Patents

Literature

48results about How to "Raw materials are environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing organosilicone hybrid resin and power type encapsulating material for light-emitting diodes (LED) thereof and application

ActiveCN102702532AEasy to prepareRaw materials are environmentally friendlyPlastic/resin/waxes insulatorsCoatingsEpoxyAdhesive

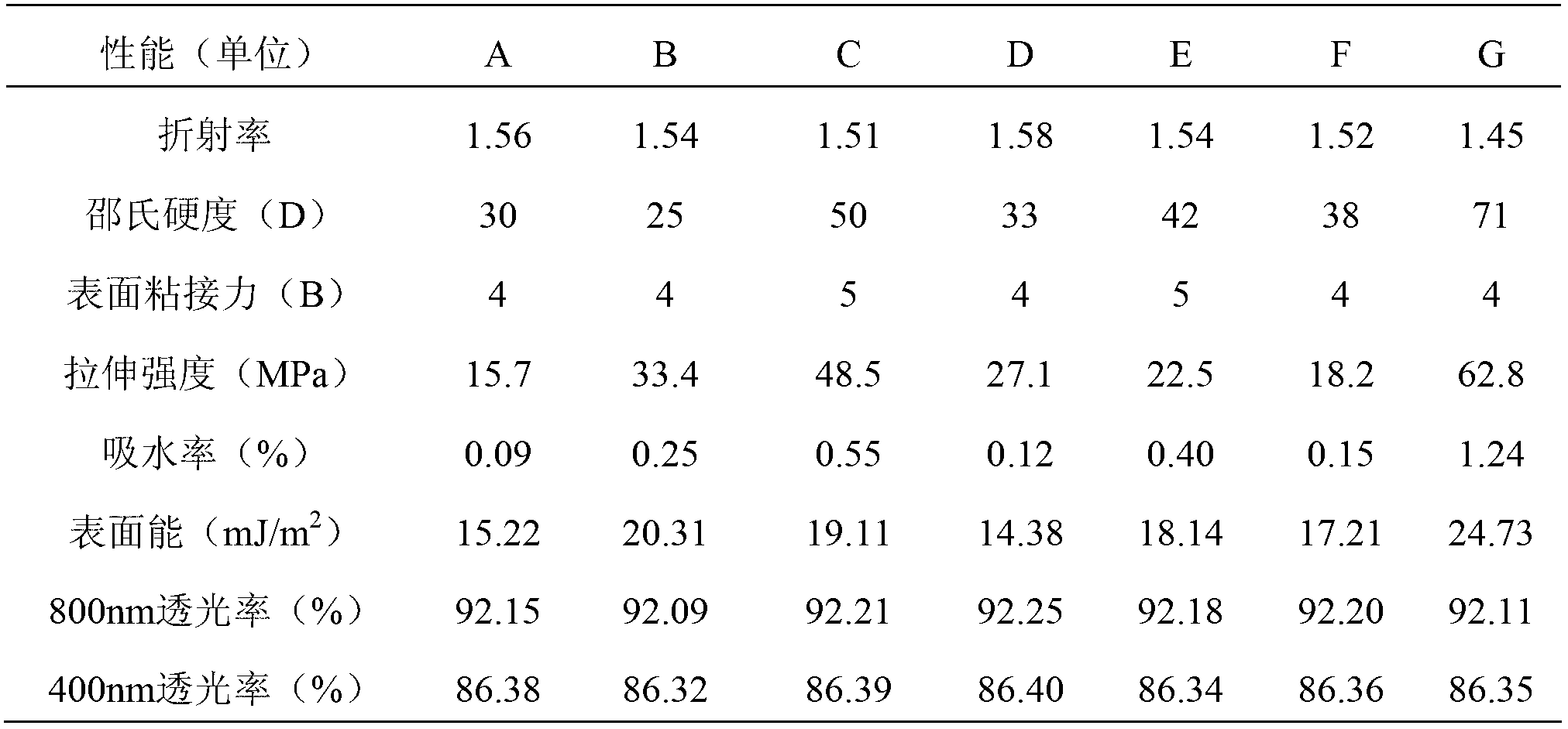

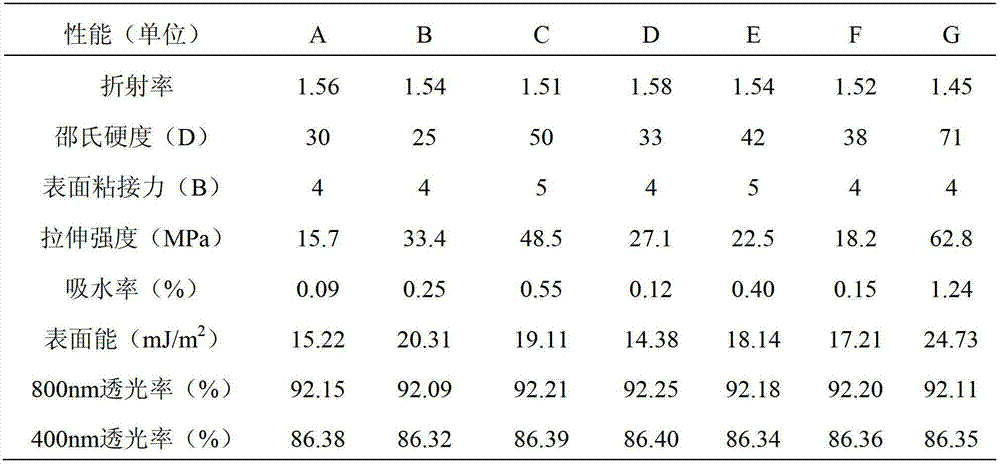

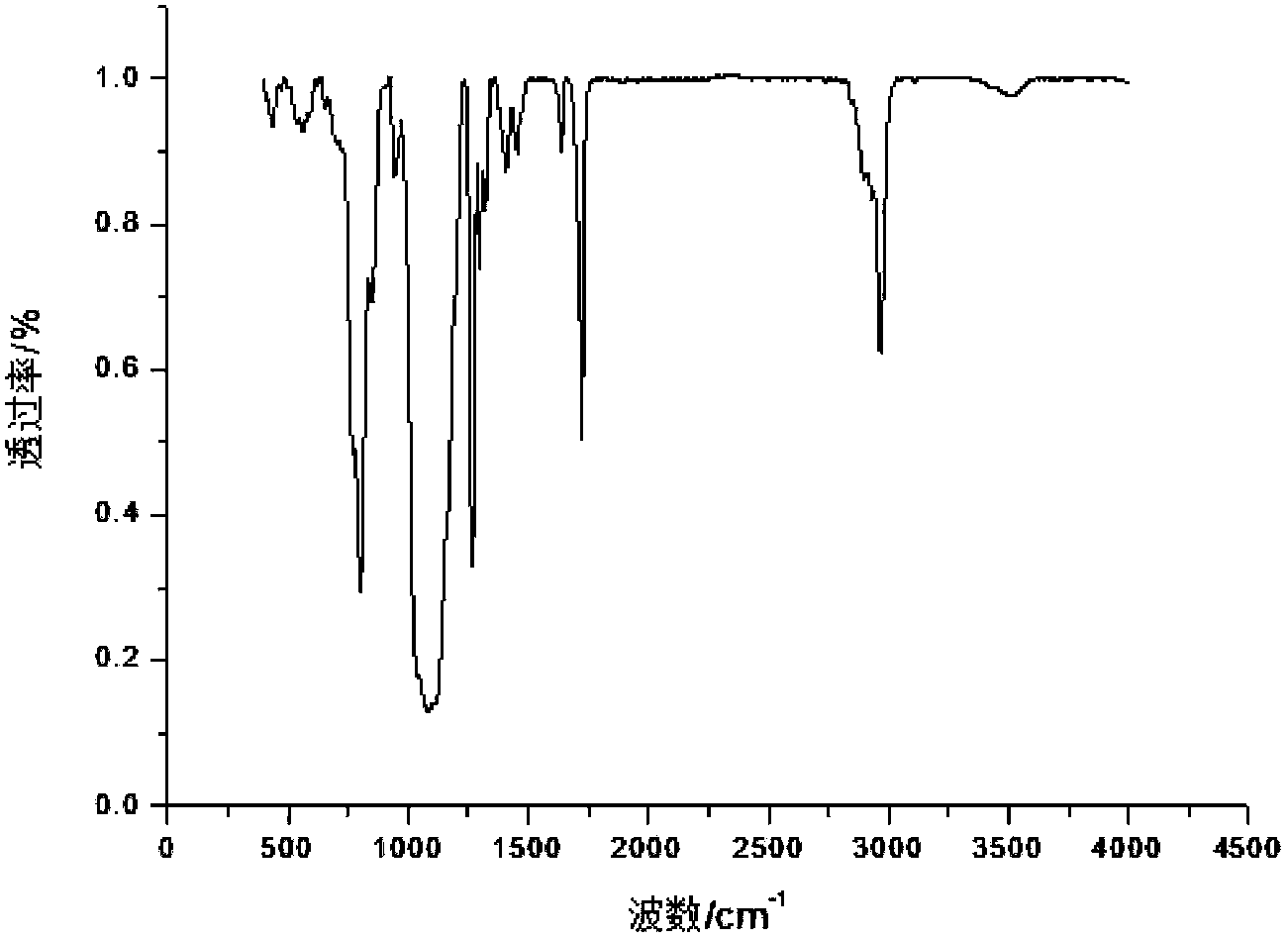

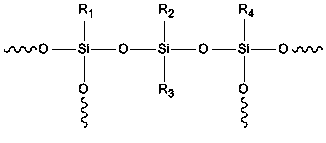

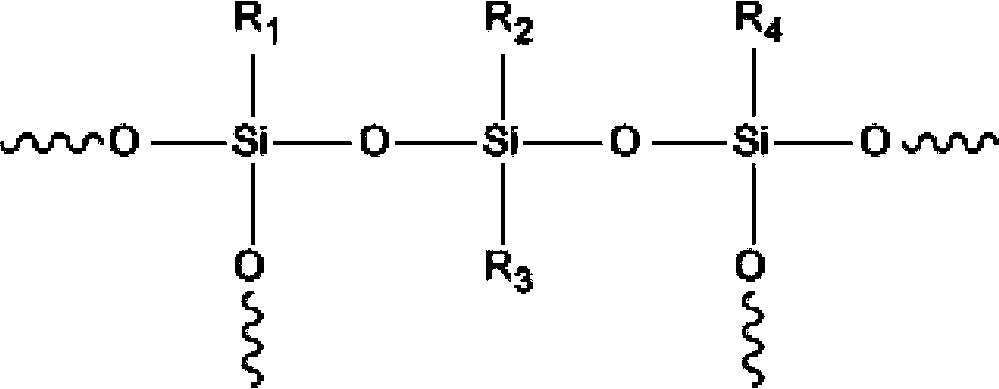

The invention discloses a method for preparing organosilicone hybrid resin and a power type encapsulating material for light-emitting diodes (LED) thereof and application. According to the method, the organosilicone hybrid resin containing three functional groups of an epoxy group, a fluorin group and a phenyl group is prepared by a cohydrolysis condensation method, and the content of each group in the resin is optimized by controlling the ratios of fluoro alkyl silicane, epoxy alkyl silicane and phenyl silicane, so that the resin is applied to the power type encapsulating material for the LEDs. The prepared encapsulating material has the advantages of epoxy resin and organosilicone, has high performance of high light transmittance and refractive index, low hygroscopicity, high mechanical property and ageing-resistant performance and the like, and the problems of low light output rate, short service life and the like of the LEDs due to dropping caused by low bonding strength and poor mechanical property of the ordinary organosilicone material for encapsulating LEDs are solved. The method for preparing the organosilicone hybrid resin and the power type encapsulating material for the LEDs is simple, and raw materials are readily available and environment-friendly; and the organosilicone hybrid resin can also be used as the raw materials to be applied to processing and preparation of optical lens materials, photovoltaic conversion materials, integrated circuit encapsulating materials, insulating materials, coating materials, adhesives and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

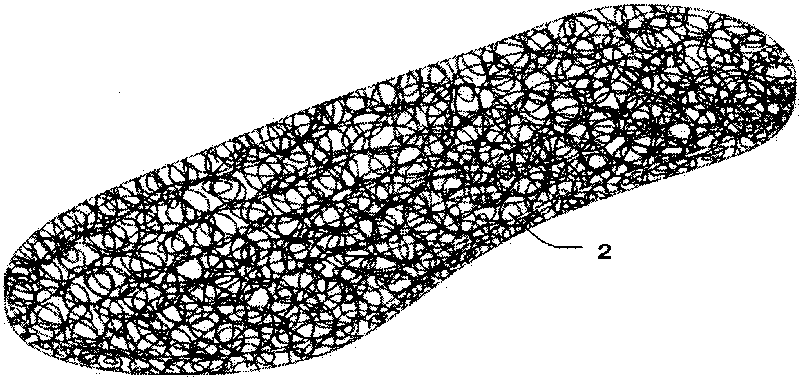

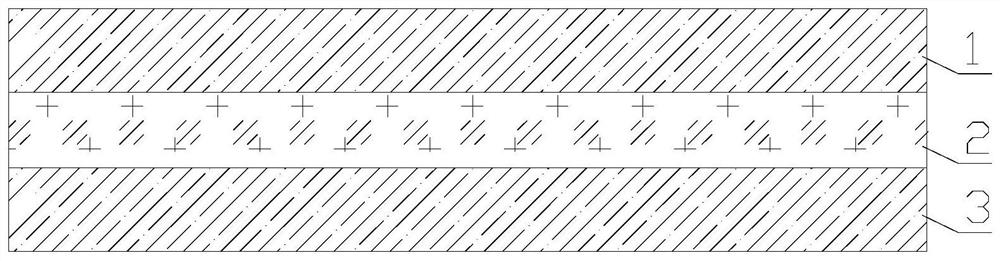

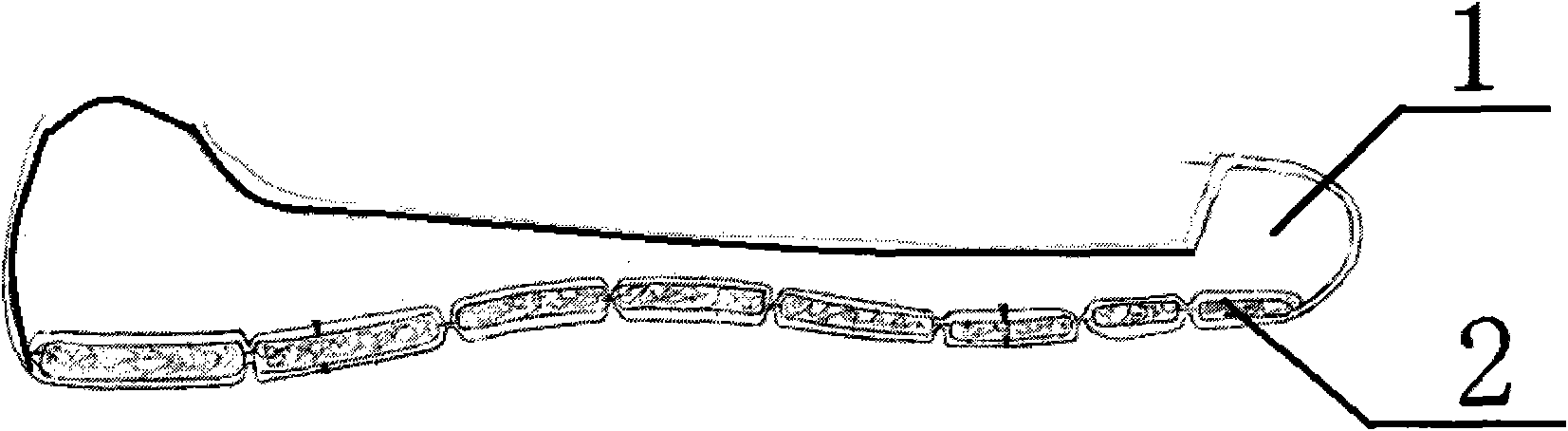

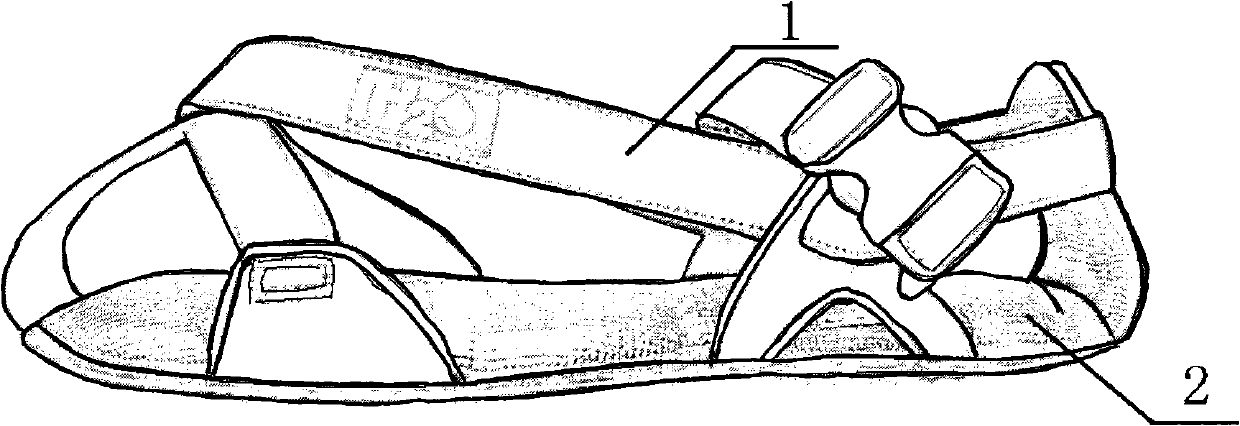

Anti-skid and anti-fatigue sole

InactiveCN101744420AReasonable structural designGood anti-skid functionSolesThermoplasticEngineering

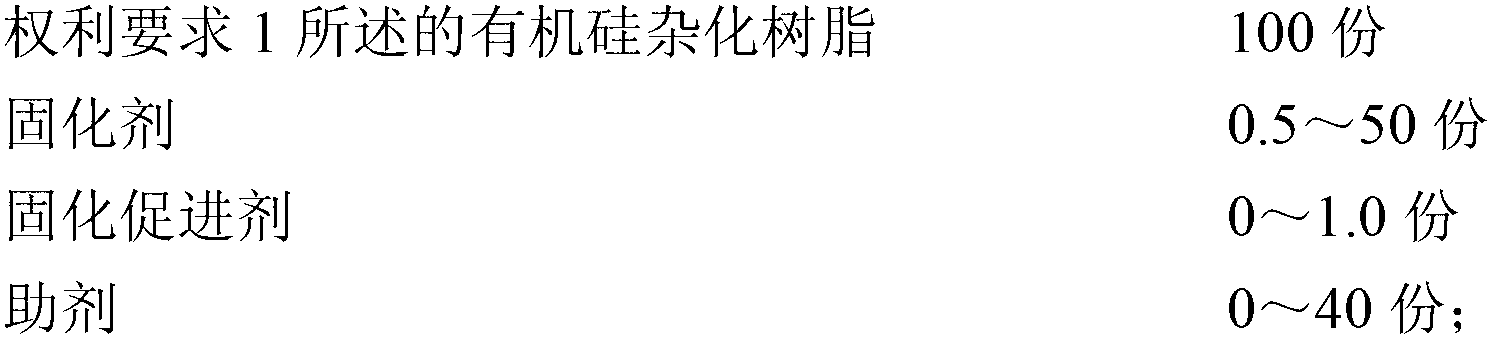

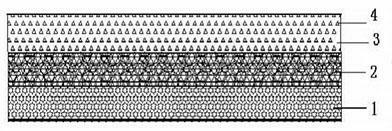

The invention discloses an anti-skid and anti-fatigue sole, which comprises a lower sole layer (1), a middle sole layer (2) adhered to the lower sole layer (1) and an upper sole layer (3) adhered to the middle sole layer (2), wherein the lower sole layer (1) is made of thermoplastic; the middle sole layer (2) is made of thermoplastic silk ring; and the upper sole layer (3) is made of a sandwich net consisting of a woven net and PVC plastic coated on the woven net. The anti-skid and anti-fatigue sole provided by the invention is rational in structural design and firm and durable, and particularly has an excellent anti-skid function, so that the sole may be widely worn in humid environments and is capable of reducing friction force during walk and conducting a buffer function and an excellent anti-fatigue function.

Owner:TAICANG ALL MATS PLASTIC IND

Method for producing ultra-high molecular weight polyethylene colored fine denier fiber

ActiveCN101718003ABright colorOvercoming issues such as emissionsFilament/thread formingMonocomponent polyolefin artificial filamentFiberPolymer science

The invention discloses a method for producing an ultra-high molecular weight polyethylene colored fine denier fiber, relating to the technical field of polymer materials and comprising the following steps of: pouring ultra-high molecular weight polyethylene powder and solvent into an untwisting kettle according to the proportion; properly untwisting ultra-high molecular weight polyethylene macromolecules in the solvent by high shearing to form uniform emulsion-shaped mixed solution; then preparing nontoxic and harmless nanometer pigment grains into emulsion by using a mixing technology, evenly and continuously adding the emulsion into the emulsion-shaped mixed solution for further shearing; and finally, quantifying the emulsion-shaped mixed solution by the storage tank while stirring and feeding the emulsion-shaped mixed solution into a screw extruder to extrude and spin. The fiber not only has excellent qualities of the conventional high-strength high-modulus polyethylene fiber, but also solves the problems of waste liquid discharge in the after finishing process and realizes the environmental protection of raw materials, production process and products.

Owner:ZHEJIANG JINHAO NEW MATERIALS CO LTD

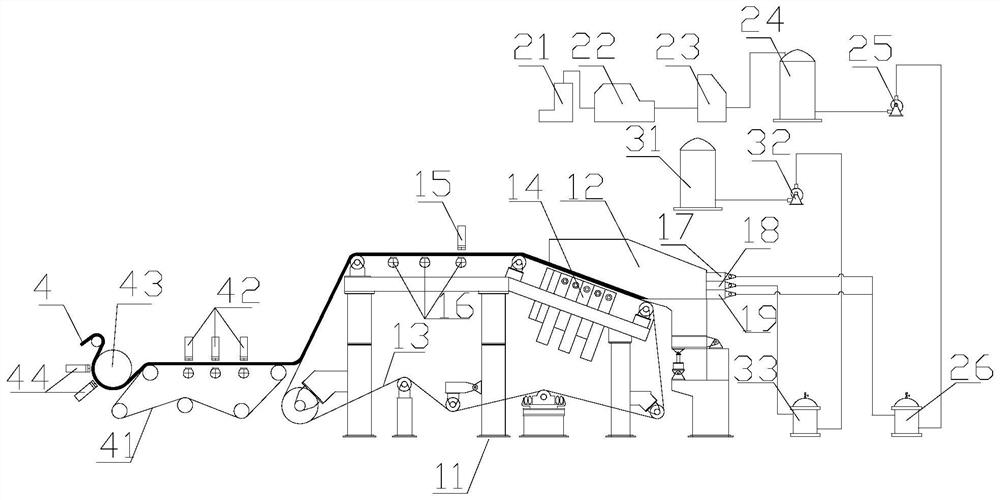

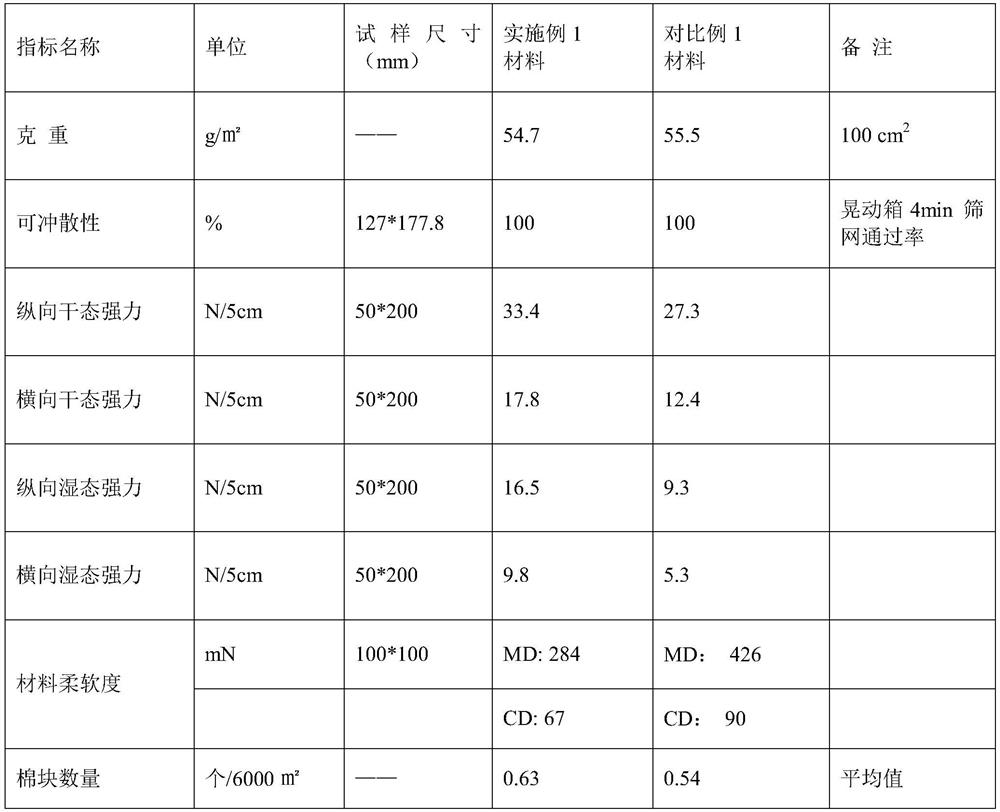

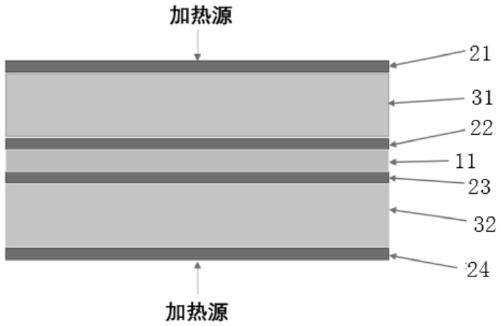

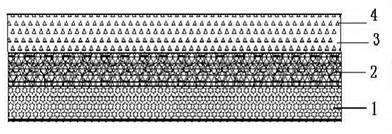

Plant fiber dispersible material and preparation method thereof

ActiveCN112411246AGood flexibilityReduced risk of tearingDomestic applicationsNon-woven fabricsPolymer sciencePlant fibre

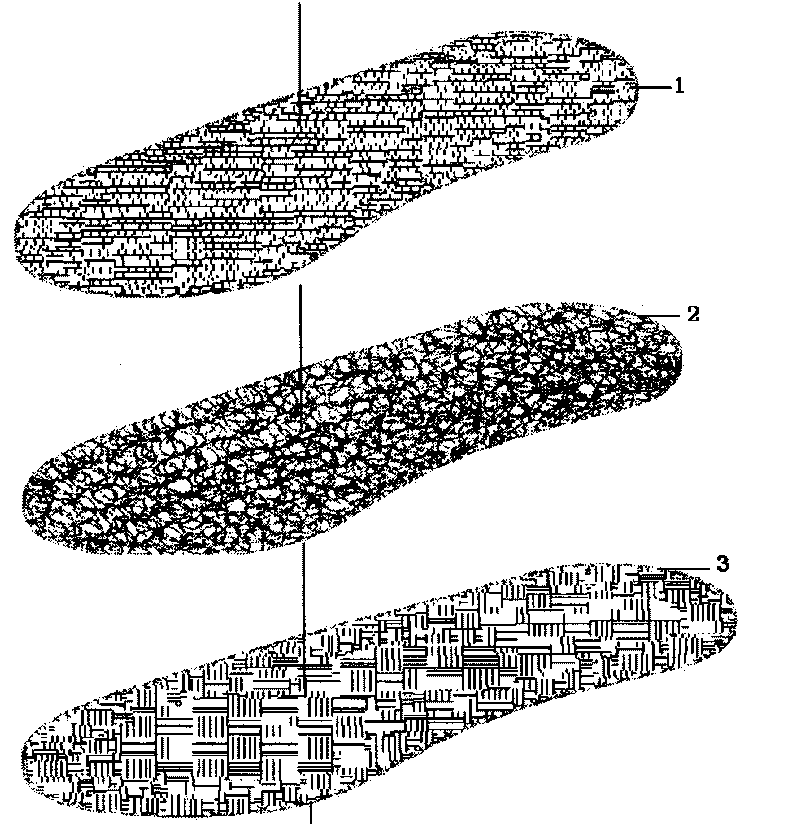

The invention relates to the field of non-woven materials, and discloses a plant fiber dispersible material and a preparation method thereof. The plant fiber dispersible material comprises an upper fiber layer (1), a middle fiber layer (2) and a lower fiber layer (3) which are mutually entangled and overlapped, wherein the average length of fibers in the upper fiber layer and the lower fiber layeris greater than the average length of fibers in the middle fiber layer; raw materials of the upper fiber layer and the lower fiber layer comprise chopped plant fibers and / or plant fiber linters; andraw materials of the middle fiber layer comprise plant fiber pulp. According to the invention, natural plant fibers are used as main raw materials, and the plant fiber dispersible material which is high in wet strength, soft in hand feeling and low in scrap falling amount can be prepared through a special wet spunlace non-woven process.

Owner:HANGZHOU NBOND NONWOVENS

One-step dyeing and functional finishing method of textiles

InactiveCN102926225AReduce the temperatureReduce energy consumptionBiochemical fibre treatmentDyeing processNeutral phSynthesis methods

The invention discloses a one-step dyeing and functional finishing method of textiles, and particularly relates to a one-step dyeing and functional finishing method of textiles by using a caffeic acid enzyme polymerization product, belonging to the field of textile dyeing and finishing. According to the invention, the caffeic acid oxidative polymerization is catalyzed by oxido-reductase to prepare a colored enzyme polymerization product solution, and the textile is put into the solution to realize one-step dyeing and functional finishing of the textiles in a weak acid condition. Compared with the traditional color synthesis method, the method for preparing functional color by catalyzing the caffeic acid oxidative polymerization with oxido-reductase provided by the invention has the advantages of low temperature, approximately neutral pH value, mild reaction conditions, low energy consumption and the like; the prepared colored enzyme polymerization product is applied to one-step one-batch dyeing and finishing of the textiles; the processing process has short flow, saves time and realizes multiple effects in one step; and the prepared textile has bright color and multiple functions such as ultraviolet protection, oxidation resistance, deodorization and the like.

Owner:SUZHOU UNIV

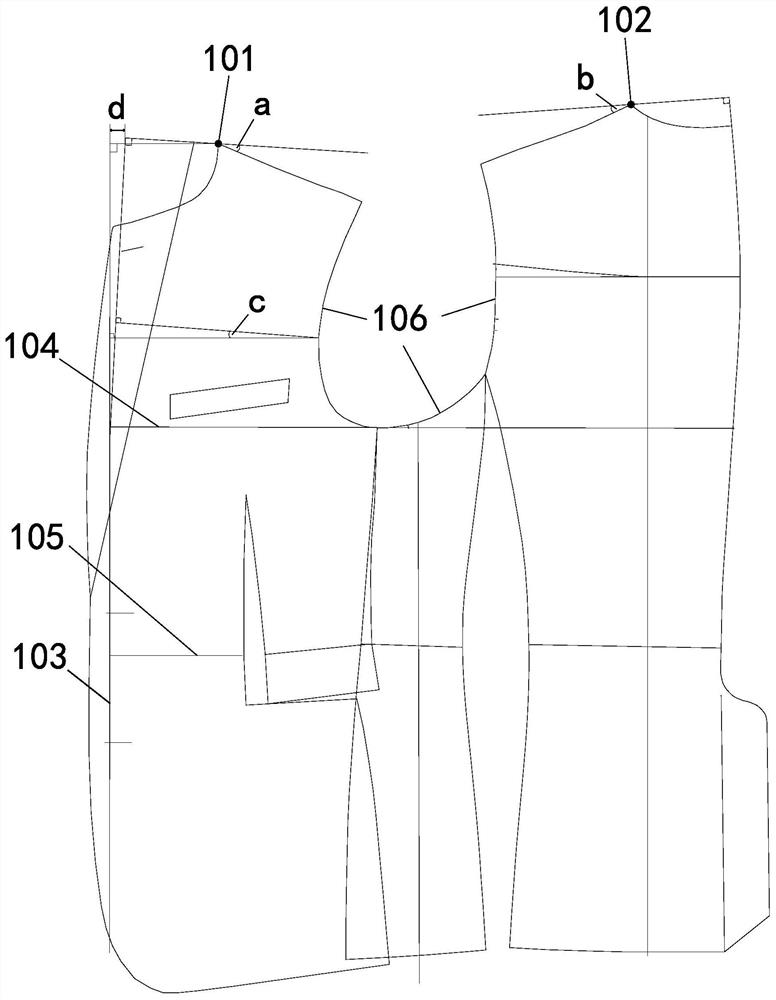

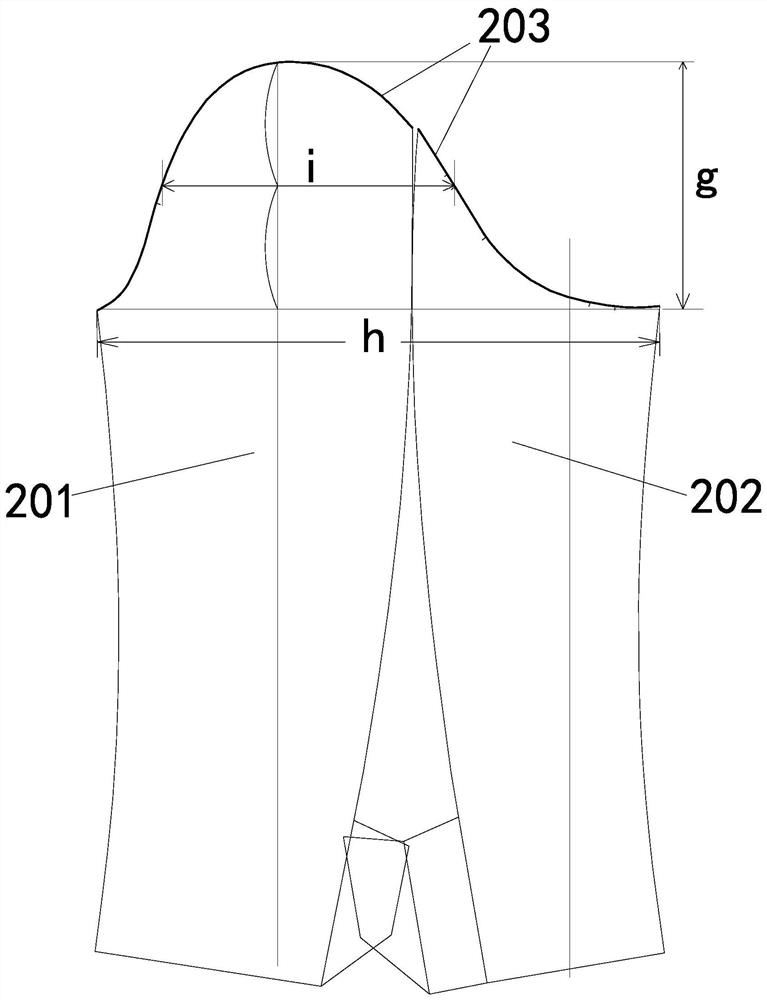

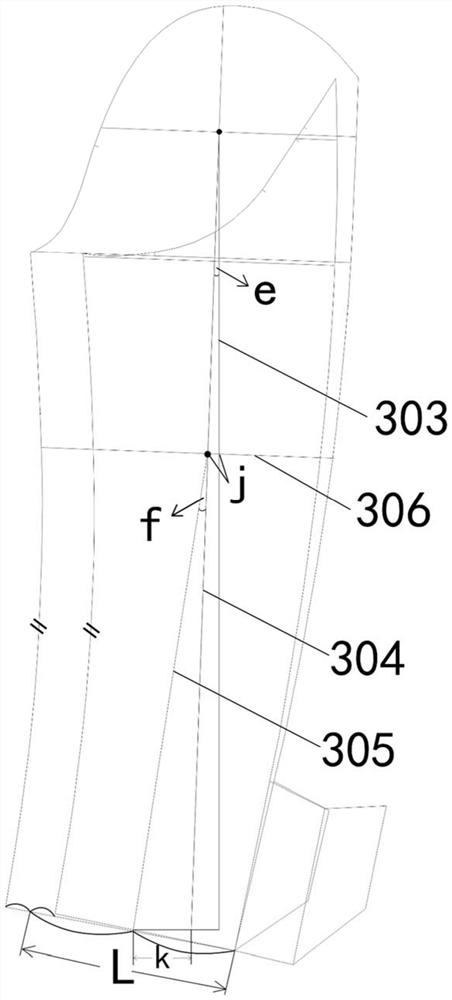

Preparation method of real silk linerless men's suit and real silk linerless men's suit

ActiveCN112401333AStable profileRaw materials are environmentally friendlyJacketsSevering textilesPolymer scienceEngineering

The invention provides a preparation method of a real silk linerless men's suit and the real silk linerless men's suit. The preparation method comprises the following steps: carrying out plane patternmaking and preliminary correction; performing three-dimensional tailoring according to the preliminarily-corrected plane pattern making, selecting a silk-like fabric with the same draping characteristic as the silk fabric as base cloth for three-dimensional tailoring, and fixing the tailored base cloth on a mannequin; adjusting the base cloth on the mannequin, and further correcting the plane pattern making according to the adjustment data; performing three-dimensional tailoring according to the further corrected plane pattern making, fixing the tailored gray fabric on a mannequin for standing, observing whether further correction is needed or not, and if correction is needed, returning to the previous step for continuous execution; if not, executing the next step; carrying out marker planning according to the further corrected plane pattern making and part sample patterns, and cutting the real silk cloth; and sewing and ironing the cut real silk cloth. The light, thin, drooping and smooth men's suit is manufactured through a completely linerless structure, and the ready-made suit is soft, light and comfortable and still has a stable outline.

Owner:上海之禾企业发展有限公司

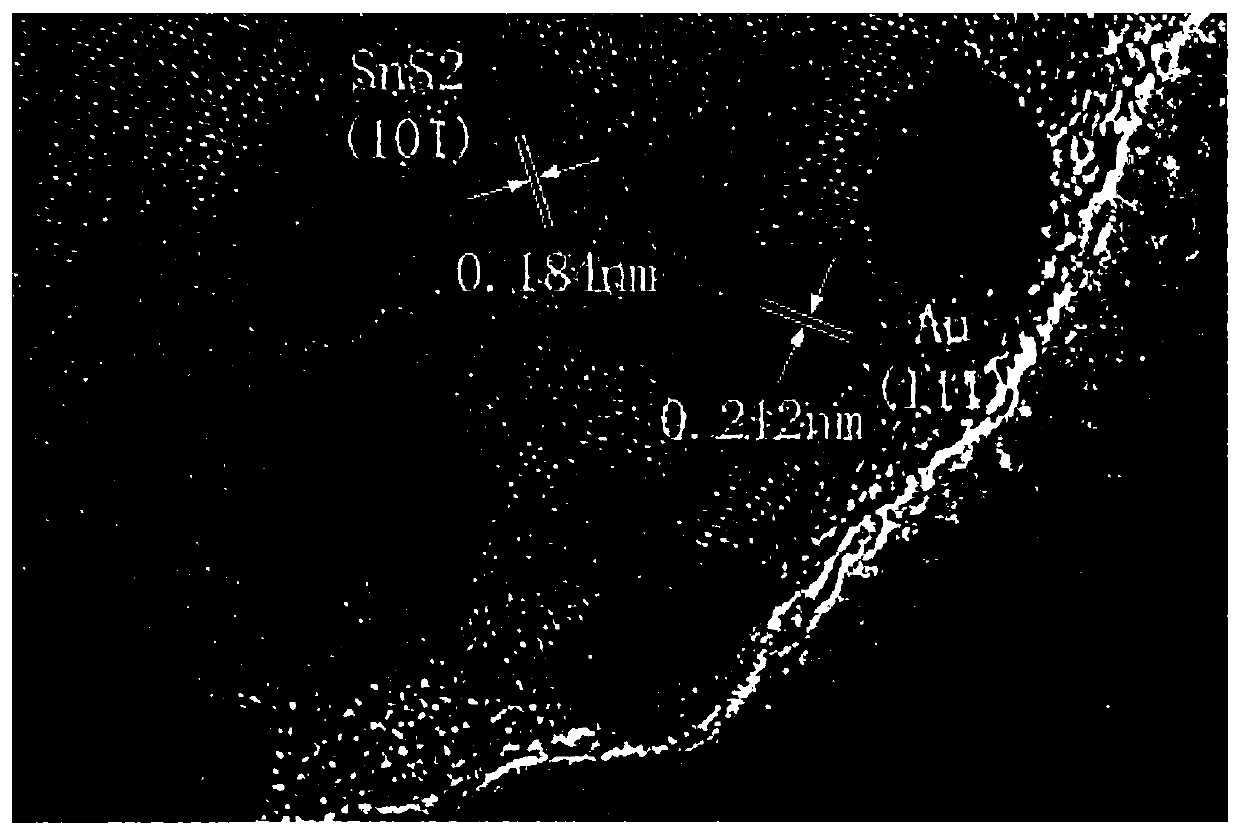

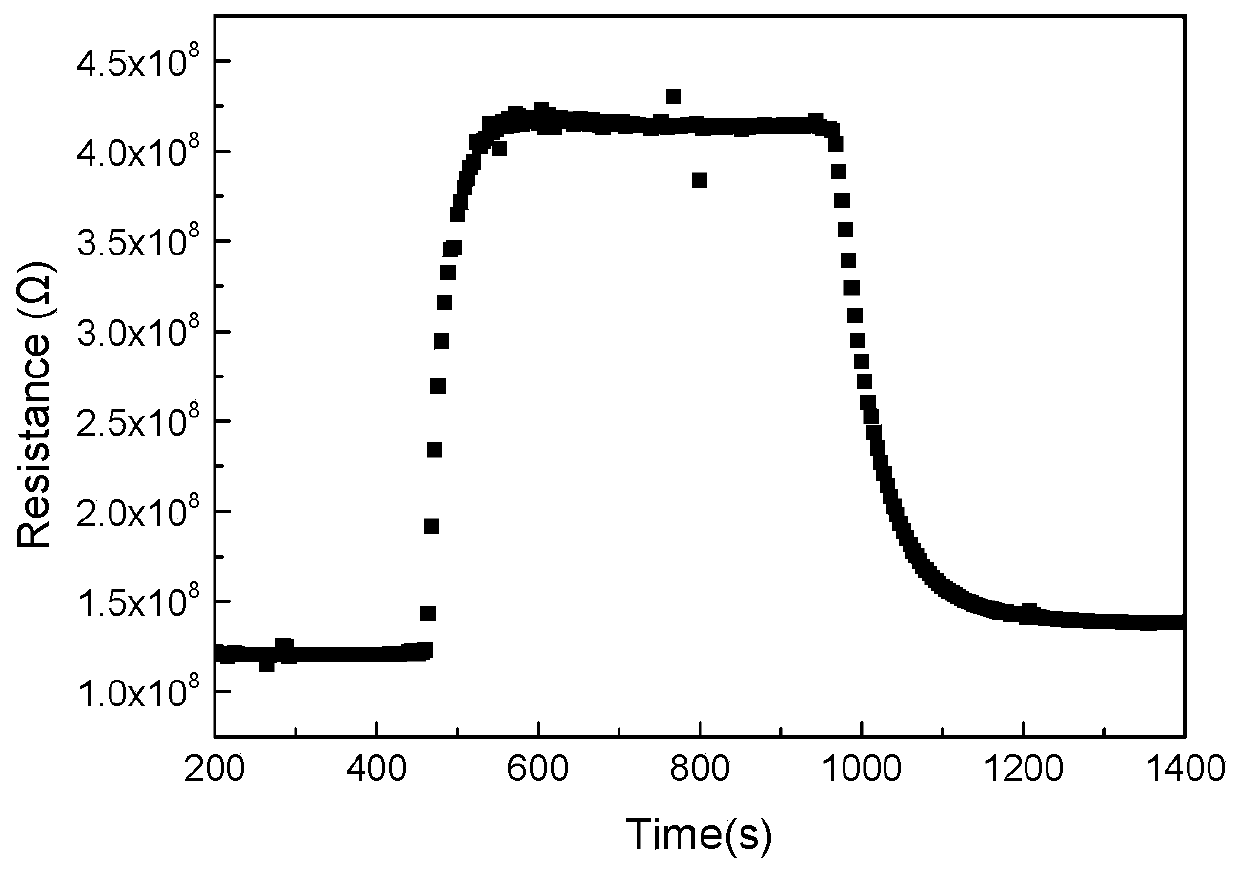

Au/SnS2 nitrogen dioxide gas sensor and preparation process and application thereof

InactiveCN110095506ARealize the craftRaw materials are environmentally friendlyMaterial resistanceDissolutionInorganic chemistry

The invention relates to an Au / SnS2 nitrogen dioxide gas sensor comprising a gas sensitive material and a heating substrate. The gas sensitive material is coated on the surface of the heating substrate in a spinning manner and includes nanocomposite material formed by gold simple-substancenano particles and SnS2 nanosheets. In addition, the preparation process comprises the following steps: step one, mixing an acidic buffer solution with absolute ethyl alcohol, adding SnCl2.2H2O into the mixed solution, and carrying out stirring for dissolution; adding Na2S2O3.5H2O and sulfur powder, carryingout stirring, pouring the mixture into a reaction kettle for reaction to obtain a yellow sediment; cleaning and drying the sediment to obtain SnS2; step two, dispersing the SnS2, adding chloroauric acid and L-lysine, carrying out stirring fully, and then adding sodium citrate to carry out gold simple substance reduction; and carrying out cleaning and drying on the obtained product to obtain Au / SnS2; and step three, adding Au / SnS2 into deionized water, carrying out fully grinding and then coating the surface of a heating substrate with the ground substance in a spinning manner, and carrying outdrying to obtain a Au / SnS2 nitrogen dioxide gas sensor. The preparation process is simple; the obtained Au / SnS2 has the great application value in the preparation of the gas-sensitive sensor; and thesensor makes a sensitive and rapid response to nitrogen dioxide.

Owner:HAINAN UNICAN SCI & TECH INNOVATION INST CO LTD

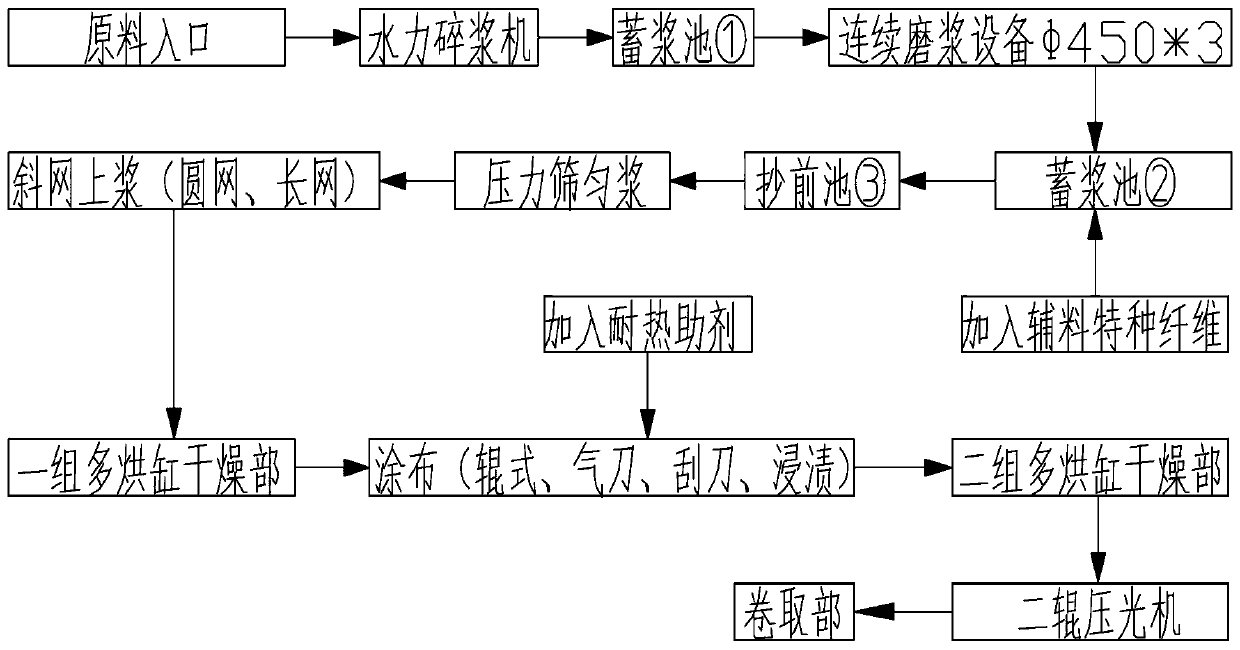

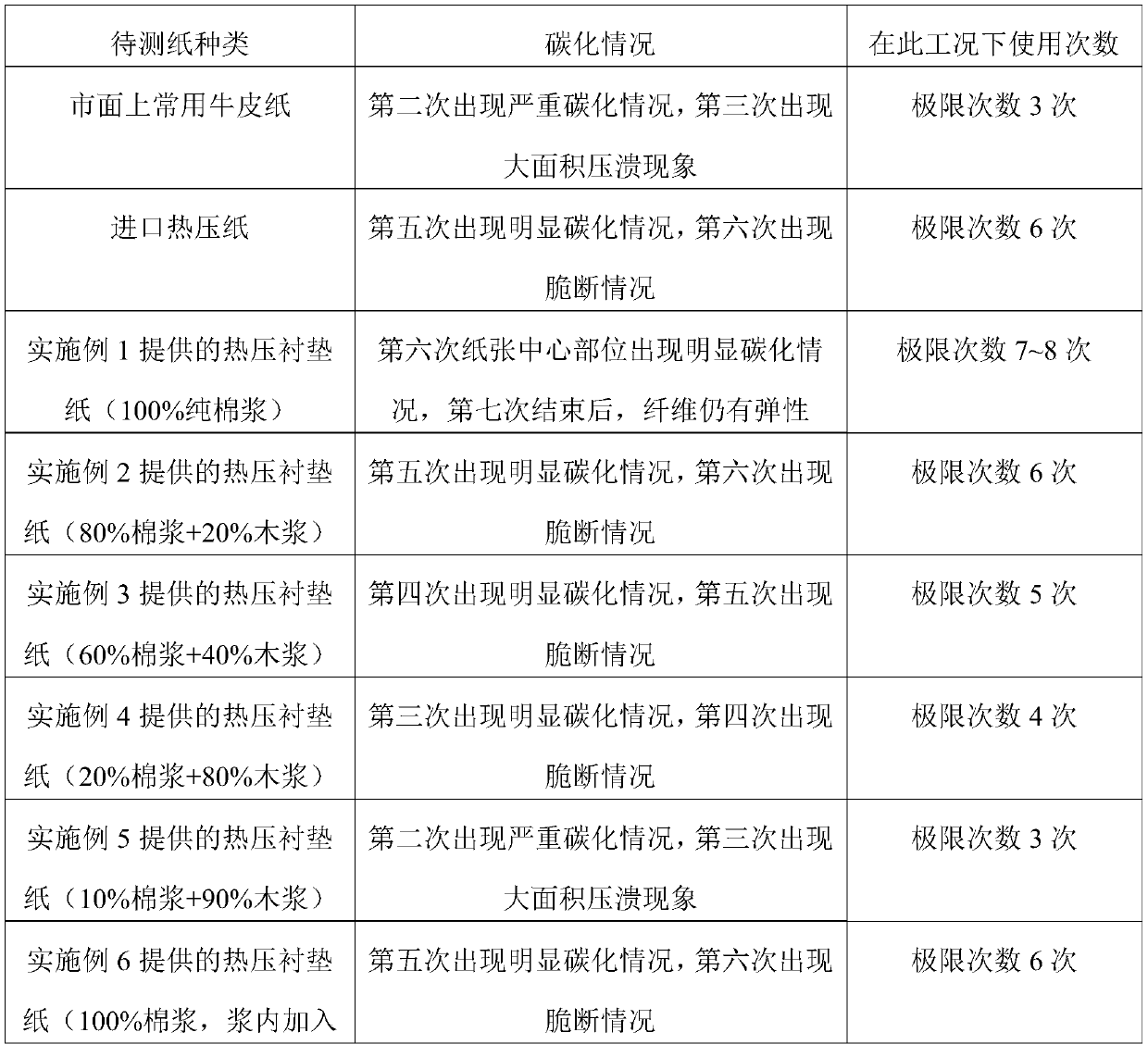

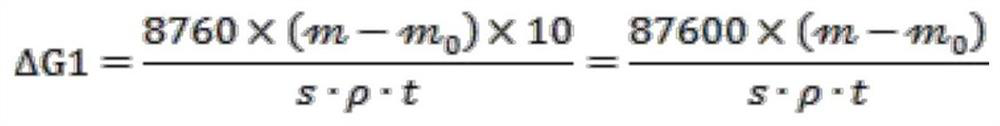

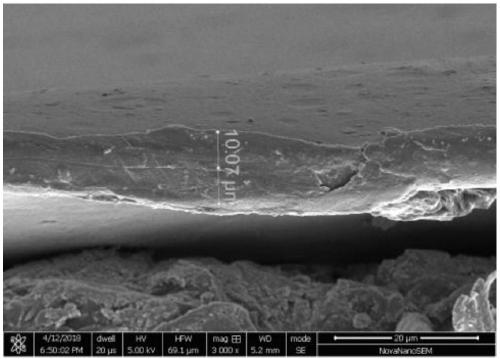

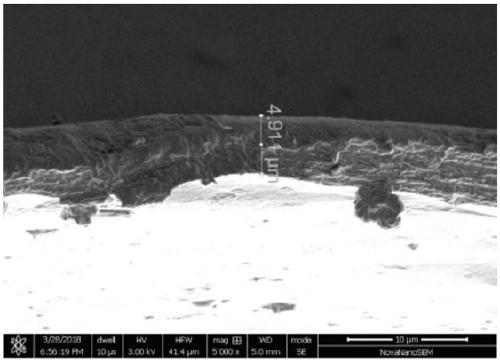

Manufacturing method of cotton pulp hot-pressing liner paper and hot-pressing liner paper obtained by the method

InactiveCN111501389AReduce dosageImprove high temperature resistanceDryer sectionMachine wet endFiberAdhesive

The invention provides a manufacturing method of cotton pulp hot-pressing liner paper. According to the method, pure cotton pulp or cotton pulp and other pulp types (such as wood pulp, hemp pulp and bamboo pulp) are mixed according to different proportions to serve as raw materials, and after wet paper sheets are formed through an in-machine pulp and out-machine addition method, the surfaces of the paper sheets are coated or soaked with a high-temperature-resistant auxiliary agent, so that the high temperature resistance and folding resistance of products are improved, and the use amount of the auxiliary agent is reduced. Due to the fact that the cotton pulp is used, extra chemical auxiliaries such as a wet strength agent, a retention aid, an adhesive and a dry strength agent do not need to be added in the manufacturing process, and the overall performance such as the high temperature resistance is improved from the raw materials. At present, hot-pressing paper made of cotton pulp doesnot exist on the market, and most of the hot-pressing paper is kraft paper made of wood pulp or a buffer pad made of composite fibers. Compared with kraft paper, the hot-pressing paper made of the cotton pulp has longer service life, and the raw materials and the manufacturing process are more environment-friendly.

Owner:上海汉伦特种纤维材料有限公司

Plant type composite efficient corrosion inhibitor as well as preparation method and application thereof

ActiveCN112680190AWide range of raw materialsRaw materials are environmentally friendlyOther chemical processesSodium molybdateSulfate zinc

The invention provides a plant type composite efficient corrosion inhibitor. The plant type composite efficient corrosion inhibitor is prepared from the following raw materials in percentage by mass: 12 to 66.0 percent of plants, 5.0 to 16.0 percent of sodium molybdate, 1.5 to 12 percent of sodium gluconate, 3.5 to 25 percent of sodium tartrate, 0 to 23 percent of zinc sulfate and 4.0 to 23.0 percent of monopotassium phosphate. The corrosion inhibitor disclosed by the invention is high in corrosion inhibition capability and can achieve a corrosion inhibition effect on a chlorine salt type snow-melting agent. After the corrosion inhibitor is added, the corrosion of the chlorine salt type snow-melting agent to metal and concrete and the harm to vegetation can be reduced. The corrosion inhibitor is mainly prepared from plants, is non-toxic, and is a very efficient and environment-friendly corrosion inhibitor. The invention further provides a preparation method and application of the plant type composite efficient corrosion inhibitor.

Owner:新疆交通科学研究院有限责任公司

Hollow integrated interlayer heat-insulating ceramic utensil and manufacturing method thereof

InactiveCN101870381ATo promote metabolismGuaranteed normal operationRemovable lids/coversCeramic shaping apparatusEnvironmental resistanceBiological activation

The invention discloses a hollow integrated interlayer heat-insulating ceramic utensil, and a utensil body is a hollow integrated ceramic body. The invention also discloses a manufacturing method of the hollow integrated interlayer heat-insulating ceramic utensil formed by slip casting integrally, which comprises the following steps of: (1) closing a female die and a male die; (2) slip casting; (3) demoulding; and (4) drying rough bodies. The rough bodies of the ceramic utensil are easy to form, and ordinary workers can operate with training; and raw materials of the ceramic utensil have environmental protection, no toxicity, innocuity and no radiation, and have antibacterial and bacteriostatic effects. Active ceramic spheres are added into a hollow part so as to play a role in magnetization, adsorption and activation on water molecules in the utensil. A heat-resistant antibacterial agent is added into glaze, so that bacteria and viruses can be killed, organic pollutants can be decomposed, the anti-pollution capability of ceramic surfaces is improved, and the ceramic surfaces are easy to clean. The hollow integrated ceramic utensil manufactured by the invention has the advantages of safety, reliability, obvious reduction in cost, suitability for batch production and product heat-insulating time which is 35 percent longer than that of common ceramic utensils.

Owner:刘少平

Heat-conducting antirust antistatic paint for electromechanical device and preparation method of heat-conducting antirust antistatic paint

InactiveCN107141924AImprove antistatic performanceStrong rust resistanceFireproof paintsAntifouling/underwater paintsEcological environmentAcrylic resin

The invention discloses heat-conducting antirust antistatic paint for an electromechanical device. The heat-conducting antirust antistatic paint is prepared from the following raw materials in parts by weight: 5 to 7 parts of antirust complexing agent, 40 to 50 parts of acrylic resin, 3 to 7 parts of nano zinc oxide, 5 to 9 parts of nano silicon dioxide, 30 to 40 parts of anhydrous ethanol, 7 to 9 parts of nano titanium dioxide, 3 to 4 parts of defoaming agent, 4 to 6 parts of antistatic agent, 10 to 14 parts of heat-conducting additive, 3 to 5 parts of tackifier and 10 to 20 parts of film forming agent. The heat-conducting antirust antistatic paint is environmentally friendly in raw materials, nontoxic and harmless both to the human beings and the ecological environment, good in film forming performance, excellent in adhesion and relatively high in heat conducting performance, and a formed film is smooth in surface, compact and free from air hole, and the corrosion and heat conduction problems of the electrochemical device can be effectively solved; and meanwhile, a preparation method of the heat-conducting antirust antistatic paint for the electromechanical device is relatively low in cost, easy for obtaining raw materials, simple in process and good in application prospect.

Owner:HEFEI DAHU ELECTRIC WIRE & CABLE TECH CO LTD

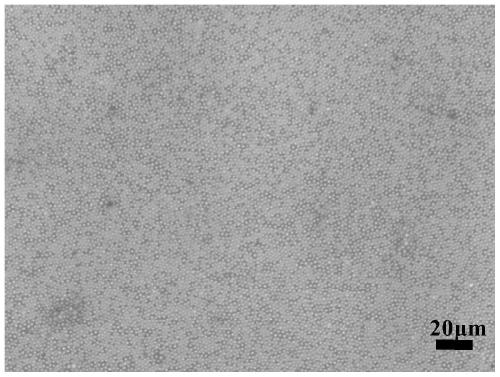

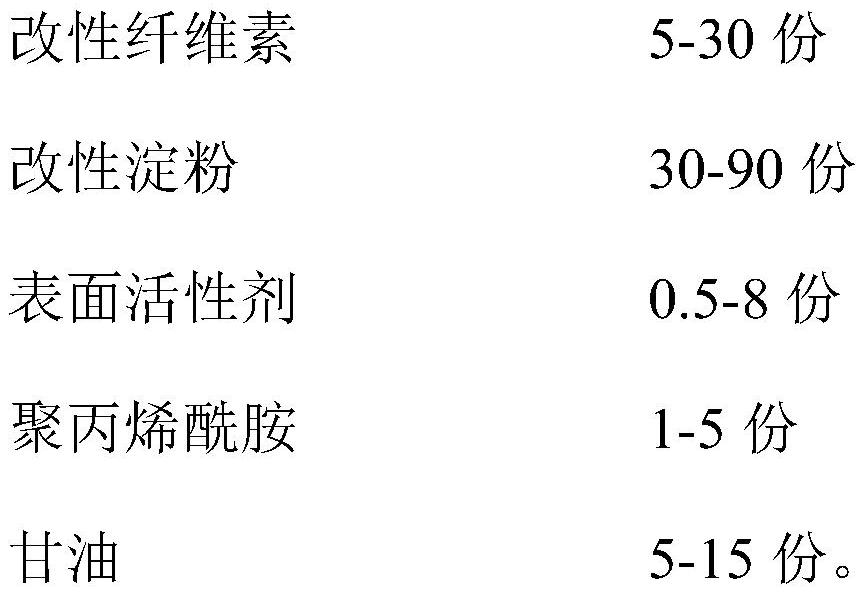

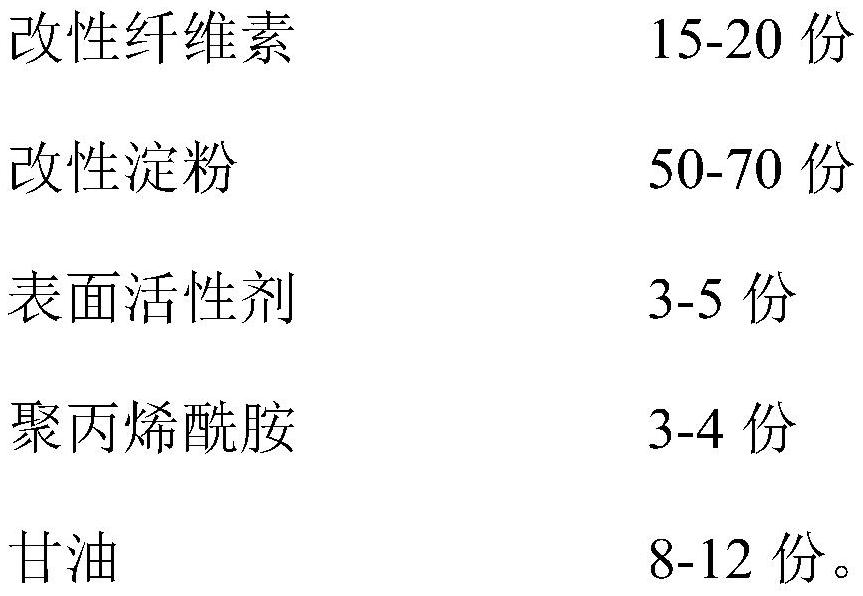

Preparation method of carboxymethyl chitosan film

The invention discloses a preparation method of carboxymethyl chitosan film. The method is conducted according to the following steps that 1, carboxymethyl chitosan is taken, and is dissolved in waterto form a 0.1-5wt% carboxymethyl chitosan solution, then appropriate amounts of plasticizer and surfactant are added to make the concentrations of the plasticizer and the surfactant equal to 1-10wt%and 0.1-1wt% respectively, and intense stirring is conducted for 0.5-2 h to obtain a casting solution; 2, an appropriate amount of the casting solution is poured in a film-forming container, at 25-50DEG C, vacuum decompression defoaming is conducted, and then in an oven, drying is conducted to form film; 3, in the film-forming container containing the dry film, excessive solidifying liquid is added for a solidifying bath for a certain time, so that wet carboxymethyl chitosan film is obtained, wherein the solidifying liquid is ethyl alcohol or methyl alcohol or acetone, and the purity of the solidifying liquid is larger than 90%; 4, the obtained wet film is dried to obtain the carboxymethyl chitosan film. The preparation method of the carboxymethyl chitosan film is simple, the raw materials are environmentally friendly, the thickness of the film is controllable, and the prepared carboxymethyl chitosan film is wide in application, and can be applied to the aspects of energy, fresh keeping, medicines and the like.

Owner:ZHEJIANG UNIV OF TECH

Waterproof material for toilet and preparation method of waterproof material

The invention discloses a waterproof material for a toilet and a preparation method of the waterproof material and relates to the technical field of waterproof materials. The waterproof material comprises the following raw materials in parts: 70-80 parts of modified starch, 55-65 parts of inorganic powder fillers, 45-50 parts of cis-1,4-polyisoprene rubber, 35-40 parts of aluminum stearate, 30-35 parts of fly ash, 25-30 parts of nano particles, 15-25 parts of organic fibers, 15-20 parts of dimethyl silicone, 10-15 parts of aids, 5-10 parts of pigments and 120-150 parts of water. The waterproof material disclosed by the invention has excellent waterproof, anti-permeability and antibacterial and anti-mold properties, the raw materials are environmental-friendly and high in affinity, water leakage in the toilet can be effectively prevented, and the waterproof material is difficult to age.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Mayenite-structure fluorescent powder for white light emitting of LED

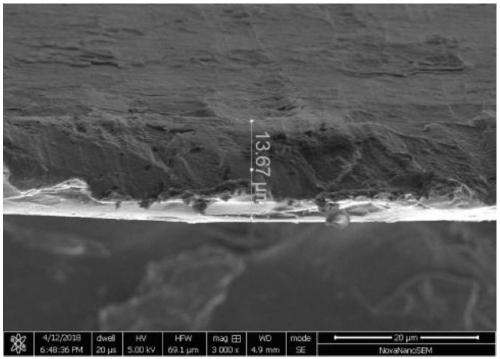

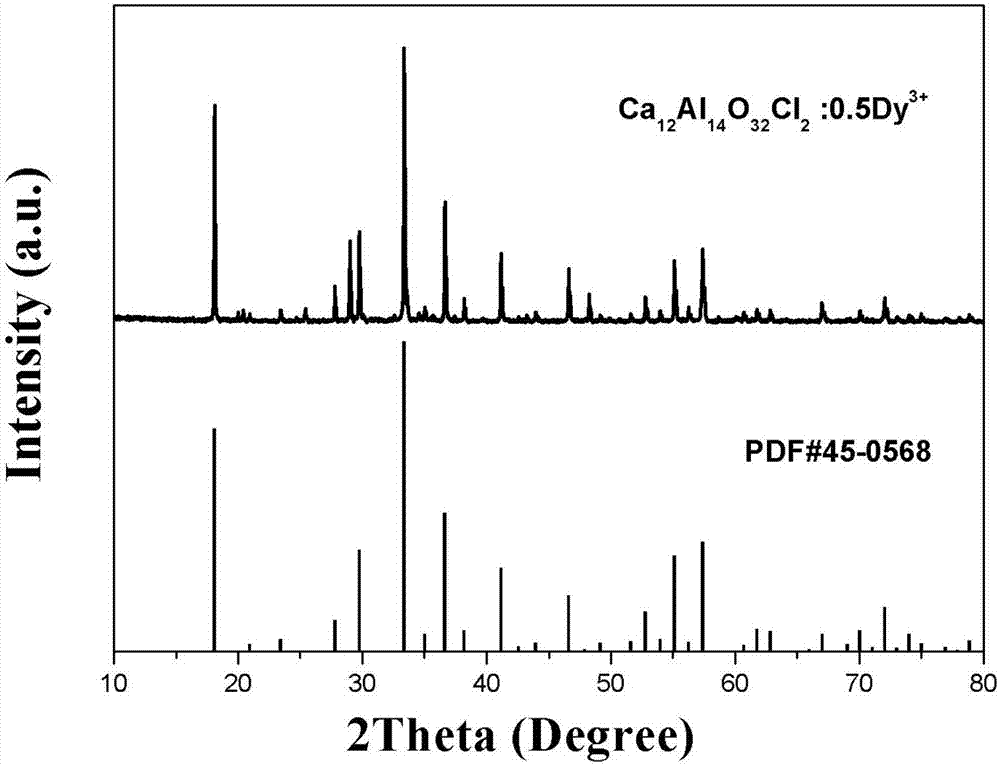

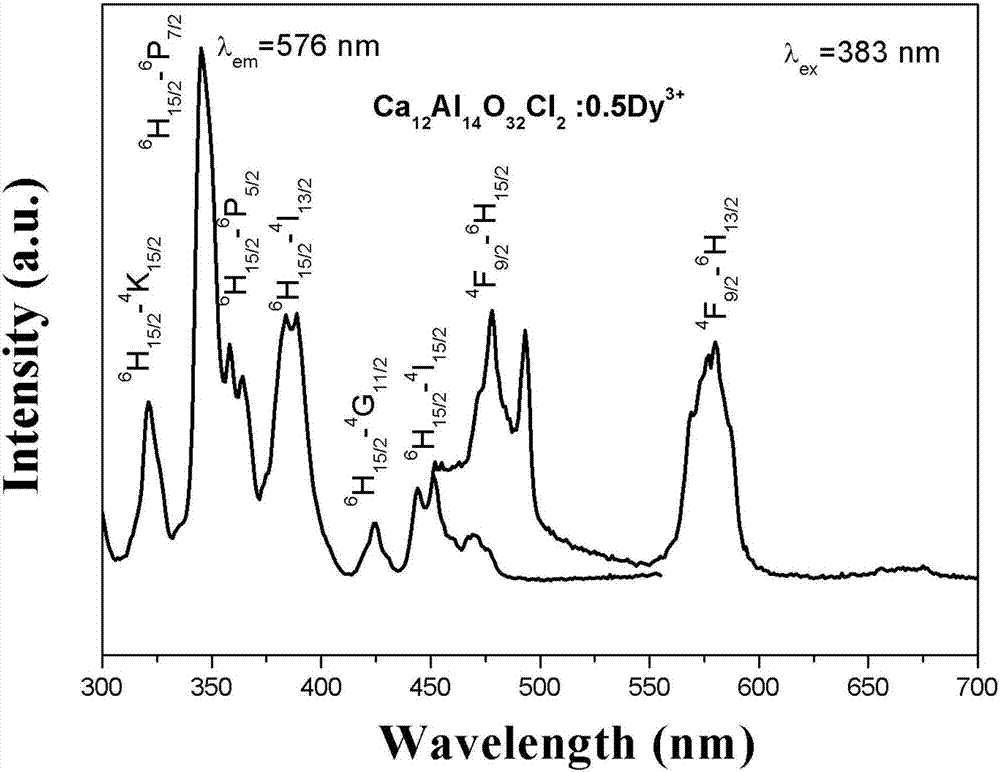

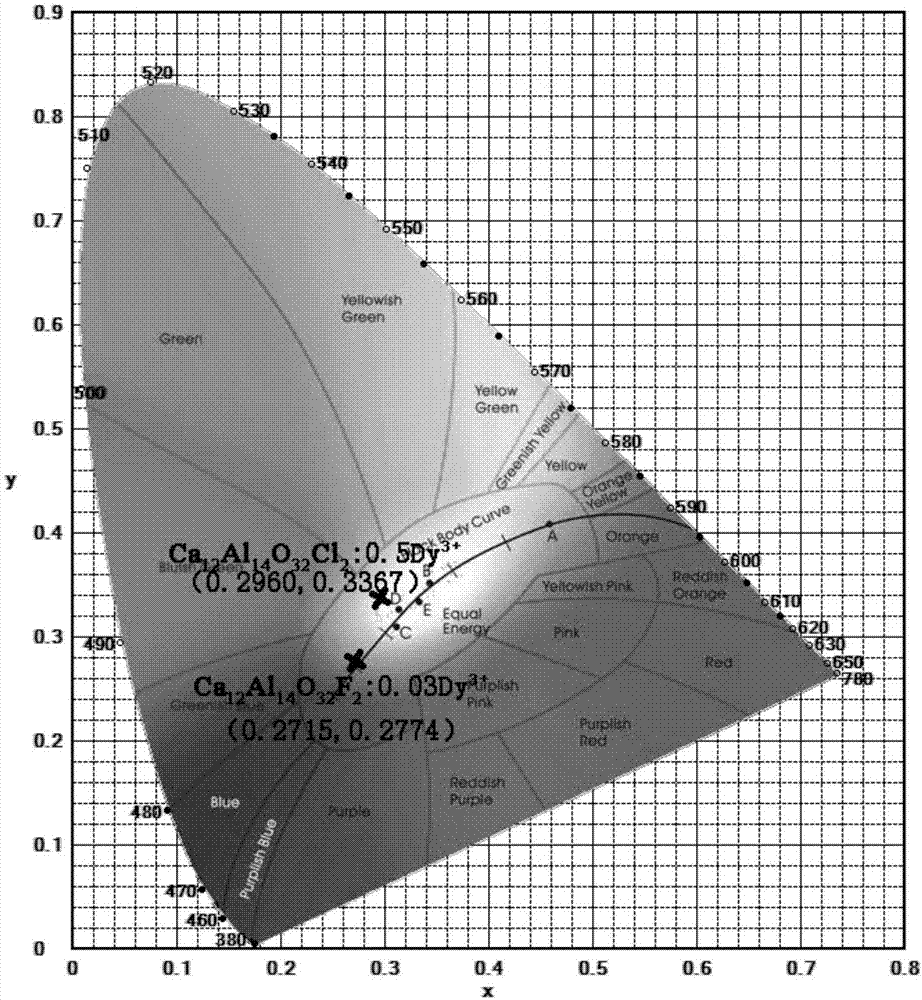

InactiveCN107987828AOvercome speedOvercome absorbencyEnergy efficient lightingLuminescent compositionsFluorescenceStructural formula

The invention relates to mayenite-structure fluorescent powder for white light emitting of LED. The chemical structural formula of the fluorescent powder is: Ca12Al14O32A2:xDy<3+>, where A is one of Cl and F; x is a molar ratio of Dy<3+> substituting Ca<2+> and is greater than or equal to 0.01 and less than or equal to 0.6. The fluorescent powder is single-substrate white-light fluorescent powderdoped with Dy<3+>, and has the advantages of long fluorescence lifetime and high light chroma and can be applied to near-ultraviolet LED excitation.

Owner:HEBEI UNIV OF TECH

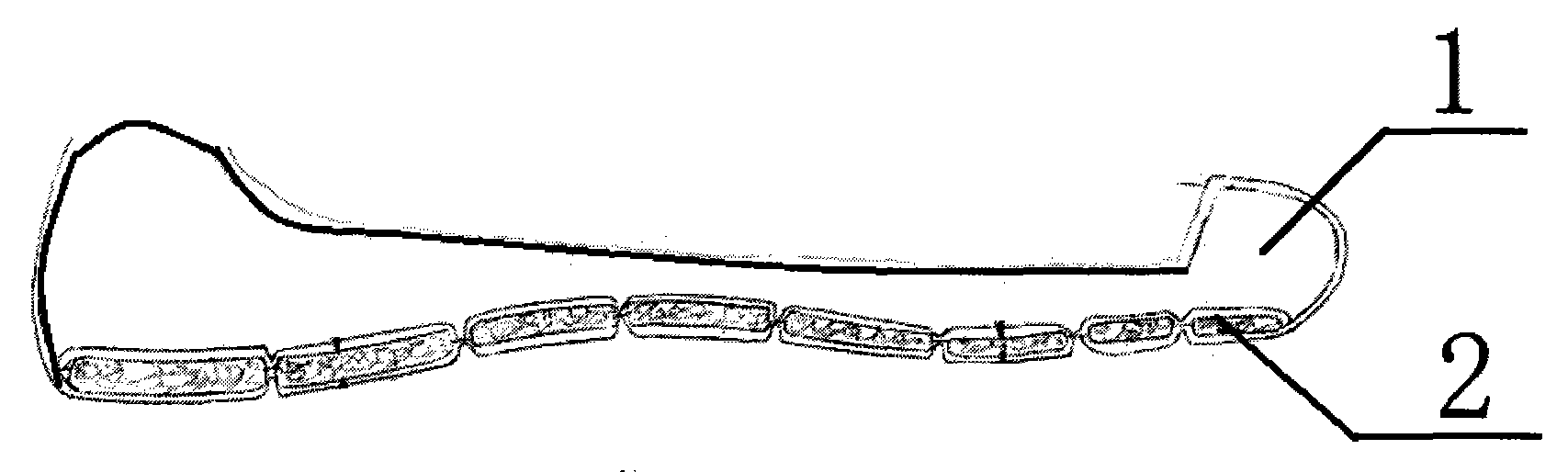

Antifatigue socks

InactiveCN101869357ANot easy to accumulateSpeed up distributionPanty-hoseHosierySolid structurePliability

The invention discloses a pair of antifatigue socks. Each sock comprises a sock body, and a wire coil layer which can resist fatigue, ventilate and limit slip, is easy to clean and mould proof and has good rebound resilience is attached to the bottom of the sock body. The wire coil layer is in a solid structure and is formed by irregular superposition and arrangement of wire coils. A bottom wire coil of the wire coil layer and a contact face form a stress surface with multiple angles and multiple directions. For the antifatigue socks, since the bottoms of the socks are provided with the wire coil layers which are plasticity elastic bodies, the bottoms of the socks have good flexibility and elasticity, and the socks have the functions of buffering and damping when being worn for sports and have the antifatigue function. In addition, the socks have the characteristics of slip limiting, good airpermeability, strong adhesive force, firmness and durability.

Owner:TAICANG ALL MATS PLASTIC IND

Method for producing ultra-high molecular weight polyethylene colored fine denier fiber

ActiveCN101718003BBright colorOvercoming issues such as emissionsFilament/thread formingMonocomponent polyolefin artificial filamentFiberPolymer science

The invention discloses a method for producing an ultra-high molecular weight polyethylene colored fine denier fiber, relating to the technical field of polymer materials and comprising the following steps of: pouring ultra-high molecular weight polyethylene powder and solvent into an untwisting kettle according to the proportion; properly untwisting ultra-high molecular weight polyethylene macromolecules in the solvent by high shearing to form uniform emulsion-shaped mixed solution; then preparing nontoxic and harmless nanometer pigment grains into emulsion by using a mixing technology, evenly and continuously adding the emulsion into the emulsion-shaped mixed solution for further shearing; and finally, quantifying the emulsion-shaped mixed solution by the storage tank while stirring andfeeding the emulsion-shaped mixed solution into a screw extruder to extrude and spin. The fiber not only has excellent qualities of the conventional high-strength high-modulus polyethylene fiber, butalso solves the problems of waste liquid discharge in the after finishing process and realizes the environmental protection of raw materials, production process and products.

Owner:ZHEJIANG JINHAO NEW MATERIALS CO LTD

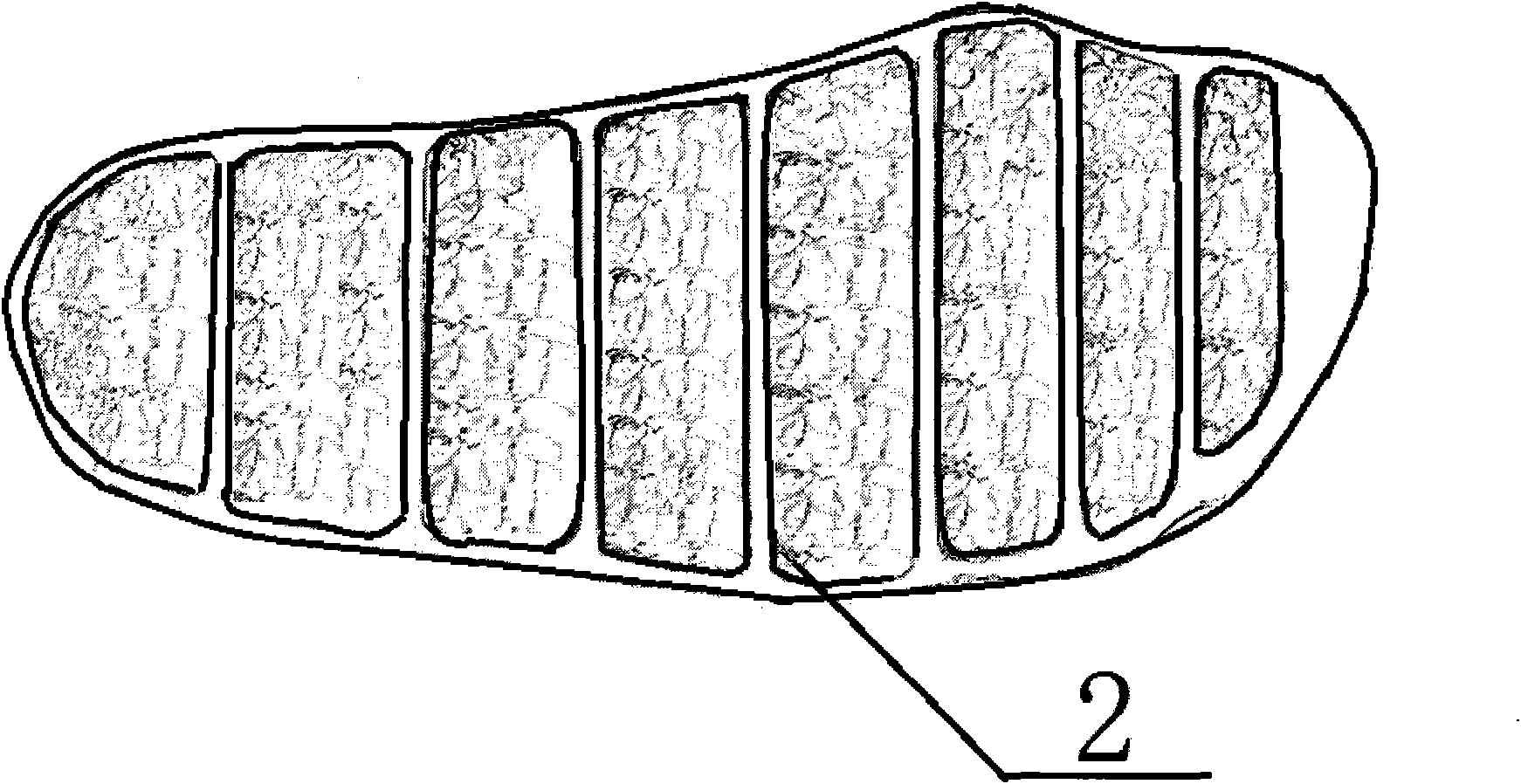

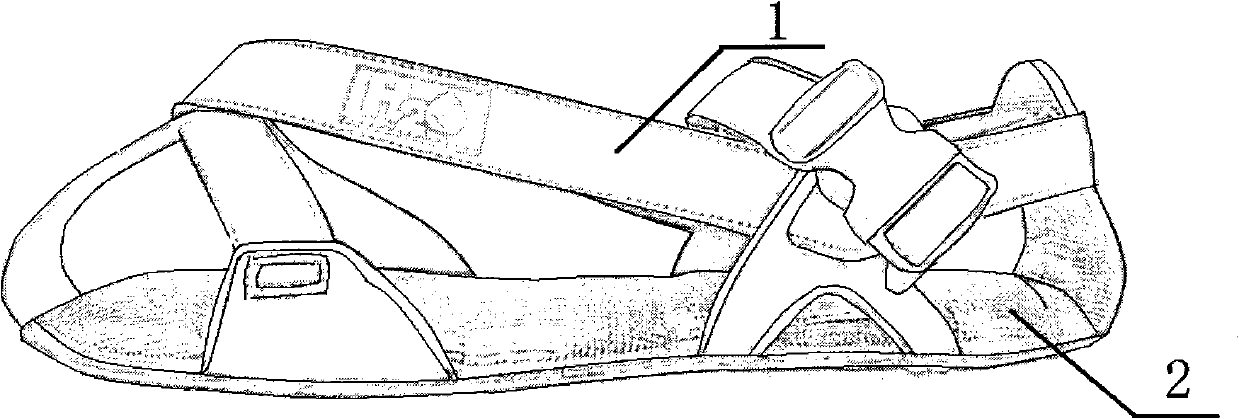

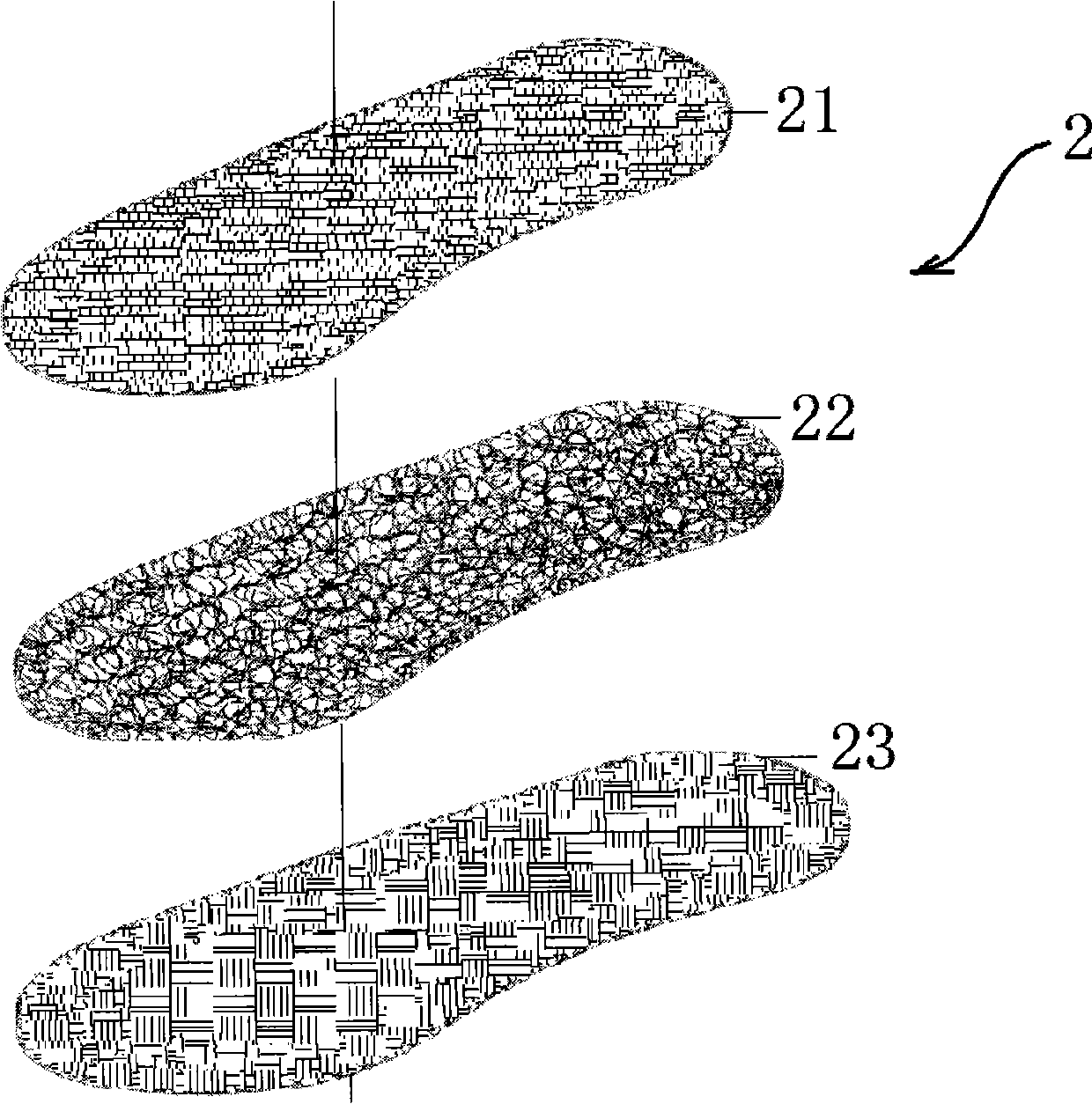

Anti-fatigue shoes with infrared magnet therapy function

InactiveCN102366191AReasonable structural designPlay a buffer roleSolesLight therapyEngineeringMechanical engineering

The invention discloses a pair of anti-fatigue shoes with an infrared magnet therapy function. Each shoe comprises a shoe upper, a shoe pad and a sole, wherein the sole comprises a sole lower layer (1), a sole middle layer (2) and a sole upper layer (3), the sole lower layer (1) is made of a thermoplastic material, the sole middle layer (2) is adhered and arranged on the sole lower layer (1) and is made of thermoplastic wire rings, and the sole upper layer (3) is adhered and arranged on the sole middle layer (2) and is internally provided with a magnet (4) with an infrared radiating function. The pair of anti-fatigue shoes with the infrared magnet therapy function, provided by the invention, has the advantages of reasonable structural design, firmness, and durability, and can be used for reducing the friction force generated during walking to play a buffering role; and the magnet therapy can be carried out on the feet of a person since the magnets with the infrared radiating function are arranged, thus a better health care function can be achieved.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

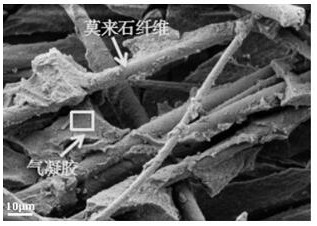

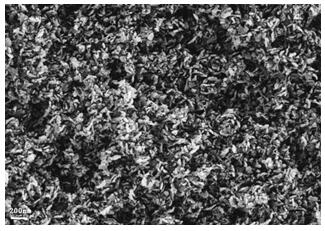

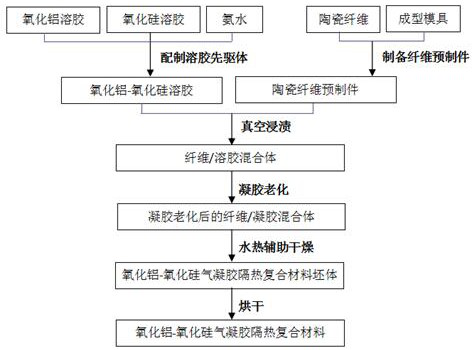

A kind of preparation method of alumina-silica aerogel thermal insulation composite material

Owner:NAT UNIV OF DEFENSE TECH

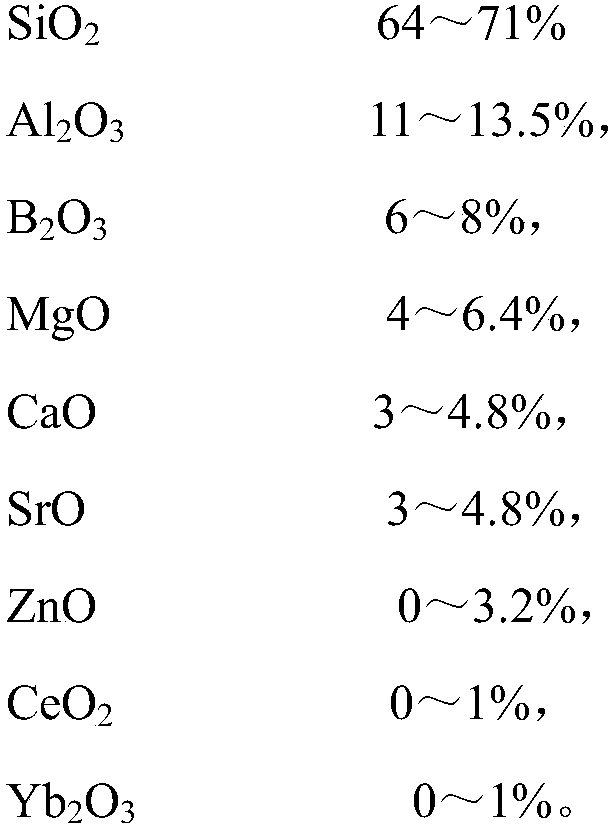

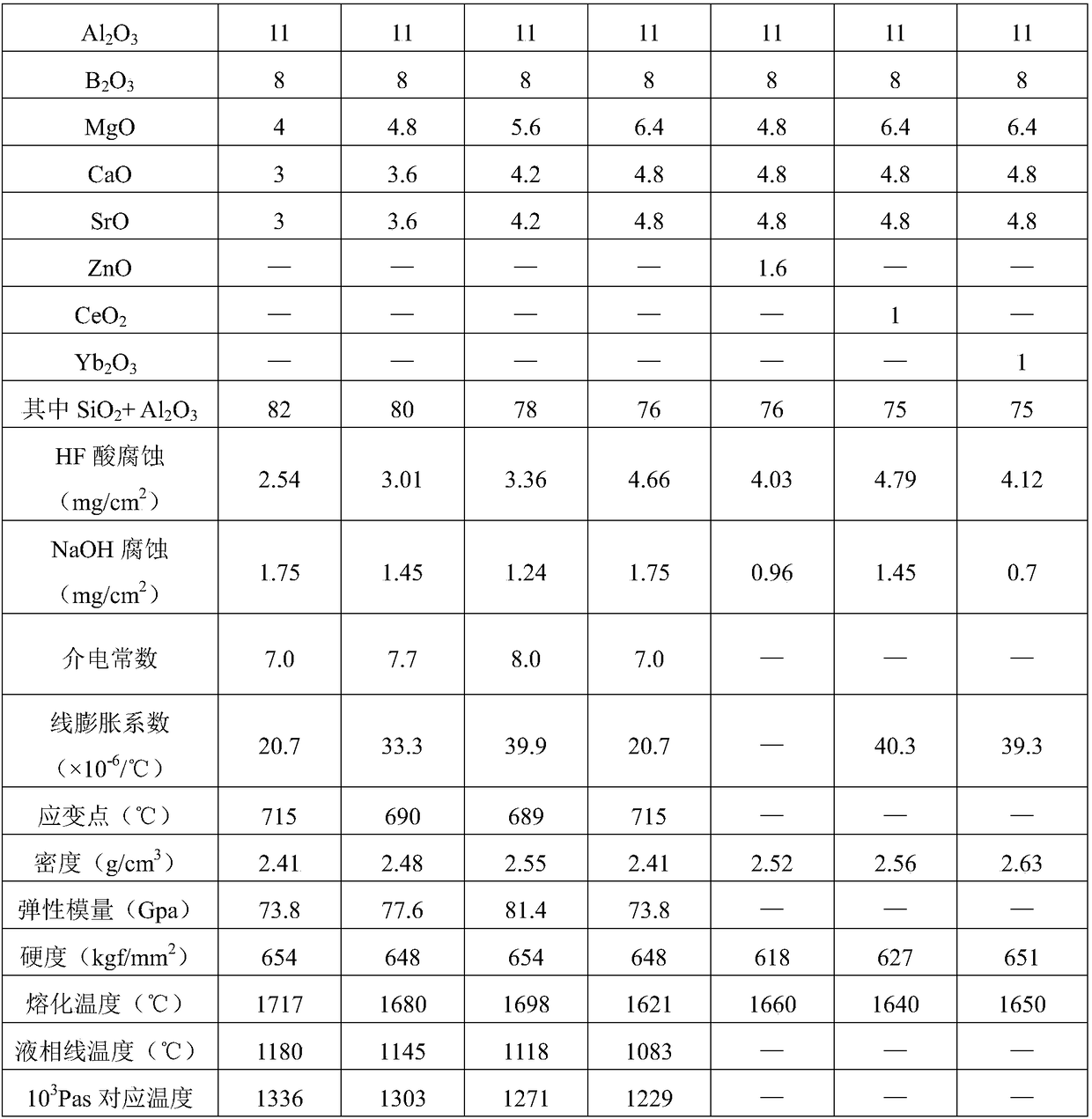

High-acid-resistant alkali-free aluminoborosilicate glass suitable for floating process, and preparation method and applications thereof

PendingCN108623150AImprove acid resistanceHigh strain pointGlass shaping apparatusAlkali freeLiquid-crystal display

The invention discloses a high-acid-resistant alkali-free aluminoborosilicate glass suitable for floating process, and a preparation method and applications thereof. 100% of the high-acid-resistant alkali-free aluminoborosilicate glass comprises, by oxide molar percentage content, 64 to 71% of SiO2, 11 to 13.5% of Al2O3, 6 to 8% of B2O3, 4 to 6.4% of MgO, 3 to 4.8% of CaO, 3 to 4.8% of SrO, 0 to 3.2% of ZnO, 0 to 1% of CeO2, 0 to 1% of Yb2O3. The optimal acir resistance parameters of the high-acid-resistant alkali-free aluminoborosilicate glass is HF-10vol%, 20 DEG C, 20min, 2.54mg / cm<2>; thehardness is high; the strain point is high; the elastic modulus is high; the high-acid-resistant alkali-free aluminoborosilicate glass is suitable for floating process, and can be used for producing glass substrates of thin film transistor liquid crystal displays.

Owner:WUHAN UNIV OF TECH

Waterproof and anti-fatigue shoes

InactiveCN101904590AWith waterproof functionHas anti-fatigue effectSolesThermoplastic elastomerPliability

The invention discloses a pair of waterproof and anti-fatigue shoes. Each shoe comprises a vamp and a sole which comprises a sole upper layer, a sole middle layer and a sole lower layer, wherein the sole middle layer is hermetically wrapped by the sole upper layer and the sole middle layer to form a sole with the waterproof function, the sole upper layer adopts an interwoven mesh coated with thermoplastic elastomer, the sole middle layer is made from thermoplastic elastomer rings, and the sole lower layer is made from the thermoplastic elastomer. The waterproof and anti-fatigue shoes of the invention has the waterproof function as the sole middle layer is hermetically wrapped by the sole upper layer and the sole middle layer, the sole middle layer has favorable flexibility and elasticity because the sole middle layer is made from thermoplastic elastomer rings, the invention can take the buffer and damping effects on a person wearing the shoes for movement, and the invention can also take the antiskid action because one side of the sole lower layer, which contacts with the ground, is provided with antiskid-structure lines.

Owner:TAICANG ALL MATS PLASTIC IND

Novel water purifying agent and preparation method thereof

InactiveCN108408923AEasy to handleImprove adsorption capacityWater contaminantsBiological water/sewage treatmentAdditive ingredientGlycerol

The invention provides a novel water purifying agent and a preparation method thereof. The novel water purifying agent is prepared from the following ingredients: waste aluminum ash, modified bentonite, graphene oxide compound, sodium oxide, glycerol, sulfuric acid solution, manganese dioxide, complex microbes, active carbon and distilled water. The water purifying agent prepared by the inventionhas strong sewage treatment capability and strong capability in adsorbing heavy metals in sewage, the effects of flocculation and decoloration, deodorization and COD (chemical oxygen demand) removal are obvious, the raw materials are environmentally friendly, secondary pollution cannot be caused on the environment, and therefore the novel water purifying agent meets an environment-friendly product.

Owner:HEFEI JINTONGWEI LOW TEMPERATURE TECH CO LTD

Fruit and vegetable cleaning agent and preparation method thereof

InactiveCN106833923AImprove securityImprove washing abilityInorganic/elemental detergent compounding agentsPolymeric surface-active compoundsAlcoholCleansing Agents

The invention provides a fruit and vegetable cleaning agent. The fruit and vegetable cleaning agent has the advantages of being green and environment-friendly, small in harm to a human body and easy to clean, is nontoxic and harmless in production and application processes, is free of chemical residue after long-term use and good in market prospect. The fruit and vegetable cleaning agent comprises the following components: alkyl glucoside, a surfactant, potassium citrate, a gleditsia sinensis extract, a grapefruit peel extract, dietary alkali, ethyl alcohol and water.

Owner:CHANGSHU NANJING NORMAL UNIV DEV RES INST

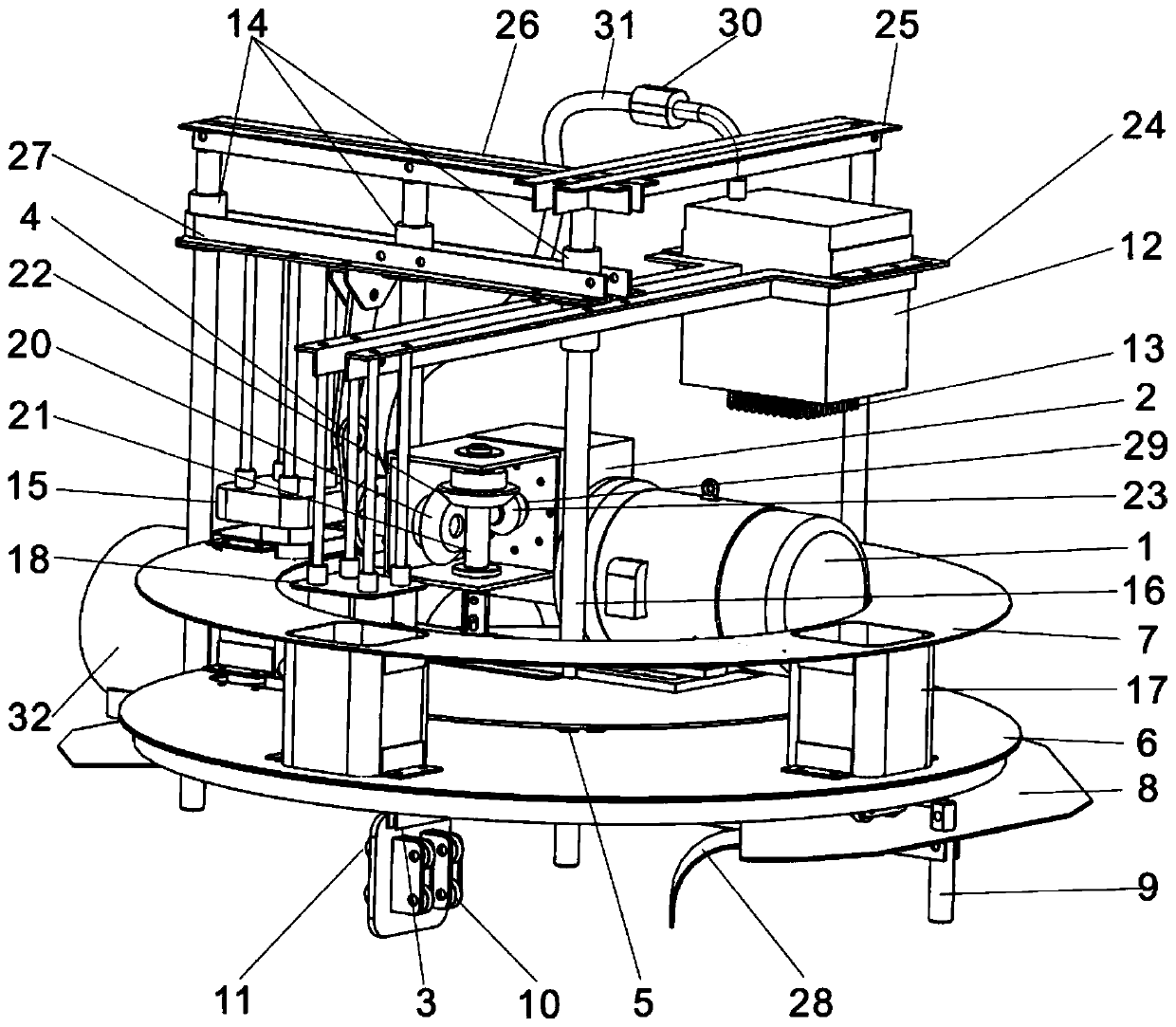

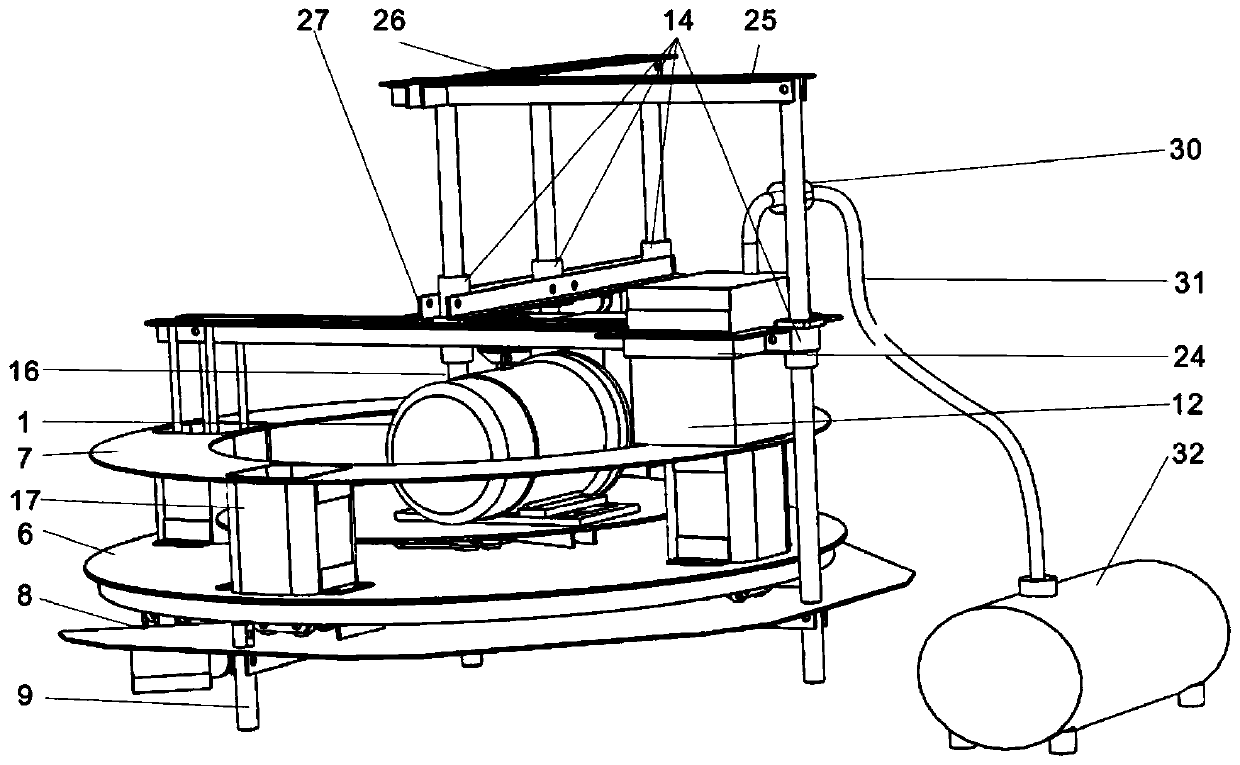

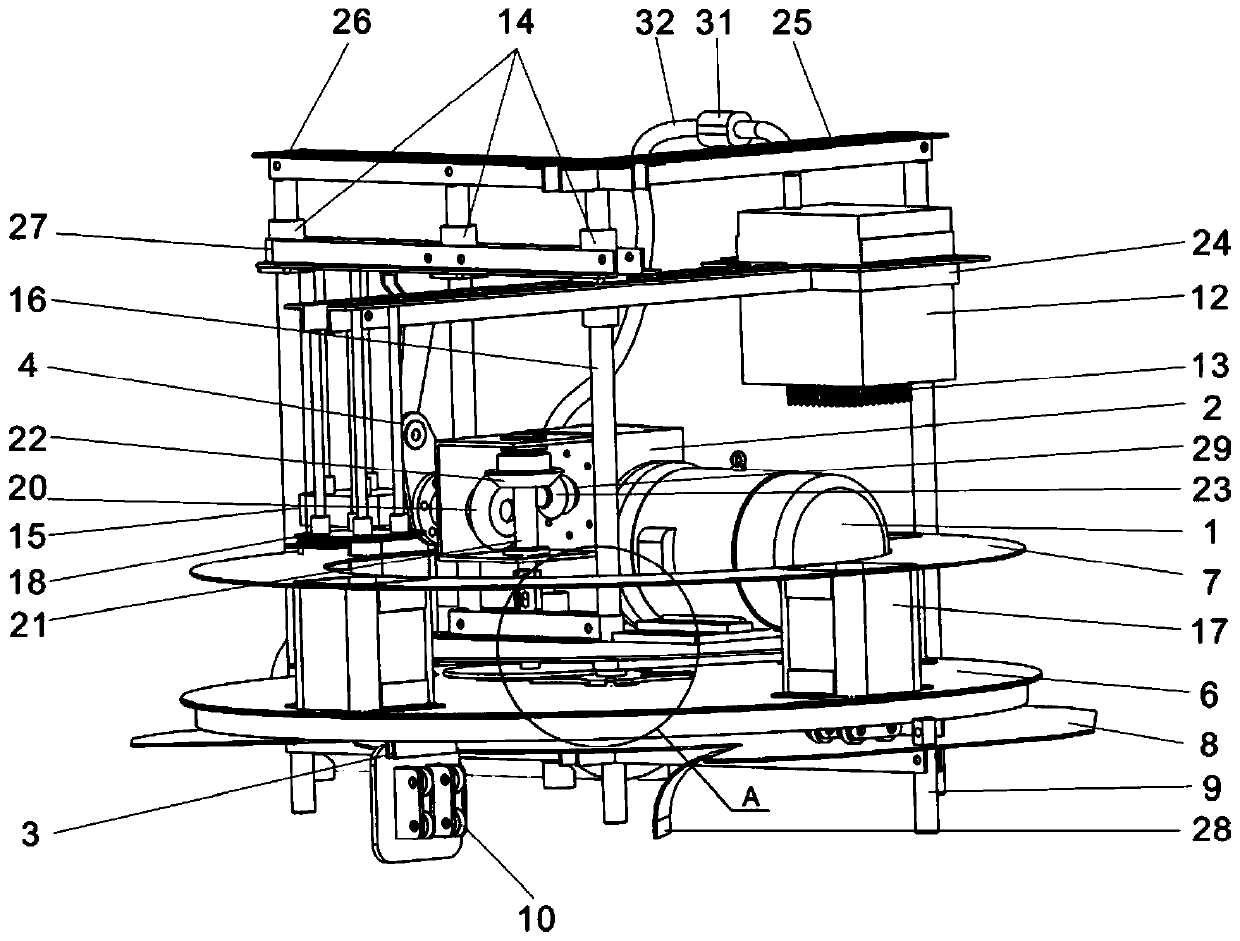

Equipment for converting straw into environment-friendly packaging box

ActiveCN110091410AReduce volumeSolve the problem of large volume and not suitable for family householdsDomestic articlesHollow articlesWork periodDevice form

The invention discloses equipment for converting straw into an environment-friendly packaging box. The equipment is characterized by comprising a rotating device, a power device and a preparation device, wherein the rotating device drives feeding ports to do periodic rotation, the power device comprises a power conversion mechanism which is connected with a motor, the power conversion mechanism ismatched with a groove wheel, and the groove wheel is fixedly connected with the rotating device; one circle rotation of the rotating device forms a working period, and each working period is sequentially provided with four stations, the four stations comprise a discharging station, a glue injection station, a pressing and modeling station and a workpiece taking station; the rotating device is provided with the four feeding ports, the four feeding ports sequentially pass through the four stations in the rotating process of the rotating device, reach the corresponding stations at the same timeand have the same staying time; and the glue injection assembly and a pressing and modeling mechanism are arranged above the rotating device correspondingly. According to the equipment, straw is crushed and converted into the dry-type environment-friendly packaging box through a rapid modeling way of glue injection and stamping, raw materials are environment-friendly, the structure is reasonable,the cost performance is high, and the environmental pollution is low.

Owner:DONGHUA UNIV

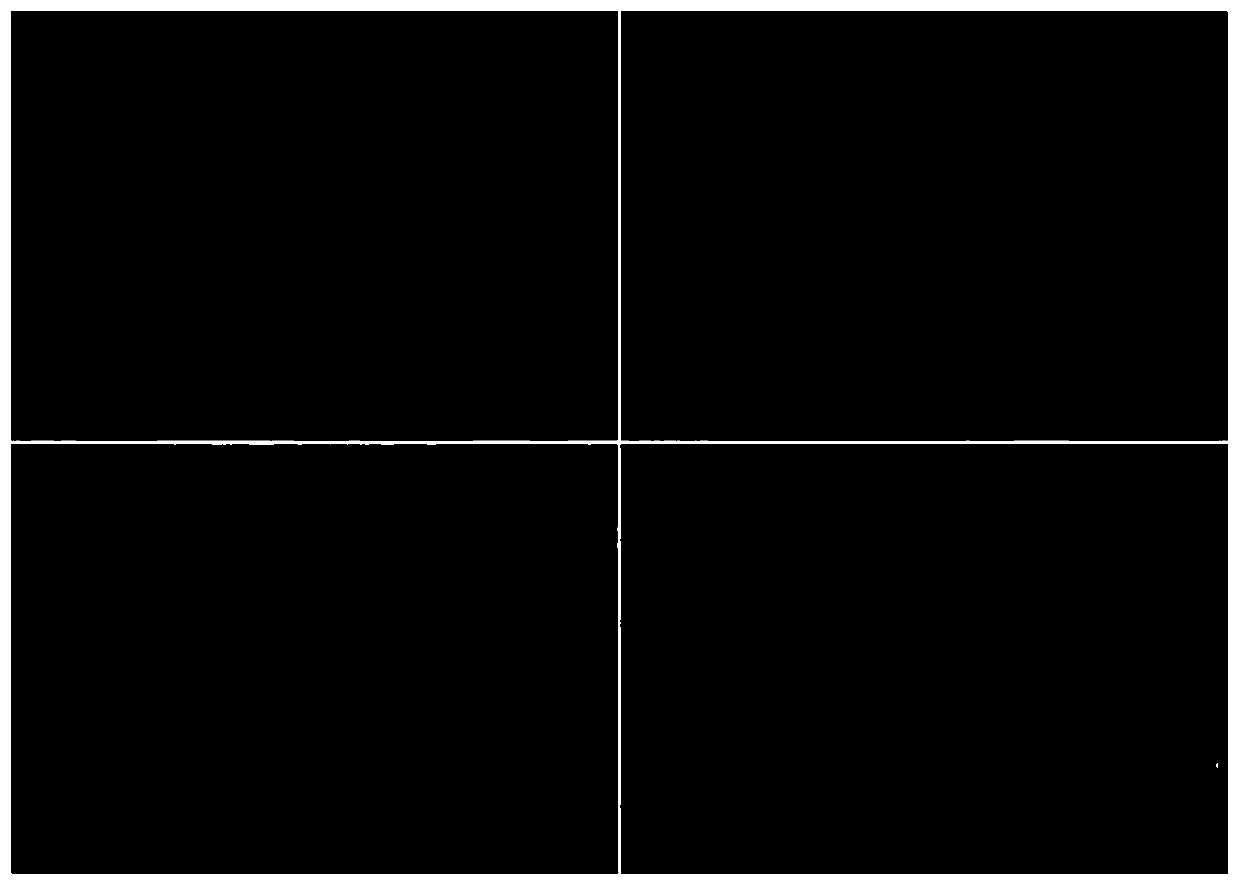

A kind of water vapor-proof coating, coating stock solution and its preparation method and application

ActiveCN107699068BImprove high temperature resistanceImprove anti-agingPolyurea/polyurethane coatingsPolyether coatingsPtru catalystSilicic acid

The invention provides a water vapor resisting water-borne coating stock solution and preparation method thereof and a water vapor resisting water-borne coating and an application thereof. The water vapor resisting water-borne coating stock solution comprises, by weight, 10%-20% of water-borne resin, 1%-5% of silicate ester, 75%-90% of a solvent and 0.1%-1% of a catalyst. The water-borne coating obtained by coating the water vapor resisting water-borne coating stock solution on a base plate is good in high temperature resistance and moisture barrier properties and good in ageing resistance, environmental stability and temperature tolerance, and the base coated is good in adhesion.

Owner:CYBRID TECHNOLOGIES INC

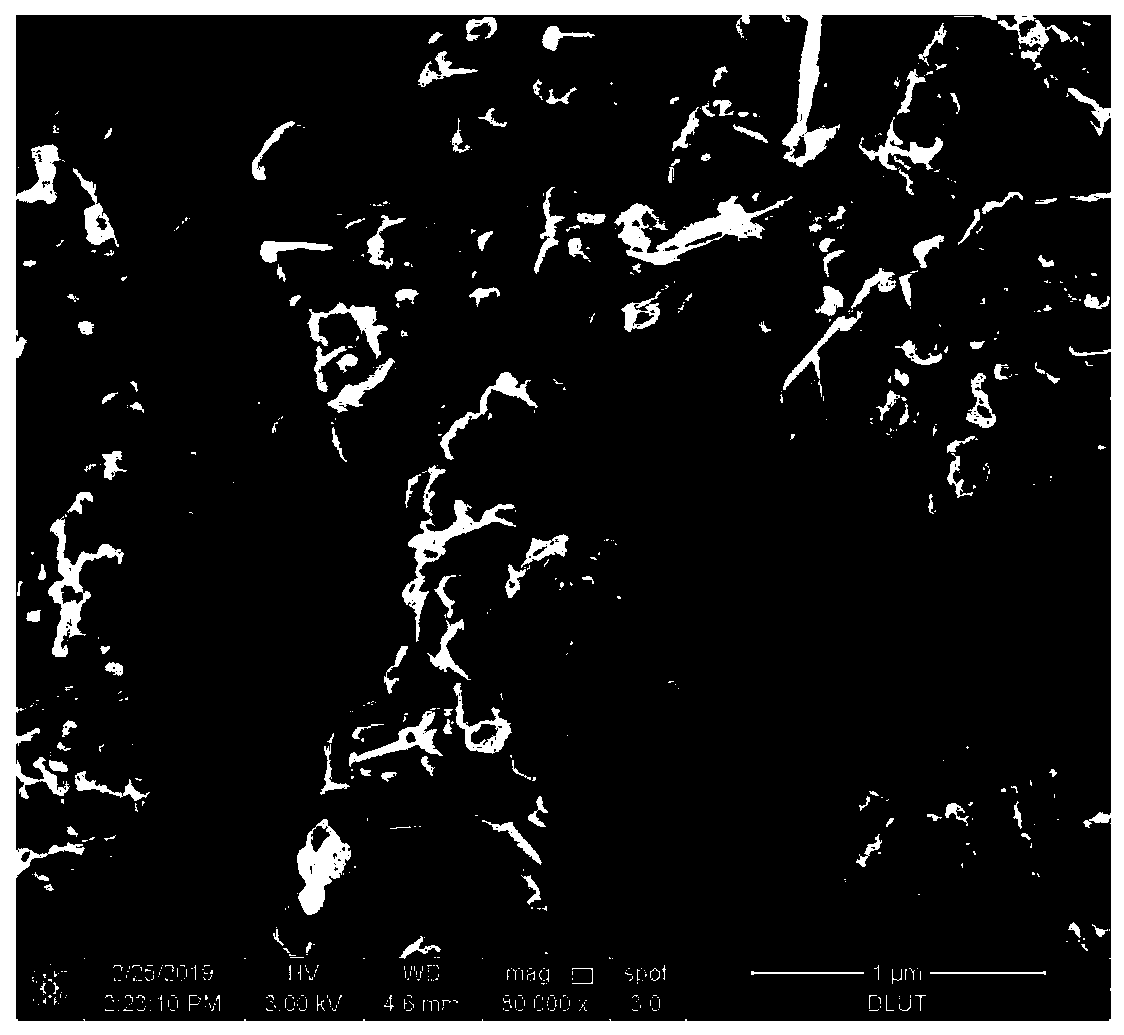

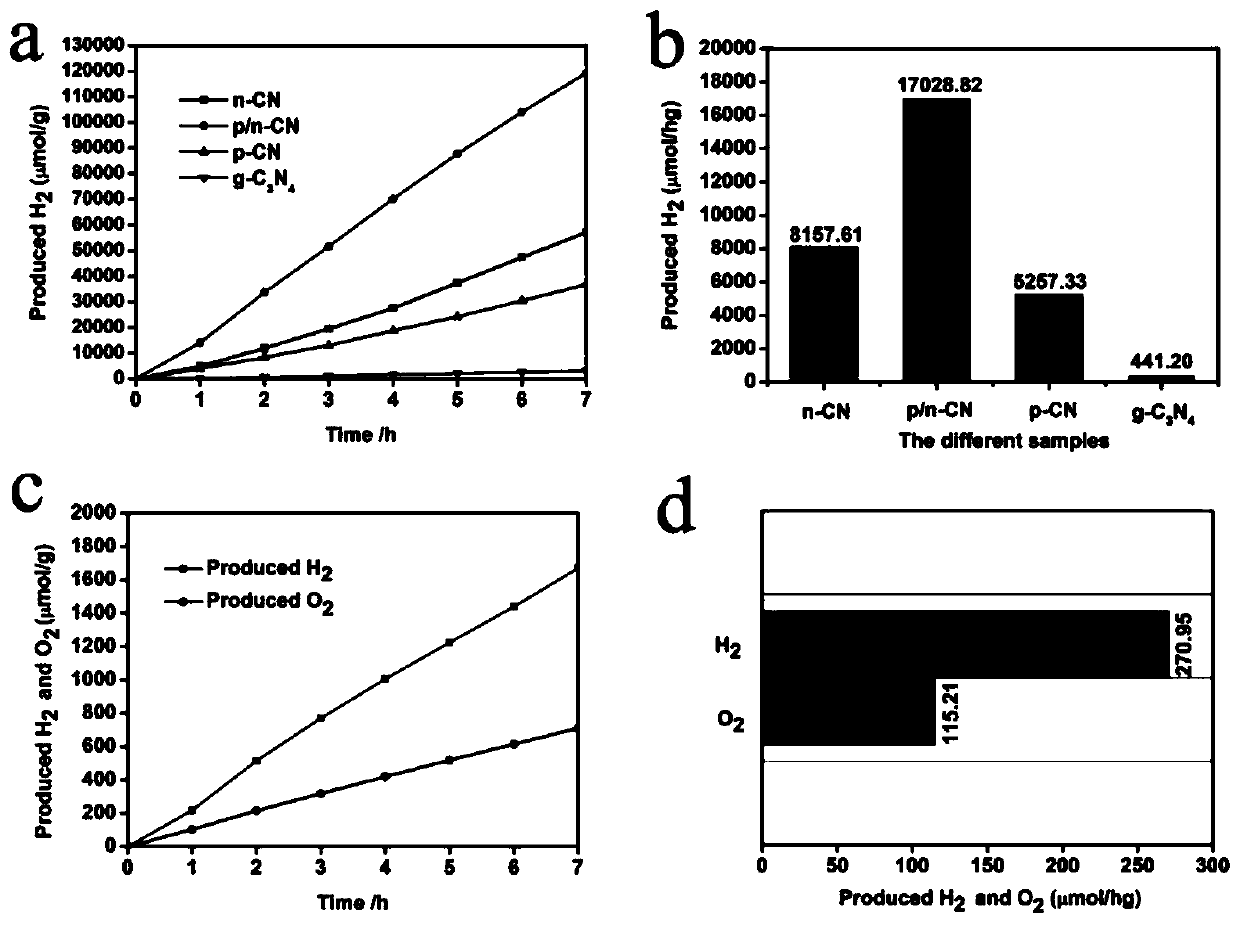

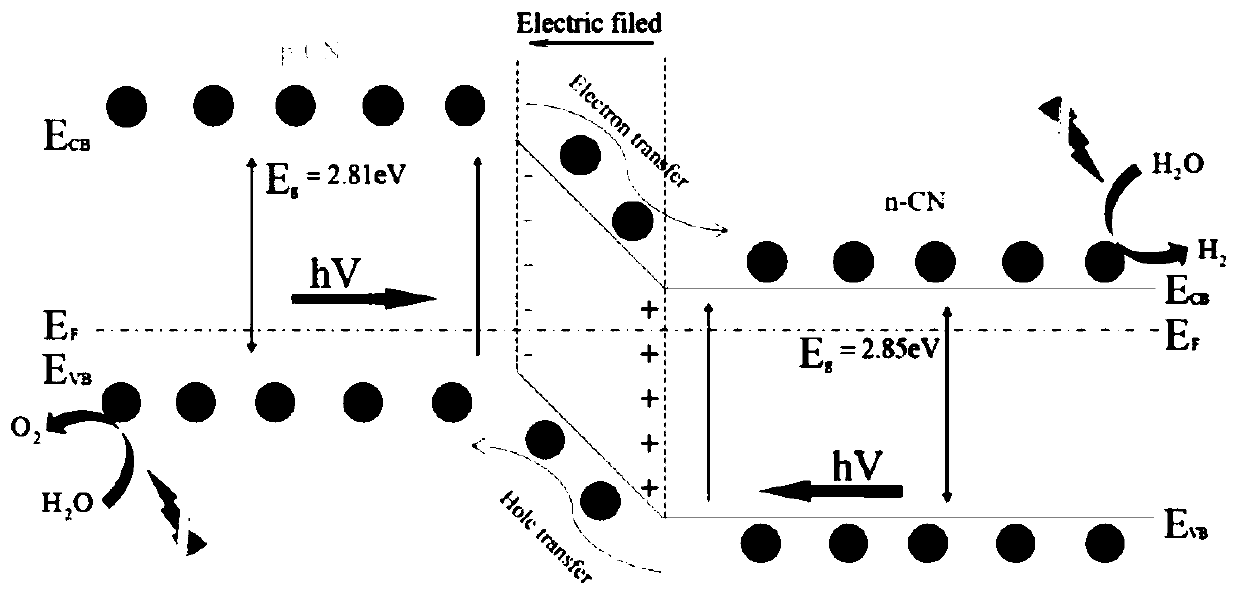

Method of preparing novel carbon-nitrogen non-metallic photocatalyst according to p/n junction principle

ActiveCN110813345AImprove catalytic performanceGood photocatalytic effectPhysical/chemical process catalystsHydrogen productionTube furnacePhysical chemistry

The invention belongs to the technical field of nanometer energy materials and particularly relates to a method of preparing a novel carbon-nitrogen non-metallic photocatalyst according to a p / n junction principle. The method comprises the steps that (1) an amine raw material and a solvent are heated to obtain a first product; (2) the first product is subjected to temperature rise and heating under inert gas protection to obtain a p-type CN photocatalyst; (3) the amine raw material, halogen ammonium salt and the solvent are mixed and heated to obtain a second product; (4) the second product issubjected to temperature rise and heating in an inert gas protection atmosphere to obtain an n-type CN photocatalyst; and (5) the p-type CN photocatalyst and the n-type CN photocatalyst are ground and mixed and then placed in a porcelain boat, the porcelain boat is placed in a tube furnace, the tube furnace is subjected to temperature rise and quenching in the inert gas protection atmosphere, andthe photocatalyst is obtained. According to the method, the novel carbon-nitrogen non-metallic photocatalyst is prepared according to the p / n junction principle, the raw materials are environmentallyfriendly, the method has the advantages of being nontoxic to the environment, low in condition requirement and high in yield, and expensive instruments and equipment are not needed.

Owner:UNIV OF JINAN

A kind of encrusting agent and its preparation method and application

ActiveCN109609094BGood moisturizing effectPromote degradationOther chemical processesActive agentGlycerol

Owner:NANJING NARI GROUP CORP +1

Environmentally friendly paint material and preparation method thereof

InactiveCN109054553ARaw materials are environmentally friendlySimple manufacturing methodAntifouling/underwater paintsRosin coatingsSolventSodium carboxymethylcellulose

The invention provides an environmentally friendly paint material and a preparation method thereof. The environmentally friendly paint material is prepared from the following components: polyamide resin, acrylic resin, calcium carbonate powder, rosin, zinc oxide, tartaric acid, plant essential oil, chlorinated paraffin, sodium carboxymethyl cellulose, dibutyltin dilaurate, an oil-resistant auxiliary, glacial acetic acid, a dilution solvent, a stabilizer, color paste and deionized water. According to the environmentally friendly paint material provided by the invention, the raw materials are environmentally friendly, the preparation method is simple, the conditions are mild, and the cost is low; the obtained paint has good spreadability and moderate drying time; the dried paint film has bright color; the prepared paint is harmless to environment and human body; moreover, the paint material has stable composition and strong adhesion and does not emit peculiar smell.

Owner:HEFEI DAHU ELECTRIC WIRE & CABLE TECH CO LTD

Method for preparing organosilicone hybrid resin and power type encapsulating material for light-emitting diodes (LED) thereof and application

ActiveCN102702532BEasy to prepareRaw materials are environmentally friendlyPlastic/resin/waxes insulatorsCoatingsEpoxyOptical transmittance

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Organosilicone hybrid and organosilicone composite paint and preparations thereof

ActiveCN102731788BSimple preparation processRaw materials are environmentally friendlyCoatingsPolymer scienceWeather resistance

The invention provides an organosilicone hybrid and an organosilicone composite paint and preparations thereof. The preparation method of the organosilicone hybrid is simple, in the prepared organosilicone hybrid, an interpenetrating network is formed by interlaced organic chains and SiO-Si, and organic chains containing C-C double band are introduced in the molecular structure. Based on this, the organosilicone composite paint is successively prepared by using the organosilicone hybrid with the advantages of simple preparation method environmental protection and easy obtainment of the used raw materials. Because of the structural characteristics of the organosilicone hybrid, the organosilicone composite paint provided by the invention correspondingly has high strength, high temperature resistance, tenacious paint film, good weather resistance, good film forming property, quick drying performance at normal temperature, UV-curable property, etc., and has a wide application prospect.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

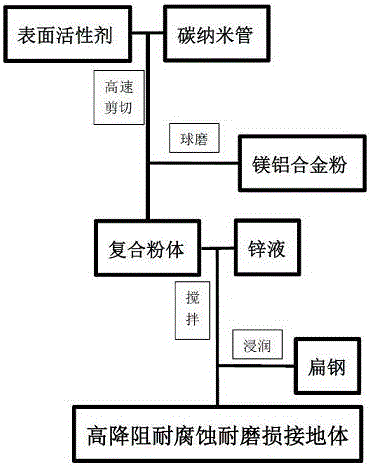

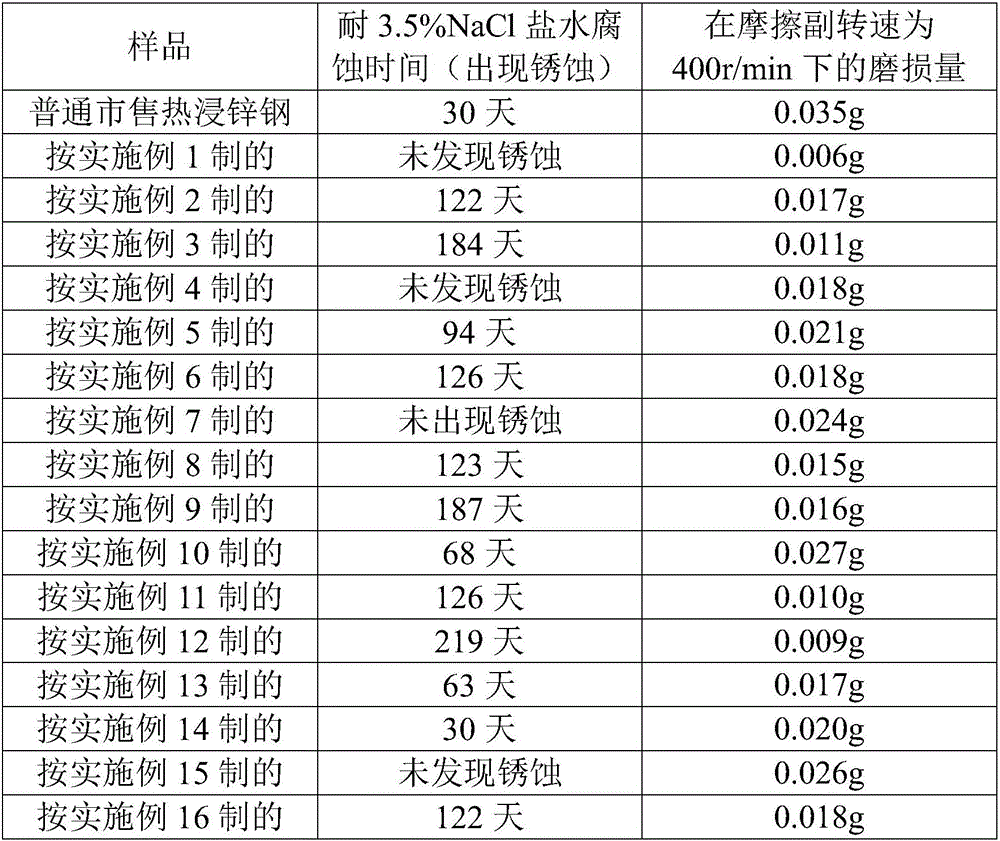

Preparation method of high-resistance reduction corrosion-resistant and abrasion-resistant grounding body

InactiveCN106025595AImprove conductivityImprove wear resistanceContact member manufacturingConnection contact member materialHigh resistanceGrounding grid

A method for preparing a high-resistance, corrosion-resistant, and wear-resistant grounding body, comprising the following steps: (1) firstly shearing a surfactant and a carbon nanotube at a high speed, so that the surface of the carbon nanotube is coated with the surfactant; (2) ) Then ball mill the low melting point magnesium aluminum alloy powder and carbon nanotubes, so that the carbon nanotubes are embedded in the alloy powder; Mix evenly; (4) Immerse the flat steel in the zinc liquid, so that the surface of the flat steel is coated with a zinc layer, and finally a high-resistance, corrosion-resistant, and wear-resistant grounding body is obtained. The grounding body produced by the invention can increase the conductivity of the zinc layer, improve the corrosion resistance and wear resistance of the zinc layer, and ensure the safe operation of the grounding grid.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com