Preparation method of high-resistance reduction corrosion-resistant and abrasion-resistant grounding body

A corrosion-resistant and wear-resistant technology, which is applied in the field of preparation of high-resistance corrosion-resistant grounding bodies, can solve problems such as damage to the electroplating layer and increase the corrosion rate of the grounding electrode, so as to achieve increased wear resistance, short preparation cycle, The effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

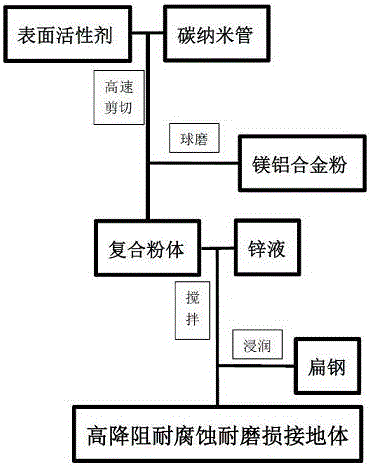

[0017] The implementation steps of a method for preparing a high-resistance, corrosion-resistant, and wear-resistant grounding body are as follows:

[0018] Step 1: subjecting the surfactant and the carbon nanotube to high-speed shearing, so that the surface of the carbon nanotube is coated with the surfactant;

[0019] Step 2: ball milling the low-melting-point magnesium-aluminum alloy powder and the carbon nanotubes obtained in step 1, so that the carbon nanotubes are embedded in the alloy powder;

[0020] Step 3: Add the composite powder after ball milling in step 2 into the molten zinc liquid, and mix evenly at a certain stirring speed;

[0021] Step 4: Immersing the flat steel into the zinc liquid in which carbon nanotubes are fused in step 3, so that the surface of the flat steel is coated with a zinc layer, and finally a high-resistance-resistance, corrosion-resistant, and wear-resistant grounding body is obtained.

[0022] The surfactant described in step 1 is any one...

Embodiment 1

[0028] (1) 10g sodium lauryl sulfate and 100g carbon nanotube are carried out the high-speed shear of 4500r / min, make carbon nanotube surface coating sodium lauryl sulfate;

[0029] (2) 1250g of low-melting-point magnesium-aluminum alloy powder and the carbon nanotubes obtained in step 1 are ball-milled for 90 minutes, so that the carbon nanotubes are embedded in the alloy powder;

[0030] (3) Add the composite powder after ball milling in step 2 into 3400g molten zinc liquid, and mix evenly with a stirring speed of 400r / min;

[0031] (4) Immersing the flat steel into the zinc liquid in which carbon nanotubes are fused in step 3, so that the surface of the flat steel is coated with a zinc layer, and finally a high-resistance-resistance, corrosion-resistant, and wear-resistant grounding body is obtained.

Embodiment 2

[0033] Example 2 is basically the same as Example 1, except that the surfactant in step 1 is polyvinylidene fluoride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com