Patents

Literature

266results about How to "Lower conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

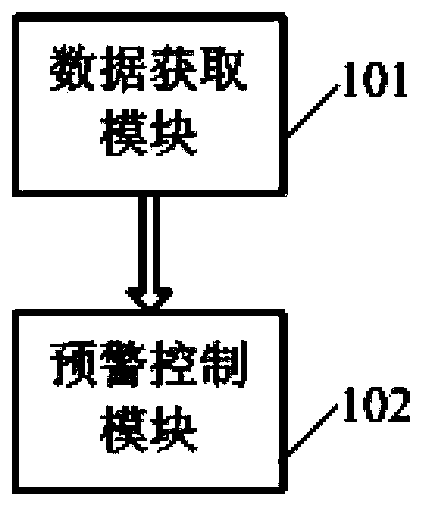

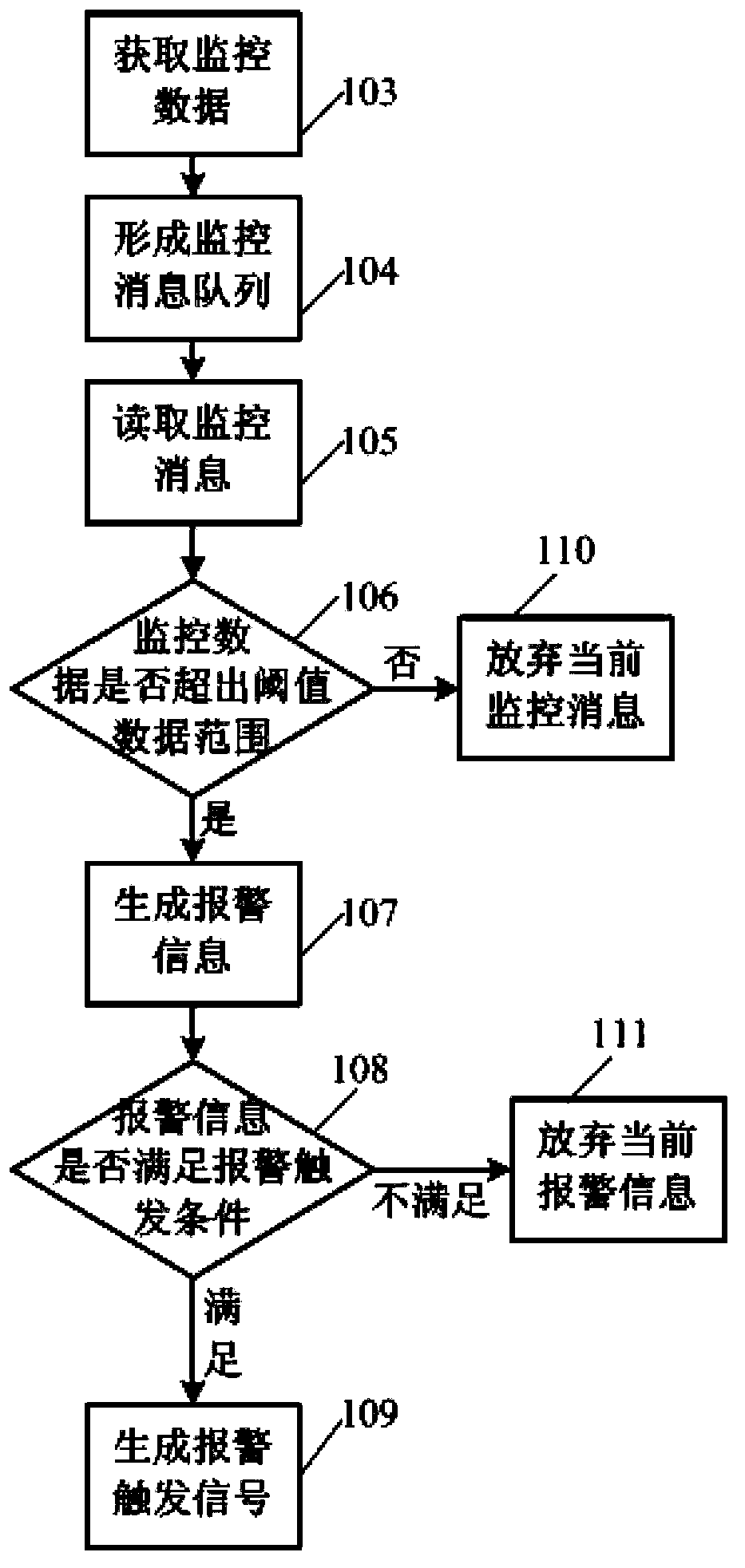

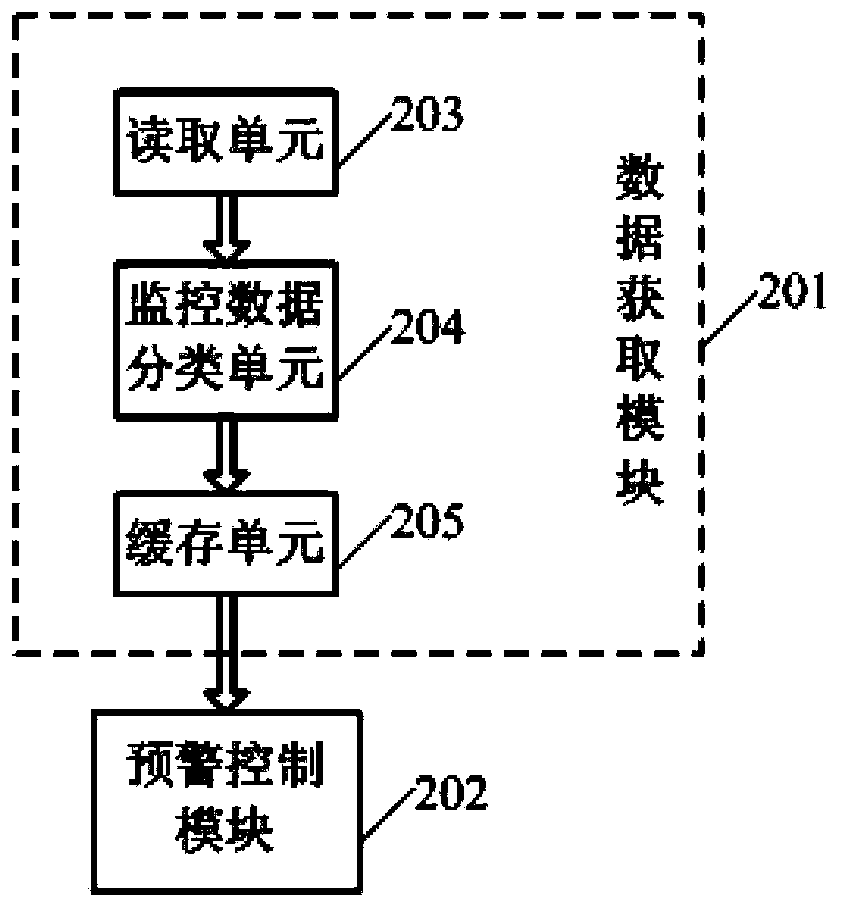

Monitoring and alarm control method and system

The invention discloses a monitoring and alarm control method and system. The method includes the steps that real-time monitoring data of a monitored terminal are acquired by a monitoring terminal, and a monitoring message queue is formed, wherein each monitoring message comprises the monitoring data; the monitoring messages are read from the monitoring message queue, the monitoring data in the monitoring messages are compared with monitoring terminal threshold value data corresponding to the monitoring data, and whether an alarm message needs generating according to the monitoring messages or not is determined according to comparison results; whether the generated alarm message meets an alarm triggering condition corresponding to the monitoring data or not is judged, and whether an alarm trigger signal needs generating or not is determined according to judgment results. The monitoring and alarm control system comprises a data acquiring module and an early warning control module. Limitations on the alarm triggering condition of the alarm message are increased, and therefore ineffective alarm is reduced, monitoring and alarm are more accurate, and users can conveniently set different monitoring conditions according to different monitored terminals.

Owner:蚌埠尚维知识产权运营有限公司

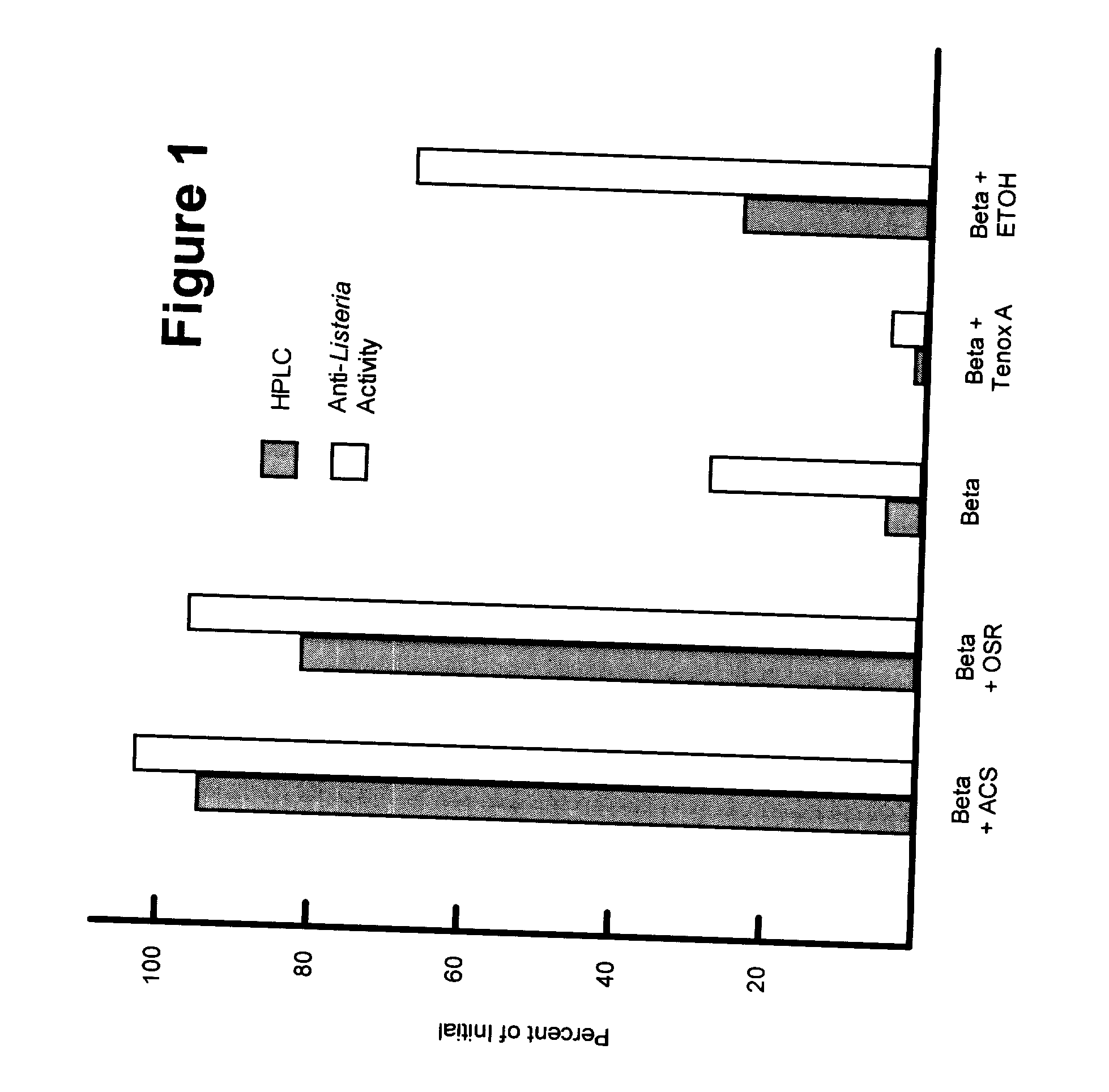

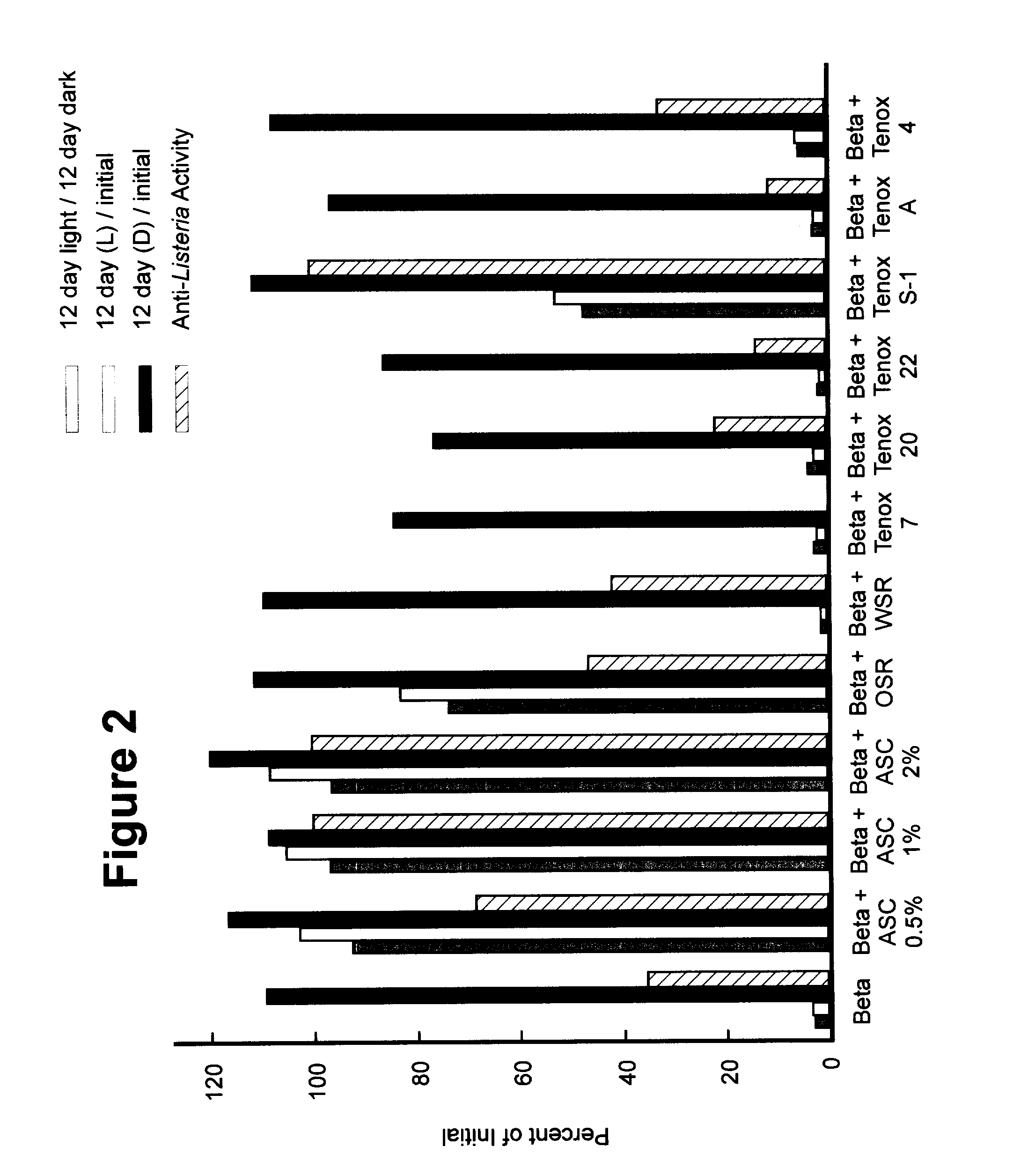

Hop beta acid compositions for use in food products

InactiveUS20040175480A1Easy to optimizeImprove stabilityMeat/fish preservation using chemicalsMeat/fish preservation using acidsFood gradeAlcohol

Hop beta acids are improved with respect to their antibacterial properties, especially their anti-Listeria properties. Enhancement in this regard is especially useful for the treatment of food products which are susceptible to bacterial contamination. This can be especially important when the hop beta acids are to be used in surface application onto the food products. The hop beta acids are rendered more effective by combining them with a food grade acid, a potassium ion source, and an optional antioxidant in a carrier solvent such as, for example, a food grade alcohols or a food grade glycol. The improved hop beta acid compositions of this invention provide increase stability, higher hop beta acid concentrations, and / or higher anti-Listeria activities.

Owner:KRAFT FOODS INC

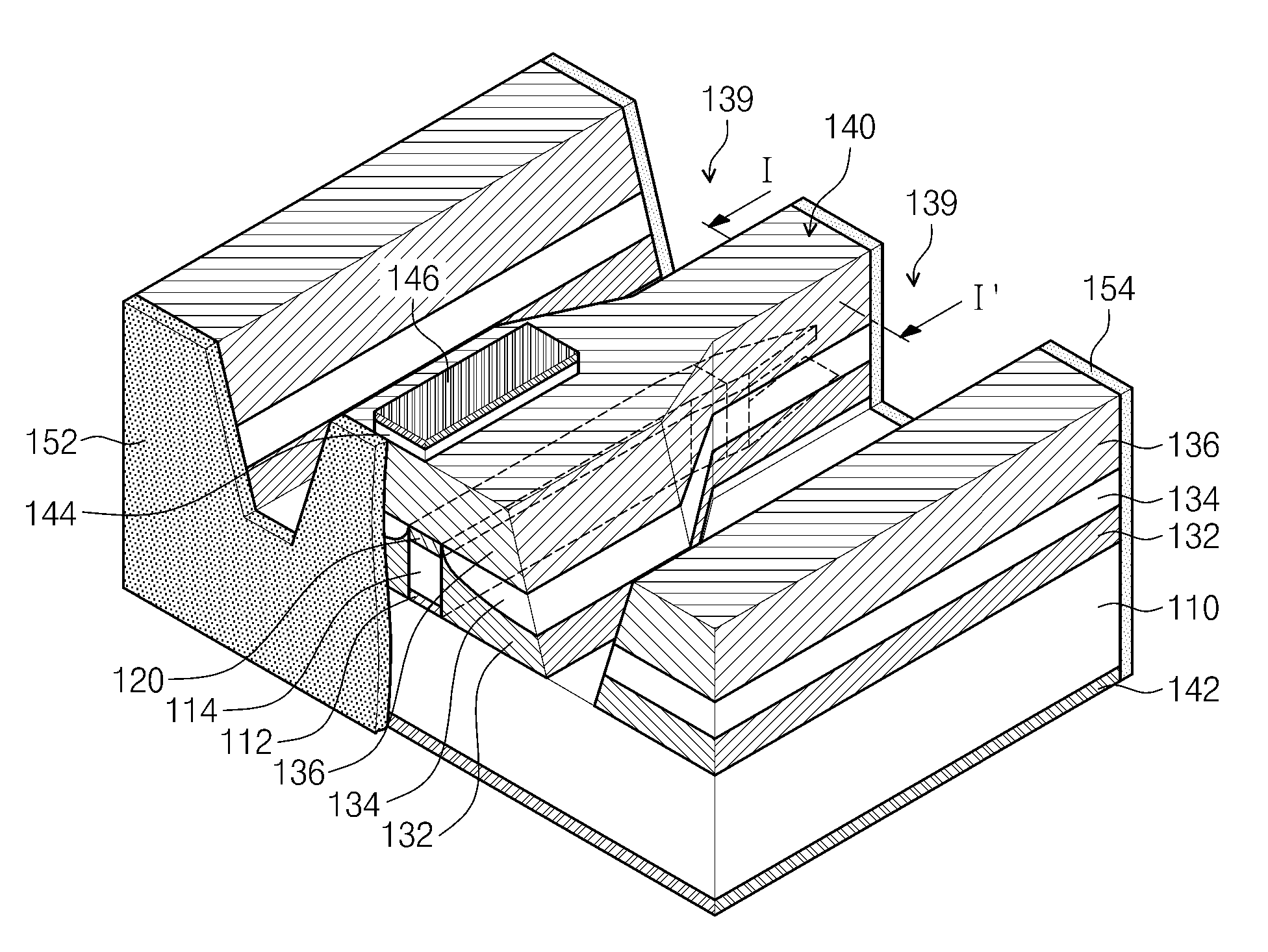

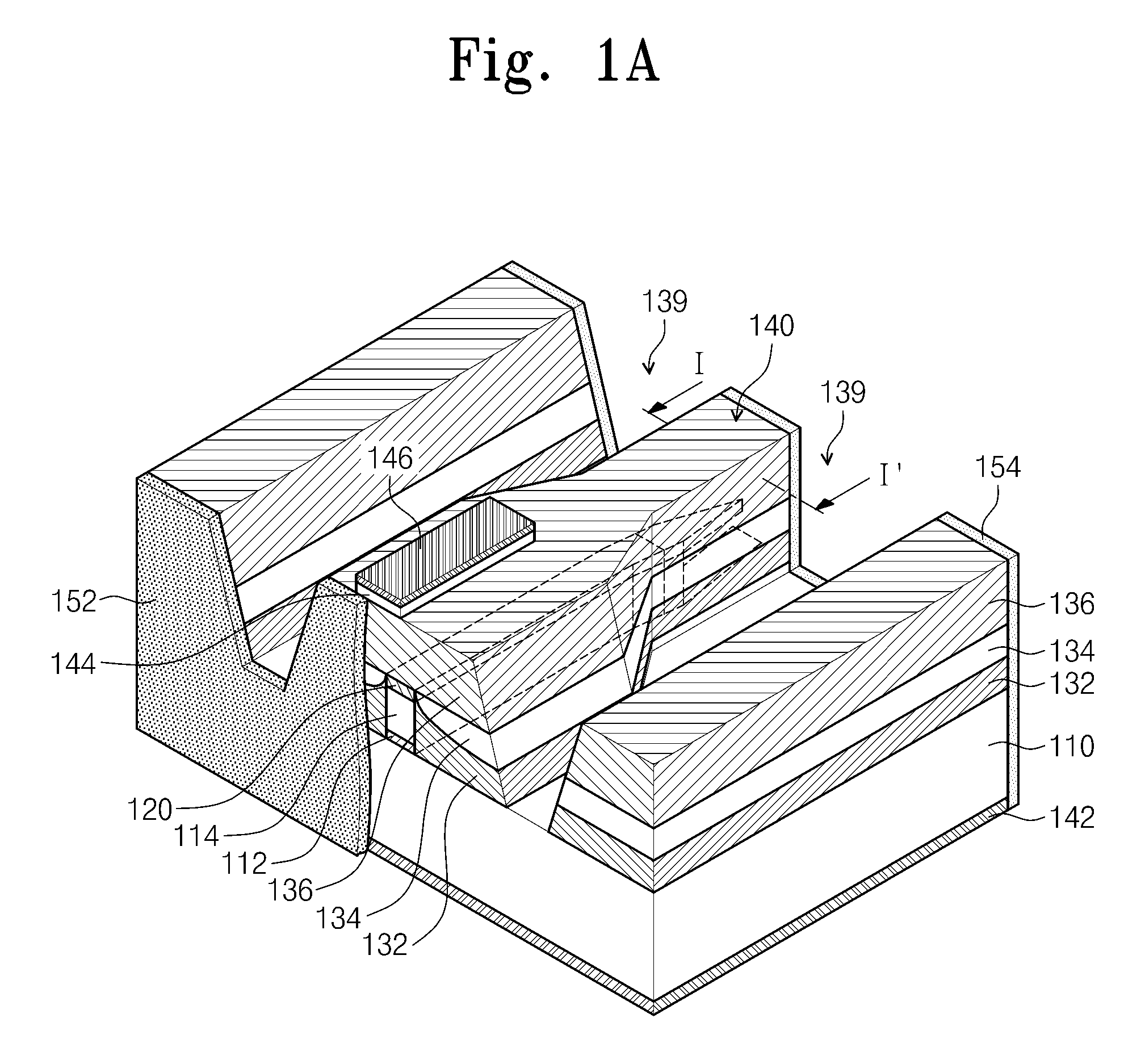

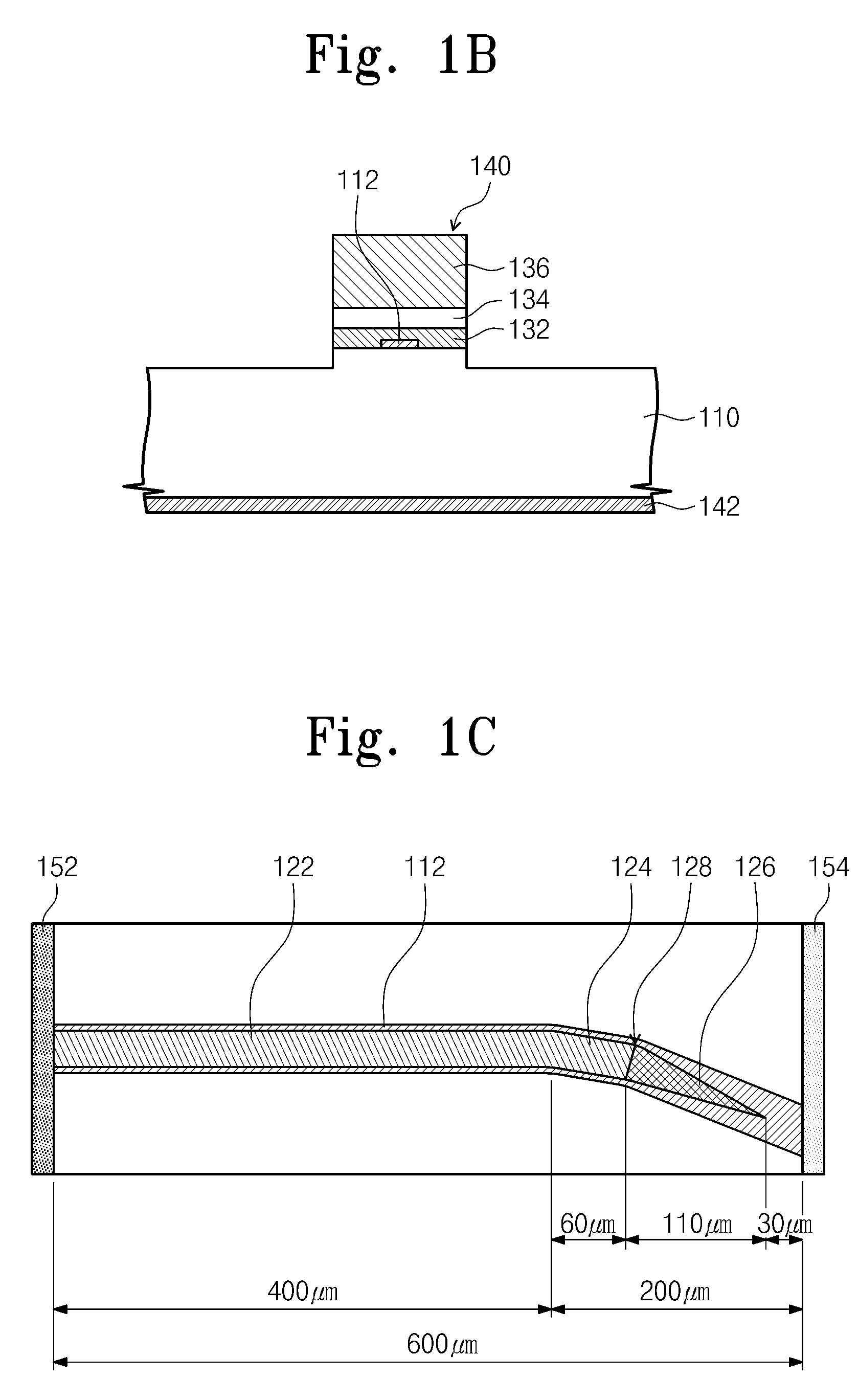

External cavity laser light source

ActiveUS20100238962A1High gainLower conditionsOptical wave guidanceLaser optical resonator constructionExternal cavity laserLeakage current reduction

Provided is an external cavity laser light source. The light source includes a substrate, an optical waveguide, and a current blocking layer. The optical waveguide includes a passive waveguide layer, a lower clad layer, an active layer, and an upper clad layer that are sequentially stacked on the substrate and is divided into regions including a linear active waveguide region, a bent active waveguide region, a tapered waveguide region, and a window region. The current blocking layer was formed an outside of the active layer to reduce leakage current. The linear and bent active waveguide regions have a buried heterostructure (BH), and the tapered waveguide region and the window region have a buried ridge stripe (BRS) structure. The passive waveguide layer a width substantially equal to a maximal width of the tapered waveguide region at least in the bent active waveguide region, the tapered waveguide region, and the window region.

Owner:ELECTRONICS & TELECOMM RES INST

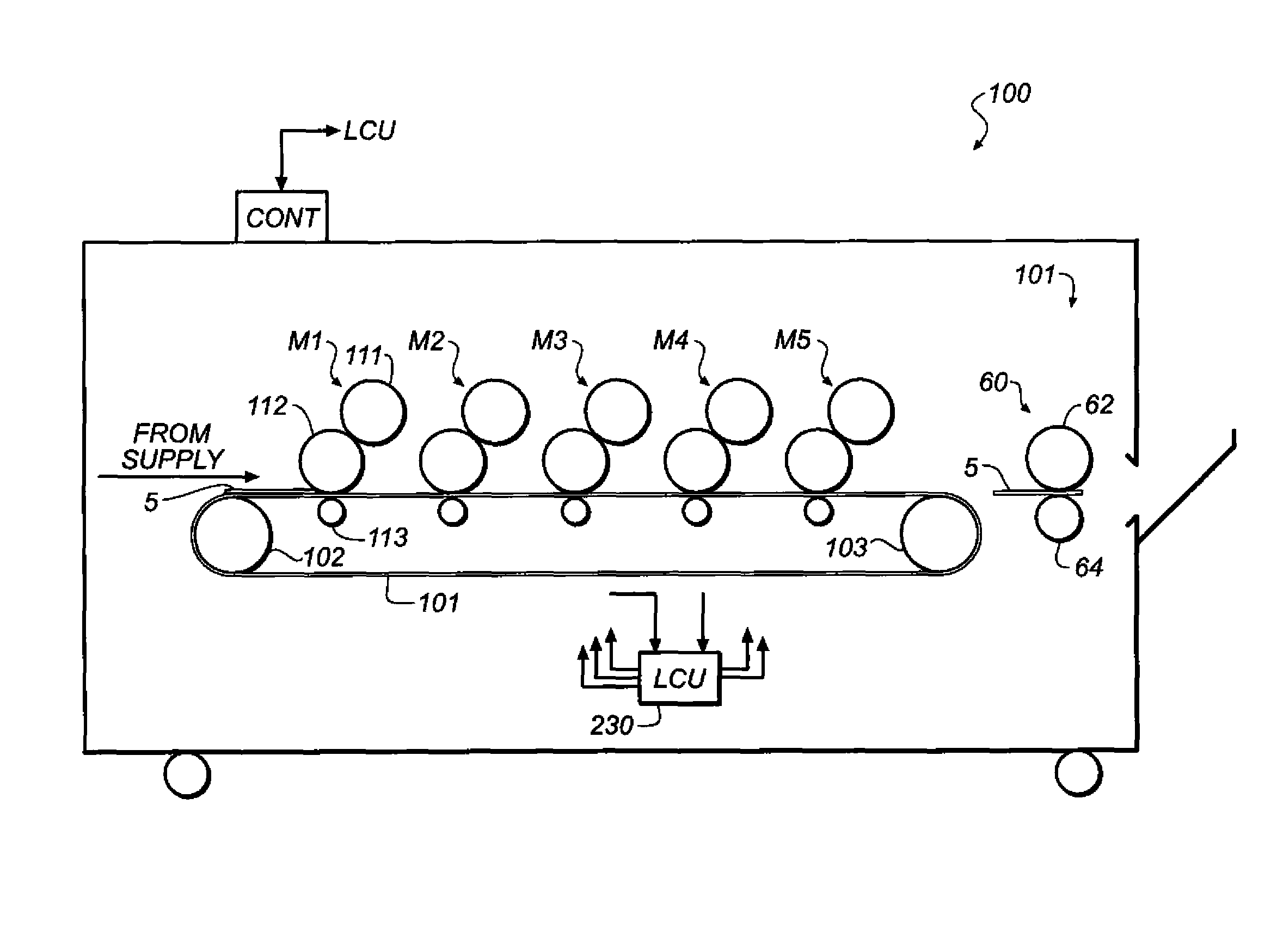

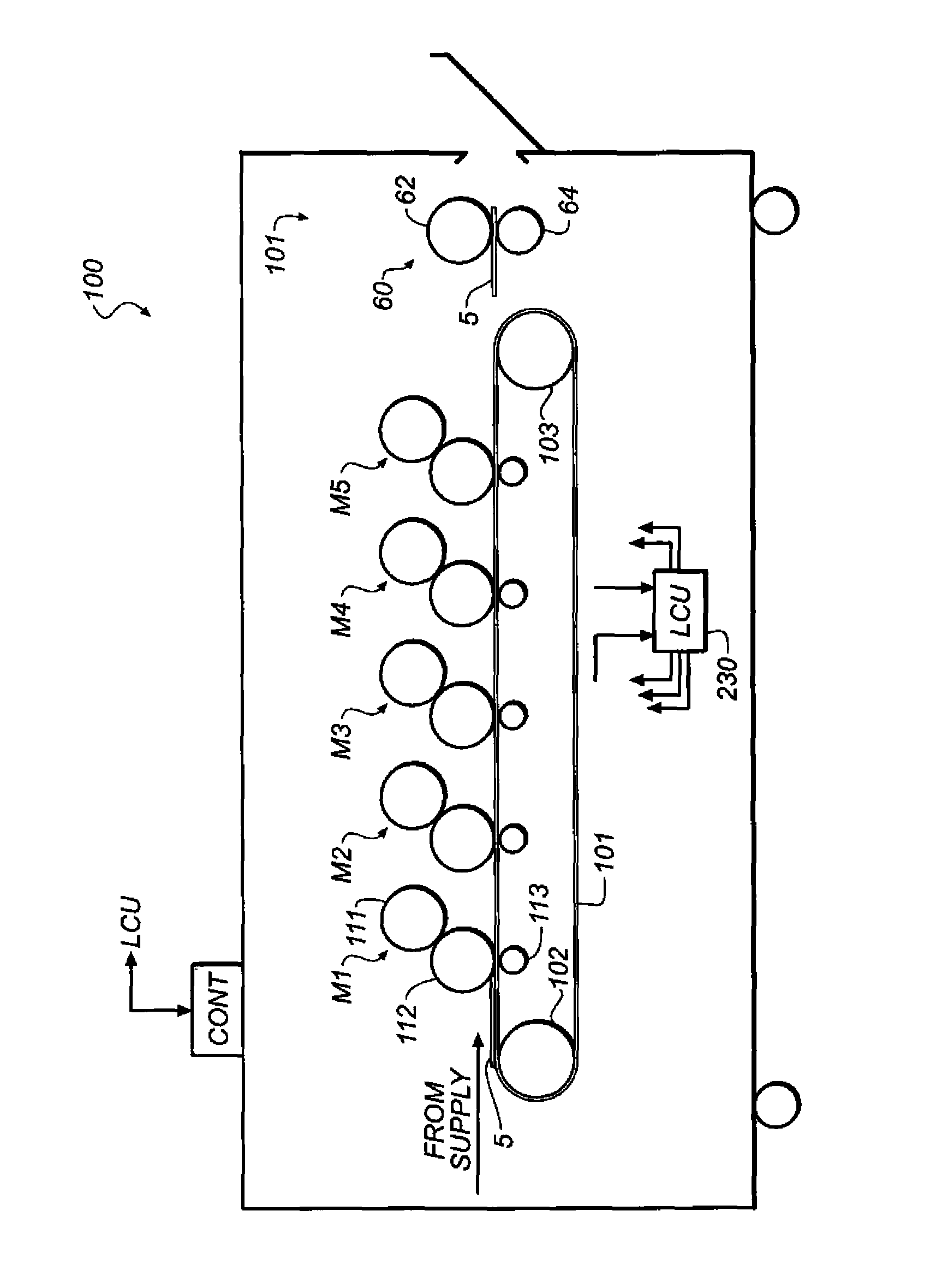

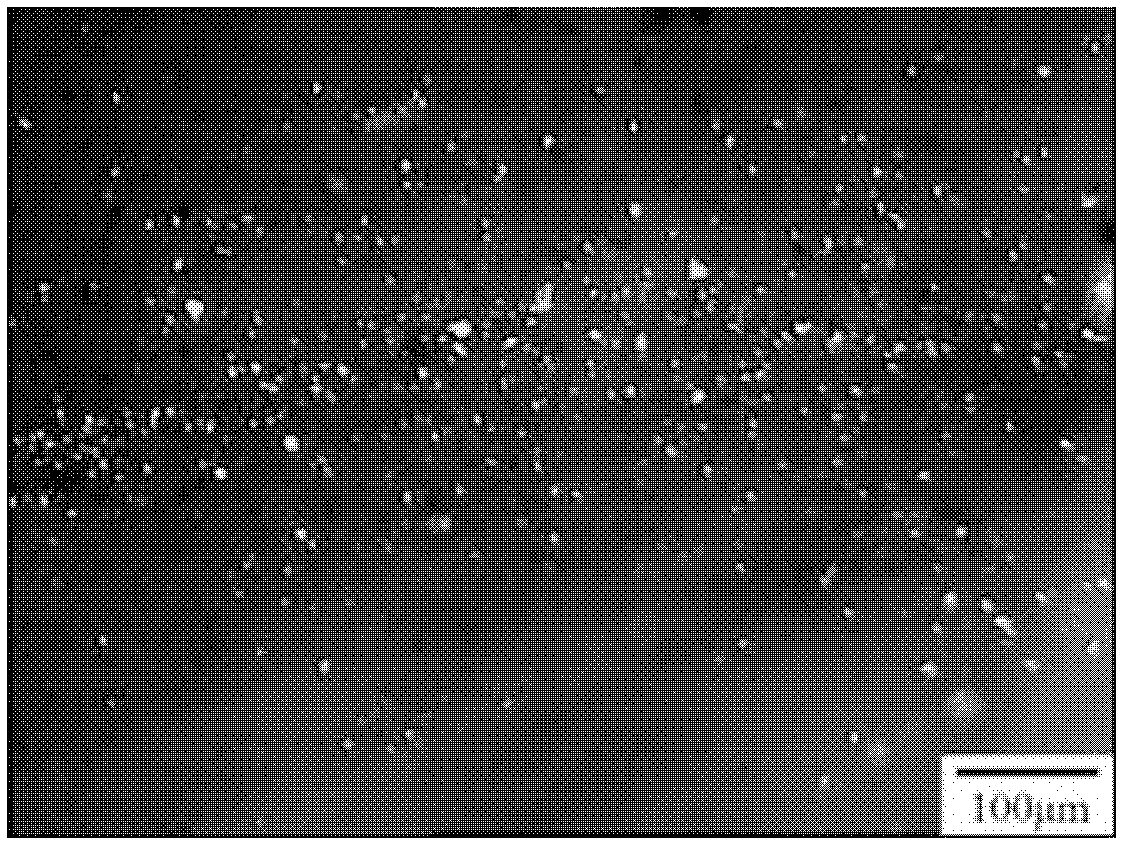

Preparing color toner images with metallic effect

ActiveUS9323169B2Highly uniform dispersionMinimize shearLayered productsDevelopersLatent imageEngineering

A color toner image with a metallic effect can be prepared by forming one or more latent images and developing them with metallic dry toner particles and color toner particles. The developed color toner image can be transferred to a receiver material, and fixed to provide a color toner image with a metallic effect. The metallic dry toner particles have a polymeric binder phase and non-conductive metal oxide particles dispersed therein. Before fixing, the metallic dry toner particle has a mean volume weighted diameter (Dvol) 15-40 μm and the non-conductive metal oxide particles are present in an amount of at least 20-50 weight % based on total metallic dry toner particle weight. The ratio of the metallic dry toner particle Dvol to the average equivalent circular diameter (ECD) of the non-conductive metal oxide particles in the metallic dry toner particles is greater than 0.1 and up to and including 10.

Owner:EASTMAN KODAK CO

Segmented copolymer with fully-saturated soft segment and crystallizable hard segment and preparation method of segmented copolymer

ActiveCN103122052AEliminate the purification processSave drynessPolymer scienceCationic polymerization

The invention relates to a segmented copolymer with a fully-saturated soft segment and a crystallizable hard segment and a preparation method of the segmented copolymer. A segmented copolymer with a fully-saturated polyisobutene segment as the soft segment and a crystallizable polystyrene or polyalkyl substituted styrene segment as the hard segment is synthesized by combining cationic polymerization of isobutene with cationic steric polymerization of styrene or alkyl substituted styrene cations, wherein as the hard segment has the crystallizability, physical crosslinking points are more stable, not only is a self-enhancement role achieved, but also the softening temperature of the segmented copolymer is effectively improved, and the melting point ranges from 150 DEG C to 210 DEG C; and according to the segmented copolymer, the use temperature is improved by 50-110 DEG C, and the heat resistance, the material size stability and the physical and mechanical properties are also improved.

Owner:BEIJING UNIV OF CHEM TECH

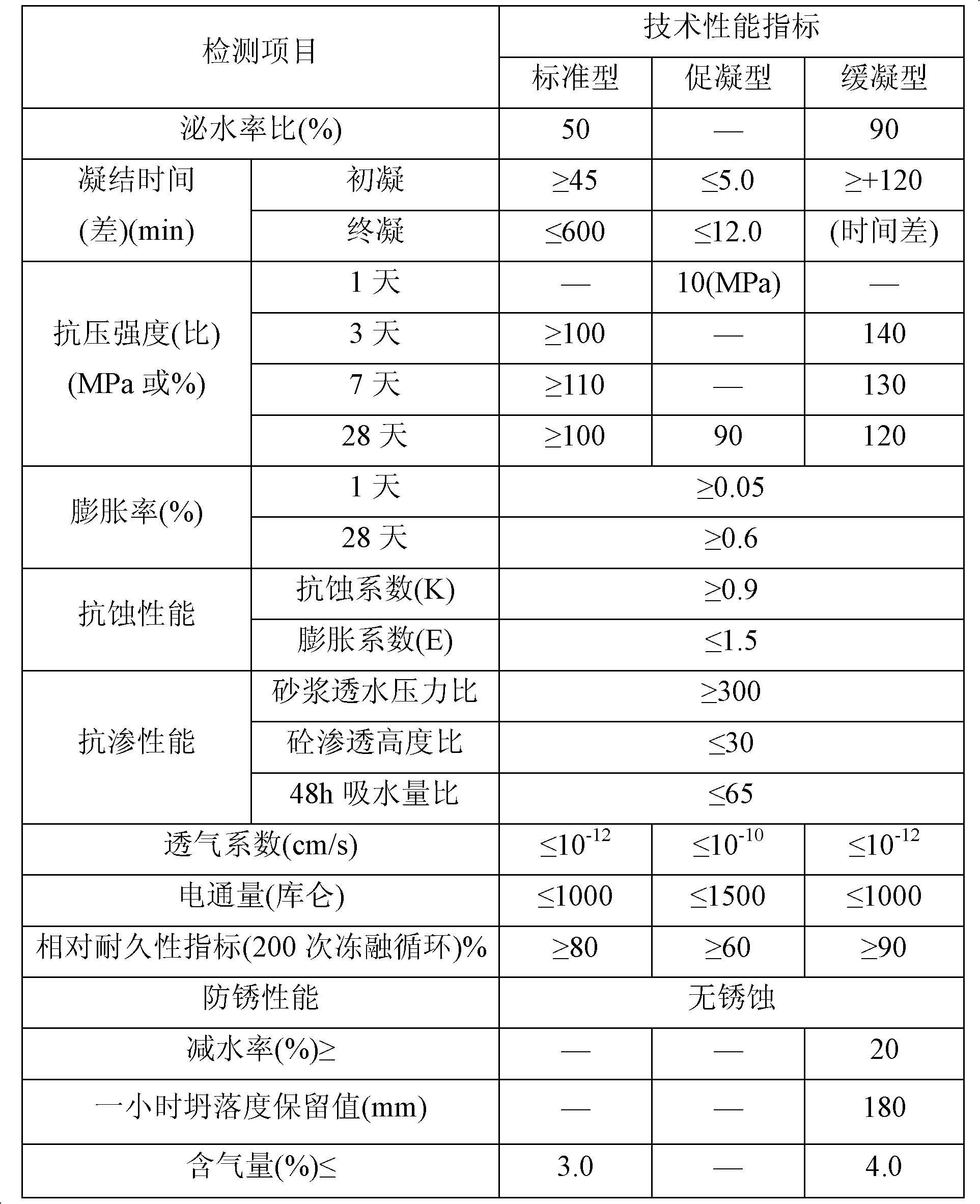

Anticorrosion expansion compacting agent composition and preparation method thereof

The invention relates to an anticorrosion expansion compacting agent composition and a preparation method thereof; the composition comprises the following components by weight: 15-35% of aluminium-containing compounds, 0-8% of zirconium-containing compounds, 2-10% of magnesium salts, 0-3% of titanium dioxide compounds, 0-6% of lithium salts, 2-6% of alkanolamine salts, 0-10% of super-plasticizers, 0-10% of solidification adjusting agents, 0-5% of acids, and the balance of carriers. The components are reacted in a reaction vessel at 80 DEG C+ / -5 DEG C for 3 hours, and then cooled to 45 DEG C+ / -5 DEG C; thermal insulation is performed for one hour; and anticorrosion expansion compacting agents of a standard type, a solidification-promoting type, or a pumping slow-solidifaction type are obtained according to the added solidification adjusting agents with different types and amounts.

Owner:苏琳

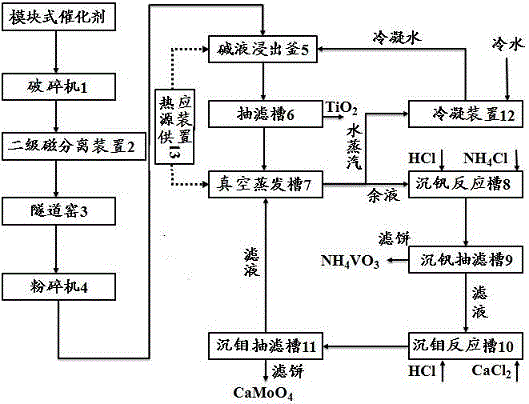

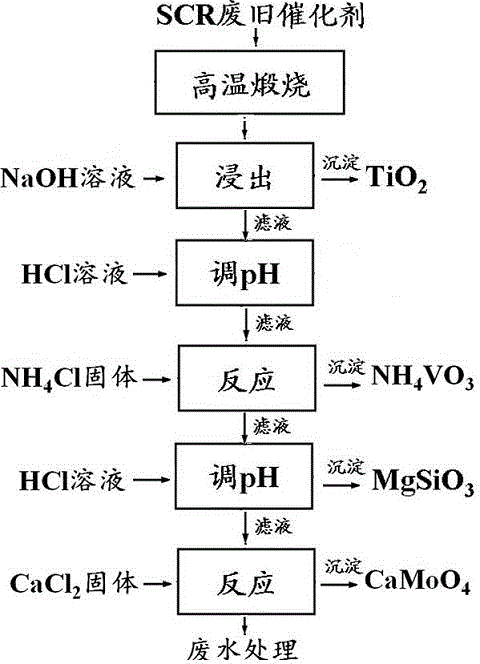

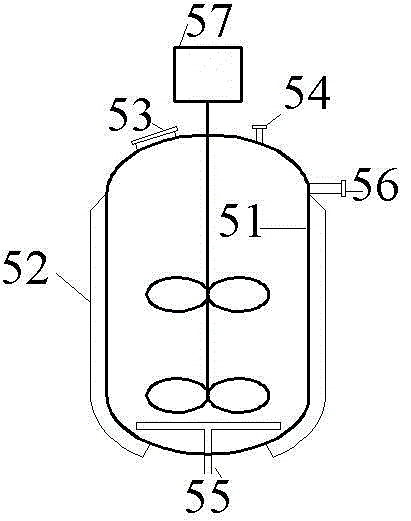

Continuous recovery device and continuous recovery process of vanadium, molybdenum and titanium in SCR (selective catalytic reduction) waste catalyst

The invention discloses a continuous recovery device and a continuous recovery process of vanadium, molybdenum and titanium in an SCR (selective catalytic reduction) waste catalyst, wherein a crusher is connected with a secondary magnetic separation device, the secondary magnetic separation device is connected with a tunnel kiln, the tunnel kiln is connected with a smasher, the smasher is connected with an alkaline leaching kettle, the alkaline leaching kettle is connected with a suction filtration groove, the suction filtration groove is connected with a vacuum evaporation tank, the vacuum evaporation tank is connected with a vanadium sedimentation reaction tank, and the vanadium sedimentation reaction tank is connected with a molybdenum sedimentation suction filtration groove; the alkaline leaching kettle is clamped outside the reaction kettle, a top overflow opening is positioned in the upper side of the jacket, a charging opening and a filling opening are positioned in the upper part of the reaction kettle, and the filling opening is guided to the middle part of the reaction kettle by virtue of a guide pipe. According to the continuous device disclosed by the invention, the production efficiency is effectively improved, thereby facilitating subsequent automatic and continuous production. A flat plate type flue gas denitrification catalyst is continuously recovered, infiltrating water is recycled, and the water yield is greatly saved.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

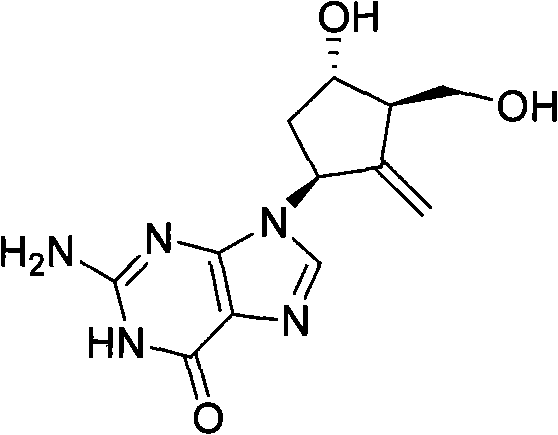

New synthesis process of antiviral drug entecavir

ActiveCN101891741AHigh purityEliminate the purification processOrganic chemistryBulk chemical productionAntiviral drugCombinatorial chemistry

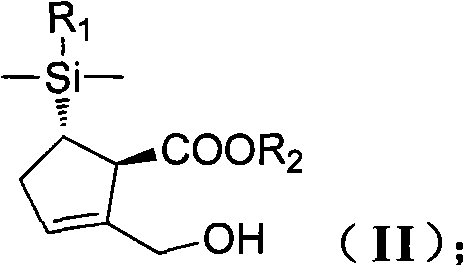

The invention discloses a method for preparing a compound shown as the formula (I), which is characterized by comprising the following steps of: (1) carrying out hydroxyl protection on a compound shown as the formula (II) by using a first hydroxyl protecting group, and then, reacting with hydride to generate a compound shown as the formula (III); (2) carrying out hydroxyl protection on the compound shown as the formula (III) by using a second hydroxyl protecting group, and then, removing the first hydroxyl protecting group to obtain a compound shown as the formula (IV); (3) enabling the compound shown as the formula (IV) to carry out non-corresponding selective epoxidation reaction to generate a compound shown as the formula (V); (4) reacting the compound shown as the formula (V) with thecompound shown as the formula (VI) in a polar aprotic solvent to obtain a compound shown as the formula (VII); and (5) carrying out condensation, desilylation and oxidization on the compound shown asthe formula (VII) to generate the compound shown as the formula (I). In the general formulas of the compounds in each step, R1 is selected from naphthyl or any substituted naphthyl; R2 is selected from alkyl or benzyl of C1-C4; P is selected from hydroxyl protecting groups, such as 2-methoxyl propyl or p-methoxyl benzyl and the like; P' is a hydroxyl protecting group capable of resisting and removing P, such as benzyl; and X is selected from Cl, Br, I or benzyloxyl.

Owner:聊城高新生物技术有限公司

Semiconductor device and electronic device

InactiveUS9773832B2Improve processing speedReduce processing timeTransistorFinal product manufacturePower semiconductor deviceSemiconductor

Owner:SEMICON ENERGY LAB CO LTD

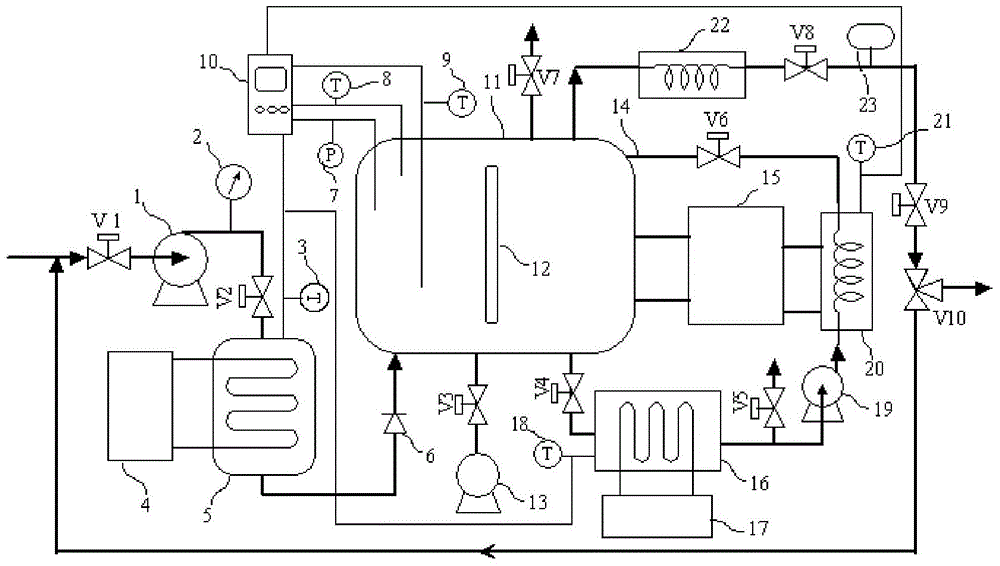

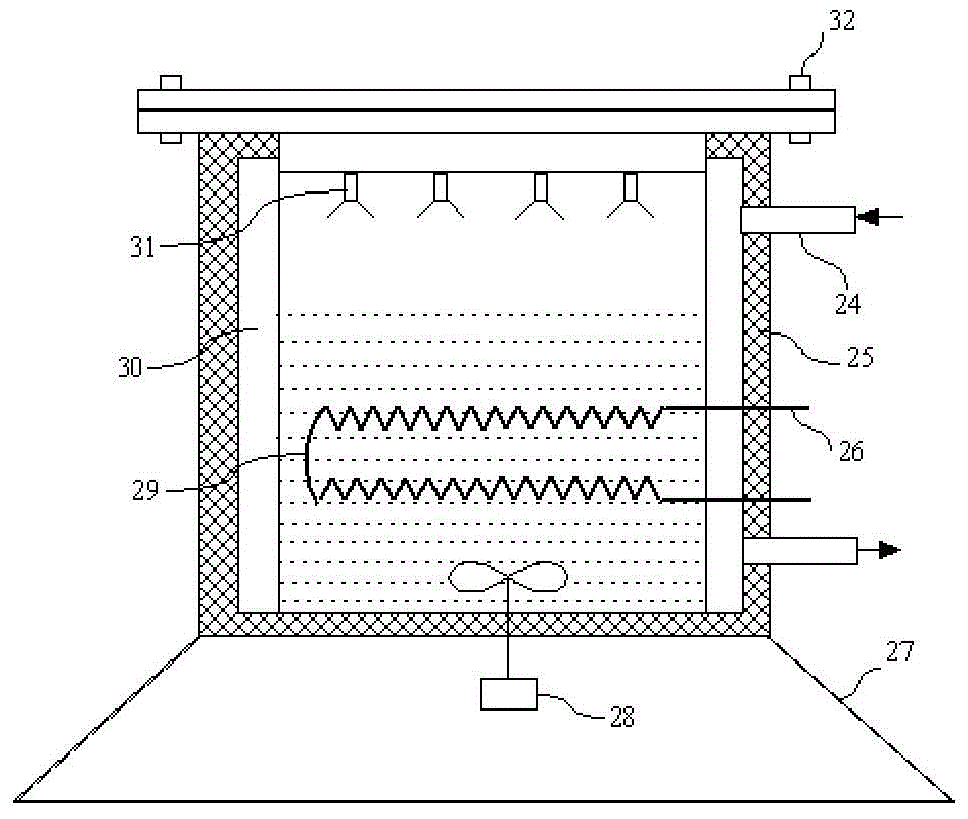

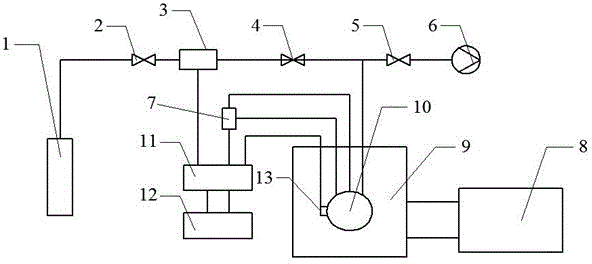

Method and apparatus for separating CO2 in biogas based on hydrate process

The invention discloses a method and an apparatus for separating CO2 in biogas based on a hydrate process. The apparatus comprises a gas booster pump, a gas cooler, a hydrate reaction kettle, a hydrate slurry heater, a liquid booster pump, a liquid cooler, a gas chromatograph, a data acquisition and processing unit, valves and a pipeline; the hydrate reaction kettle is inside plated with a titanium layer for preventing more and more hydrate from being aggregated on the wall of the reaction kettle and solving the problems that a hydrate slurry in a hydrate separation gas is aggregated in the reaction kettle and circulation is not smooth; and the hydrate reaction kettle employs an outer jacket cooling and inner coil pipe cooling method, and also is coated with a thermal-insulation material layer at the outside, so that a large cooling environment in the hydrate reaction process is guaranteed, heat loss is reduced, and also the temperature in the hydrate reaction kettle is uniform. The apparatus structure is simple, the technology is relatively simple, more energy is saved, and the separation effect on biogas is relatively good.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Ready-made clothes grade cloth burnt-out printing process

ActiveCN101187180ASimple printing processShort timePattern makingFibre treatmentScreen printingDistilled water

The invention relates to a ready-made clothes cloth burnt-out process, which belongs to the field of fabric pattern or design embroidery in the fabric industrial production, wherein the process adopts material composed of cotton, nylon or artificial cotton and comprises steps of cracking down the cloth, making the pattern printing screen plate, mixing pattern slurry, burnt-out pattern printing, baking and washing. The process is characterized in that: firstly cracking down the material into pieces according to the design of the ready-made clothes, then according to the ready-made clothes pattern processing the screen printing plate, according to the pattern design color, mixing the printing slurry, then processing the burnt-out printing on the cloth pieces by use of the printing screen plate and the printing slurry, that is, the slurry penetrates the cracked pieces to erode the cotton, nylon or artificial cotton in the cracked pieces and after baking to finish the washing of the cracked pieces of the burnt-out printing. The printing slurry is made by charging concentrated sulfuric acid into the common slurry or by mixing the ready-made clothes printing slurry which can be bought in the market and contains acid component with the auxiliary agent in the distilled water. The process has low energy consumption per unit of ready-made clothes and simple process with low requirements on production field and devices and is suitable for industry production.

Owner:QINGDAO TENGHUA APPAREL CO LTD

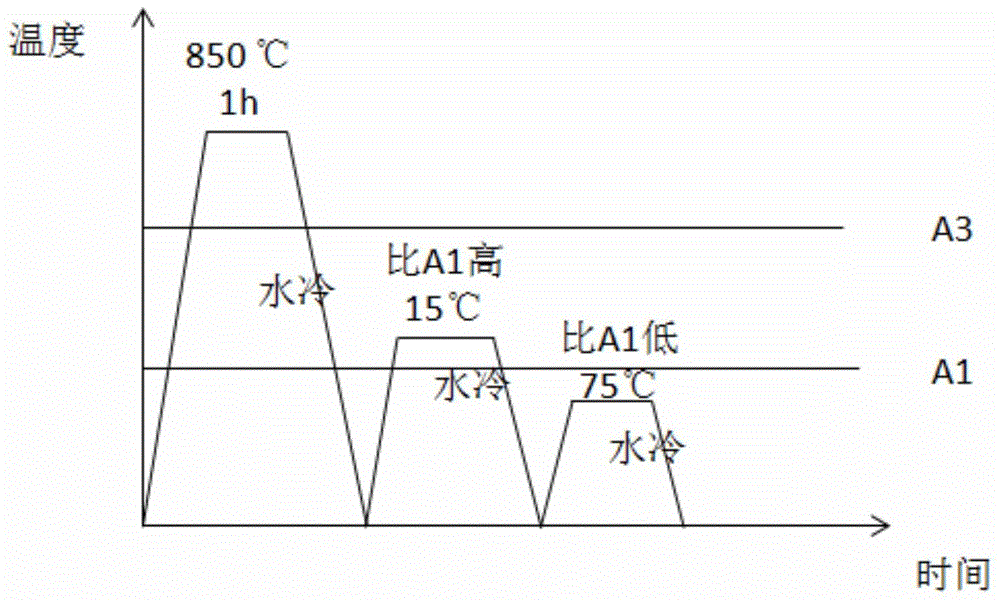

High-strength low-temperature-resistant steel and heat processing technology thereof

The invention provides high-strength low-temperature-resistant steel. The steel is composed of, by mass, 2.0-7.05% of nickel, 0.02-0.1% of carbon, 0.02-0.1% of silicon, 0.60-8.00% of manganese, 0.3-0.5% of chrome, 0.05-0.6% of molybdenum, 0.02-0.3% of copper, 0.03-2.0% of aluminum, smaller than or equal to 0.010% of phosphorus, smaller than or equal to 0.002% of sulfur, 0.004-0.010% of nitrogen, 0.0005-0.002% of oxygen, 0.0005-0.005% of calcium, and the balance iron. The invention further provides the heat processing technology and application of the high-strength low-temperature-resistant steel. By the adoption of the high-strength low-temperature-resistant steel and the heat processing technology thereof, low-temperature toughness is high, structural steel used in a low-temperature environment can be manufactured, application cost is reduced, and economical applicability is high.

Owner:SHANGHAI JIAO TONG UNIV

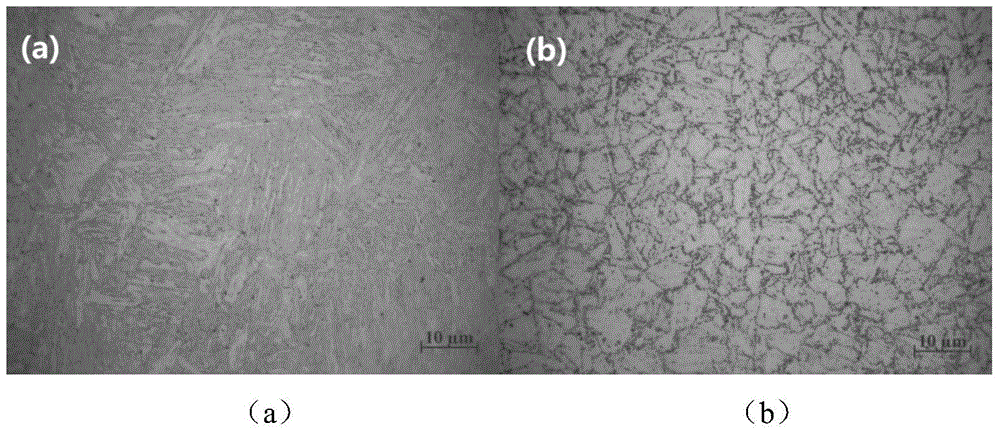

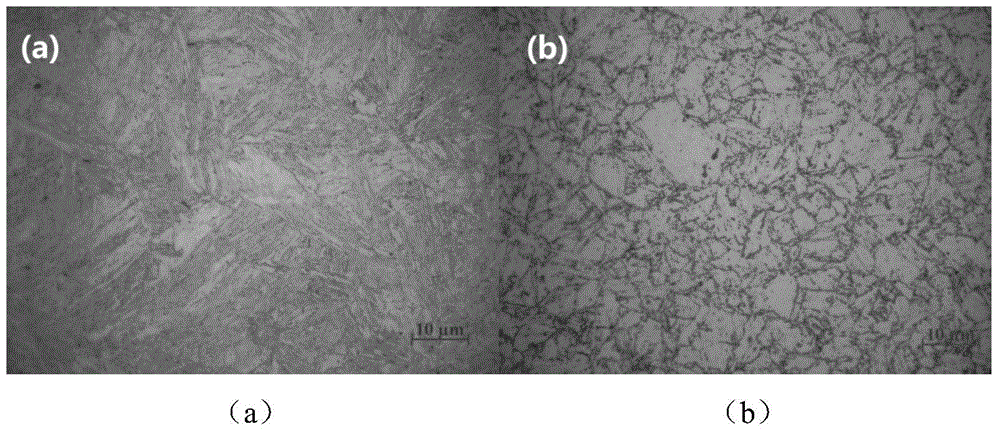

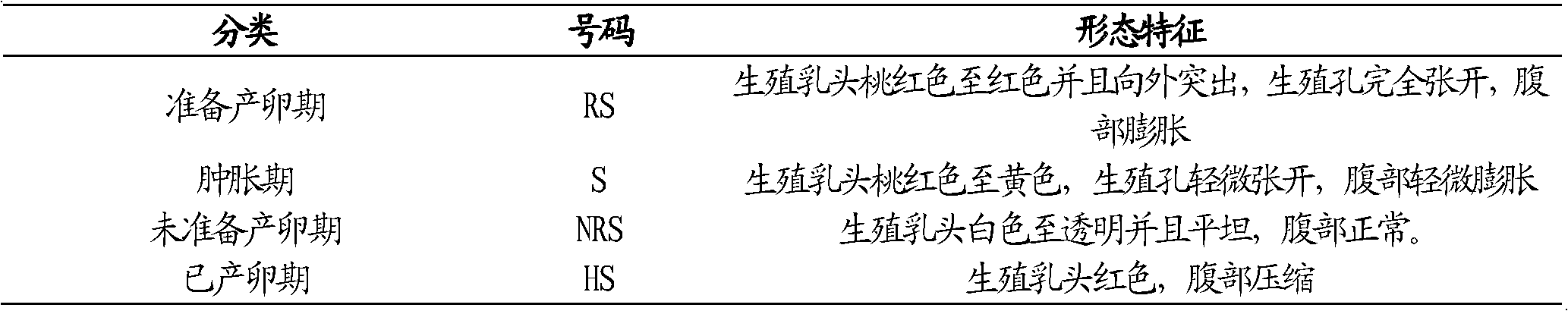

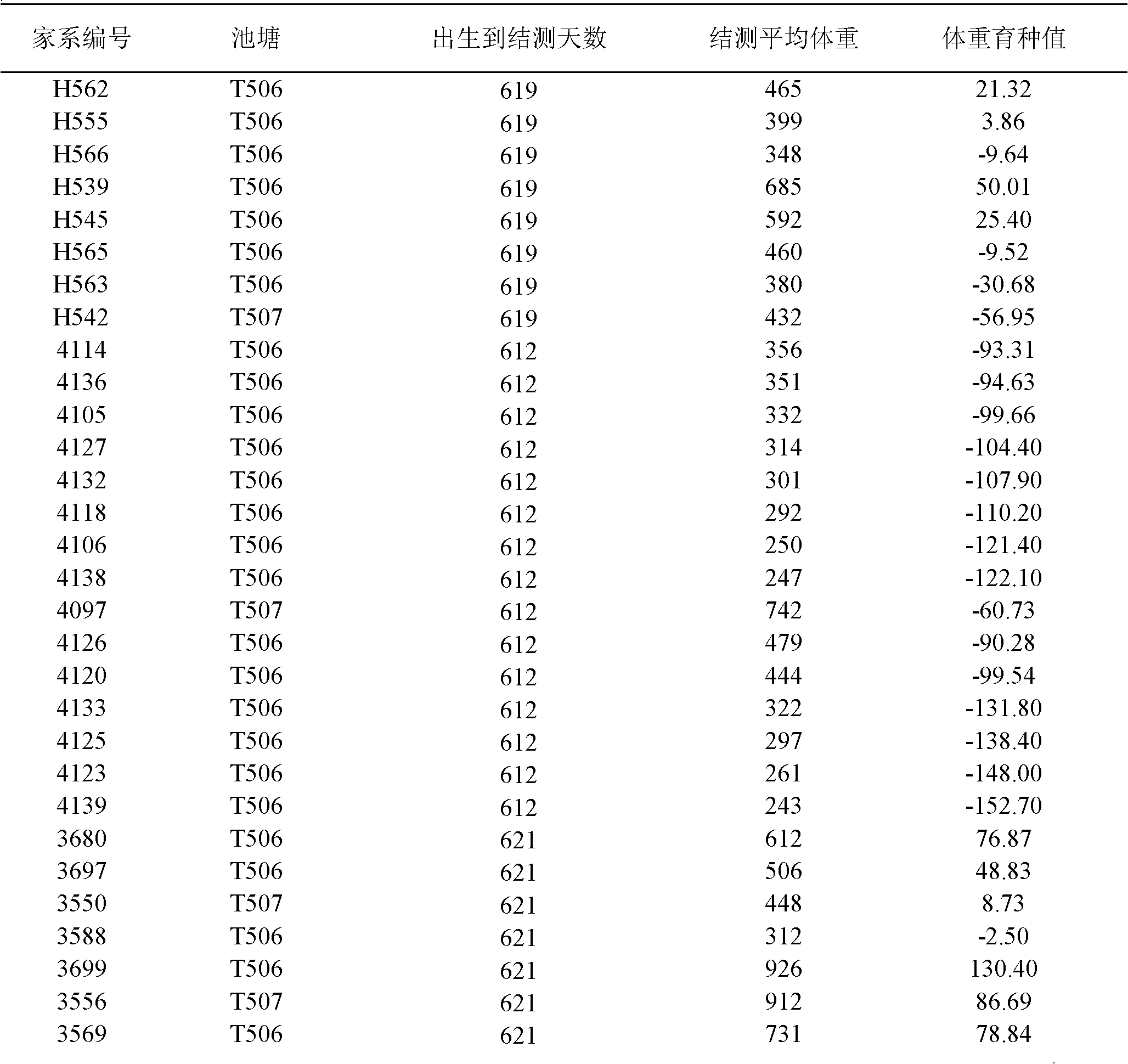

Breed conservation, screening and breed production method in tilapia complete set lines as well as between two lines of complete sets

ActiveCN102630617ALower conditionsEasy to operateClimate change adaptationPisciculture and aquariaTilapiaBase population

The invention relates to a breed conservation, screening and breed production method in tilapia complete set lines, comprising the following steps of: construction of complete set line base populations rich in hereditary variation, establishment of operation procedures of family production and management in the complete set lines, marking of individuals in the complete set lines, genetic evaluation analysis of important production traits and establishment of individual mating selection programs in the complete set lines. The invention also provides a hybrid breed production method between twolines of complete sets, which is established by utilizing the method. The method disclosed by the invention has the characteristics of high pertinence, high selection breeding efficiency, capability of effectively preventing parent inbreeding depression of the complete set lines and the like; the harvest weight of the hybrid fine breed of tilapia is averagely increased by more than 30% than that of control groups; and the culture survival rate is also obviously higher than that of the control groups. According to the invention, a new technical approach is developed for cultivation of fish fine breeds; particularly a new selection breeding method is applied in the breed conservation, the screening and the breed production of the complete set lines in fish hybrid breeding; and the method isalso suitable for being popularized and applied in all cultured fishes and has broad popularization and application prospects.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

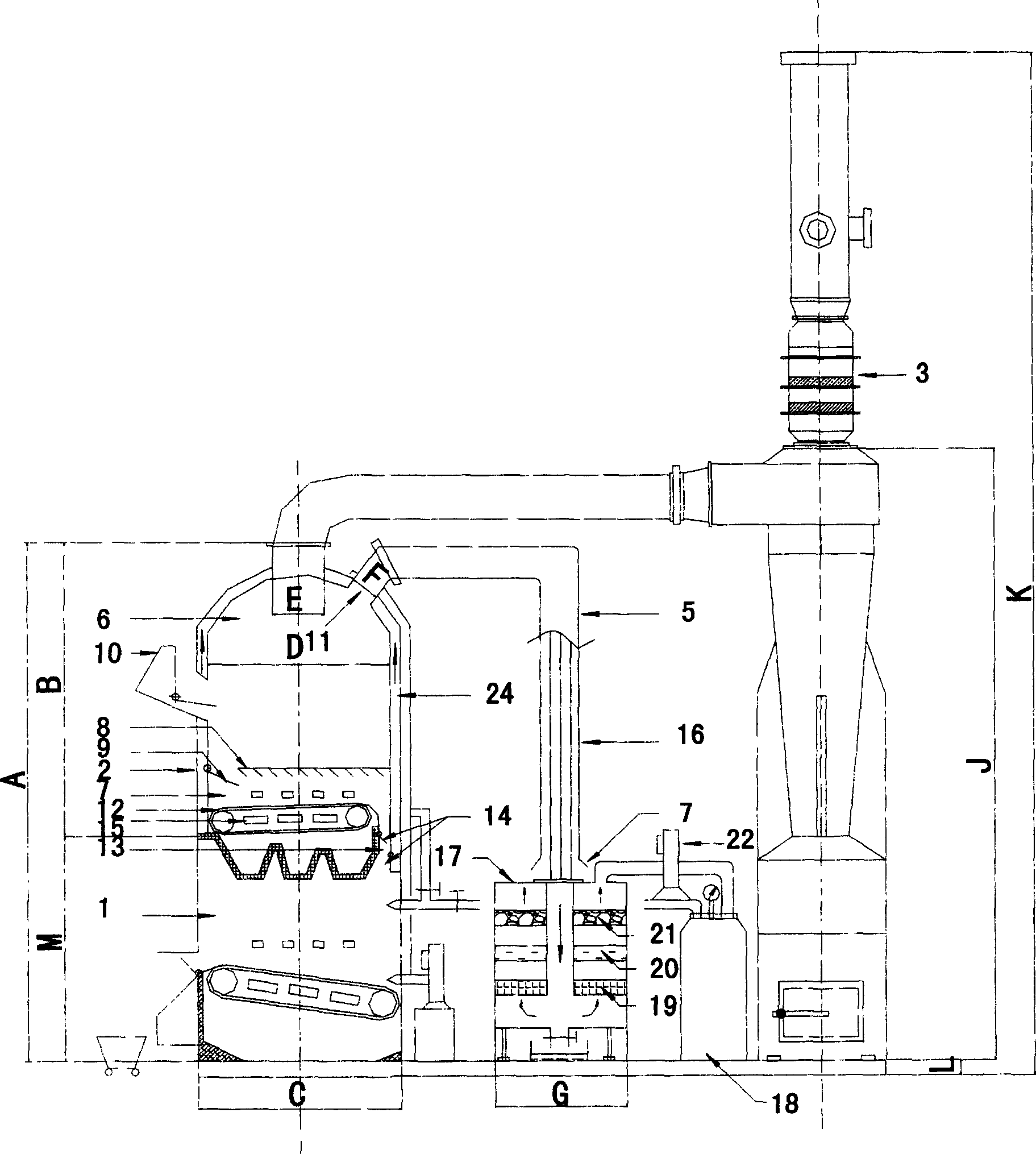

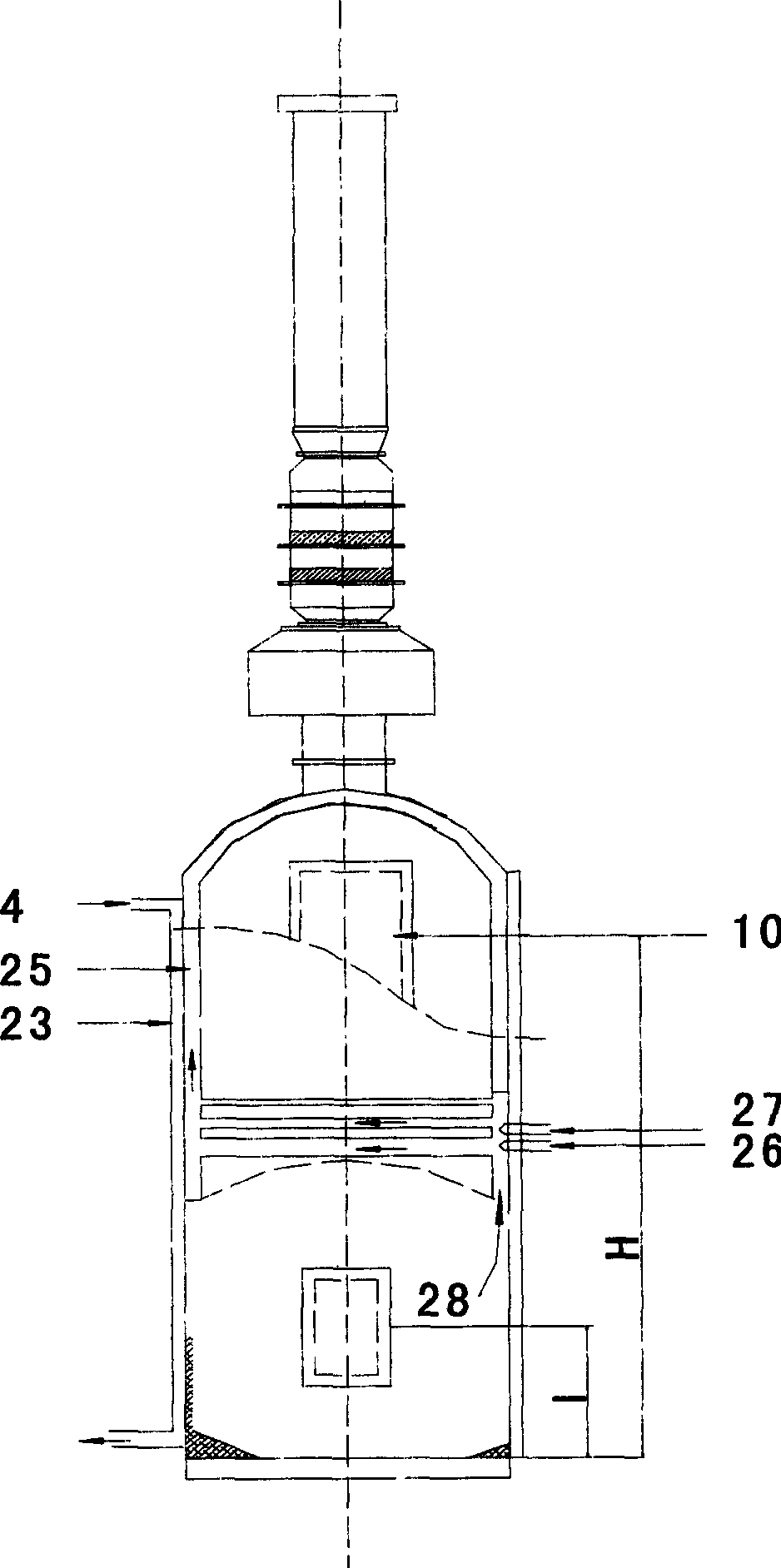

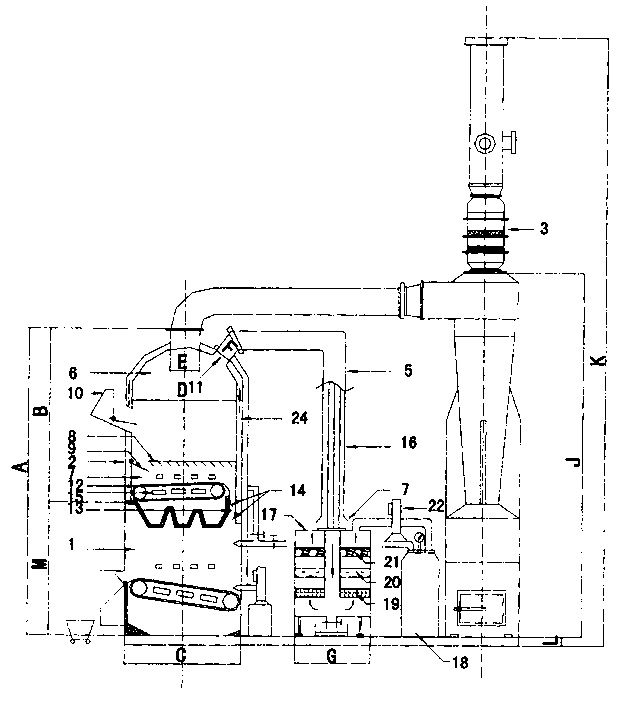

Medical refuse pyrolytic-gasification incineration apparatus

InactiveCN1470801ASource of reductionReduce generation conditionsIncinerator apparatusCombustion chamberEngineering

The incinerator, the gasifying pyrolysis stove as well as the dust removal and fume extractor are utilized in the invented equipment. The incinerator, the pyrolysis gasifying stove and the collector for cracked gas are integrated as whole body. The furnace body of the gasifying pyrolysis oven is divided into a stove chamber and a cracking chamber. The exit of the chain on the bottom of the cracking chamber is connected to the incinerator through a channel. Cracked coke can pass through two windshields in the channel, but fume and frame produced in the incinerator cannot enter into the stove. Thus, gasifying pyrolysis effect is happened in the stove without burning on. Garbage is decomposed into cracked coke, which will be burning in the incinerator, and cracked gas, which will be filteredout. The beneficial effect is that if burning these gases, dioxin will be produced. The combustible gas generated in the stove is as the fuel for the incinerator.

Owner:TIANJIN UNIV

Double-layered crystal glaze and preparation method thereof

The invention discloses double-layered crystal glaze and a preparation method thereof. The double-layered crystal glaze comprises bottom glaze and surface glaze, wherein the bottom glaze is prepared from the following components in parts by weight: 30-35 parts of feldspar, 21-23 parts of quartz, 7-12 parts of calcite, 4-5 parts of Guizhou soil, 3-5 parts of zinc oxide, 7.5-10 parts of zirconium silicate and 7-11 parts of strontium carbonate; the surface glaze is prepared from the following components in parts by weight: 22-25 parts of feldspar, 24-25 parts of borax, 5-10 parts of quartz, 12-15 parts of calcite, 4-5 parts of Guizhou soil, 23-25 parts of zinc oxide, 9-10 parts of zirconium silicate, 5-8 parts of dolomite and 0.5 part of chromophore. According to the invention, the sintering time of the crystal glaze can be shortened, so that the cost is lowered. The double-layered crystal glaze can be produced on a large scale, and the production quantity of the double-layered crystal glaze is improved.

Owner:LILING TAORUN INDAL DEV

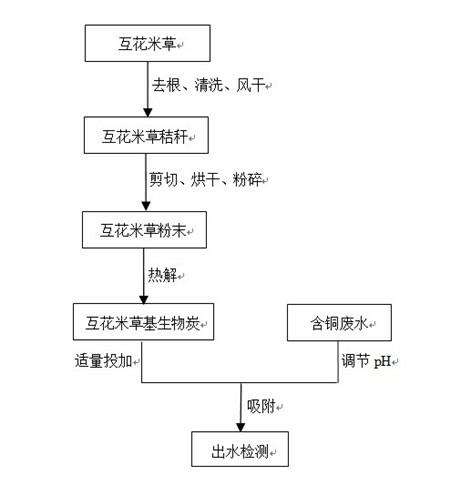

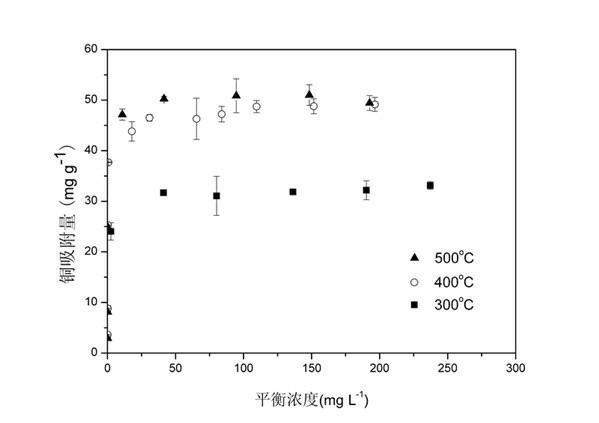

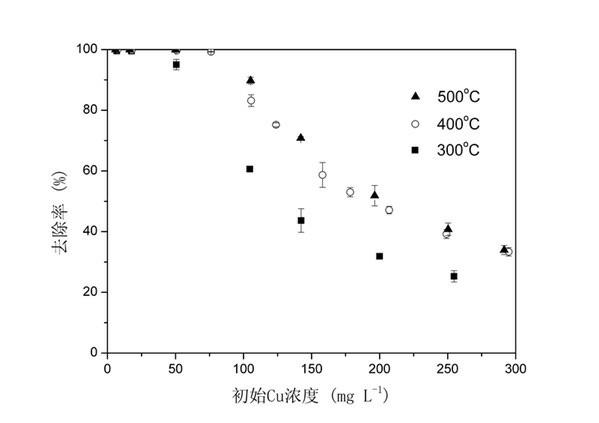

Method for treating wasterwater containing copper by utilizing Spartina alterniflora Loisel-based biochar

InactiveCN102600799AAbundant resourcesEasy to prepareOther chemical processesWater/sewage treatment by sorptionBiomassEnvironmental chemistry

The invention discloses a method for treating wasterwater containing copper by utilizing Spartina alterniflora Loisel-based biochar, belonging to the field of resource utilization of biomass. The method comprises the following steps: 1) removing roots of Spartina alterniflora Loisel, cleaning, airing, then completely stoving and smashing; 2) pyrolyzing Spartina alterniflora Loisel power at a temperature of 300-550 DEG C for 1-4 hours under the protection of N2, cooling to room temperature, and grinding and screening, wherein the productivity is 39-43%; and 3) adding the prepared biochar into the wastewater containing copper according to a proper proportion, and treating for 6-48 hours, wherein the adsorption quantity of copper is 33.12-50.99%. The biochar prepared by the method is low in cost, simple in operation and high in adsorption quantity, so that good environment, social benefit and considerable economic benefit can be created.

Owner:SHANGHAI UNIV

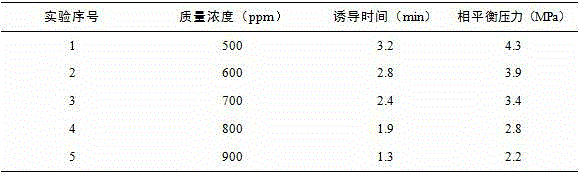

Composite gas hydrate accelerant and application method thereof

ActiveCN104893660APromote generationEasy to prepareOther chemical processesGaseous fuelsSulfonateAcetic acid

The invention relates to the technical field of the production and utilization of natural gas hydrate, and particularly relates to a composite gas accelerant and an application method thereof. The composite accelerant is prepared by mixing betaine acetate used as an additive, mahogany petroleum sulfonate used as a surface active agent and alkyl amine oxide, wherein by total mass of a mixed aqueous solution, the mass percentage of betaine acetate is 1 to 3 percent; the mass percentage of the surface active agent mahogany petroleum sulfonate is 1.2 to 4.5 percent; the mass percentage of amphiprotic surface active agent alkyl amine oxide is 3 to 5 percent; and the rest is deionized water. The prepared hydrate accelerant is simple in preparation method and good in accelerating effect; the accelerant can effectively improve the generation of hydrate, and the gas hydrate generation condition and generation time can be greatly reduced by virtue of little accelerant, so that the energy consumption can be effectively reduced, and the energy and cost can be saved.

Owner:泉州职业技术大学

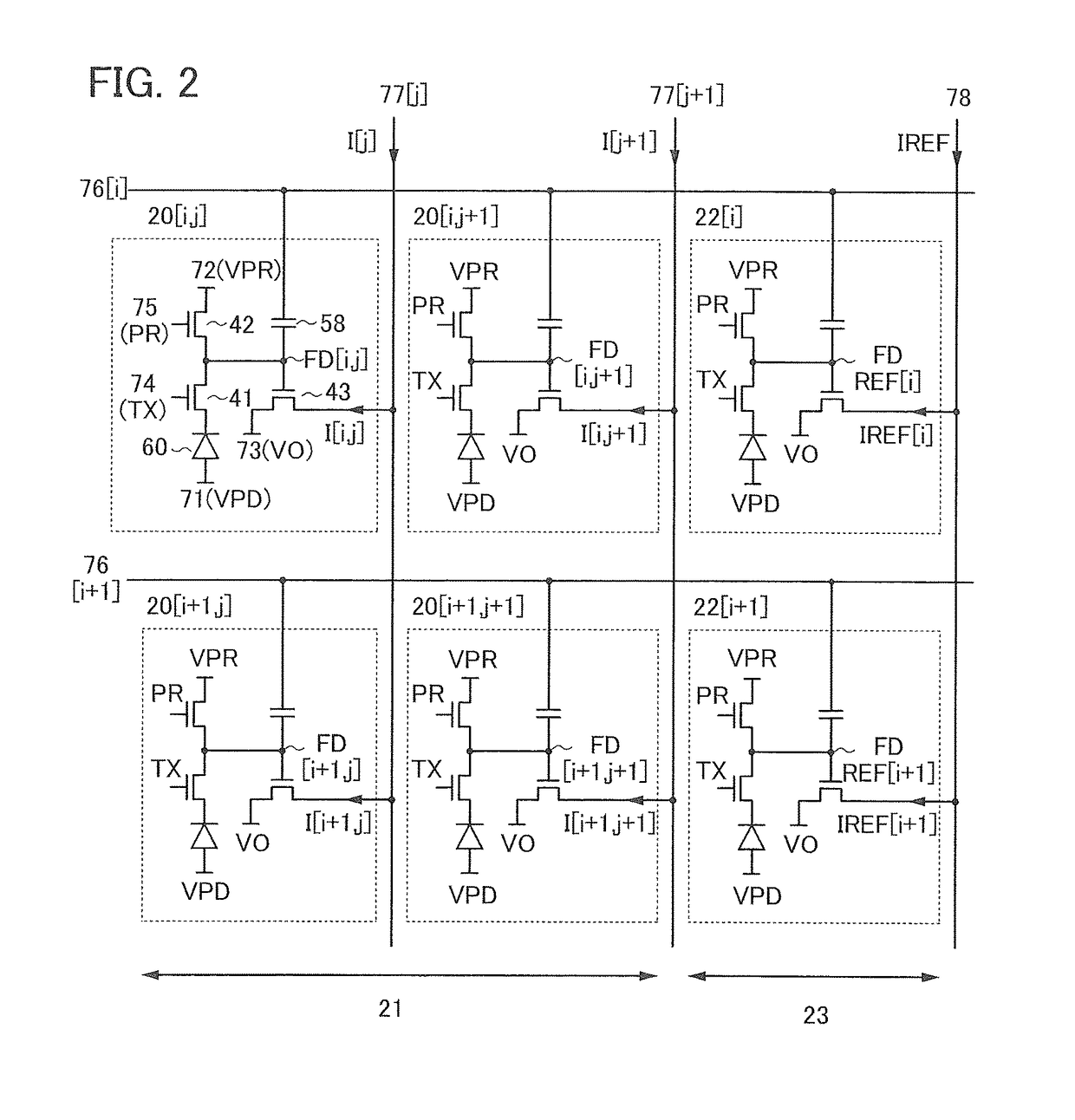

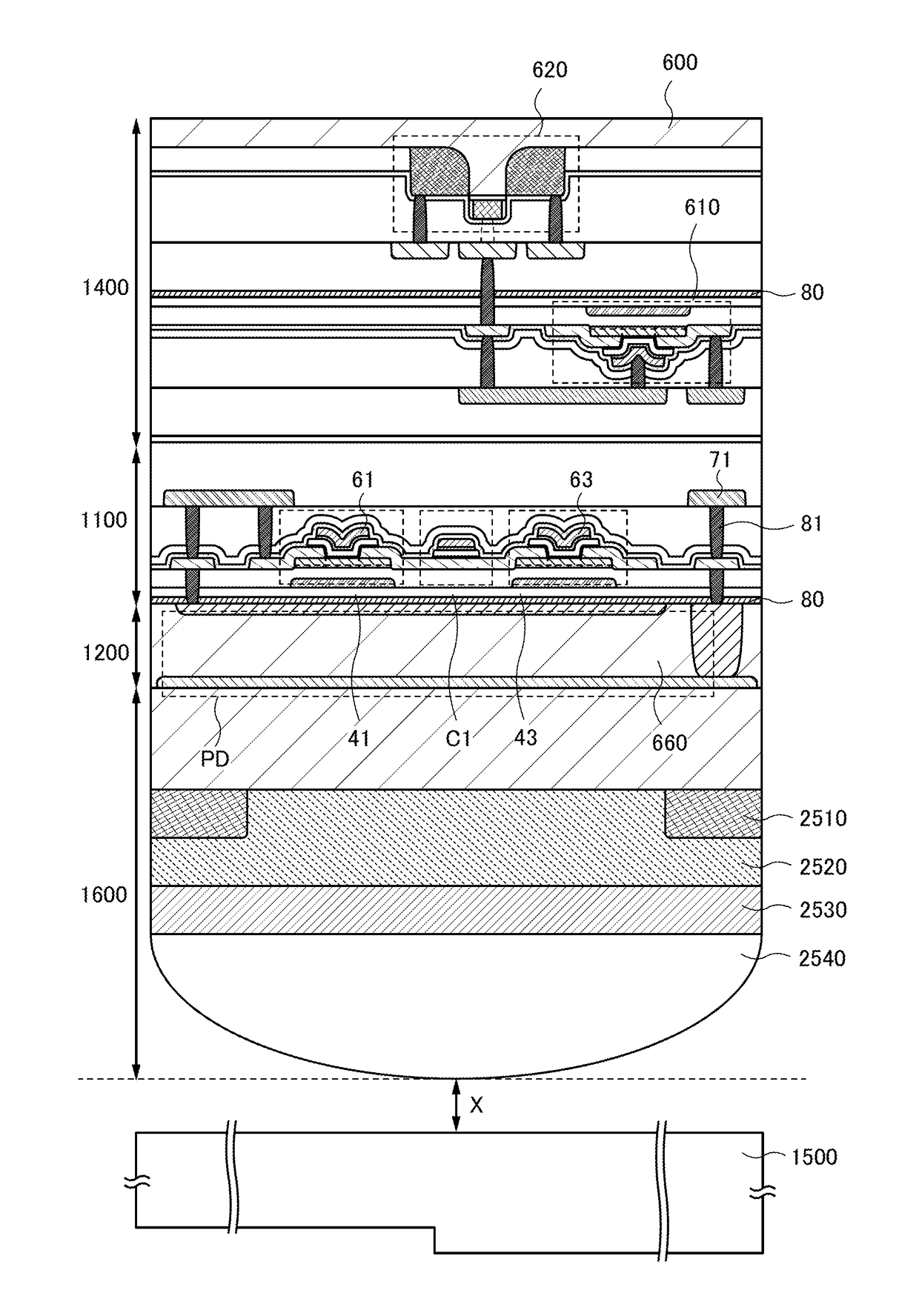

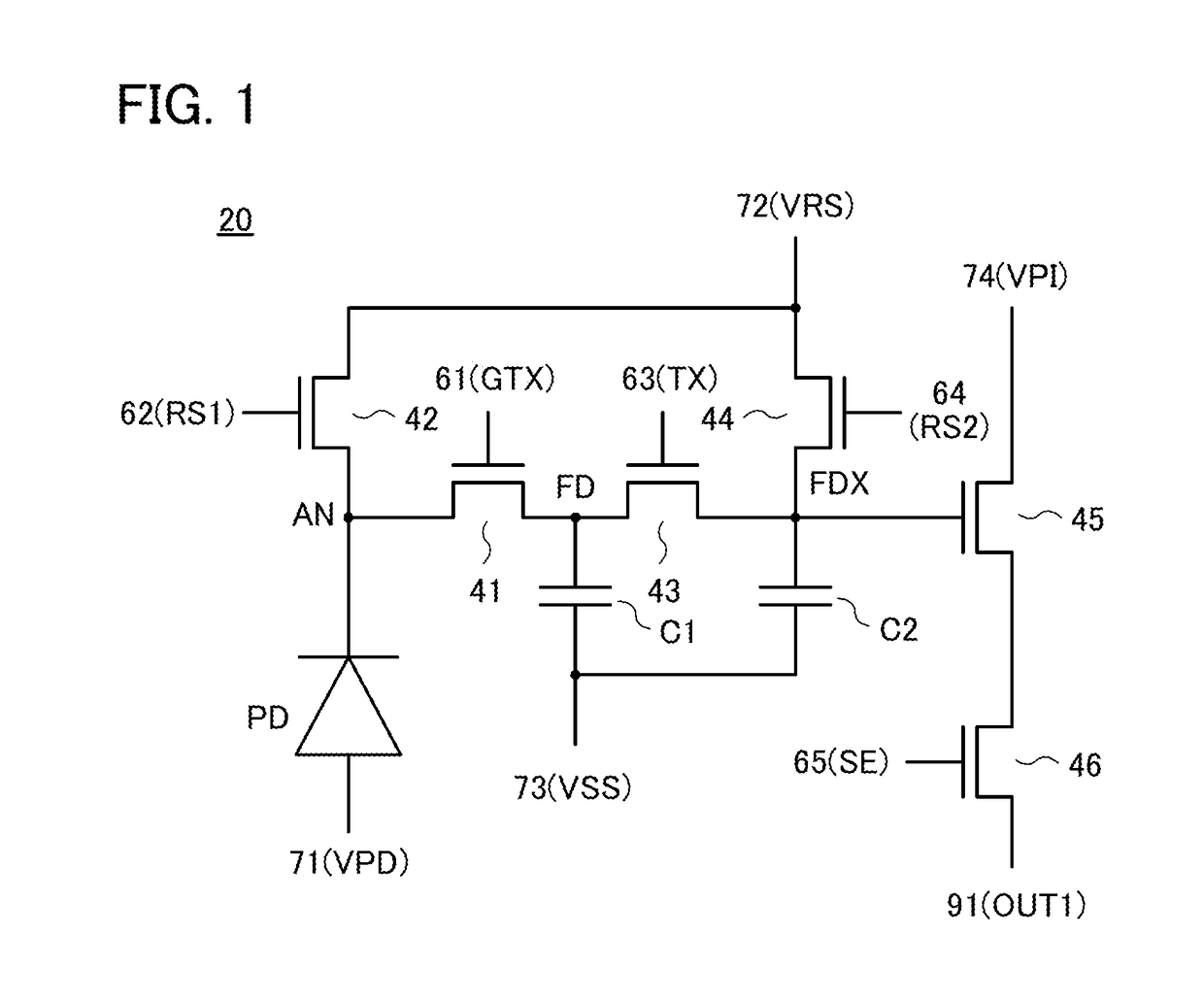

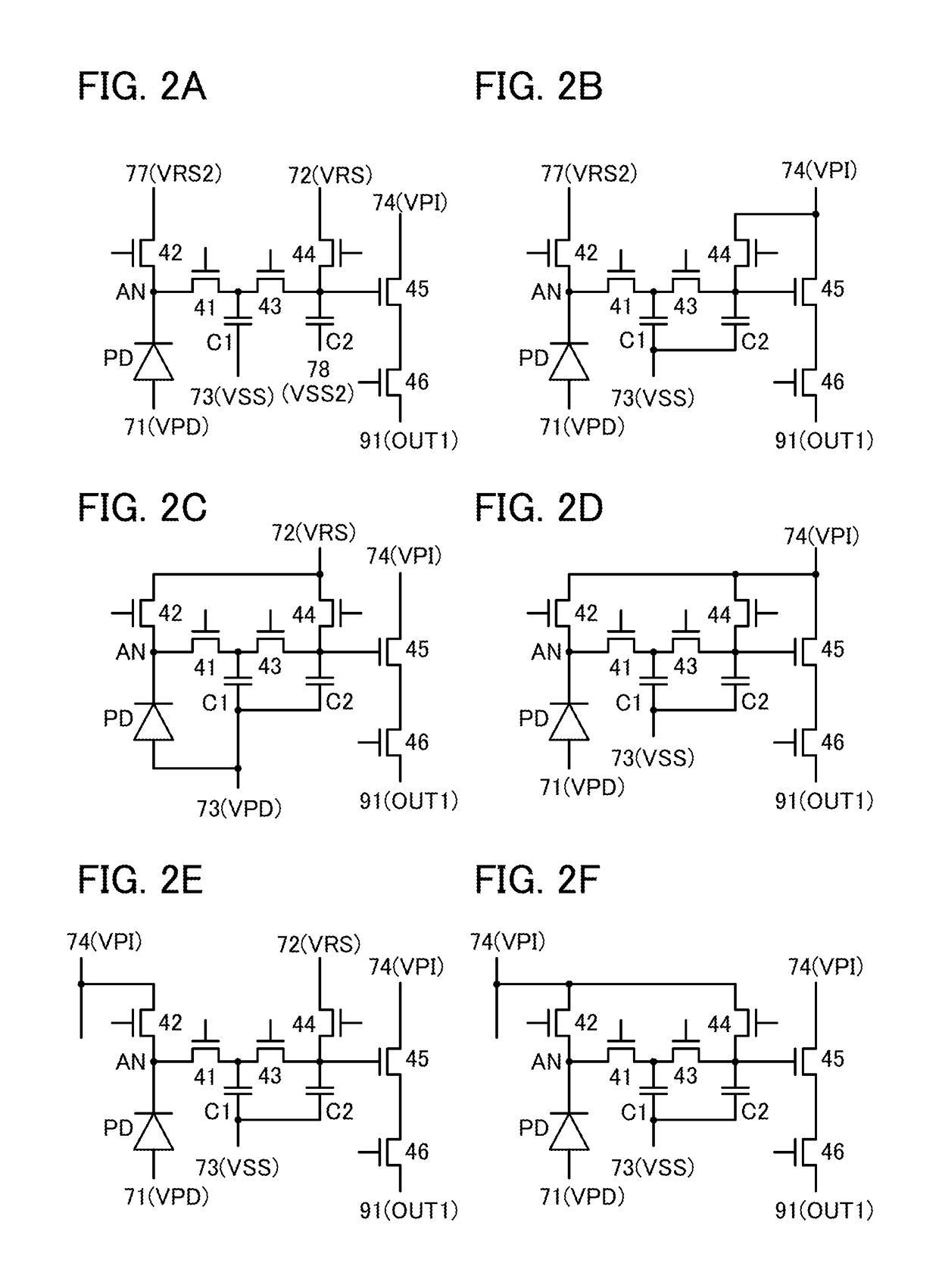

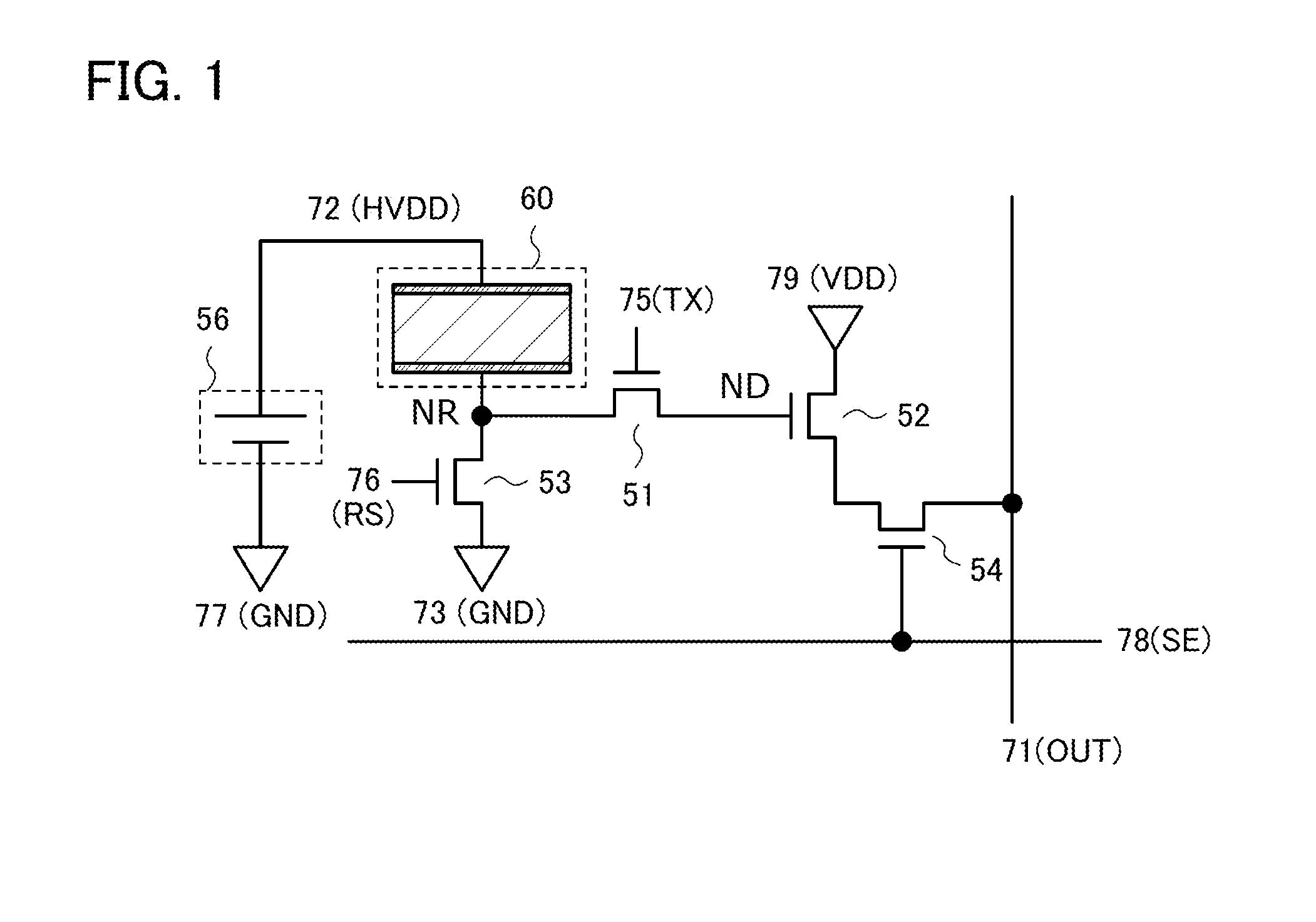

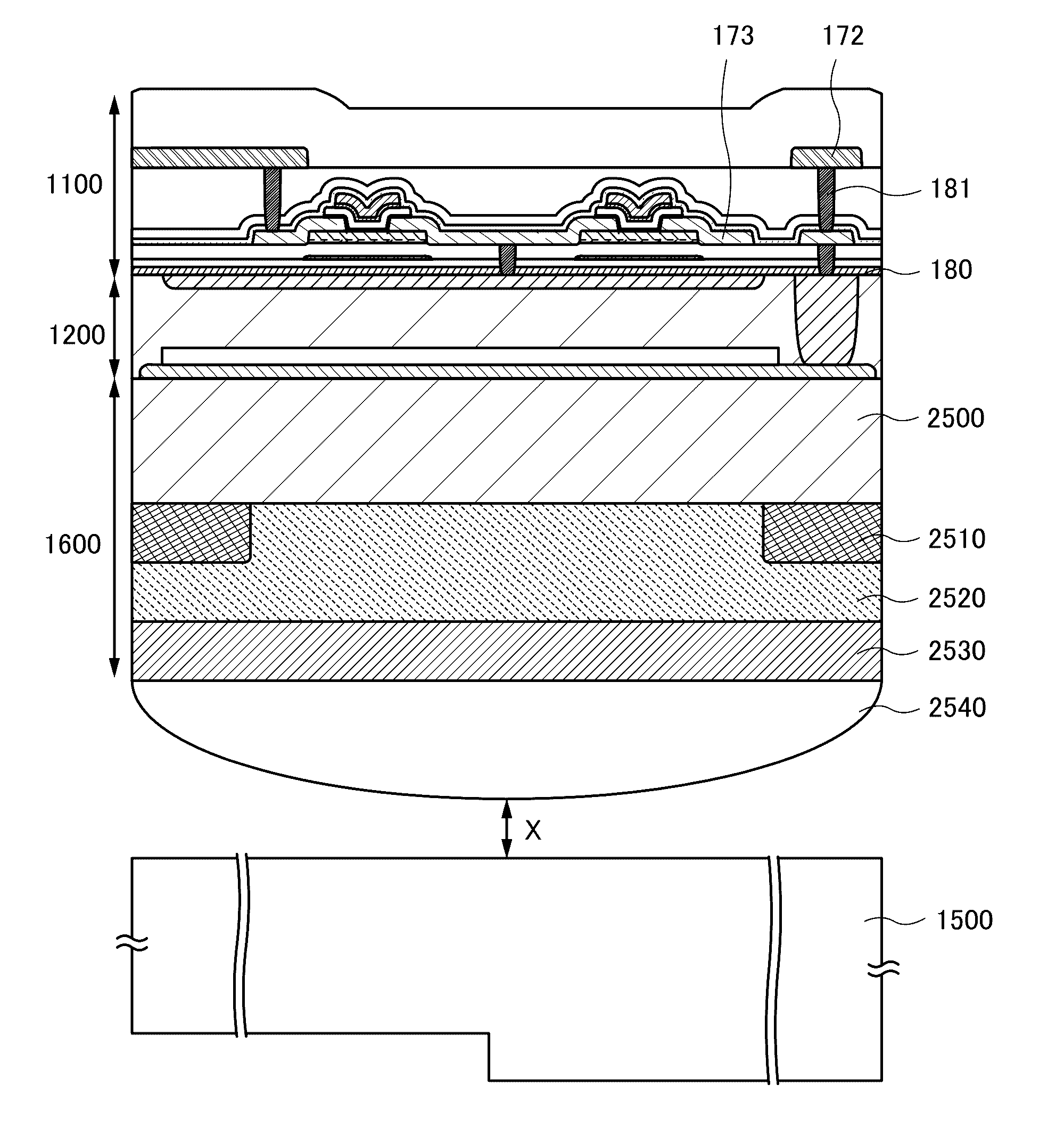

Imaging device, module, electronic device, and method of operating the imaging device

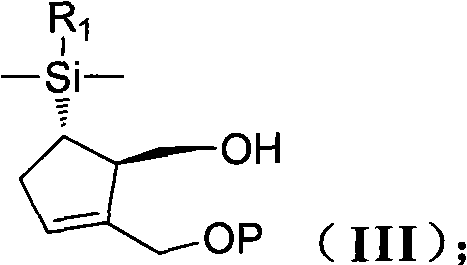

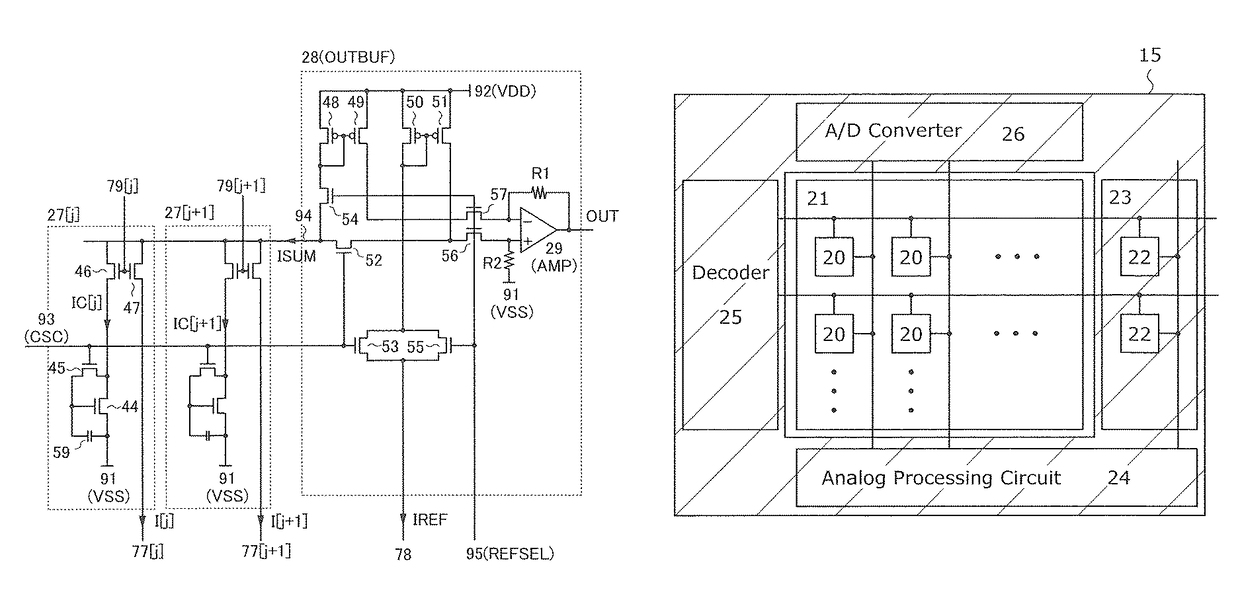

ActiveUS20170084649A1Simple designReduce in quantityTransistorTelevision system detailsCharge retentionCharge detection

An imaging device that has a structure where a transistor is used in common by a plurality of pixels and is capable of imaging with a global shutter system is provided. A transistor that resets the potential of a charge detection portion, a transistor that outputs a signal corresponding to the potential of the charge detection portion, and a transistor that selects a pixel are used in common by the plurality of pixels. A node AN (a first charge retention portion), a node FD (a second charge retention portion), and a node FDX (the charge detection portion) are provided. Imaging data obtained in the node AN is transferred to the node FD, and the imaging data is sequentially transferred from the node FD to the node FDX to be read.

Owner:SEMICON ENERGY LAB CO LTD

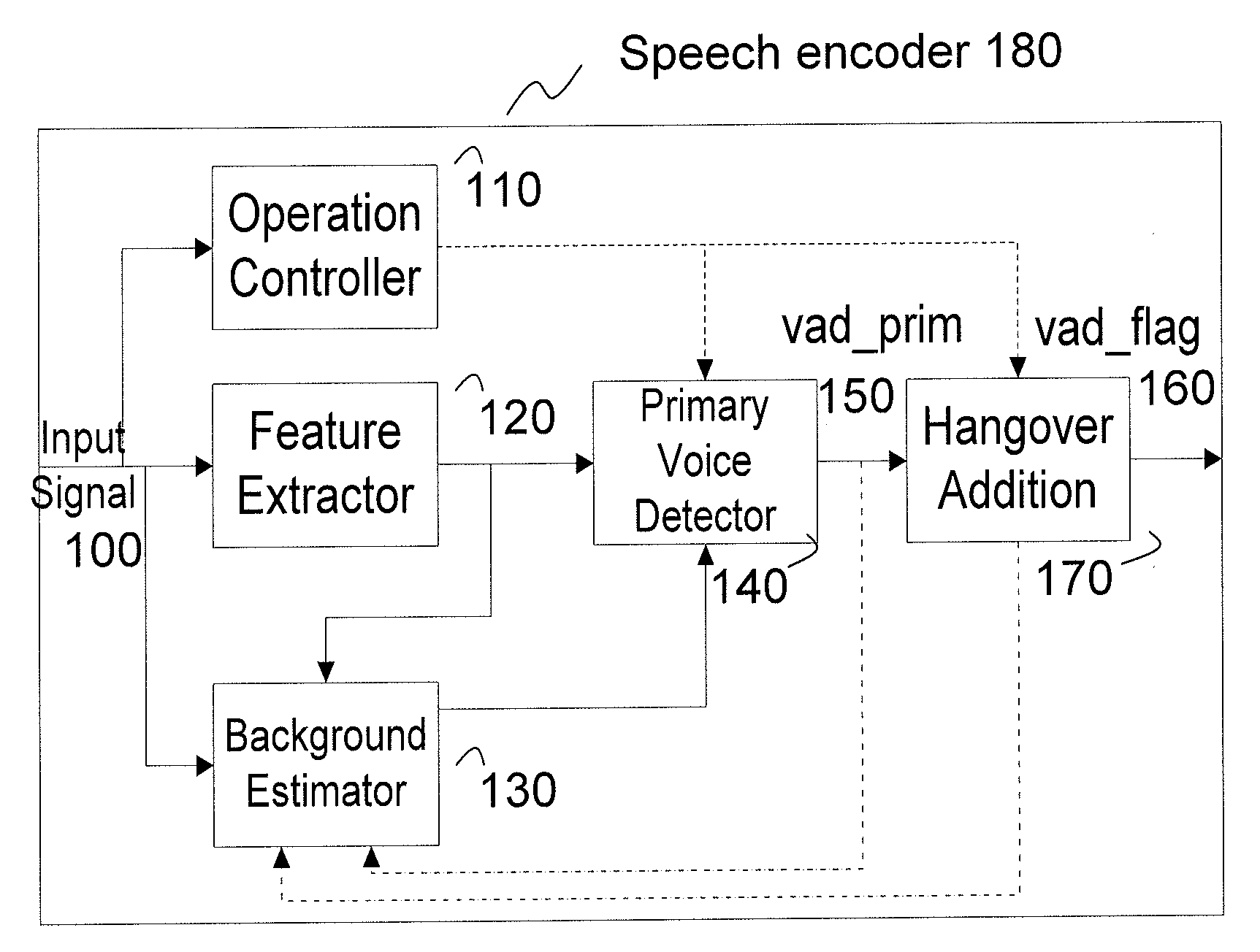

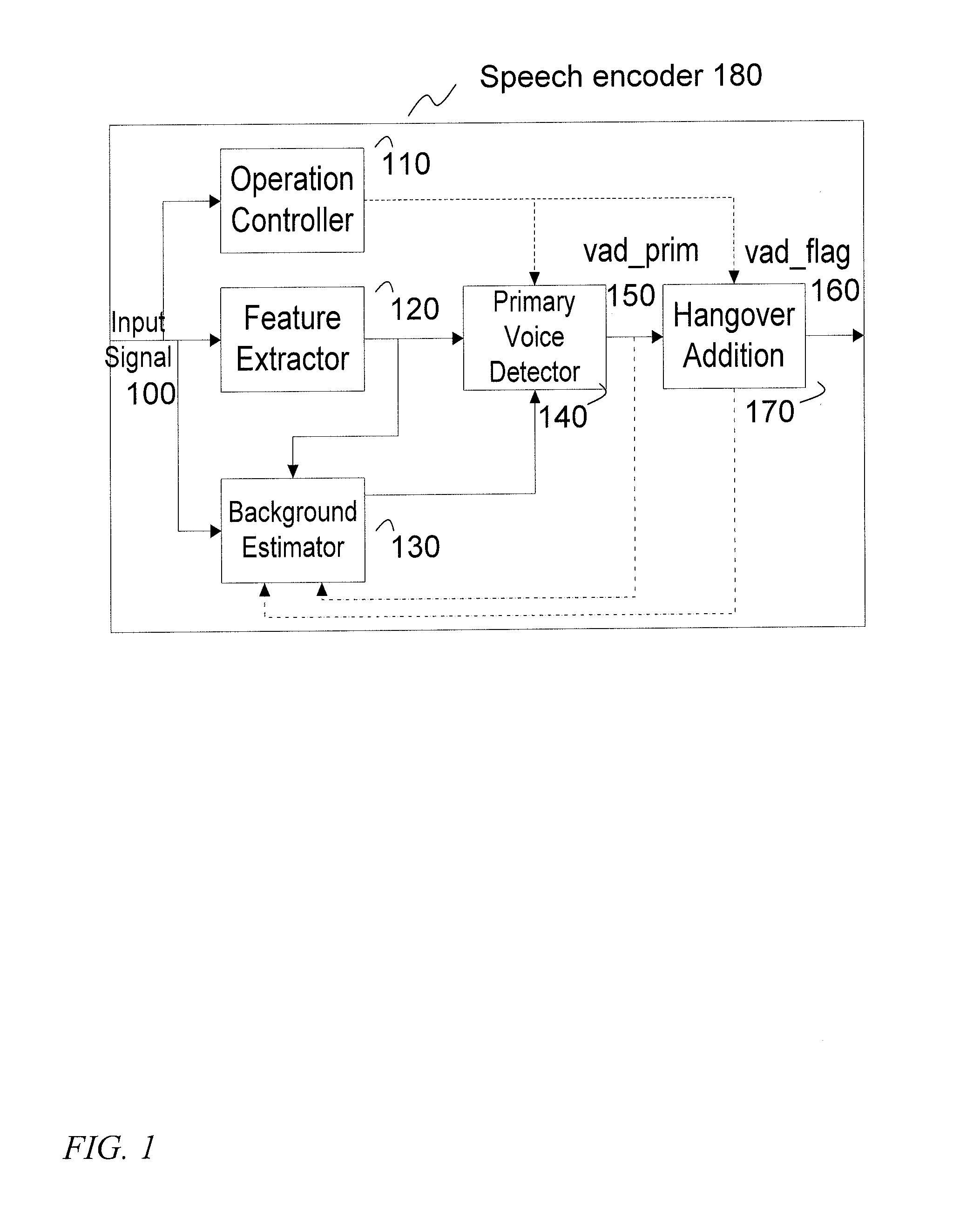

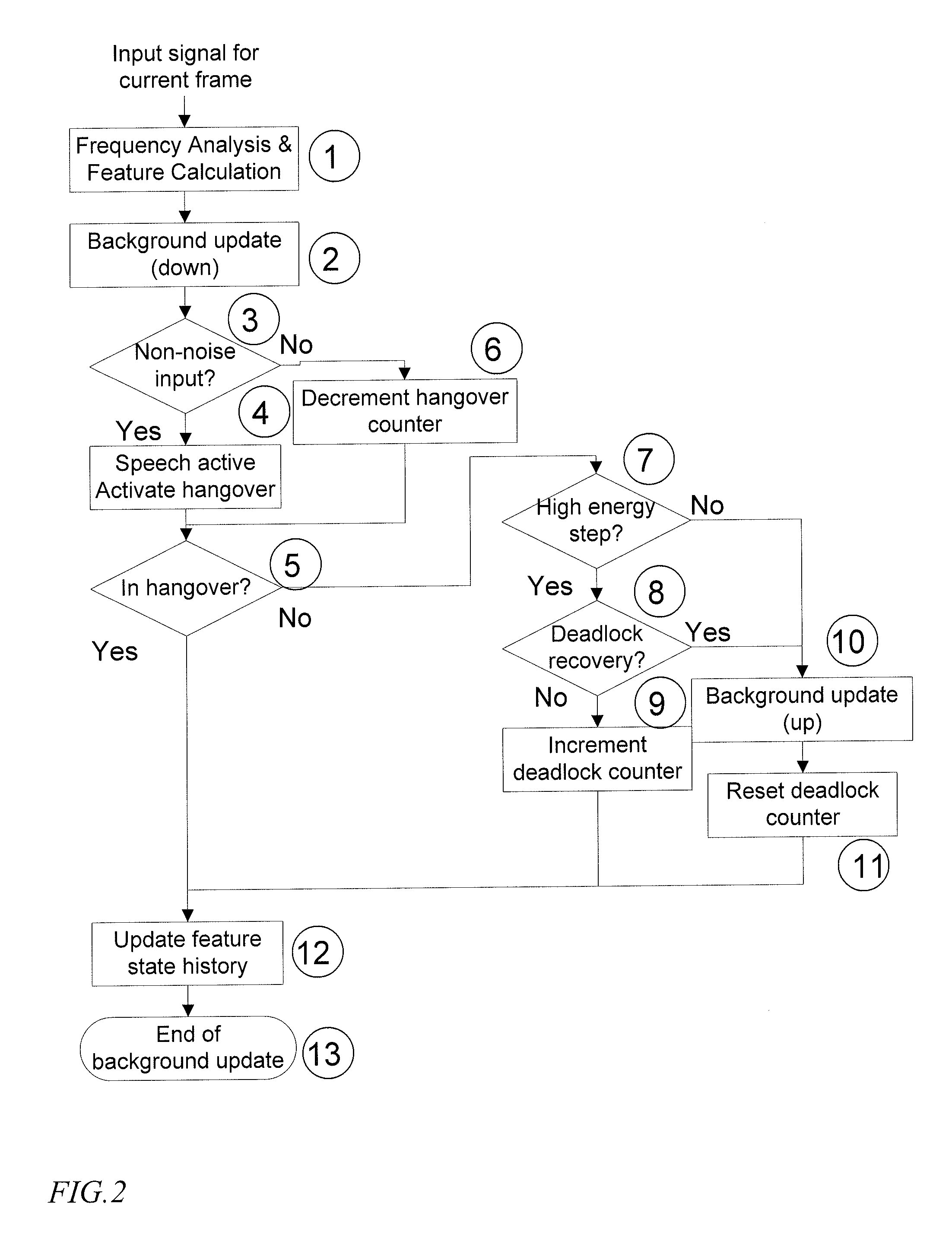

Method And Background Estimator For Voice Activity Detection

ActiveUS20120209604A1Improve performanceLower conditionsSpeech recognitionBackground noiseEnergy level

The present invention relates to a method and a background estimator in voice activity detector for updating a background noise estimate for an input signal. The input signal for a current frame is received and it is determined whether the current frame of the input signal comprises non-noise. Further, an additional determination is performed whether the current frame of the non-noise input comprises noise by analyzing characteristics at least related to correlation and energy level of the input signal, and background noise estimate is updated if it is determined that the current frame comprises noise.

Owner:TELEFON AB LM ERICSSON (PUBL)

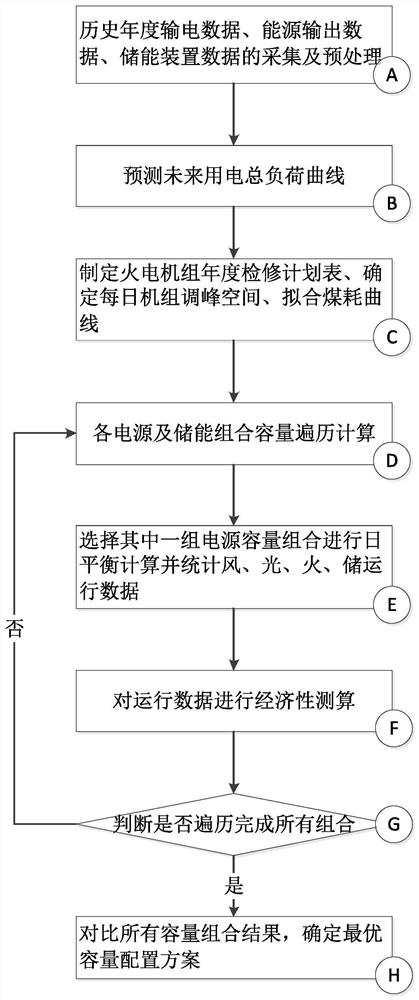

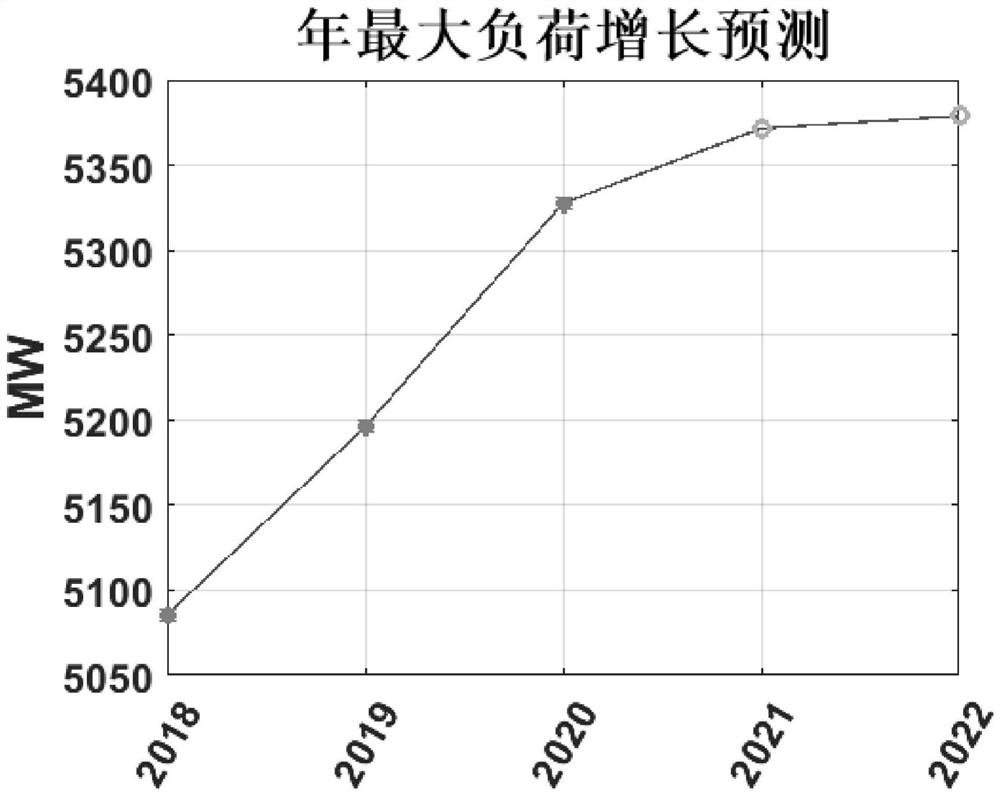

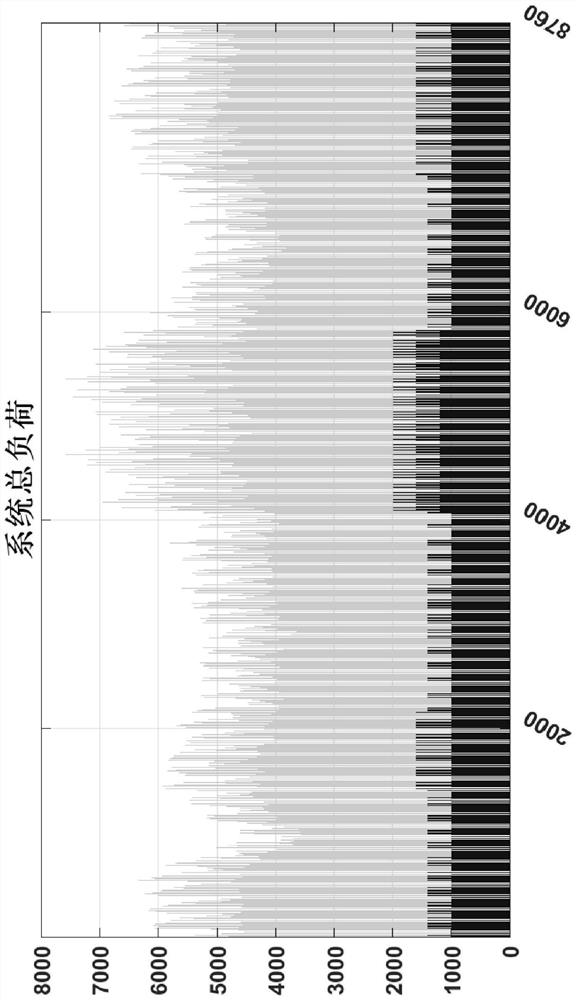

Wind-solar-thermal storage capacity optimal configuration method in power grid planning

ActiveCN112564183AReduce capacityEnsure safe, efficient and economical operationSingle network parallel feeding arrangementsEnergy storageControl engineeringPower grid

The invention relates to a wind-solar-thermal storagecapacity optimization configuration method in power grid planning. The method operates by computer equipment and programs and comprises the following steps: step A, acquiring and preprocessing historical annual power transmission data, energy output data and energy storage device data; step B, predicting a future total power consumption load curve; step C, making an annual maintenance schedule of a thermal power generating unit, determining a peak regulation space of the unit every day, and fitting a coal consumption curve of each unit; stepD, carrying out traversal calculation on the capacity of each power supply and energy storage combination; step E, selecting a group of power supply capacity combinations to perform daily balance calculation and counting wind power, photoelectricity, thermal power and energy storage operation data; step F, performing economical efficiency measurement and calculation on the operation data; step G,judging whether all combinations are traversed or not; step H, comparing all capacity combination results, and determining an optimal capacity configuration scheme; and the optimization effect of system investment and operation economy is achieved.

Owner:NORTH CHINA POWER ENG

Preparing toner images with metallic effect

InactiveUS20130295502A1Enhance original colorHigh glossDevelopersElectrographic process apparatusLatent imagePolymer

A method is used to provide a toner image with a metallic effect. After forming a latent image, it is developed with metallic dry toner particles to form a developed toner image that is transferred and fixed to a receiver material. Each metallic dry toner particle consists essentially of a polymeric binder phase and non-conductive metal oxide particles. Before fixing, the metallic dry toner particle has a mean volume weighted diameter (Dvol) of at least 15 μm and up to and including 40 μm. The non-conductive metal oxide particles are present in an amount of 20-50 weight %. The ratio of the metallic dry toner particle Dvol to the average equivalent circular diameter (ECD) of the non-conductive metal oxide particles in the metallic dry toner particles, before fixing, is greater than 0.1 and up to and including 10.

Owner:EASTMAN KODAK CO

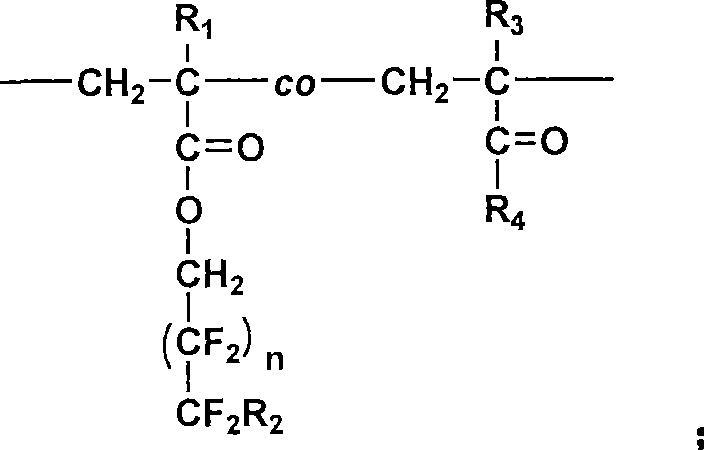

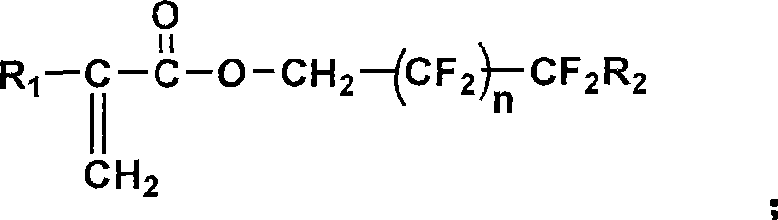

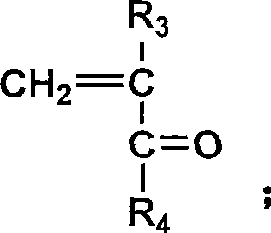

Random copolymerization fluorine-containing macromole emulsifying agent and preparation thereof

The invention discloses a fluorine-containing macro-molecule emulsifying agent which is a comb-type random copolymer which consists of hydrophobic fluorine-containing monomers and hydrophilicity monomers; in the invention, conventional radical polymerization is adopted for obtaining the fluorine-containing macro-molecule emulsifying agent, the requirements of reaction conditions and devices are low and the reaction monomers are easily obtained, thus overcoming the disadvantages that methods such as active polymerization, and the like, are carried out under highly-demanding conditions in the prior art, and the cost is high. The reaction of the invention has rapid speed, and the conversion percent is high; at present, the conventional radical polymerization with low cost is still one of the simplest and most convenient methods in the point of industrialized production and production cost reduction, therefore, the fluorine-containing macro-molecule emulsifying agent is easy for industrial application.

Owner:SUZHOU UNIV

Growth and cultivation matrix used for ecological remediation and preparation method thereof

The invention relates to the field of water and soil conservation, in particular to a growth and cultivation matrix used for the ecological remediation and a preparation method thereof. Every 1500kg of matrix comprises 30-40kg of urea formaldehyde foam particle, 60-70kg of peat soil, 20kg of organic matter, 0.5-1kg of probiotics powder, 5-10g of water-retaining agent, 5-10g of adhesive, 0.5-1g of plant growth conditioning agent and 3.203kg of trace element. The growth and cultivation matrix disclosed by the invention is favorable for remediating, improving and stabilizing bare rock and ecological fragility areas as well as other environment bad for plants to grow, and especially has an obvious remediation action on slopes, elevations and bare rock surfaces bad for the plants to grow. Meanwhile, the growth and cultivation matrix is favorable for a remediated surface to quickly form a self-supply microecosystem, and the whole curing condition and cost can be lowered.

Owner:辽宁易发成林生态技术有限公司

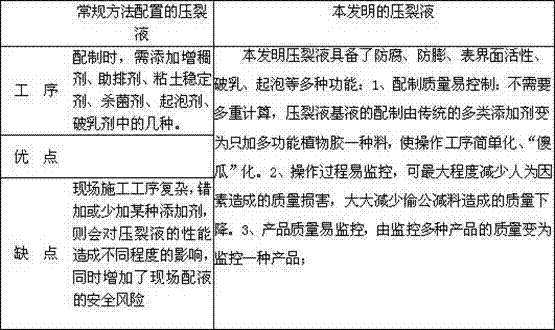

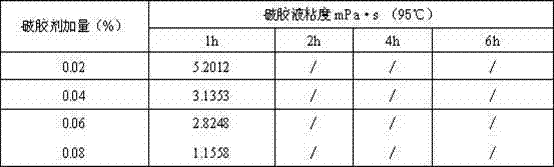

A method for preparing water-based fracturing fluid by using multi-effect thickener

InactiveCN102286276AOptimized formulaQuality improvementDrilling compositionDemulsifierFoaming agent

The invention discloses a method for preparing a water-based fracturing fluid by using a multi-effect thickener, which is characterized in that the fracturing fluid is composed of a base fluid and a cross-linking fluid containing a gel breaker, and is mixed according to the following parts by weight Uniform: 60-99.99 parts of base liquid, 0.01-40.0 parts of cross-linking liquid containing gel breaker; the base liquid is mixed according to the following parts by weight: 99-99.9 parts of water, multi-effect Thickener is 0.1-1.0 parts; the cross-linking liquid containing breaker is mixed according to the following parts by weight: water is 0-99.9 parts, cross-linking agent is 0.1-100.0 parts and breaker is 0.001- 0.1 part. The water-based fracturing fluid formulated with this multi-effect thickener can meet the requirements of use without adding bactericides, clay stabilizers, surfactants, demulsifiers, and foaming agents. Under the condition that the performance indicators of the fracturing fluid are equivalent to those of the traditional fracturing fluid, the operation process is simplified, which is more conducive to improving the quality of the fluid, reducing the conditions required for monitoring, reducing construction procedures and time applications.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

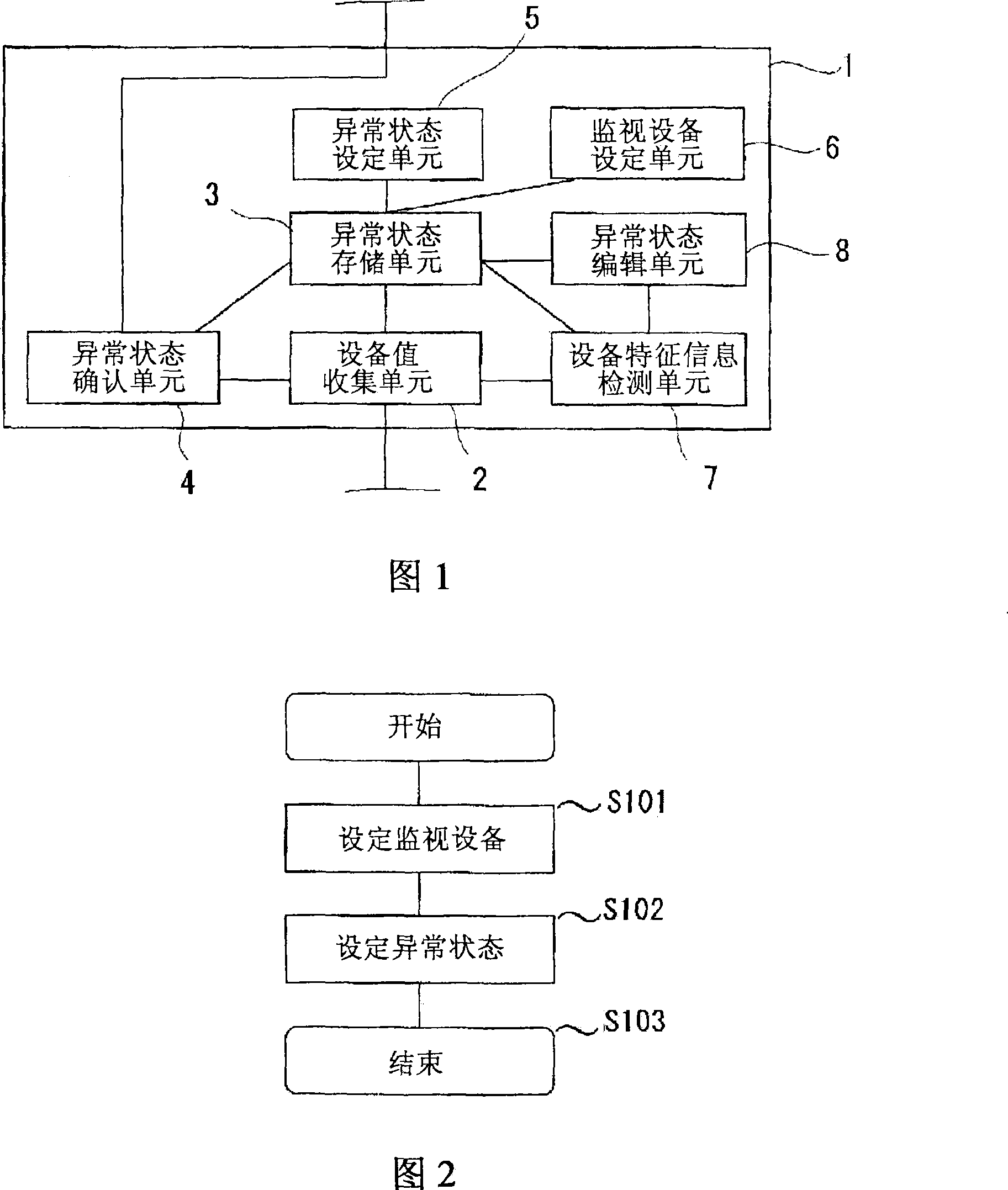

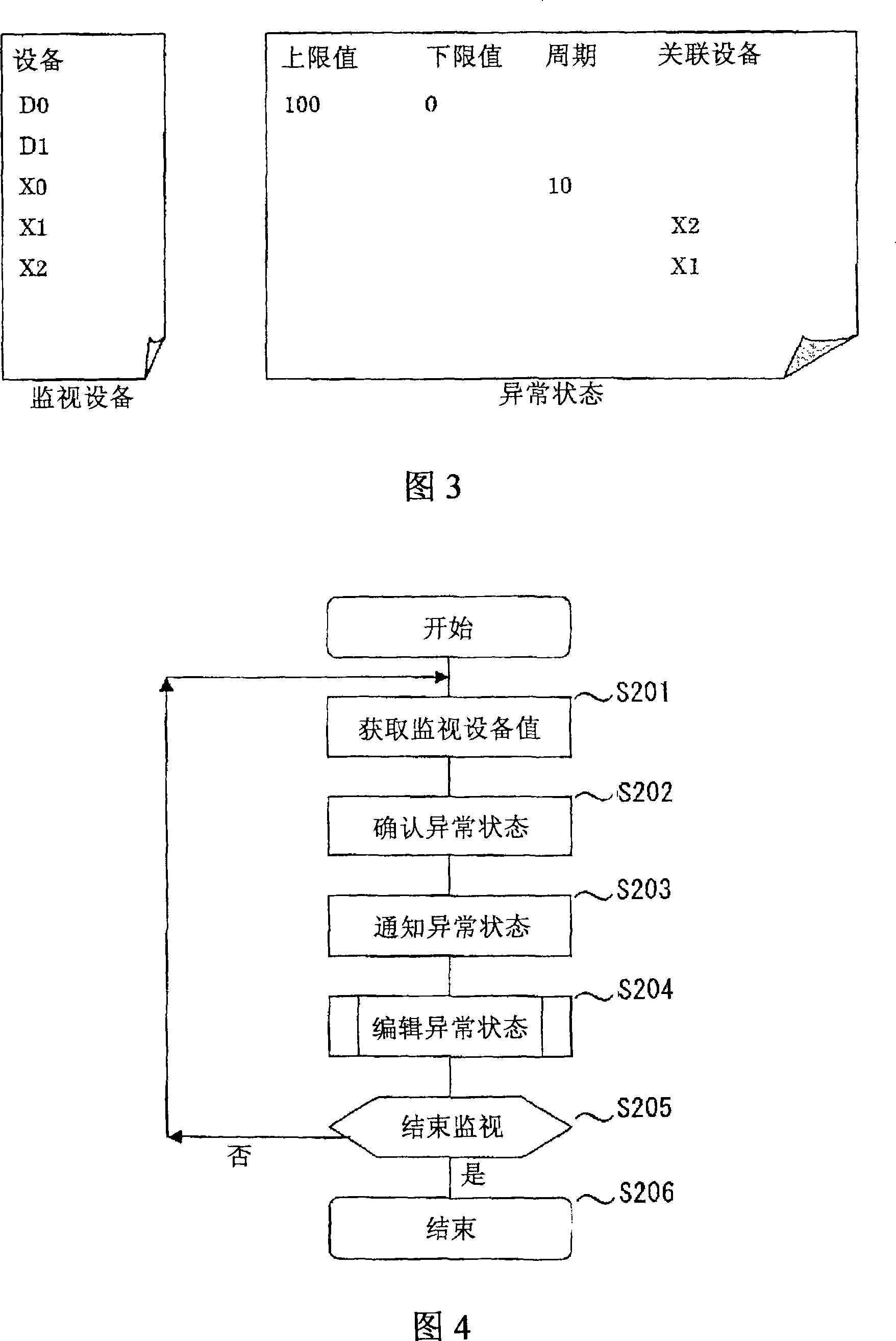

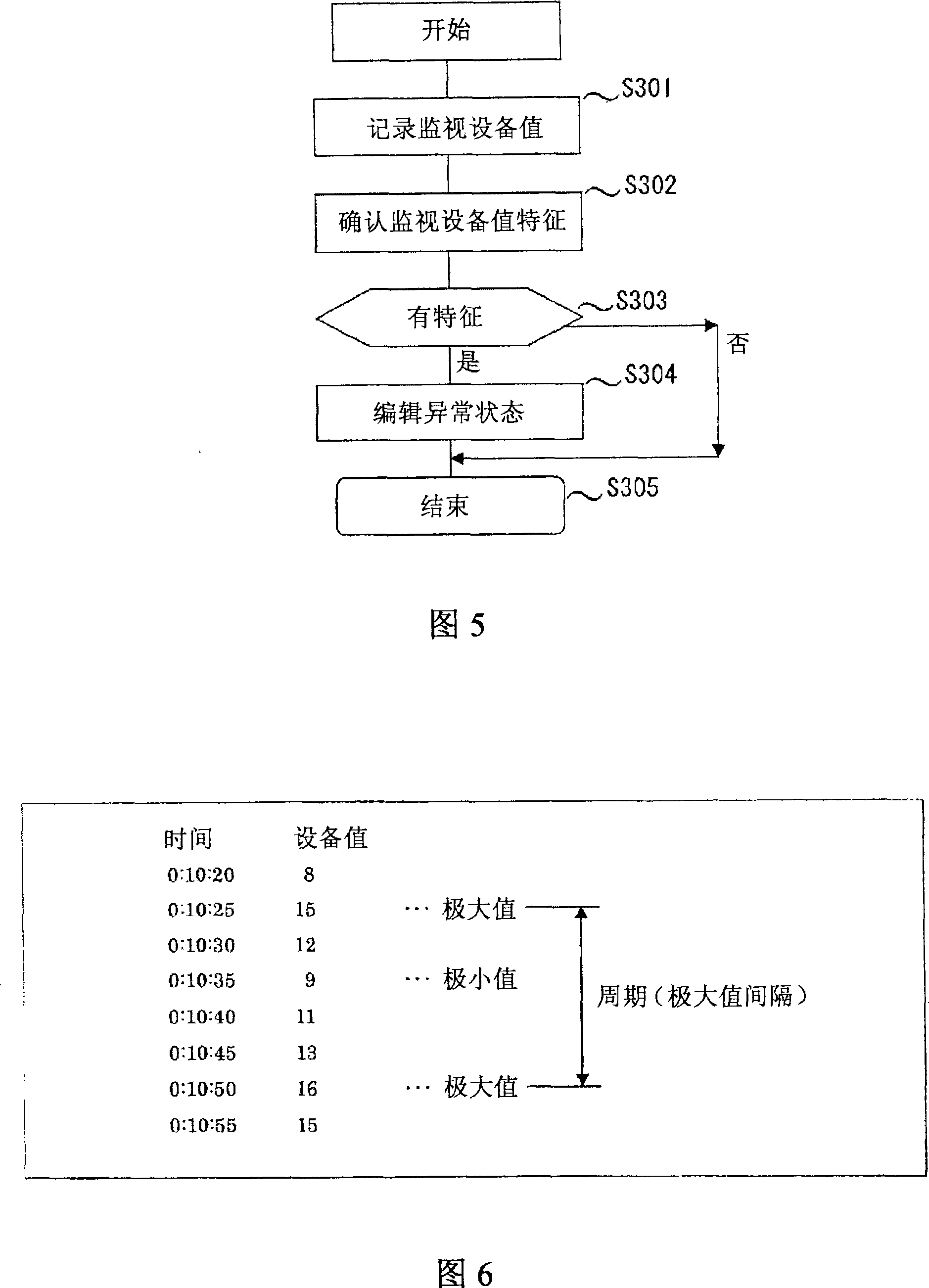

Data collection device and gateway device

InactiveCN101167026ALower the thresholdLower conditionsElectric testing/monitoringData miningSmall range

The invention aims at obtaining a data collection device and a gateway device capable of saving some work required for setting a threshold value and a condition for actual operation, reducing the case of setting an erroneous threshold value or condition, and setting a small range for a threshold value and a condition. The data collection device includes: device value collection means (2) for collecting device values from a plurality of devices; a device-to-be-monitored and abnormal state storage means (3) for storing a threshold value or a condition judging that the device-to-be-monitored has failed; abnormal state check means (4) for comparing device values of devices to the threshold value or condition judging that the device has failed and if so, outputting a corresponding message to a management device of the upper node; device characteristic information detection means (7) for detecting characteristic information from the device values collected by the device value collection means (2); and abnormal state edition means (8) for editing a threshold value or a condition which judges that the device-to-be-monitored has failed and is stored in the abnormal state storage means (3), by using the detected characteristic information.

Owner:MITSUBISHI ELECTRIC CORP

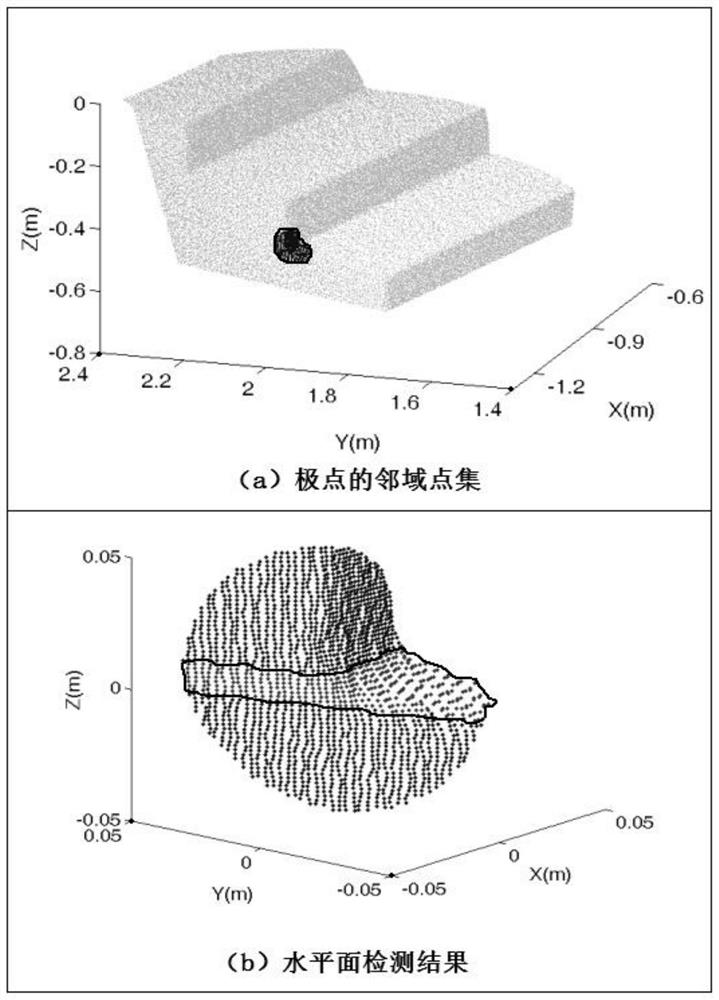

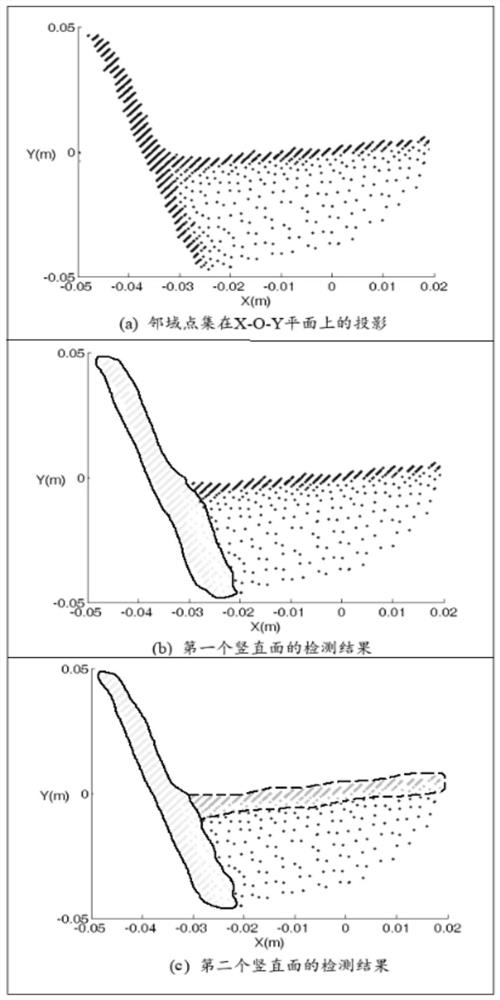

Indoor three-dimensional point cloud automatic registration method for pole extraction

PendingCN113052881AEasy to set upSolve the accuracy problemImage enhancementImage analysisPoint cloudComputer graphics (images)

According to an indoor three-dimensional point cloud automatic registration method for pole extraction, on the premise of avoiding network construction and normal direction estimation of point cloud data, automatic registration of multi-station ground laser scanning point cloud data in an indoor scene of a building is achieved, and the method mainly comprises two parts of pole extraction and point cloud registration. The method is analyzed and verified by using real indoor point cloud data of a building, registration parameter calculation is performed on multiple groups of point cloud data, a registration result is compared with a result calculated through a manual target selection mode, and the precision and reliability of the method are further verified. According to the point cloud automatic registration method based on pole extraction provided by the invention, the reliability and the precision meet the working requirements, the target does not need to be manually arranged, the parameter setting is simple, and the automation degree is high.

Owner:王程

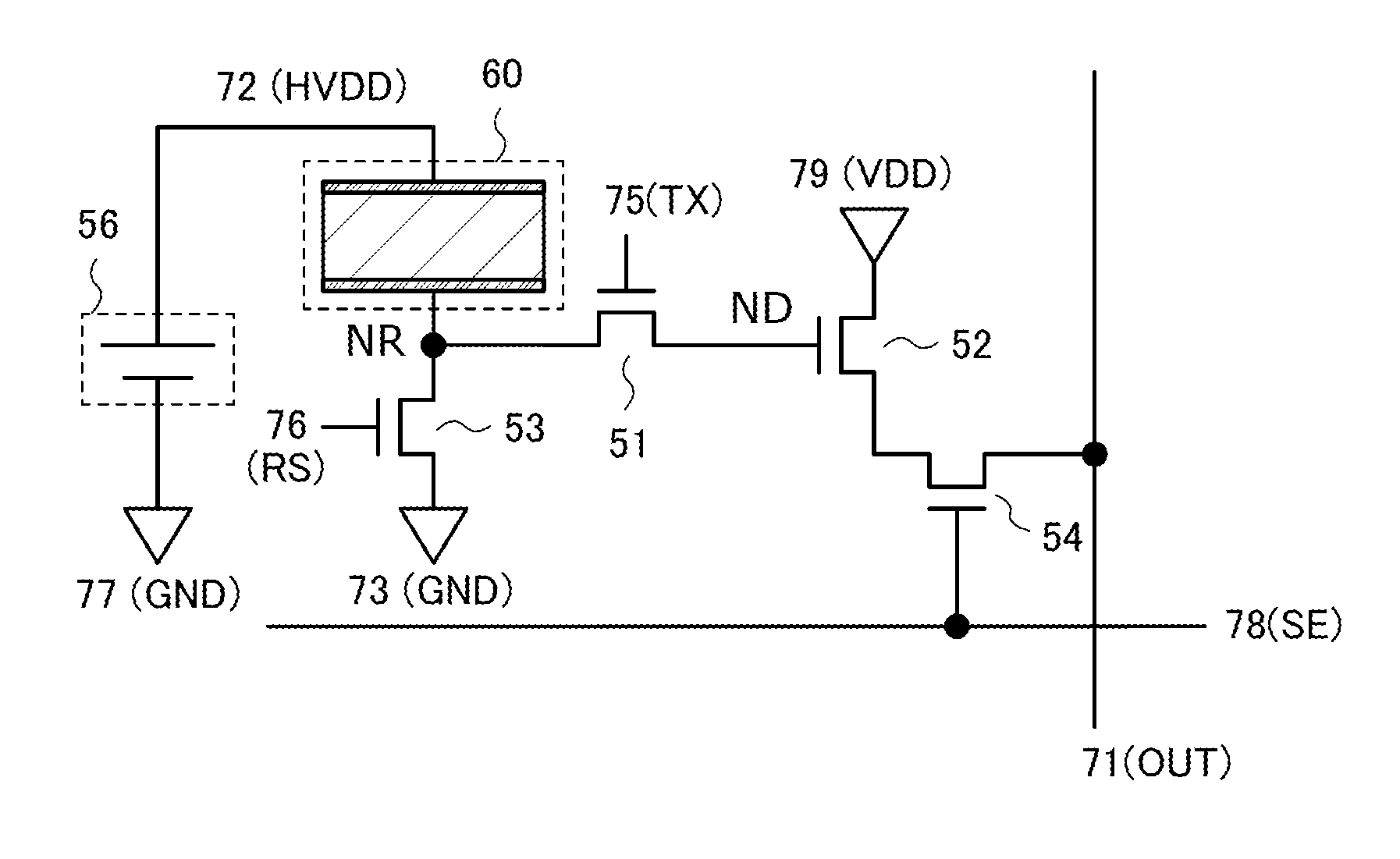

Imaging device and electronic device

InactiveUS20160225808A1Easily performsSuitable for high-speed operationTransistorSolid-state devicesElectricityPhotoelectric conversion

A highly sensitive imaging device that can perform imaging even under a low illuminance condition is provided. One electrode of a photoelectric conversion element is electrically connected to one of a source electrode and a drain electrode of a first transistor and one of a source electrode and a drain electrode of a third transistor. The other of the source electrode and the drain electrode of the first transistor is electrically connected to a gate electrode of the second transistor. The other electrode of the photoelectric conversion element is electrically connected to a first wiring. A gate electrode of the first transistor is electrically connected to a second wiring. When a potential supplied to the first wiring is HVDD, the highest value of a potential supplied to the second wiring is lower than HVDD.

Owner:SEMICON ENERGY LAB CO LTD

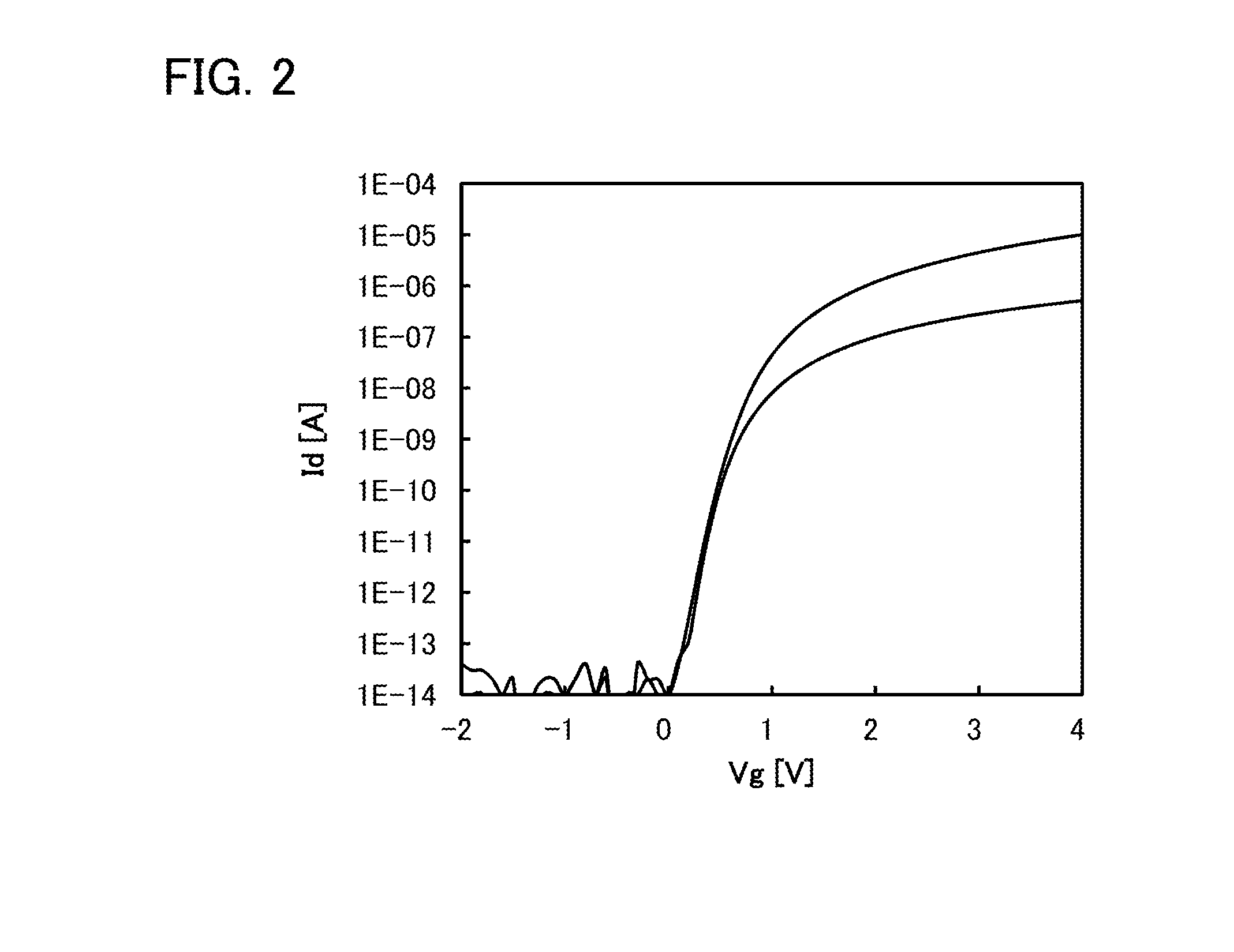

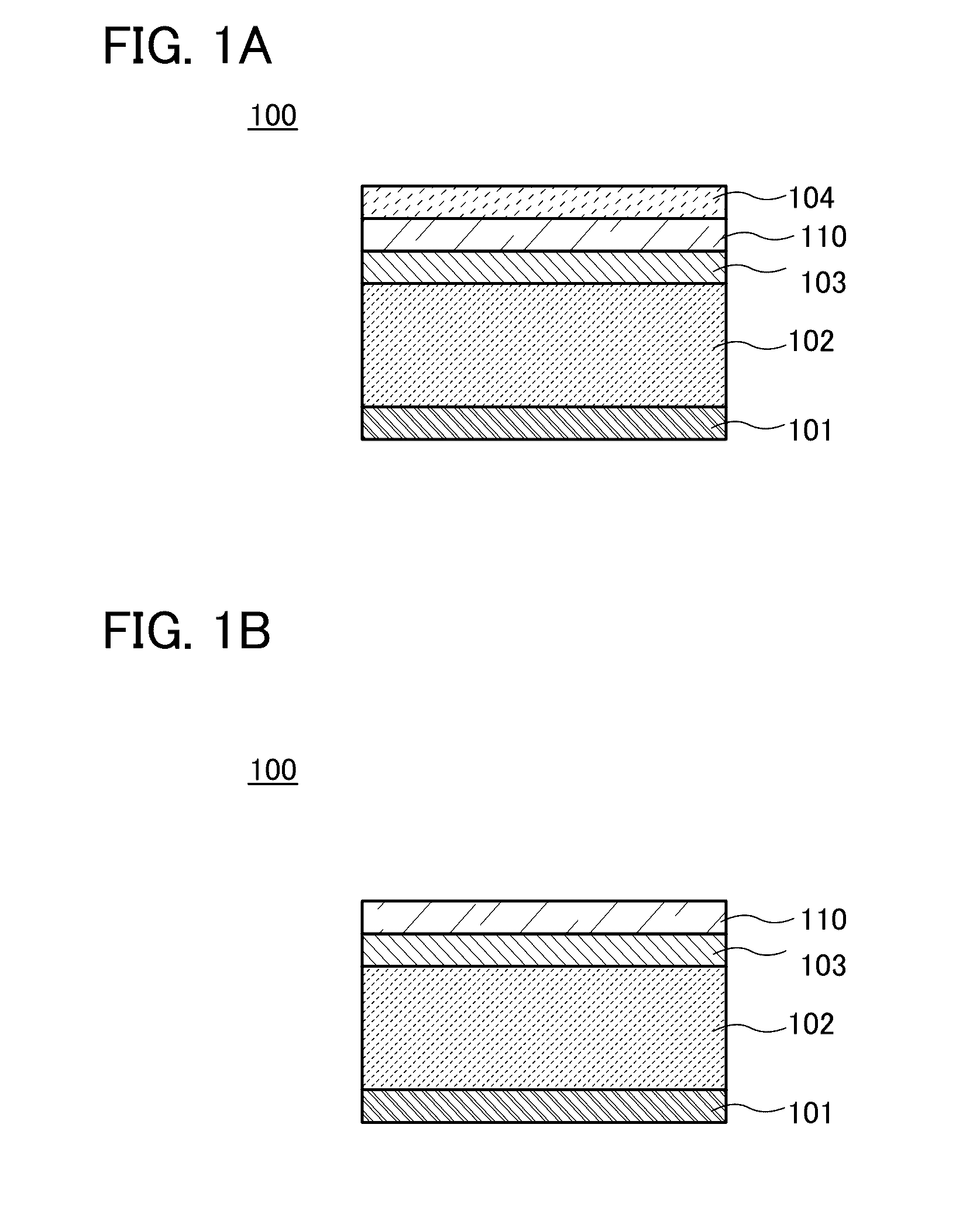

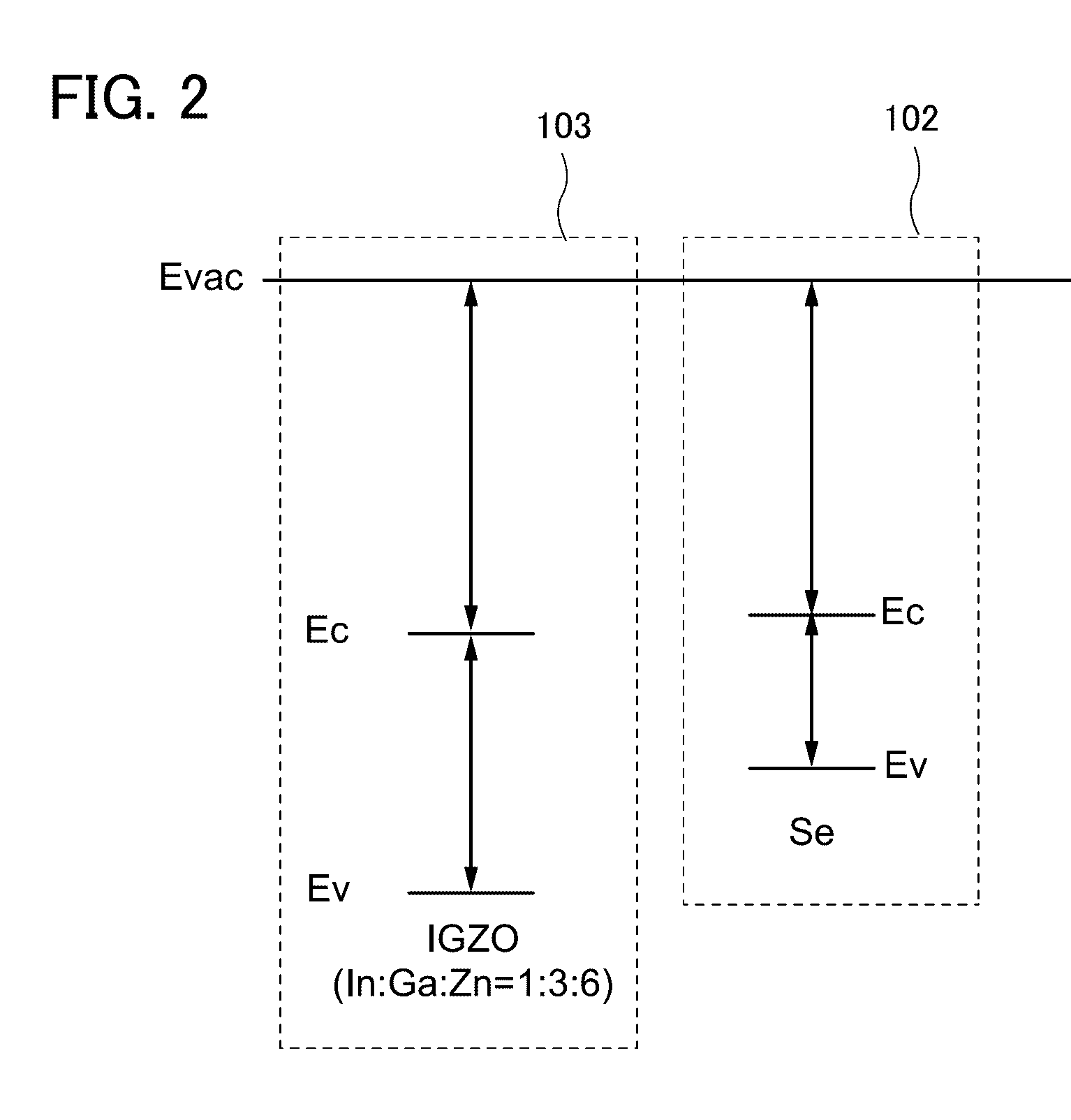

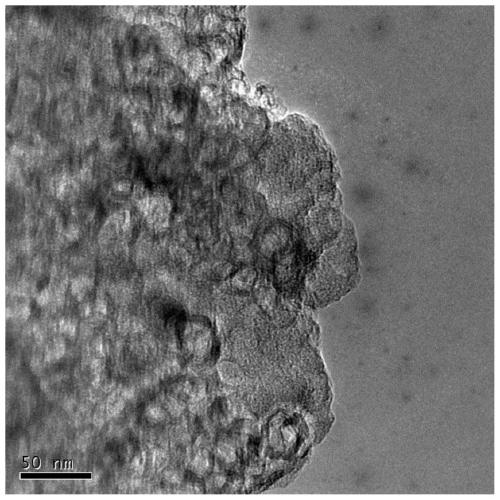

Photoelectric conversion element and imaging device

ActiveUS20170005126A1Improve imaging effectEasily performsTransistorSolid-state devicesNoble gasEngineering

An imaging device with excellent imaging performance is provided. An imaging device that easily performs imaging under a low illuminance condition is provided. A low power consumption imaging device is provided. An imaging device with small variations in characteristics between its pixels is provided. A highly integrated imaging device is provided. A photoelectric conversion element includes a first electrode, and a first layer, a second layer, and a third layer. The first layer is provided between the first electrode and the third layer. The second layer is provided between the first layer and the third layer. The first layer contains selenium. The second layer contains a metal oxide. The third layer contains a metal oxide and also contains at least one of a rare gas atom, phosphorus, and boron. The selenium may be crystalline selenium. The second layer may be a layer of an In—Ga—Zn oxide including c-axis-aligned crystals.

Owner:SEMICON ENERGY LAB CO LTD

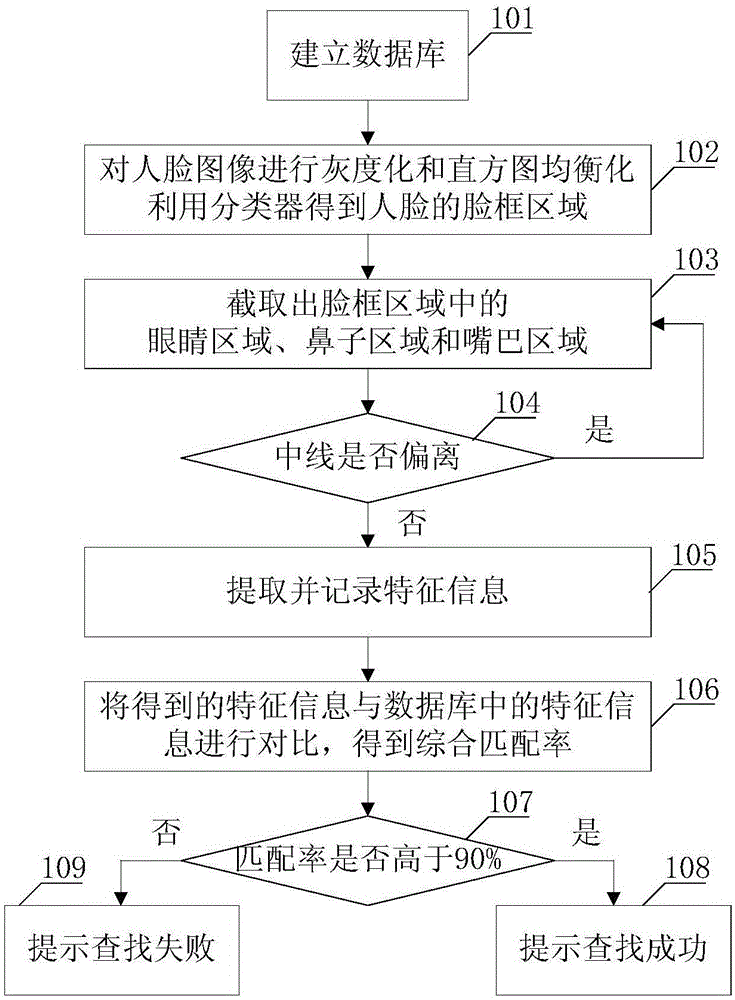

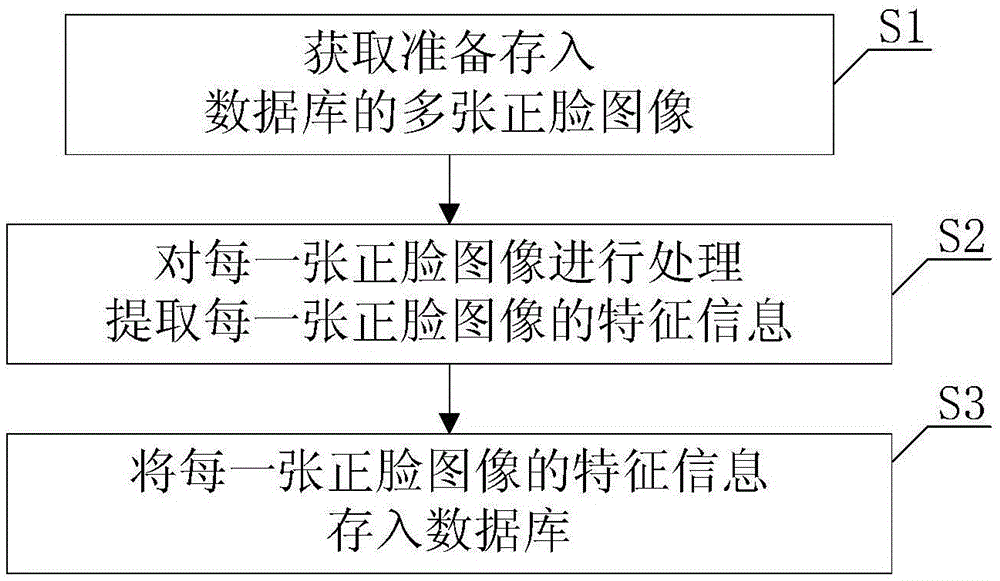

Hidden Markov model based face geometrical feature identification method

InactiveCN105160331AReduce rigidityLower conditionsCharacter and pattern recognitionHide markov modelHistogram equalization

The invention discloses a hidden Markov model based face geometrical feature identification method. The method comprises: performing graying and histogram equalization on a face image and obtaining a face frame region of a face by utilizing a classifier; setting a shrinkage coefficient of the face frame region, shrinking the face frame region, and intercepting an eye region, a nose region and a mouth region in the face frame region by utilizing the classifier; extracting and recording feature information; and comparing the obtained feature information with feature information stored in a database, to obtain the comprehensive matching rate. Comparative matching is performed by utilizing length and angle ratios of parts of the face, so that the influence caused by non-rigid and illumination conditions of the face is greatly reduced, the influence caused by change of the length and angle ratios of the parts of the face along with change of age and weight of people is avoided, and the accuracy and scientificity of matching are ensured.

Owner:镇江锐捷信息科技有限公司

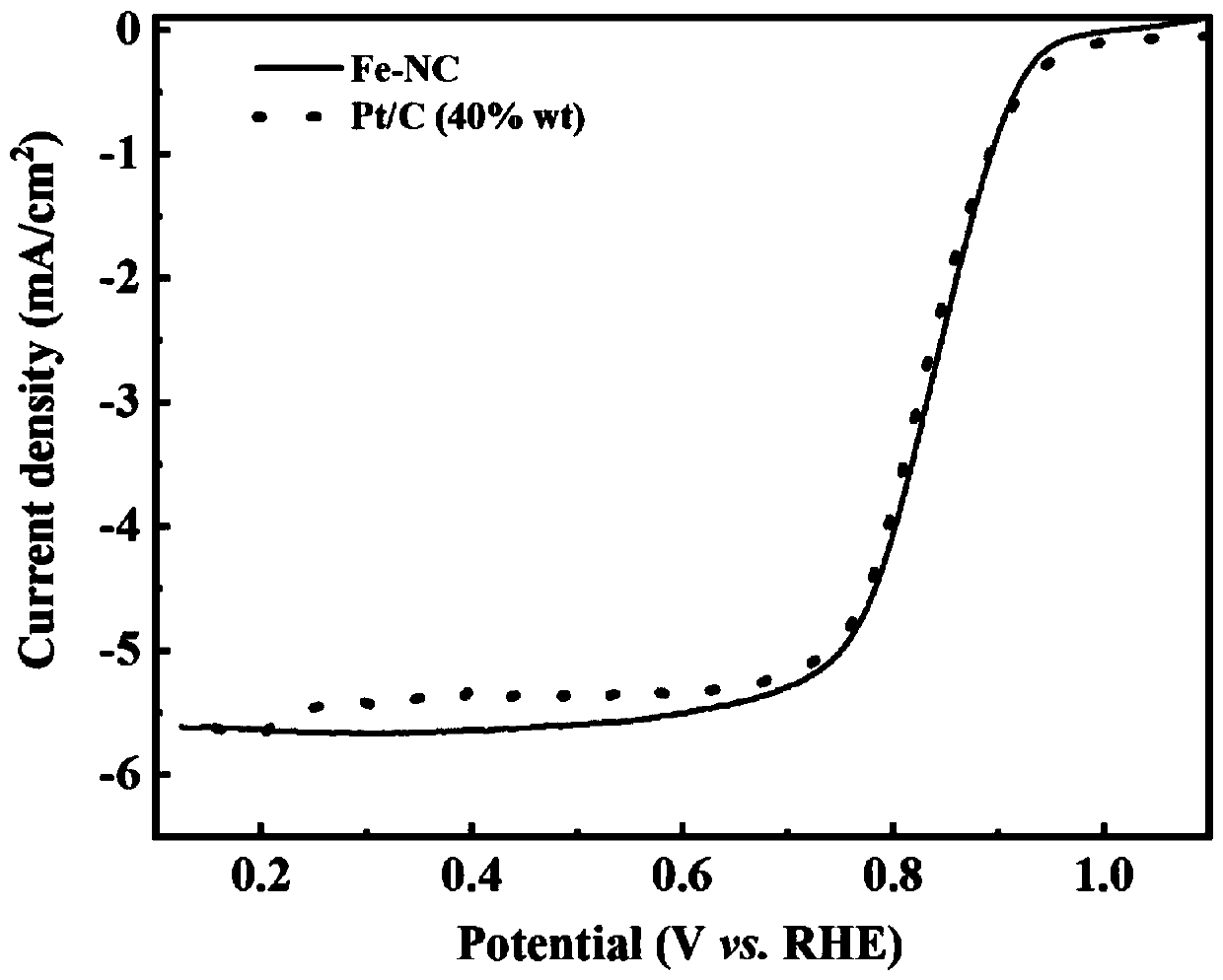

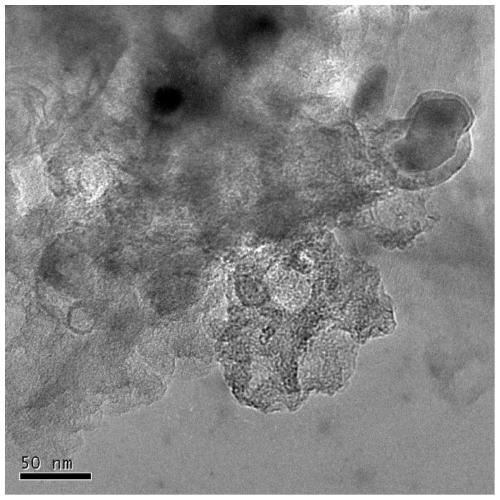

Catalyst for fuel cell and preparation method thereof

The invention discloses a catalyst for a fuel cell and a preparation method of the catalyst. The catalyst is a nitrogen-hybridized carbon-based catalytic material containing one or more metals. The catalyst is an M-NC single-metal nitrogen-carbon catalyst, a double-metal nitrogen-carbon catalyst or a multi-metal nitrogen-carbon catalyst, wherein M is one or more of metal elements. The catalyst isof a large-volume pore structure, has excellent gas and electron conductivity, high graphitization degree and nitrogen content, large specific surface area, multiple active sites, uniform distribution, high activity and strong stability, has the advantages of high catalytic activity, long service life and low comprehensive cost, and can be used for proton exchange membrane fuel cells and direct alcohol fuel cells. In addition, the preparation method is simple in process, controllable in operation, mild in condition, environmentally friendly and high in universality, no solvent is used in the synthesis process, various raw materials are subjected to a solid-phase thermal reaction to directly form a precursor and then are carbonized, the raw material cost is low, and the utilization rate ishigh.

Owner:CHINA-SINGAPORE INT JOINT RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com