Pearl powder artificial bone supporting material with multi-stage micro-nano structure and technique for producing the same

A scaffold material and pearl powder technology, applied in medical science, prosthesis, etc., can solve the problems of poor material plasticity and formability, poor porosity and connectivity, and loss of activity of active ingredients, and achieve improved biocompatibility and good Biocompatibility, regeneration-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

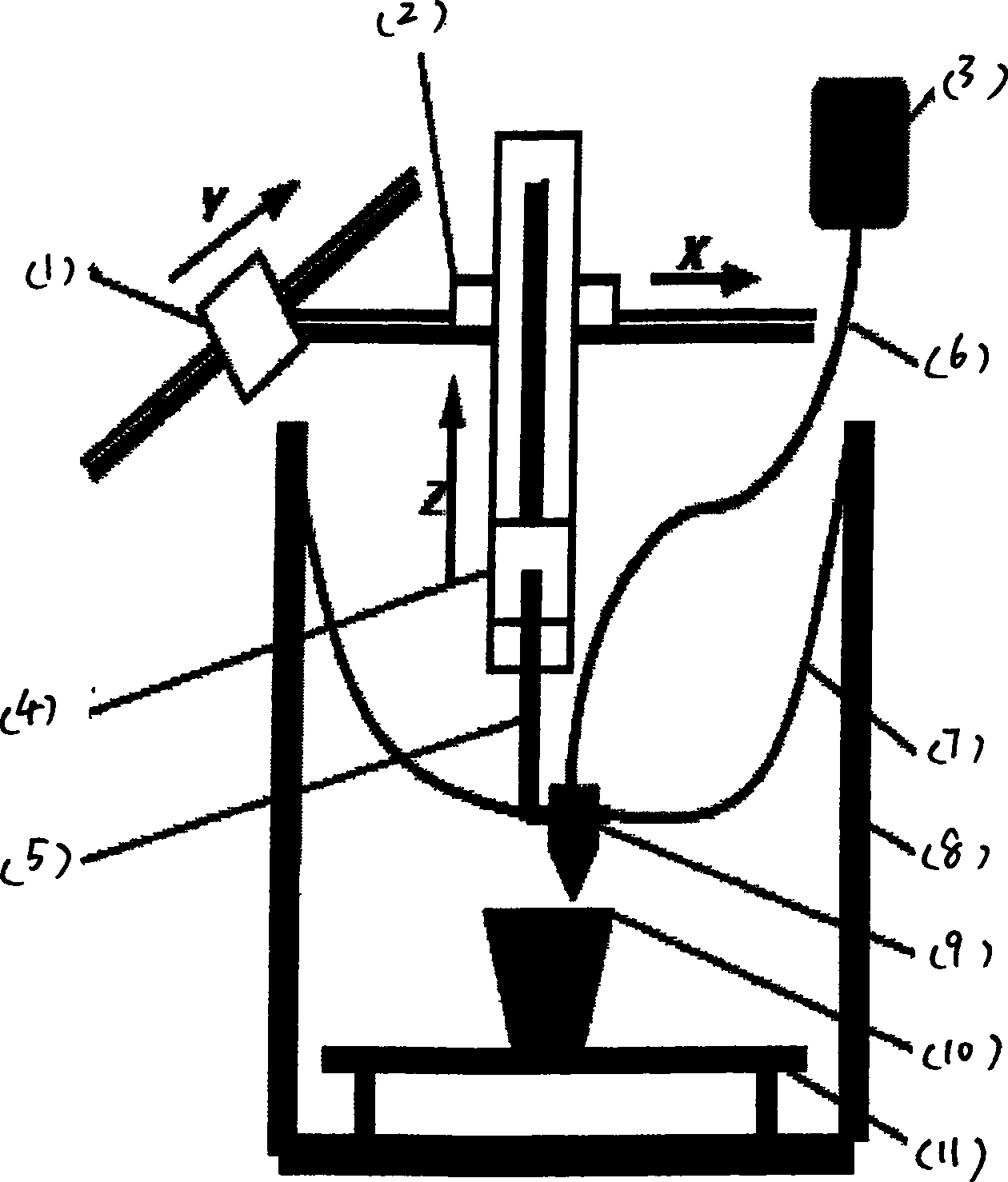

Method used

Image

Examples

Embodiment 1

[0037] Take pearl powder (Zhejiang Shanxia Lake Pearl Group), and use a vibrating sieve to sieve it with -2000 mesh and +3000 mesh to obtain pearl powder with a diameter of 1 μm-10 μm, and then degrease the pearl powder with 1:1 chloroform / methanol for 12 hours ; Soak in PBS+NaOH+NaN3 mixed solution for 12 hours at 37°C and rinse with triple distilled water; 200g / L H at 37°C 2 o 2 Soak for 6 hours to partially deproteinize; rinse with triple-distilled water for 6 times, put in a constant temperature drying oven at 37°C to dry; seal the package, and sterilize with cobalt 60 for later use.

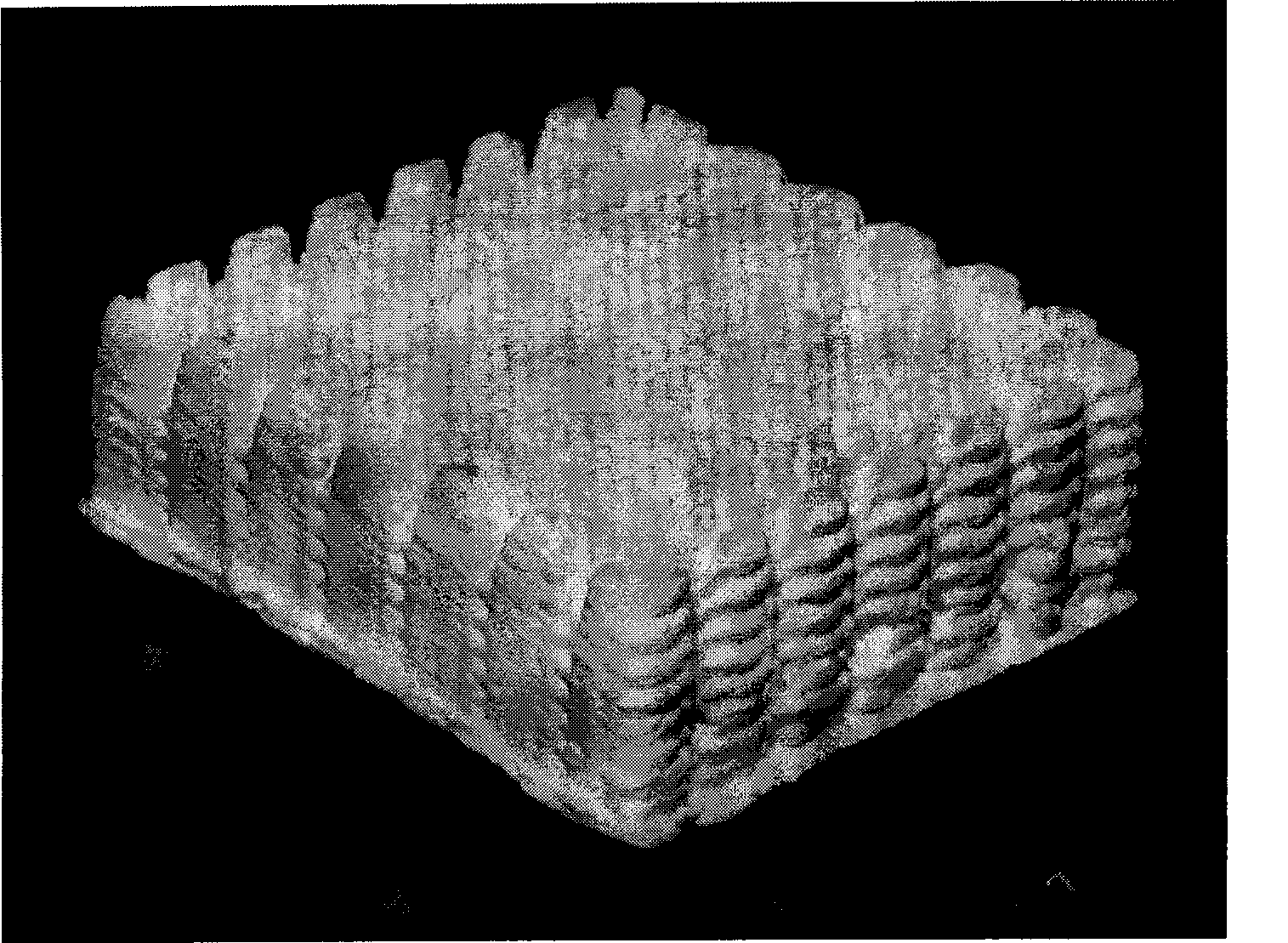

[0038] PLGA / PLA (3:1) was dissolved in 1,4-dioxane (Shanghai Chemical Reagent Purchase and Supply Wulian Chemical Factory, analytically pure) organic solvent according to the concentration of 15% (w / v), stirred and dissolved at 40°C, The cloud point of the formed liquid-liquid phase separation system is 28°C; add pearl powder according to the ratio of PLGA / PLA: pearl powder=70 / 30 (w / w) to p...

Embodiment 2

[0042] Take pearl powder (Zhejiang Shanxia Lake Pearl Group), and sieve it with a vibrating sieve with 2000 meshes to obtain pearl powder with a diameter of 3-6 μm, and then degrease the pearl powder with 1:1 chloroform / methanol for 12 hours; 37°C PBS+NaOH +NaN3 mixed solution soaked for 12h and then rinsed with triple distilled water; 37°C 200g / L H 2 o 2 Soak for 24 hours to completely deproteinize; rinse with triple-distilled water for 6 times, put in a constant temperature drying oven at 37°C to dry; seal the package, and sterilize with Co60 irradiation for later use.

[0043] Configuration 1, the mixed solution of 4-dioxane (Shanghai Chemical Reagent Purchase and Supply Wulian Chemical Factory, analytically pure) and water, wherein the content of water in the mixed solution is 5% (V 水 / V 总 ). PLGA / PLA (4:1) was dissolved in the mixed liquid at a concentration of 15% (w / v), stirred and dissolved at 40°C; pearls were added according to the ratio of (PLGA+PLA) / pearl powder...

Embodiment 3

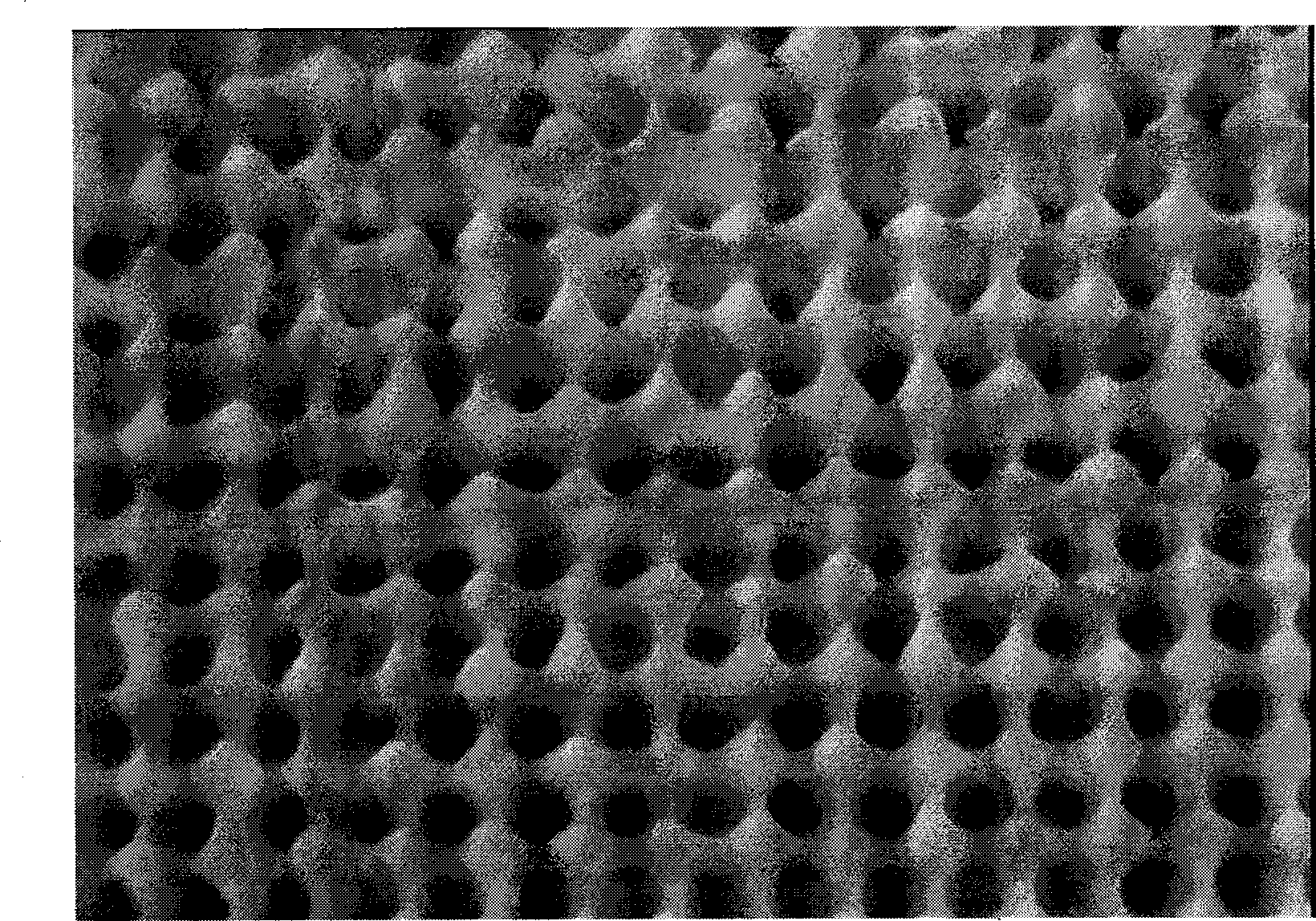

[0047] Get the composite material scaffold prepared in Example 1 and New Zealand white rabbit bone marrow mesenchymal stem cells (MSCs), and co-culture them in a three-dimensional cell / tissue culture system (RCCS TM , NASA), cultured for 10 days, fixed with glutaraldehyde at 4°C, fixed with acetic acid at 4°C for 1h, double stained with uranyl acetate-lead citrate, and observed the structure with a scanning electron microscope (Figure 3). It shows that the cells grow, proliferate, and migrate well in the three-dimensional scaffold structure. The cells stretch in a certain direction in the three-dimensional space, and form a network structure in the pores, leaving channels for nutrients to pass through.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com