Method for preparing porous charcoal-ceramic composite material

A technology of ceramic composite material and porous carbon, which is applied in ceramic products, other household utensils, household utensils, etc., can solve the problems of difficult to achieve effect and low mechanical strength, prevent partial carbon oxidation, improve mechanical strength, and improve sewage treatment efficiency effect

Inactive Publication Date: 2008-10-22

何姗 +2

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the existence of a large number of micropores in activated bamboo charcoal, it has a huge specific surface area (the specific surface area is 200-300m2 / g). Effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

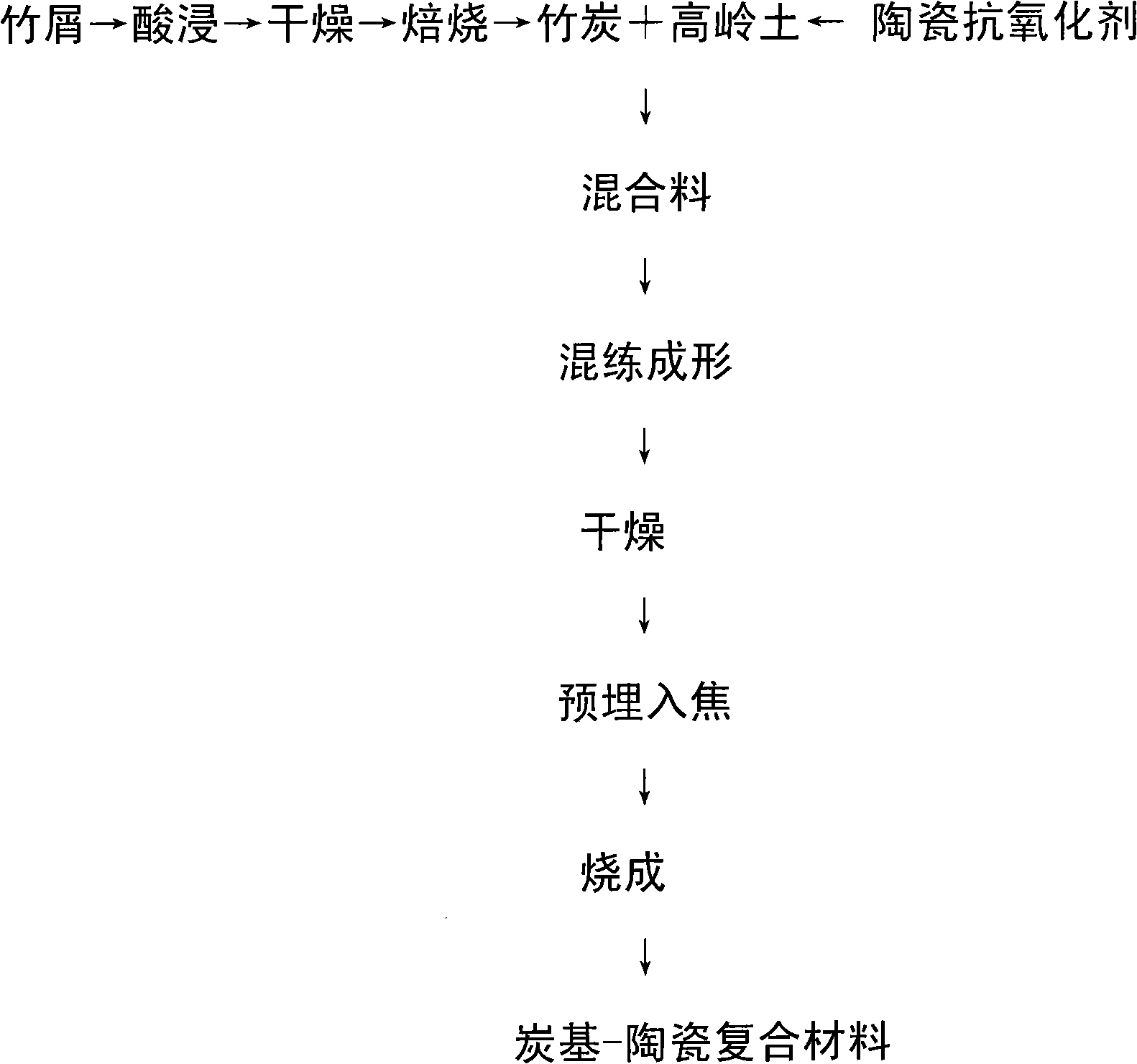

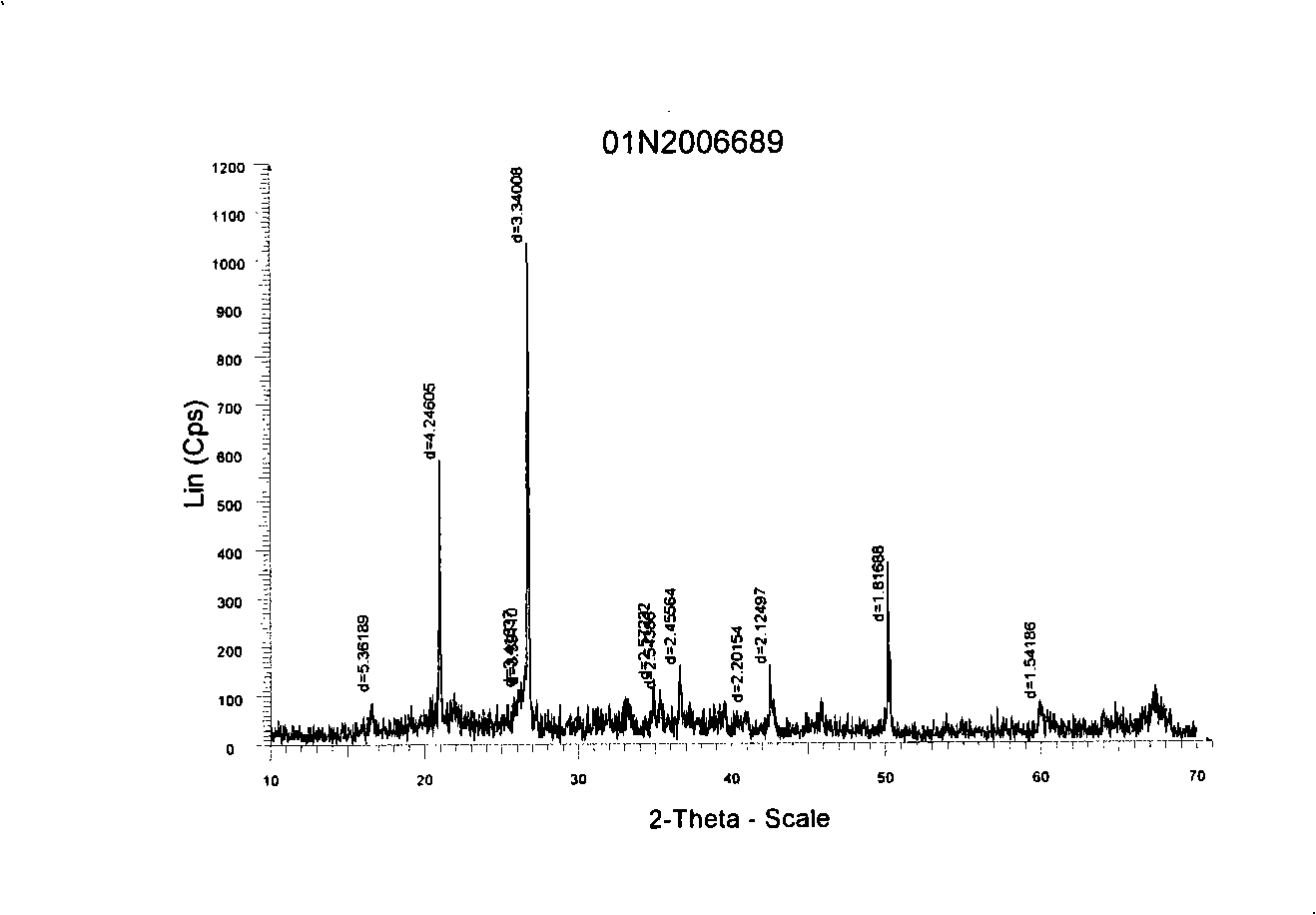

The invention relates to a preparation method of lacunaris carbon matrix-ceramics composite material, which is characterized by: taking the waste of processed bamboo filings as raw material, adopting phosphoric acid to infuse, dry, bake, grind and sift out to obtain active bamboo charcoal powder; taking silica sol and trihydrate alumina to prepare antioxidant collosol; taking bamboo charcoal power and kaoline which are mixed with SOi2-A12O3 collosol and millet to blend into a mud pie to form dry body which is imbedded into a chark and is put in a ceramic crucible. The carbon matrix-ceramics composite material is obtained by being baked at the temperature of 900 to 1100 DEG C.

Description

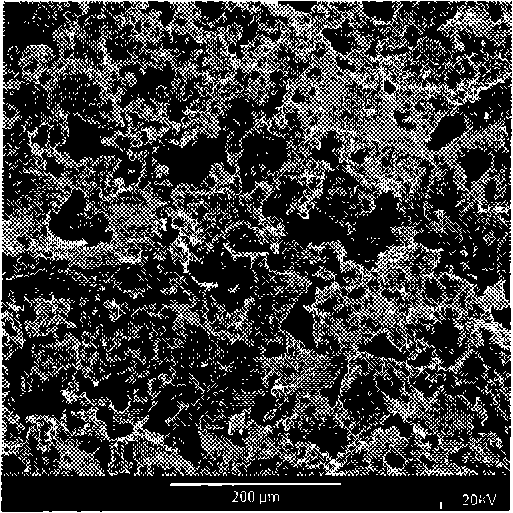

A kind of preparation method of porous carbon matrix-ceramic composite material technical field The invention belongs to the technical field of manufacturing inorganic non-metallic materials, and in particular relates to a preparation method of a porous carbon base-ceramic composite material. Background technique With the continuous deepening of my country's reform and opening up, China's economy has maintained a momentum of rapid growth, but at the same time, it has brought serious environmental problems, such as air pollution and water pollution. In the study of solving environmental pollution problems, activated carbon has been widely used because of its ability to adsorb harmful substances. Due to the existence of a large number of micropores in activated bamboo charcoal, it has a huge specific surface area (the specific surface area is 200-300m2 / g). Effect. How to utilize the excellent characteristics of activated bamboo charcoal to develop a new porous material th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B38/00C04B35/52

Inventor 何姗夏仲力齐逸梅

Owner 何姗

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com