Data collection device and gateway device

A technology of data collection and collection unit, applied in the direction of instruments, electrical testing/monitoring, control/regulation systems, etc., it can solve the problems such as troublesome calculation and setting of thresholds, time-consuming device debugging, and inability to use actual operation, etc., to reduce the thresholds or condition hassle, reduce time, reduce the effect of setting wrong thresholds or conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

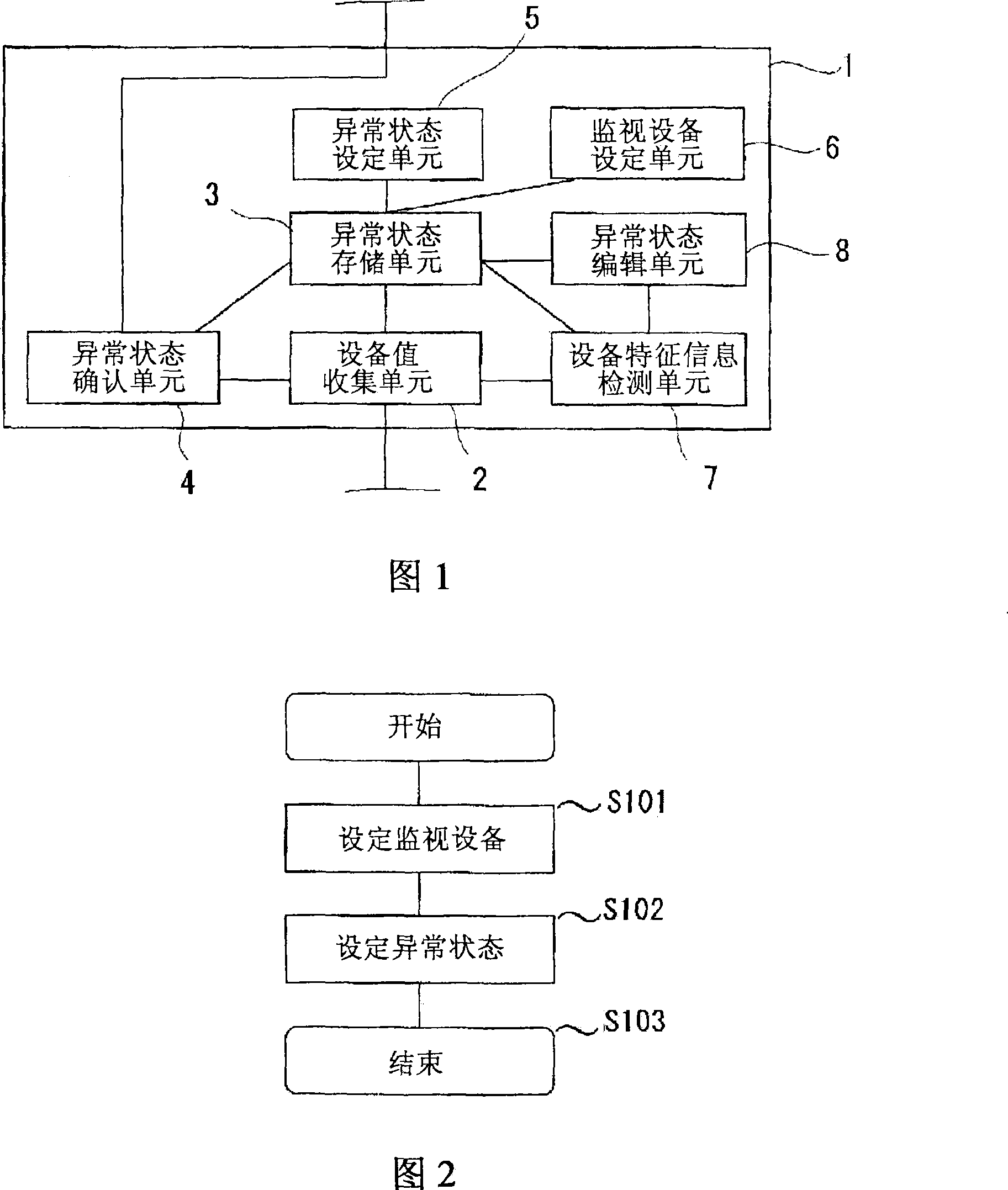

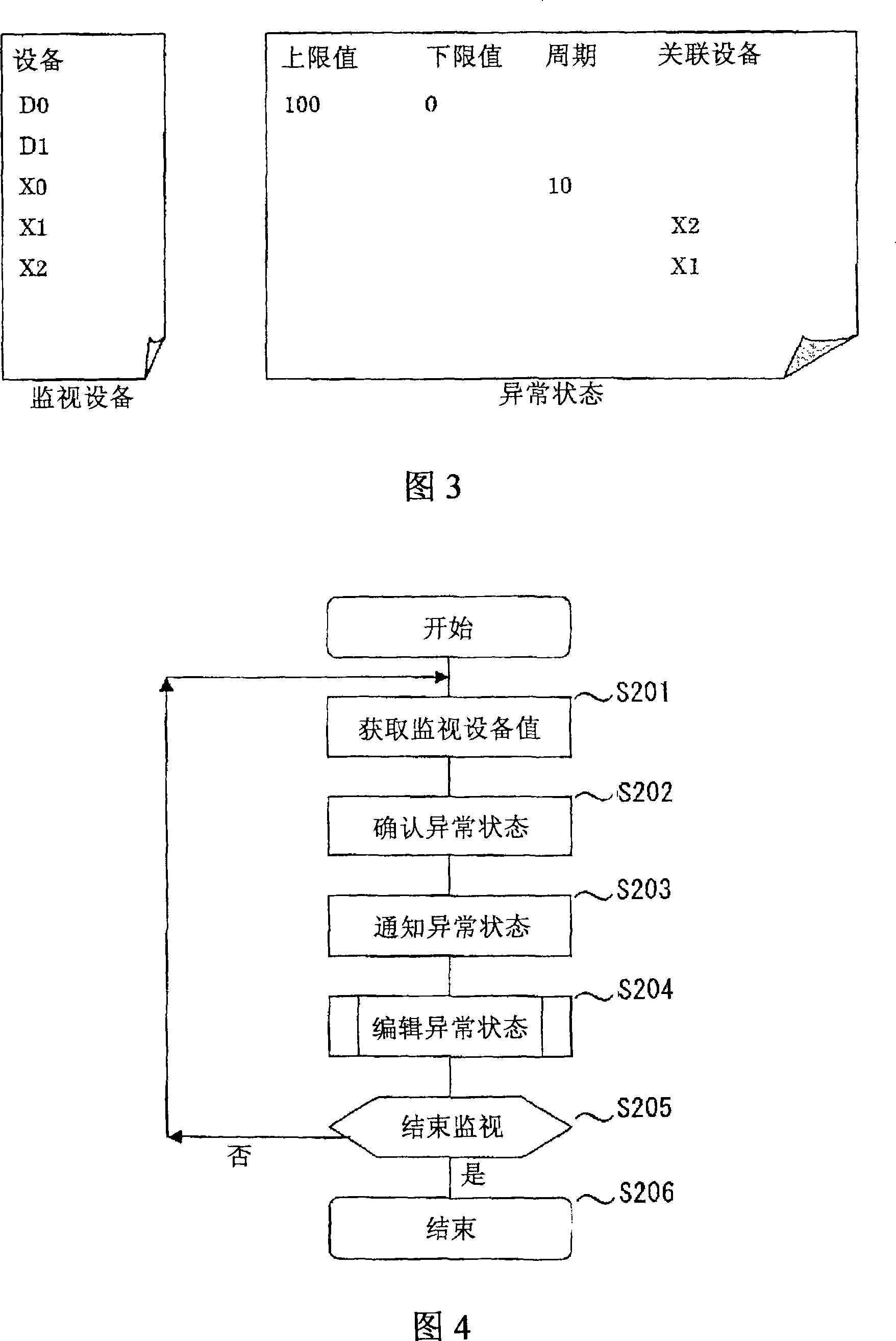

[0029] FIG. 1 is a structural diagram of a data collection device according to Embodiment 1 of the present invention.

[0030] The data collection device 1 in FIG. 1 collects data on equipment values of, for example, a programmable logic controller (hereinafter referred to as PLC) as a monitored device, and monitors the equipment values. Specifically, the data collection device 1 reads and records equipment values, monitors changes in the equipment values, and transmits the abnormality to a management device such as a higher-level computer when an abnormality is detected.

[0031] Describe the structure.

[0032] The data collection device 1 is connected to a control network such as LAN, and the device value collection unit 2 in the data collection device 1 collects device values of PLCs connected to the network.

[0033] The equipment value collection unit 2 is communicably connected with the following units: an abnormal state storage unit 3, which stores thresholds or c...

Embodiment 2

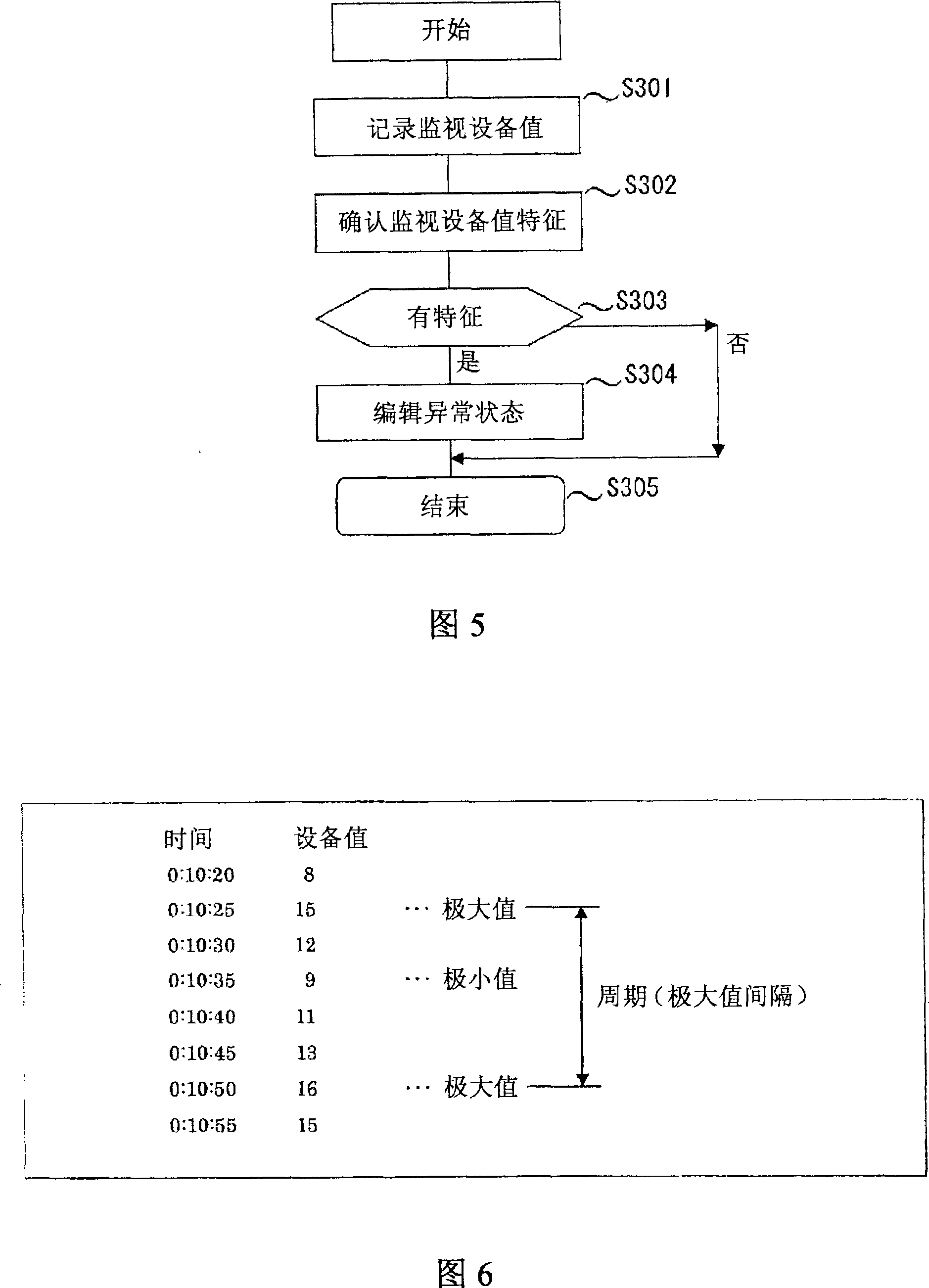

[0060] In Embodiment 1, there is no particular description of the threshold value or condition set by the abnormal state editing unit 8 changing with time, but in Embodiment 2, the threshold value or condition set for the abnormal state editing unit 8 is time Functions are explained. In addition, it is the same as Example 1 unless otherwise indicated.

[0061] The PLC or the like to be monitored is the device value of the monitoring device. For example, if the maximum value is not exceeded within a certain period of time, it is predicted that it may be normal that the maximum value is not exceeded. The longer the elapsed time, if it is still normal, it can be presumed that the maximum value will not be greatly exceeded. In other words, an abnormal state can be detected earlier by making the upper limit value gradually approach the maximum value as the threshold value for diagnosing abnormality as time passes.

[0062] Therefore, in order to detect the abnormal state earlier,...

Embodiment 3

[0071] In Example 3, another example of the case where the upper limit value shown in Example 2 is a function of time will be described. In addition, unless otherwise specified, it is the same as in Example 1.

[0072] In the formula (1) of Embodiment 2, since exponential calculation is required, calculation processing time of a computer such as exponential calculation increases. Furthermore, as the data collection device 1 for monitoring PLCs and the like, not only the calculation processing capacity is designed to be the minimum required, but also the collection of device values is given priority, so the calculation processing time is further increased. Therefore, the time required for editing the abnormal state may be increased, and the timing of the next abnormal state monitoring may be delayed.

[0073] Therefore, in the third embodiment, the new upper limit value is set using the expression (2) so that the new upper limit value is a linear function of time t.

[0074...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com