Method of preparing novel carbon-nitrogen non-metallic photocatalyst according to p/n junction principle

A photocatalyst and non-metal technology, applied in the field of preparing new carbon-nitrogen non-metal photocatalysts, can solve the problems of expensive and toxic metal-based materials, and achieve the effects of low required conditions, simple instruments and equipment, and good photocatalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

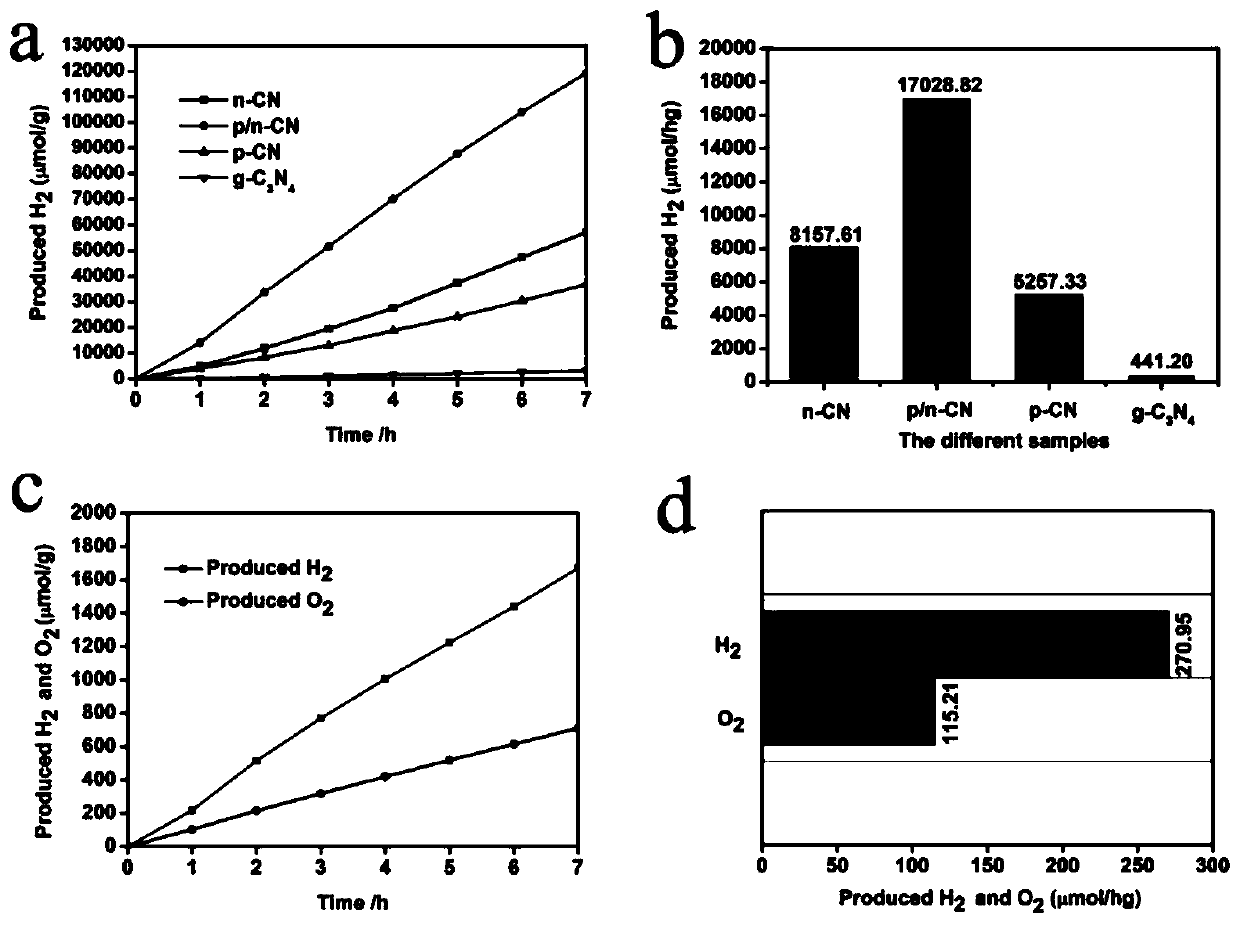

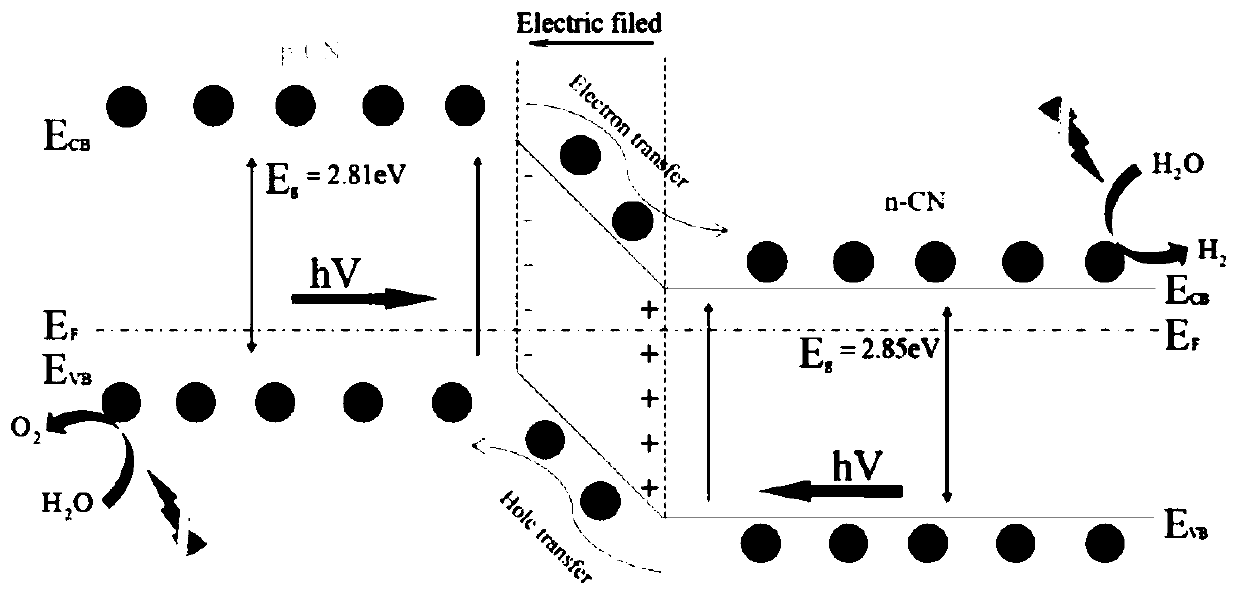

Image

Examples

Embodiment 1

[0035] Utilize p / n junction principle to prepare the method for novel carbon-nitrogen non-metallic photocatalyst, comprise the following steps:

[0036] (1) Weigh 5g of melamine material and 15ml of deionized water into a container, heat at 180°C for 24h to obtain the first product;

[0037] (2) Put the first product into a porcelain boat and then into a tube furnace, protect the atmosphere with argon gas, raise the temperature to 550°C at a heating rate of 3°C / min, and heat for 1h to obtain a p-type CN photocatalyst;

[0038] (3) Put 1 g of melamine mixed with ammonium fluoride and 15 ml of deionized water into a container, and heat at 100° C. for 1 hour to obtain the second product;

[0039] (4) Put the second product into the porcelain boat and then into the tube furnace, protect the atmosphere with argon gas, raise the temperature to 500°C at a heating rate of 1°C / min, and keep it for 1h to obtain n-type CN photocatalyst;

[0040] (5) Grind and mix the p-type CN photocata...

Embodiment 2

[0044] The difference between this example and Example 1 is that urea is added as the amine raw material in steps (1) and (3), and the rest are the same as Example 1.

Embodiment 3

[0046] The difference between this embodiment and embodiment 1 is that the amount of melamine material added in steps (1) and (3) is 8 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com