Steamed buns with lactobacillus sanfrancisco and preparation method thereof

A technology of Lactobacillus San Francisco and its production method is applied in the direction of Lactobacillus, bacteria used in food preparation, food ingredients containing yeast, etc. It can solve the problems of poor re-steaming performance, flat flavor of steamed buns, difficulty in ensuring hygiene, etc., and achieve the best taste fluffy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Ingredients: 400 g of wheat flour; 4 g of Angel’s highly active dry yeast; 50 mL of Lactobacillus San Francisco Ls-1001 fermentation broth (the number of colonies is 3.9×10 13 CFU / mL).

[0032] (1) After centrifuging 50 mL of Lactobacillus San Francisco Ls-1001 fermentation liquid, the sludge was dissolved in tap water, then 30 g of wheat flour was added and stirred into batter, and fermented at 28-32 °C for 12 h to prepare seed batter.

[0033] (2) Add 4 g of Angel high-active dry yeast and 370 g of wheat flour to the seed batter, stir to form a dough, ferment (28~32°C, 60 minutes), proof for 30 minutes before putting into the pot, and steam for 30 minutes.

[0034] The moisture content of steamed bread was determined to be 37.49%.

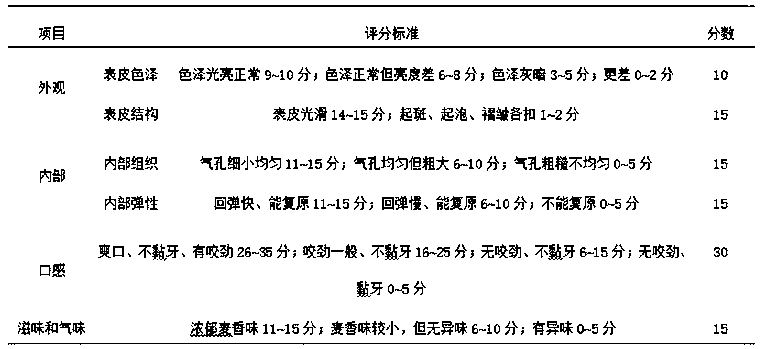

[0035] The sensory scores measured at 0 h, 24 h, and 48 h were: 71 points, 65 points, and <40 points, respectively. The dough of the steamed buns at 0 h was hard, and the steamed buns had no obvious smell, tasted sweet, chewed hard and ...

Embodiment 2

[0037] Ingredients: 400 g of wheat flour; 4 g of Angel’s highly active dry yeast; 100 mL of Lactobacillus San Francisco Ls-1001 fermentation broth (the number of colonies is 3.9×10 13 CFU / mL).

[0038] The preparation method of this embodiment is the same as that of Example 1, and the moisture content of the steamed bread is determined to be 35.56%.

[0039]The sensory scores measured at 0 h, 24 h, and 48 h were: 90 points, 80 points, and 68 points, respectively. The dough at 0 h is soft, the steamed buns have the aroma of old noodles, they rebound quickly and can be restored, the pores in the longitudinal section are small and uniform, the taste has obvious fermentation aroma, it is easy to chew, the moisture is moderate, and the skin of the steamed buns is soft and delicious. It began to harden, and the inside was relatively soft; after 48 hours, the skin of the steamed bread was obviously aging, and the inside began to lose slag.

Embodiment 3

[0041] Ingredients: 400 g of wheat flour; 4 g of Angel high active dry yeast; 150 mL of fermentation broth of Lactobacillus San Francisco Ls-1001 (the number of colonies is 3.9×10 13 CFU / mL).

[0042] The preparation method of this embodiment is the same as that of Embodiment 1, and the moisture content of the steamed bread is determined to be 32.63%.

[0043] The sensory scores measured at 0 h, 24 h, and 48 h were 84 points, 80 points, and 70 points, respectively. The dough at 0 h was extremely soft and viscous, and the steamed buns were soft with less water content and had a greater sour taste, and the air pores increased significantly compared with the second group; at 24 h, the sour taste of the steamed buns decreased, but the steamed buns were still soft; Less, but there is no significant difference between the softness and the second group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com