A kind of preparation method of alumina-silica aerogel thermal insulation composite material

A technology of silica airgel and composite materials, which is applied in the field of heat insulation materials, can solve problems such as high manufacturing costs, complicated process flow, and potential safety hazards, and achieve the effects of simple preparation methods, green preparation processes, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

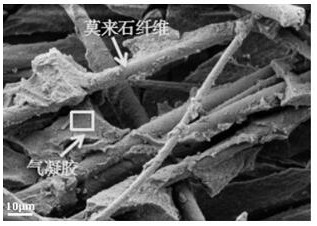

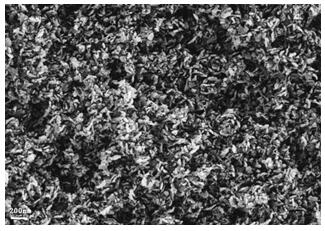

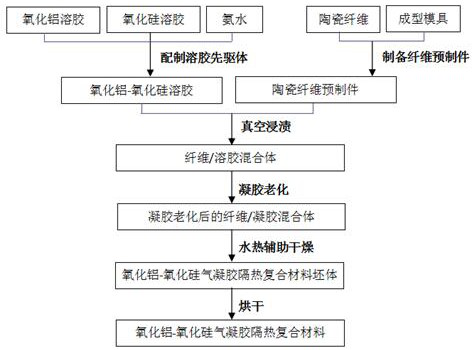

[0036] like figure 1 As shown, the preparation method of an alumina-silica airgel thermal insulation composite material provided by the present invention includes preparing fiber preforms, preparing alumina-silica sol, vacuum impregnation, gel aging, hydrothermal assisted drying, Drying in 6 steps. Specifically:

[0037] In the first step, the fiber preform is prepared by:

[0038] Forming molds are adopted (the volume of the mold is selected according to the volume of the alumina-silica airgel thermal insulation composite material to be prepared, and the volume of the alumina-silica airgel thermal insulation composite material is equal to the volume of the fiber prefabricated part, so the mold The volume of the fiber preform can be just enough to hold the fiber prefabricated part) Clamp and fix a certain quality of inorganic ceramic fiber to form a fiber prefabricated part. Before clamping, the apparent density of the inorganic ceramic fiber is 0.15-0.30g / cm 3 (Fiber mass ...

Embodiment 1

[0054] A preparation method of alumina-silica airgel thermal insulation composite material, comprising the following steps:

[0055] (1) Preparation of fiber preforms

[0056] Use a mold to clamp and fix a certain quality of mullite fiber to form a fiber prefabricated part. Before clamping, the apparent density of the mullite fiber is 0.15g / cm 3 , and make the mullite fiber arrangement direction perpendicular to the heat flow direction during heat insulation to obtain the mullite fiber preform.

[0057] (2) Preparation of alumina-silica sol

[0058] First, the commercially available water-based alumina sol (15% solid content, Zibo Jinqi Chemical Technology Co., Ltd.) and the commercially available water-based silica sol (15% solid content, Hangzhou Wanjing New Material Co., Ltd.) were mixed and stirred for 10 minutes, and then Add ammoniacal liquor to the above-mentioned mixed sol, continue to stir for 30min, and obtain an alumina-silica sol with a solid content of 15%, the ...

Embodiment 2~11

[0070] In the process of preparing the fiber preform in the first step of the present invention, the fiber type basically has no effect on the high temperature thermal conductivity and mechanical properties of the composite material, but the fiber apparent density has an important influence on the high temperature thermal conductivity and mechanical properties of the composite material. Appropriately increasing the apparent density can further reduce the high-temperature thermal conductivity of the material and improve the mechanical properties of the material, but the fiber type and apparent density have little effect on the temperature resistance of the material (heat treatment at 1500°C for 1800s, the thickness shrinkage rate is average less than 1.5%). In the second step of preparing the alumina-silica sol, the addition of the catalyst is to control the gelation time of the sol, which basically has no effect on the final performance of the material; the increase in the soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com