Method for separating alpha-ketoglutaric acid from conversion solution

A technology of ketoglutaric acid and ketoglutarate, which is applied in the field of preparation of α-ketoglutaric acid, can solve the problems that materials cannot be recycled multiple times, separation and purification are difficult, and there are many by-products of fermentation, etc., to achieve Good crystal form, avoid a large amount of distilled water, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

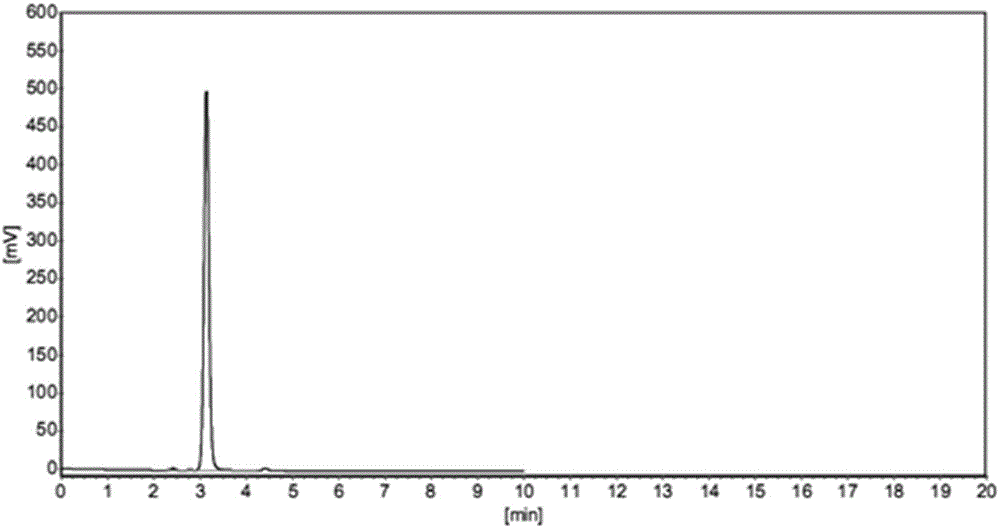

[0026] (1) Take 5L of conversion solution containing 8% ketoglutaric acid and 5kg, filter it through a ceramic filter membrane with a membrane pore size of 0.05μm, control the pressure at 6.5-7.5Mpa, and the temperature at 20-30°C, collect Permeate;

[0027] (2) Filtrate the Tao filter permeate through a polyvinylidene fluoride ultrafiltration membrane with a molecular weight cut-off greater than 3000. The operating pressure is 7.5-8.5Mpa and the operating temperature is 20-30°C, and the ultrafiltration permeate is collected;

[0028] (3) Pass the ultrafiltration permeate through the composite membrane of cellulose acetate and polyamide, concentrate and filter by reverse osmosis, the operating pressure is 10-12Mpa, the operating temperature is 20-30°C, collect and extract 1.7L of concentrated solution, and detect its Light transmission is 96.3%;

[0029] (4) Heat the extracted concentrated solution to 33°C to 37°C, slowly add 132g of calcium chloride to the concentrated solut...

Embodiment 2

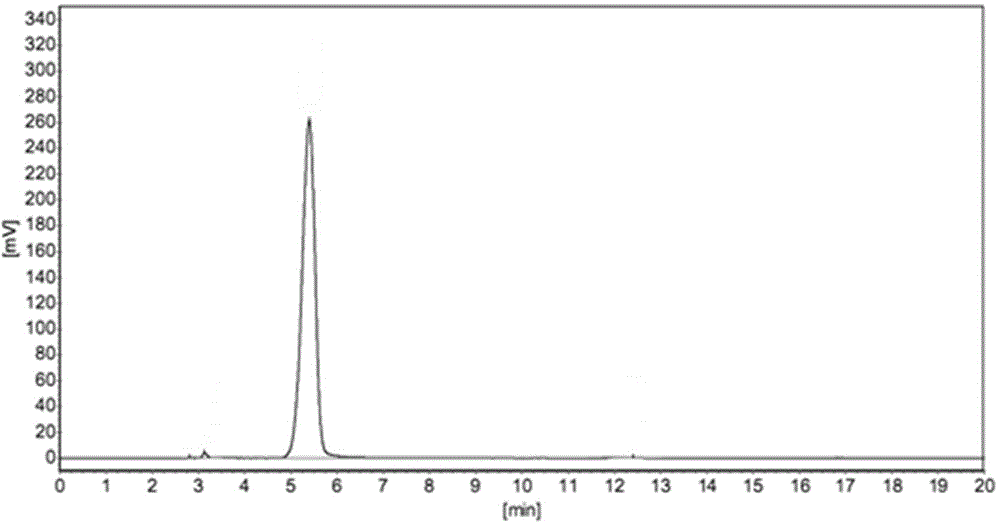

[0037] (1) Take 8kg of 8L conversion solution containing 11% ketoglutaric acid, filter through a ceramic filter membrane with a membrane pore size of 0.01 μm, control the pressure at 8.5-9.3Mpa, and the temperature at 30-35°C, collect Permeate;

[0038](2) Filter the Tao filter permeate through a polycarbonate ultrafiltration membrane with a molecular weight cut-off greater than 3000. The operating pressure is 8.5-9.3Mpa and the operating temperature is 30-35°C, and the ultrafiltration permeate is collected;

[0039] (3) Pass the ultrafiltration permeate through the polyamide reverse osmosis membrane, reverse osmosis concentration and filtration, the operating pressure is 14-15Mpa, the operating temperature is 30-35°C, collect and extract the concentrated solution of 2.8L, and the light transmission is 97 %;

[0040] (4) Raise the temperature of the extracted concentrated solution to 35°C-40°C, add 300g of calcium chloride to the concentrated solution with stirring, the addit...

Embodiment 3

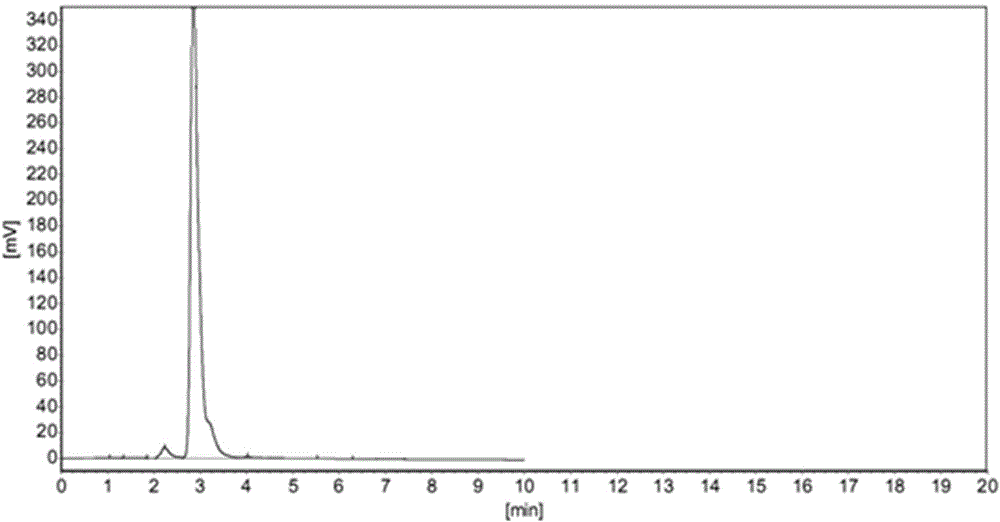

[0048] (1) Take 3kg of 3L conversion solution containing 9% ketoglutaric acid, filter through a ceramic filter membrane with a membrane pore size of 0.10μm, control the pressure at 5.5-6.5Mpa, and the temperature at 10-20°C, collect Permeate;

[0049] (2) Filter the Tao filter permeate through a polysulfoneamide ultrafiltration membrane with a molecular weight cut-off greater than 3000, operate at a pressure of 5.5-6.5Mpa, and operate at a temperature of 10-20°C to collect the ultrafiltration permeate;

[0050] (3) Pass the ultrafiltration permeate through the cellulose acetate reverse osmosis membrane, reverse osmosis concentration and filtration, the operating pressure is 12-14Mpa, the operating temperature is 10-20°C, collect and extract the concentrated solution of 0.95L, and detect its light transmission as 97.5%;

[0051] (4) Heat the extracted concentrated solution to 30°C to 35°C, slowly add 85g of calcium chloride to the concentrated solution under stirring, the addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| translucency | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com