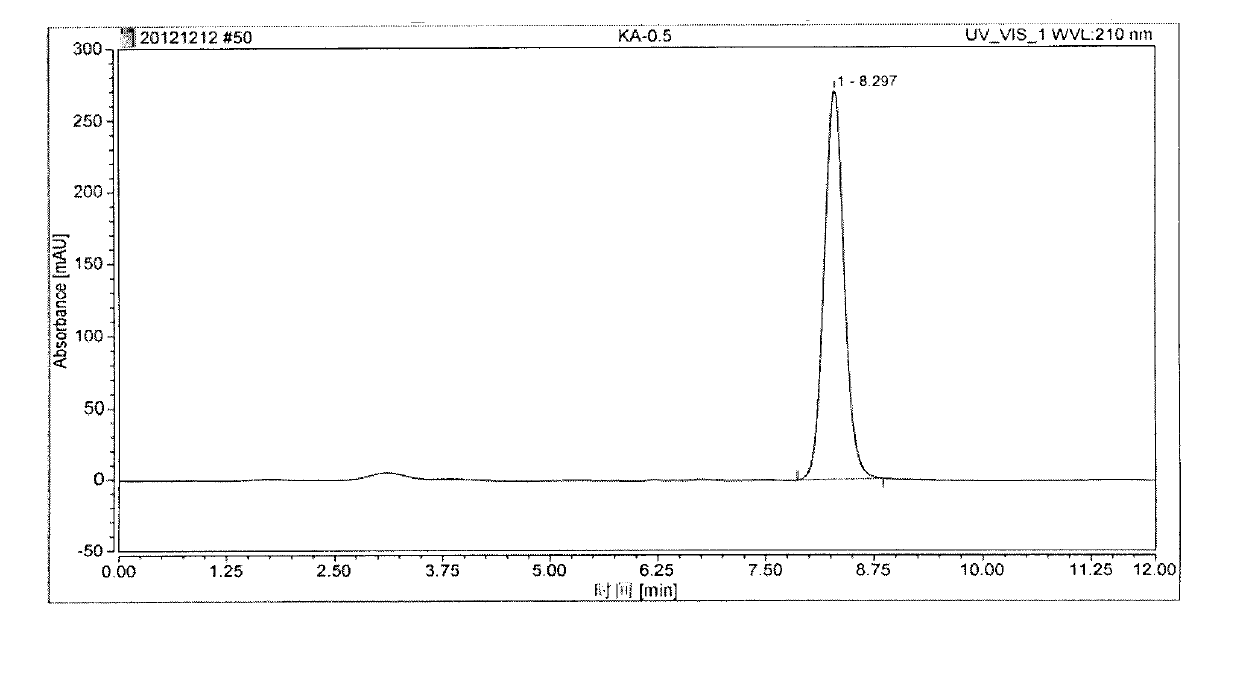

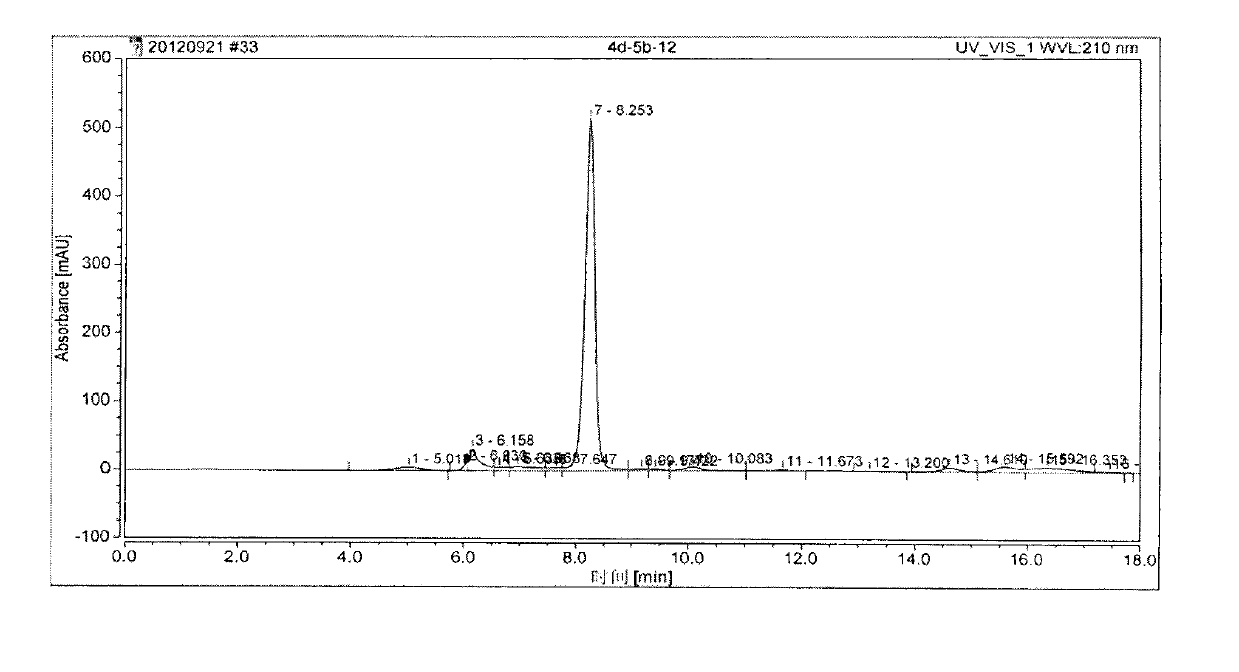

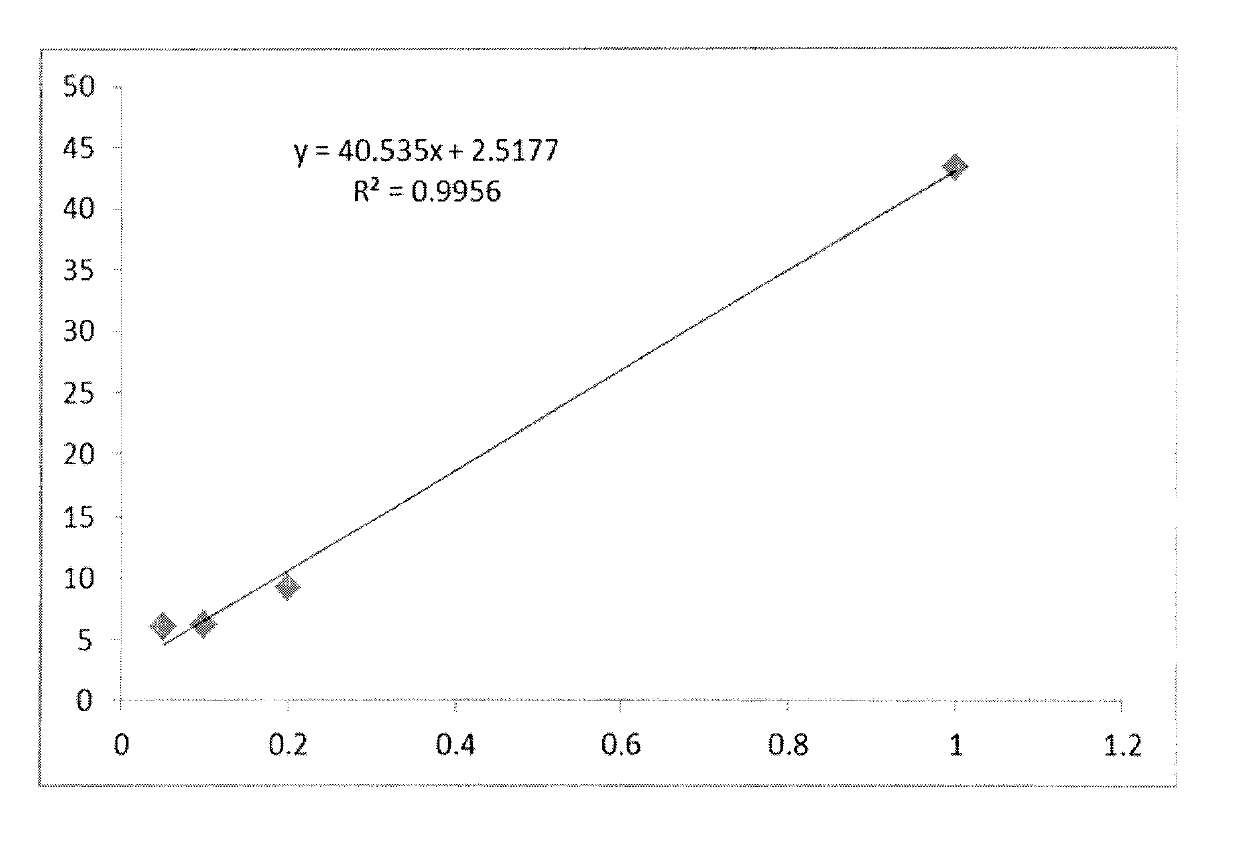

High-efficiency liquid-phase chromatography detection method of L-arginine-alpha-ketoglutarate

The invention discloses a high-efficiency liquid-phase chromatography detection method of L-arginine-alpha-ketoglutarate, and relates to the technical field of column chromatography. According to chromatographic condition, a chromatographic column adopts a C18 chromatographic column; a mobile phase adopts a 0.02mol / L to 0.08mol / L phosphate buffer solution with pH value of 3.0 to 4.0; the flow rate of the mobile phase is 0.5 to 1.3 ml / min; the detection wavelength is 200nm to 210nm; the temperature of the chromatographic column is 15 to 30 DEG C, and the content of L-arginine and the content of alpha-ketoglutarate in L-arginine-alpha-ketoglutarate or preparations of the L-arginine-alpha-ketoglutarate are determined by carrying out the high-efficiency liquid-phase chromatographic analysis. The content of L-arginine and the content of alpha-ketoglutarate in L-arginine-alpha-ketoglutarate or preparations of the L-arginine-alpha-ketoglutarate can be accurately determined by virtue of one-step high-efficiency liquid-phase chromatographic detection, and the two components can be well separated; moreover, the balance time of the C18 chromatographic column is short and is about 30 to 40 minutes, and the working efficiency can be improved.

Owner:JING JING PHARMA

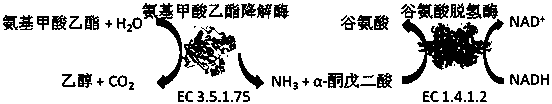

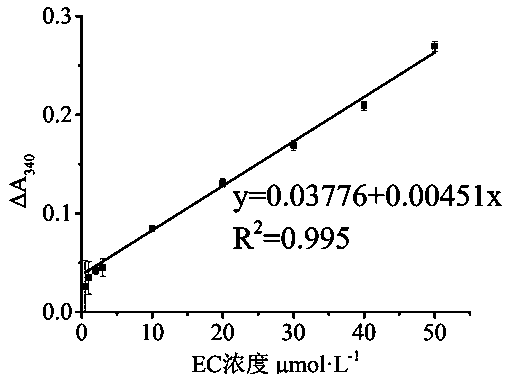

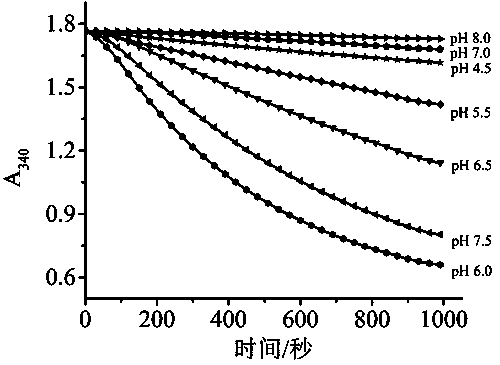

Spectrophotometric method for quickly detecting content of ethyl carbamate

ActiveCN104266984AColor/spectral properties measurementsPhotochemistryNicotinamide adenine dinucleotide

The invention discloses a spectrophotometric method for quickly detecting the content of ethyl carbamate, and belongs to the technical field of analytical chemistry and food safety inspection. Ethyl carbamate degrading enzyme and glutamate dehydrogenase construct a double-enzyme coupled system; the ethyl carbamate degrading enzyme hydrolyzes the ethyl carbamate to generate ethyl alcohol, water and ammonia, the ammonia reacts with a cosubstrate alpha-ketoglutarate under the catalysis of the glutamate dehydrogenase to generate glutamic acid, and reduced coenzyme namely NADH (Nicotinamide Adenine Dinucleotide Hydrogen) is oxidized concomitantly, so that the system changes the content of the ethyl carbamate into the content of the NADH, and the content of the ethyl carbamate in a liquid-state system can be detected by using the change of the light absorption value of the NADH at 340nm. By virtue of the method, the ethyl carbamate in a solution can be quickly detected, the ethyl carbamate in a yellow wine system can be simulated, the detection limit is as low as 0.1mu mol. L<-1>, and an effective way is provided for the detection of the ethyl carbamate in fermented food and beverages.

Owner:ANHUI HUATENG AGRI TECH CO LTD

Method for extracting alpha-ketoglutaric acid from fermentation liquor

InactiveCN105198732AEmission reductionEfficient emissionsOrganic compound preparationCarboxylic compound separation/purificationHigh concentrationMycoprotein

The invention discloses a method for extracting alpha-ketoglutaric acid from fermentation liquor. The method comprises the following steps: heating fermentation liquor containing the alpha-ketoglutaric acid for sterilization and decolorization, and drying mycoprotein; adding Ca(OH)2 into a filtration liquid, and performing centrifugal separation to obtain calcium 2-oxoglutarate and Ca(OH)2; adding H2SO4 into the calcium 2-oxoglutarate and Ca(OH)2, and performing centrifugal separation to obtain CaSO4 sediments; enabling the filtration liquid to flow into an ion exchange column for adsorption, and adding activated carbon into eluant for decolorization for 30 min; performing pressure reduction evaporation on the high-concentration alpha-ketoglutaric acid solution to obtain alpha-ketoglutaric acid crystals, and performing centrifugal separation to obtain an alpha-ketoglutaric acid crude product, washing the alpha-ketoglutaric acid crude product with methanol, removing impurities through washing, and performing centrifugation to remove methanol, so as to obtain the alpha-ketoglutaric acid, wherein the volume ratio of the alpha-ketoglutaric acid crude product to the methanol is 5:1. Through the adoption of the method, the problems in the prior art that pyruvic acid as a by-product during the extraction process of the alpha-ketoglutaric acid cannot be effectively separated and the discharge amount of waste liquid is high are solved.

Owner:SHANDONG YANGCHENG BIOLOGY TECH CO LTD

5'-nucleotidase diagnosing reagent kit and 5'-nucleotidase activity concentration measurement method

InactiveCN101097200AMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementNucleotidaseExtinction

The invention relates to a 5'-nucleotidase diagnosis reagent box of Enzymatic Recycling Method, and the invention also relates to method principle for detecting the solution of 5'-nucleotidase, constitute and component of reagent, which belongs to the technical field of medical checking measurements. The reagent box in the invention can be dry powder state, and used after dissolution; it also can be formulated to be liquid agent for direct usage. The component of reagent box mainly contains: buffering liquid, alpha- ketoglutaric acid, reduction type coenzyme, Adenosine Deiminase EC 3.5.4.4, glutamate dehydrogenase EC 1.4.1.2, EC 1.4.1.3, EC 1.4.1.4, Glutamate oxidase EC 1.4.3.7, EC 1.4.3.11, peroxidase EC 1.11.1.7, reduction type chromogen assembly, stabilizer and anti-interference agent; and the component can be mixed to form single-reagent reagent box, two-reagent reagent box, and three-reagent reagent box; by series of enzymatic reaction, the colorless reduction type chromogen assembly is oxygenated to form color dye, and the content of dye can be measured by visible light analyzer at wavelength of 400-700nm to reflect the concentration of 5'-nucleotidase directly. Comparing with present technique, the invention can be spread easily, and because the produced dye has higher molar extinction coefficient, the sensitivity is high, and the precision is well.

Owner:SUZHOU ANJ BIOTECHNOLOGY CO LTD

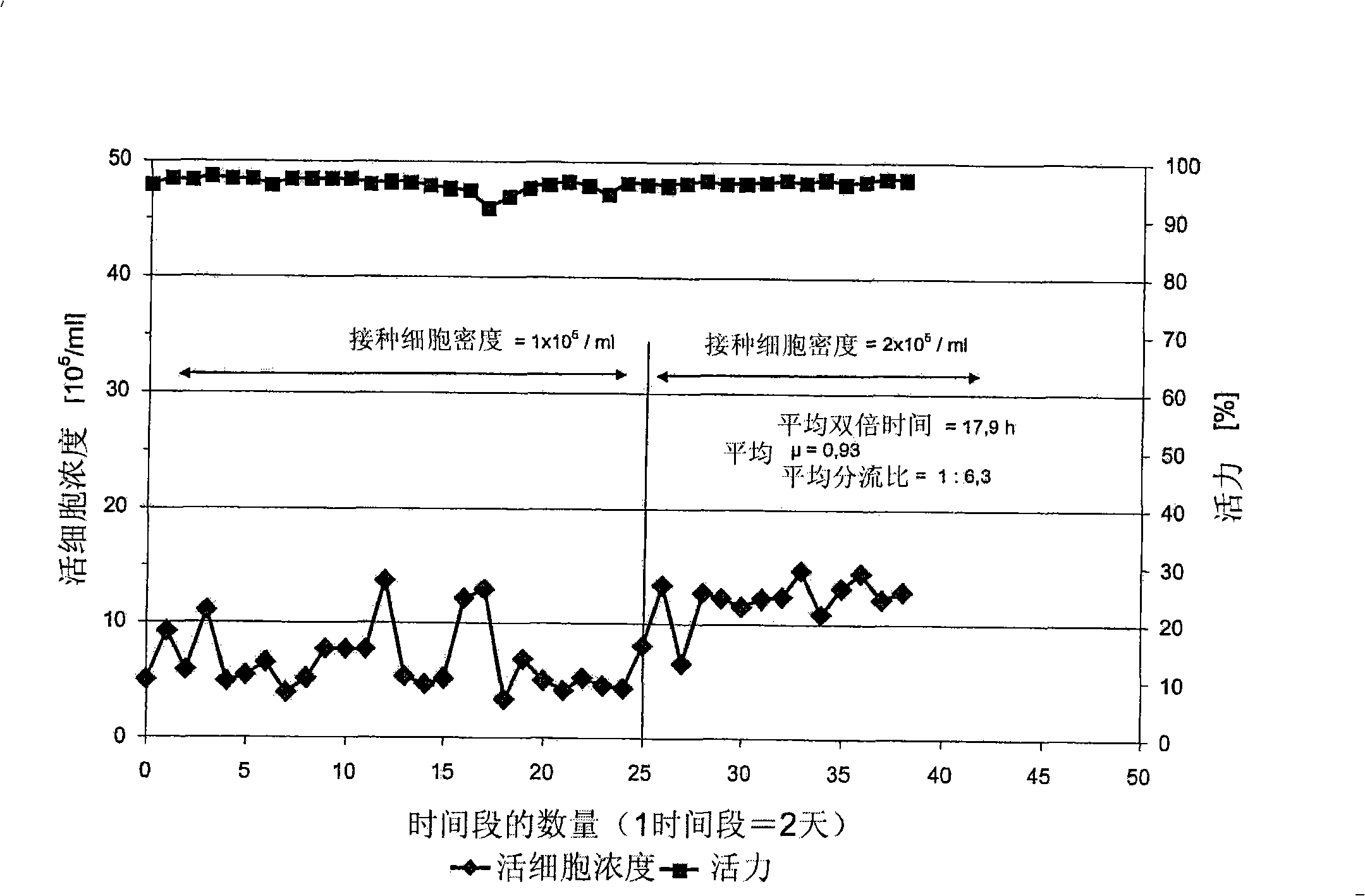

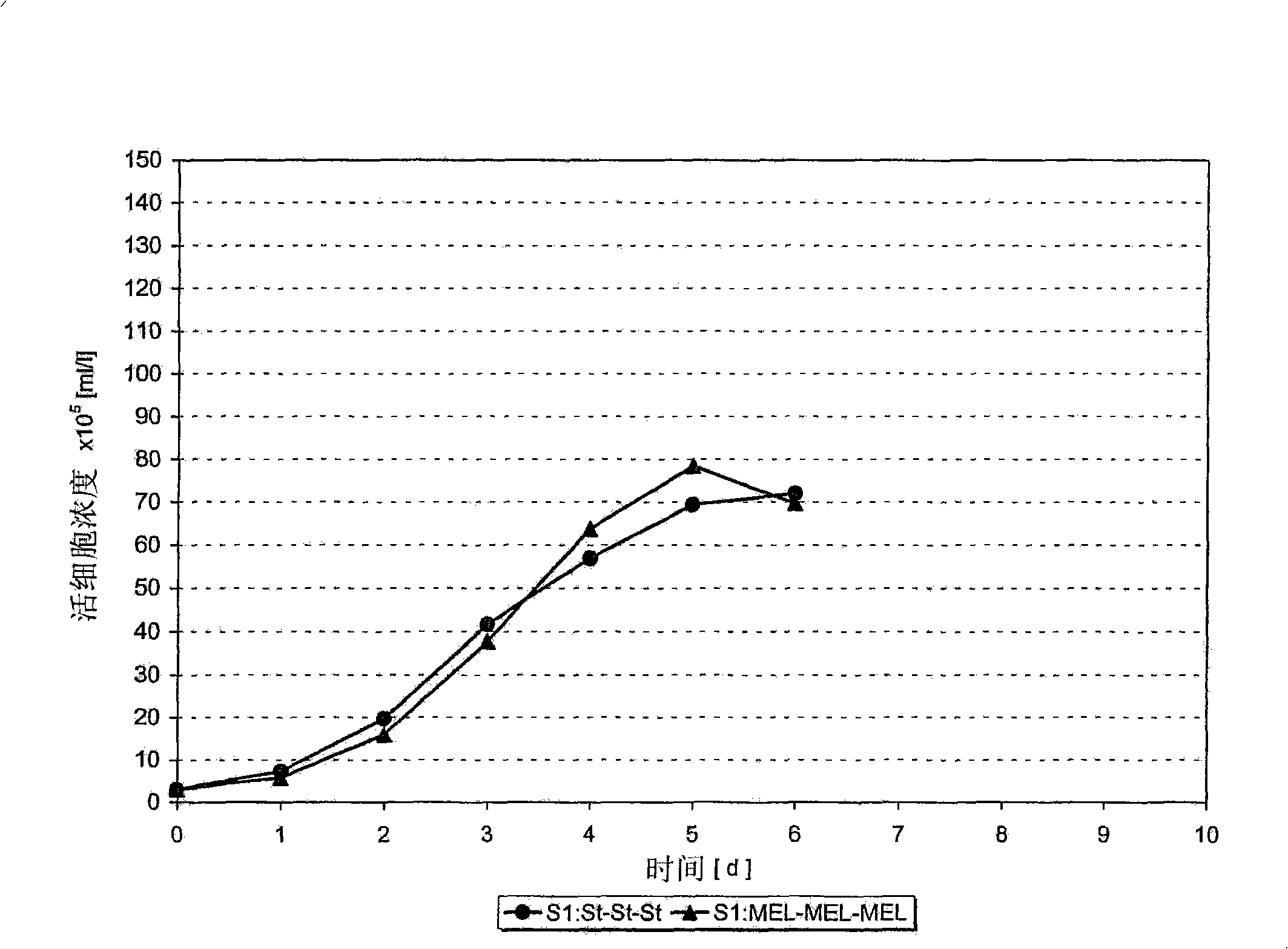

Cell culture medium

The invention relates to nutrient media, particularly cell culture media, containing at least one substance selected among the group that comprises citric acid, succinic acid, malic acid, a-ketoglutaric acid, fumaric acid, oxaloacetic acid, isocitric acid, oxalosuccinic acid, tartaric acid, lactic acid, adipic acid, mixtures thereof, and salts, derivatives, or complexes of said acids. The invention also relates to the use of and methods for producing such cell culture media, methods for cultivating a cell culture in an inventive cell culture medium, and cells that can be obtained with the aid of such methods.

Owner:SARTORIUS STEDIM CELLCA GMBH

Preparation method for L-ornithine-alpha-ketoglutarate

InactiveCN102373245AHigh purityIncrease productionOn/in organic carrierFermentationTransformation efficiencyL-Ornithine

The present invention relates to a preparation method for L-ornithine-alpha-ketoglutarate. The L-ornithine-alpha-ketoglutarate is produced by arginase transformation. The preparation method comprises the following steps: (1) preparation of immobilized enzyme; (2) optimization of transformation conditions; (3) product extraction and refining process. Compared to the prior art, the preparation method of the present invention has the following advantages that: the preparation method of the present invention has characteristics of low production cost, mild production conditions, less impurities in the transformation system, simple process steps, safe production operation and high purity; qualified products meeting the light transmission requirements can be synthesized; each liter of the reaction solution contains 300-320 g of the L-ornithine-alpha-ketoglutarate, and the transformation efficiency of the alpha-ketoglutaric acid is more than 90%; the preparation method further has other advantages.

Owner:湖南天成生化科技有限公司

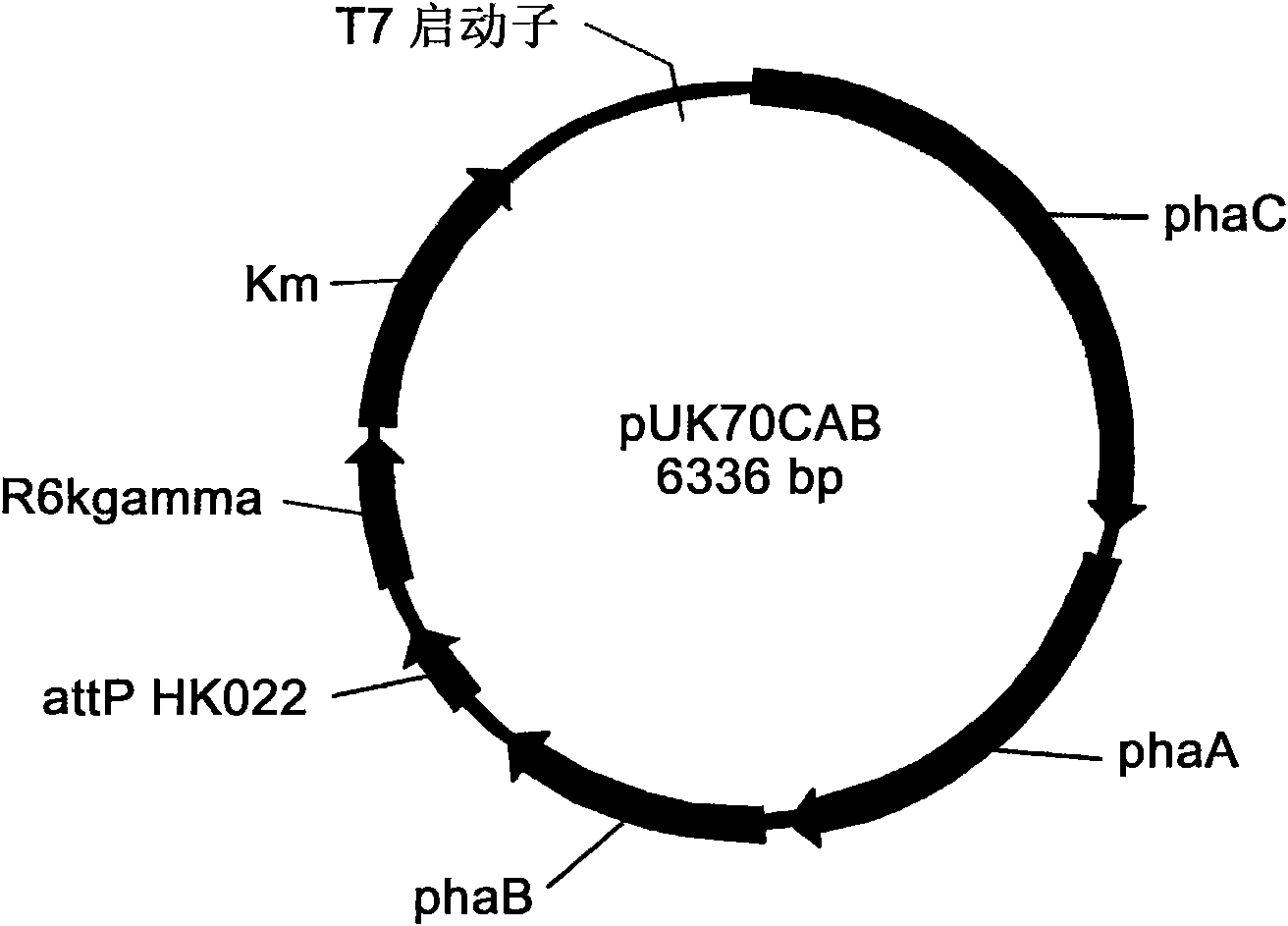

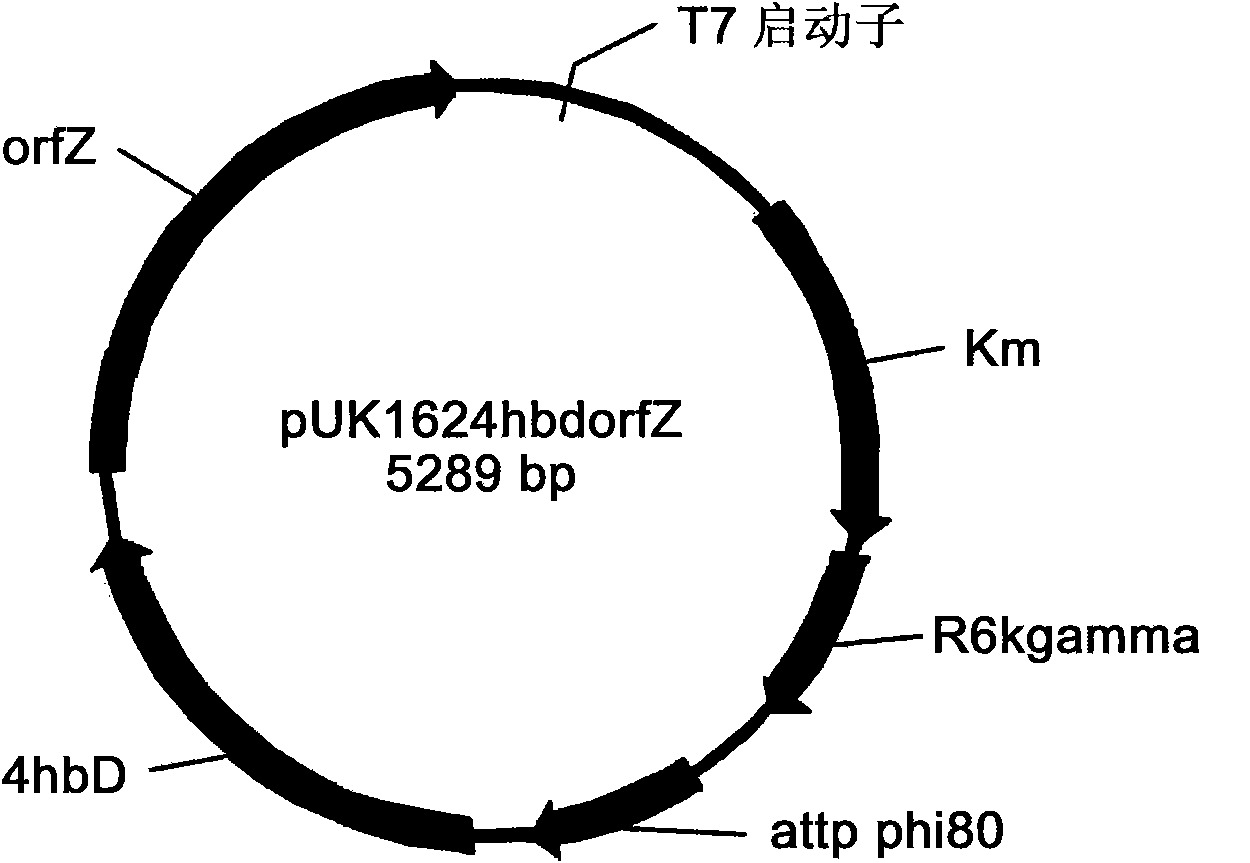

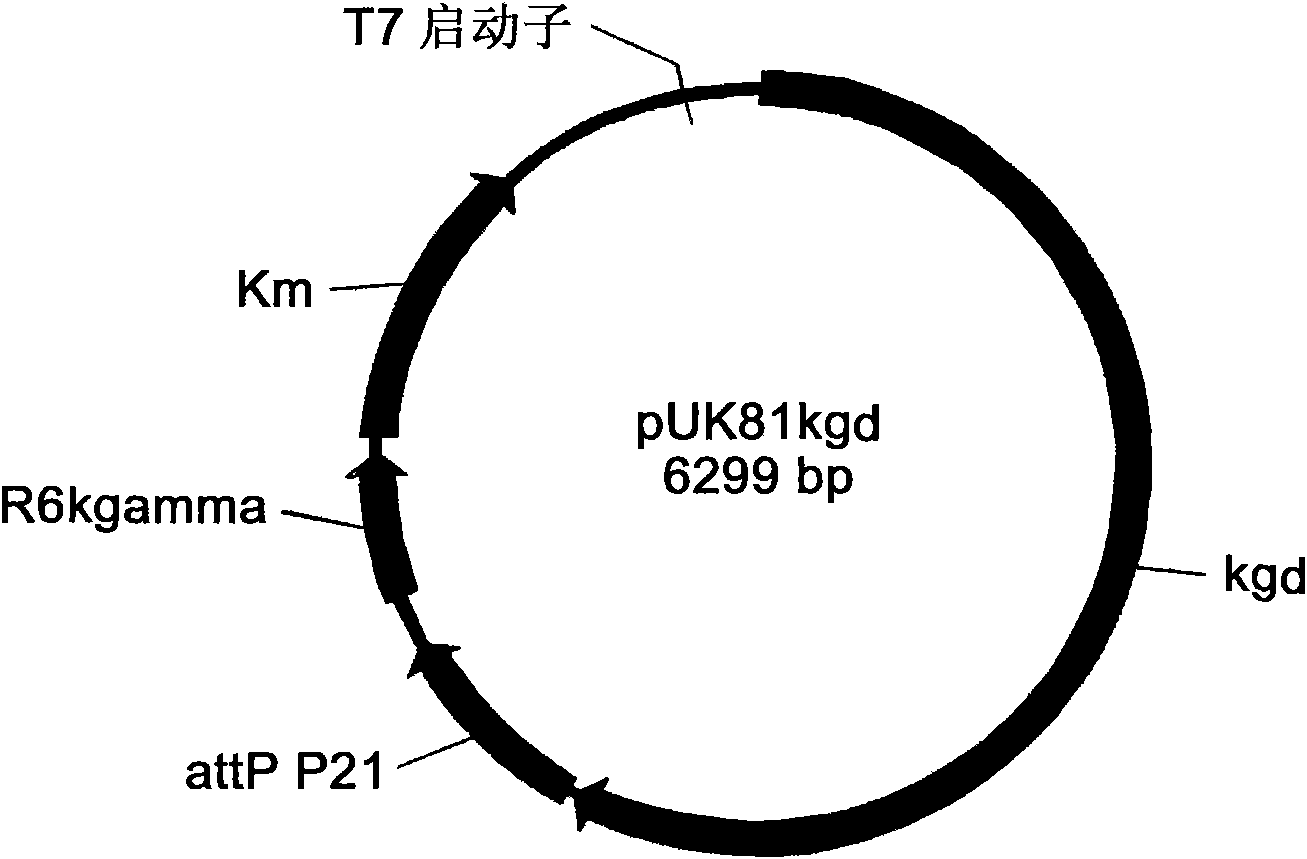

Engineering bacterium containing 2-oxoglutarate decarboxylase gene kgd and applications thereof

InactiveCN102382789AReduce manufacturing costBacteriaMicroorganism based processesCoenzyme A biosynthesis2-Oxoglutarate Dehydrogenase

The invention belongs to the technical field of genetic engineering and fermentation, and particularly discloses an engineering bacterium for producing 3-hydroxybutyric acid and 4-hydroxybutyric acid copolyester (P3HB4HB) by utilizing a sugar carbon source. Exogenous genes needed for combining the P2HB4HB are recombined and integrated on the genome of the engineering bacterium and comprise poly-3-hydroxybutyrate synthetic gene phaCAB and 4-hydroxybutyryl coenzyme A which is transferase gene orfZ, 4-hydroxybutyric acid dehydrogenase gene 4hbD and 2-oxoglutarate dehydrogenase gene kgd. By utilization of the engineering bacterium, the P3HB4HB can be produced by using the sugar carbon source with relatively cheap price, the production cost is effectively reduced, and the large-scale industrial production and the commercial application and development are pushed.

Owner:TIANJIN GREENBIO MATERIAL CO LTD

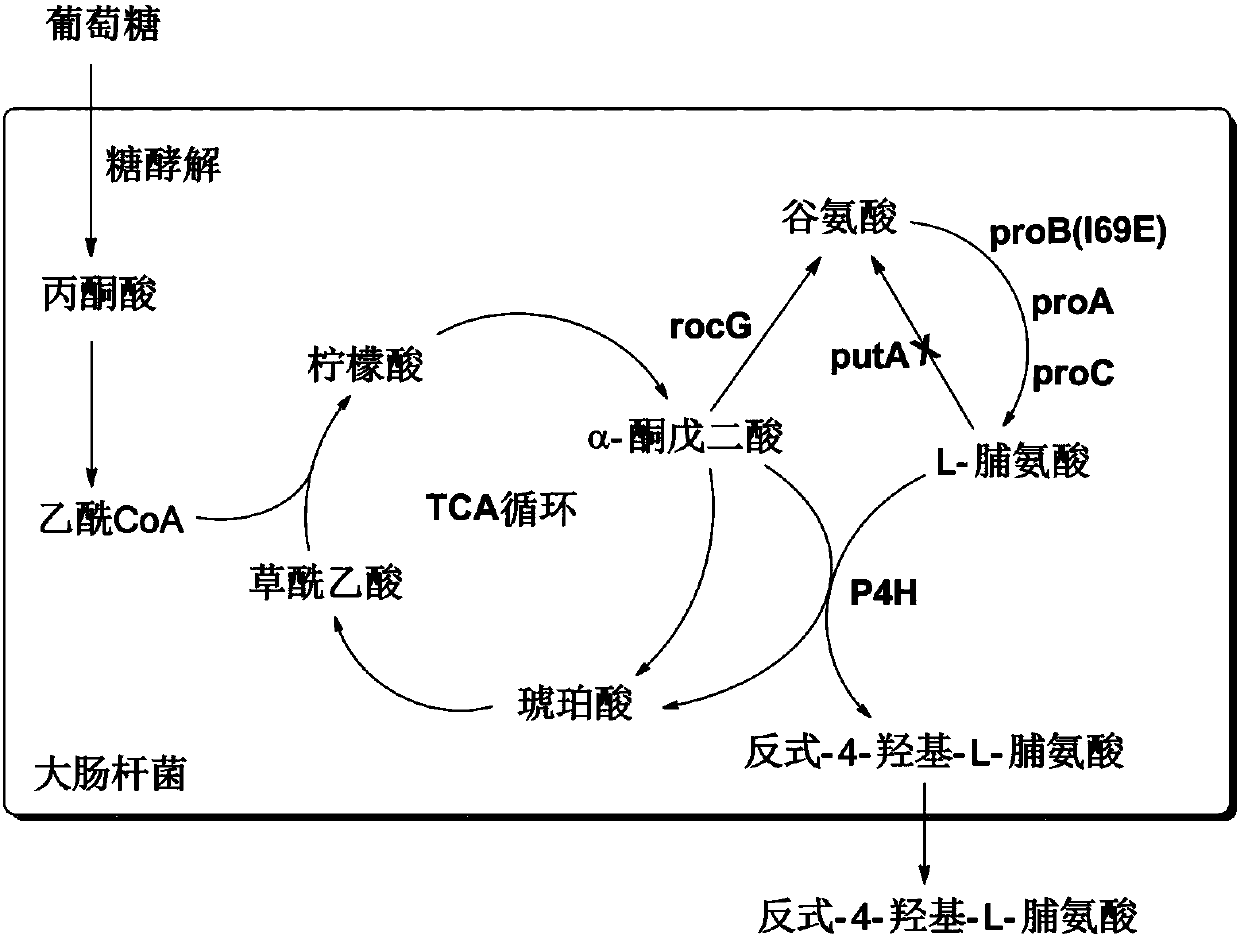

Method for synthesizing trans-4-hydroxy-L-proline by virtue of escherichia coli

PendingCN107805621AClear genetic backgroundGenetic manipulation is simpleBacteriaMicroorganism based processesEscherichia coliSynthesis methods

The invention belongs to the field of medical chemistry, and aims at providing a method for synthesizing trans-4-hydroxy-L-proline. According to the technical scheme, by virtue of genetiuc engineeringmodified escherichia coli, [alpha]-ketoglutaric acid, which is generated from autologous TCA circulation of a catalysis host, is converted into an L-proline gene, and the L-proline gene undergoes tandem and over-expression, so that the yield of L-proline is improved; and prolyl hydroxylase is introduced, so that a reaction that the L-proline is converted into the trans-4-hydroxy-L-proline and a reaction that the [alpha]-ketoglutaric acid is converted into succinic acid are coupled; therefore, the efficient synthesis of the trans-4-hydroxy-L-proline under a condition of not adding exogenous L-proline is achieved. The synthesis method of the trans-4-hydroxy-L-proline provided by the invention is optimized, so that the yield of the target product (the trans-4-hydroxy-L-proline) is greatly improved.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Method for alpha-ketoglutarate production by catalysis of L-glutamate dehydrogenase

ActiveCN106834366AGood reaction selectivityHigh yieldChemical recyclingFermentationL-glutamate dehydrogenaseBuffer solution

The invention discloses a method for alpha-ketoglutarate production by catalysis of L-glutamate dehydrogenase. Under conditions of existence of a hydrogen peroxide scavenging agent and in buffer solution, alpha-ketoglutarate is generated by oxidation reaction of L-glutamic acid or salts thereof under catalysis of L-glutamate dehydrogenase and cofactors. The L-glutamate dehydrogenase depending on the cofactors obtained by organic small-molecular catalytic regeneration is adopted for catalysis of L-glutamic acid or salts thereof to generate alpha-ketoglutarate through oxidation reaction, low cost of raw material and low production cost are realized, a production process is simple and easy to operate and free of environment pollution, resource recycling is realized, and a theoretical foundation is laid for industrial efficient production of alpha-ketoglutarate. The L-glutamic acid or salts thereof are directly used as raw materials to generate alpha-ketoglutarate through one-step reaction, and high reaction selectivity and high yield are realized.

Owner:NANJING UNIV OF TECH

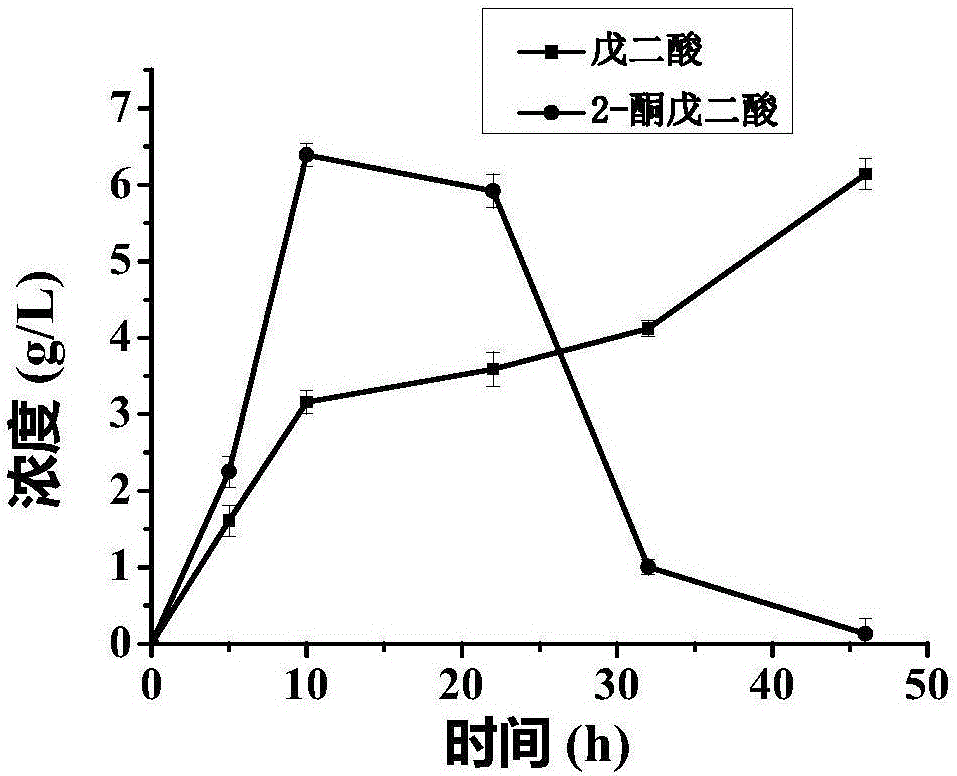

Method of whole-cell-biocatalytically producing glutaric acid

ActiveCN106367445ASolve economic problemsEfficient use ofBacteriaMicroorganism based processesGlutaric acidMetabolite

The invention discloses a method of whole-cell-biocatalytically producing glutaric acid. The method includes the steps of: performing induced expression and collecting cells of a recombinant strain E.coli BL-22AB-YDT and a recombinant strain E.coli 28LGOX, and mixing the cells of the recombinant strain E.coli 28LGOX and the recombinant strain E.coli BL-22AB-YDT according to the ratio of 1:1-5; adding substrates including L-glutamic acid and L-lysine according to the molar ratio of 1:0.5-4; and adding a surfactant to perform the whole-cell-catalytic production to obtain the glutaric acid. The method is free of addition of 2-ketoglutaric acid, so that production cost is reduced, and problems of long production period, complex metabolic products, low substrate conversion rate, difficulty in separation and extraction of products, and high energy consumption in a fermentation method are solved. The method also solves a defect that a cascade catalytic process in enzymic catalysis is difficult to achieve, so that the method can improve catalytic efficiency and is free of an enzyme purifying process.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Enzymic method for producing [alpha]-ketoglutaric acid Enzymic method for producing [alpha]-ketoglutaric acid](https://images-eureka.patsnap.com/patent_img/19d198b9-0f9f-4c65-a274-1d6f28e643a1/2013101346746100003DEST_PATH_IMAGE001.PNG)

![Enzymic method for producing [alpha]-ketoglutaric acid Enzymic method for producing [alpha]-ketoglutaric acid](https://images-eureka.patsnap.com/patent_img/19d198b9-0f9f-4c65-a274-1d6f28e643a1/2013101346746100003DEST_PATH_IMAGE002.PNG)

![Enzymic method for producing [alpha]-ketoglutaric acid Enzymic method for producing [alpha]-ketoglutaric acid](https://images-eureka.patsnap.com/patent_img/19d198b9-0f9f-4c65-a274-1d6f28e643a1/2013101346746100003DEST_PATH_IMAGE003.PNG)

![Construction method of dual-enzyme co-expression strains for producing [alpha]-ketoglutarate Construction method of dual-enzyme co-expression strains for producing [alpha]-ketoglutarate](https://images-eureka.patsnap.com/patent_img/7716da72-e28e-4620-aa0e-9ef7ebcea745/HDA0001000627060000011.PNG)

![Construction method of dual-enzyme co-expression strains for producing [alpha]-ketoglutarate Construction method of dual-enzyme co-expression strains for producing [alpha]-ketoglutarate](https://images-eureka.patsnap.com/patent_img/7716da72-e28e-4620-aa0e-9ef7ebcea745/HDA0001000627060000012.PNG)

![Construction method of dual-enzyme co-expression strains for producing [alpha]-ketoglutarate Construction method of dual-enzyme co-expression strains for producing [alpha]-ketoglutarate](https://images-eureka.patsnap.com/patent_img/7716da72-e28e-4620-aa0e-9ef7ebcea745/HDA0001000627060000021.PNG)