Patents

Literature

36results about How to "Increase the rate of acid production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing table vinegar by adopting two-step acetic acid fermentation method

ActiveCN102433255AEfficient conversionKeep the flavorMicroorganism based processesVinegar preparationAlpha-amylaseTwo step

The invention discloses a method for producing table vinegar by adopting a two-step acetic acid fermentation method and belongs to the technical field of brewing of the table vinegar. According to the method, the problems of low alcohol intolerance, long fermentation period and low acetification rate for acetic acid fermentation in a traditional method are solved. The method comprises the following steps of: uniformly stirring sorghum flour, corn flour, rice meal and water; adding thermostable alpha amylase for liquefying; after liquefying, reducing the temperature, adding Daqu, saccharifyingkoji, red starter, saccharomyces cerevisiae and aroma-producing yeast and carrying out alcoholic fermentation to obtain liquor; adopting the two-step acetic acid fermentation method: firstly, mixing the liquor; adding acetic acid bacteria subjected to liquid amplification culture for carrying out primary acetic acid fermentation; when the alcoholic strength of brewing mass is reduced to 6-5DEG C,adding wheat bran and rice husk as accessories for mixing; inoculating fire fermented liquor for carrying out secondary acetic acid fermentation; sealing the liquor; smoking the liquor; spraying vinegar; filtering; and packaging to obtain a finished product. According to the method disclosed by the invention, the high-content alcohol can be effectively converted; the acid yield and the acetification rate in unit time are improved; and the flavor of the table vinegar produced by adopting a traditional solid acetic acid fermentation method is ensured.

Owner:山西金龙鱼梁汾醋业有限公司

Fermenting type apple vinegar beverage and preparation method thereof

ActiveCN102771864ARetain nutrientsPreserve the flavorVinegar preparationFood preparationFood flavorCulture fungus

The invention discloses a fermenting type apple vinegar beverage and a preparation method thereof. The fermenting type apple vinegar beverage is characterized by being prepared by preparing, filtering, sterilizing and filling the following raw materials by weight proportion: 50-70 parts of apple vinegar, 80-120 parts of concentrated apple juice, 2-8 parts of honey, 1-3 parts of aspartame and 799-867 parts of water. The fermenting type apple vinegar beverage has the advantages of well retaining the original nutrient substances and flavor of apple, having high acid production rate, being obviously shortened in fermenting time, further being capable of separating cured acetic bacteria cells and products easily and being used repeatedly, enabling strains to be efficient, greatly improving production efficiency, saving production cost and reducing pollution discharging.

Owner:YANTAI QIWEI WINE IND

Method for improving methanogenesis of residual sludge by heat and alkali combined pretreatment

ActiveCN103172242AIncrease productionIncrease the rate of hydrolysisWaste based fuelBiological sludge treatmentMethanogenesisSludge

The invention belongs to the technical field of environmental protection and relates to a method for improving the methanogenesis of residual sludge by heat and alkali combined pretreatment. According to the method, after the residual sludge is thermally pretreated, the dissolving in water of organic matters such as protein and polysaccharide in the residual sludge can be improved significantly so that abundant water-soluble organic matrixes can be provided for the fermentation of the sludge and the generation of acids; and in addition, after the residual sludge is pretreated under the initial alkaline condition, the dissolving and the dehydrating of the sludge can be promoted further and short chain fatty acids can be produced continuously. Therefore, the residual sludge dehydrating efficiency and the acid generating efficiency can be improved greatly by the combination of thermal pretreatment and the initial alkaline condition so that the yield of methane can be increased to the maximum extent.

Owner:TONGJI UNIV

Short-chain volatile fatty acid and preparation method thereof

The invention discloses a short-chain volatile fatty acid and a preparation method thereof. The preparation method for the short-chain volatile fatty acid comprises the following steps of employing sludge as a fermentation substrate; adding sodium nitrite into the fermentation substrate, performing pretreatment in an acid environment, and performing anaerobic fermentation under an alkaline condition to obtain the short-chain volatile fatty acid. According to the short-chain volatile fatty acid and the preparation method thereof, the sludge of a sewage treatment plant is taken as a raw material, and is jointly treated by virtue of free nitrite pretreatment and alkaline anaerobic fermentation, and the concentration of free nitrite in the system, the pretreatment time, the fermentation pH value and the action of microorganisms in the sludge are controlled to maximally convert undissolved sludge organic matters in the sludge into the short-chain volatile fatty acid, so that the yield of the volatile fatty acid produced from the sludge is further increased on the basis of resourcefully utilizing the sludge and reducing environmental pollution caused by the sludge, and the reaction time is shortened; the short-chain volatile fatty acid and the preparation method thereof have the advantages of high product yield, simple preparation method, energy conservation, consumption reduction, low running cost and the like.

Owner:HUNAN UNIV

Method for improving short-chain fatty acid produced by excess sludge through hot alkali combined pretreatment

The invention belongs to the technical field of environmental protection, and relates to a method for improving short-chain fatty acid produced by excess sludge through hot alkali combined pretreatment. According to the method, the excess sludge in a sewage treatment plant serves as raw material, through hot pretreatment, controlling of initial alkaline power of hydrogen (PH) value conditions and the functions of microorganism is conducted, not only are non-aqueous resolvable organic matters in the sludge promoted to be dissolved and are the non-aqueous resolvable organic matters hydrolyzed to be converted to resolvable organic matters, but also the resolvable organic matters such as protein and polysaccharide are fully converted into the short-chain fatty acid, and pollution of the sludge to the environment is reduced. The temperature of the hot pretreatment is 60-120 DEG C, the time of the hot pretreatment is 15-60min, the initial PH value range of the functions of the microorganism is 8-12, the standing time of the sludge in a reactor is 1-12 days, and the temperature is 30-40 DEG C.

Owner:TONGJI UNIV

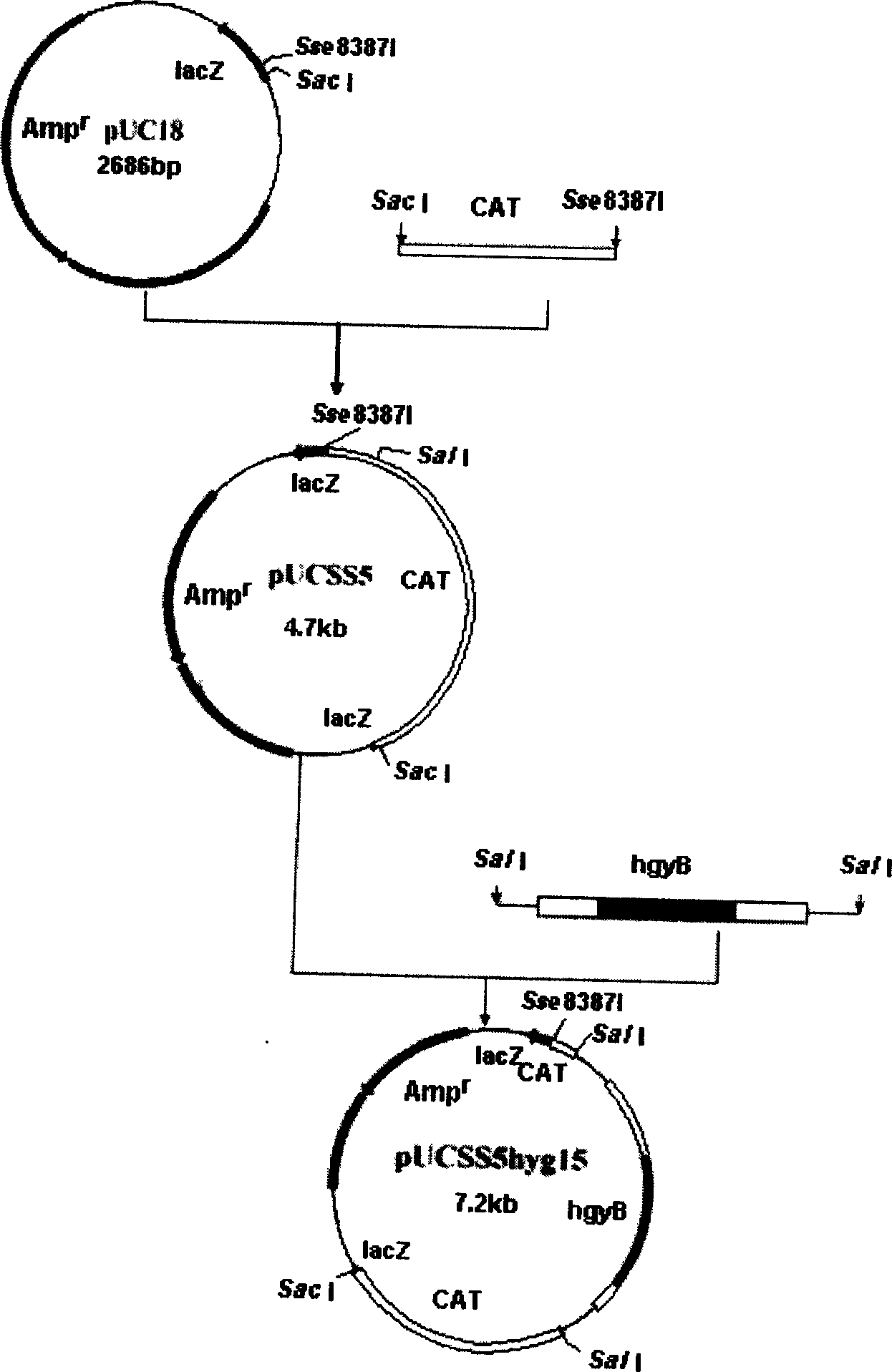

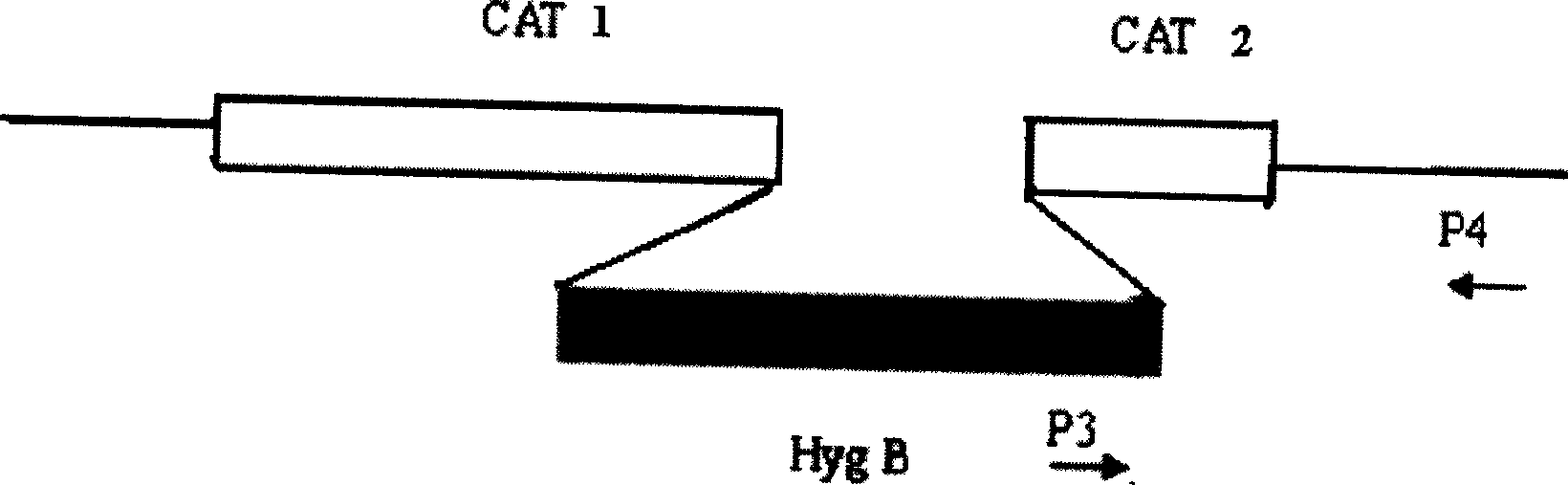

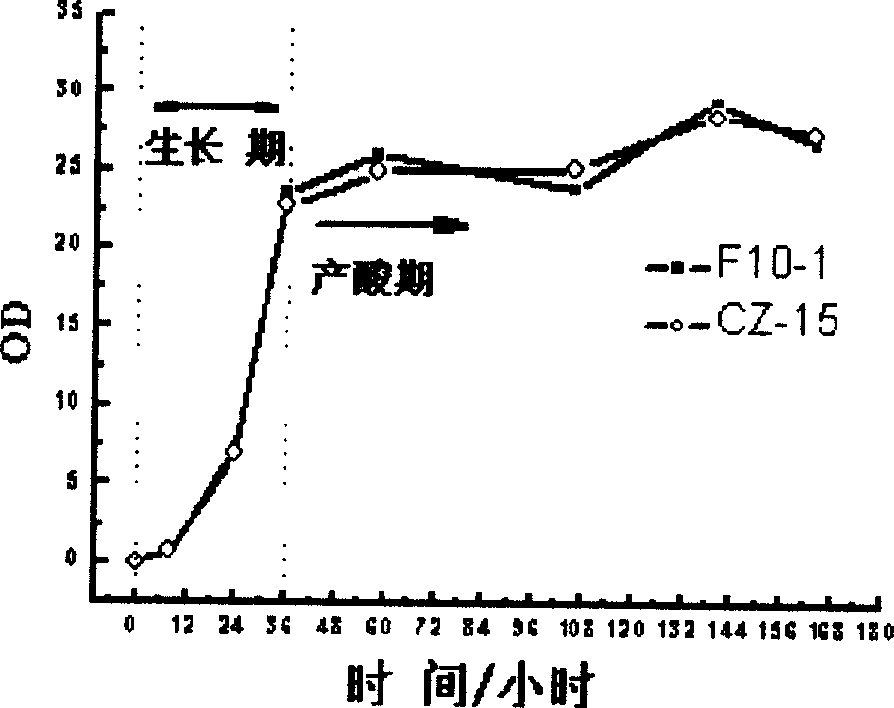

Constructing method for candida tropicalis gene engineering recombinant bacterium

InactiveCN1614004AIncrease the rate of acid productionIncrease productionFungiFermentationBiotechnologyCandida tropicalis

This invention relates to a construction method of tropic Candida gene engineering strain. Initial strain is product strain for industry, blocking one copy gene of carnitine acetyl CoA CAT and constructing a gene engineering recombination strain. At the same conditions, growth state of initial and recombination strain are same. CAT enzyme activity of recombination strain drops to half of that of initial strain. Speed rate of producing acid is improved. Crop of dibasic acid and percent conversion increases obviously.

Owner:TSINGHUA UNIV

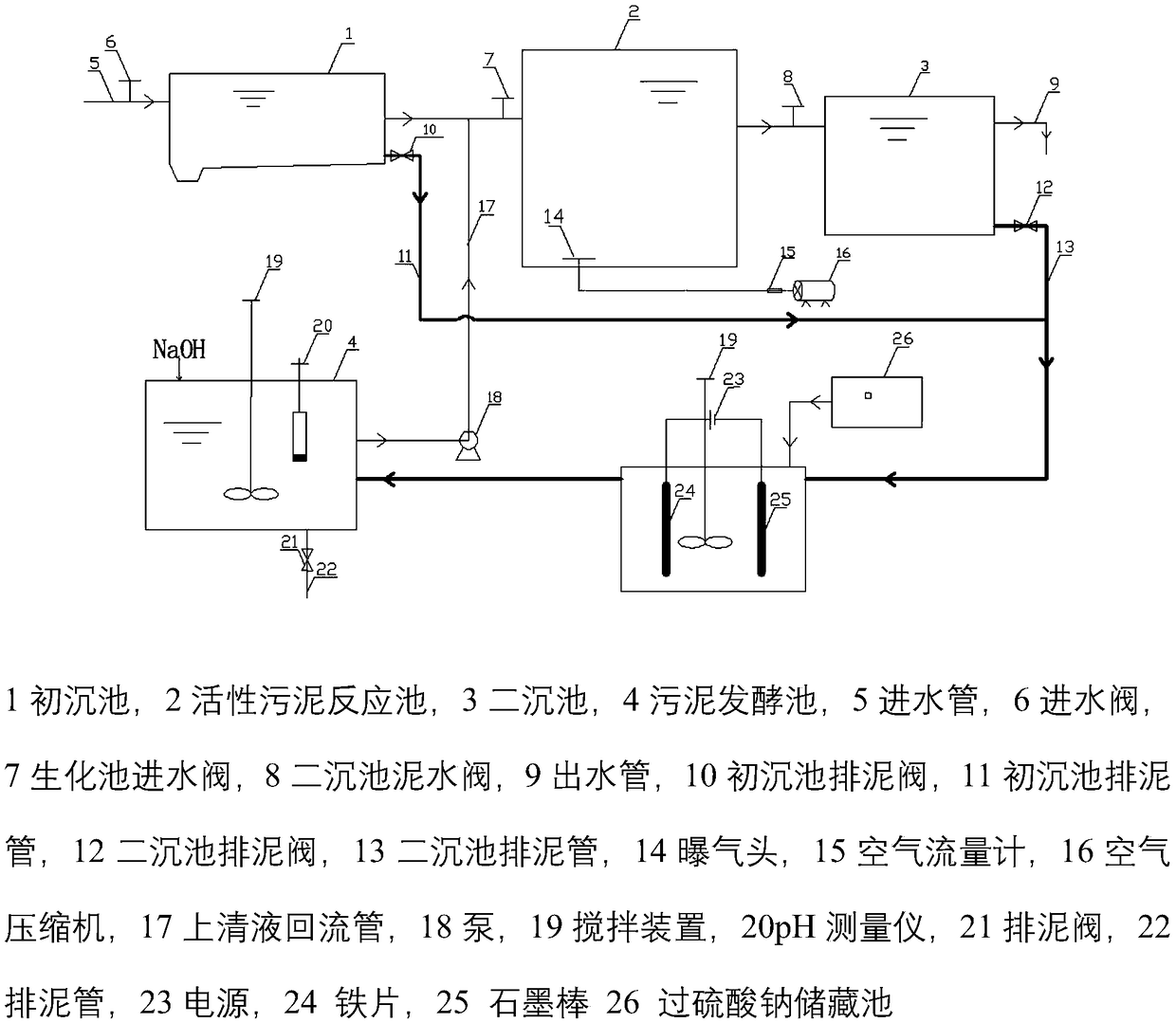

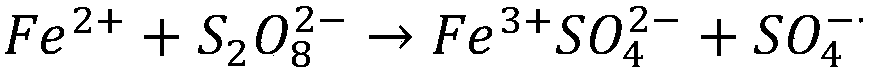

Method of optimizing acid production structure through pretreatment of iron electrode activation of persulfate

InactiveCN109231746AAchieve reductionRealize resourcesFatty oils/acids recovery from wasteFatty substance recoveryElectrochemical responseVolatile fatty acids

The invention discloses a method of optimizing an acid production structure in an anaerobic fermentation acid production process of excess sludge and increasing a short chain fatty acid yield throughpretreatment of iron anode and electricity combined activation of persulfate. The method comprises the steps of: taking sludge as a fermentation substrate, a single-chamber electrolytic tank as a reaction device, an iron sheet as an anode and a graphite rod as a cathode, adding the sludge into an electrochemical reaction tank, adding persulfate into the fermentation substrate at the same time, electrifying for pretreatment, adjusting an initial pH (potential of hydrogen) to 10 for anaerobic fermentation, and obtaining structure optimized short chain volatile fatty acid. The method takes the sludge of a sewage treatment plant as a raw material; an acetic acid yield can be increased to the maximum extent by controlling an iron concentration, a current magnitude, electrifying time and a persulfate concentration in a pretreatment system; and the method contributes to achieving carbon source internal circulation of the sewage treatment plant and promoting sludge reclamation utilization. Atthe same time, the method also has the advantages of simplicity in operation, convenient management and high cost performance.

Owner:HUNAN UNIV

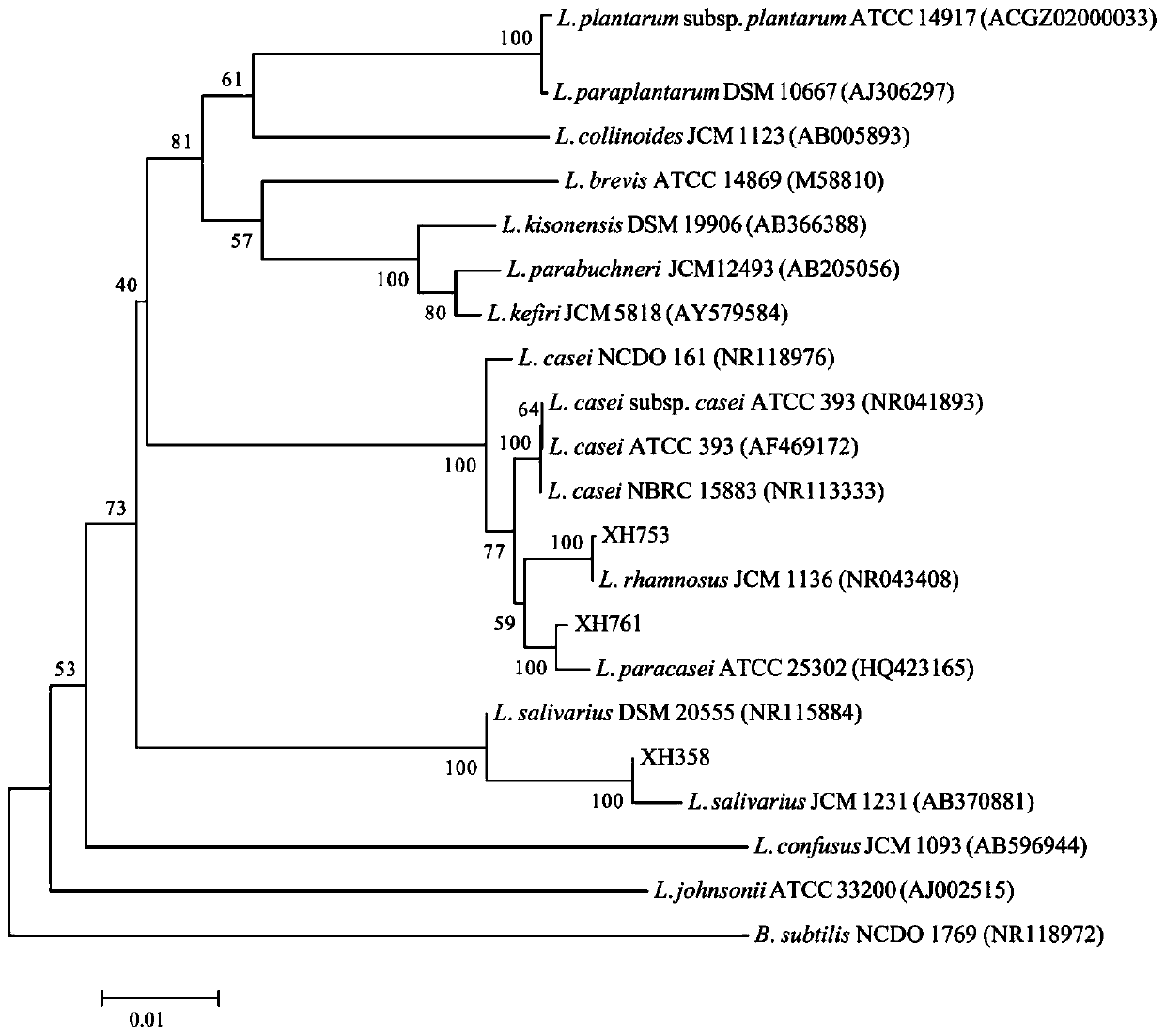

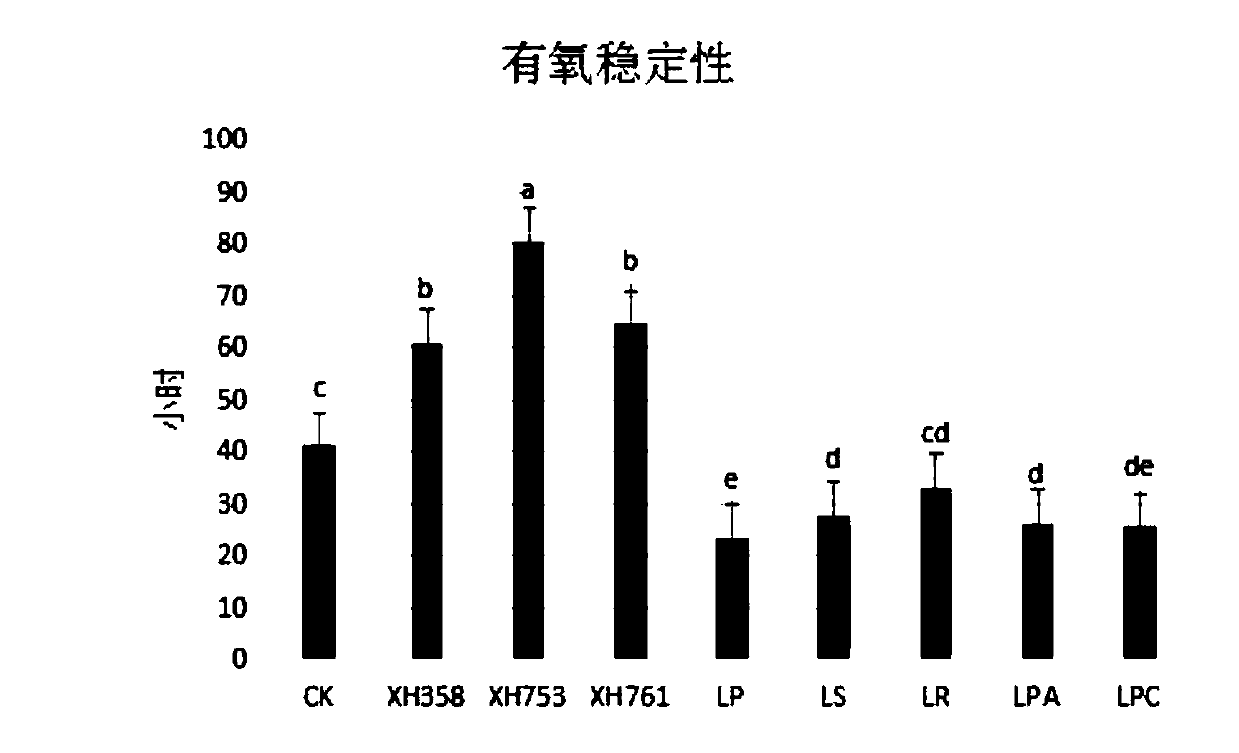

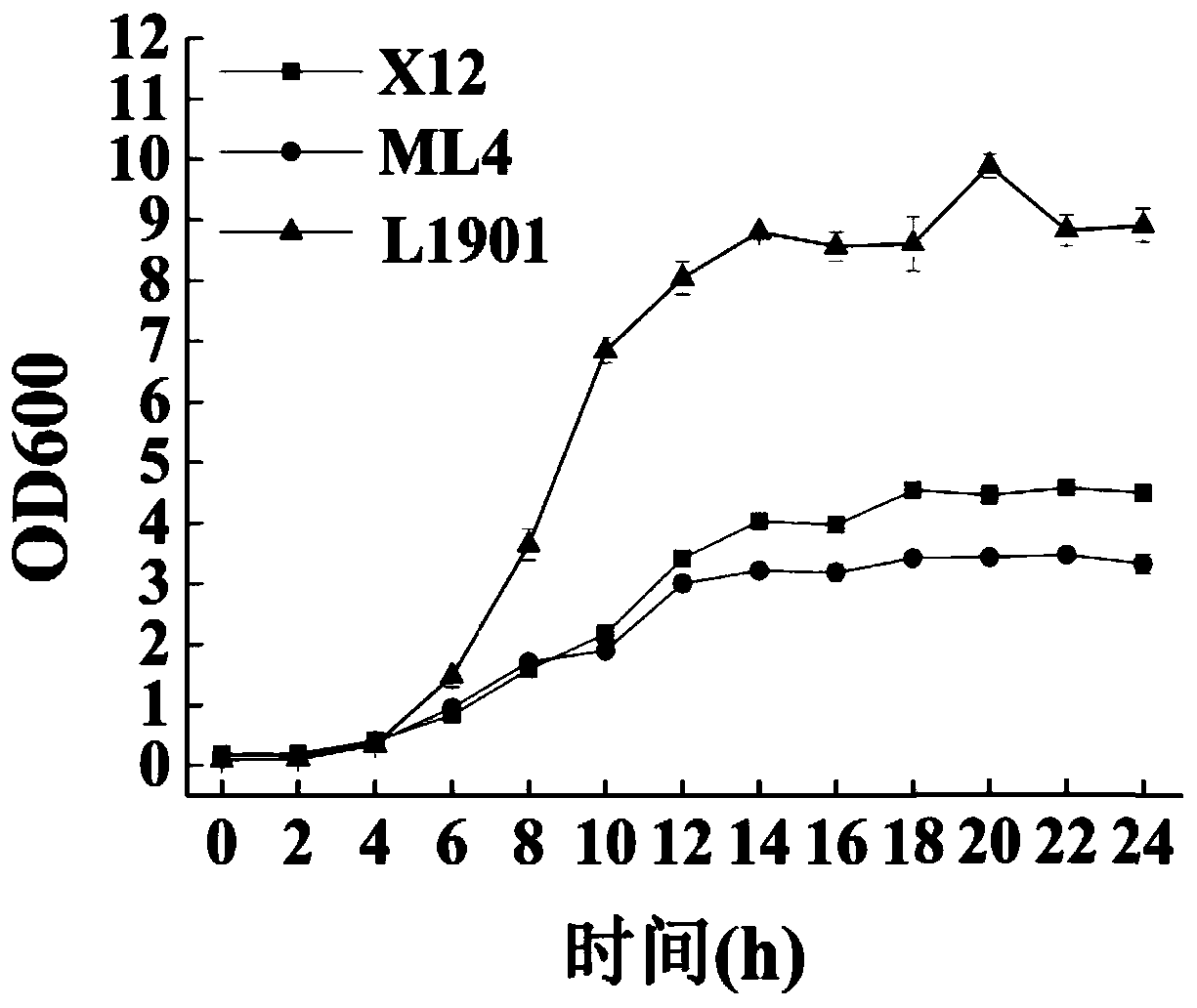

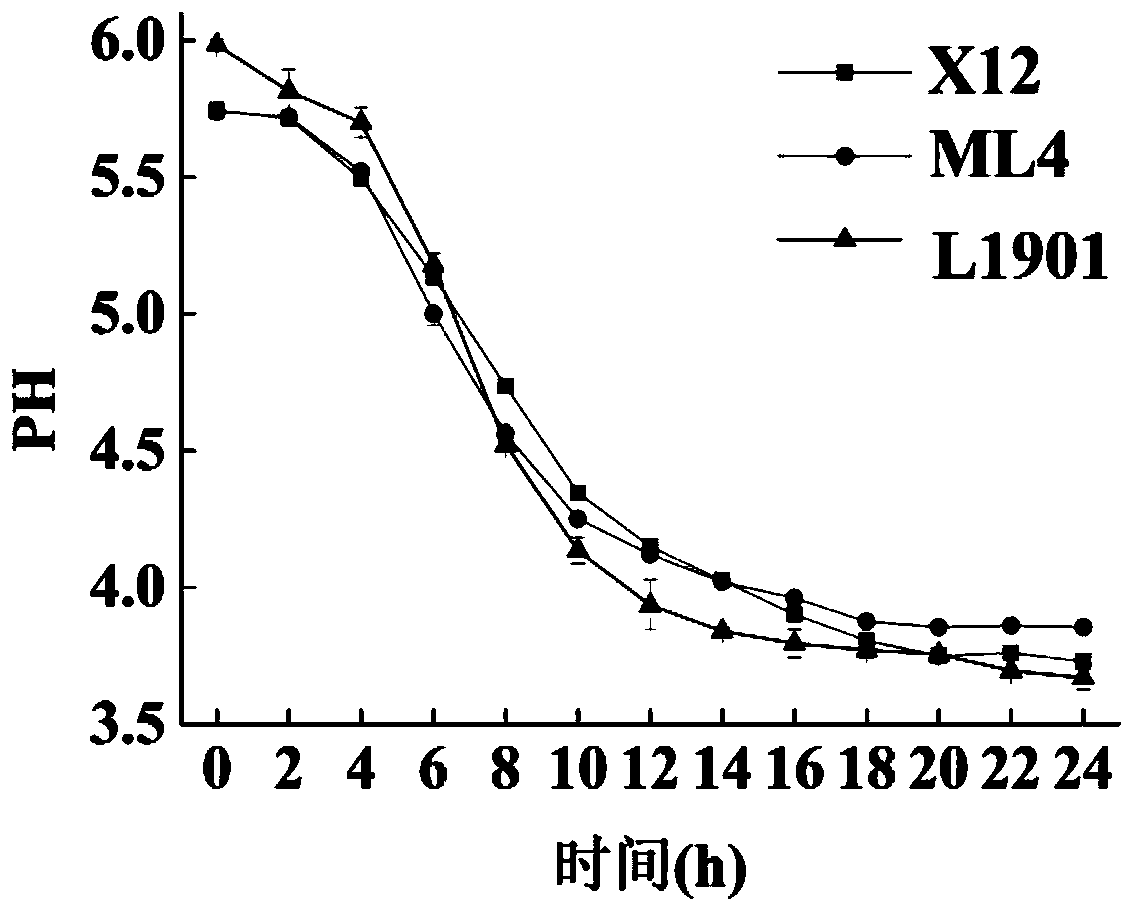

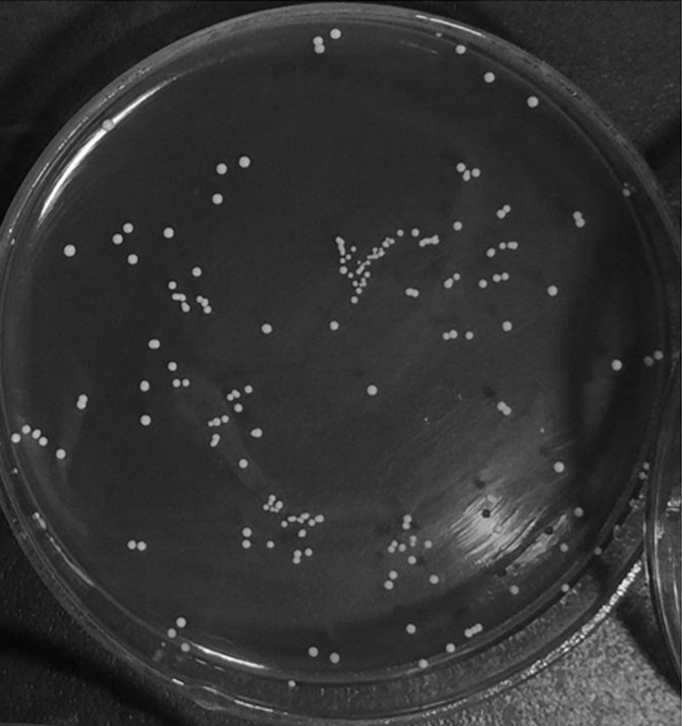

Lactobacillus paracasei 761, application of Lactobacillus paracasei 761, silage additive and silage

ActiveCN110643544AGood high temperature resistanceGood acid resistanceBacteriaMicroorganism based processesMicrobiologyLactobacillus paracasei

The invention discloses a Lactobacillus paracasei 761, application of the Lactobacillus paracasei 761, a silage additive and silage. The Lactobacillus paracasei 761 is deposited at China General Microbiological Culture Collection Center, and the deposit number is CGMCCNo.18234; the Lactobacillus paracasei 761 can improve the quality of the silage in high-temperature and high-humidity areas, and the silage treated by the Lactobacillus paracasei 761 has better aerobic stability, can reduce pH, aflatoxin B1 and dry matter loss and has good high-temperature resistance and acid resistance and goodadaptability to the environment, under culturing in high-temperature conditions, the growth and acid production of the Lactobacillus paracasei 761 has no significant lag phase, and can achieve rapid acid production to achieve the effect of lower pH .

Owner:SICHUAN AGRI UNIV

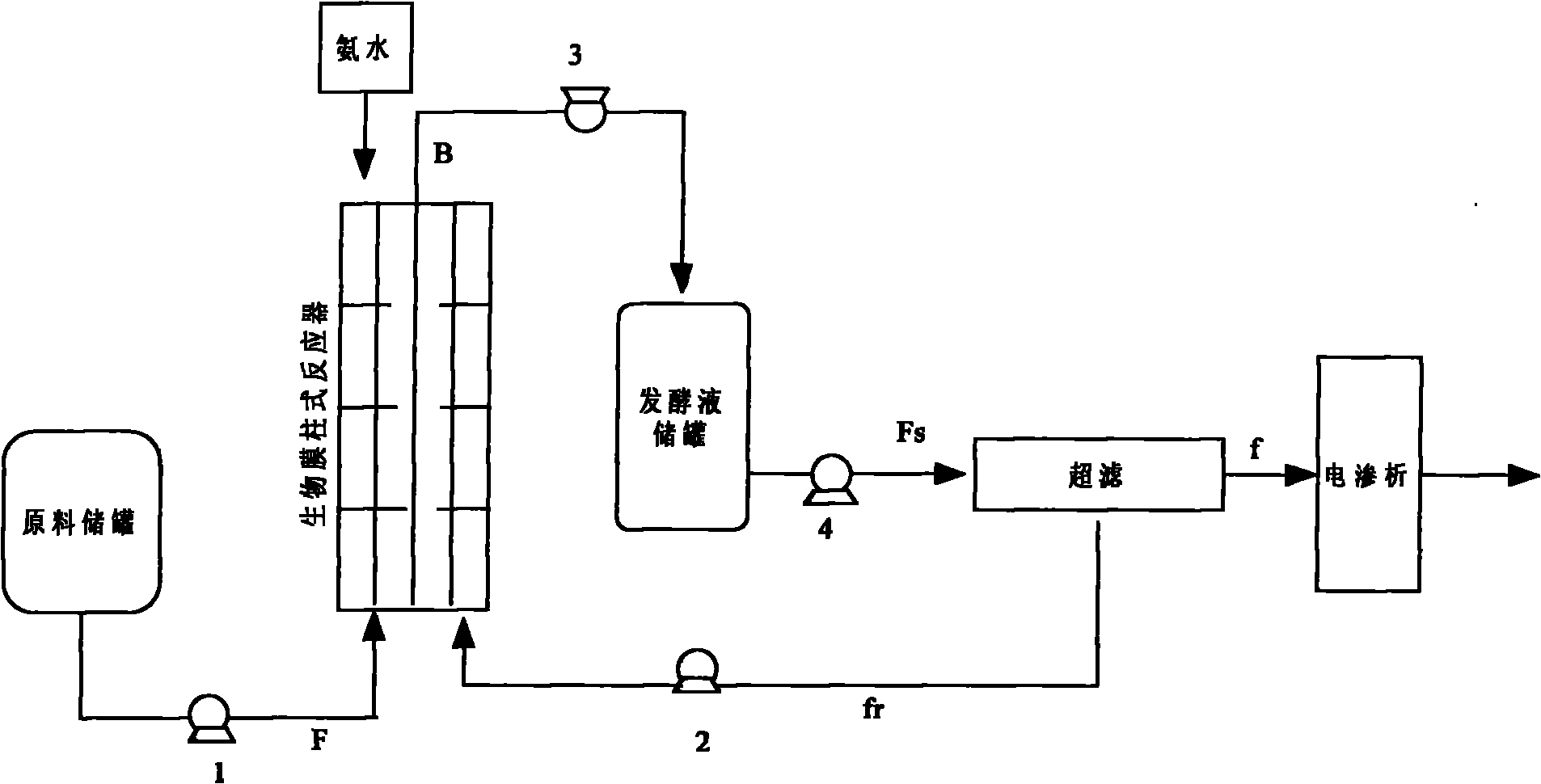

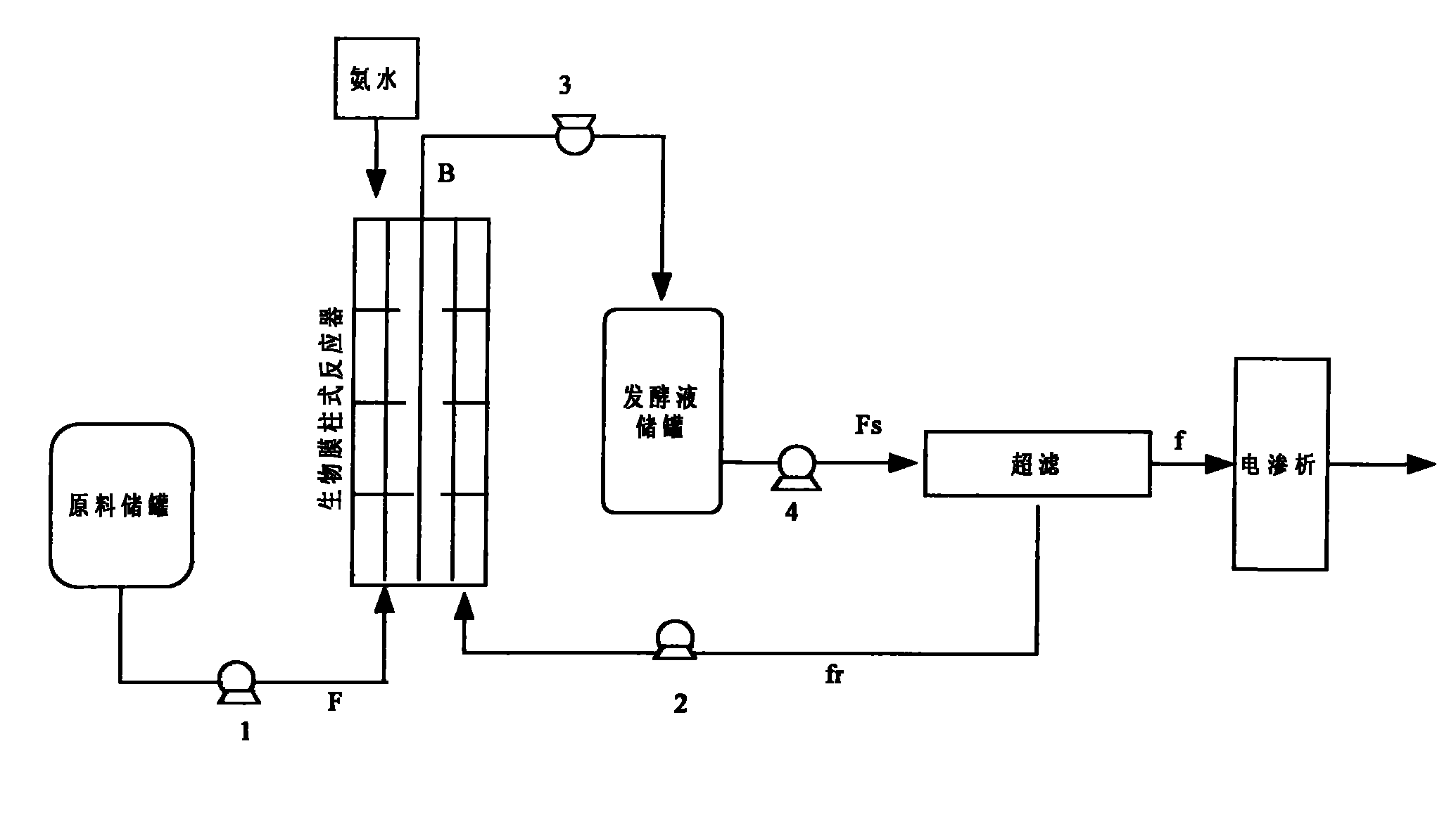

Biomembrane-electrodialysis coupling continuous production technology of L-lactic acid

ActiveCN102041279ATake advantage ofReduce pollutionMicroorganism based processesFermentationUltrafiltrationGlucose polymers

The invention provides a biomembrane-electrodialysis coupling continuous production technology of L-lactic acid. The production technology comprises the following steps: a clear liquid biomembrane column reactor is used to perform continuous anaerobic fermentation, the lactic acid producing strains are adsorbed by combined perforated ring filler, an ultrafiltration membrane is used to filter the fermentation liquor, thalli are blocked by the ultrafiltration membrane, the blocked thalli and liquid are sent back to the biomembrane column reactor, and L-lactic acid is separated through electrodialysis. The method provided by the invention uses the biomembrane column reactor to adsorb lactic acid producing strains on the membrane and uses the ultrafiltration membrane to block lactic acid bacteria, thus the thalli concentration and sugar utilization rate can be effectively increased, and the lactic acid concentration, the acid producing rate and the conversation rate from glucose to lacticacid can be increased greatly.

Owner:CHINA PETROLEUM & CHEM CORP +1

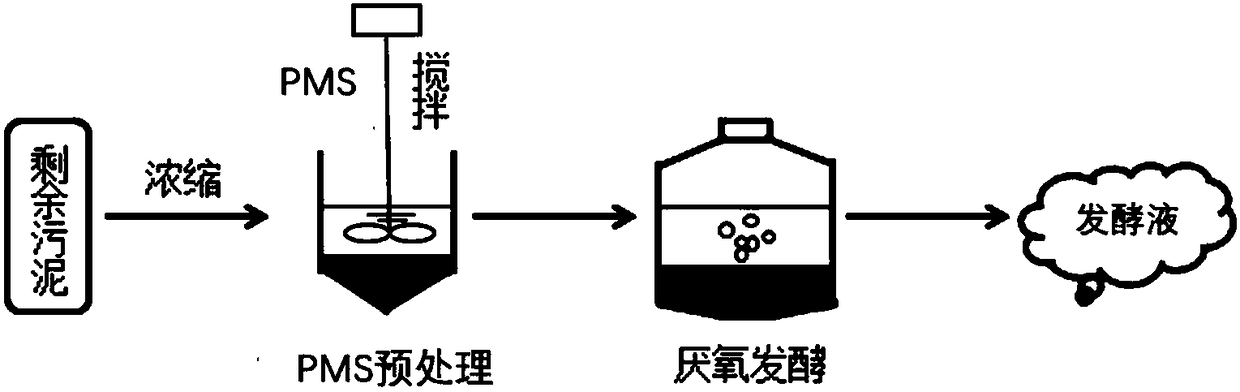

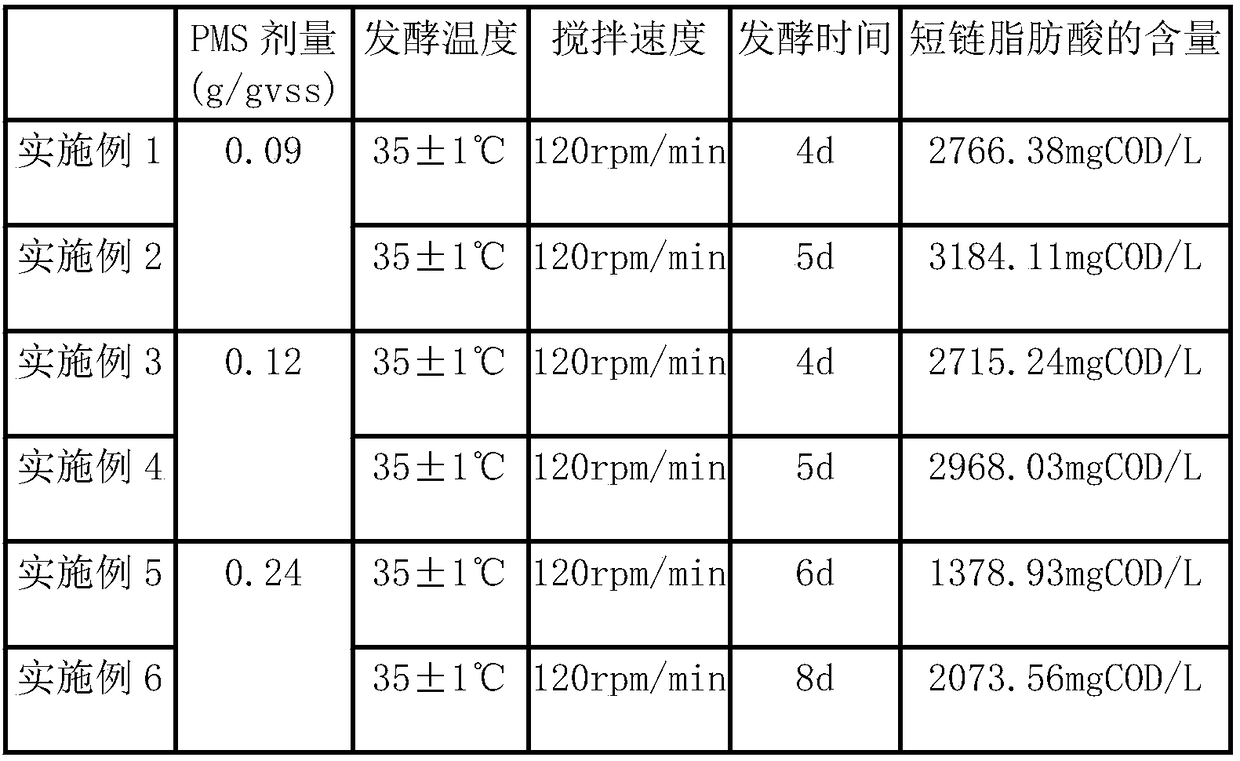

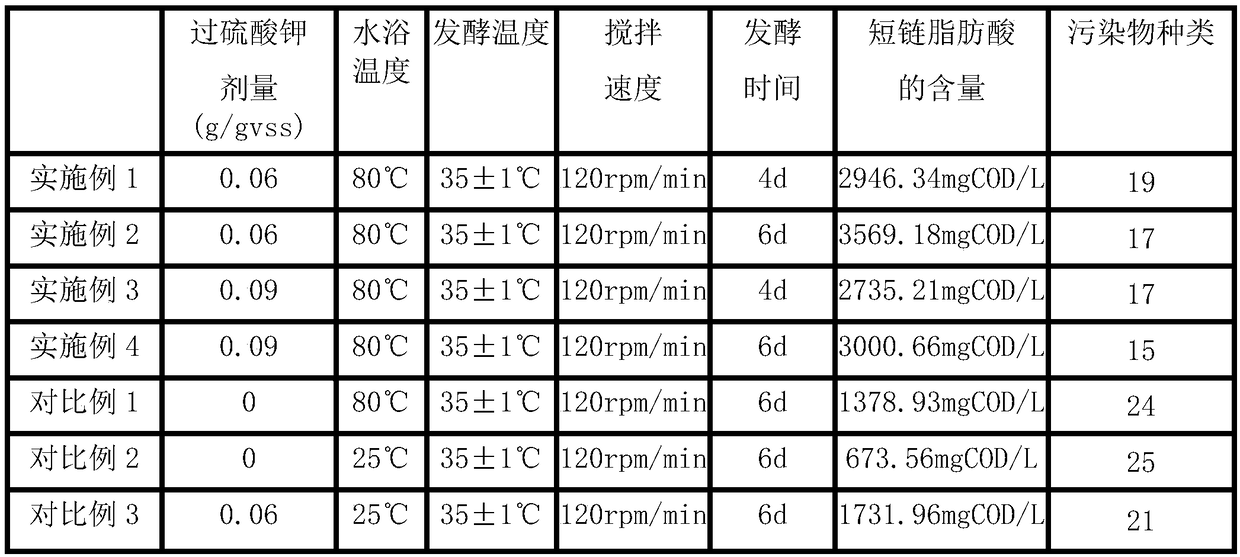

Method for promoting residual sludge anaerobic fermentation to produce fatty acid through potassium peroxymonosulfate sulfate compound salt (PMS)

InactiveCN108441522AIncrease the rate of acid productionShorten the time of anaerobic fermentationFermentationFatty acidFermentation

The invention relates to a method for promoting residual sludge anaerobic fermentation to produce fatty acid through potassium peroxymonosulfate sulfate compound salt (PMS). The method specifically comprises the following steps: (1) treating residual active sludge generated by a secondary sedimentation tank of a municipal sewage treatment plant as a fermentation raw material, and naturally settling to remove liquid supernatant to concentrate and treat to obtain a sludge sample; (2) mixing and pre-treating the sludge sample with potassium peroxymonosulfate sulfate compound salt (PMS), and fermenting under an anaerobic environment to generate fatty acid. After residual sludge is subjected to PMS pretreatment, dissolving of organic substances in sludge is quickened, and activity of acid-consuming microorganisms such as methanogenic bacteria is further inhibited sufficiently, and therefore, the acid yield is greatly increased, and sludge anaerobic fermentation time is shortened; and moreover, the method provided by the invention is simple in operation, and has important environment-friendly ecological significance for reducing, recycling and stabilizing sludge.

Owner:HUNAN UNIV

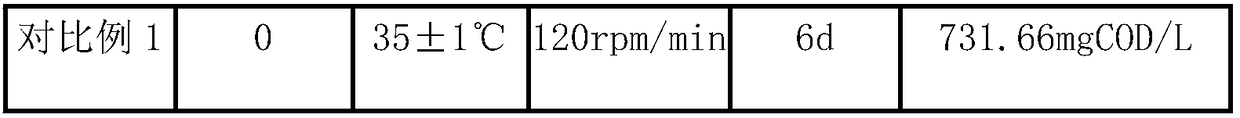

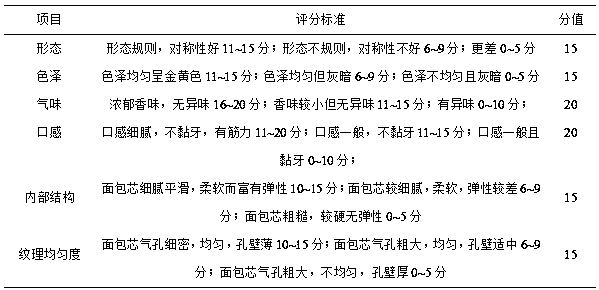

Steamed buns with lactobacillus sanfrancisco and preparation method thereof

The invention discloses steamed buns with lactobacillus sanfrancisco and a preparation method thereof, and belongs to the technical field of food processing. The steamed buns with the lactobacillus sanfrancisco is prepared from the following raw materials in proportion by weight: 380-420 grams of wheat flour, 3-4 grams of Angel high-active dry yeast and 40-160 mL of lactobacillus sanfrancisco Ls-1001, wherein colony forming units of the lactobacillus sanfrancisco Ls-1001 is 3.80x10<13> to 4.00x10<13> CFU / mL. According to embodiments of the steamed buns with the lactobacillus sanfrancisco and the preparation method thereof, the steamed buns are loose and soft in taste, as well as appropriate in sour-sweet flavor, by adding the lactobacillus sanfrancisco Ls-1001 at different bacterium amount; moreover, the steamed buns have aroma of old dough fermented steamed buns in terms of sensory quality. According to the embodiments of the steamed buns with the lactobacillus sanfrancisco and the preparation method thereof, fermentation of the lactobacillus sanfrancisco Ls-1001 in the steamed buns is beneficially promoted by adding beer; and thus, the prepared steamed buns are loose and soft intaste, uniform in texture and mellow in old dough aroma.

Owner:SHANXI UNIV

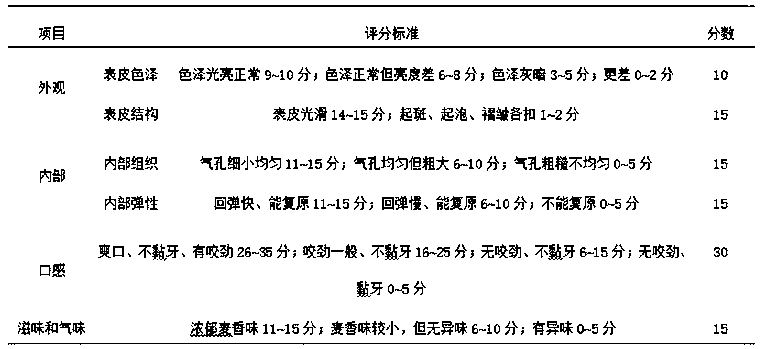

Method for reducing biogenic amine through cyclic rice soaking by inoculating lactobacillus plantarum not generating biogenic amine

ActiveCN110747143AIncrease the rate of acid productionShorten the soaking timeBacteriaAlcoholic beverage preparationBiotechnologyMicrobiology

The invention discloses a method for reducing biogenic amine through cyclic rice soaking by inoculating lactobacillus plantarum not generating the biogenic amine, and belongs to the technical field offood processing and manufacturing. The lactobacillus plantarum is inoculated in the rice soaking process of a grain product; the result shows that by inoculating the lactobacillus plantarum, the content of the biogenic amine in rice soaking water can be effectively reduced, so that the rice soaking water is clear; and conditions are created for the cyclic utilization of rice milk water.

Owner:JIANGNAN UNIV +2

Method for producing short-chain fatty acid employing combined pretreatment of activated sludge

ActiveCN104445849AIncrease the rate of acid productionShorten the timeFermentationBiological sludge treatmentChemistryGamma ray irradiation

The invention relates to a method for producing a short-chain fatty acid employing combined pretreatment of activated sludge. The method comprises the following steps: (1) carrying out gamma-ray irradiation on activated sludge, so as to prepare gamma-ray irradiated sludge; (2) carrying out ultrasonic treatment on the gamma-ray irradiated sludge, so as to prepare ultrasonic-treated sludge; and (3) adjusting the pH value of ultrasonic-treated sludge, carrying out anaerobic fermentation, so as to prepare the combined pretreated activated sludge. After the activated sludge is subjected to gamma-ray irradiation and ultrasonic treatment, organic matters such as protein and polysaccharide in the sludge dissolved into water can be significantly improved, so that an abundant organic matrix which can be dissolved into water is provided for fermentation and acidogenesis of sludge; the acid production rate of the sludge is improved; the anaerobic fermentation time of the sludge is shortened; and the method has important significance in improvement and optimization of an existing sludge treatment system, energy conservation and consumption reduction, and reduction of the operation cost.

Owner:UNIV OF JINAN

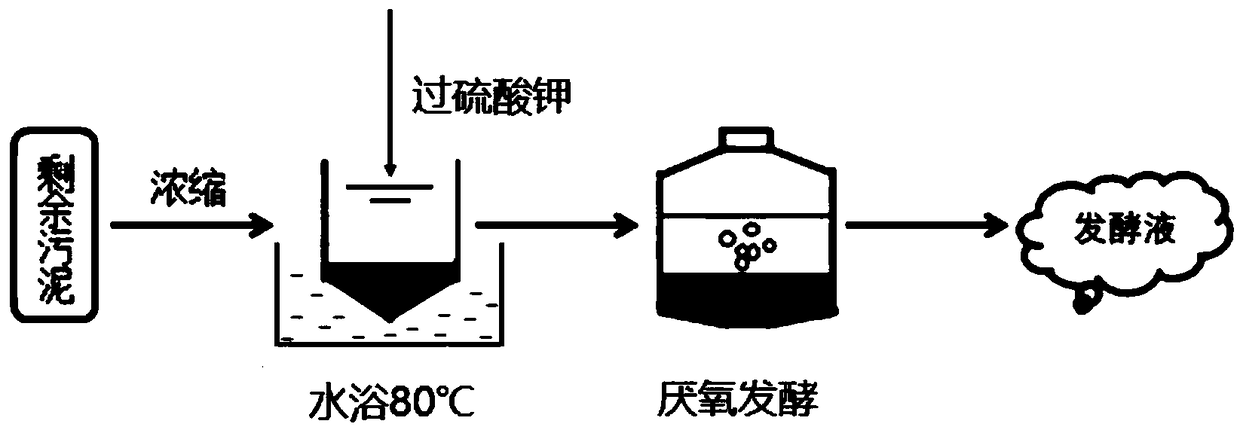

Method for promoting degradation of pollutants in excess sludge and producing fatty acid

InactiveCN108624629AIncrease the rate of acid productionShorten the time of anaerobic fermentationFermentationWater bathsPotassium persulfate

The invention relates to a method for promoting degradation of pollutants in excess sludge and producing fatty acid. The method comprises the following specific steps: firstly, taking excess activatedsludge generated by a secondary sedimentation tank of an urban sewage treatment plant as a fermentation raw material, naturally settling to remove supernate and carrying out concentrated treatment toobtain a sludge sample; secondly, mixing the sludge sample with potassium persulfate, pretreating a mixture in a water bath with the temperature of 80 DEG C for one hour, and fermenting in an anaerobic envirnoment to produce the fatty acid. After the excess sludge is pretreated, dissolution of organic matters in the sludge is accelerated, and the activity of acid-consuming microbes of methanogenic bacteria and the like is sufficiently inhibited, so that acid yield is greatly improved, and the anaerobic fermentation time of the sludge is shortened; meanwhile, kinds and quantity of the pollutants in the sludge are reduced. The method provided by the invention is simple to operate and has important environment-friendly ecological significance for reduction, recycling and stabilization.

Owner:HUNAN UNIV

Rice source ferment and preparation method and application thereof

PendingCN110484569AGood emulsificationPleasant smellCosmetic preparationsMicroorganismsBacillus licheniformisProteinase activity

The invention provides a rice source ferment and a preparation method and application thereof. The preparation method mainly comprises the following steps that 1) bacillus subtilis, bacillus licheniformis, streptococcus thermophilus and lactobacillus acidophilus are mixed and inoculated into a seed medium to obtain a seed solution; 2) rice is smashed and then placed in a drying oven for hot baking; 3) the seed solution is inoculated into a fermentation medium and placed in a constant temperature incubator for culture to obtain a fermentation solution; 4) the smashed rice is added into the fermentation solution, protease is added, then culture continues to be carried out, fermented rice is obtained, and fermentation is stopped; 5) the fermented rice is taken out and cleaned with distilled water, xanthan gum or a sodium hyaluronate solution is added, stirring is carried out to form slurry, a grinder is used for grinding and smashing, then a drying machine is used for adjusting the watercontent, and rice source ferment powder is obtained. The prepared rice source ferment has the advantages of stable emulsifying performance, pleasant smell, excellent compatibility and the like.

Owner:SHANGHAI INST OF TECH

Method for producing table vinegar by adopting two-step acetic acid fermentation method

ActiveCN102433255BEfficient conversionKeep the flavorMicroorganism based processesVinegar preparationAlpha-amylaseTwo step

The invention discloses a method for producing table vinegar by adopting a two-step acetic acid fermentation method and belongs to the technical field of brewing of the table vinegar. According to the method, the problems of low alcohol intolerance, long fermentation period and low acetification rate for acetic acid fermentation in a traditional method are solved. The method comprises the following steps of: uniformly stirring sorghum flour, corn flour, rice meal and water; adding thermostable alpha amylase for liquefying; after liquefying, reducing the temperature, adding Daqu, saccharifying koji, red starter, saccharomyces cerevisiae and aroma-producing yeast and carrying out alcoholic fermentation to obtain liquor; adopting the two-step acetic acid fermentation method: firstly, mixing the liquor; adding acetic acid bacteria subjected to liquid amplification culture for carrying out primary acetic acid fermentation; when the alcoholic strength of brewing mass is reduced to 6-5DEG C, adding wheat bran and rice husk as accessories for mixing; inoculating fire fermented liquor for carrying out secondary acetic acid fermentation; sealing the liquor; smoking the liquor; spraying vinegar; filtering; and packaging to obtain a finished product. According to the method disclosed by the invention, the high-content alcohol can be effectively converted; the acid yield and the acetification rate in unit time are improved; and the flavor of the table vinegar produced by adopting a traditional solid acetic acid fermentation method is ensured.

Owner:山西金龙鱼梁汾醋业有限公司

Nutritive salt solution and application thereof

PendingCN109868226AAcid Yield IncreasedHigh yieldFungiMicroorganism based processesPhosphatePotassium

The invention discloses nutritive salt and an application thereof to a method for producing long-chain binary acid through continuous fermentation. A solution containing nutritive salt comprises the following components of 0.0%-1.0% of glucose, 0.05-0.15% of corn steep liquor, 0.0%-0.3% of yeast cream, 0.005%-0.015% of potassium dihydrogen phosphate, 0.005%-0.015% of urea, 0.01%-0.15% of ammoniumsulphate and the balance water. The continuous fermentation method comprises the steps of performing fermentation for 100-150h, performing continuous flow feeding on substrates, and besides, performing continuous flow feeding on the solution containing nutritive salt. According to the nutritive salt solution disclosed by the invention, the acid production rate of long-chain binary acid can be increased by a fermentation method, and the acid yield can be substantially increased. According to the method disclosed by the invention, on the base that no equipment is additionally arranged, the long-term activity of thalli can be guaranteed, so that sustained production of the long-chain binary acid can be guaranteed, the yield of the long-chain binary acid can be substantially increased, and theyield is also increased.

Owner:CATHAY R&D CENT CO LTD +1

Lactobacillus sanfranciscensis Ls-1001 bread and preparation method thereof

The invention discloses lactobacillus sanfranciscensis Ls-1001 bread and a preparation method thereof. The bread is prepared from secondary fermentation dough and main dough by adopting a secondary fermentation method; the secondary fermentation dough comprises 110-130 grams of high protein flour, 0.3-0.4 gram of Angel high-activity dry yeast, 65-75 grams of water and 3-37 grams of lactobacillus sanfranciscensis Ls-1001 fermentation broth, wherein the number of bacterial colonies is 6.0*108-7.3*108 CFU / mL; the main dough comprises 70-90 grams of high protein flour, 0.7-1.6 grams of Angel high-activity dry yeast, 15-25 grams of water, 25-35 grams of white granulated sugar, 1.5-2.5 grams of salt, 18-25 grams of butter, 55-65 grams of egg and 8-15 grams of skim milk powder. The lactobacillussanfranciscensis Ls-1001 bread and the preparation method thereof have the advantage that the bread is delicate and soft in taste and moderate in sour and sweet by adding lactobacillus sanfranciscensis Ls-1001 with different bacterial counts.

Owner:SHANXI UNIV

Edible vinegar processing method

InactiveCN107828627AKeep the flavorAdd flavorMicroorganism based processesVinegar preparationAcetic acidAlcohol

The invention discloses an edible vinegar processing method and relates to the field of an edible vinegar processing technology. The edible vinegar processing method comprises the following steps: (1)auxiliary fermentation broth preparation; (2) raw material liquefaction; (3) alcoholic fermentation; and (4) acetic acid fermentation. By the edible vinegar processing method of the invention, alcohol can be effectively converted, acid generation amount and acid generation rate per unit time are raised, and traditional vinegar flavor is guaranteed.

Owner:安徽鲜福临食品有限责任公司

Fermenting type apple vinegar beverage and preparation method thereof

ActiveCN102771864BRetain nutrientsPreserve the flavorVinegar preparationFood preparationFlavorNutrients substances

The invention discloses a fermenting type apple vinegar beverage and a preparation method thereof. The fermenting type apple vinegar beverage is characterized by being prepared by preparing, filtering, sterilizing and filling the following raw materials by weight proportion: 50-70 parts of apple vinegar, 80-120 parts of concentrated apple juice, 2-8 parts of honey, 1-3 parts of aspartame and 799-867 parts of water. The fermenting type apple vinegar beverage has the advantages of well retaining the original nutrient substances and flavor of apple, having high acid production rate, being obviously shortened in fermenting time, further being capable of separating cured acetic bacteria cells and products easily and being used repeatedly, enabling strains to be efficient, greatly improving production efficiency, saving production cost and reducing pollution discharging.

Owner:YANTAI QIWEI WINE IND

Lactobacillus plantarum with fast acid production and high acid production and application thereof

ActiveCN112410251BIncrease the rate of acid productionIncrease speedBacteriaHybrid cell preparationBiotechnologyLactobacillus

The present invention provides a kind of Lactobacillus plantarum with fast acid production and high acid production and application thereof, which is Lactobacillus plantarum ( Lactobacillus plantarum ) WG03, the preservation unit is China General Microorganism Culture Collection Management Center, the preservation number is CGMCC 20876, and the preservation date is October 12, 2020. The present invention provides a microbial inoculum comprising the above-mentioned Lactobacillus plantarum. The above-mentioned Lactobacillus plantarum or bacterial agent can be applied to the fermentation of silage. In the present invention, a strain of Lactobacillus plantarum with fast acid production and high acid production is obtained by protoplast fusion technology combined with traditional mutagenesis. Using this strain as a silage additive can well inhibit the growth of spoilage bacteria and quickly start Anaerobic fermentation process to improve the quality of silage.

Owner:HEBEI UNIVERSITY

A method of combined pretreatment of activated sludge to produce short-chain fatty acids

ActiveCN104445849BIncrease the rate of acid productionShorten the time of anaerobic fermentationFermentationBiological sludge treatmentActivated sludgeGamma ray

The invention relates to a method for producing a short-chain fatty acid employing combined pretreatment of activated sludge. The method comprises the following steps: (1) carrying out gamma-ray irradiation on activated sludge, so as to prepare gamma-ray irradiated sludge; (2) carrying out ultrasonic treatment on the gamma-ray irradiated sludge, so as to prepare ultrasonic-treated sludge; and (3) adjusting the pH value of ultrasonic-treated sludge, carrying out anaerobic fermentation, so as to prepare the combined pretreated activated sludge. After the activated sludge is subjected to gamma-ray irradiation and ultrasonic treatment, organic matters such as protein and polysaccharide in the sludge dissolved into water can be significantly improved, so that an abundant organic matrix which can be dissolved into water is provided for fermentation and acidogenesis of sludge; the acid production rate of the sludge is improved; the anaerobic fermentation time of the sludge is shortened; and the method has important significance in improvement and optimization of an existing sludge treatment system, energy conservation and consumption reduction, and reduction of the operation cost.

Owner:UNIV OF JINAN

Lactobacillus plantarum with fast acid production and high acid yield and application of lactobacillus plantarum

ActiveCN112410251AIncrease the rate of acid productionIncrease speedBacteriaHybrid cell preparationBiotechnologyMicroorganism

The invention provides lactobacillus plantarum with fast acid production and high acid yield and an application of the lactobacillus plantarum. The lactobacillus plantarum is lactobacillus plantarum WG03, the preservation unit is China General Microbiological Culture Collection Center, the preservation number is CGMCC 20876, and the preservation date is October 12, 2020. The invention provides a microbial agent containing the lactobacillus plantarum. The lactobacillus plantarum or the microbial inoculum can be applied to silage fermentation. The lactobacillus plantarum with rapid acid production and high acid yield is obtained by combining a protoplast fusion technology with a traditional mutagenesis method, and the lactobacillus plantarum is used as a silage additive, so that the growth of spoilage bacteria can be well inhibited, the anaerobic fermentation process is quickly started, and the quality of silage is improved.

Owner:HEBEI UNIVERSITY

Biotin supplemented fermentation method for producing glutamic acid

ActiveCN103088081BGuaranteed normal growthGuarantee normal metabolismMicroorganism based processesFermentationPenicillinCulture mediums

The invention relates to a biotin supplemented fermentation method for producing glutamic acid. The method comprises the following steps: treating biotin deficient strains as production strains, controlling the initial content of biotins in a fermentation culture medium, and supplementing penicillin and biotins in the fermentation process. The fermentation method which allows penicillin and biotins to be added in the middle and later fermentation process can overcome a biotin poorness problem in the later fermentation period of a suboptimal-dose technology, guarantees the sufficient biotins in the culture medium for the growth and the metabolism of thalli, and substantially improves the glutamic acid synthesis speed of the thalli; and compared with present glutamic acid suboptimal-dose technologies, the fermentation method provided by the invention allows the acid production rate of unit thalli to be improved by above 10%, the fermentation period to be substantially shortened and the production cost to be reduced.

Owner:COFCO BIO CHEM ENERGY LONGJIANG CO LTD

Control method for microbial fermentation production of gluconate

InactiveCN103352089ADirect controlReal-time controlMicrobiological testing/measurementMicrobiologyGluconic acid

The invention discloses a control method for microbial fermentation production of gluconate. A glucose acid high-producing strain is adopted as a starting strain, after seed culture, the strain is transferred into a fermentation tank to undergo fermentation production of gluconate. During fermentation, the fermentation tank air inflow rate and stirring speed can be adjusted automatically according to an on-line measured oxygen uptake rate (OUR). Thus, an enough dissolved oxygen concentration is guaranteed, the acid production rate is enhanced, and direct, real-time, and accurate control of a gluconate fermentation process can be realized.

Owner:山东福洋生物科技股份有限公司

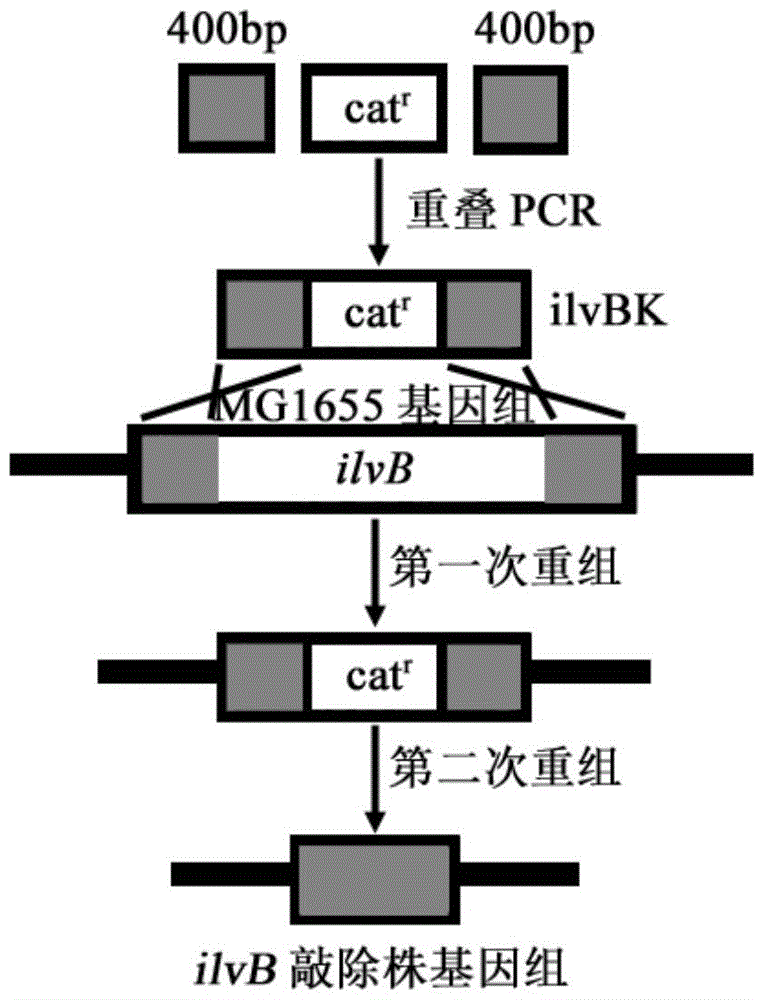

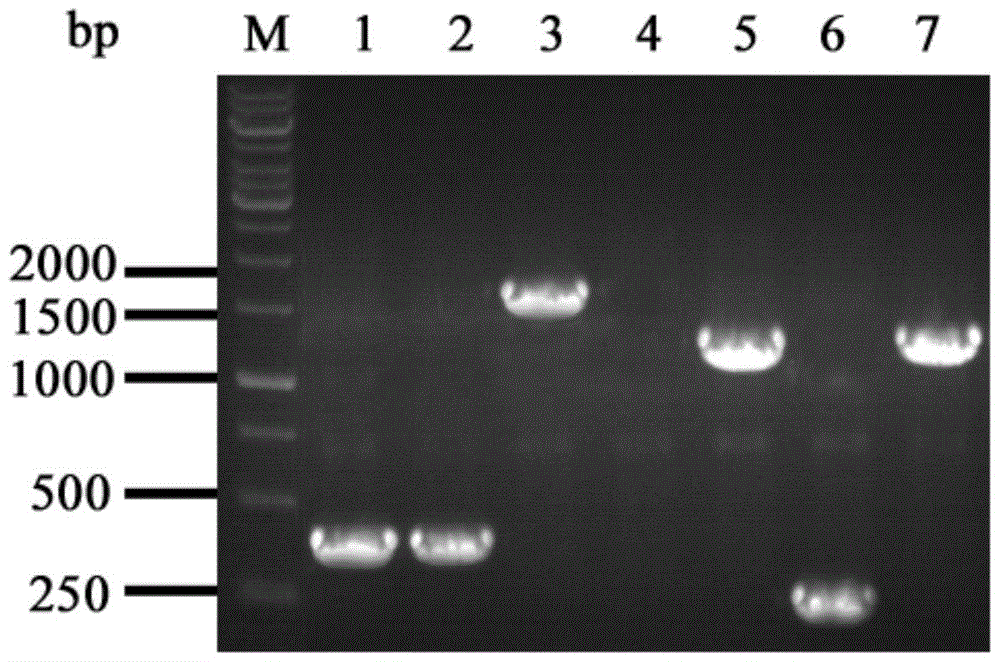

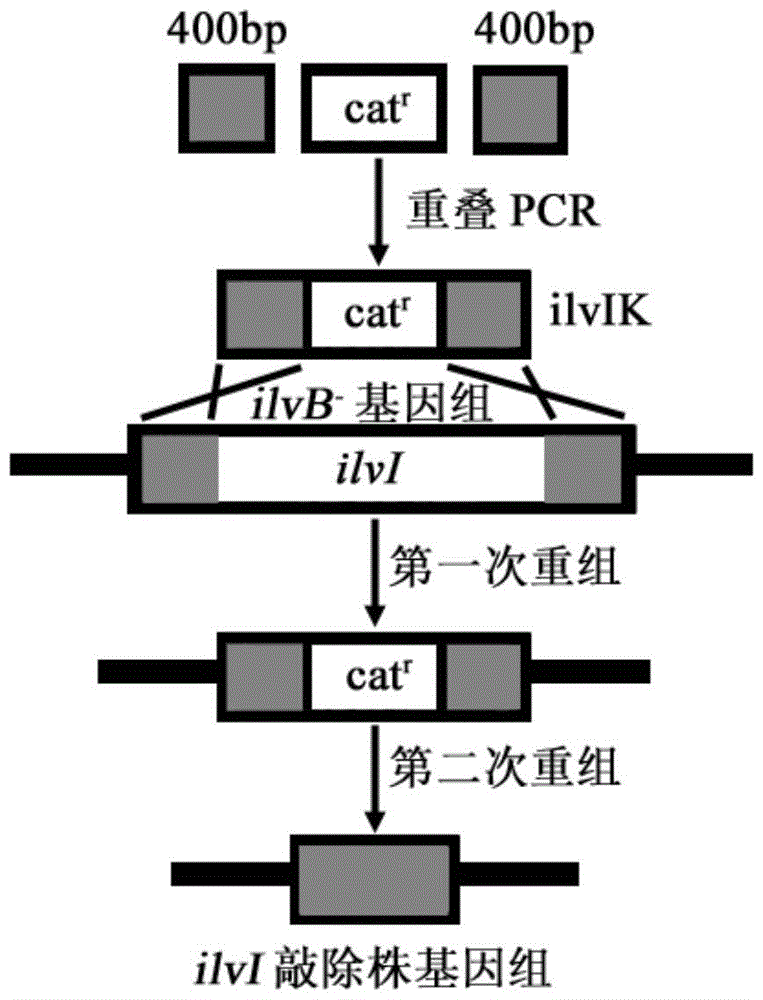

A genetically engineered bacterium producing α-ketobutyric acid and its application

ActiveCN103865869BGrow fastShort fermentation cycleBacteriaMicroorganism based processesBiotechnologyChemical synthesis

The invention relates to a genetically engineered bacterium for producing alpha-ketobutyric acid as well as a construction method and application of the genetically engineered bacterium, belonging to the technical field of biology. The strain is relatively high in production efficiency when used for producing alpha-ketobutyric acid through fermentation. The genetically engineered bacterium is obtained through carrying out genetic engineering modification on Escherichia coli MG1655; the genetic engineering modification is realized by knocking out a large-subunit encoding gene ilvB of acetohydroxyacid synthase I, a large-subunit encoding gene ilvI of acetohydroxyacid synthase III and a threonine operon leading peptide encoding gene thrL in an over-expressive threonine dehydratase encoding gene ilvA. When the bacterium is used for producing alpha-ketobutyric acid by using a fermentation method, defects such as complex reaction conditions, high energy consumption, serious pollution or high production cost, serious pollution and the like existing in a chemical synthesis method, an enzyme method or a microbial conversion method can be overcome; after the bacterium is fermented for 20-24h, the yield of alpha-ketobutyric acid is up to 8.5-15.7g / L; aerobic fermentation is adopted in a fermentation process; the bacterium is rapid in growth, short in fermentation period and high in acid production rate; any reports for producing alpha-ketobutyric acid by using a direct fermentation method are not found at present.

Owner:江苏澳创生物科技有限公司

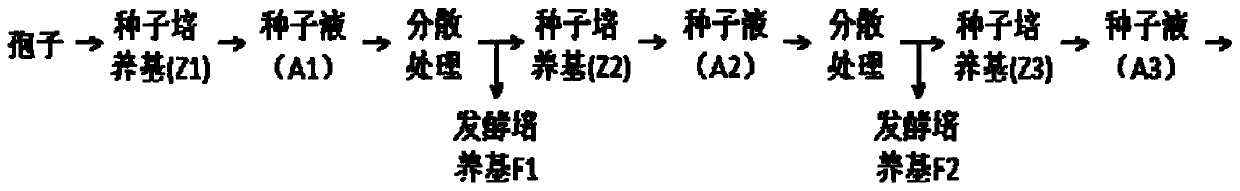

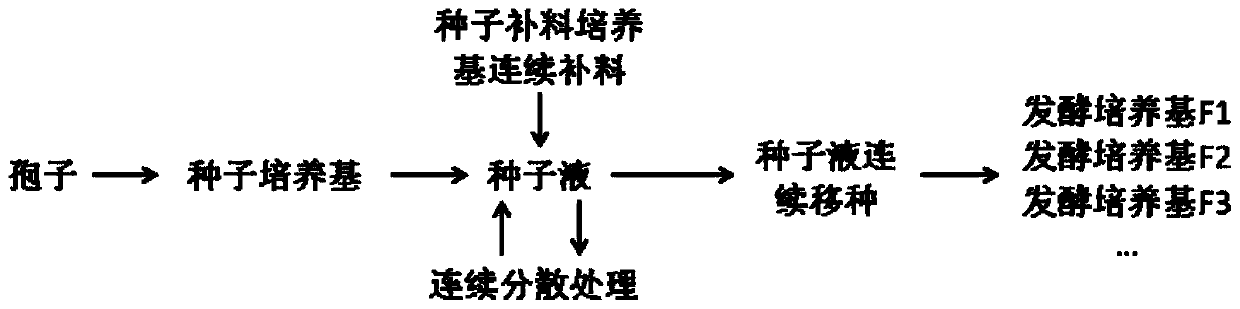

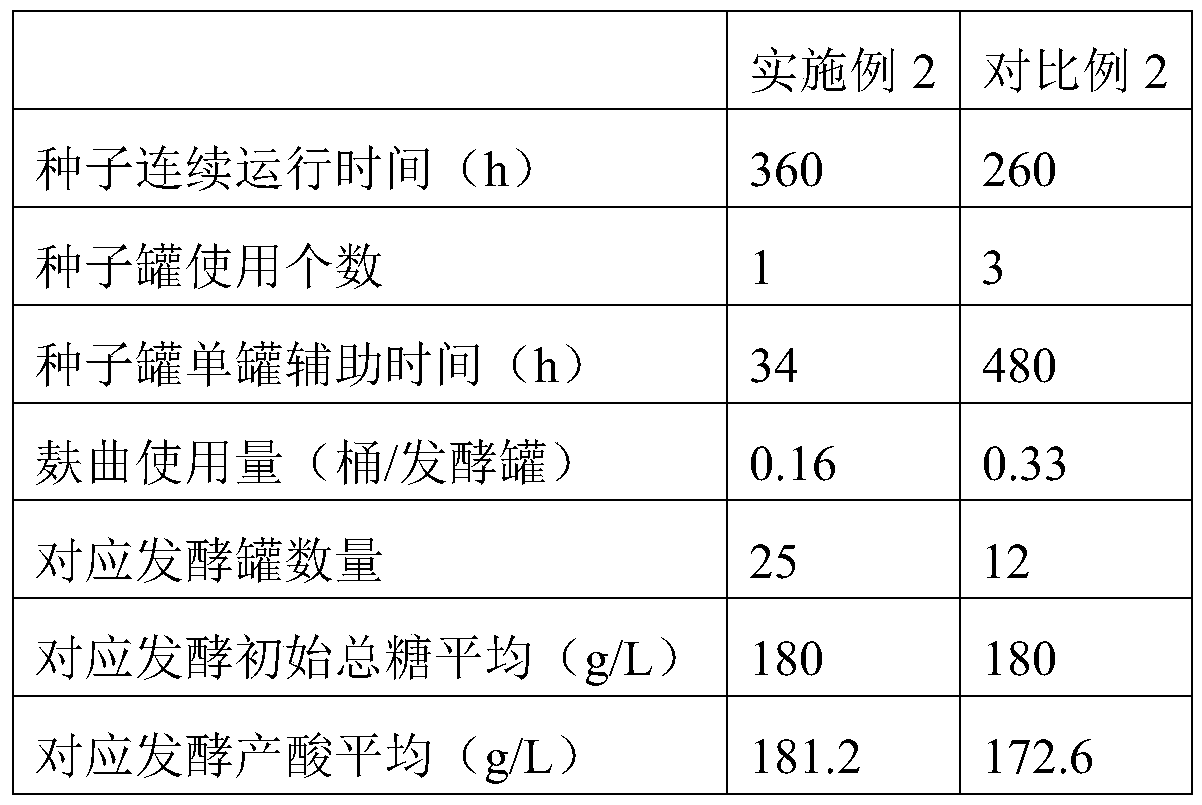

A kind of Aspergillus niger seed continuous culture and method for producing citric acid thereof

ActiveCN109055444BRealize continuous cultureTime-saving training assistanceFungiMicroorganism based processesSporelingAspergillus niger

The invention discloses a method for continuous cultivation of Aspergillus niger seeds. The method comprises the following steps: (1) in the start-up stage, inoculating the Aspergillus niger spores into the seed medium to obtain a seed liquid; (2) in the continuous cultivation stage of the seeds, The seed solution obtained in step (1) is subjected to continuous dispersion treatment, and the seed solution obtained by dispersing is continuously cultivated, and fresh seed feed medium is supplemented at the same time; (3) stop stage, stop supplementing fresh seed feed medium and disperse treatment, Continue culturing to obtain seed liquid, which is transferred into the fermentation medium for fermentation and cultivation. The method of the present invention solves the problem of slow growth of multicellular filamentous bacteria and easy loss of mycelium balls in continuous culture, completely realizes the continuous cultivation of seeds, keeps the bacteria in the most suitable growth environment, and avoids the Seed degradation, so that the seed liquid is in a continuous and stable high-activity state, corresponding to the improvement of the performance of citric acid production by fermentation.

Owner:JIANGSU GUOXIN UNION ENERGY CO LTD +1

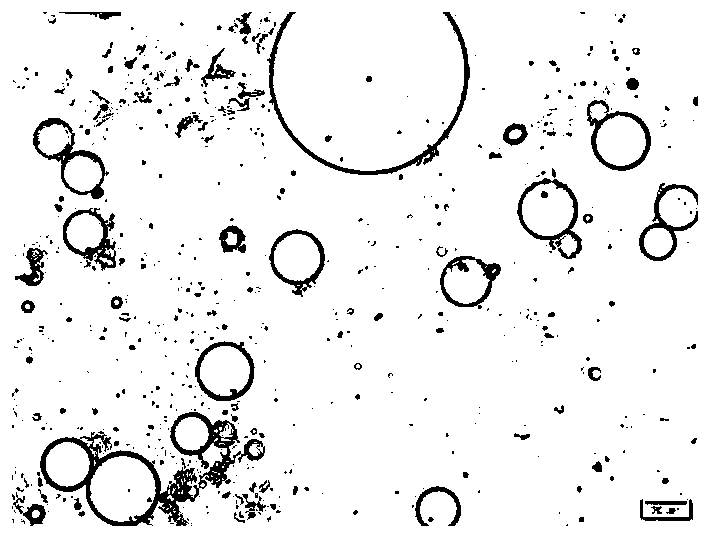

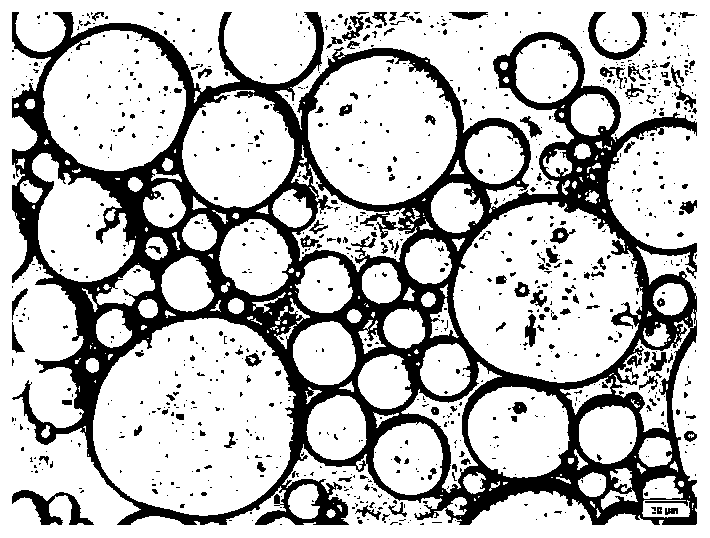

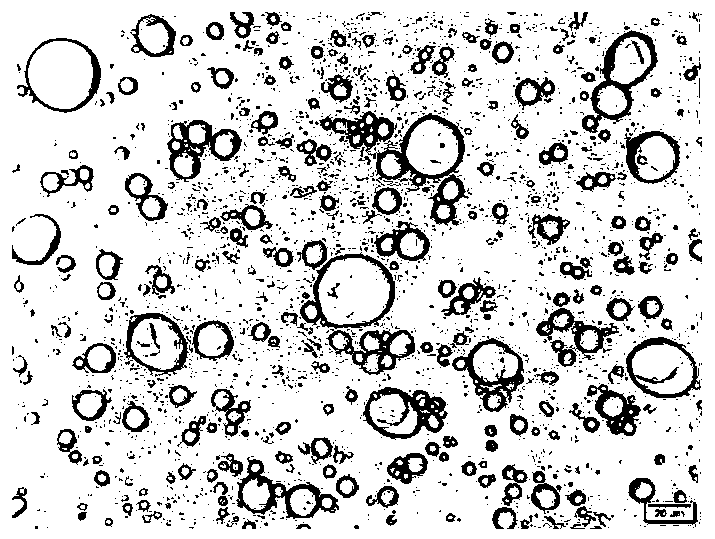

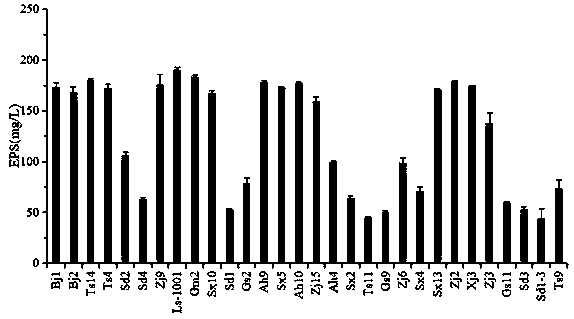

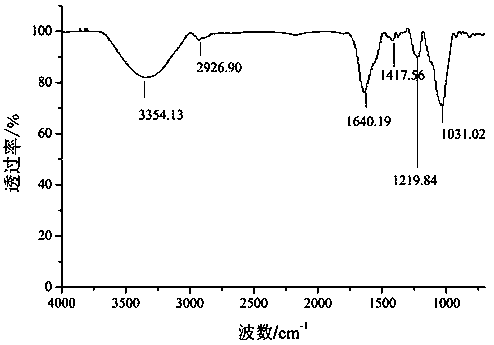

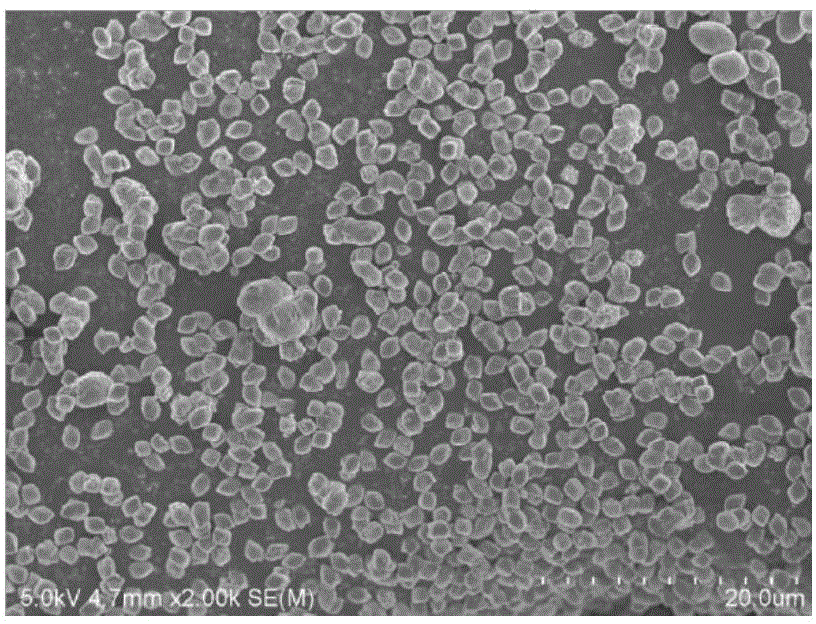

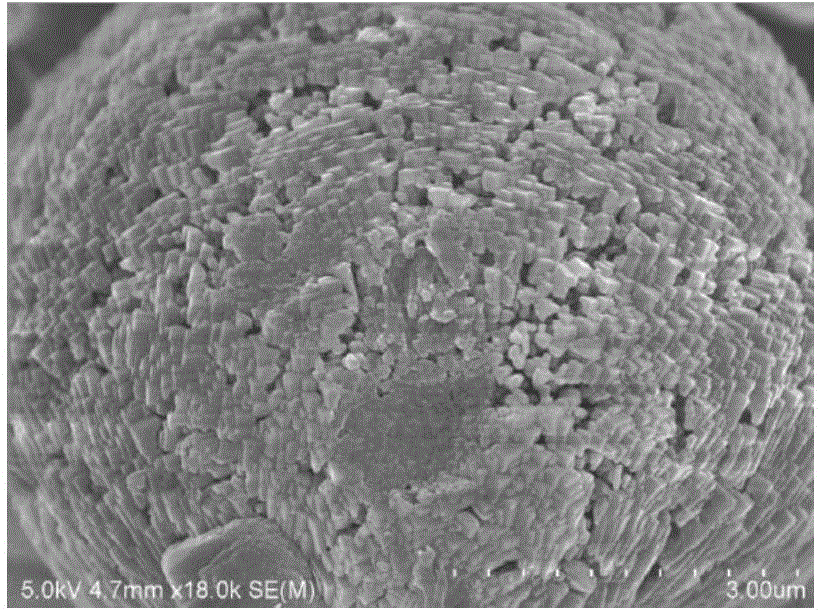

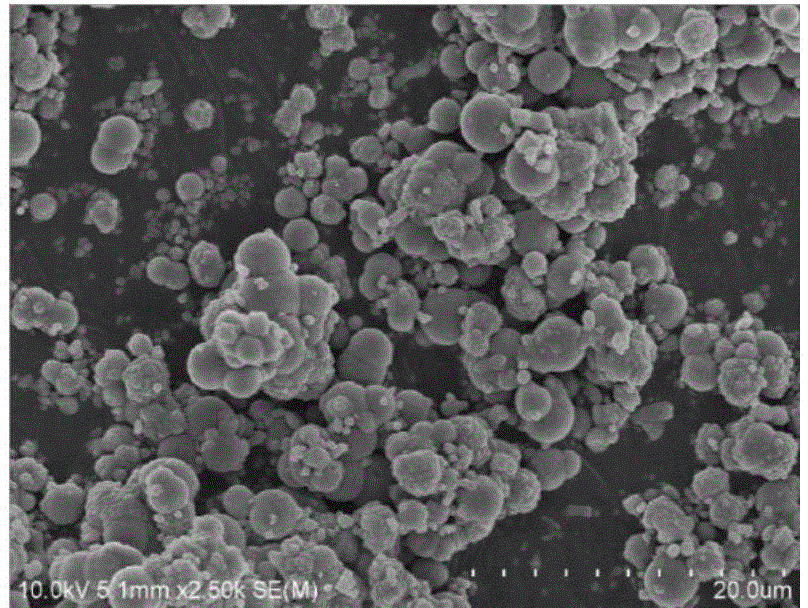

Activated calcium carbonate for increasing acid production rate of fermentation organic acid and preparation method of activated calcium carbonate

InactiveCN105985988AIncrease the rate of acid productionLow densityMicroorganism based processesFermentationOrganic acidMicrometer

The invention discloses activated calcium carbonate for increasing the acid production rate of fermentation organic acid and a preparation method of activated calcium carbonate. The preparation method of activated calcium carbonate comprises the following steps that in a fermentation liquor system, organic acid calcium salt reacts with matter containing carbonate and / or bicarbonate radicals, or reacts with matter capable of generating carbonate and / or bicarbonate radicals react, and activated calcium carbonate for increasing the acid production rate of the fermentation organic acid is generated. Particles of prepared activated calcium carbonate are spherical or fusiform, the particle size (D50) ranges from 1 micrometer to 20 micrometers, and the size of crystal nucleuses in the particles ranges from 10 nanometers to 200 nanometers; organonitrogen and polysaccharide matter are contained, activated calcium carbonate serves as an acidity and alkalinity modifier for fermenting organic acid, the acid production rate and the thallus concentration can be increased, and the preparation cost is low.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A method of using redox mediator to promote the fermentation of excess sludge to produce acid

ActiveCN103952445BHigh activityIncrease productionFermentationVolatile fatty acidsOxidation-Reduction Agent

The invention discloses a method for promoting production of fermentation acid from remaining sludge by utilizing redox mediator. The method comprises the steps of stirring the remaining sludge by an underflow stirrer for 1-6h at the stirring speed of 30-100rpm under anaerobic conditions, adding redox mediator stock solution to enable the concentration of redox mediator in a fermentation system to be 0.5-200mg / L and performing production of fermentation acid in a fermentation tank or an anaerobic reactor; the fermentation conditions are as follows: the fermentation temperature is controlled to be 15-35 DEG C, the pH value of the fermentation system is regulated to 6.0-12.0, the redox potential is controlled to be below -100mV, the underflow stirrer is adopted for stirring, the stirring speed is set to be 50-200rpm and the fermentation time is 3-30d. The remaining sludge can be directly mixed with redox mediator without alkali, hot alkali or ultrasonic pretreatment and volatile fatty acids can be fast and efficiently produced by controlling the operation conditions disclosed by the invention.

Owner:杭州微净科技有限公司

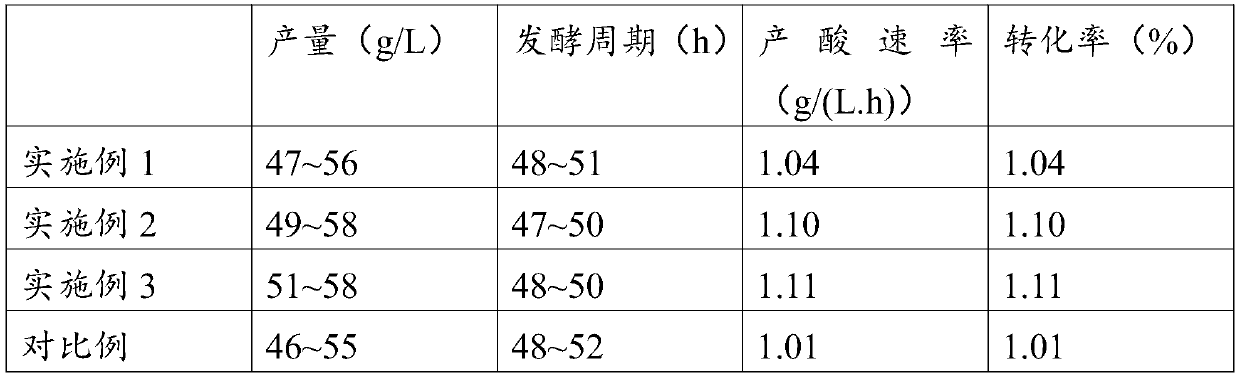

Method for improving acid production rate and conversion rate of butyric acid fermentation

InactiveCN111363707AIncrease the rate of acid productionIncrease speedBacteriaMicroorganism based processesBiotechnologyButyric acid

The invention provides a method for improving the acid production rate and conversion rate of butyric acid fermentation, and relates to the technical field of butyric acid fermentation. According to the method disclosed by the invention, a new ORP control standard is utilized; the ORP range standard of secondary seed culture is minus 400 to minus 200; and the ORP range standard of fermentation culture is minus 450 to minus 350. By utilization of the method disclosed by the invention, the period is shortened; the butyric acid content and conversion rate are improved; and compared with the priorart, the method improves the acid production rate by 9.9%.

Owner:ZHUMADIAN HUAZHONG CHIA TAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com