Patents

Literature

106results about How to "Has a corrosion inhibitory effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphorus-free corrosion and scale inhibitor

InactiveCN101607763AReduce dosagePlay a role in corrosion inhibitionTreatment using complexing/solubilising chemicalsChelationPrecipitation types

The invention relates to a phosphorus-free corrosion and scale inhibitor, which is prepared from sodium molybdate, zinc salt, citrate, triethanolamine, benzotriazole (BTA), polyaspartic acid (PASP), polyepoxysuccinic acid (PESA), AA / AMPS terpolymer, solid alkali and water. The phosphorus-free corrosion and scale inhibitor inhibits corrosion of metals by forming oxidization type and precipitation type films on the surfaces of the metals, has the effect of inhibiting scale through chelation and dispersive action on salts causing scale in cooling water, is non-toxic and phosphorus-free, has easily biodegradable major organic compositions, does not cause environmental pollution and is not limited by phosphorus in emission.

Owner:SHANGHAI WEILAI ENTERPRISE

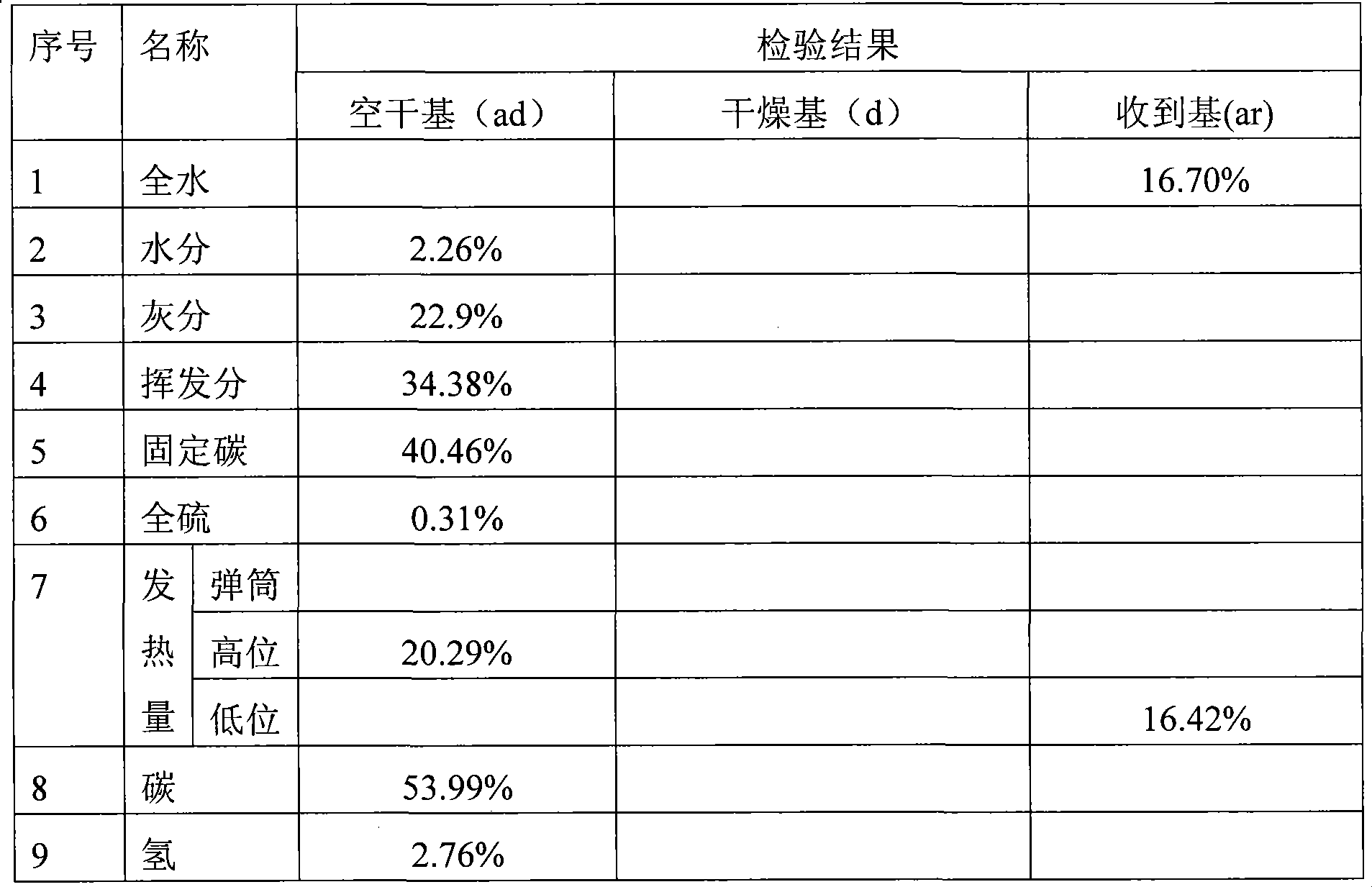

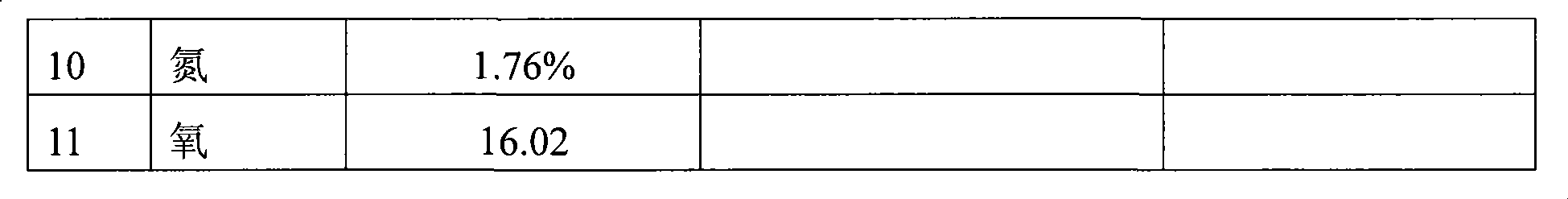

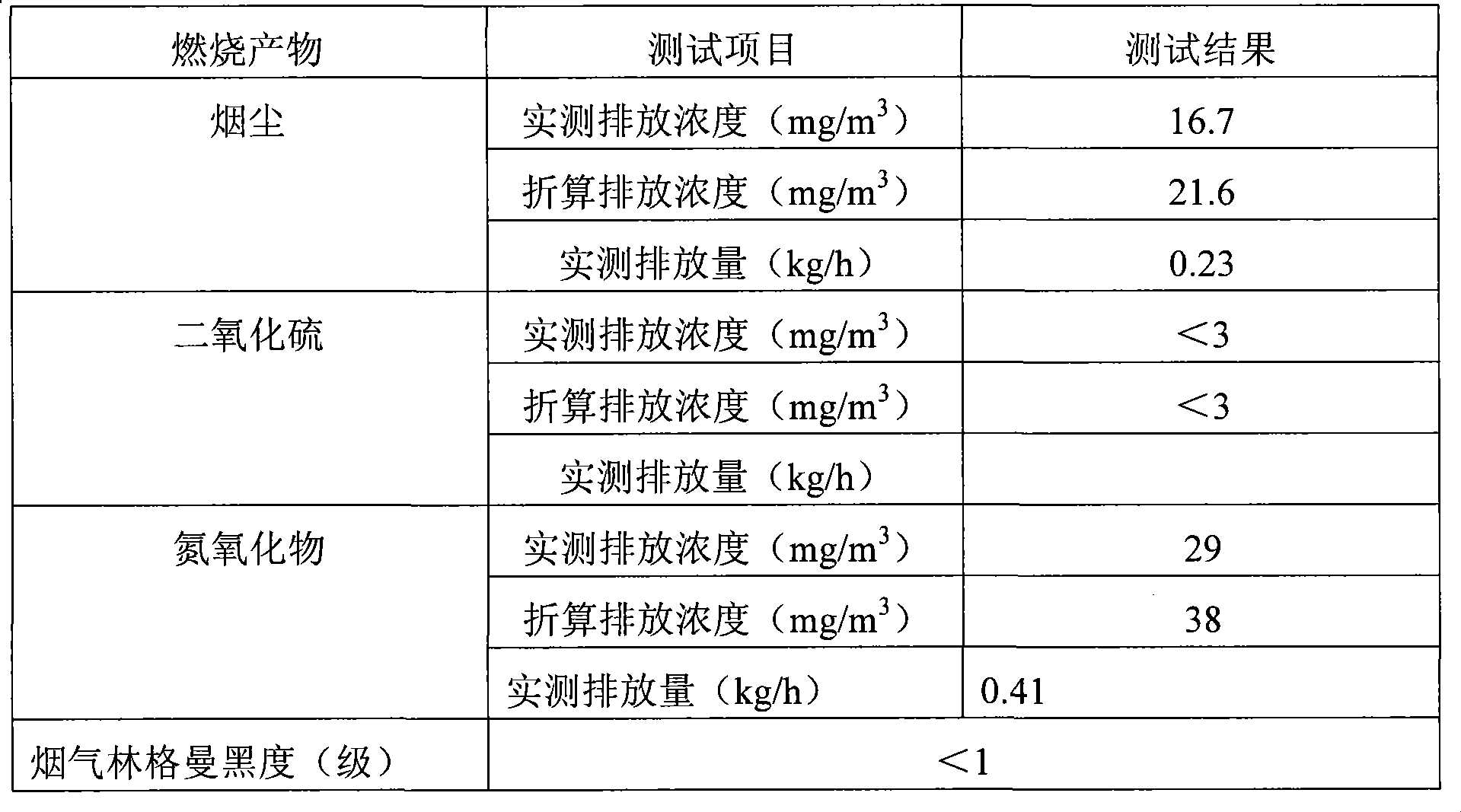

Sludge synthetic fuel and preparation thereof

The invention provides a mud synthesizing fuel which includes mud, coal powder and the materials of plant fiber. The mud includes the mud generated by the treatment and drainage of living sewage, river mud as well as the mud generated during the industrial treatment process of paper making or dejection; besides, the following pre-treatments are carried out on the mud: (1) a microorganism inoculant is added in the mud for processing; (2) an odour removing agent is added in the mud after being treated by step (1) for processing. When pre-treatments are carried out on the mud in the mud synthesizing fuel disclosed in the invention, the microorganism inoculant and the odour removing agent are added for processing, thus being capable of removing the metals and the peculiar smells in the mud, thereby reducing the pollution to the environment when the fuel is burnt.

Owner:汤广武

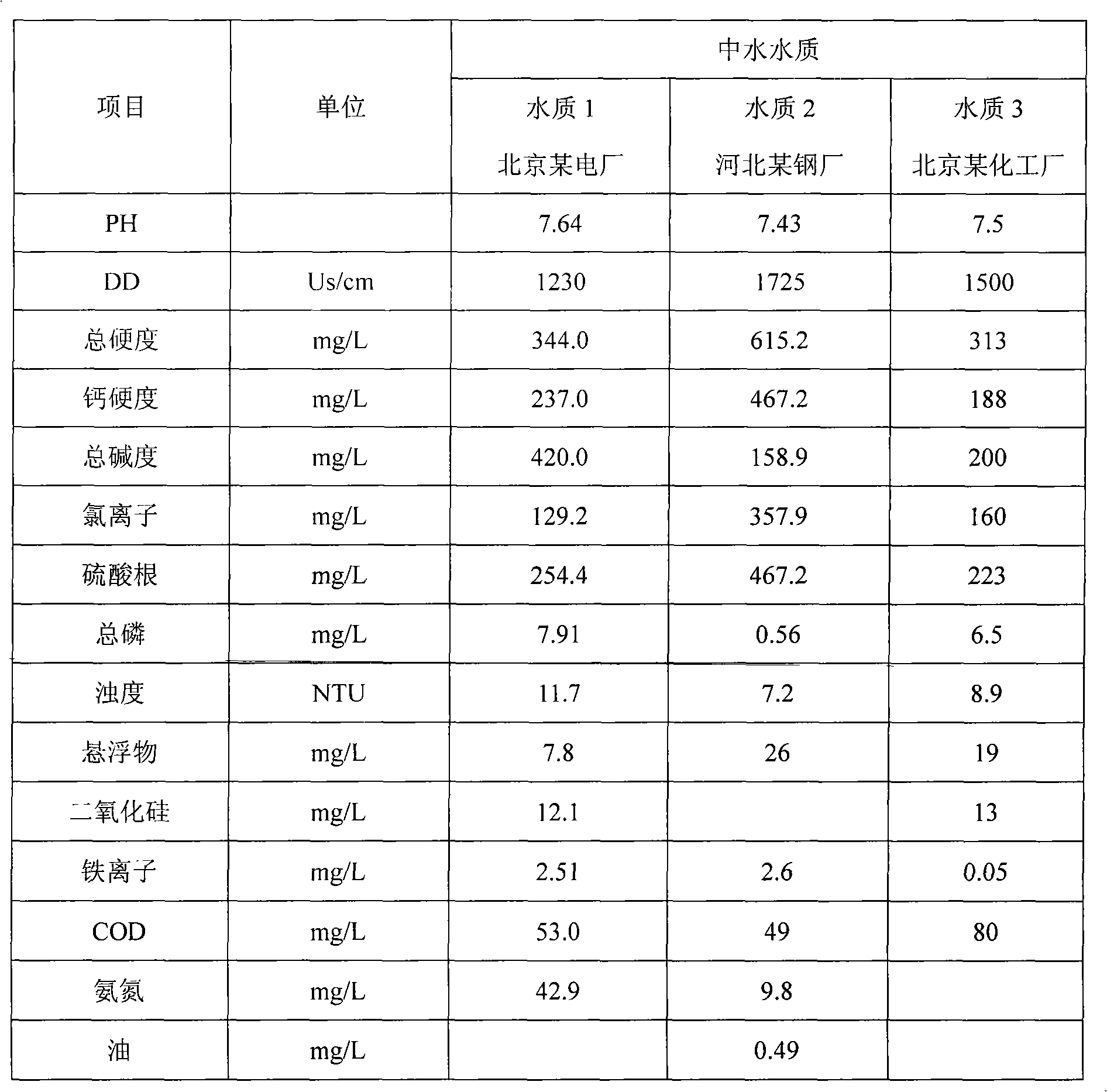

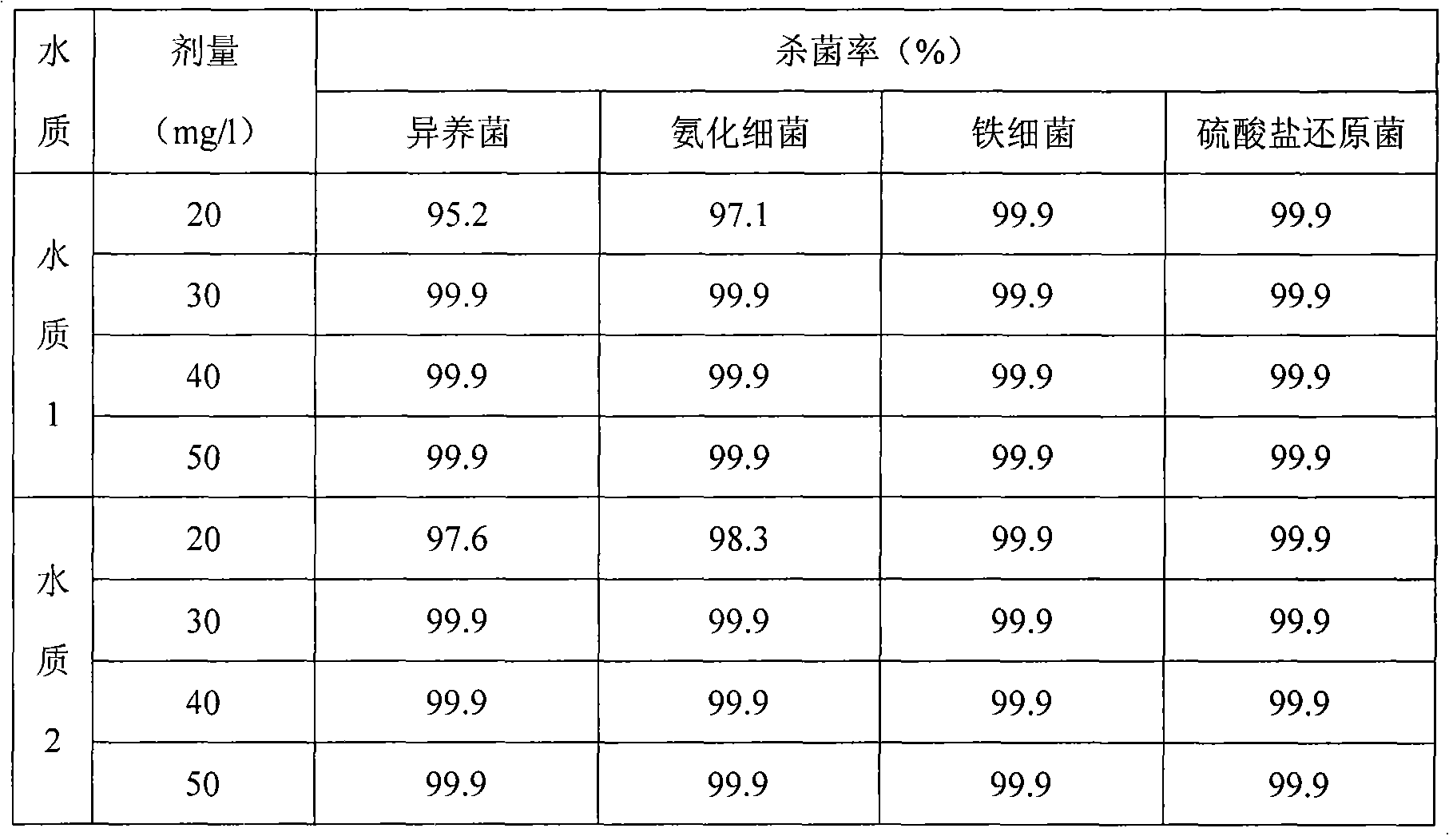

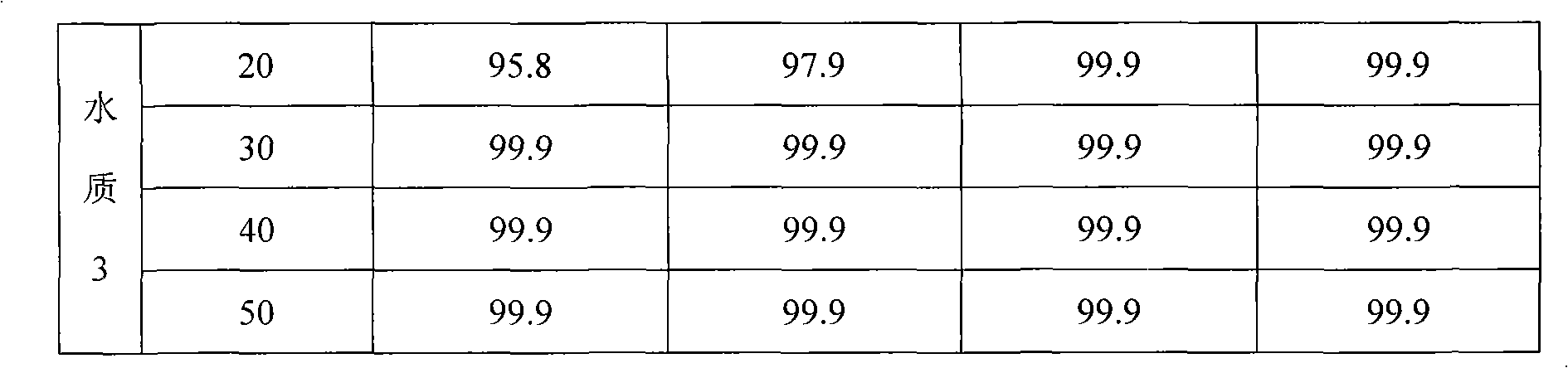

Bactericidal and algaecidal composition for intermediate water system, preparation method and application thereof

InactiveCN101637155AEasy to useStable chemical propertiesBiocideWaste water treatment from metallurgical processWater qualitySolvent

The invention relates to a bactericidal and algaecidal composition for an intermediate water system, a prepration method and an application thereof, wherein, the composition comprises the following components of bisquaternary ammonium salt, modified quatemary ammonium salt, penetrating agent, synergist and water, wherein, the water is used as a solvent. The bactericidal and algaecidal compositioncan effectively prevent the propagation of bacteria and algae and other phenomena in cooling water. The bactericidal and algaecidal composition simultaneously has the roles of stripping slime, removing odor and the like. The result shows that the composition has significant bactericidal and algaecidal effects, the bactericidal rate of heterotrophic bacteria, iron bacteria, ammonifying bacteria andsulfate-reducing bacteria can be more than 95%, the bactericidal effect is excellent, the composition is applicable to water quality with complicated change (high high-temperature and float indicators, high ammonia nitrogen indicators, high oil indicators and high organic phosphorus indicators), a wide range of fluctuations and the like, the dose is small, and the excellent bactericidal and algaecidal requirements can be achieved by only 50-100mg / l. In addition, the product has small toxicity and easy degradation. Therefor, the composition has good economic benefits, environmental protectionbenefits and social benefits for enterprises.

Owner:北京拓凯化工技术有限公司

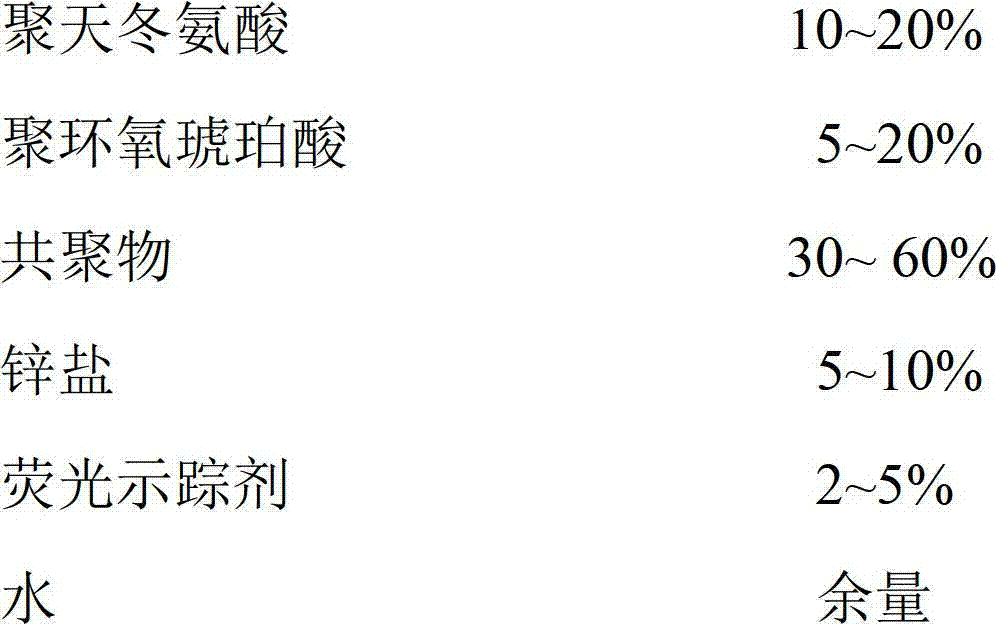

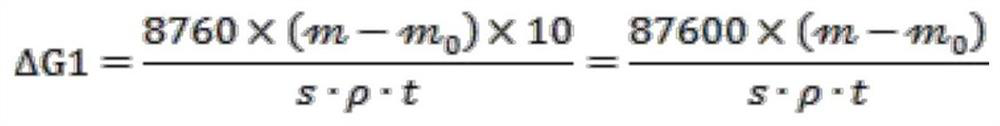

Biodegradable non-phosphorous anti-scale corrosion inhibitor and preparation method thereof

InactiveCN102774969AEasily biodegradableNo environmental problemsScale removal and water softeningPhosphorous acidBalance water

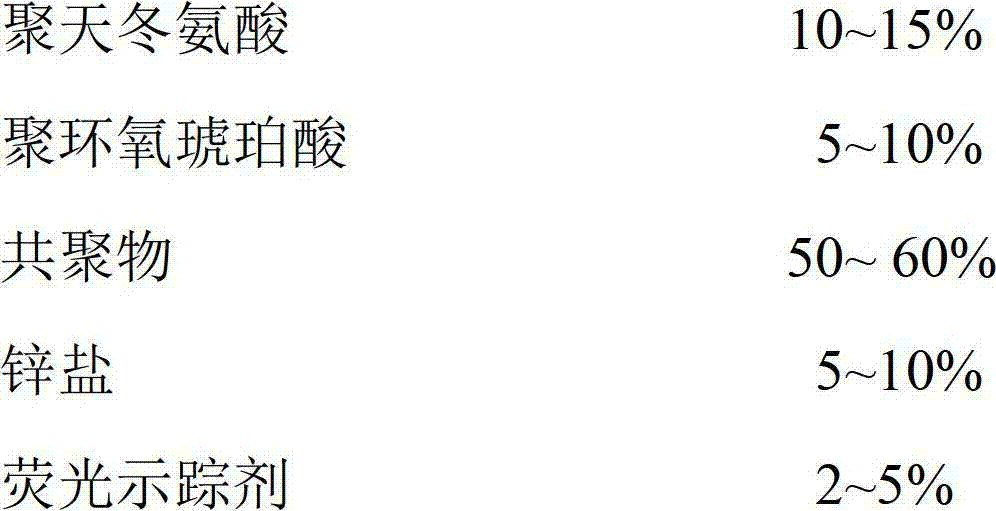

The invention discloses a biodegradable non-phosphorous anti-scale corrosion inhibitor and a preparation method thereof. The biodegradable non-phosphorous anti-scale corrosion inhibitor comprises, by mass, 10-20% of polyaspartic acid, 5-20% of polyepoxysuccinic acid, 30-60% of copolymers, 5-10% of zinc salt, 2-5% of fluorescent tracers and the balance water, wherein the molecular weight of the copolymers ranges from 2000-10000, and the copolymers are maleic anhydride / acrylic acid / acrylic acid oxylactone / 2-acrylamide-2-methylpro panesulfonic acid quaternary copolymers. The non-phosphorous anti-scale corrosion inhibitor is used for stainless steel condenser circulating cooling water systems of thermal power plants, is non-phosphorous, non-toxic, easily biodegradable, free from environmental problems and unlimited in discharge, and is capable of controlling carbon steel corrosion rate to be smaller than or equal to 0.075mm / a, controlling corrosion rate of copper, copper alloy and stainless steel to be smaller than or equal to 0.005mm / a, controlling dirt deposition rate to be smaller than or equal to 15mcm and controlling scale inhibition rate to be larger than or equal to 80%.

Owner:ZHEJIANG ZHENENG TECHN RES INST +1

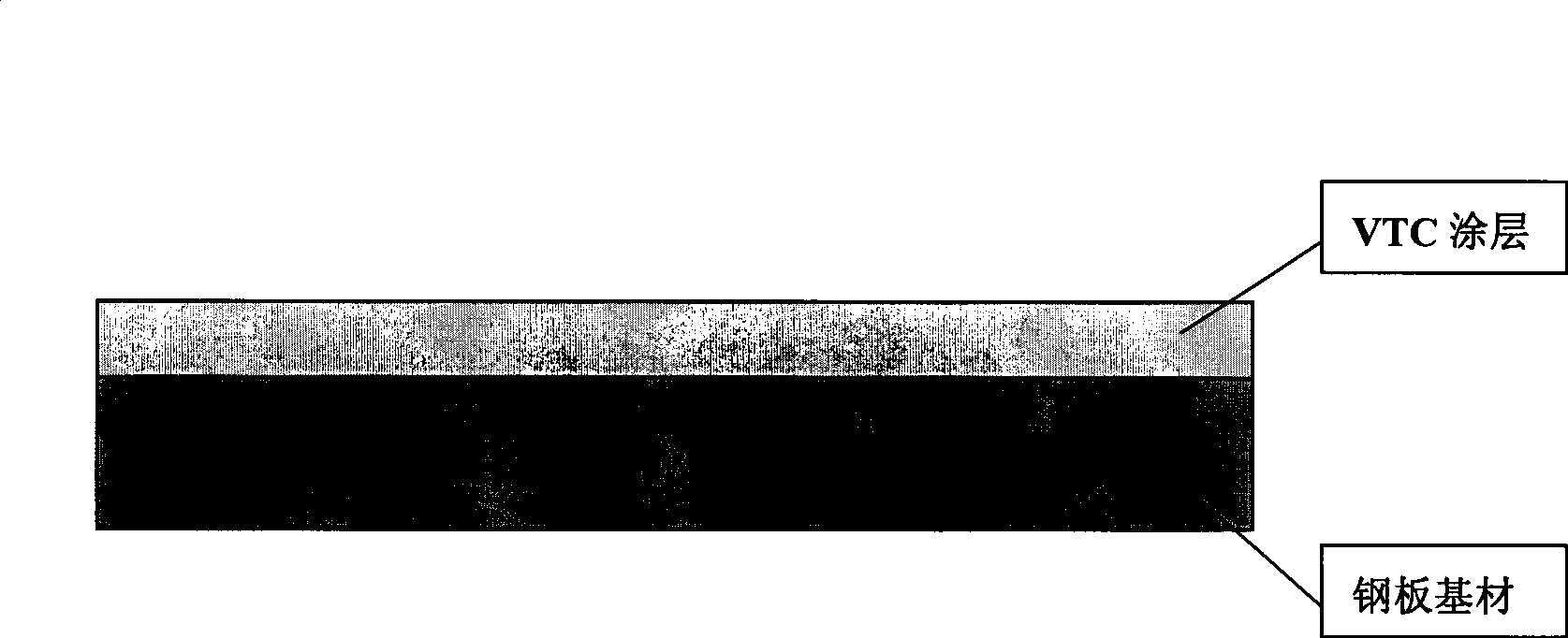

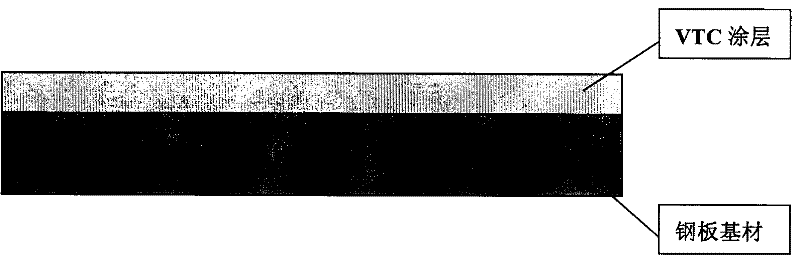

VCI-containing flake cold-plating zinc and aluminum protective coating on steel structure surface and preparation method thereof

ActiveCN101397413AHarsh salt spray resistanceGood anti-ultraviolet aging performanceAnti-corrosive paintsEpoxy resin coatingsCoating systemZinc

A squama type cold galvanizing aluminum coating used on the surface of steel structure and containing VCI (Vapor corrosion inhibitor). Besides, the invention also provides a VCI squama type cold galvanizing aluminum complex coating system on the surface of steel structure and prepared from the coating.

Owner:AVIC BIAM NEW MATERIALS TECH ENG

Dirt dispersion agent containing sulfonic acid copolymer

InactiveCN1837103AGood anti-scaling effectGood dispersionScale removal and water softeningPhosphateSodium lignosulfonate

The invention provides an anti-scaling disperser, which comprises 2-acrylamide-2-methyl propanesulfonic acid copolymer, sodium lignosulfonate, tannic acid, sodium humate and water. 78{>The invention also provides a method for using the anti-scaling disperser by compounding with organic phosphate and zinc salts, or compounding with zinc chloride to 8-12%.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

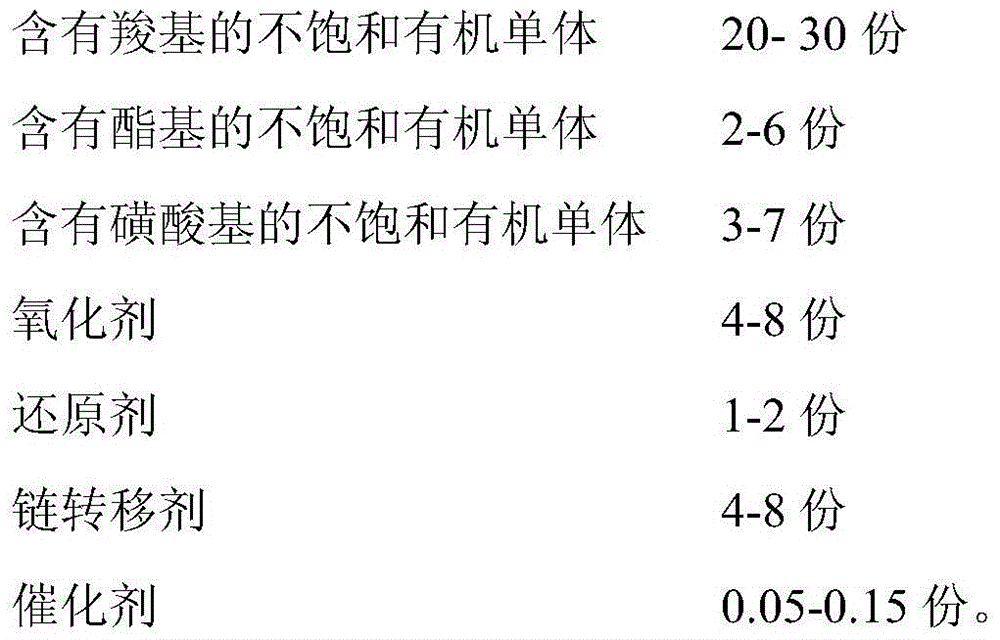

Multi-copolymer and preparation method and use thereof

ActiveCN105542055AWith anti-scalingWith dispersionWaste water treatment from quariesSeawater treatmentAcid groupCopolymer

The present invention belongs to the technical field of water treatment, relates to a multi-copolymer used for recycled water for industry and a preparation method and use thereof, particularly use as a scale and corrosion inhibitor, and especially as a low-phosphorus environmental-friendly scale and corrosion inhibitor. The multi-copolymer is obtained by copolymerization of a carboxyl-group-containing unsaturated organic monomer, an ester-group-containing unsaturated organic monomer and a sulfonic-acid group-containing unsaturated organic monomer, and the limiting viscosity number of the multi-copolymer is 0.035-0.055dL / g. The multi-copolymer has scale inhibition, dispersion, corrosion resistance, temperature resistance and other properties, can be used as a scale inhibition dispersant, especially as the low-phosphorus environmental-friendly scale and corrosion inhibitor, and can be used in circulating cooling water systems, oil field water injection systems, seawater desalination and other fields.

Owner:CHENGDU QIDA WATER TREATMENT ENG

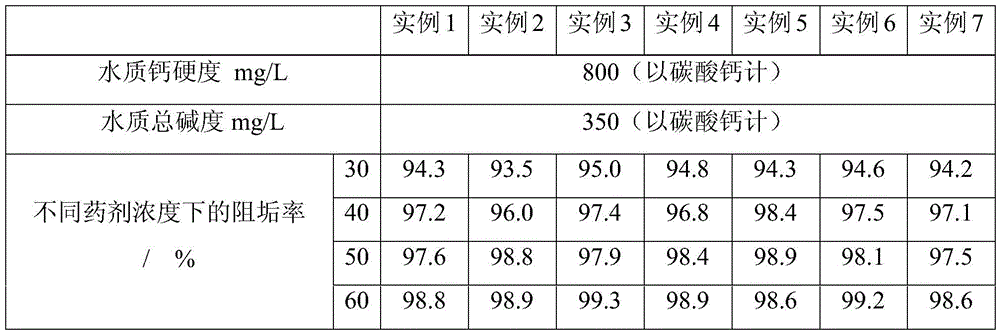

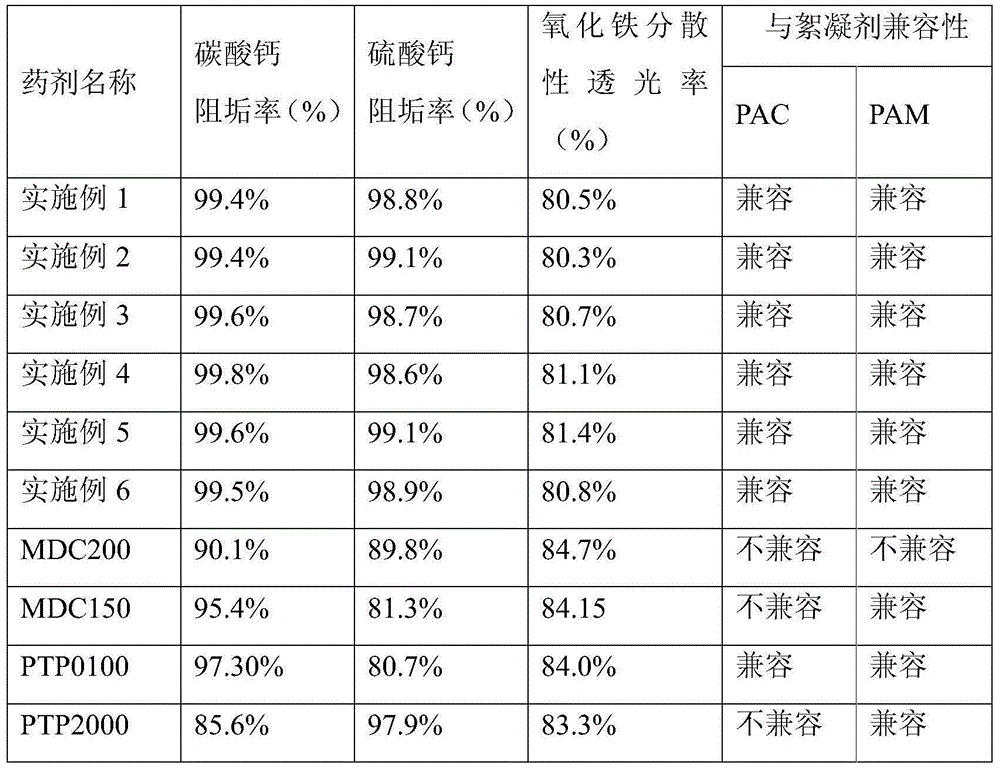

Reverse osmosis membrane scale inhibitor and application thereof

InactiveCN105126627AReduce or control aggregation and scalingCrystalline effectiveSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPhosphonium saltAluminium chlorohydrate

The invention provides a reverse osmosis membrane scale inhibitor. The reverse osmosis membrane scale inhibitor mainly comprises organic phosphonic acid, organic carboxylic polymers, sulfonic copolymers, a quaternary phosphonium salt, and methane dithiocyanate. The invention further provides an application of the reverse osmosis membrane scale inhibitor in scale inhibition of a reverse osmosis system. When used for reverse osmosis water treatment, the reverse osmosis membrane scale inhibitor provided by the invention can effectively eliminate membrane pollution caused by deposition of CaCO3, CaSO4, SiO2 and silicate; working efficiency of the reverse osmosis system is improved, service lives of the reverse osmosis membrane and reverse osmosis equipment are prolonged, and reverse osmosis cost is reduced; the reverse osmosis membrane scale inhibitor is compatible with various common flocculating agents such as polyaluminum chloride and cationic polyacrylamide; and a pH value is not required to regulate.

Owner:SHANDONG TIANQING TECH DEV

VCI-containing flake cold-plating zinc and aluminum protective coating on steel structure surface and preparation method thereof

ActiveCN101397413BNo pollution in the processImprove shielding effectAnti-corrosive paintsEpoxy resin coatingsCoating systemZinc

A squama type cold galvanizing aluminum coating used on the surface of steel structure and containing VCI (Vapor corrosion inhibitor). Besides, the invention also provides a VCI squama type cold galvanizing aluminum complex coating system on the surface of steel structure and prepared from the coating.

Owner:AVIC BIAM NEW MATERIALS TECH ENG

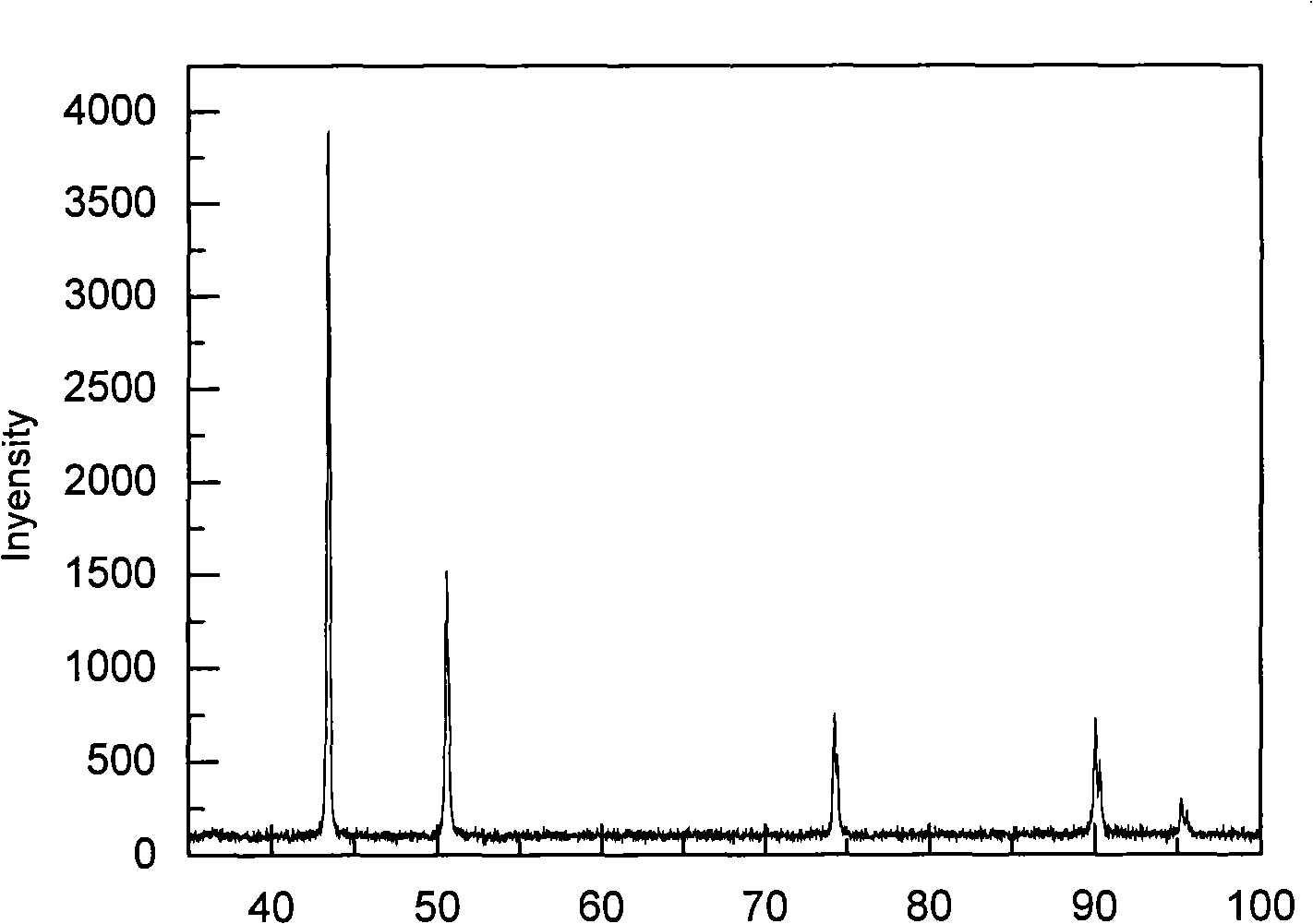

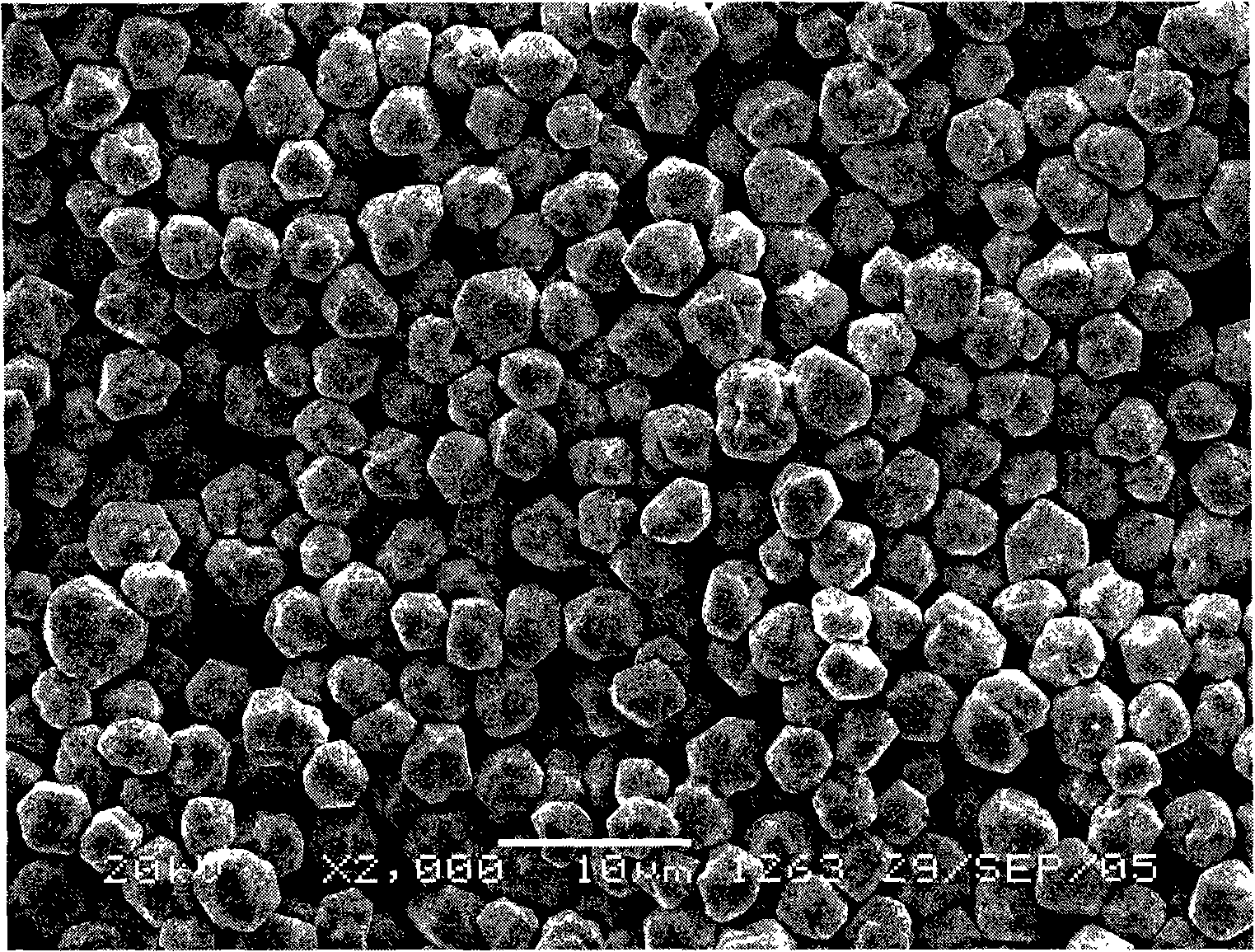

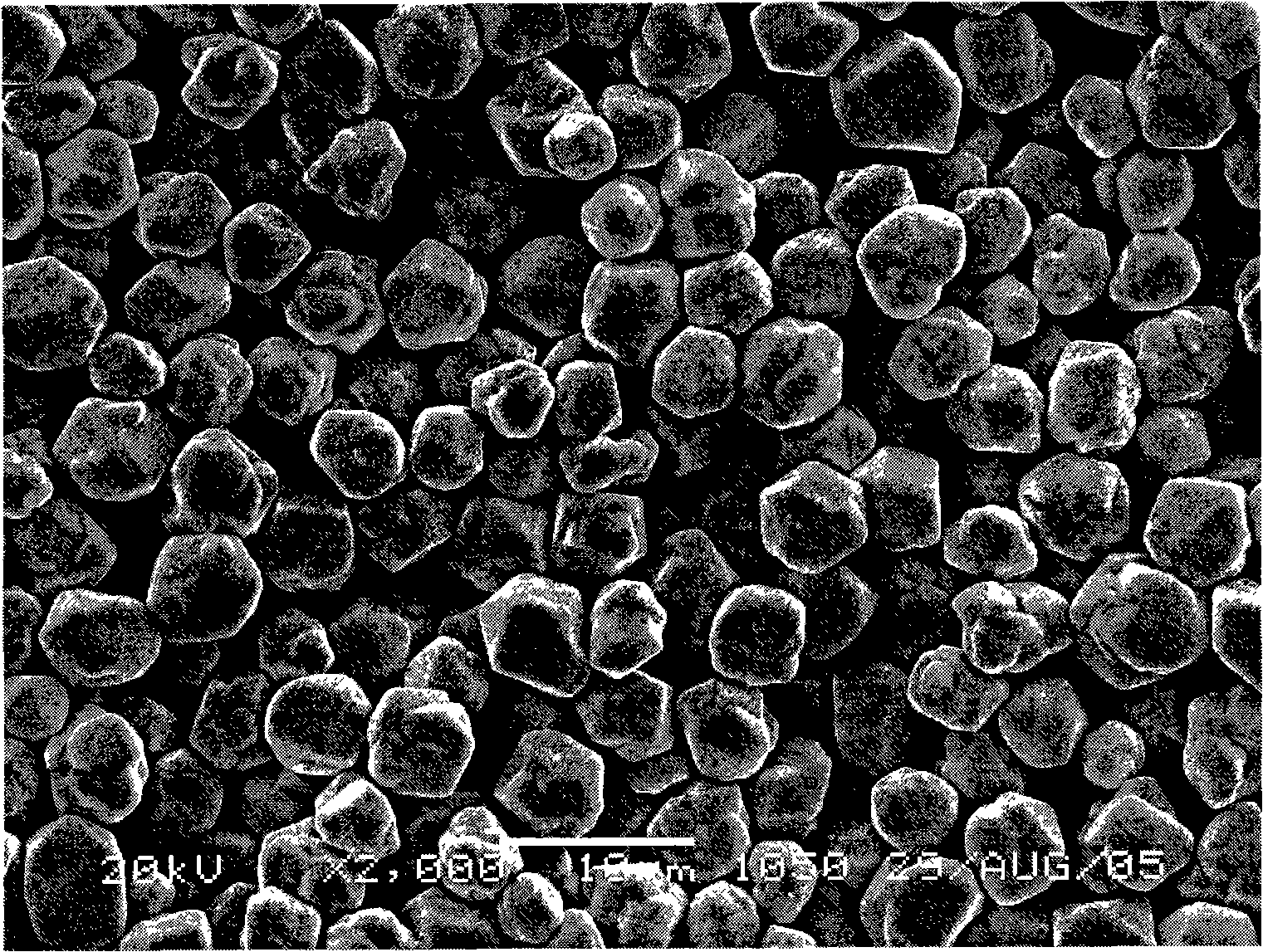

Method for preparing monodisperse high-crystallinity copper powder

A preparation method of monodisperse high crystallinity copper powder is provided, which relates to a method for preparing copper powder used in conductive paste by using cupreous compound, in particular to a preparation method of the copper powder used in the conductive paste that is applicable to ceramic electronic components with a plurality of layers. The method is characterized in that: cupric salt and copper oxide or copper hydroxide are taken as raw materials, a reductant and a reaction control agent are added into an alcohol-water system and fully mixed, reaction occurs under the conditions that the pH of the solution is 6.0 to 7.5 and the temperature is 50 to 95 DEG C, inert gas is used as carrier gas during the reaction process and the flux of the carrier gas is 50 to 500 ml / min question mark L, then solid-liquid separation, washing and drying are carried out to an obtained product after heat preservation for 1 to 6 h, and the monodisperse high crystallinity copper powder is obtained. The copper powder prepared by the invention is in spheroid shape or polyhedron shape, of which the grains are monodisperse and non-aggregating and have smooth surface, good crystallinity and certain antioxidant capacity. The size distribution of the copper powder is narrow and the average grain size can be regulated between 0.1 and 10 um.

Owner:CENT SOUTH UNIV +1

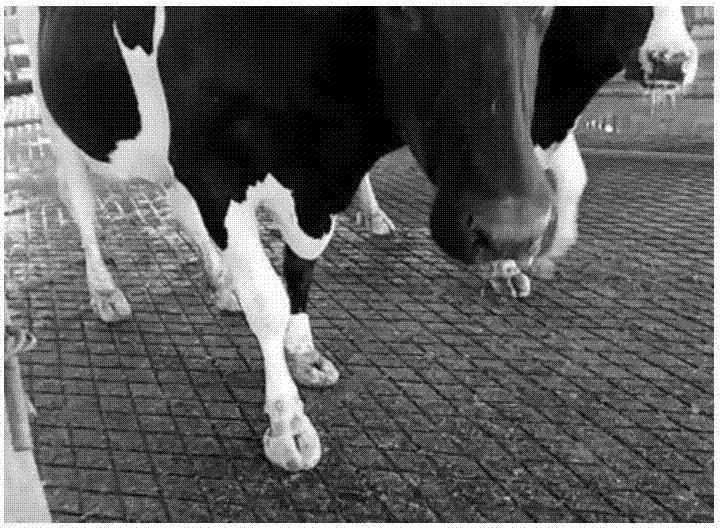

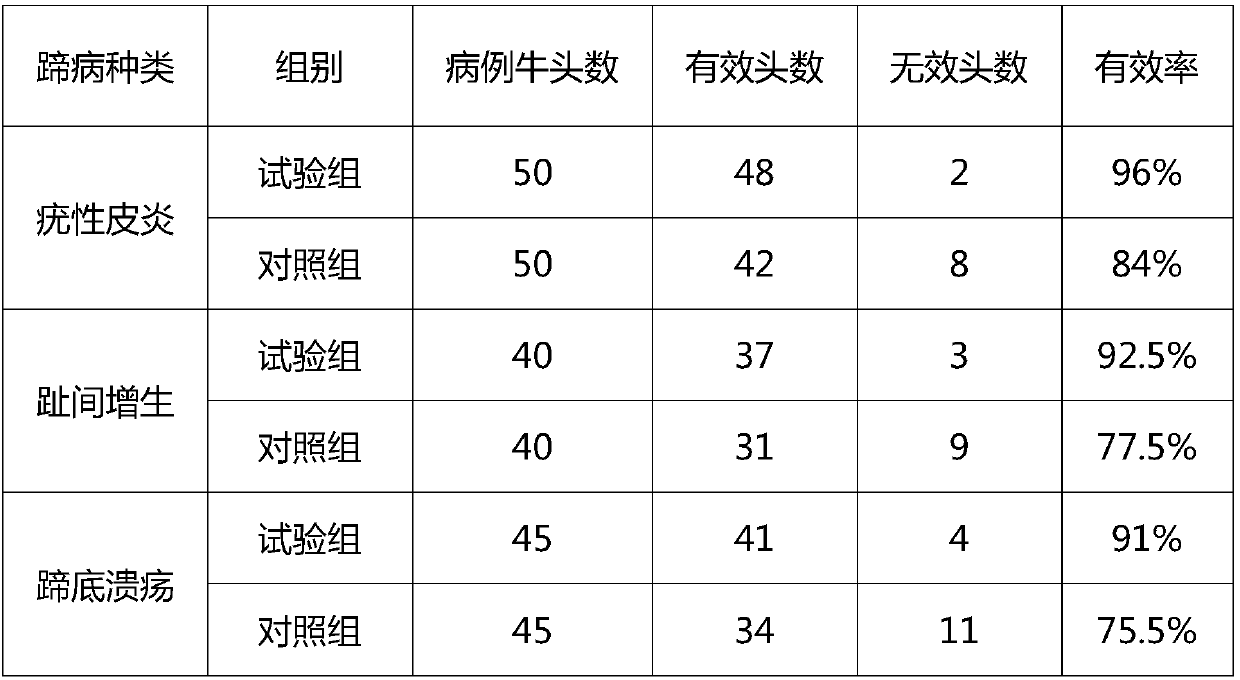

Foam-type lotion for preventing and treating hoof disease of dairy cow, preparation method and application thereof

InactiveCN107485606ABroad-spectrum bactericidal algicidal abilityGood slime stripping effectAntibacterial agentsAntisepticsDiseaseFoaming agent

The invention discloses a foam-type lotion for preventing and treating hoof disease of dairy cow. The lotion includes, by weight, 0.1-30 parts of glutaraldehyde, 0.1-20 parts of quaternary ammonium salt, 1-15 parts o a foaming agent, 0.5-5 parts of a foam stabilizer, 0.1-5 parts of a pH regulator, 0.01-1 part of a coloring agent, and 5-20 parts of water. The foam-type lotion can uniformly coat the surface of hoofs of dairy cow and effectively prevents and treats the hoof disease of dairy cow. The lotion has good sterilizing effect, is high in curative rate, is environment-friendly and has significant management distinguishing effect.

Owner:SHANGHAI CONSON BIOLOGICAL TECH

Compound cow hoof bath lotion and preparation method thereof

InactiveCN107837398ABroad-spectrum bactericidal algicidal abilityGood slime stripping effectAntibacterial agentsAntisepticsDiseaseLotion

The invention discloses a compound cow hoof bath lotion. The compound cow hoof bath lotion comprises the following components in parts by weight: 1-45 parts of a sterilizing agent, 1-40 parts of a hoof protection agent, 1-20 parts of a plant extract product, 1-20 parts of an astringent, 1-15 parts of a synergist, and 10-30 parts of deionized water. The protect can be used for preventing generationof cow hoof disease, disease condition can be controlled while disease happens, the compound cow hoof bath lotion does not contain formaldehyde, excitant and carcinogenicity on people and livestock can be avoided, and environment pressure due to hoof bath by single usage of copper sulphate can be alleviated through direct discharge. The invention also discloses a preparation method of the compound cow hoof bath lotion, which has the advantages of simple operation and easy acquisition of raw material, and is suitable for large-scale production.

Owner:SHANGHAI CONSON BIOLOGICAL TECH

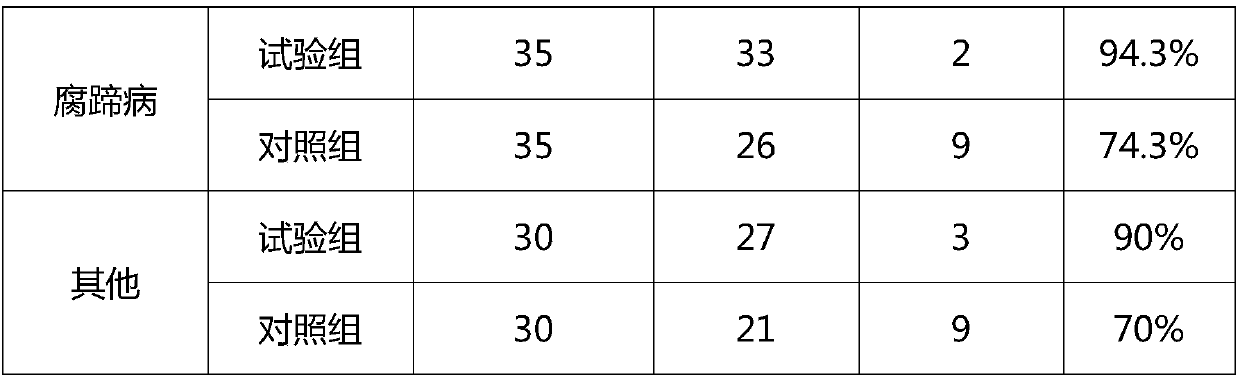

Preparation method of microcapsule with double-coated structure, and microcapsule prepared thereby

ActiveCN110433742AEnsure Structural IntegrityReverse corrosionAnti-corrosive paintsMicroballoon preparationPotassium persulfatePolystyrene

The invention discloses a preparation method of a microcapsule with a double-coated structure. The preparation method comprises the following steps: (1) reacting styrene to obtain a PS prepolymer, adding an emulsifier to a repairing solution, adding the PS prepolymer to obtain an emulsion, adding resorcinol, performing a reaction, and performing separation to obtain a PS / repairing solution microcapsule; (2) dissolving aniline in water, adding the PS / repairing solution microcapsule, allowing the aniline to swell into PS / repairing solution particles;, adding potassium persulfate, dropwise addinghydrochloric acid, and performing polymerization to obtain a polystyrene / polyaniline / repairing solution microcapsule; (3) adding the polystyrene / polyaniline / repairing solution microcapsule to an aqueous solution of CaCl2 and an aqueous solution of Na2CO3, performing mixing to precipitate calcium carbonate in order to obtain a multilayer microcapsule, and removing the polystyrene template to obtain a calcium carbonate-coated polyaniline double-layer self-repairing microcapsule; and (4) adding the calcium carbonate-coated polyaniline double-layer self-repairing microcapsule to tung oil, performing stirring and reacting, filtering the obtained system, and centrifuging and washing the obtained material to obtain the calcium carbonate / polyaniline / tung oil microcapsule.

Owner:CHENGDU TECHCAL UNIV

Bactericidal scale and corrosion inhibitor for seawater desalination

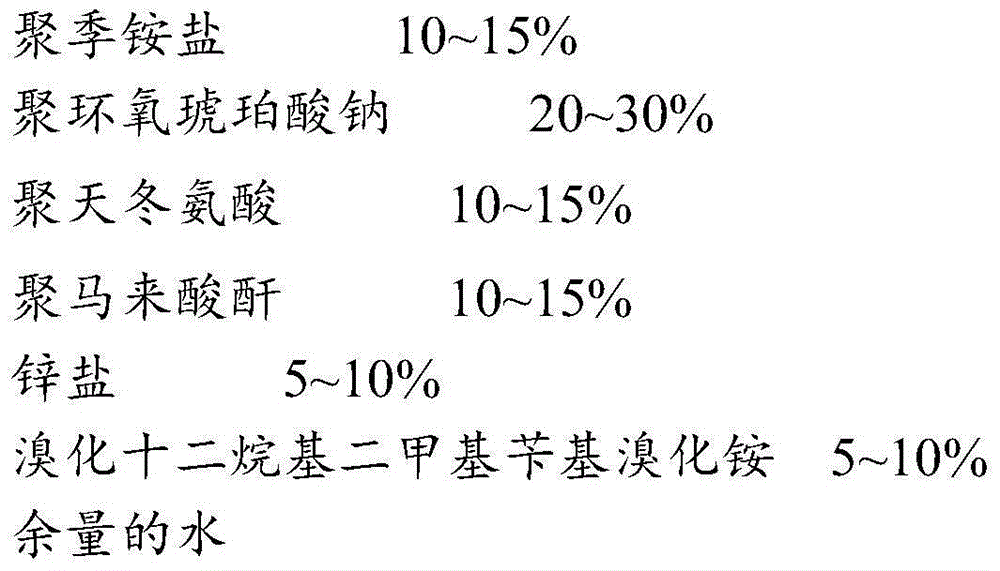

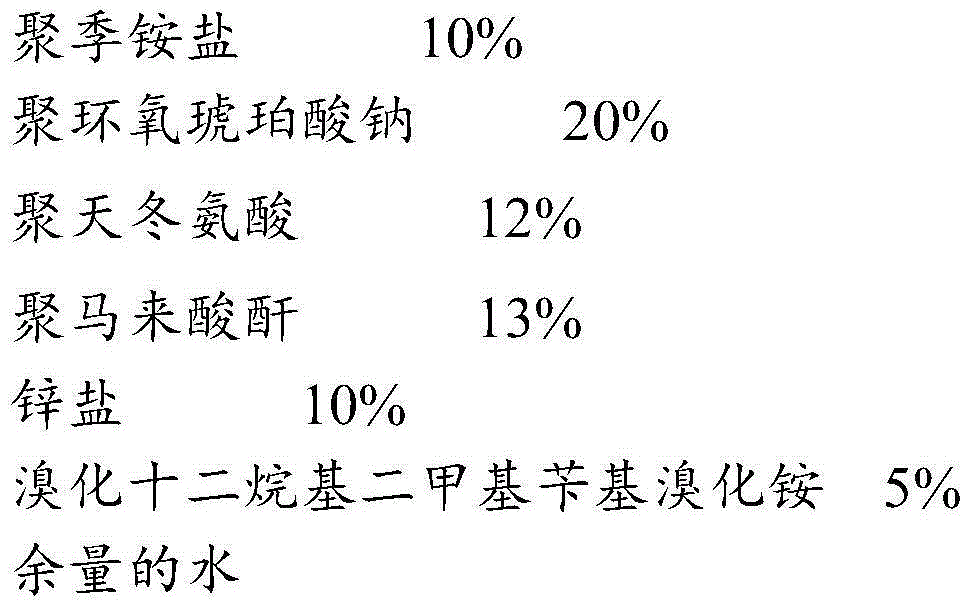

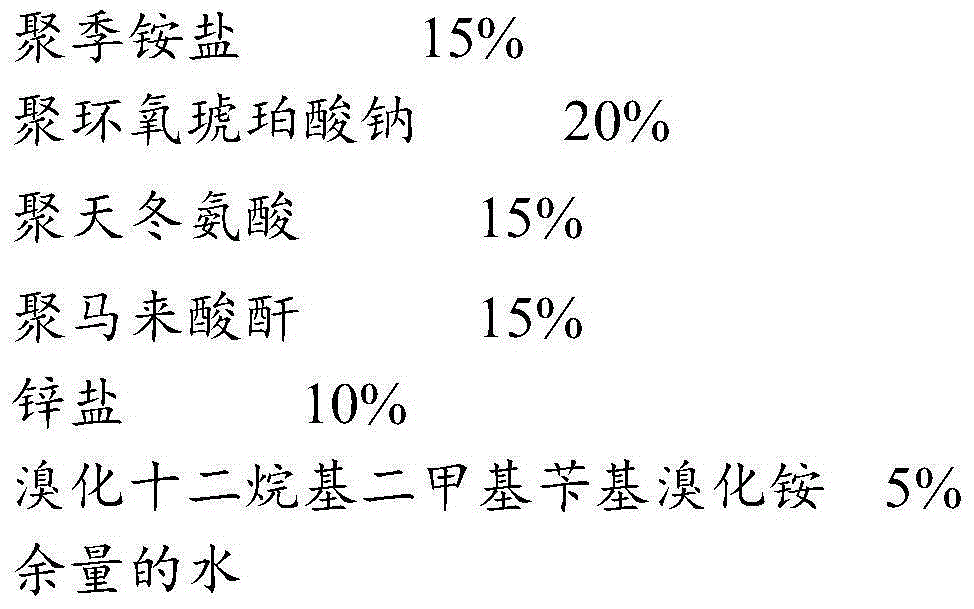

The invention provides a bactericidal scale and corrosion inhibitor for seawater desalination, and belongs to the technical field of chemical engineering. The bactericidal scale and corrosion inhibitor comprises, by weight, 10-15% of polyquaternary ammonium salt, 20-30% of sodium polyepoxysuccinate, 20-30% of polyaspartic acid-polymaleic anhydride, 5-10% of a zinc salt, 5-10% of dodecyl dimethyl benzyl ammonium bromide, and the balance of water. The bactericidal scale and corrosion inhibitor has scale inhibition, corrosion inhibition and sterilization functions, and all components of the bactericidal scale and corrosion inhibitor have very good intermiscibility, cooperativity and complementarity, so the bactericidal scale and corrosion inhibitor can substitute present single function scale and corrosion inhibitors and bactericides, and has comprehensive functions; and a formula and a preparation method of the bactericidal scale and corrosion inhibitor are green, compound raw materials adopted in the invention contain no phosphorus and cause no water eutrophication, discharged water causes no pollution to environment, and the preparation method is simple and feasible, is a clean technology, and has no emission of industrial three wastes.

Owner:安徽省蓝天能源环保科技有限公司

Novel reverse-osmosis scale inhibitor

ActiveCN104906961AHigh anti-scaling efficiencyReduce dosageSemi-permeable membranesScale removal and water softeningHexamethylenetetramineRoom temperature

The invention discloses a novel reverse-osmosis scale inhibitor which comprises the following raw materials in parts by weight: 2-8 parts of sodium citrate, 33-45 parts of hydrolytic polymaleic anhydride, 28-37 parts of polyepoxysuccinic acid salt, 9-15 parts of urotropine, 13-20 parts of polylactic acid, and 40-50 parts of water. A preparation method comprises the following steps: adding sodium citrate, hydrolytic polymaleic anhydride, polyepoxysuccinic acid salt, urotropine and half of water into a reaction kettle, heating to 40-50 DEG C, and stirring for uniformly dissolving; dissolving polylactic acid with the rest water to obtain a polylactic acid solution; heating the materials in the reaction kettle to 70-75 DEG C, dropwise adding the polylactic acid solution, and keeping the temperature for 3-4h after the dropwise adding is finished; and cooling to room temperature so as to obtain the novel reverse-osmosis scale inhibitor. The novel reverse-osmosis scale inhibitor disclosed by the invention has the scale inhibition rate being up to 95%, is small in adding amount, environmentally friendly, stable in property, and long in storage period, and can be used for solving the problems that existing reverse-osmosis inhibitors mainly are foreign products and are limited in treatment capacity, complex in synthesis, relatively high in production cost, and the like in the prior art.

Owner:浙江川宁环保科技有限公司

Method for polishing copper by chemical and mechanical methods

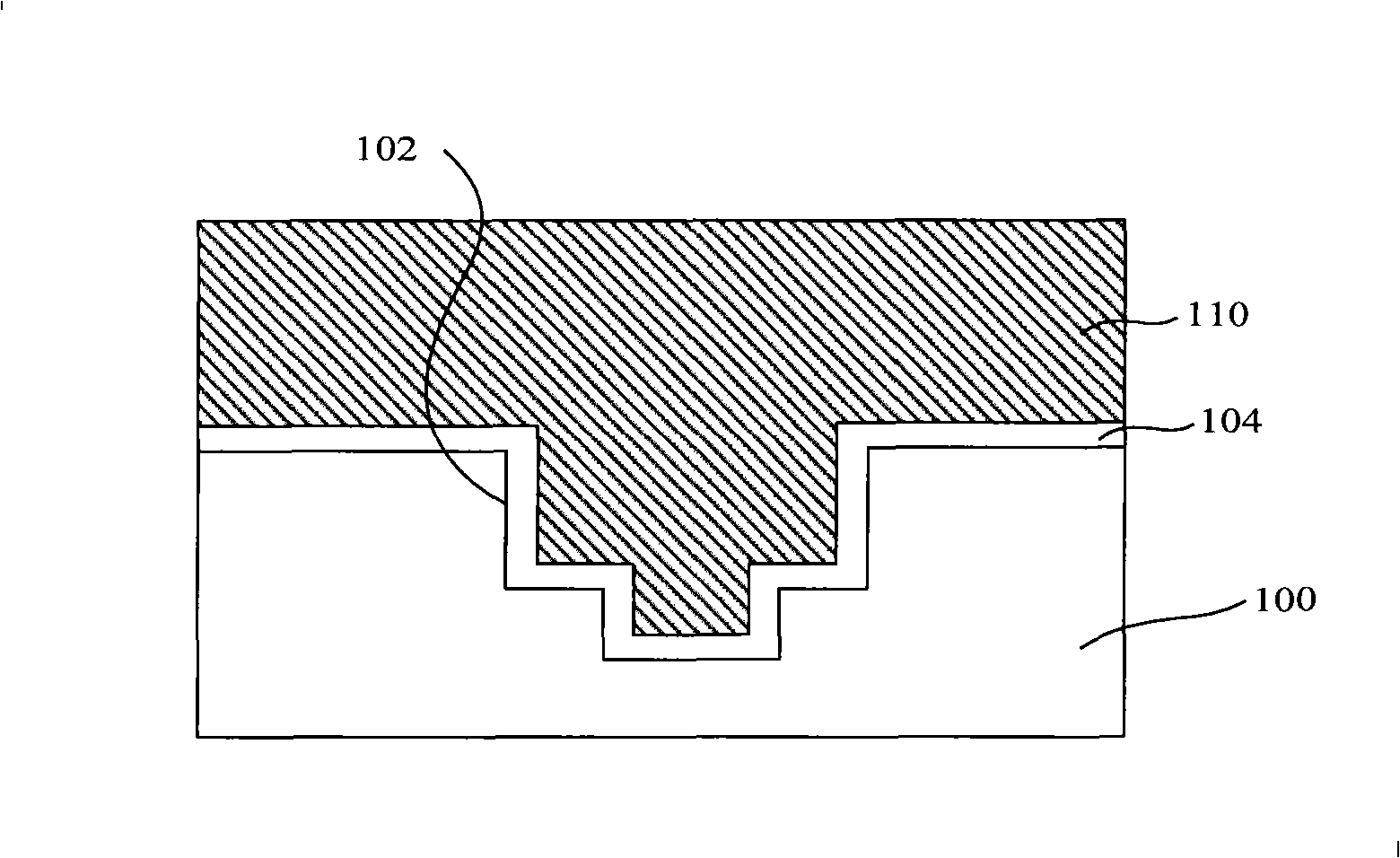

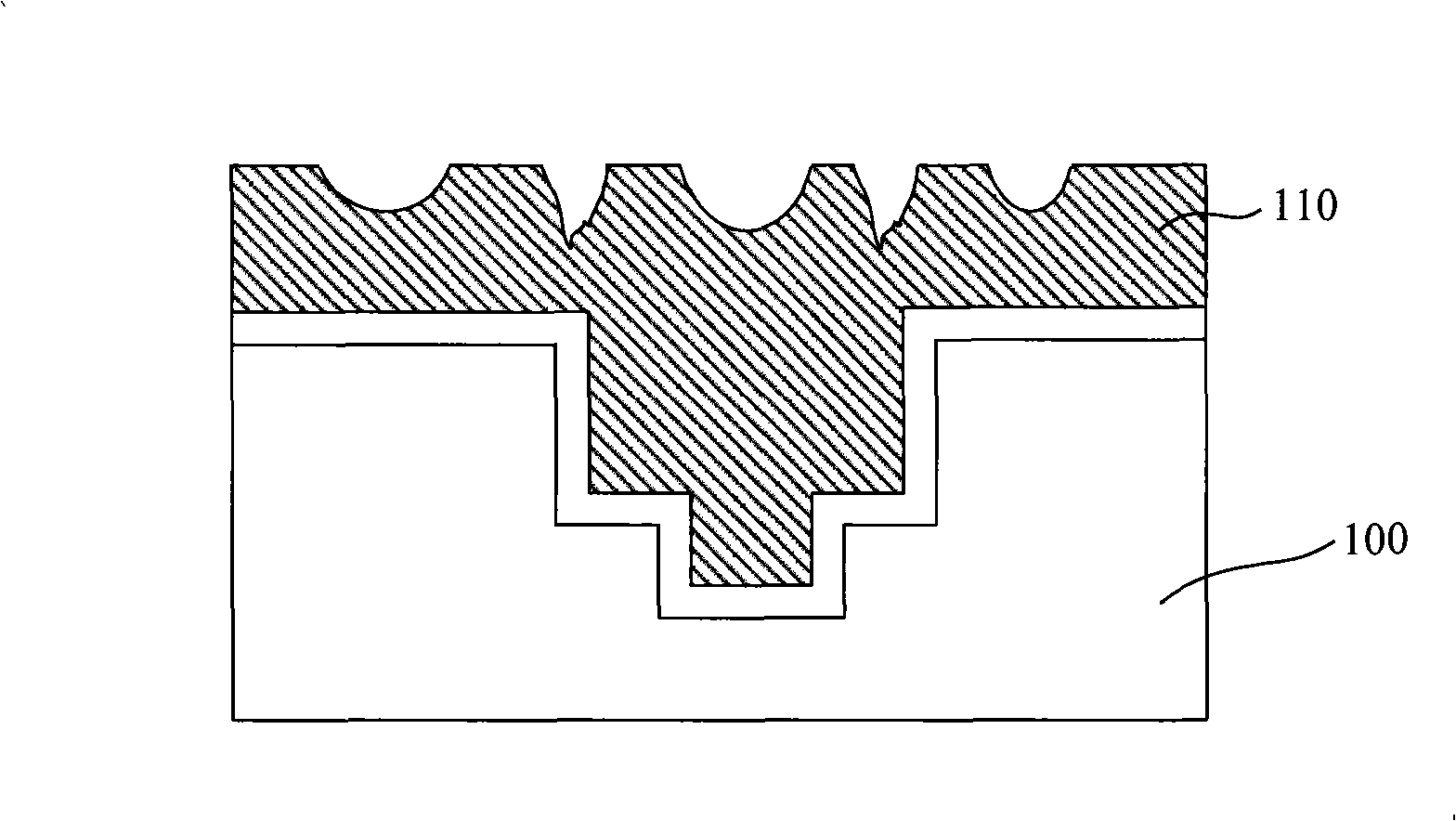

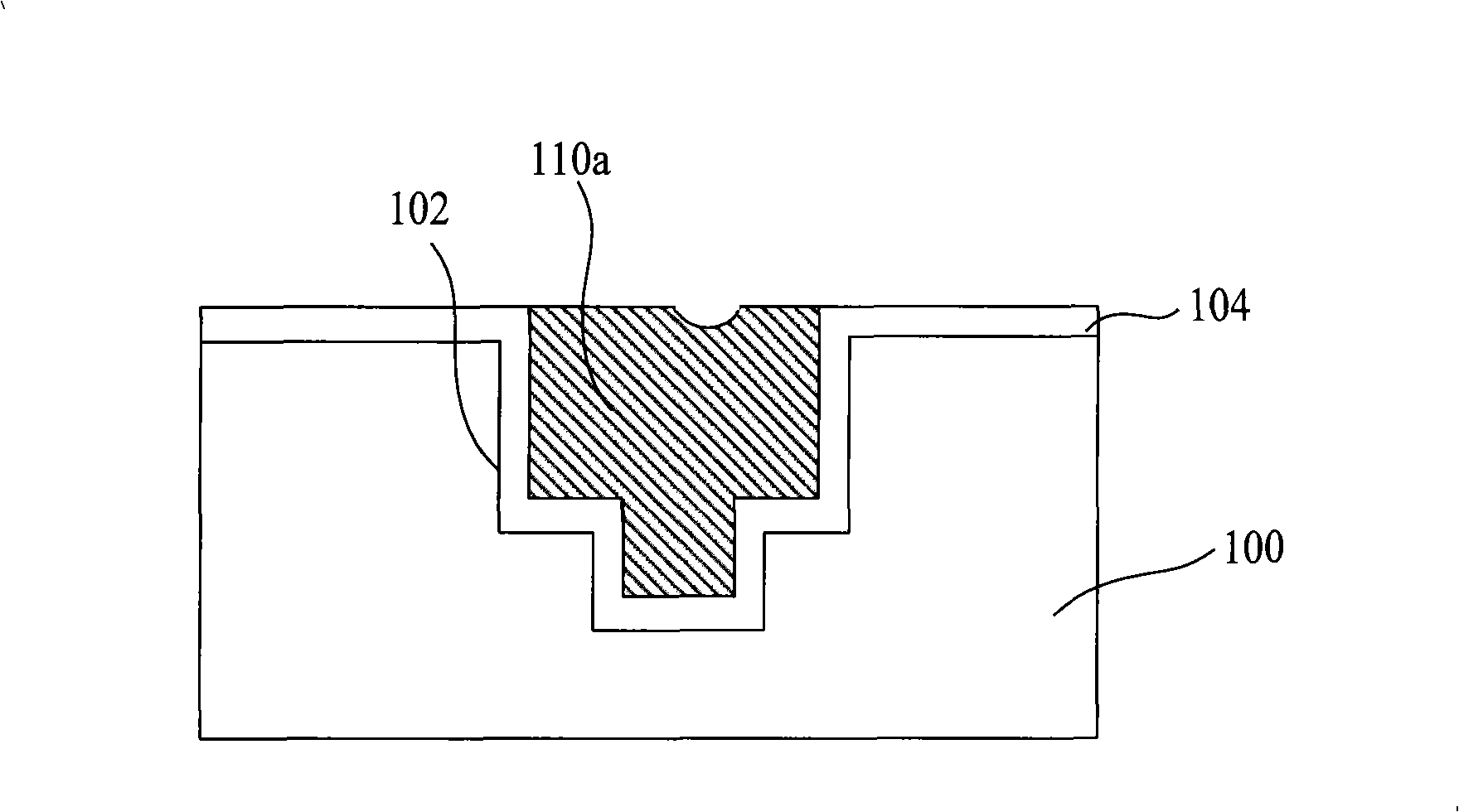

InactiveCN101352833AReduce corrosion rateHas a corrosion inhibitory effectSemiconductor/solid-state device manufacturingLapping machinesBasementSecondary stage

The invention discloses a chemical mechanical planarization method for copper, which is used for flattening the copper metal layer of semiconductor basements, and includes the following steps: executing first-stage grinding to remove the copper metal layer of semiconductor basements, executing second-stage grinding to remove the barrier layer under the copper metal layer; wherein, the second-stage grinding including the following steps: using grinding agent to carry out main grinding, using corrosion inhibitor to carry out grinding after finishing main grinding, and using deionized water to grinding and washing. The method can reduce or eliminate the corrosion on copper during the process of grinding.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Dispersing agent

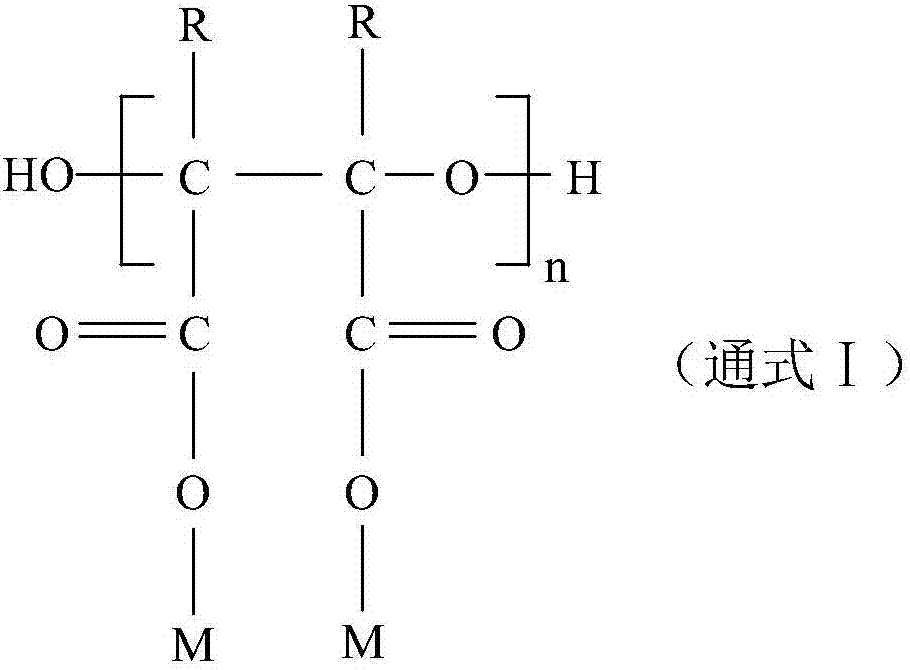

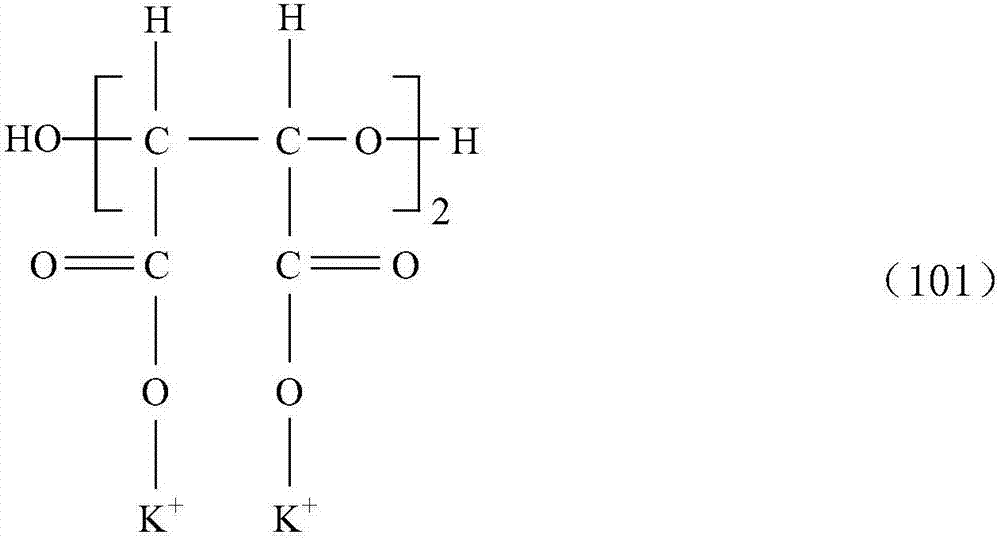

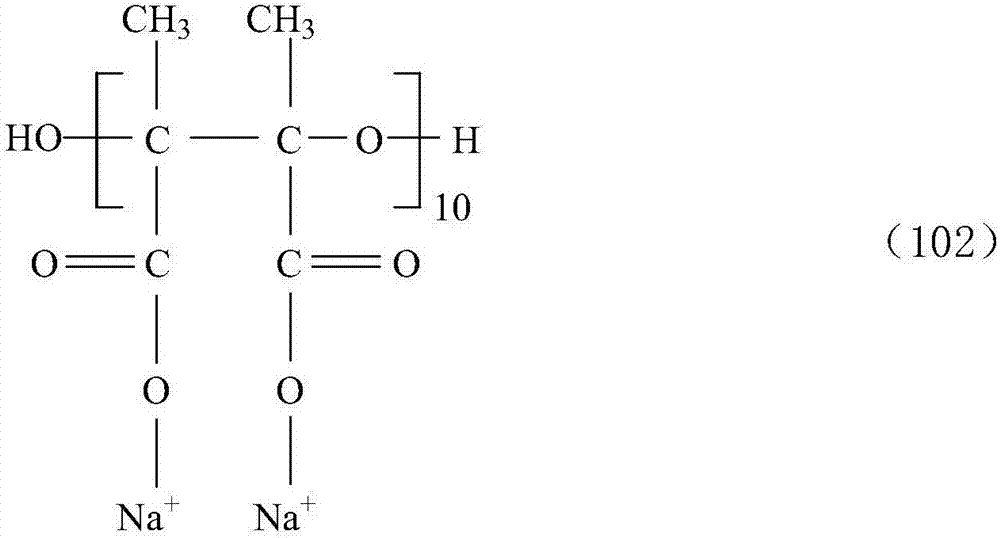

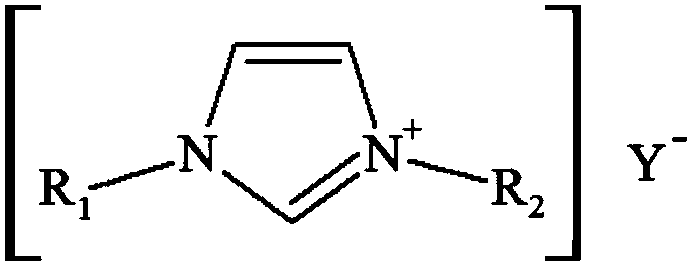

InactiveCN107313271AGood scale inhibition and dispersibilityHas a corrosion inhibitory effectDyeing processSolubilitySulfate

The invention relates to a dispersing agent, in particular to a dispersing agent for printing and dyeing. The dispersing agent comprises the following components in parts by mass: 50 to 70 parts of a dispersing agent as shown in a general formula I, 30 to 40 parts of organic phophonic acid and 25 to 35 parts of polyacrylic acid or salt thereof. The dispersing agent as shown in the general formula I has high scale-inhibiting and dispersing properties on calcium carbonate, calcium sulfate, barium sulfate, calcium fluoride and silicon scale, also has an excellent corrosion-inhibiting effect and is a polynary scaling inhibitor. The polyacrylic acid or the salt thereof can disperse microcrystals or silt of the salt such as calcium carbonate and calcium sulfate into water to avoid precipitation so as to fulfill the scale-inhibiting purpose. The dispersing agent as shown in the general formula I and the organic phophonic acid mutually cooperate to have good synergistic effect; furthermore, the dispersing agent has high biodegradability, is widely applied and has high solubility with other aids for printing and dyeing.

Owner:王蒙

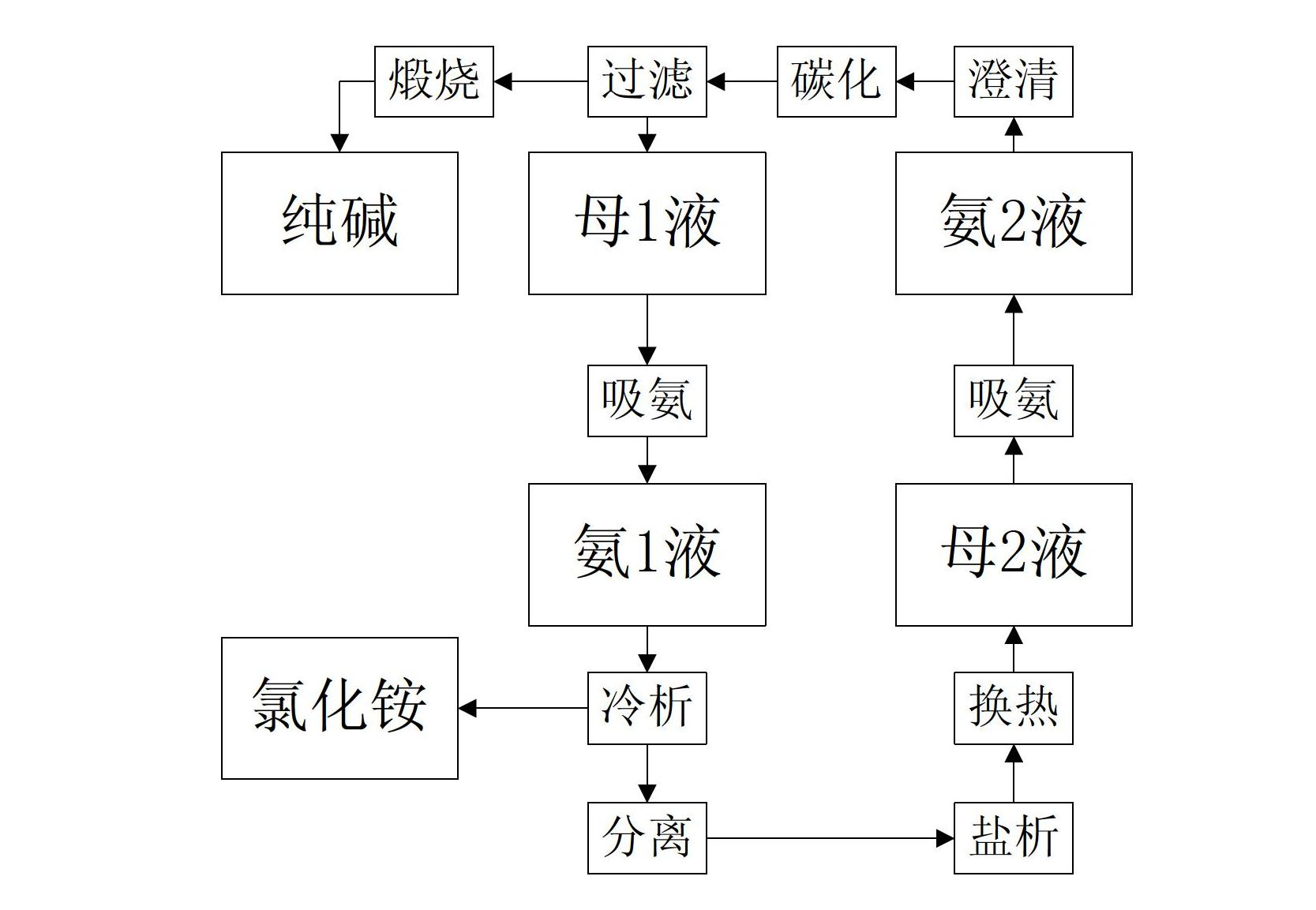

Scale inhibitor for soda ash mother liquid

ActiveCN102649605AGood scale inhibition and dispersibilityGood compatibilityScale removal and water softeningGluconic acidChemical cleaning

The invention discloses a scale inhibitor with soda ash mother liquor and belongs to the technical field of fine chemical products. The scale inhibitor comprises the following components in part by mass: 50 to 70 parts of HK-101 scale inhibitor, 5 to 15 parts of sodium gluconate, 10 to 20 parts of polyepoxysuccinic acid and 3 to 7 parts of pH regulator, wherein the HK-101 scale inhibitor is prepared through crylic acid, maleic acid, hydroxy-propyl acrylate, an initiator and a molecular weight regulator. The scale inhibitor applied to the soda ash mother liquid can prolong the scaling time of calcium ions and magnesium ions in the mother liquid, reduces the chemical cleaning frequency of a soda ash mother liquid production system from 2 to 4 times per year to 1 time per 2 to 3 years, guarantees long-period and stable operation of soda ash mother liquid production, greatly reduces damage to equipment caused by chemical cleaning and does not influence the quality of the soda ash product.

Owner:四川鸿康科技股份有限公司

Corrosion inhibitor for high-temperature equipment and preparing method of corrosion inhibitor

The invention discloses a corrosion inhibitor for high-temperature equipment and a preparing method of the corrosion inhibitor, and relates to the technical field of corrosion inhibitors. The corrosion inhibitor comprises following raw materials including, by weight, 40-60 parts of organic amine, 10-30 parts of imidazolines, 20-35 parts of phosphoric acid or phosphate, 15-25 parts of metal hydroxide, 10-20 parts of phosphate ester and 0.8-5 parts of a surface active agent. The preparing method comprises the first step of organic acid salt preparing, the second step of oxygen amino phosphate preparing and the third step of high-temperature equipment corrosion inhibitor preparing. The high-temperature equipment corrosion inhibitor meets the requirements for high temperature resistance and efficient corrosion inhibition, the production and usage processes are safe and reliable, irritant peculiar smells are avoided, and the corrosion inhibitor is environment-friendly.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

Antibacterial-enhanced aqueous aluminum pigment with zinc oxide/silver compound powder

InactiveCN106221309AImprove corrosion resistanceGood dispersionAntifouling/underwater paintsInksTalc / Zinc OxideDibenzoyl Peroxide

The invention discloses an antibacterial-enhanced aqueous aluminum pigment with zinc oxide / silver compound powder. The antibacterial-enhanced aqueous aluminum pigment is characterized by being prepared from the following raw materials in parts by weight: 40 to 45 parts flaky aluminum powder, 100 to 110 parts of isopropyl alcohol, 0.3 to 0.35 part of copper sulfate crystal, a proper amount of deionized water, 4 to 4.5 parts of phenolic ether type phosphate, a proper amount of absolute ethyl alcohol, 9 to 10 parts of tetraethoxysilane, 6 to 7 parts of vinyltriethoxysilane, 9 to 10 parts of ammonia water with the weight concentration of 20 percent, 200 to 220 parts of butyl acetate, 5 to 6 parts of crylic acid, 5 to 6 parts of methacrylic acid, 0.6 to 0.65 part of dibenzoyl peroxide, 13 to 15 parts of propylene glycol monomethyl ether, 2 to 3 parts of zirconium phosphate, 4 to 5 parts of nano-zinc oxide, 2 to 3 parts of carboxymethylcellulose, 0.8 to 1 part of sodium polyacrylate, 2 to 3 parts of glycerinum and 4 to 5 parts of a silver nitrate solution with the weight concentration of 10 percent. The product disclosed by the invention can be well dispersed in finished products such as an aqueous coating and ink, and is high in antibacterial property.

Owner:HEFEI SUNRISE PIGMENTS

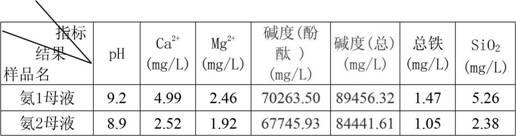

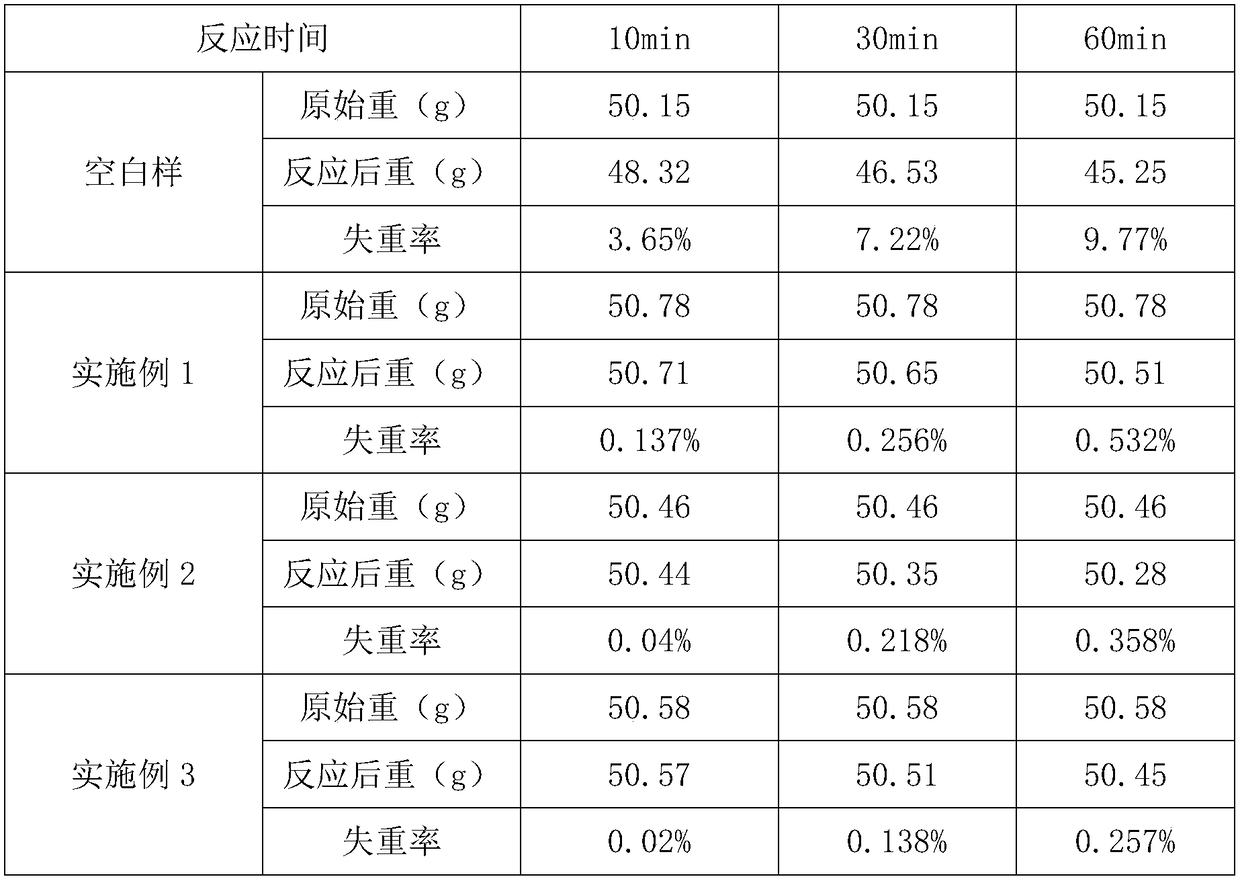

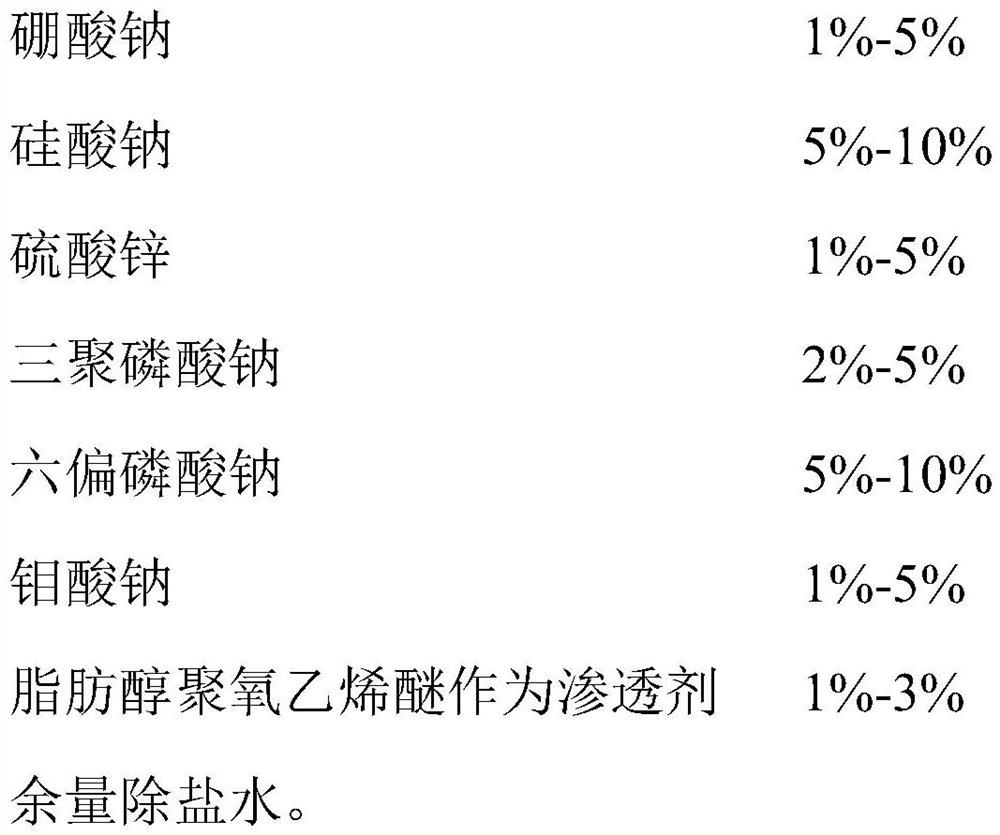

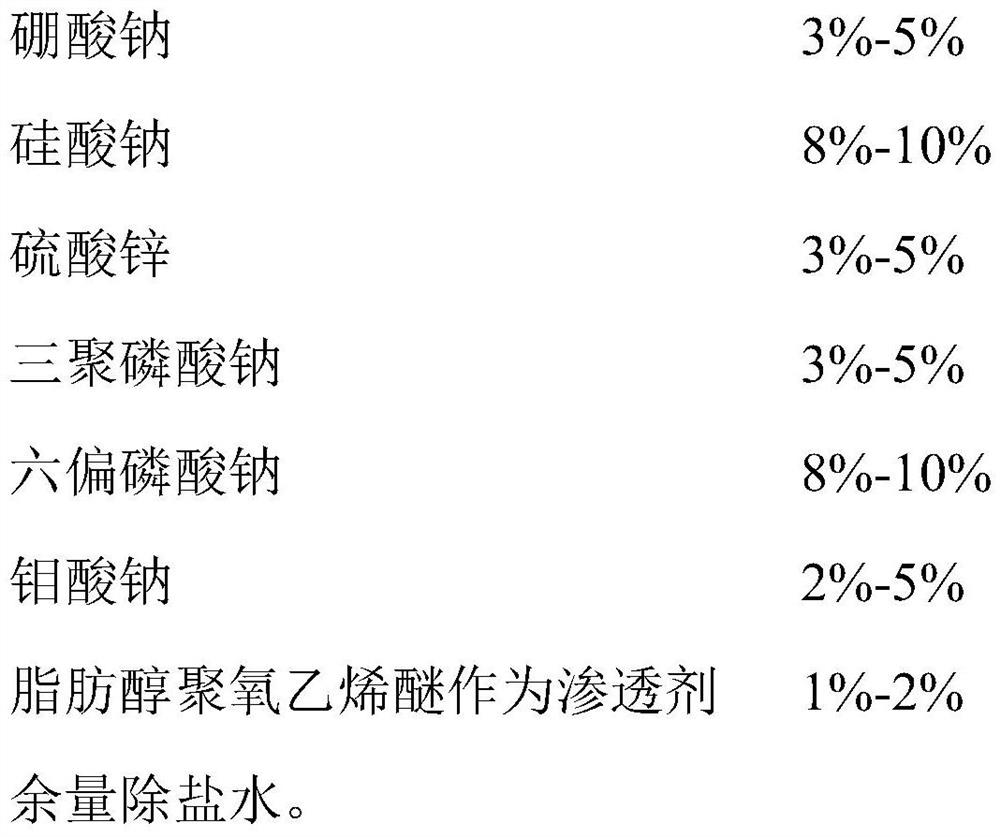

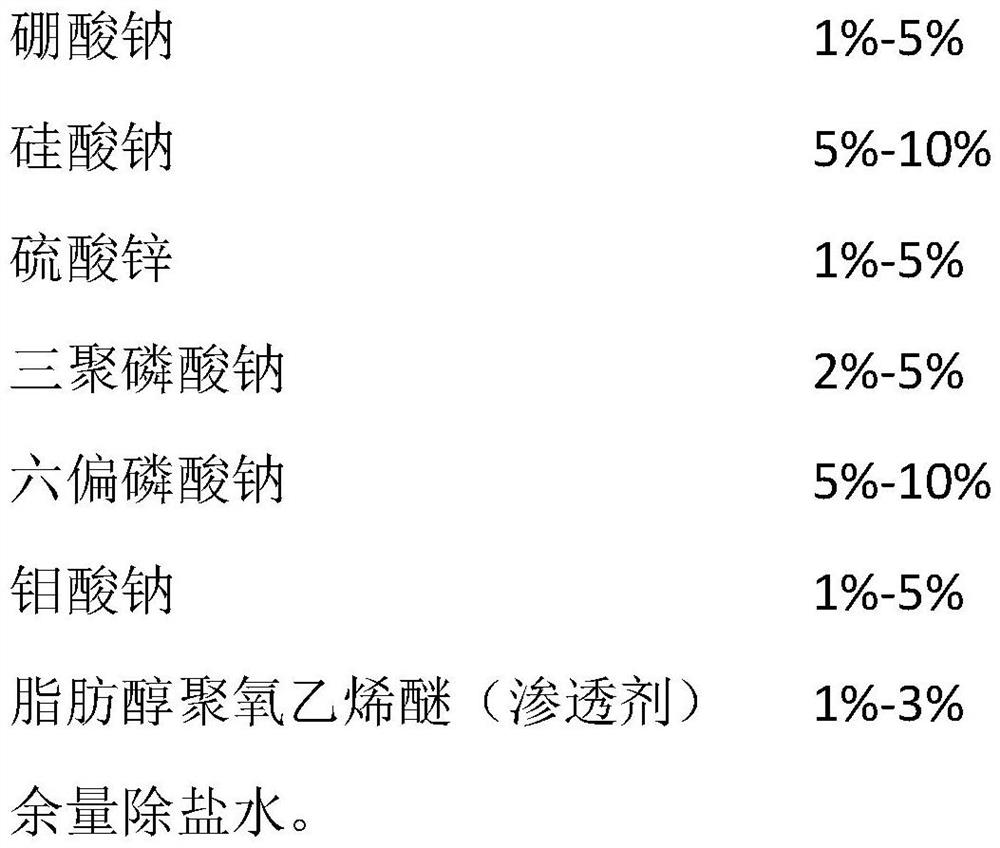

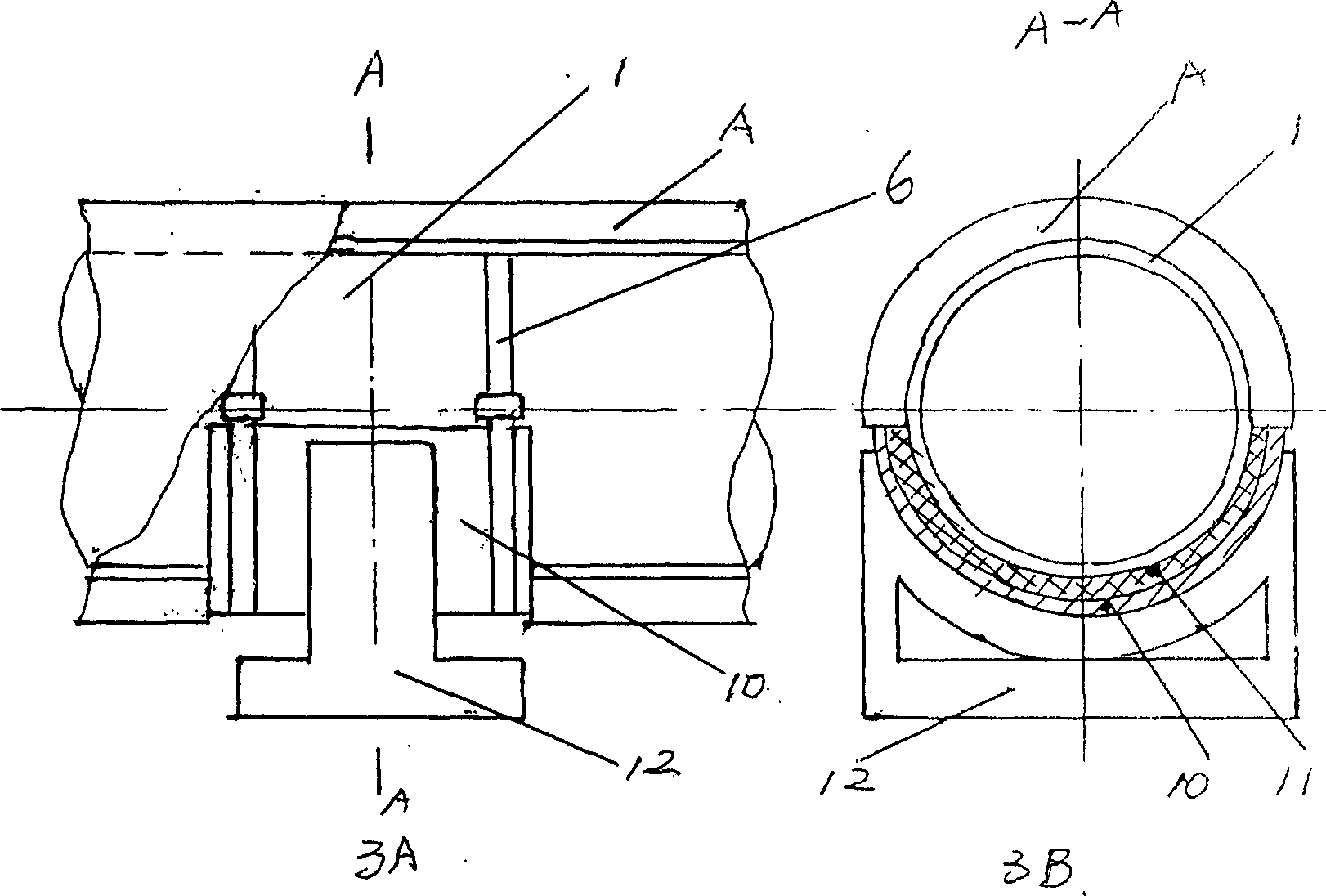

Corrosion inhibitor applied to SCAL type indirect cooling system and chemical adding method of corrosion inhibitor

ActiveCN111876784AReduce corrosion rateHas a corrosion inhibitory effectSODIUM METAPHOSPHATESodium phosphates

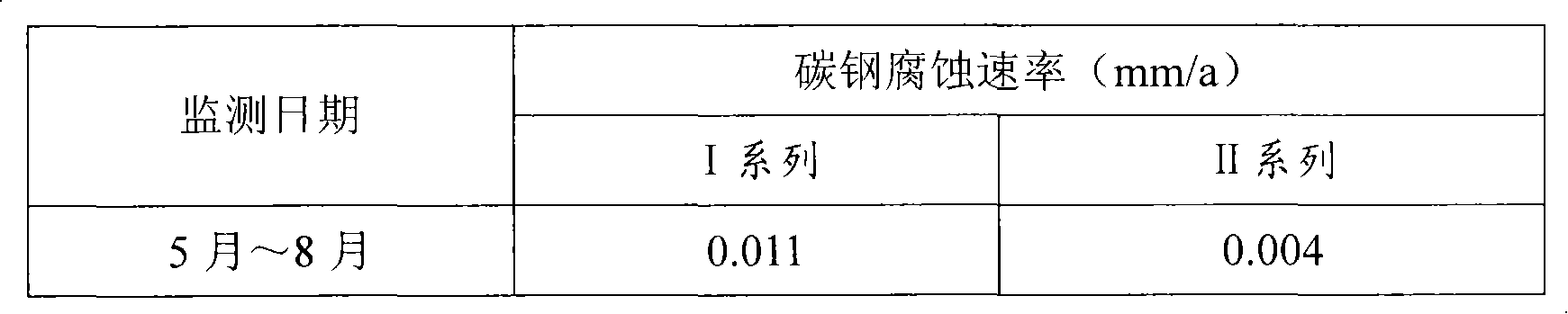

The invention belongs to the technical field of corrosion prevention of thermal power plant equipment, and particularly relates to a corrosion inhibitor applied to an SCAL type indirect cooling systemand a chemical adding method of the corrosion inhibitor. The chemical adding method comprises two steps of preparation of the corrosion inhibitor and addition of the corrosion inhibitor into the indirect cooling system. The corrosion inhibitor and the chemical adding method are characterized in that the corrosion inhibitor is prepared from sodium borate, sodium silicate, zinc sulfate, sodium tripolyphosphate, sodium hexametaphosphate, sodium molybdate, fatty alcohol-polyoxyethylene ether (penetrant) and desalted water in a chemical adding tank, and the corrosion inhibitor is injected into theSCAL type indirect cooling water system through a metering pump. The corrosion inhibitor and the chemical adding method have the beneficial effects that after the corrosion inhibitor is added into the SCAL type indirect cooling system, the corrosion rate of carbon steel in the SCAL type indirect cooling system can be controlled to be smaller than 0.075 mm / a, and the corrosion rate of pure aluminum in the SCAL type indirect cooling system can be controlled to be smaller than 0.0075 mm / a; after the corrosion inhibitor is applied, the water quality control range of the system can be properly widened, and the water changing frequency is reduced; after the corrosion inhibitor forms a film, the shutdown corrosion rate of the system can be reduced; and the components of the corrosion inhibitor are environment-friendly and low in toxicity.

Owner:XIAN THERMAL POWER RES INST CO LTD

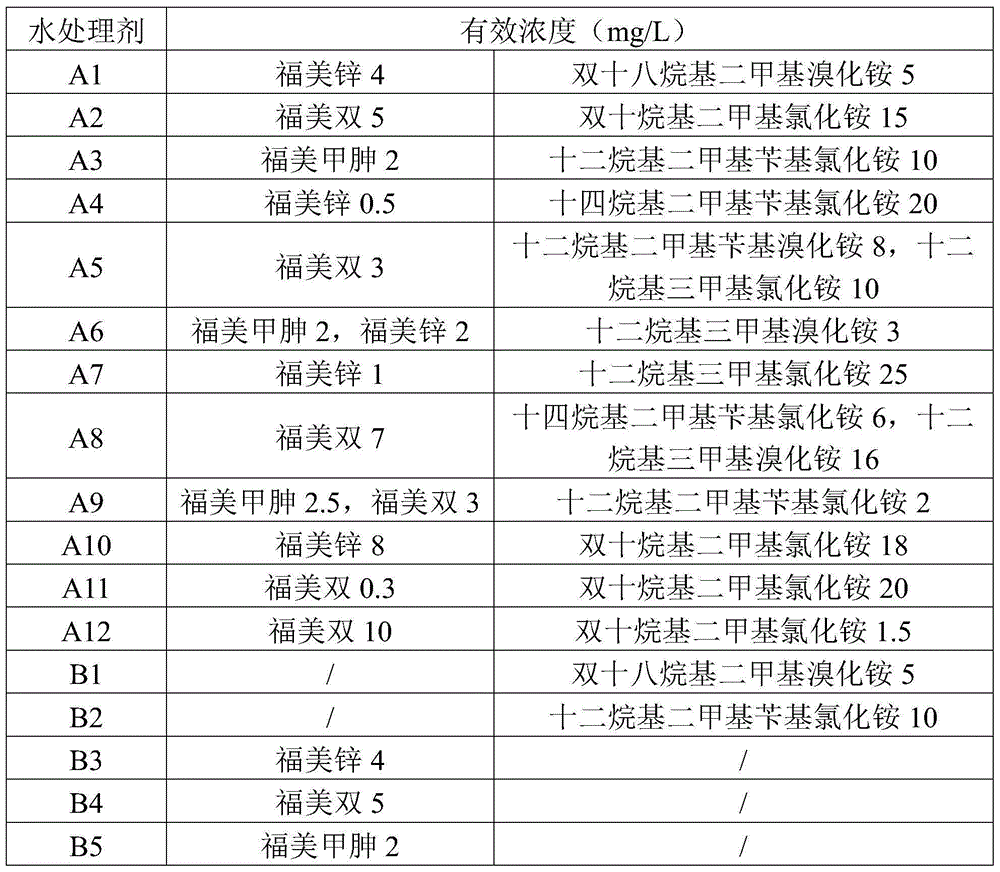

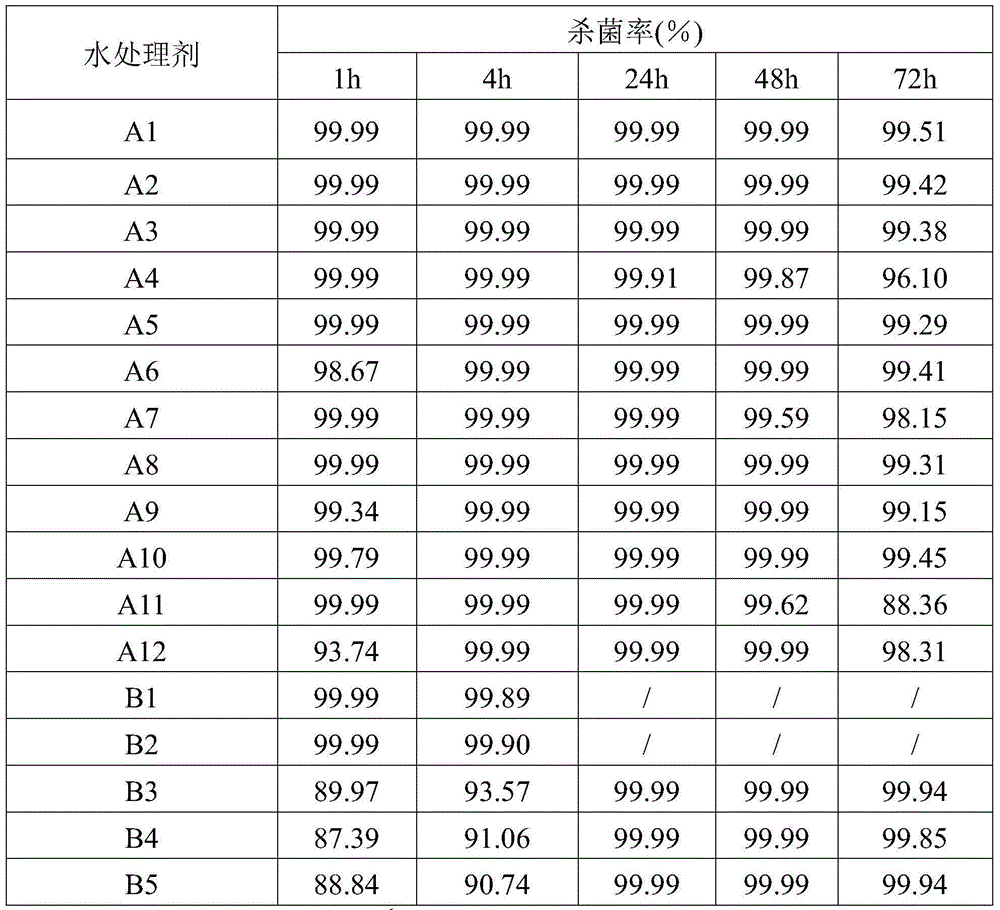

Bactericide composition and application thereof in water treatment

ActiveCN104542655AHas a corrosion inhibitory effectFull effectBiocideScale removal and water softeningSludgeCarbon steel

The invention discloses a bactericide composition. The composition comprises a Fumei-series bactericide and a quaternary ammonium bactericide. The invention further discloses application of the bactericide composition in water treatment. The sludge stripping capability, bacterium killing capability and carbon steel coupon corrosion speed of a water treatment agent of the bactericide composition are tested, and testing results indicate that the bactericide composition serving as a water treatment agent has a good sludge stripping effect, quick bacterium killing effect, long duration and excellent corrosion inhibition effect for carbon steel coupons.

Owner:CHINA PETROLEUM & CHEM CORP +1

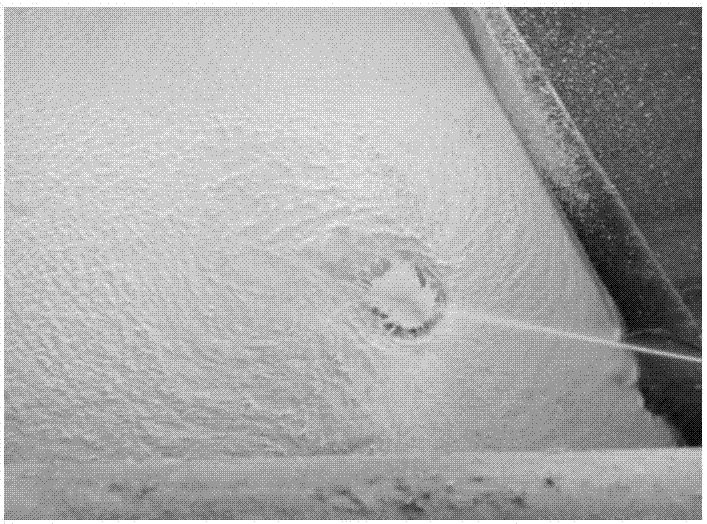

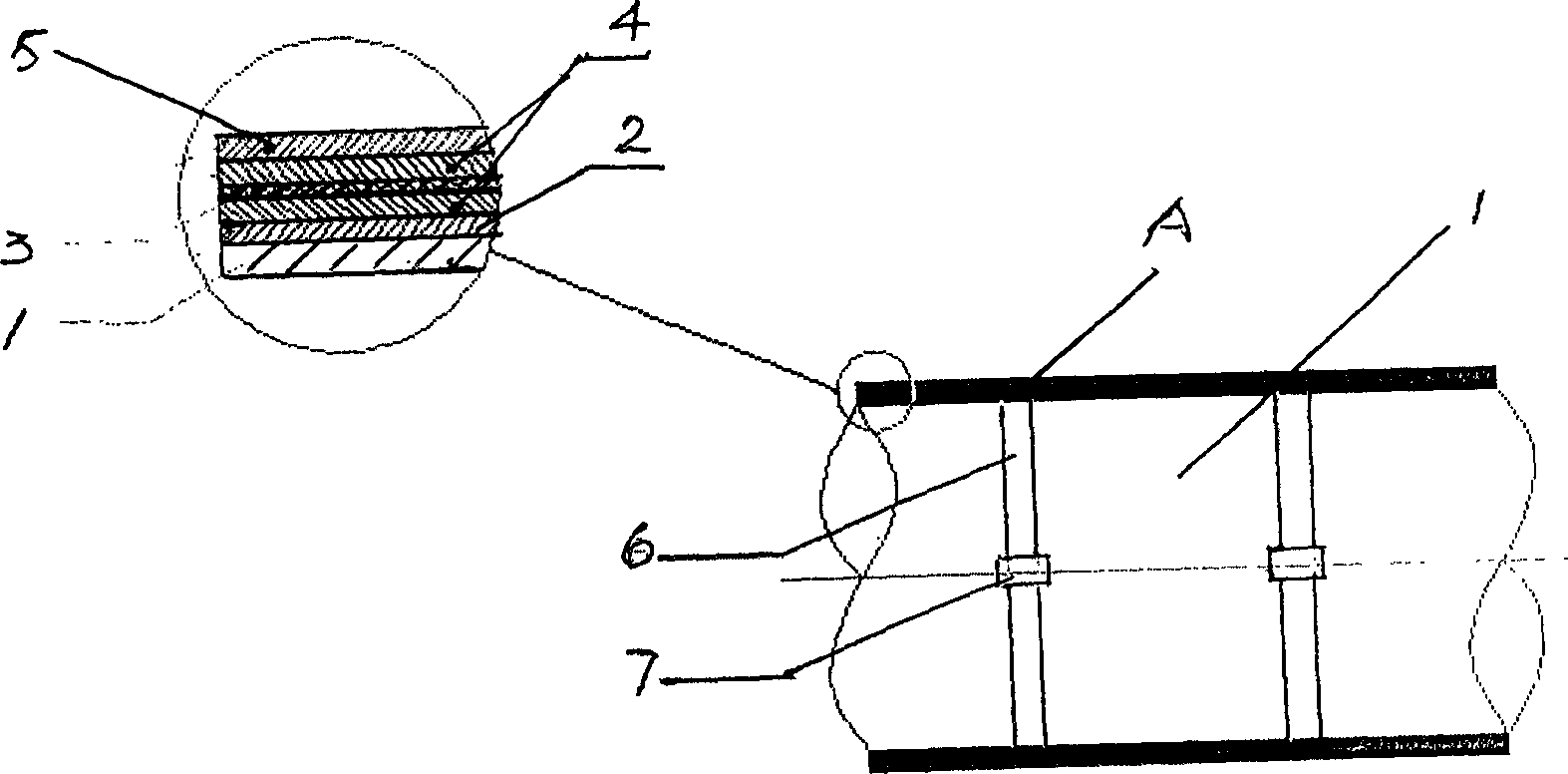

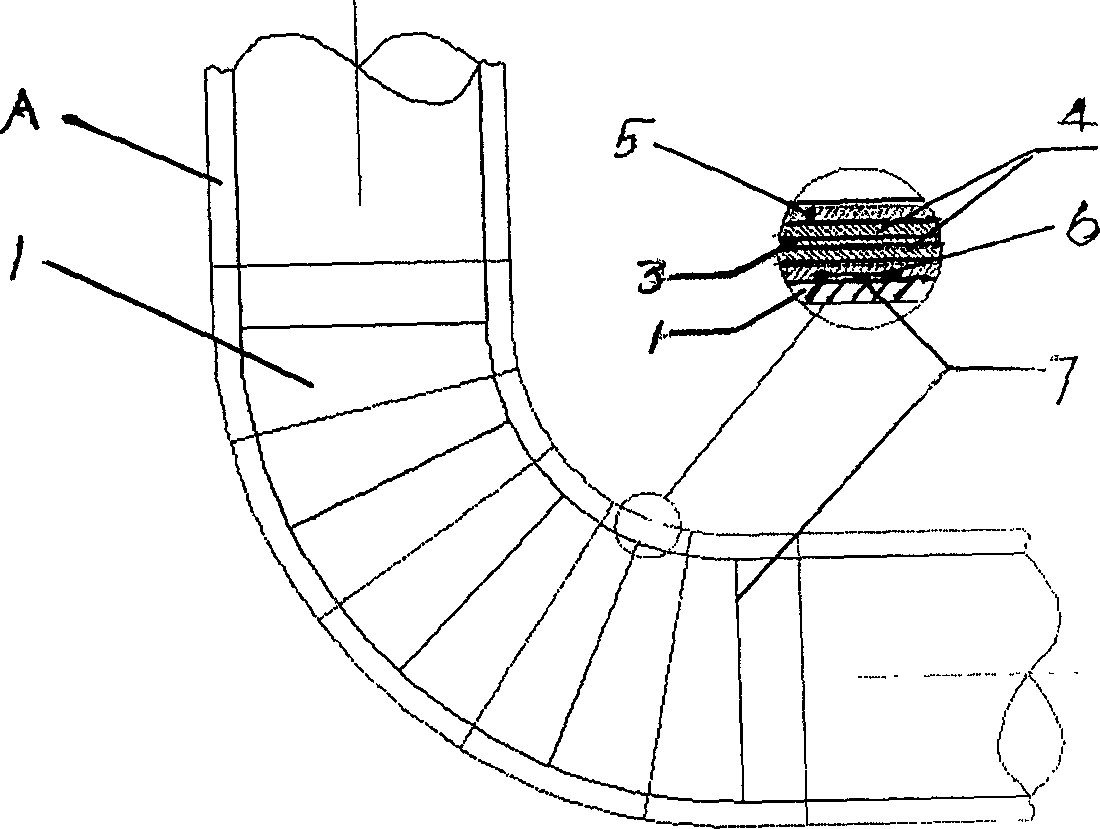

Gas pipe-line composite reinforcement construction and construction method thereof

InactiveCN1632363AReduced additional weight loadReduce corrosion ratePipe elementsEpoxy resin adhesivesGlass fiberKeel

A gas pipeline composite reinforcement structure and a construction method thereof. The reinforcement structure is wrapped around the gas pipeline to be repaired, including the main reinforcement and auxiliary parts. The primer layer bonded to the gas pipeline is composed of additives with effective corrosion inhibition effect added to the primer layer; the auxiliary parts include reinforcing keel belts and / or special reinforcing parts that meet the special requirements of the pipeline. The construction steps are: measure the thickness of the main body of the repaired pipeline, and perform surface treatment and plugging treatment; process special parts of the pipeline or fix special reinforcements for special parts of the pipeline; apply stainless steel keel belts; coat the primer layer, Lay the working layer and reinforcement layer; bond the protective layer. The reinforced structure of the invention is light in weight, high in specific strength, low in cost, convenient in construction, has corrosion inhibition effect and excellent anticorrosion performance. There is no open flame, no high temperature, and no impact on the pipeline.

Owner:BAOSTEEL DEV CO LTD

Plant type composite efficient corrosion inhibitor as well as preparation method and application thereof

ActiveCN112680190AWide range of raw materialsRaw materials are environmentally friendlyOther chemical processesSodium molybdateSulfate zinc

The invention provides a plant type composite efficient corrosion inhibitor. The plant type composite efficient corrosion inhibitor is prepared from the following raw materials in percentage by mass: 12 to 66.0 percent of plants, 5.0 to 16.0 percent of sodium molybdate, 1.5 to 12 percent of sodium gluconate, 3.5 to 25 percent of sodium tartrate, 0 to 23 percent of zinc sulfate and 4.0 to 23.0 percent of monopotassium phosphate. The corrosion inhibitor disclosed by the invention is high in corrosion inhibition capability and can achieve a corrosion inhibition effect on a chlorine salt type snow-melting agent. After the corrosion inhibitor is added, the corrosion of the chlorine salt type snow-melting agent to metal and concrete and the harm to vegetation can be reduced. The corrosion inhibitor is mainly prepared from plants, is non-toxic, and is a very efficient and environment-friendly corrosion inhibitor. The invention further provides a preparation method and application of the plant type composite efficient corrosion inhibitor.

Owner:新疆交通科学研究院有限责任公司

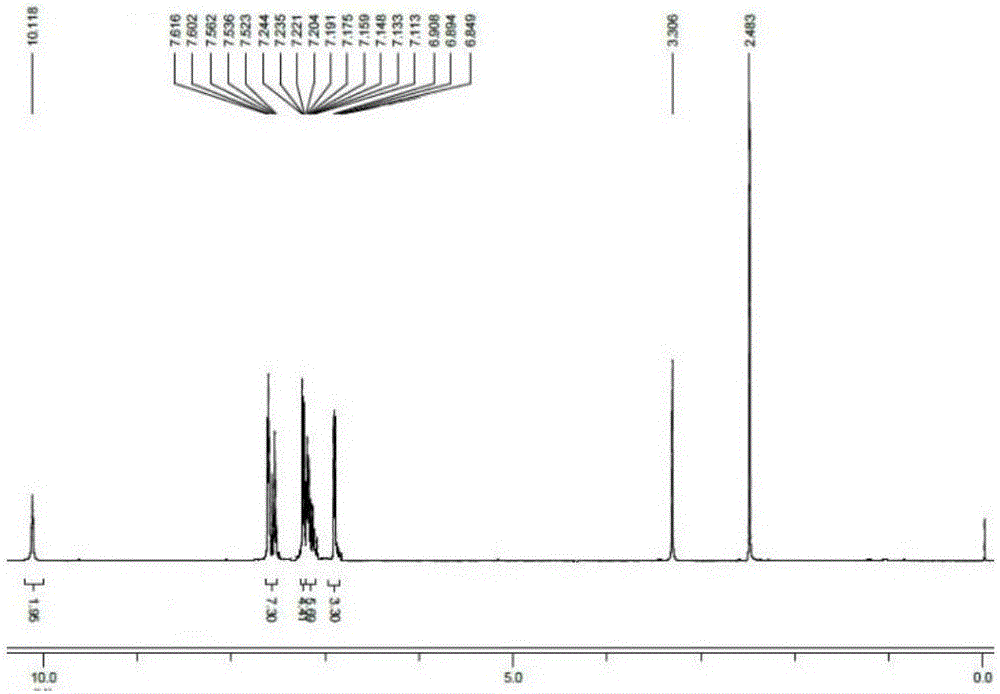

Syntheses and application of water-soluble bis-Schiff base potassium salts

InactiveCN106278938AGood water solubilityHas a corrosion inhibitory effectImino compound preparationChemical structureSolubility

As a corrosion inhibitor of copper, a type of water-soluble bis-Schiff base potassium salts have a chemical structural formula described in the description, wherein in the structural formula, C1, R1=-OK, R2=R3=H; C2, R2=-OK, R1=R3=H; C3, R3=-OK, R1=R2=H. As the corrosion inhibitor, the type of water-soluble bis-Schiff base potassium salts have a corrosion inhibition effect for the metal copper in a sodium chloride solution with a mass ratio of 3.5%; due to the chemical structure of the organic salt, the water solubility of the corrosion inhibitor is greatly improved, and the corrosion inhibition effect of the corrosion inhibitor is further facilitated to be improved; furthermore, a synthesis method and a separation method of the water-soluble bis-Schiff base potassium salts are simple, and raw materials are conveniently obtained.

Owner:CHONGQING UNIV

Highly water-resistant iron oxide black pigment and preparation method therefor

InactiveCN105153757AHigh tinting strengthHas a corrosion inhibitory effectPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsWeather resistanceIron oxide black

The invention discloses a highly water-resistant iron oxide black pigment which is prepared from the following raw materials in parts by weight: 80-100 parts of modified iron oxide black, 3-5 parts of barite powder, 3-5 parts of sericite powder, 6-8 parts of sodium silicate, 0.1-0.2 part of azodiisobutyronitrile, 1-2 parts of polytetrafluoroethylene micropowder, 10-15 parts of styrene, 5-10 parts of triethanolamine and 1-2 parts of caster oil. The iron oxide black pigment disclosed by the invention not only is high in tinting strength, good in temperature resistance and weather resistance, easy to disperse and good in processing performance, but also has the characteristic of high water resistance, and is good in using performance.

Owner:TONGLING RELY TECH

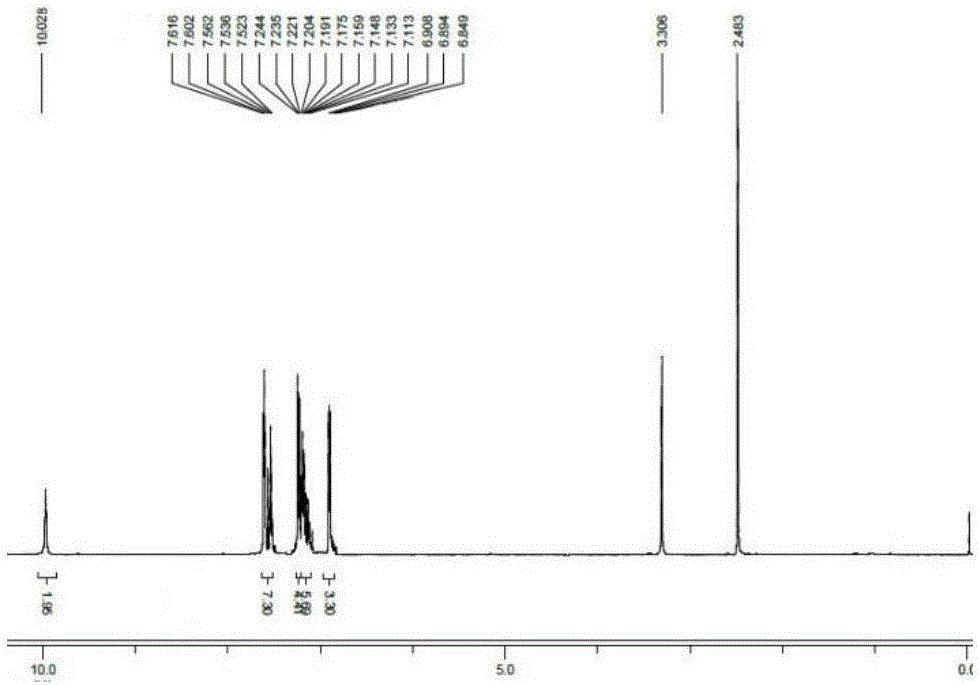

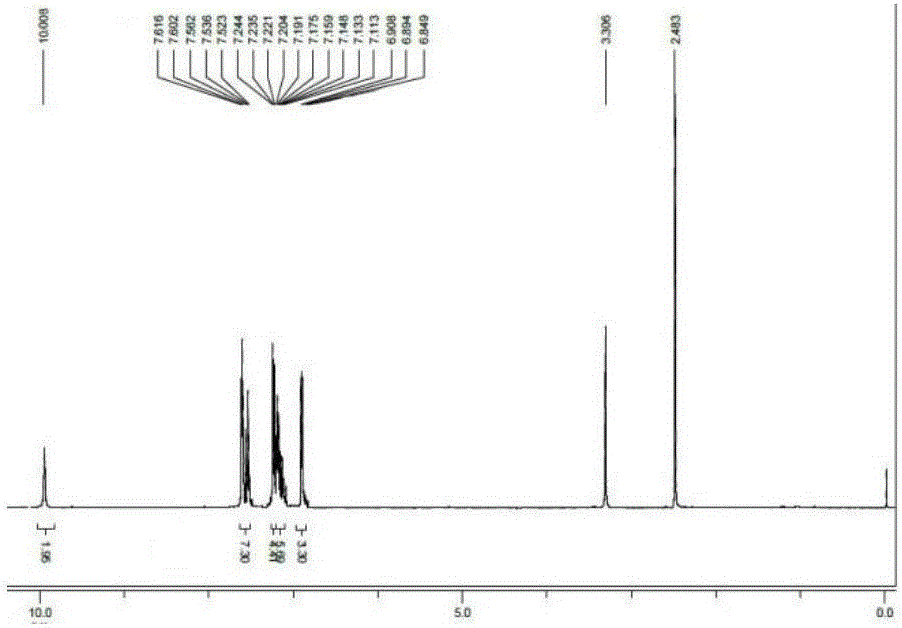

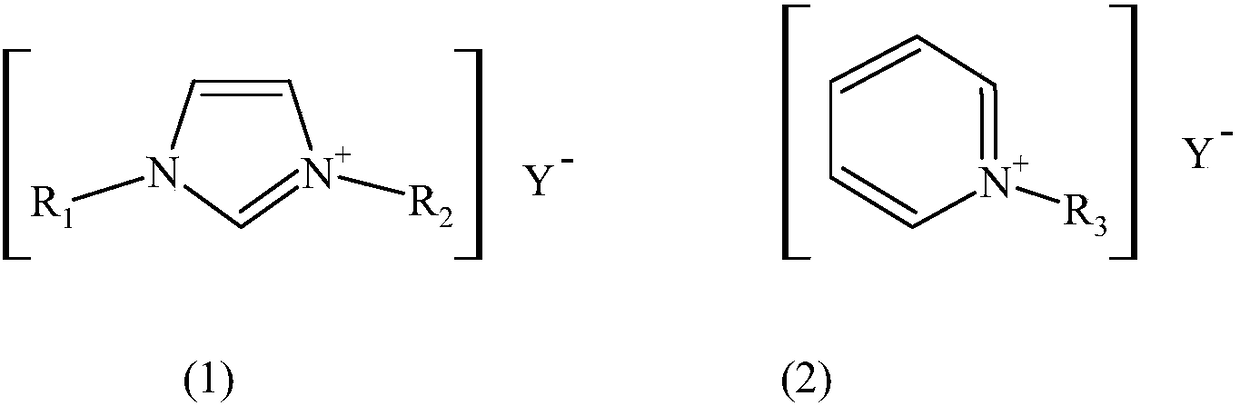

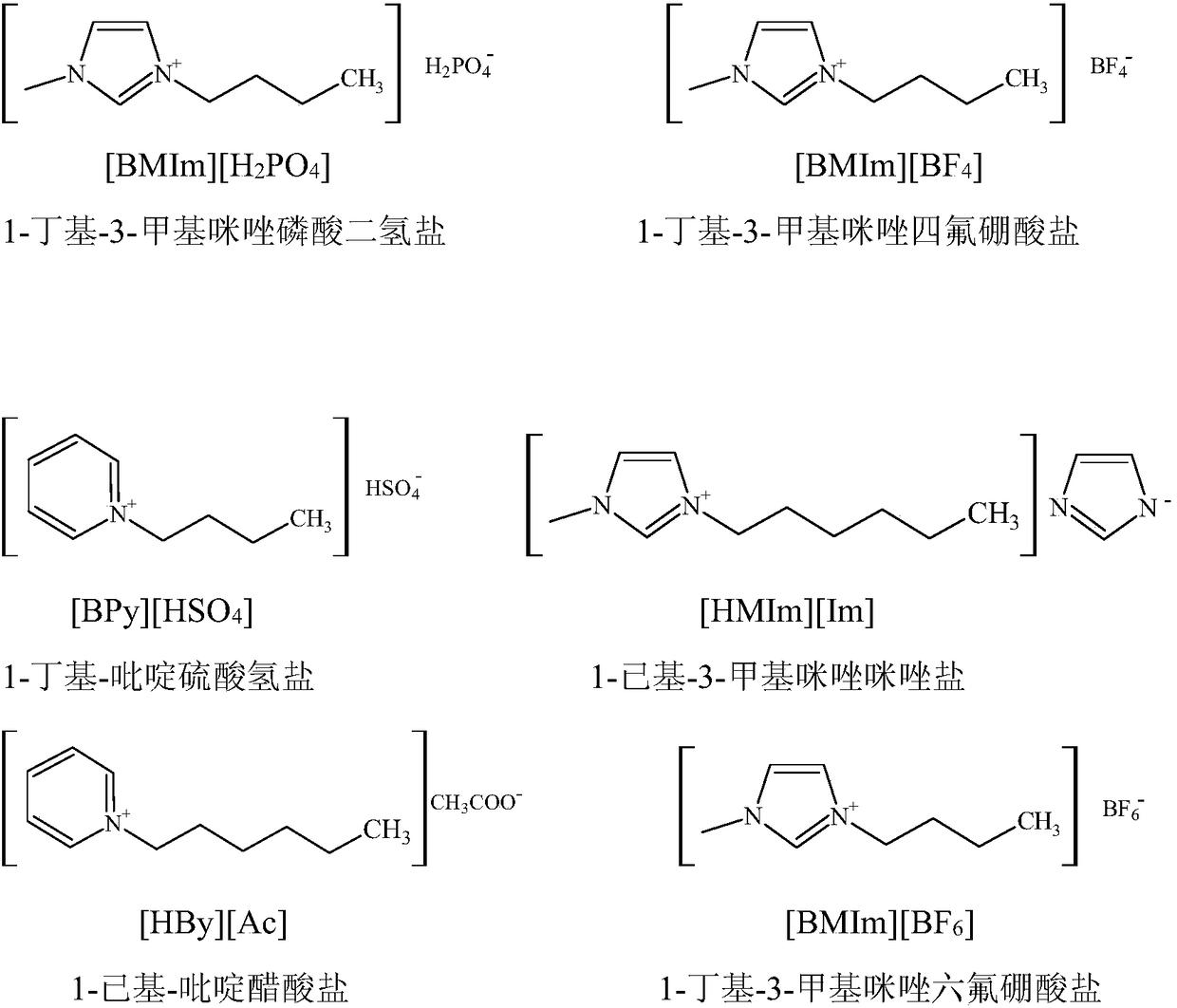

Electrolyte and method for preparing adiponitrile by electrolytic acrylonitrile dimerization

ActiveCN108517536AHas a corrosion inhibitory effectReduce corrosionElectrolysis componentsElectrolytic organic productionSupporting electrolytePhosphate

The invention relates to an electrolyte and a method for preparing adiponitrile by electrolytic acrylonitrile dimerization. The electrolyte comprises 2-7 wt% of acrylonitrile, 0.1-5 wt% of imidazole or pyridine ionic liquid, 0.1-5 wt% of EDTA or EDTA salt, 5-15 wt% of phosphate and the balance water, and the pH value range is 7-10. Electrolysis is carried out in a membrane-free electrolytic cell,anode materials of the membrane-free electrolytic cell are carbon steel or graphite, and cathode materials are cadmium or lead, the temperature of the electrolyte is 20-60 DEG C, and the linear speedof the electrolyte between the electrode plates is larger than 1 m.s <-1>, continuous electrolysis is carried out under the condition that the current density is 500-4000 A.m <-2>, and oil-water separation, rectification and other processes are carried out to obtain adiponitrile products. Compared with the prior art, ionic liquid is adopted as the support electrolyte, so that the yield and currentefficiency of adiponitrile can be improved, and the corrosion of the anode material and the crude product separation equipment can be greatly reduced; and the property of the ionic liquid is stable,so that the loss of the electrolyte can be greatly reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

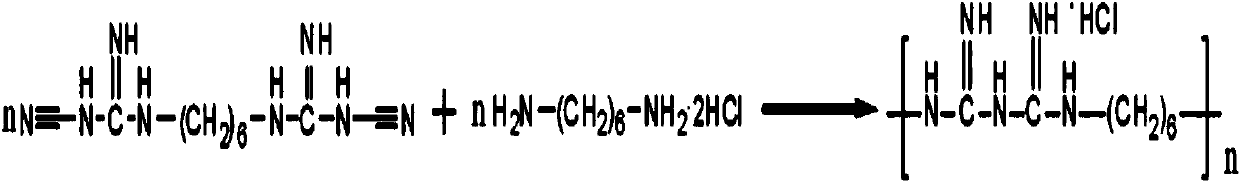

Novel efficient composite guanidyl papermaking bactericide

ActiveCN110074105AImprove effective activityHigh activityBiocidePaper/cardboardPapermakingPotassium hydrogen phthalate

The invention provides a novel efficient composite guanidyl papermaking bactericide, and belongs to the technical field of papermaking bactericide production. The bactericide comprises following components in parts by weight: 10-30 parts of a guanidyl polymer, 5-15 parts of 2-octyl-2H-isothiazol-3-one, 150-450 parts of diethylene glycol, 0.5-1.5 parts of dodecyl dimethyl benzyl ammonium chloride,0.3-1.8 parts of hydroxymethyl cellulose and 0-100 parts of potassium hydrogen phthalate, wherein the guanidyl polymer is polyhexamethylene biguanidine hydrochloride. Polyhexamethylene biguanidine hydrochloride is a broad-spectrum antibacterial product, has killing capacity on Gram-positive bacteria, Gram-negative bacteria, fungi and saccharomycetes and can be used for producing and manufacturingantibacterial paper for health products to replace silver-containing Kuerxin paper, and meanwhile, a polyhexamethylene biguanidine hydrochloride solution also improves physical properties and hygroscopic property of the paper and strength and breathability of the paper stained with water, so that the solution is a papermaking bactericide with excellent performance; the bactericide is one efficientand broad-spectrum composite type TS-302 papermaking bactericide under the synergistic effect of the components.

Owner:甘肃泰升化工科技有限公司

Cleaning synergist for heating supply system

The invention discloses a cleaning synergist for a heating supply system. The cleaning synergist specifically comprises thiourea, 5-chloro-2-methyl-4-isothiazolin-3-one, sodium nitrite, mercaptobenzothiazole, polyoxyethylene lauryl ether, zinc sulfate, diethylene triamine pentamethylene phosphonic acid, potassium chromate, sodium alginate, and the balance water. The invention further discloses a preparation method of the cleaning synergist. By the adoption of the strong cleaning synergist, a cleaning agent can be assisted in effectively and thoroughly cleaning away various rust spots, dirt and cured products attached to the inside of a boiler and the inside of a pipeline, and the scale formation speed of the boiler and the pipeline is decreased. The cleaning synergist for the heating supply system is high in acidity and good in water solubility, has no toxicity to human bodies, has no corrosiveness to the boiler and the pipeline, can remarkably improve the heat efficiency of the boiler and the pipeline, and is simple in preparation process, convenient to operate and safe and reliable to use.

Owner:科谱研发技术中心(青岛)有限公司

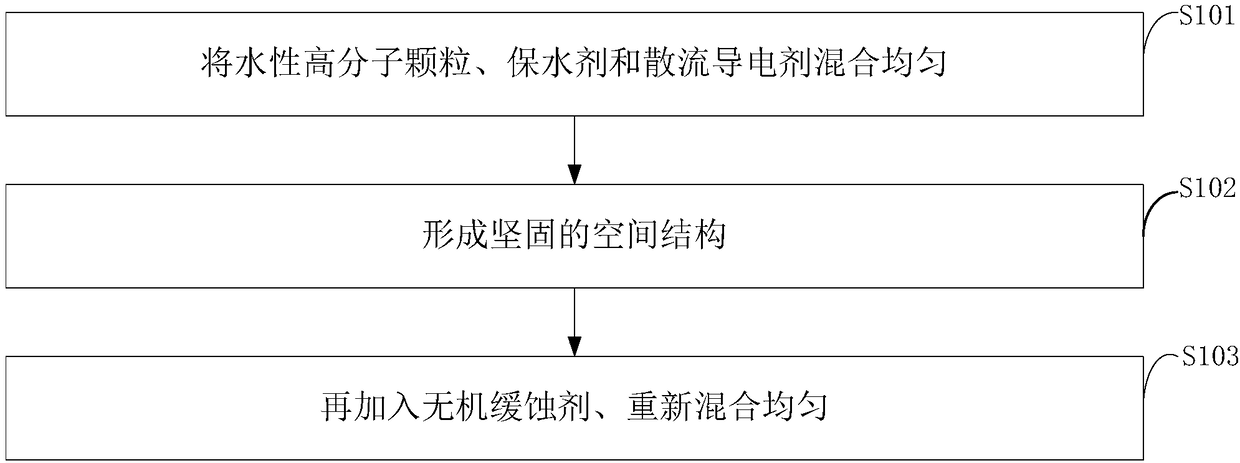

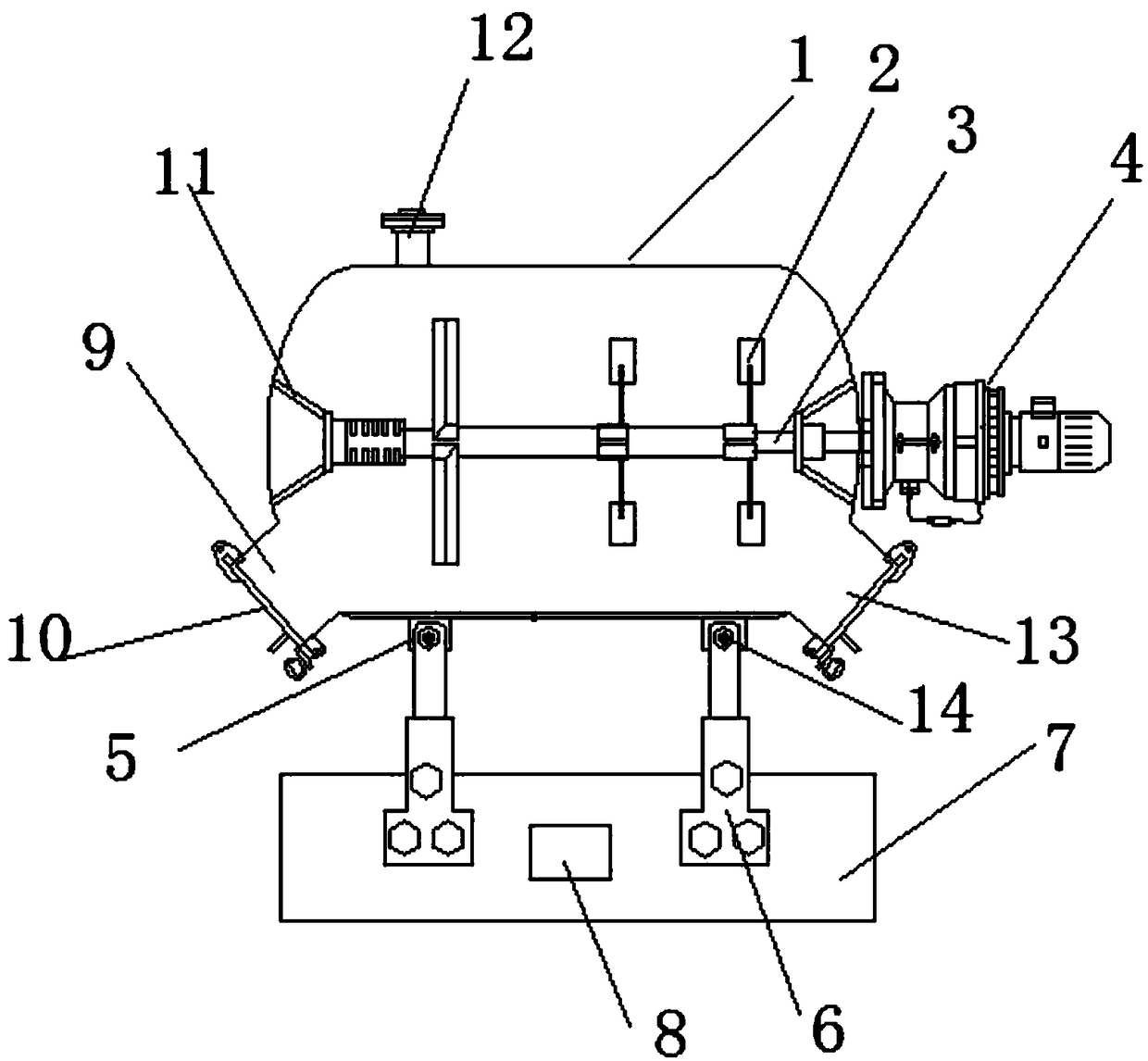

Novel physical resistance-reducing agent of aqueous polymer skeleton structure

InactiveCN108538449AImprove space densityTightly boundBlastingNon-conductive material with dispersed conductive materialPower stationElectric power system

The invention belongs to the technical field of resistance-reducing agents, and discloses a novel physical resistance-reducing agent of an aqueous polymer skeleton structure. The skeleton resistance-reducing agent contains a water-soluble polymer as a skeleton material of the resistance-reducing agent, the water-soluble resistance-reducing agent forms a skeleton structure under the action of waterand an auxiliary agent during construction and realizes a cage effect on other components applied inside, a dispersing agent, a water-retaining agent and the like are fixed in a cage formed by the polymer, and a solid space structure is formed. A certain quantity of an inorganic corrosion inhibitor is added, so that corrosion of a grounding material can be reduced; the product is non-toxic and harmless and does not cause environmental pollution; the resistance-reducing agent is suitable for being used as a physical resistance-reducing material for grounding of power system transmission substations, power stations and other large-scale electrical equipment.

Owner:DEZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com