Patents

Literature

61results about How to "Form contributes to" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphorus-free corrosion and scale inhibitor

InactiveCN101607763AReduce dosagePlay a role in corrosion inhibitionTreatment using complexing/solubilising chemicalsChelationPrecipitation types

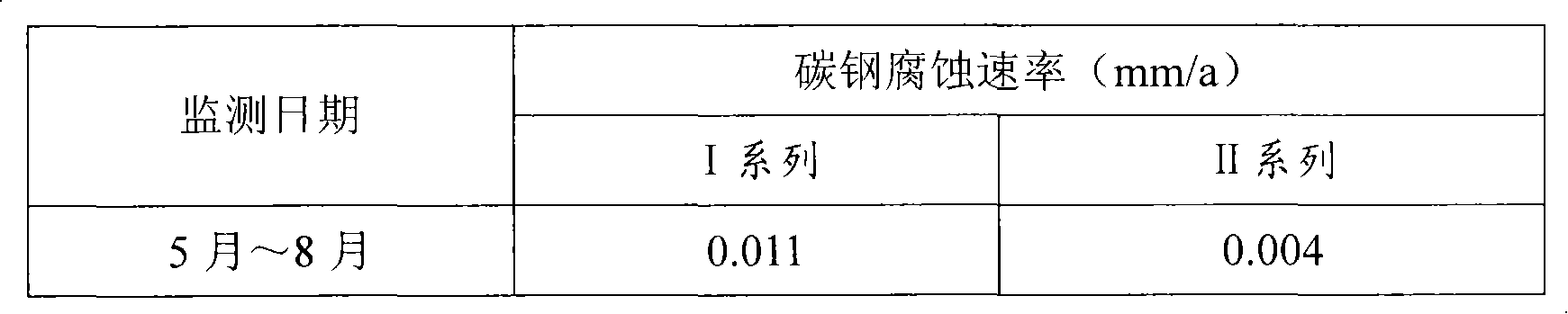

The invention relates to a phosphorus-free corrosion and scale inhibitor, which is prepared from sodium molybdate, zinc salt, citrate, triethanolamine, benzotriazole (BTA), polyaspartic acid (PASP), polyepoxysuccinic acid (PESA), AA / AMPS terpolymer, solid alkali and water. The phosphorus-free corrosion and scale inhibitor inhibits corrosion of metals by forming oxidization type and precipitation type films on the surfaces of the metals, has the effect of inhibiting scale through chelation and dispersive action on salts causing scale in cooling water, is non-toxic and phosphorus-free, has easily biodegradable major organic compositions, does not cause environmental pollution and is not limited by phosphorus in emission.

Owner:SHANGHAI WEILAI ENTERPRISE

Novel preparation method of mesoporous active carbon

InactiveCN103359729AStrong ability to dissolve biomassImprove abilitiesCarbon compoundsBulk chemical productionCarbonizationReaction temperature

The invention discloses a novel preparation method of mesoporous active carbon. The novel preparation method comprises the step that carbohydrate, wood or bamboo as raw materials undergo a reaction in the presence of an acidic ionic liquid as an ion heat carbonization solvent and a catalyst; and the reaction product is activated by CO2 to form the mesoporous active carbon. The mesoporous active carbon has a specific surface area of 289-469m<2> / g and an aperture size of 3.55-3.62nm. The mesoporous active carbon has a rod-shaped, spherical or membrane-shaped structure because of different surfactants. The ionic liquid has a strong biomass dissolution capability, does not volatilize, can be recovered easily and has good heat stability. The ion heat carbonization reaction is adopted so that a reaction temperature is low; pressurization is avoided; and operation is simple. The mesoporous active carbon can be used in fields of environmental protection, energy storage, catalysis, foods and medicine.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

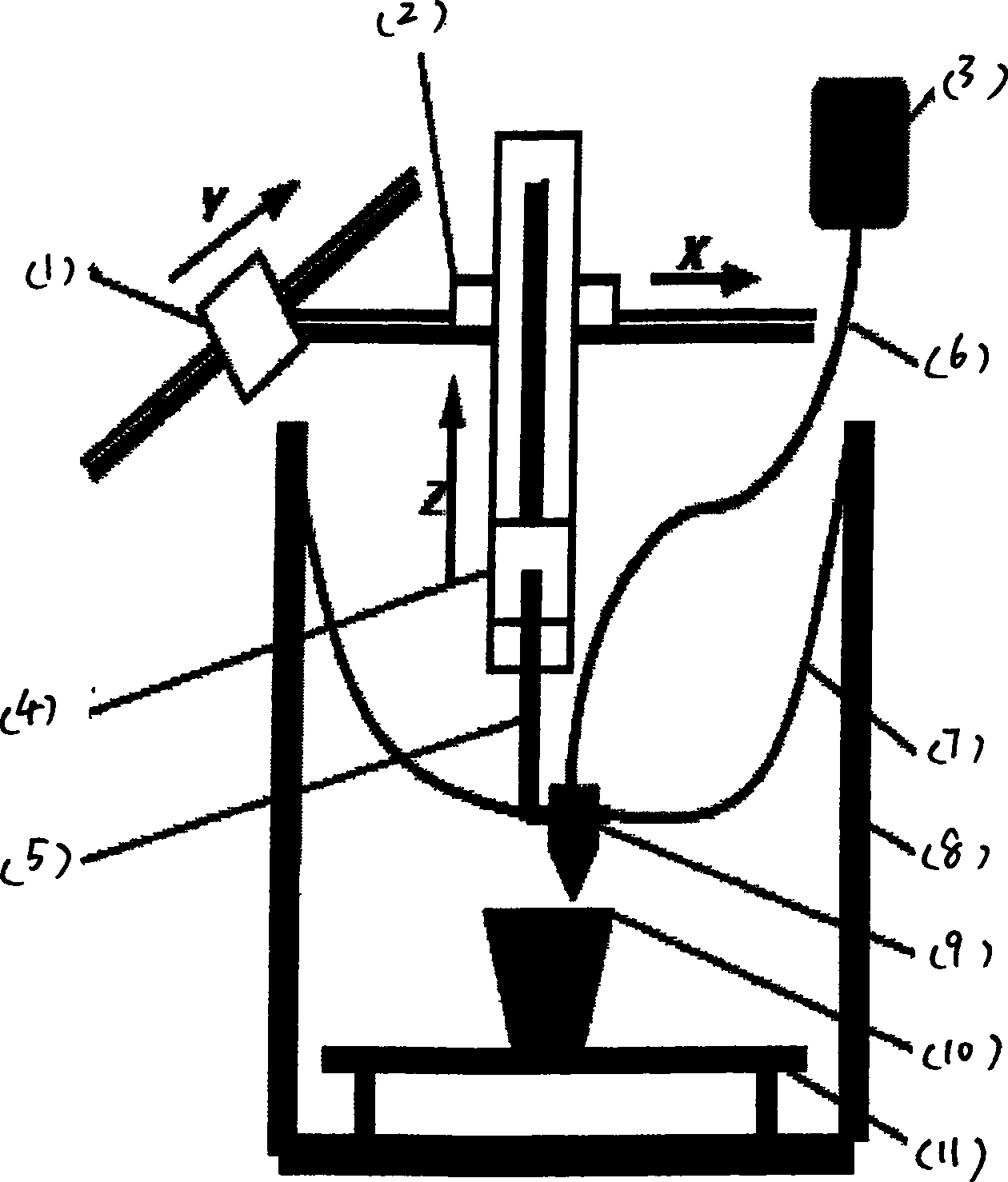

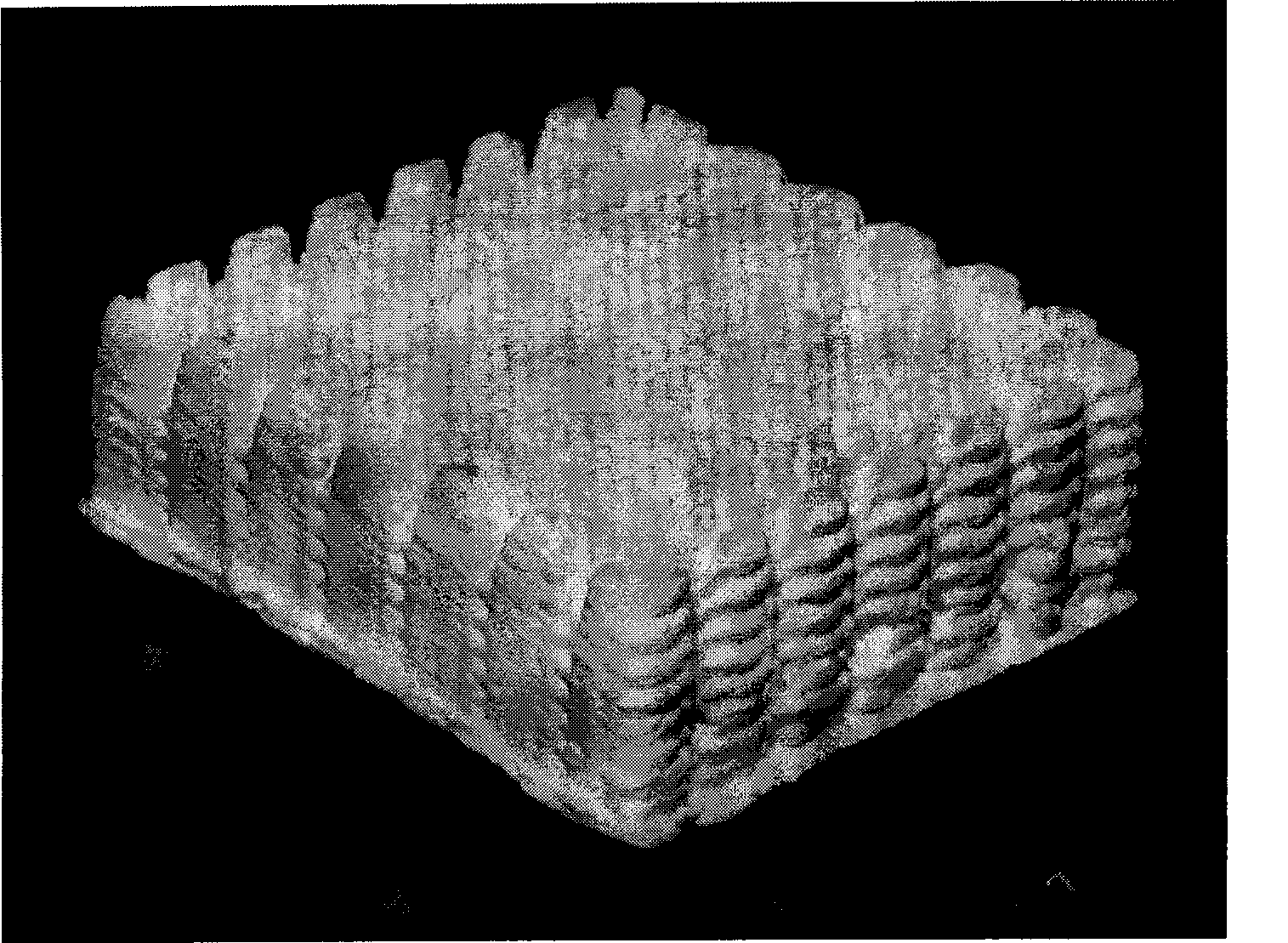

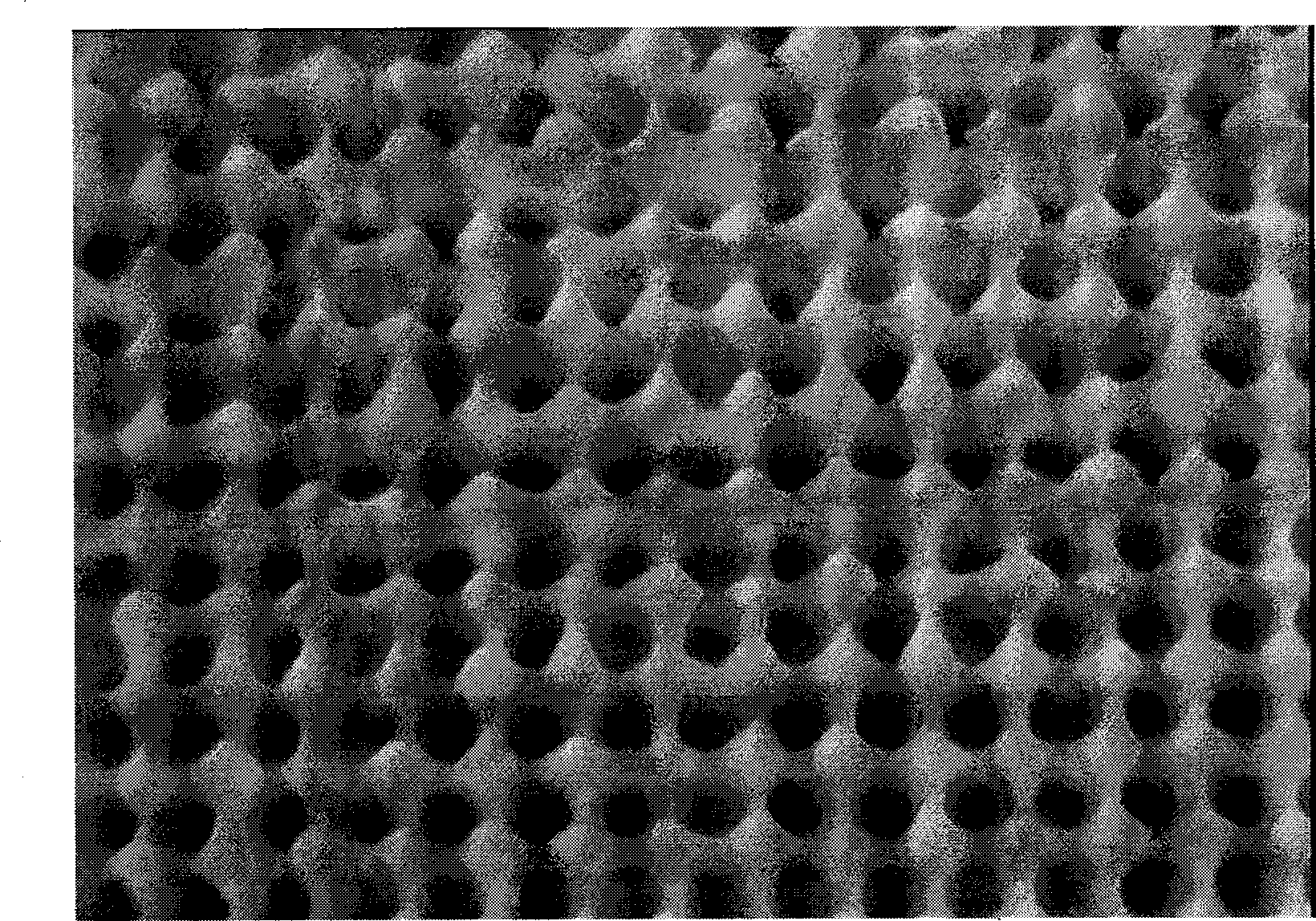

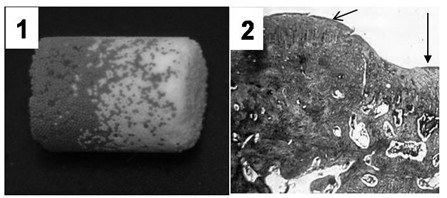

Pearl powder artificial bone supporting material with multi-stage micro-nano structure and technique for producing the same

The invention relates to a novel biological scaffold material for bone repair and a preparation method thereof. PLGA and PLA with a mass ratio of 1: 1-10: 1 are dissolved into chloroform, dimethyl sulfoxide, 1, 4-dioxane or a mixed liquid of the 1, 4-dioxane and ultrapure water, and then pearl powder which is subjected to partial or complete deproteinization treatment is added into the obtained product according to the proportion of the PLGA / a PLA mixture to the pearl powder (mass ratio) is 1: 1-10: 1 to obtain forming slurry. A three-dimensional scaffold with high porosity and connectivity rate is designed through a 3D software, and then a low-temperature rapid forming system is utilized to ensure that the three-dimensional scaffold is formed to obtain a scaffold with a microporous structure. An artificial bone biological scaffold material prepared by the method has a three-dimensional scaffold structure that a macroscopic structure has aperture channels with diameters of between 100 and 500mu m and a microstructure has micropores with diameters of between 10 and 20mu m, wherein micron pearl powder is dispersedly distributed on walls of the micropores. The porosity is between 60 and 90 percent, and a macroporous structure is perforated in three directions of X axis, Y axis and Z axis, and has 100 percent of connectivity.

Owner:REGENOVO BIOTECH

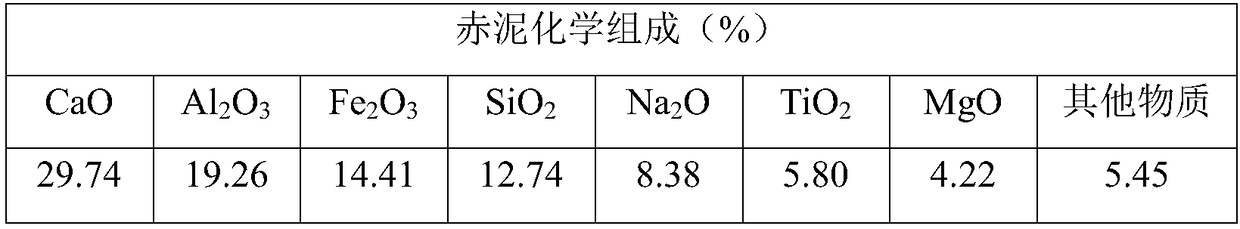

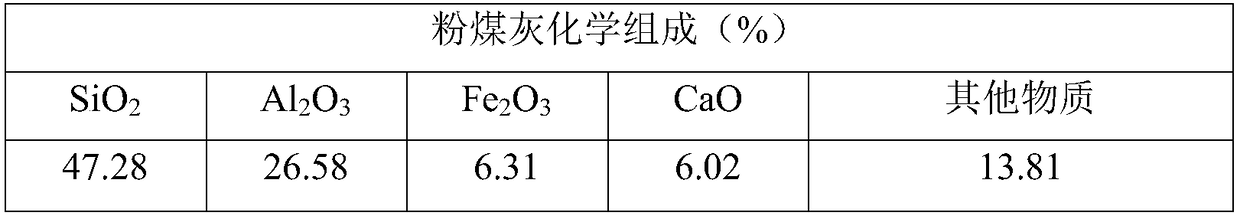

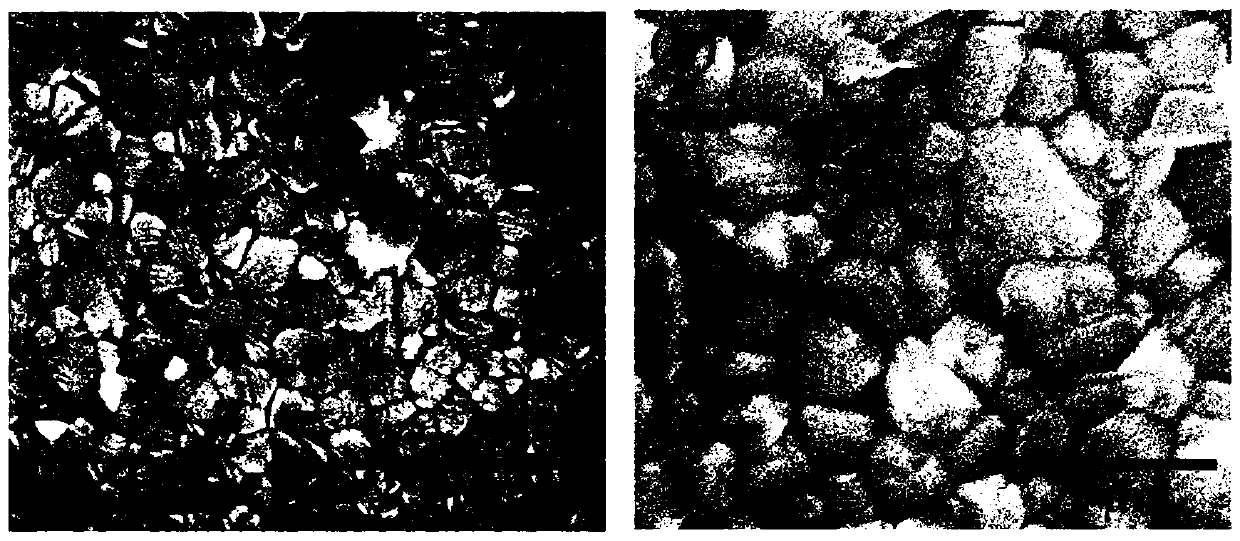

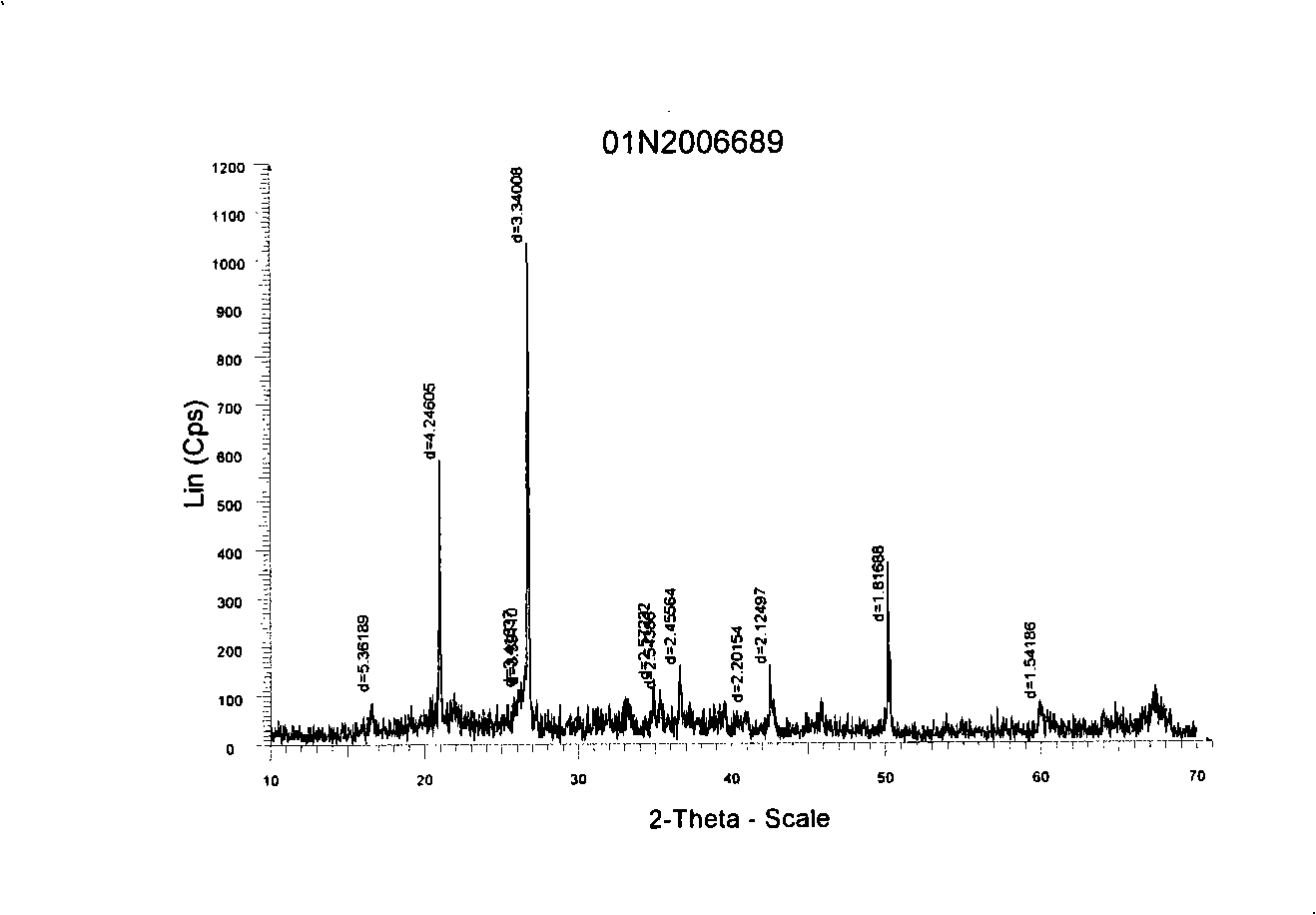

Method for preparing porous granular composite material from red mud and fly ash as raw materials

ActiveCN108264279AHigh activityHigh strengthSolid waste managementOther chemical processesPrillRed mud

The invention provides a method for preparing a porous granular composite material from red mud and fly ash as raw materials. The method utilizes cement waste as a binder and comprises uniformly mixing fly ash, red mud and the binder according to a mass ratio of fly ash to red mud of 10-30% and a mass ratio of the binder of less than or equal to 5%, carrying out granulation through a granulator toobtain raw material particles with the uniform diameters of 5-8mm, adding the raw material particles into a microwave activation reactor with the unit mass power of 5 to 20w / g, feeding water vapor into the microwave activation reactor, carrying out activation for 15-30min, and carrying out cooling at the room temperature to obtain the porous granular composite material. CaO in the red mud can promote the excitation of the fly ash activity. Through microwave heating, a part of metal oxides and silicon oxide in the red mud and fly ash can increase the particle material strength. The fly ash contains unburned carbon and through the microwave activation, the specific surface area of the particles is increased and the porous structure is formed. The produced porous granular composite materialhas the advantages of large specific surface area, strong adsorption property, good temperature resistance stability, simple processes, low energy consumption and environmental friendliness.

Owner:CHINA UNIV OF MINING & TECH

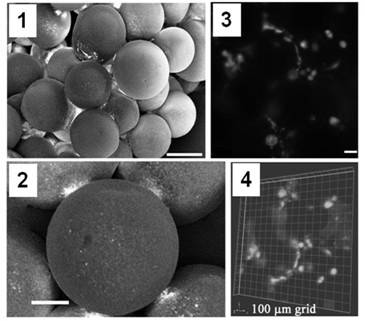

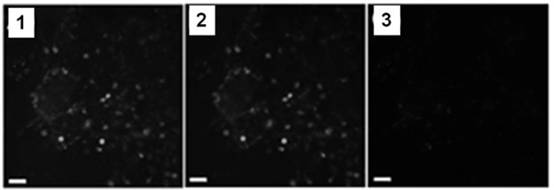

Poly(lactic-co-glycolic acid)-based growth factor gradient release microsphere stent as well as preparation method and application thereof

The invention provides a poly(lactic-co-glycolic acid)-based growth factor gradient release microsphere stent. The microsphere stent is prepared by a method comprising the following steps: firstly, preparing a poly(lactic-co-glycolic acid) (PLGA) homogeneous microsphere and a transforming growth factor (TGF)-beta3 and bone morphogenetic protein (BMP)-2 / PLGA microsphere; dispersing the two microspheres into ddH2O to prepare suspension; injecting the suspension into a die with a filter device at the bottom; filtering by adopting the ddH2O, and regulating the position of the ddH2O in the die; accumulating the microspheres in the die; and sintering the microspheres by adopting absolute ethanol. According to the microsphere stent prepared in the invention, the original excellent biocompatibility of the PLGA is maintained, and the mechanical performance, osteochondral induction effect and seed cell carrying capability of the microsphere stent are remarkably improved. The microsphere stent has excellent biocompatibility, can carry an enough amount of seed cells, and is used for treatment of osteochondral defects caused by tumors, trauma, severe sepsis, congenital malformation and other various diseases.

Owner:赵亮

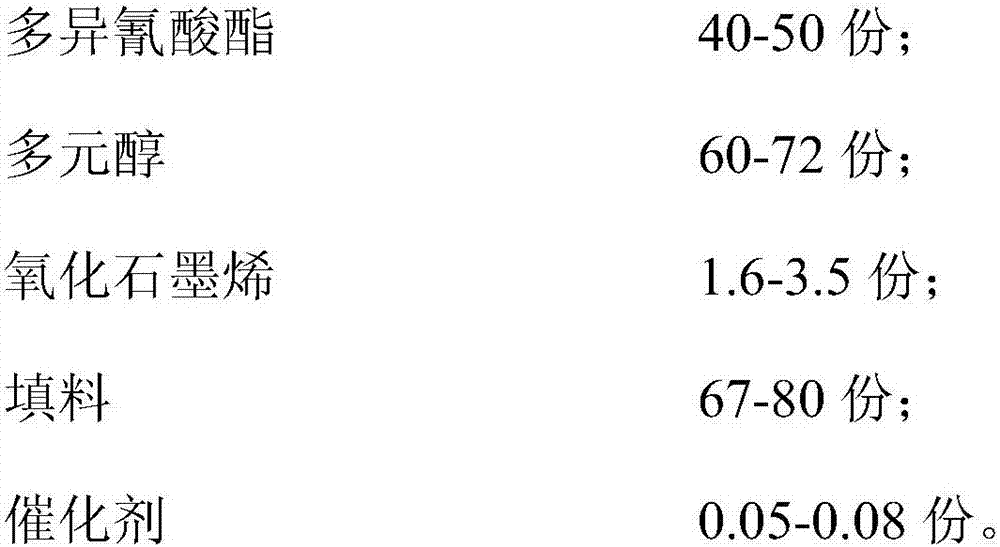

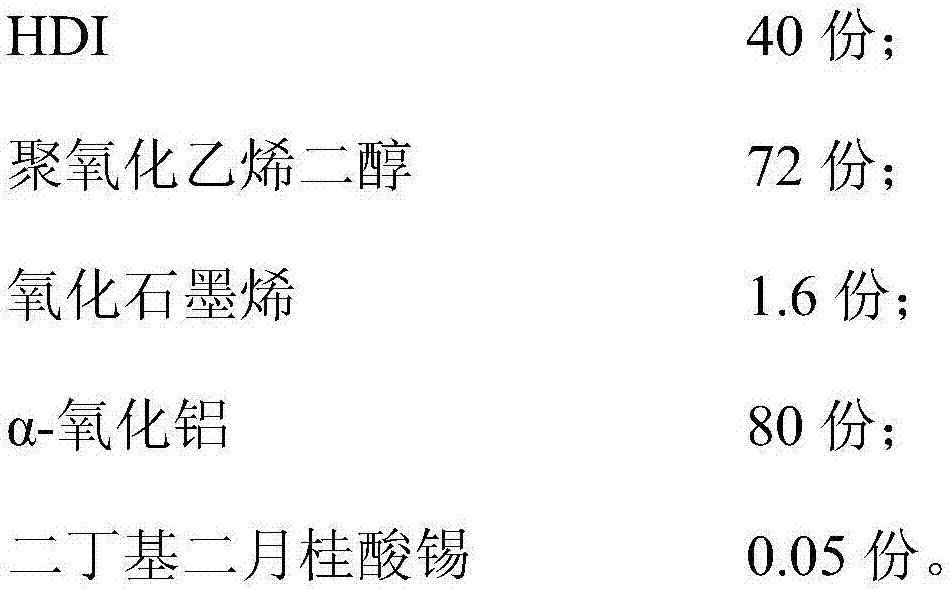

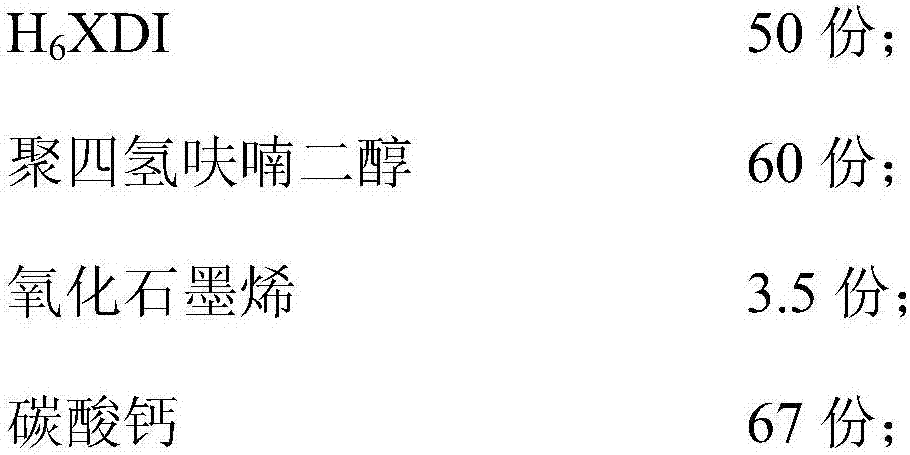

Anti-static polyurethane pouring sealant and using method thereof

ActiveCN107474782ALarge specific surface areaImprove adsorption capacityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAlcoholStatic performance

The invention provides an anti-static polyurethane pouring sealant and a using method thereof. The anti-static polyurethane pouring sealant comprises the following components in parts by weight: 40 to 50 parts of polyisocyanates, 60 to 72 parts of polyhydric alcohols, 2 to 2.4 parts of oxidized graphene, 67 to 80 parts of a filler and 0.05 to 0.08 part of a catalyst. The using method comprises the following steps: after all components of the anti-static polyurethane pouring sealant are mixed, pouring an object to be poured, and then curing the object to be poured at the temperature of 20 to 30 DEG C for 24 to 48 h to form a sealant block. The anti-static polyurethane pouring sealant provided by the invention has good mechanical performance after being cured, has relatively high insulation performance and anti-static performance, and is particularly applicable for pouring of electrical apparatus elements.

Owner:驻马店进化伙伴机器人有限公司

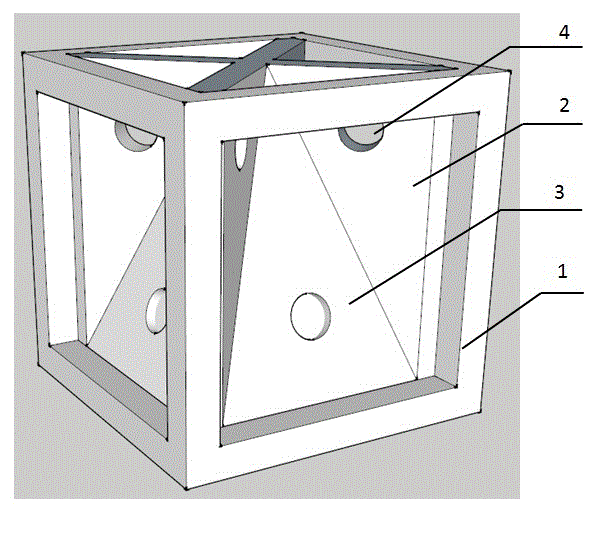

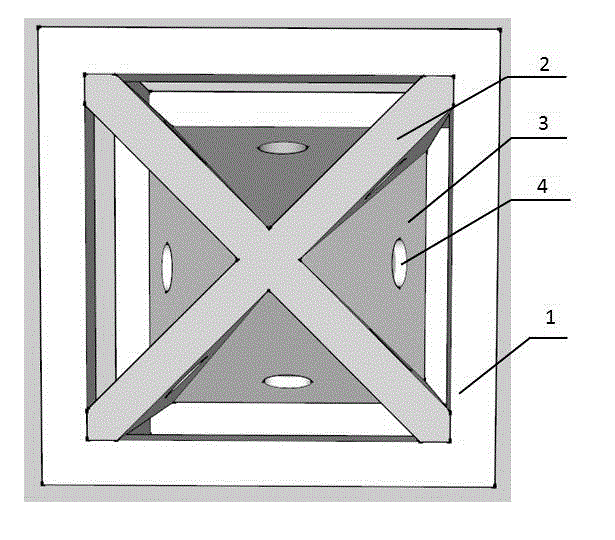

Rising streaming artificial fish reef

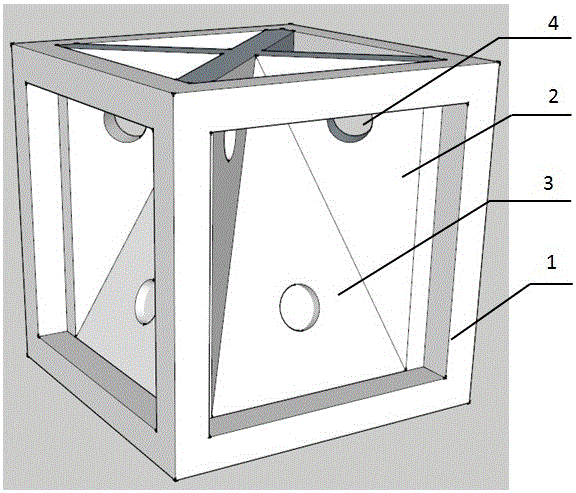

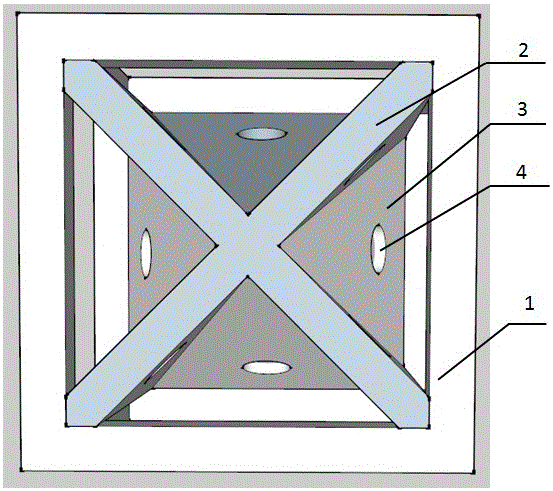

InactiveCN104521839AForm contributes toPromote exchangeClimate change adaptationPisciculture and aquariaRight triangleEngineering

The invention relates to a rising streaming artificial fish reef. The rising streaming artificial fish reef is composed of a cube frame, right triangle plates and isosceles triangle plates, the inner side of each upright post of the cube frame is provided with a right triangle plate, the upper edges of four groups of the right triangle plates with a same specification are connected in a cross shape at the top surface center of the cube frame, the inner side of each bottom edge of the cube frame is provided with an isosceles triangle plate, point angles of four groups of the isosceles triangle plate with a same specification are intersected at the top surface center of the cube frame to form a rectangular pyramid structure, each side of the rectangular pyramid is connected with the hypotenuse of the right triangle plate at the inner side of each upright post of the cube frame, and open pores are formed in the right triangle plates and the isosceles triangle plates. The rising streaming artificial fish reef has the advantages of rising streaming effect and remarkable stability performance.

Owner:SHANDONG UNIV

Carbon nanotube-filled silicon/hollow carbon composite negative electrode material and preparation method thereof

ActiveCN109585801ABuffer volume expansionPrevent infiltrationMaterial nanotechnologyCell electrodesCarbon compositesCarbonization

Disclosed are a carbon nanotube-filled silicon / hollow carbon composite negative electrode material and a preparation method thereof. The composite negative electrode material is of a core-shell structure, wherein the core is a carbon nanotube cluster inlaid with silicon particles, and the shell is pyrolytic carbon. The preparation method comprises the following steps of uniformly mixing silicon particles, a metal catalyst and organic matters, and carrying out negative pressure heat treatment under a protective atmosphere to prepare the silicon / carbon nanotube cluster, adding the silicon / carbonnanotube cluster into a carbon source precursor solution to be uniformly stirred, and carrying out solid-liquid separation and drying, grinding, and then carrying out high-temperature carbonization treatment, and then dispersing in a hydrochloric acid solution, dissolving the metal catalyst, and performing washing and drying, and drying to obtain the carbon nanotube-filled silicon / hollow carbon composite negative electrode material. The prepared silicon-carbon composite negative electrode material can be used for improving the rate performance and the cycling stability when the silicon-carboncomposite negative electrode material is used for a lithium ion battery, and is simple in preparation process, wide in raw material source and suitable for large-scale production.

Owner:湖南宸宇富基新能源科技有限公司

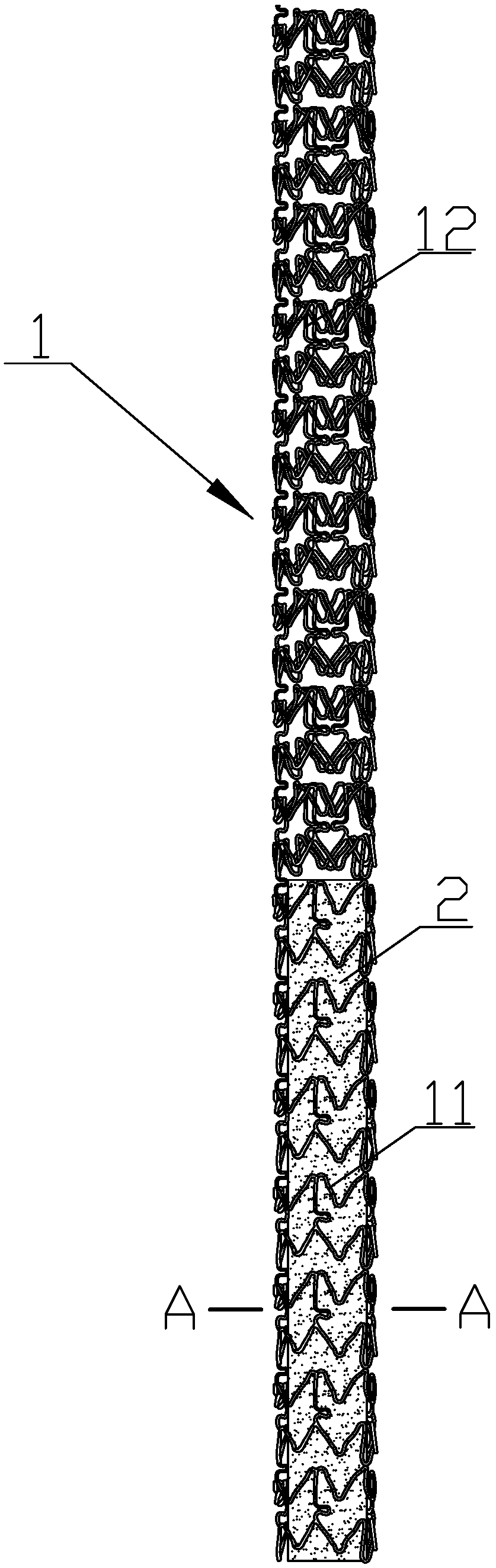

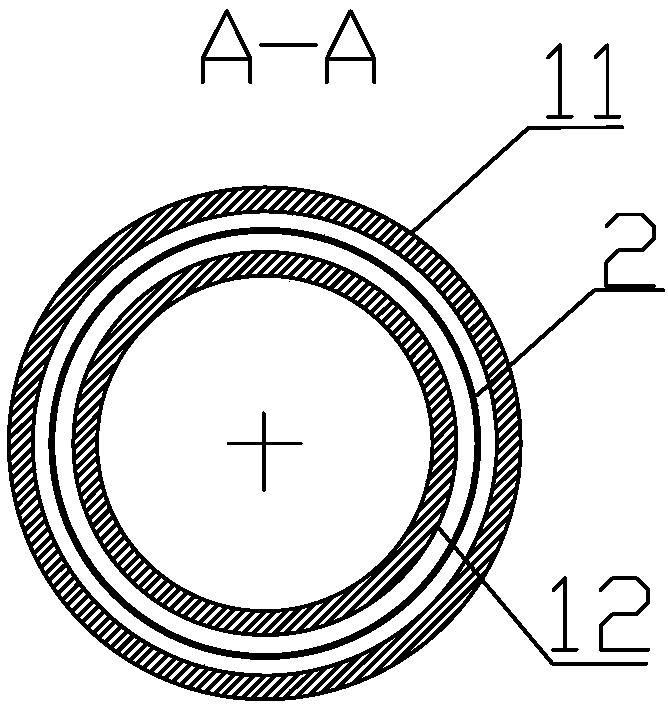

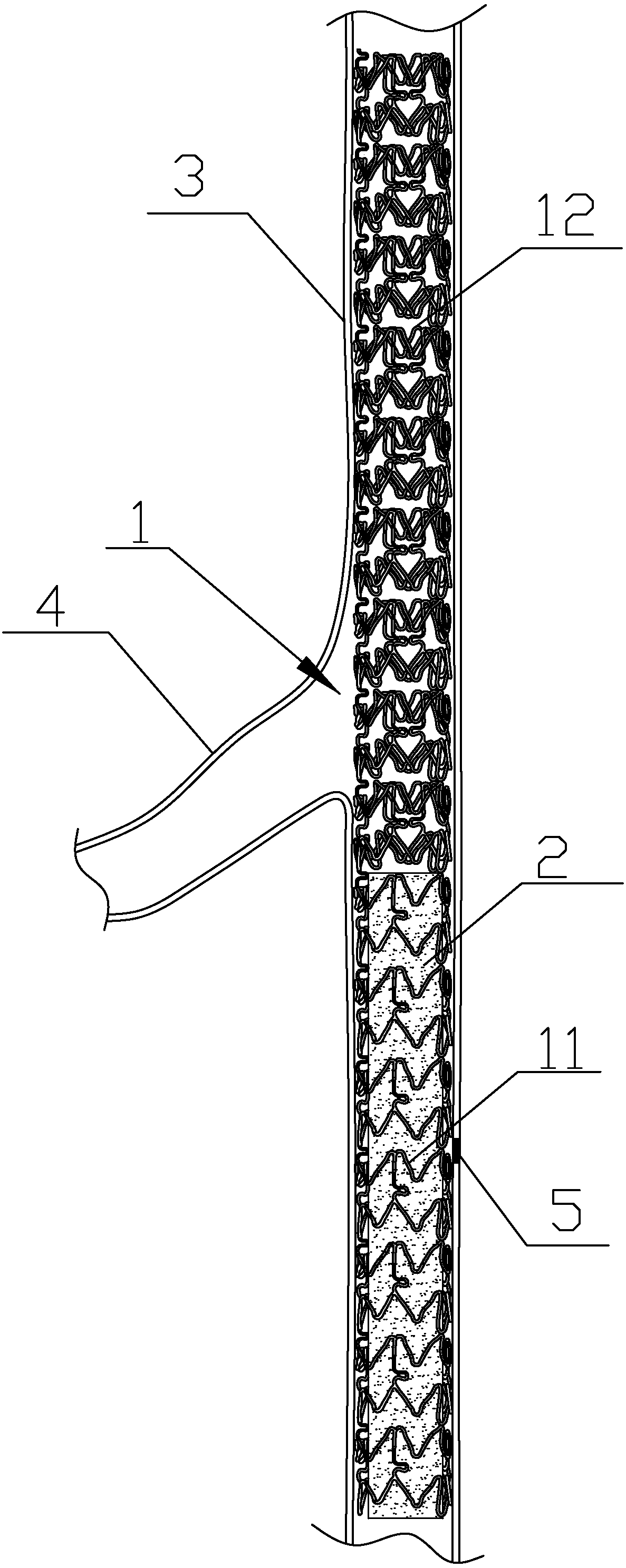

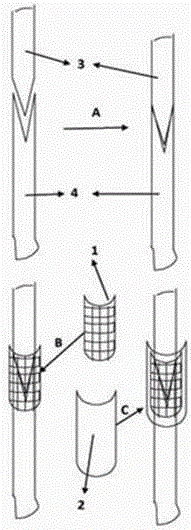

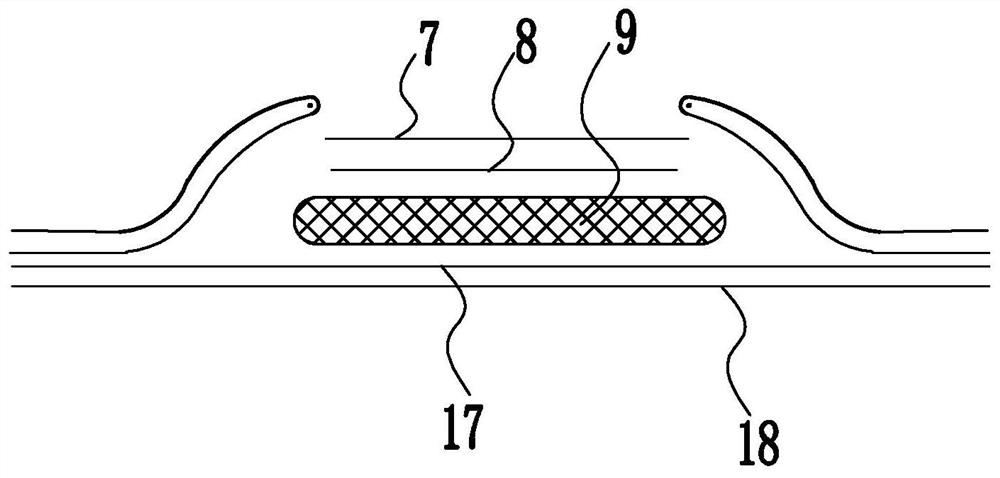

Partially covered stent used for treating bifurcation lesion coronary perforation and provided with biological absorption film

PendingCN108158701AAids in endothelializationAvoid blockageStentsMedical devicesInsertion stentThrombus

The invention relates to a partially covered stent used for treating bifurcation lesion coronary perforation and provided with a biological absorption film. The partially covered stent comprises a stent body composed of a tubular inner layer stent and a tubular outer layer stent, wherein the tubular inner layer stent and the tubular outer layer have identical length concentric line engraved nettedstructures, a tubular covering film is clamped between the inner layer stent and the outer layer stent, and the partially covered stent is characterized in that one end of the covering film is flushwith the stent body, and the length of the covering film accounts for 30-50% that of the stent body; the covering film is the biological absorption film; the biological absorption film is a poly-DL-lactic acid film. The partially covered stent has the advantages of being capable of covering a blood vessel perforation part to form a complete blood flow channel, effectively preventing closing and plugging of side branches, meanwhile easily realizing endothelialization in a stent body, and effectively reducing forming of thrombi.

Owner:TIANJIN CHEST HOSPITAL

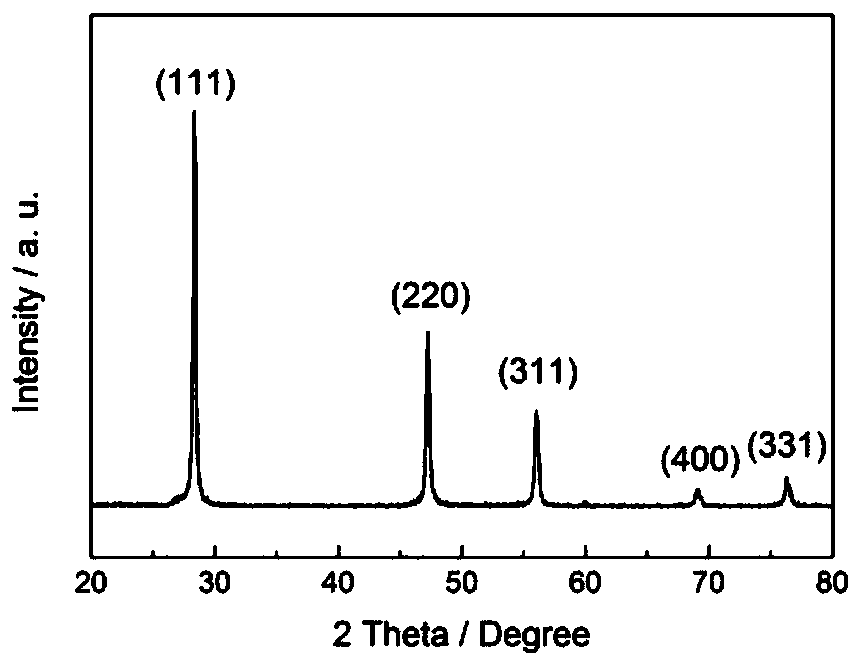

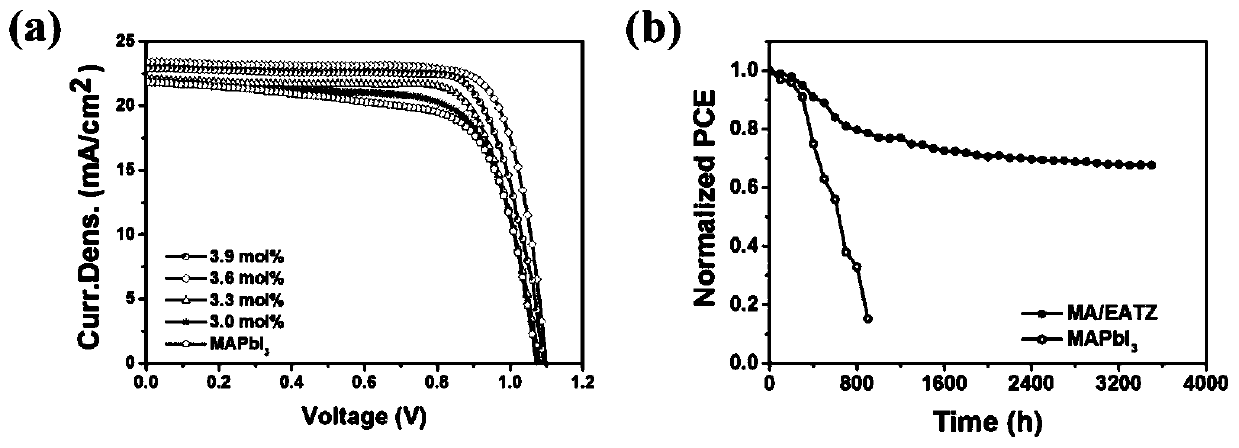

Triazole ionic liquid-doped perovskite solar cell and preparation method thereof

ActiveCN109817810AImprove hydrophilicityLow steam pressureSolid-state devicesSemiconductor/solid-state device manufacturingIonic liquidElectron

The invention relates to a triazole ionic liquid-doped perovskite solar cell and a preparation method thereof. According to the preparation method, [EATZ]I is added into a perovskite precursor MAI solution, and a light-absorbing layer film is prepred through a spin-coating method, which is called an MA / EATZ method (E represents ethyl) for short. Because -NH2 in ionic liquid contains lone pair electrons, the unsaturated Pb<2+> defects in perovskite films can be effectively passivated under the action of a Pb-N coordination bond, and charge recombination is inhibited; in addition, due to the formation of the Pb-N coordination bond, the probability is provided for the self-assembly behavior of hydrophilic ILs on the surface of the perovskite, so that alkyl chains in the ILs are almost vertically distributed along the surface of the perovskite, and the improvement of the humidity stability of the perovskite solar cell is successfully realized. Meanwhile, due to the excellent hydrophilic performance of the ILs, the hydrophilicity of the perovskite precursor solution on the surface of a titanium dioxide electron transport layer is improved, and crystal nucleus formation and crystal growth are facilitated. And the crystallization rate of the perovskite in the thermal annealing process is reduced, so that the growth of large-size crystal grains is caused.

Owner:RES & DEV INST OF NORTHWESTERN POLYTECHNICAL UNIV IN SHENZHEN +1

Band-aid used for grafting plants

InactiveCN105165422APromote formationThe promotion effect is obviousGraftingSterile waterRibbon gauze

The invention relate to the technical field of plant grafting, and particularly to a method for making and using a band-aid used for grafting plants. The method for making band-aid used for grafting plants is characterized in that, a waterproof protection film seals the periphery of upper and lower layers of cotton ribbon gauze which is saturated after being immersed in an immersion solution using a hot adhering method. The immersion solution is prepared from macroelement, microelement, ferric salt, an organic component, a hormone, a bactericide and sterile water, and the pH value of the solution is within the range from 5.7 to 6.0. The method for using the band-aid used for grafting plants comprising removeing the thin protection film on the upper layer of the band-aid to expose the ribbon gauze containing the immersion solution, tightly wrapping and covering a wound to be used for grafting, and winding the periphery of the outer layer of the band-aid using a binding film special for grafting to tightly wrapping the band-aid, so as to making the wound tightly closed in the binding film special for grafting. The band-aid used for grafting plants can induct callus of a wound, provide nourishment, prevent from pollution, moisturize and shade the wound, so as to facilitate healing of a grafting wound and raise the survival rate. The band-aid used for grafting plants is low in production cost, convenient to use and can widely applied to plant grafting.

Owner:ANHUI SCI & TECH UNIV

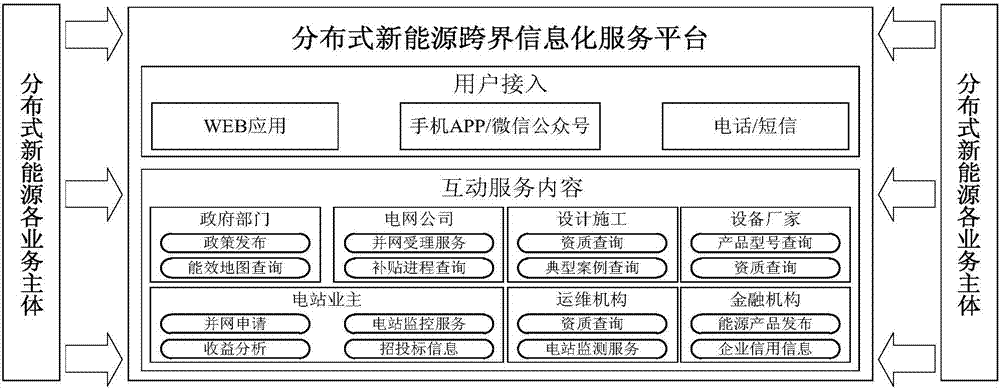

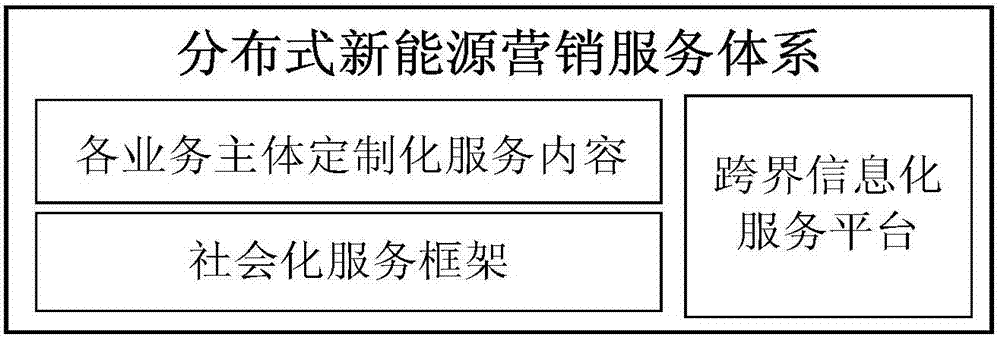

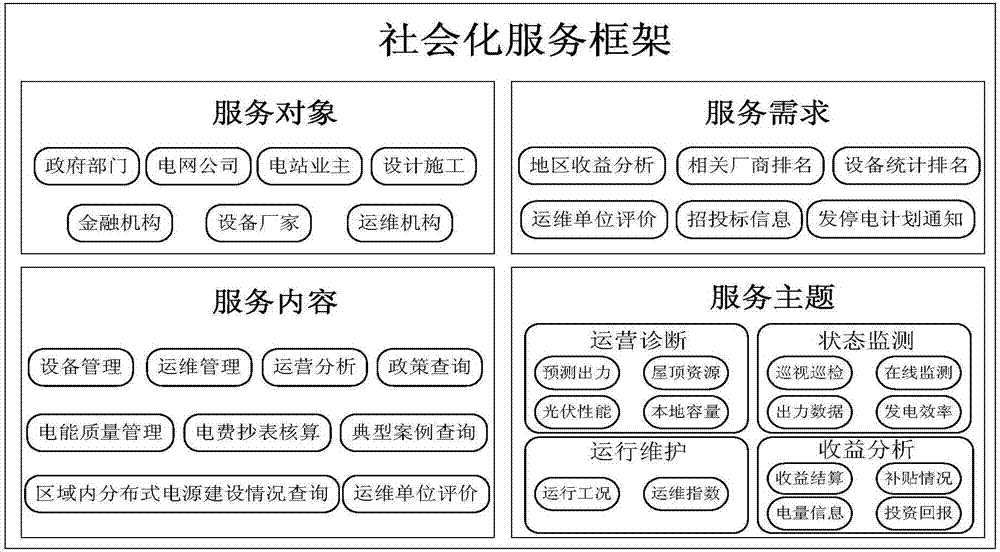

Distributed new energy service platform based on mobile Internet and construction method thereof

InactiveCN107133885AForm contributes toMeet differentiated needsData processing applicationsInformation technology support systemUniversal serviceNew energy

The invention discloses a distributed new energy service platform based on a mobile Internet and a construction method thereof. The platform comprises a universal service module, a customized service module and an interactive channel module. The universal service module includes universal service sub-modules corresponding to social main bodies, the social main bodies send service requests to the universal service sub-modules through a platform interface, and the universal service sub-modules provide corresponding services to the corresponding social main bodies on the basis of the service requests of the social main bodies. The customized service module includes multiple customized service sub-modules and a service push module. The customized service sub-modules push corresponding customized services to the corresponding social main bodies through the service push module. The interactive channel module is provided with corresponding interactive channels among the social main bodies of different kinds and among the social main bodies of the same kind. The platform can provide different data and services to various participating main bodies, enables the utilization rate of distributed new energy to be improved, and facilitates the development of distributed new energy.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +4

Low-activation bainitic steel applicable to neutron-irradiated environment and preparation method thereof

The invention discloses low-activation bainitic steel applicable to a neutron-irradiated environment and a preparation method thereof. A structural steel material has a matrix element of an element Fe, contains 2.5 to 3.5 percent (by weight) of Cr, 2.2 to 2.8 percent (by weight) of W, 0.2 to 0.25 percent (by weight) of V, 0.12 to 0.18 percent (by weight) of Ta, 0.40 to 0.80 percent (by weight) of Mn, 0.40 to 0.45 percent (by weight) of Si, 0.08 to 0.12 percent (by weight) of C and 0.01 to 0.05 percent (by weight) of N, and is suitably used in a fusion-reactor environment. Radioactive nuclides Mo, Ni, Cu, Nb and the like, which can be enabled to have long service life after being subjected to neutron irradiation, are strictly controlled in the componential formula of the steel, so as to guarantee that the low-activation bainitic steel applicable to the neutron-irradiated environment has a low-activation characteristic. A bainitic structural steel material has a favorable high-temperature property, particularly has a high-temperature croop property, can need no heat treatment after being welded, and is suitable for making large-sized components of a fusion-reactor vacuum container and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

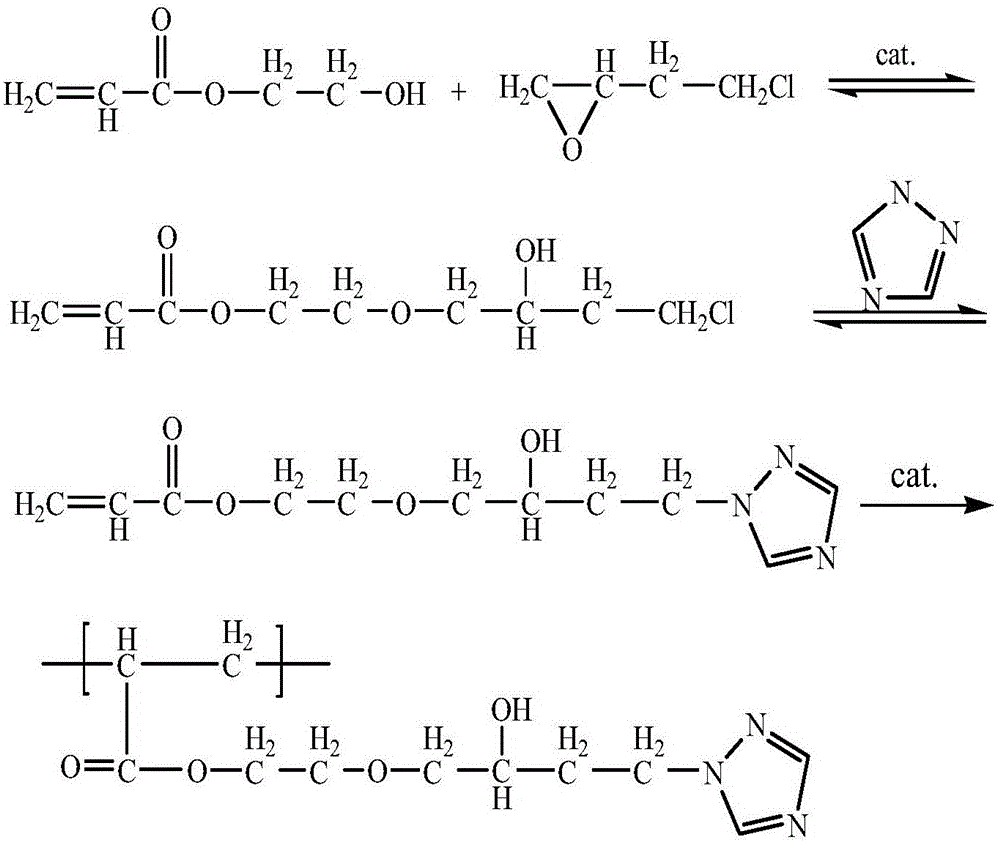

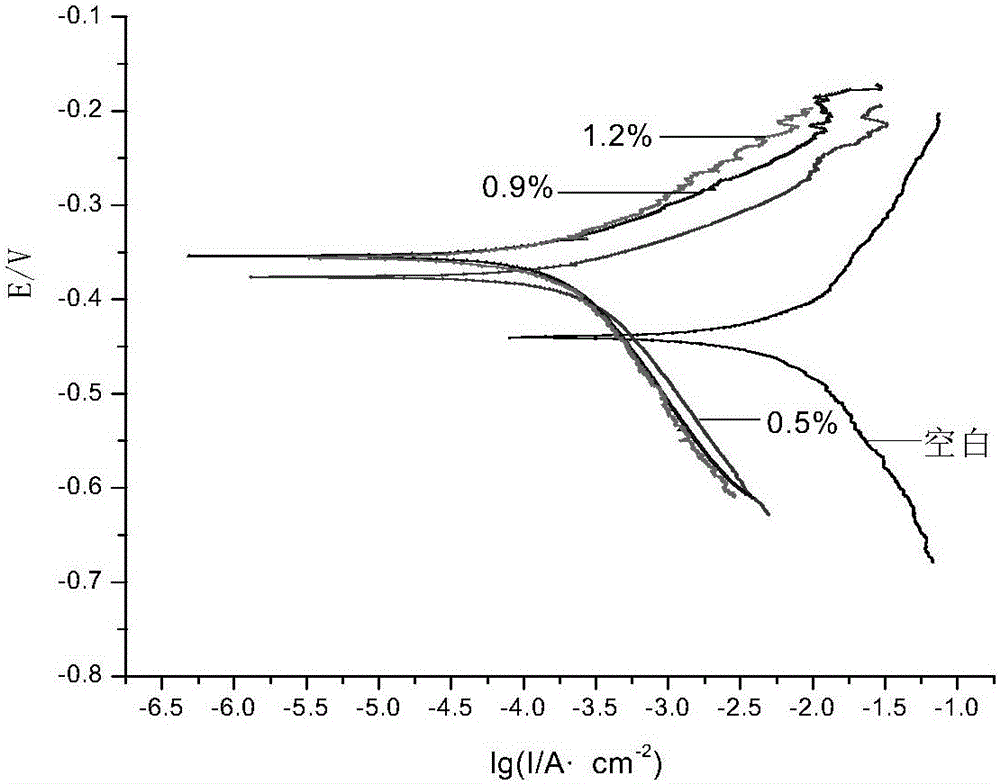

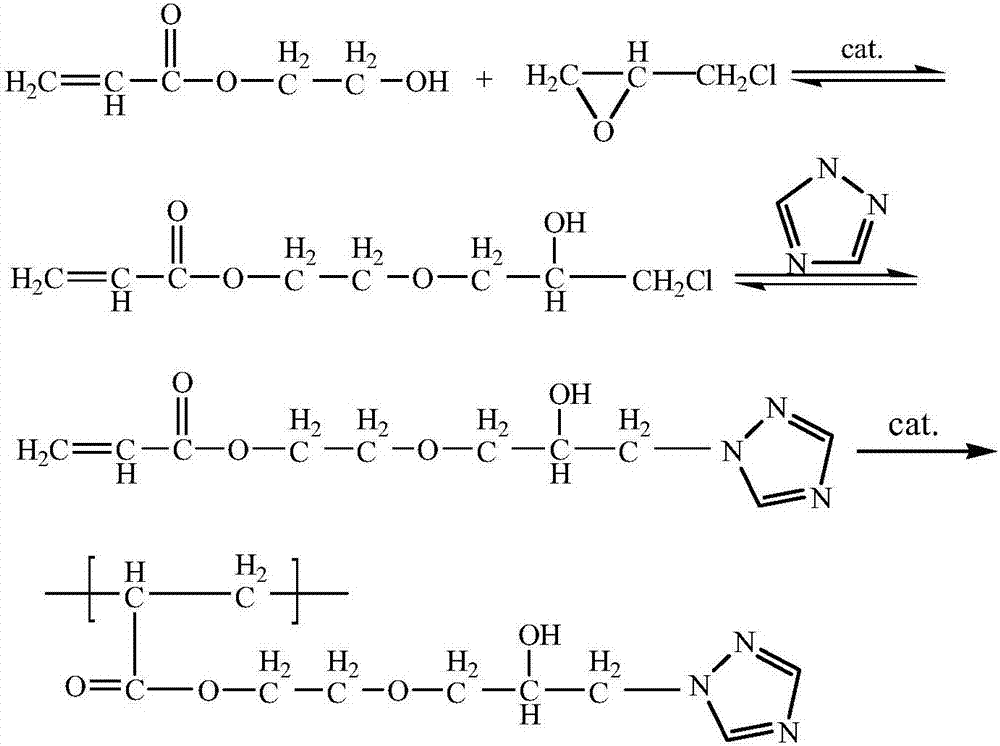

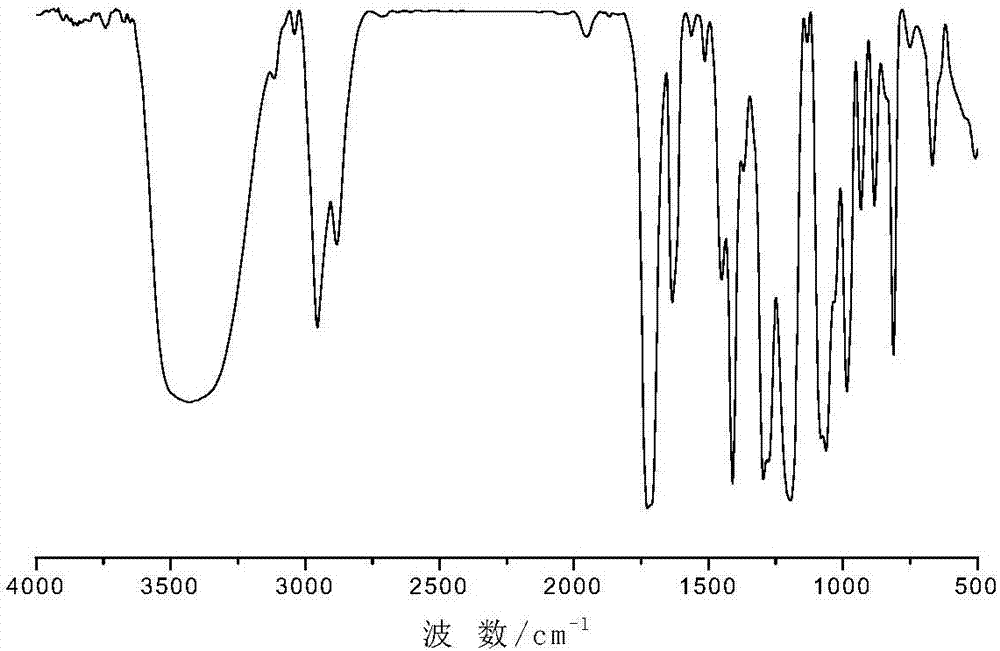

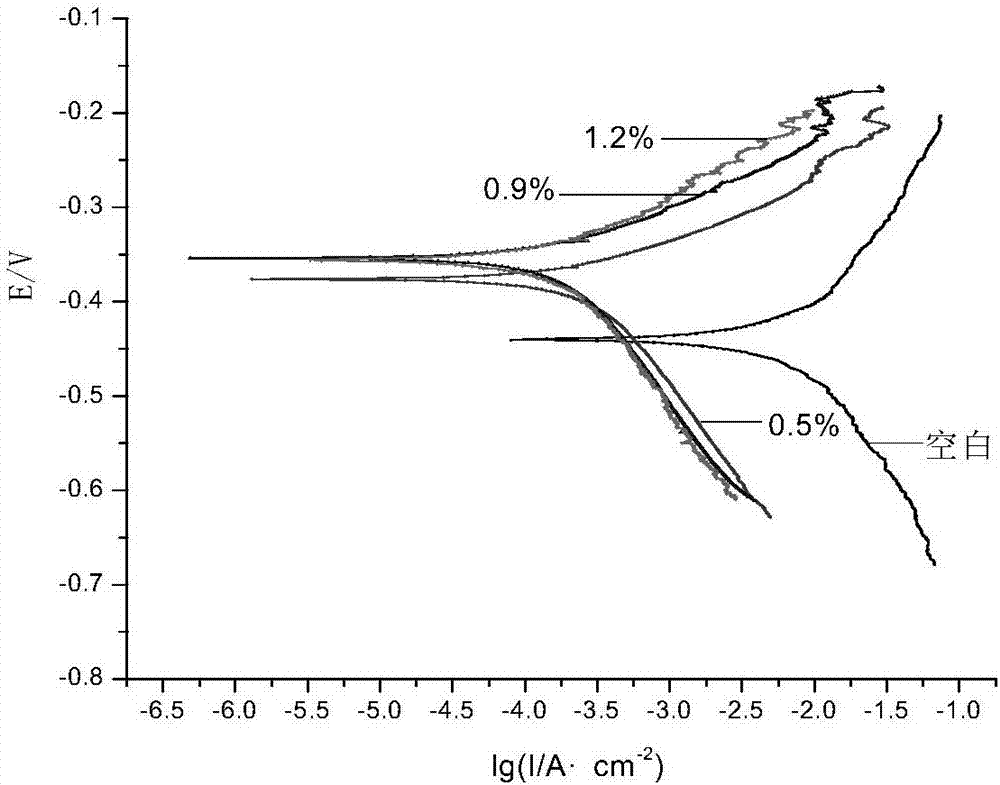

Polyvinyl triazole compound and preparation method thereof

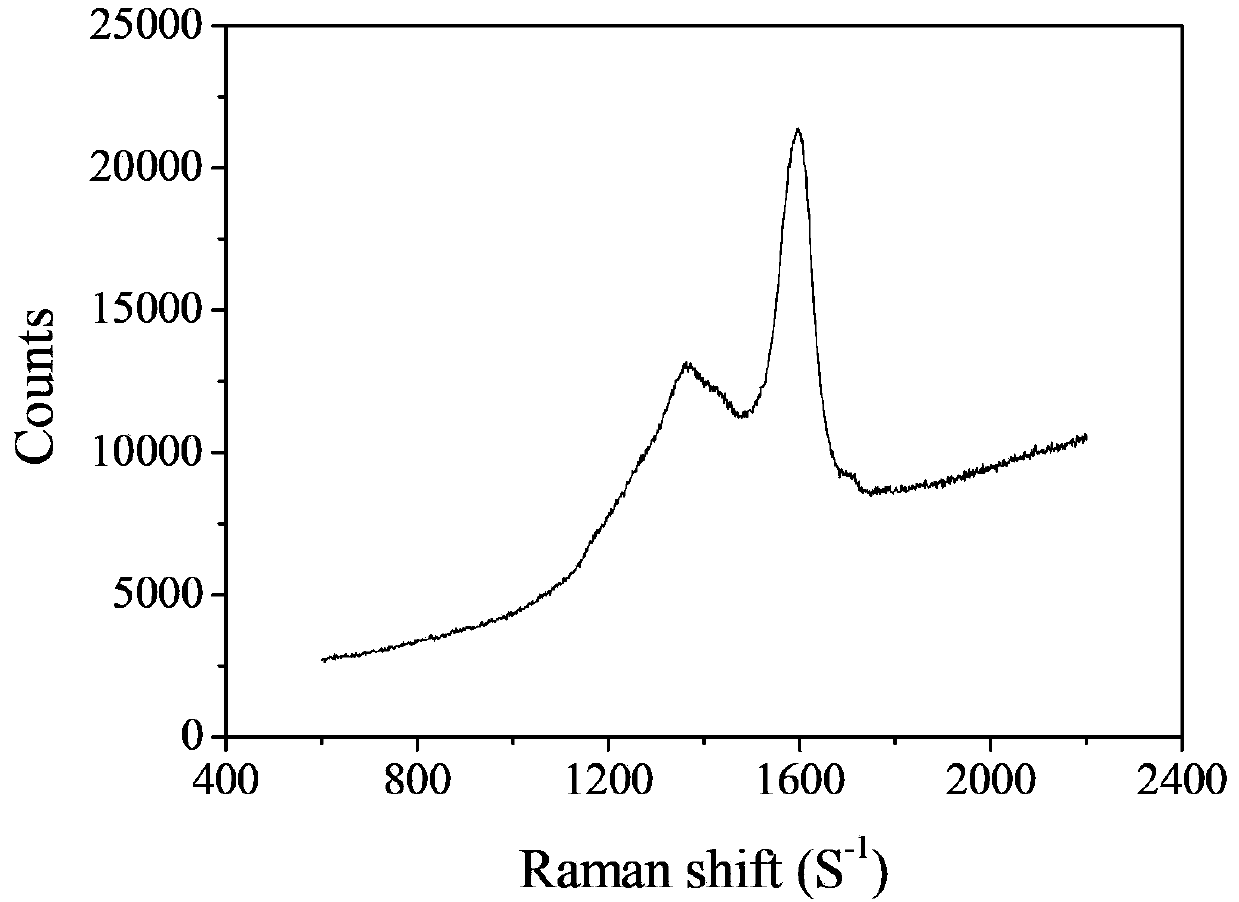

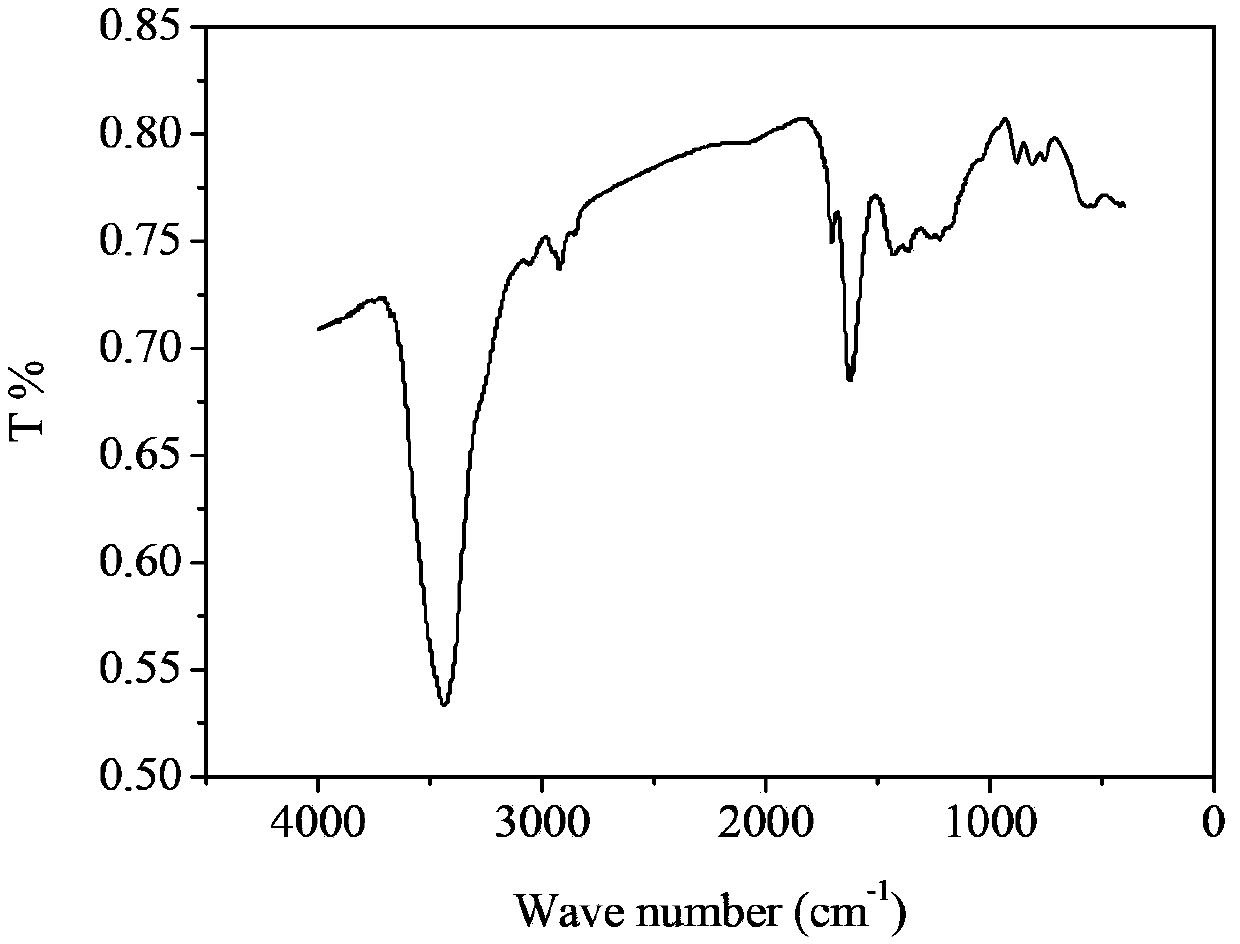

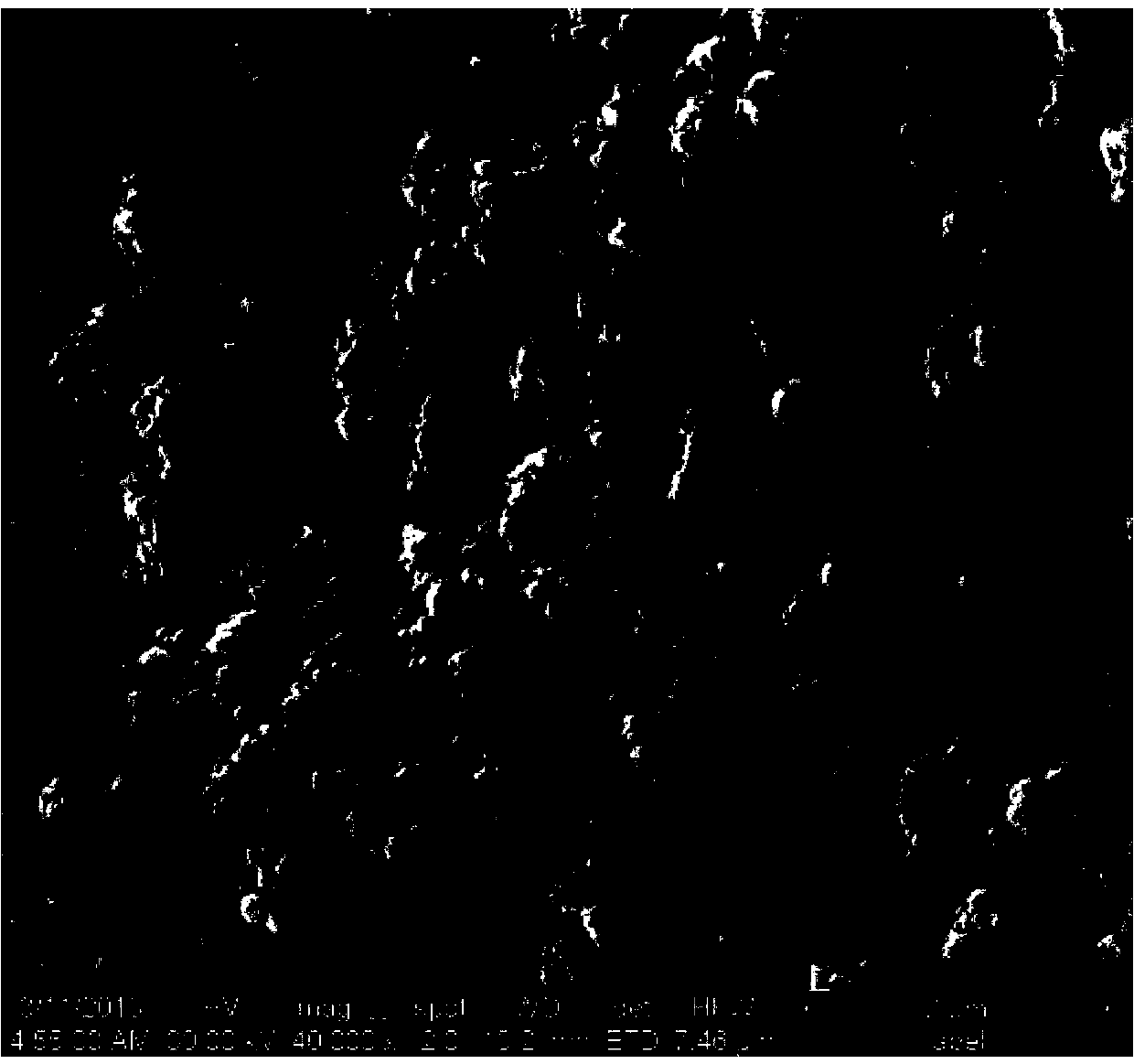

ActiveCN105801736AGood sustained release effectImprove thermal stabilityOrganic chemistryEpoxyElectron

The invention discloses a polyvinyl triazole compound and a preparation method thereof.An acetone solution of hydroxyethyl acrylate is added into a reactor, the pH value is adjusted to be 3-6, then, epoxy chloropropane is added into the reactor drop by drop, and a reaction is performed to obtain 1-chloro-3-hydroxy-butyl-acrylic acid ethyl ether; a DMF solution of the 1-chloro-3-hydroxy-butyl-acrylic acid ethyl ether is dropped into a reaction system containing 1,2,4-triazole and inorganic base, a thermostatic reaction is performed at the temperature 60-90 DEG C for 7-10 h, deionized water, an initiator, a chain transfer agent and a chelating agent are added, and the reaction is performed for 2-5 h.The corrosion inhibitor is corrosion inhibitor molecules by adopting N and O atoms as active centers, and lone pair electrons on heteroatoms can be complex with metal ions in a coordination bond mode to form a polymer and can be combined with metal ions so as to cover the surface of equipment in the mode of an adsorption membrane to achieve corrosion inhibition.

Owner:湖南隆铼新材料科技有限公司

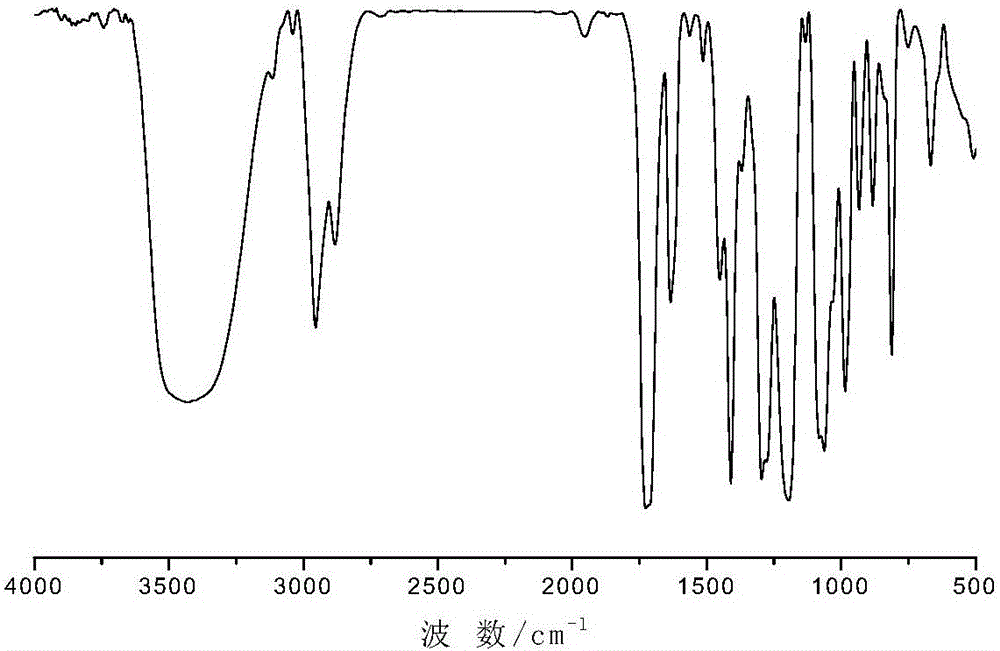

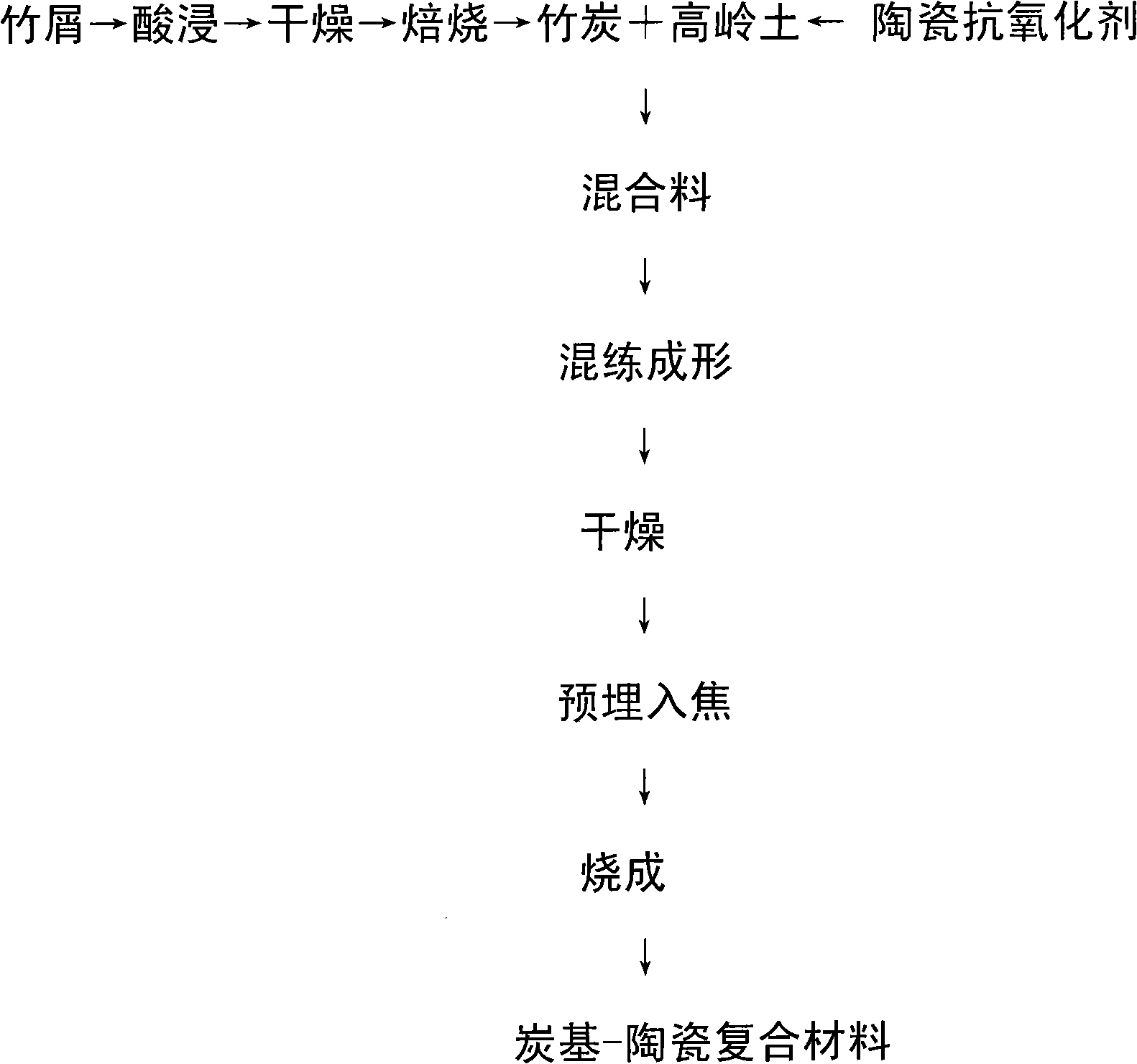

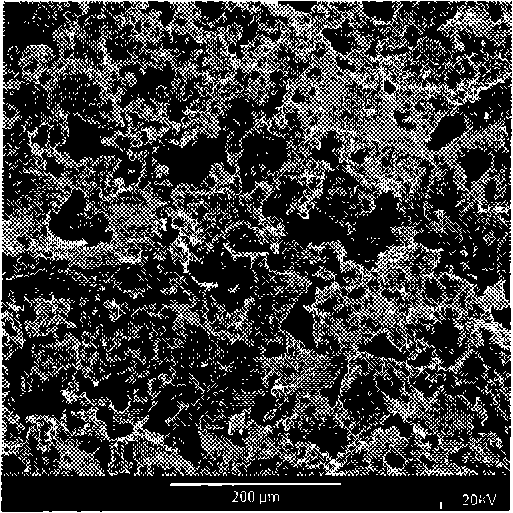

Method for preparing porous charcoal-ceramic composite material

The invention relates to a preparation method of lacunaris carbon matrix-ceramics composite material, which is characterized by: taking the waste of processed bamboo filings as raw material, adopting phosphoric acid to infuse, dry, bake, grind and sift out to obtain active bamboo charcoal powder; taking silica sol and trihydrate alumina to prepare antioxidant collosol; taking bamboo charcoal power and kaoline which are mixed with SOi2-A12O3 collosol and millet to blend into a mud pie to form dry body which is imbedded into a chark and is put in a ceramic crucible. The carbon matrix-ceramics composite material is obtained by being baked at the temperature of 900 to 1100 DEG C.

Owner:何姗 +2

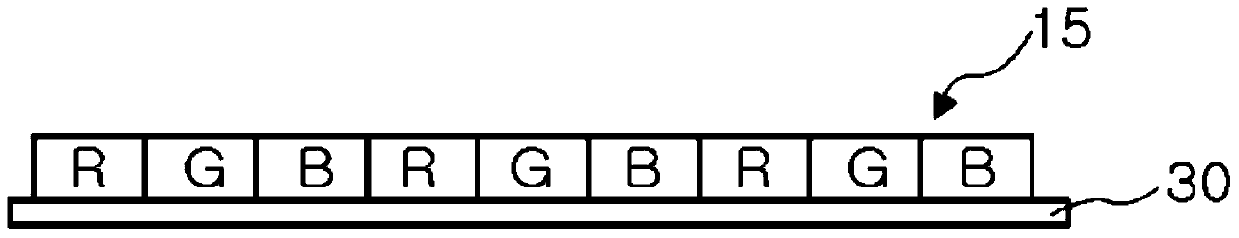

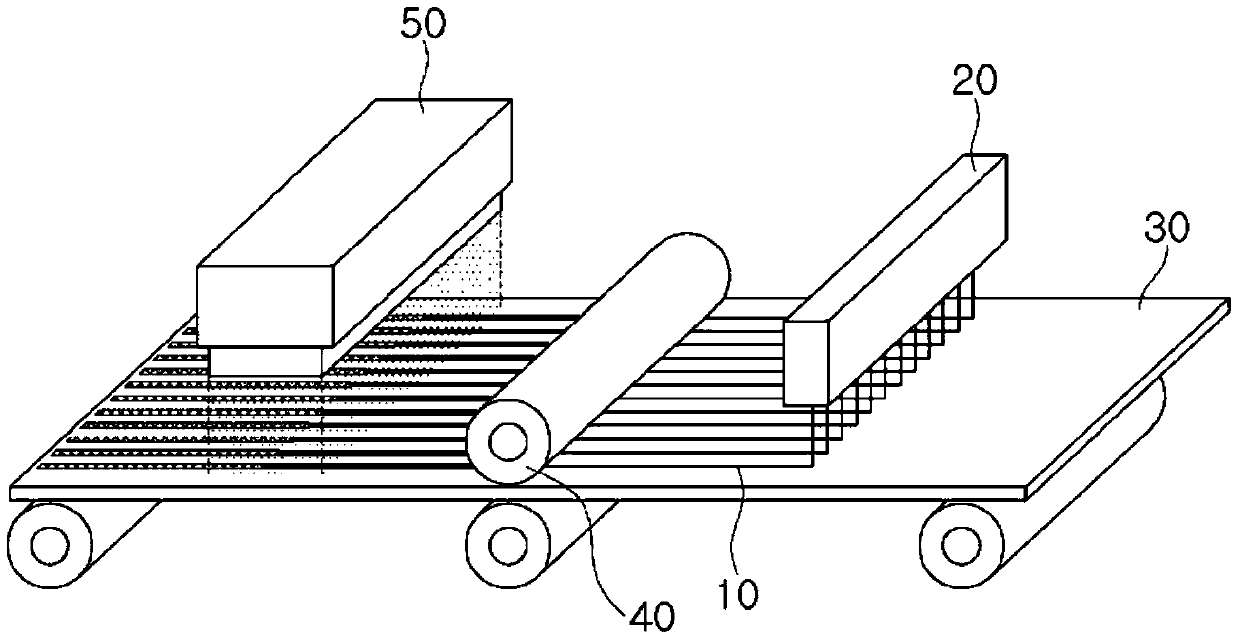

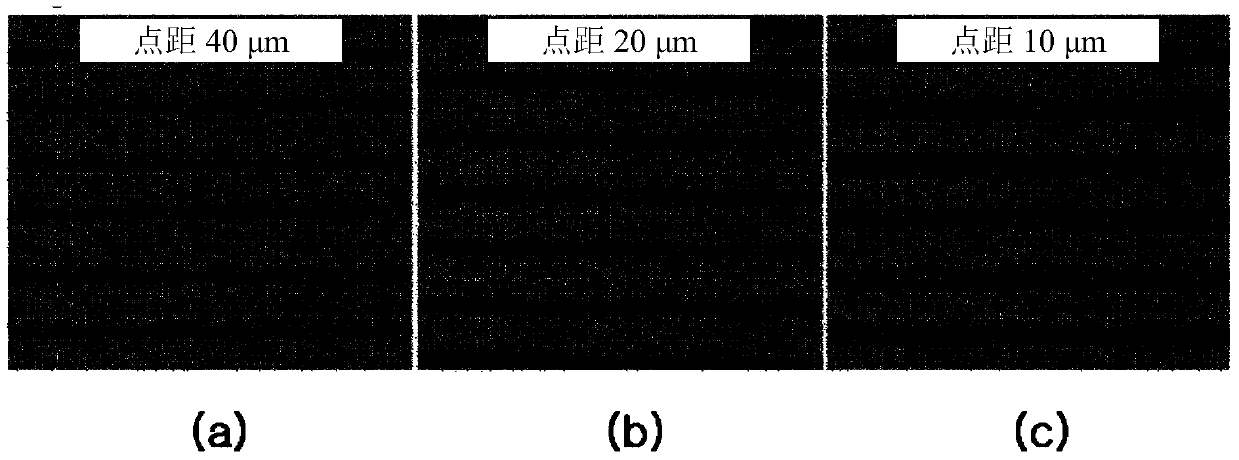

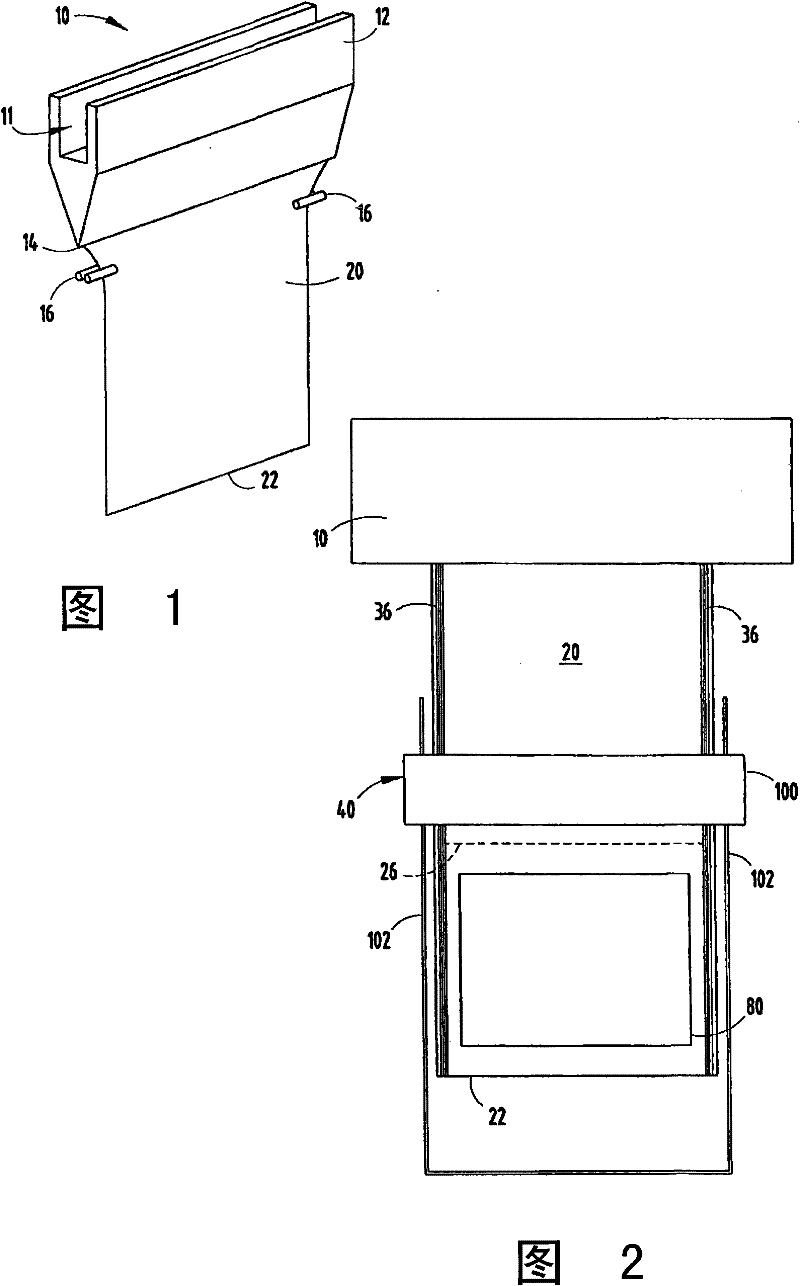

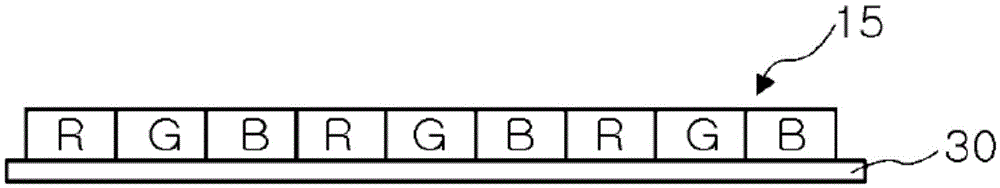

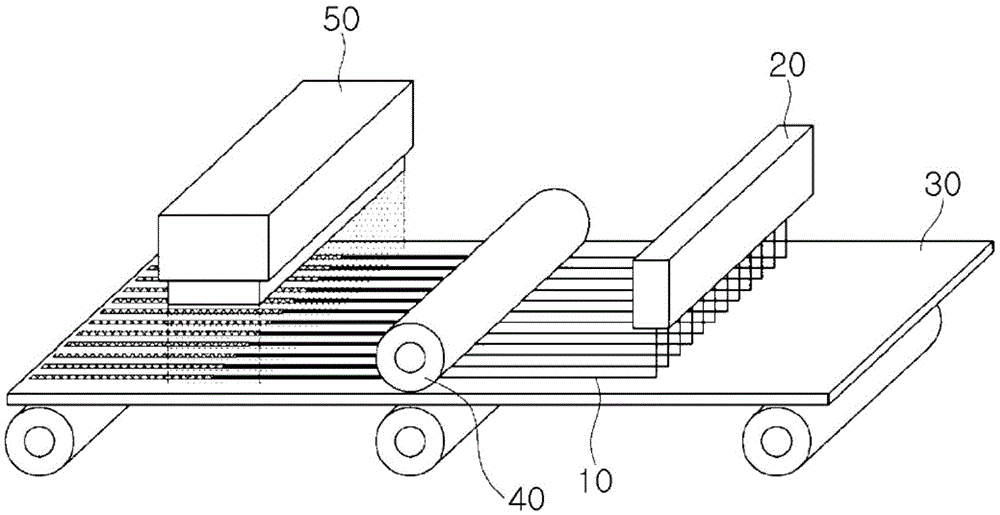

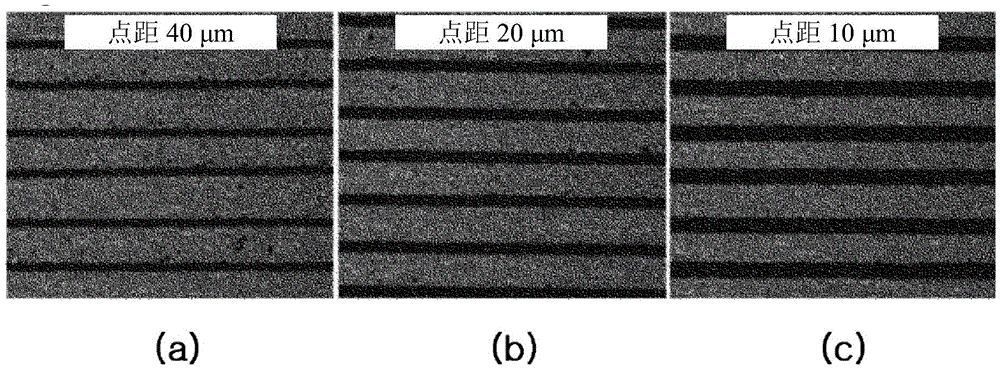

Flexible color filter substrate using phase-change ink, and method for manufacturing same

ActiveCN103797562AAvoid color mixingReduce light leakageSemiconductor/solid-state device manufacturingNon-linear opticsColor gelEngineering

Owner:LG CHEM LTD

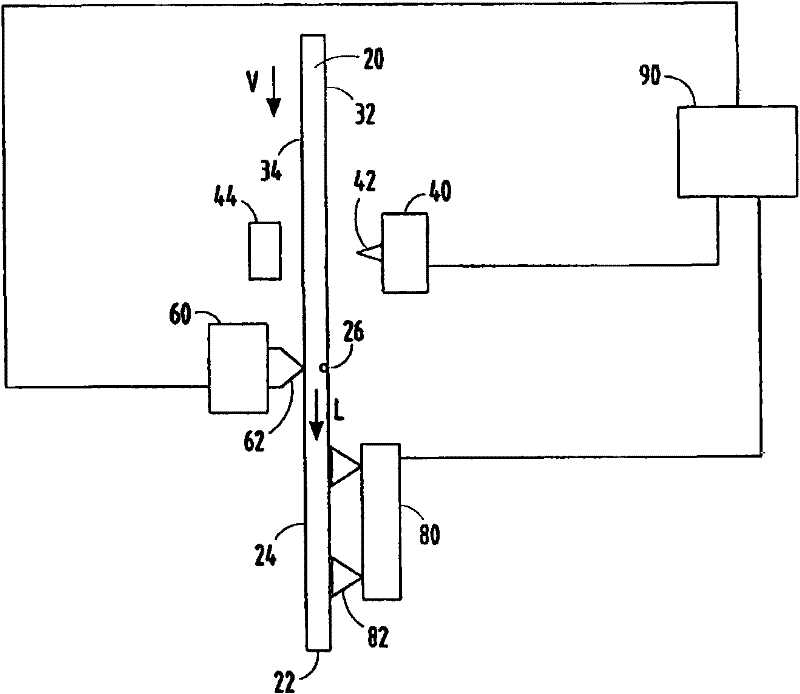

Deposit monitor

ActiveCN109690246AReduce formationForm contributes toWeather/light/corrosion resistanceThermometers using electric/magnetic elementsEngineeringEnvironmental geology

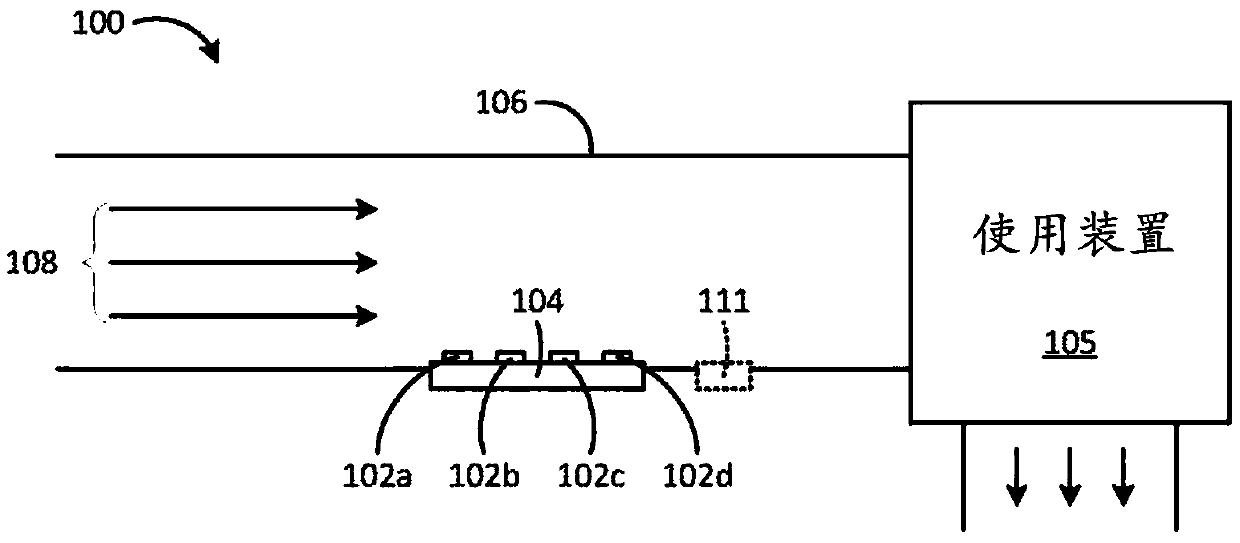

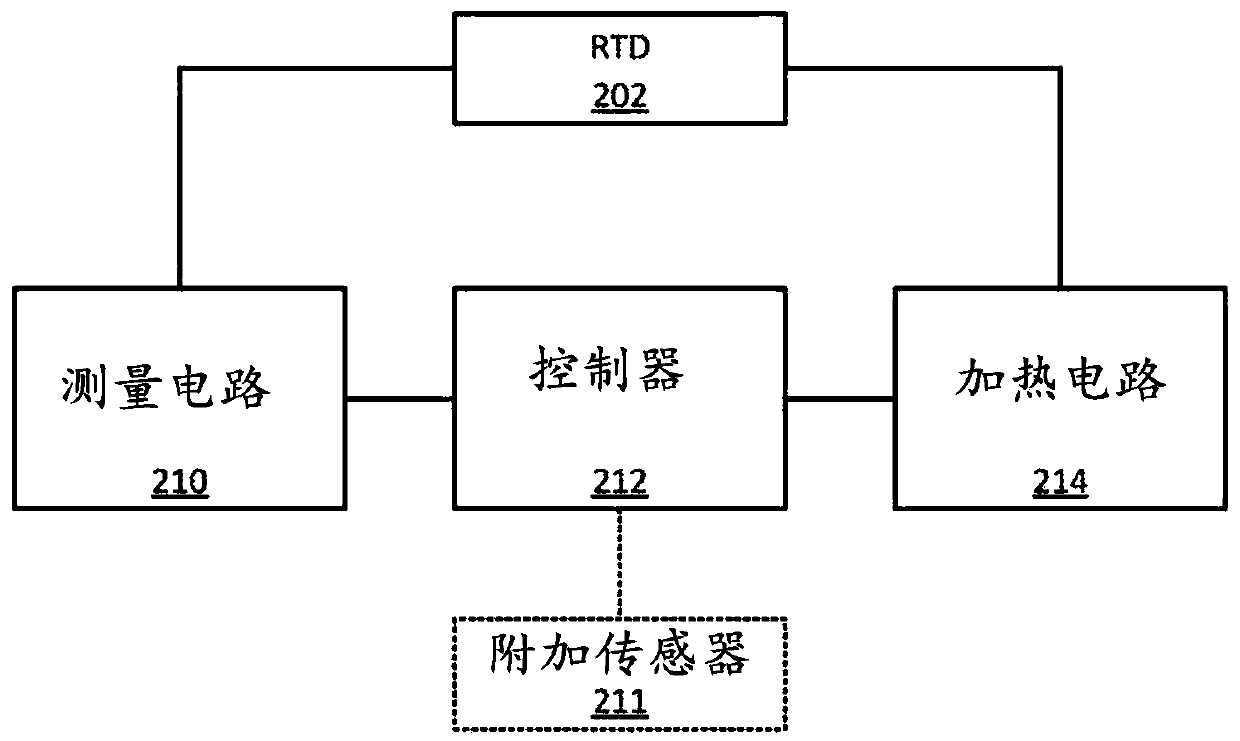

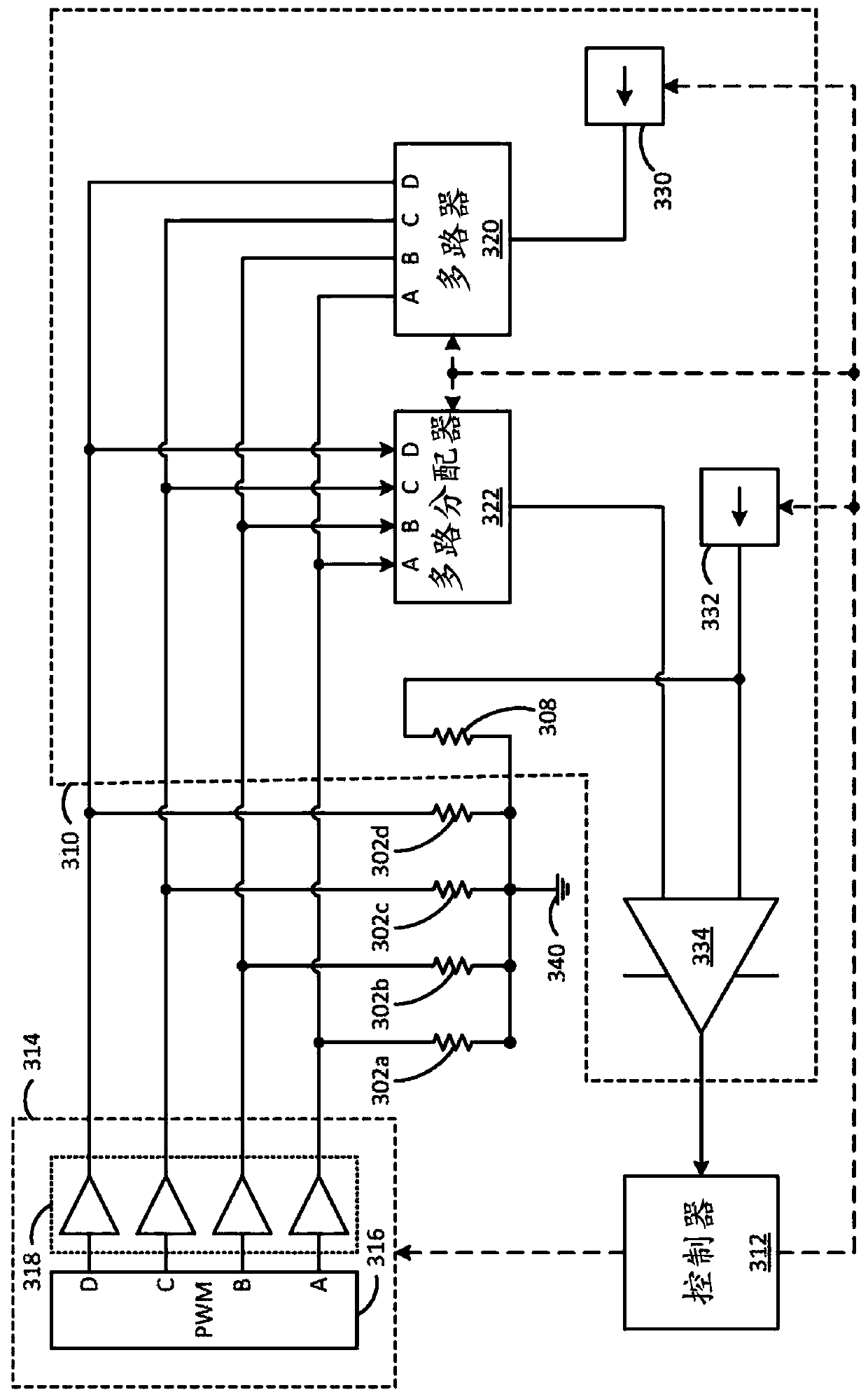

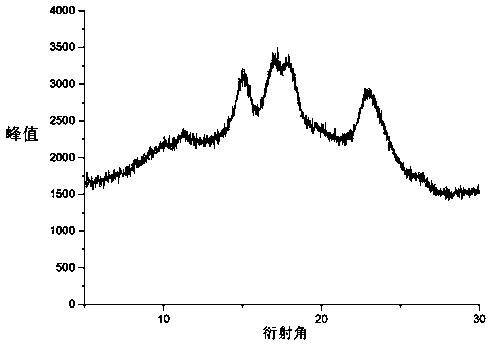

Fluid flow systems can include one or more resistance temperature detectors (RTDs) in contact with the fluid flowing through the system. One or more RTDs can be operated in a heating mode and a measurement mode. Thermal behavior of the one or more RTDs can be analyzed to characterize a level of deposit formed on the RTD(s) from the fluid flowing through the system. Characterizations of depositionon RTDs operated at different temperatures can be used to establish a temperature-dependent deposition profile. The deposition profile can be used to determine if depositions are likely to form at certain locations in the fluid flow system, such as at a use device. Detected deposit conditions can initiate one or more corrective actions that can be taken to prevent or minimize deposit formation before deposits negatively impact operation of the fluid flow system.

Owner:ECOLAB USA INC

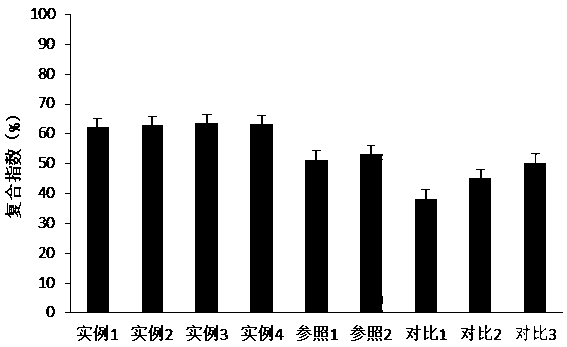

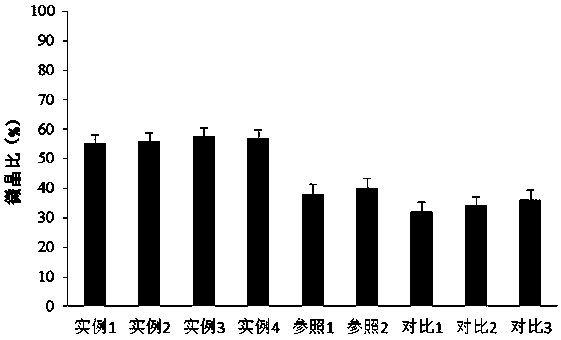

Processing method of high-stability lotus seed starch-soybean lecithin compound

ActiveCN109288035AAvoid heavy useEnsure safetyFood preservationFood ingredientsStability indexFreeze-drying

The invention relates to a processing method of a high-stability lotus seed starch-soybean lecithin compound, and belongs to the field of processing of modified starch. According to the method, lotusseed starch is used as a raw material, lecithin is used as a ligand substance, and through processing steps of vibration type ultramicro crushing, high-pressure micro jet homogenizing and compounding,liquid nitrogen spraying, cooling and crystallization, water washing and centrifuging, freeze drying, crushing and packaging, the lotus seed starch-soybean lecithin compound is prepared. Through theadoption of the method disclosed by the invention, the retrogradation stability of original lotus seed starch can be improved, the compounding indexes and the minicrystal ratio of the lotus seed starch compound can also be increased, high-quality production of lotus seed starach-lecithin compounds is realized, and products have the characteristics of quickly dissolving, being uniform to disperse,being high in safety and the like. The compounding indexes of the obtained lotus seed starch-lecithin compound are 55-70%, the minicrystal ratio is 50-60%, and the stability indexes are 60-75%.

Owner:FUJIAN AGRI & FORESTRY UNIV

Normal-pressure removing method of ceramic core in aero-engine titanium alloy casting

ActiveCN111390143APrevent settling and coagulationStop dirtFoundry mouldsFoundry coresCitric acidTitanium alloy

The invention relates to a normal-pressure removing method of a ceramic core in an aero-engine titanium alloy casting. The method comprises the steps that: (1) preparation of core removing liquid: thecore removing liquid contains the following chemical components in percentage by mass: 10-40% of NaOH or KOH or a mixed solution thereof, 3-5% of a penetrating agent, 3-5% of a dispersing agent, 3-5%of an auxiliary, and the balance of water; (2) ultrasonic and heating assisted normal-pressure core removal: a titanium alloy casting to be treated is put in the core removing liquid in step (1), thetemperature of the core removing liquid is 70-90 DEG C, and ultrasonic waves are intermittently applied; and (3) acid liquid neutralization and cleaning: the titanium alloy casting in step (2) is putin a 0.01 M dilute hydrochloric acid or citric acid solution accompanied with compressed air stirring for 20-40 minutes, and then, the titanium alloy casting is taken out and put in clear water to clean by 10-30 minutes. The normal-pressure removing method has the advantages of low cost of needed raw materials, simple process flow, implementation of the removing process under a normal pressure and low energy loss.

Owner:DONGGUAN FUXING DETERGENT TECH

Composite wear-resistant steel plate and preparation method thereof

The invention relates to the field of composite steel plates, and particularly discloses a composite wear-resistant steel plate and a preparation method thereof. The composite wear-resistant steel plate comprises a base plate and a wear-resistant plate, wherein the wear-resistant plate is composed of the following components: Cr, Mn, Al, V, C, Zr, TiB2, MoSi2 and the balance Fe and inevitable impurities. The preparation method comprises the steps that Cr, Fe, Al, Mn, V, Zr and ethyl alcohol are mixed to form a first primary mixture; TiB2, MoSi2 and C are mixed to form a second primary mixture;the first primary mixture and the second primary mixture are mixed, heated, melted, pressed into a blank, annealed, cooled and ground to obtain a wear-resistant plate; and then the wear-resistant plate and the base plate are subjected to heating pressure welding to obtain the composite wear-resistant steel plate. The composite wear-resistant steel plate provided by the invention has the advantageof being good in wear resistance.

Owner:北京华锦源耐磨材料有限公司

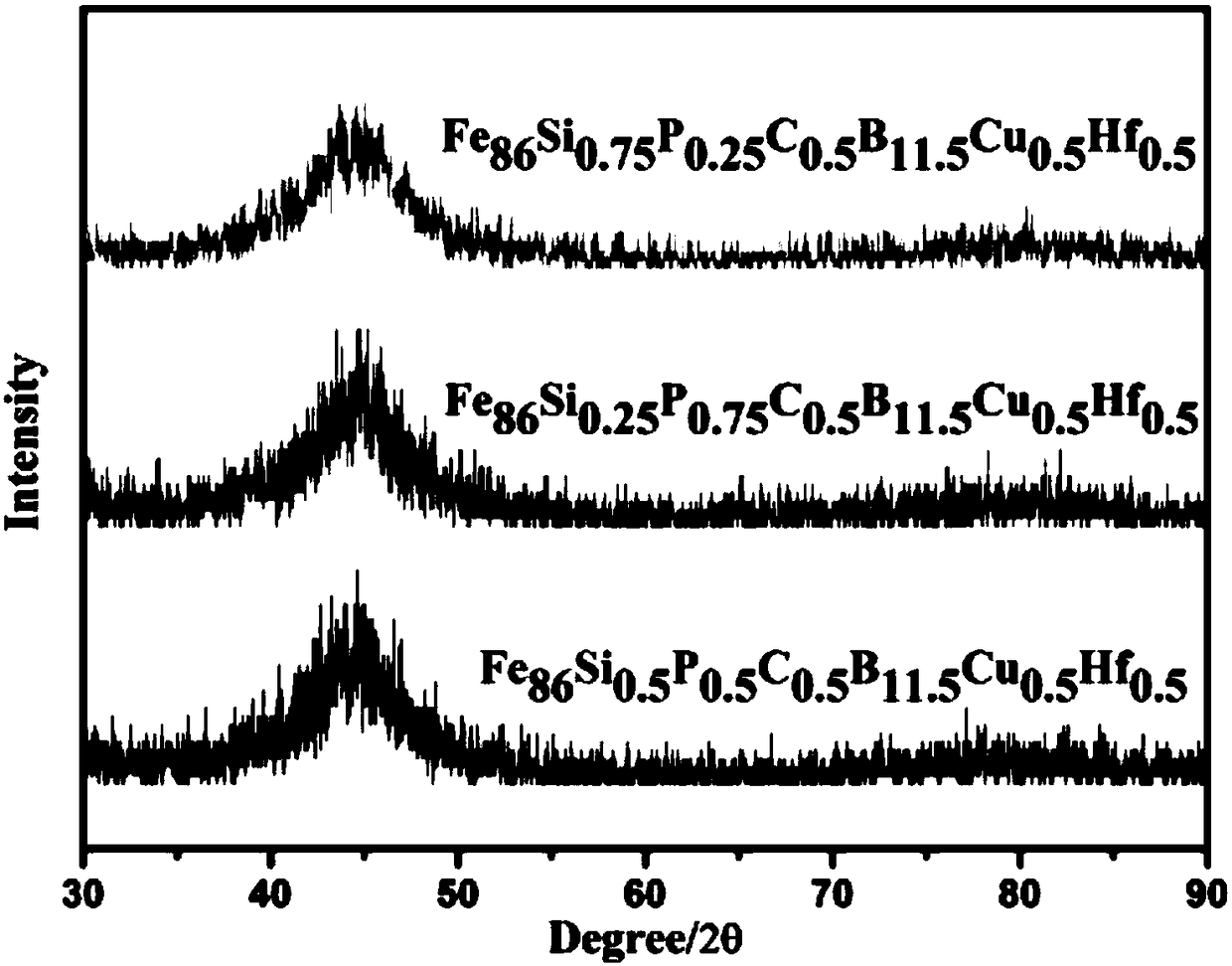

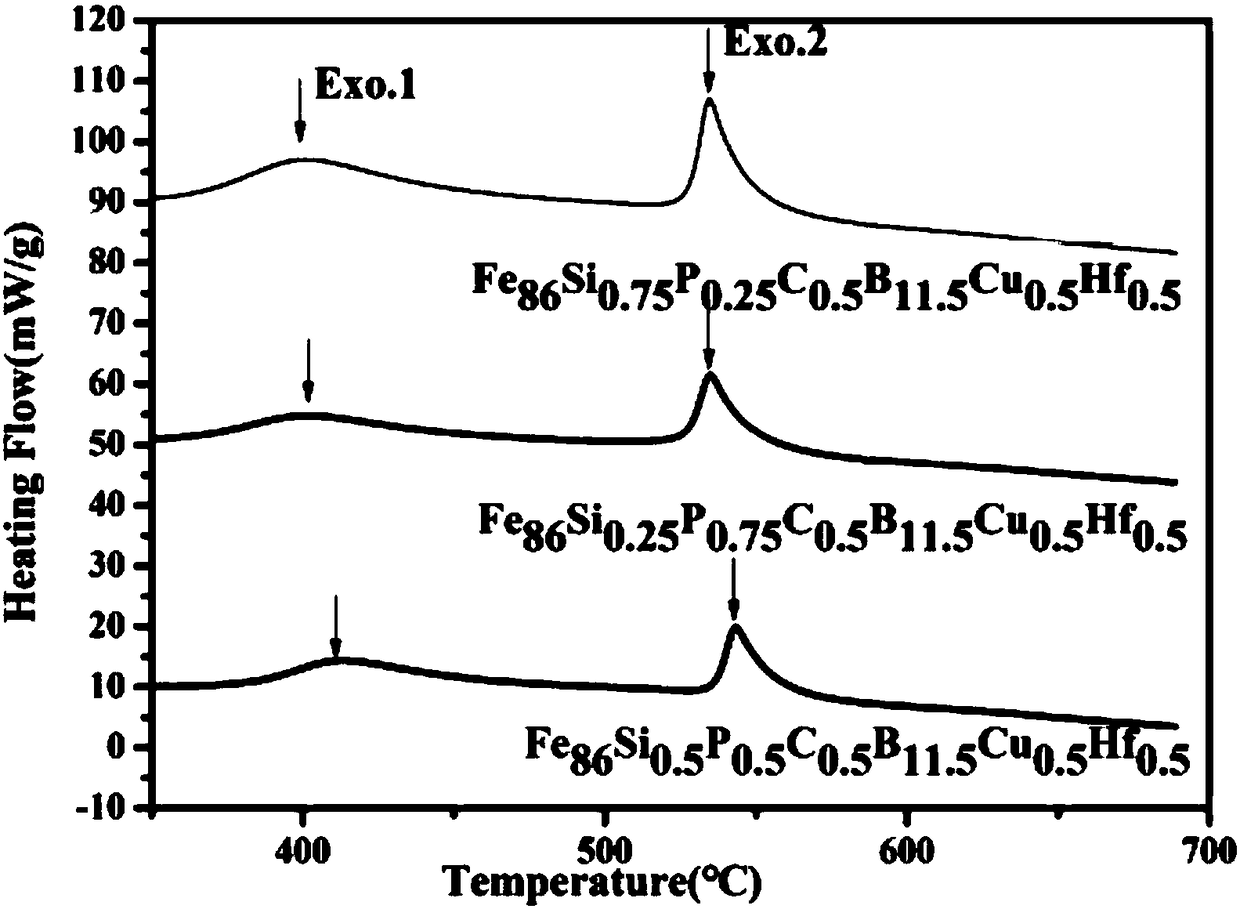

Iron-based nanocrystalline alloy and preparation method thereof

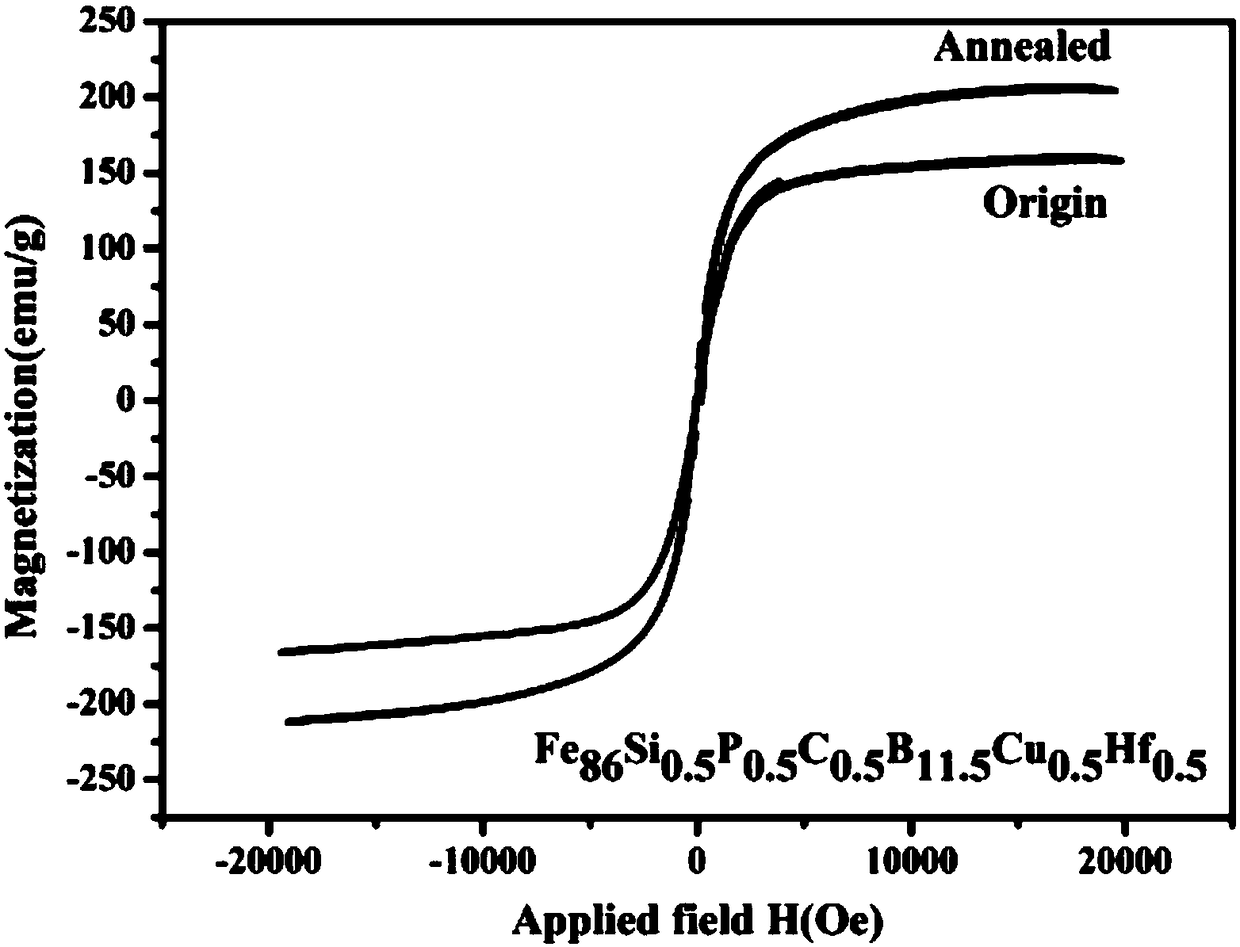

ActiveCN108220776AEnhanced Amorphous Formation AbilityHigh magnetic permeabilityNanocrystalline siliconHeat treated

The invention provides an iron-based nanocrystalline alloy represented by the formula (I), wherein a, b and c represent the atomic percentage contents of the corresponding components respectively, a=86-87, b=12-13, c=1, and a+b+c=100; the atomic percentage content of B is 11-13, the atomic percentage content of Si is 0.01-1, the atomic percentage content of P is 0.01-1, the atomic percentage content of C is 0.01-1, the atomic percentage content of Cu is 0.01-1, and the atomic percentage content of Hf is 0.01-1. The invention also provides a preparation method of the iron-based nanocrystallinealloy. By adjusting the alloy composition and heat treatment system, the amorphous forming ability and the saturation magnetic induction intensity of the iron-based nanocrystalline alloy are improved;the formula (I) is represented by Fea(BSiPC)b(CuHf)c (I).

Owner:GUANGDONG UNIV OF TECH

Novel injection composition for beautifying filling

InactiveCN108578775AFilled withAnti-wrinklePharmaceutical delivery mechanismProsthesisFiberWrinkle skin

The invention discloses a novel injection composition for beautifying filling. The injection composition is prepared from, by weight, 12-18 parts of tranexamic acid, 5-12 parts of glutathione, 12-18 parts of vitamin C, 12-18 parts of NK cells, 5-12 parts of platelet-derived growth factors, 8-15 parts of epidermal growth factors, 3-8 parts of fiber binding protein, 2-6 parts of glass adhesion protein, 20-40 parts of protease-activated receptor and 2-7 parts of cross-linking agent. The novel injection composition solves the problems that an existing injection-type product is monotonous in function, only achieves the filling effect, and does not have the functions of oxidation resistance, ageing resistance and whitening. The novel injection composition not only has multiple effects of filling, resisting of wrinkles and ageing and whitening, but also has stable performance, safety and durability.

Owner:白晋

An upwelling artificial fish reef

InactiveCN104521839BForm contributes toPromote exchangeClimate change adaptationPisciculture and aquariaRight triangleEngineering

The invention relates to a rising streaming artificial fish reef. The rising streaming artificial fish reef is composed of a cube frame, right triangle plates and isosceles triangle plates, the inner side of each upright post of the cube frame is provided with a right triangle plate, the upper edges of four groups of the right triangle plates with a same specification are connected in a cross shape at the top surface center of the cube frame, the inner side of each bottom edge of the cube frame is provided with an isosceles triangle plate, point angles of four groups of the isosceles triangle plate with a same specification are intersected at the top surface center of the cube frame to form a rectangular pyramid structure, each side of the rectangular pyramid is connected with the hypotenuse of the right triangle plate at the inner side of each upright post of the cube frame, and open pores are formed in the right triangle plates and the isosceles triangle plates. The rising streaming artificial fish reef has the advantages of rising streaming effect and remarkable stability performance.

Bacteriostatic deodorant Jun porcelain glaze

InactiveCN109399927ALarge loss on ignitionForm contributes toClaywaresCarboxymethyl celluloseDeodorant

Bacteriostatic deodorant Jun porcelain glaze is prepared from, by weight, 25-31 parts of feldspar, 13-17 parts of calcite, 11-15 parts of quartz, 6-10 parts of talcum, 10-14 parts of coal powder, 8-12parts of negative ion powder, 4-6 parts of copper cooper ore, 4-6 parts of carclazyte, 1.5-2.5 parts of plant ash and 1.5-2.5 parts of carboxymethyl cellulose. The glaze after being fired at high temperature has good bacteriostatic and deodorant effects and high ornamental value and can be used for bacteria inhibiting and deodorizing of space like indoors, refrigerators and wardrobes.

Owner:张晓艳

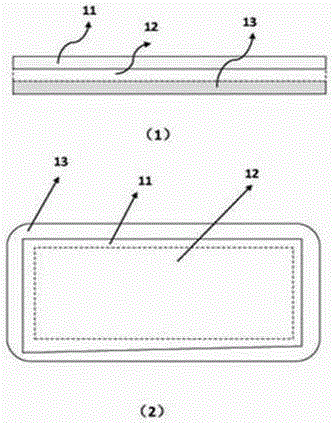

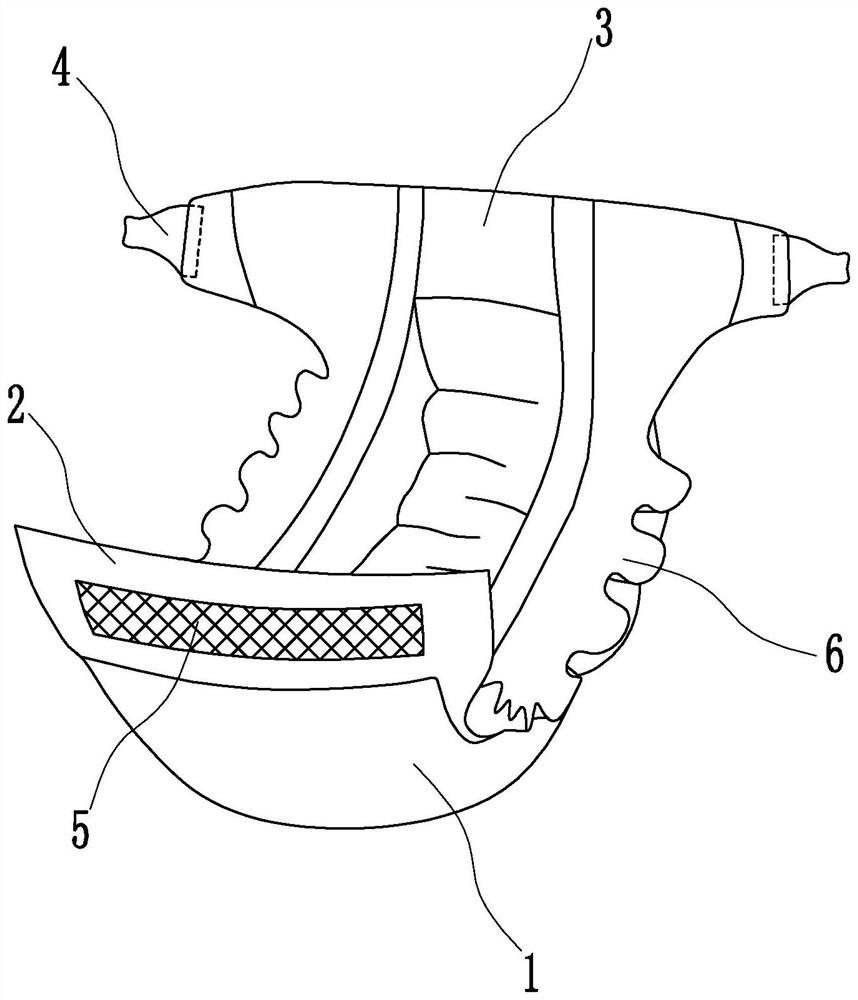

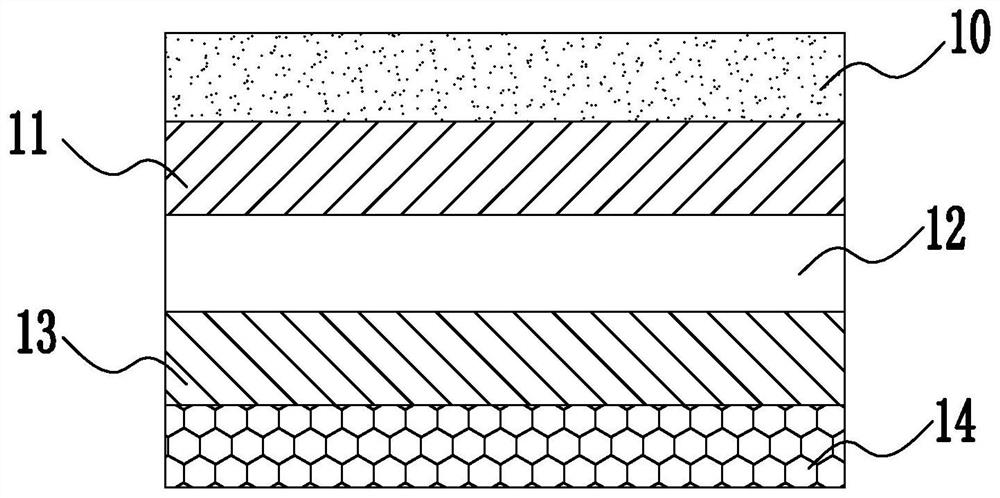

A reinforced structure paper diaper with a composite core

The invention relates to the field of disposable hygiene products, and discloses a reinforced structural diaper with a composite core, which includes a diaper body, and the diaper body is composed of an air-permeable surface layer, a diversion layer, a composite core body, and a leak-proof bottom layer. Bonded with degradable hot-melt adhesive, the composite core consists of a dust-free paper, an upper absorbent layer, an elastic layer, a lower absorbent layer, and a spun-bonded non-woven fabric from top to bottom, and the upper absorbent layer includes a middle area and a Anti-side leakage areas on both lateral sides of the middle area, the middle area has several upper absorption sections distributed along the longitudinal direction, each of the upper absorption sections is arranged at intervals, and the distribution density of the superabsorbent resin on the anti-side leakage area is greater than The upper absorbing section, the lower absorbing layer is longitudinally distributed with several lower absorbing sections, each of the lower absorbing sections is arranged at intervals, and the layers of the composite core are bonded by degradable hot-melt adhesives. It solves the problem that the existing paper diapers are easy to agglomerate, break and delaminate, and the hot melt adhesive used for bonding has good bonding effect and is degradable.

Owner:GUANGDONG YINYIN CO LTD

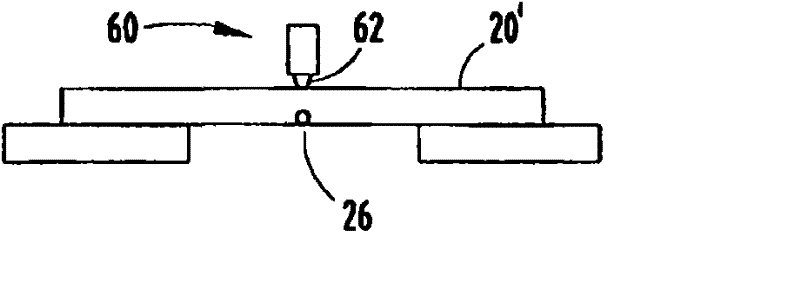

Propagation of impact-induced cracks in brittle materials

InactiveCN101616778BEasy to separateImprove stress concentrationConveyorsFine working devicesCrazingContact force

Vibrational energy is applied through a probe into a pre-scored brittle sheet, separating the sheet along the score line, such as flat or domed glass. Separation times are less than 1 second with smooth edge quality. The sheet may be in the form of a moving ribbon of sheet glass to which a vibrational load is applied in a direction transverse to the score line to promote crack propagation along the score line. The controller steers the probe according to the selected vibration frequency, amplitude, contact velocity, impact contact force, alignment with the scribe line, etc., depending on material properties and structures, and optimal process parameters.

Owner:CORNING INC

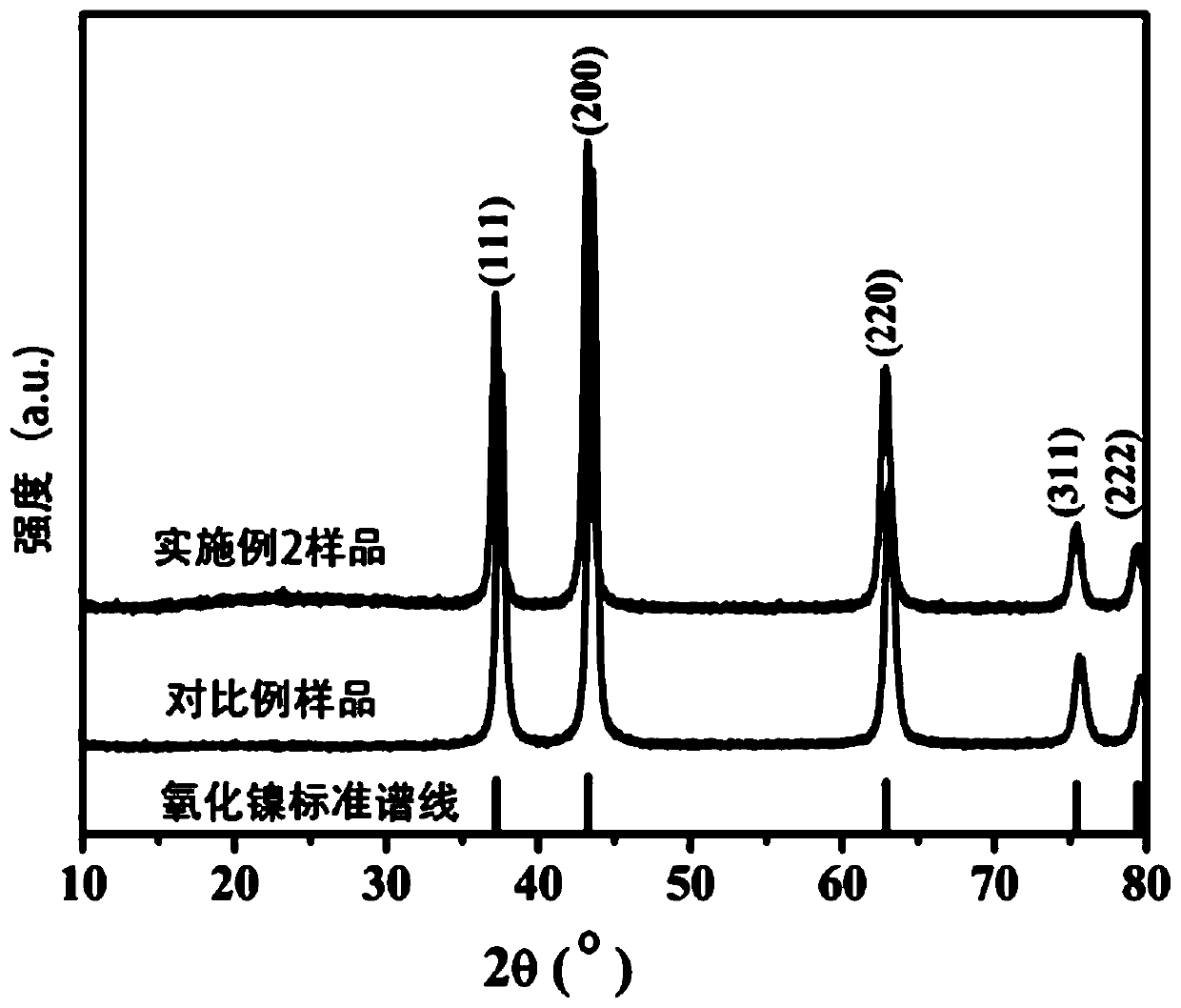

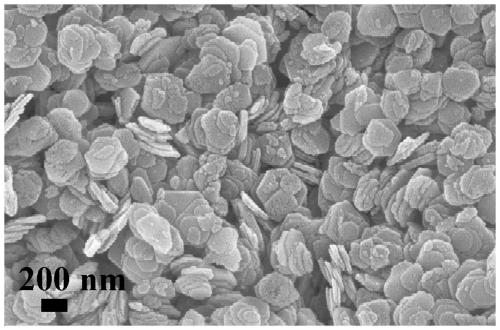

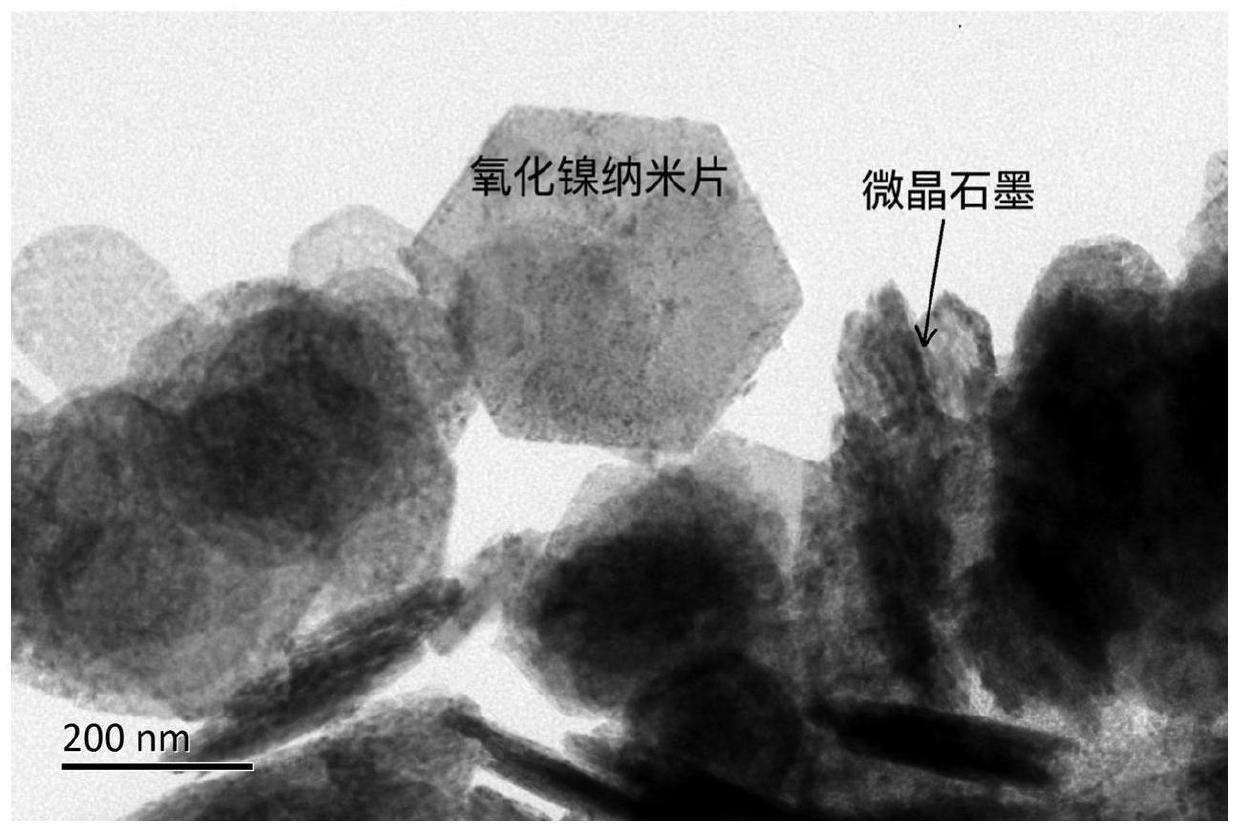

A kind of nickel oxide and microcrystalline graphite composite and its preparation method and application

ActiveCN110137471BLow costAchieve decompositionGraphiteCell electrodesPhysical chemistryCarbon nanofiber

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Flexible color filter substrate using phase change ink and preparation method thereof

ActiveCN103797562BAvoid color mixingReduce light leakageSemiconductor/solid-state device manufacturingNon-linear opticsColor gelEngineering

Owner:LG CHEM LTD

A kind of polyvinyl triazole compound and preparation method thereof

ActiveCN105801736BGood sustained release effectImprove thermal stabilityOrganic chemistryEpoxyElectron

The invention discloses a polyvinyl triazole compound and a preparation method thereof.An acetone solution of hydroxyethyl acrylate is added into a reactor, the pH value is adjusted to be 3-6, then, epoxy chloropropane is added into the reactor drop by drop, and a reaction is performed to obtain 1-chloro-3-hydroxy-butyl-acrylic acid ethyl ether; a DMF solution of the 1-chloro-3-hydroxy-butyl-acrylic acid ethyl ether is dropped into a reaction system containing 1,2,4-triazole and inorganic base, a thermostatic reaction is performed at the temperature 60-90 DEG C for 7-10 h, deionized water, an initiator, a chain transfer agent and a chelating agent are added, and the reaction is performed for 2-5 h.The corrosion inhibitor is corrosion inhibitor molecules by adopting N and O atoms as active centers, and lone pair electrons on heteroatoms can be complex with metal ions in a coordination bond mode to form a polymer and can be combined with metal ions so as to cover the surface of equipment in the mode of an adsorption membrane to achieve corrosion inhibition.

Owner:湖南隆铼新材料科技有限公司

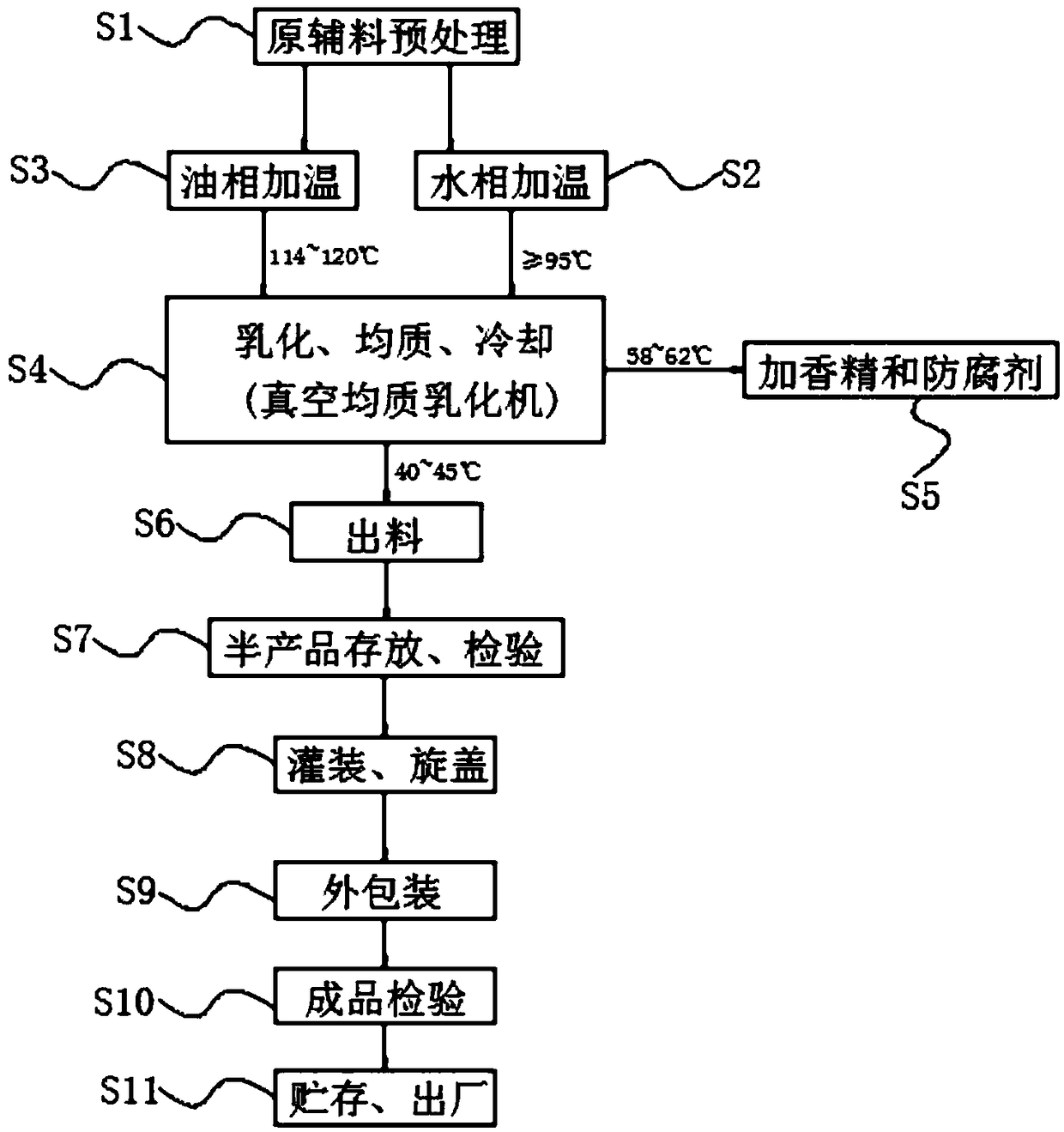

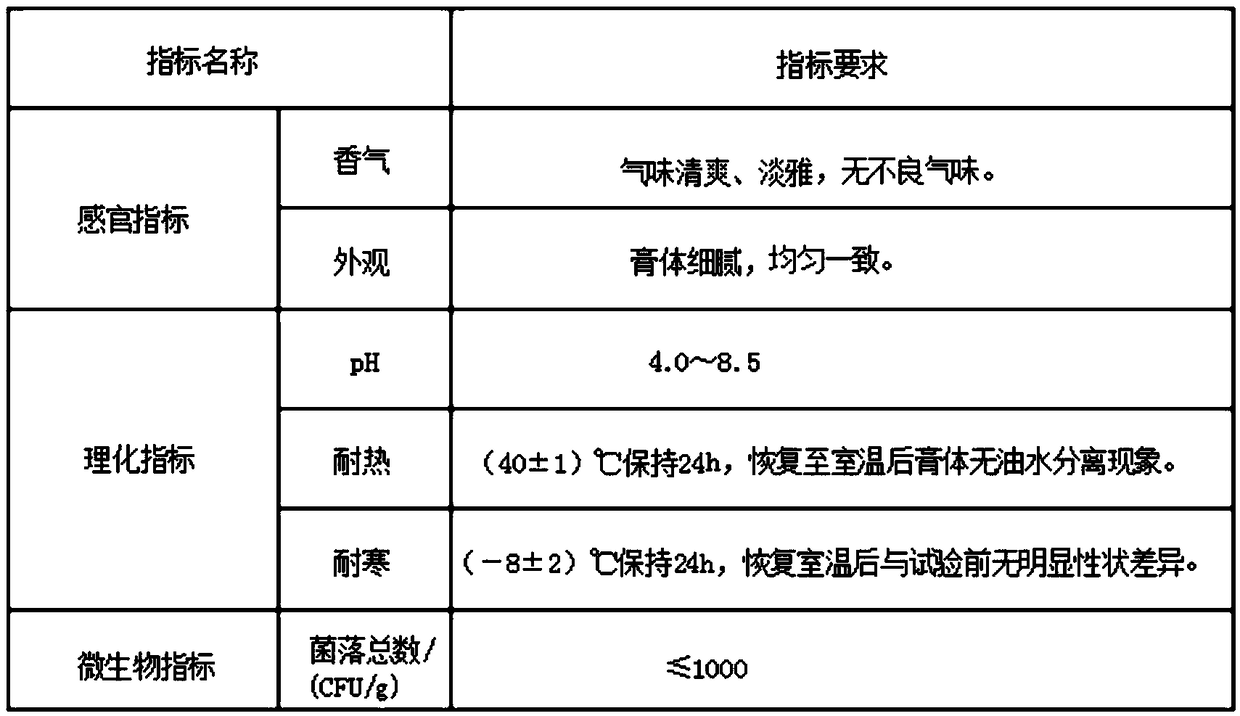

Foot skin-softening cream technology

InactiveCN109106609AImprove cold resistanceHelp sootheCosmetic preparationsToilet preparationsAdditive ingredientHeat resistance

The invention discloses a foot skin-softening cream technology and relates to the technical field of skincare products. The process flow comprises the following steps: S1) pretreatment of raw ingredients; S2) aqueous phase operation; S3) oil phase; S4) emulsification, homogenizing and cooling; S5) adding of essence and preservative; S6) discharging; S7) storage and check of semi-finished products;S8) filling and covering; S9) external packing; S10) inspection of finished product; S11) storage and delivery. The invention designs a foot skin-softening cream with excellent effects of softening heel and foot skin, restraining the forming of thick and hard skin on foot and other parts, enhancing skin elasticity, preventing rhagadia and seasoning crack and removing necrotic tissues and scale ofskin; the foot skin-softening cream designed by the invention has excellent heat resistance and cold resistance; the oil-water separating phenomenon is difficult to occur in the cream; the foot skin-softening cream is low in limit of toxic substance, is harmless to human body, is beneficial to skin softening and repairing and is capable of supplementing comprehensive nutrition and water to skin in time.

Owner:张家港市绮丽日用化学品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com