Patents

Literature

98results about How to "Eliminate the purification process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

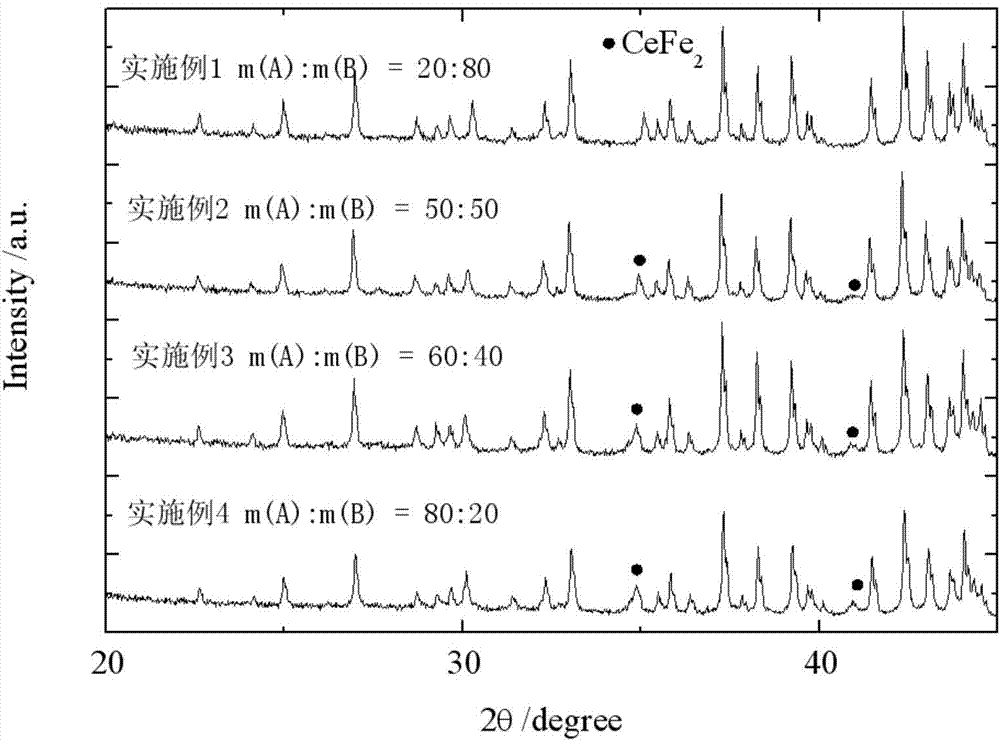

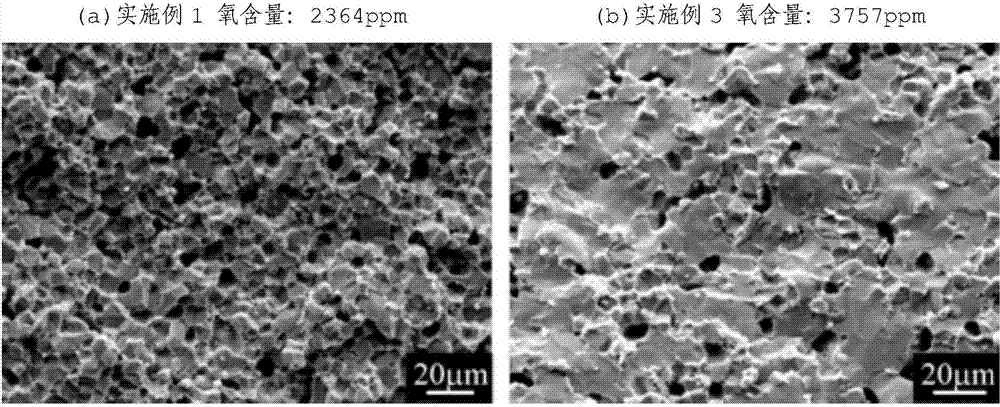

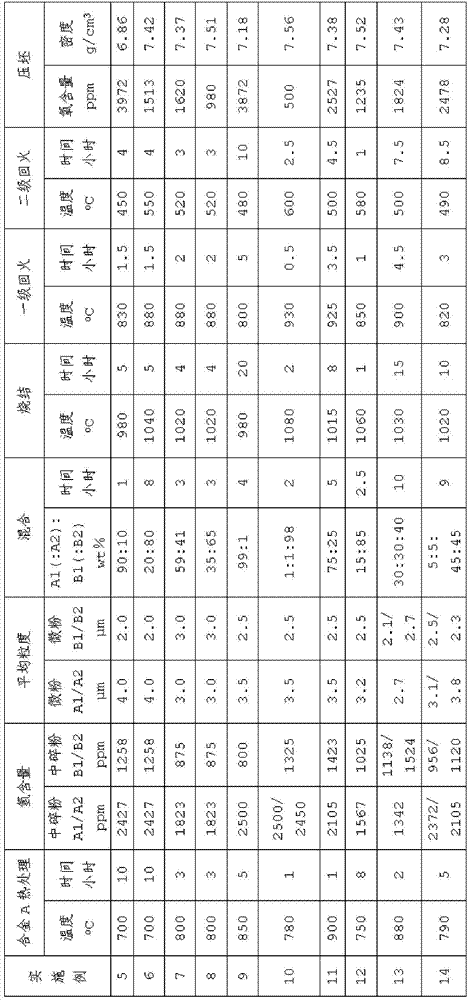

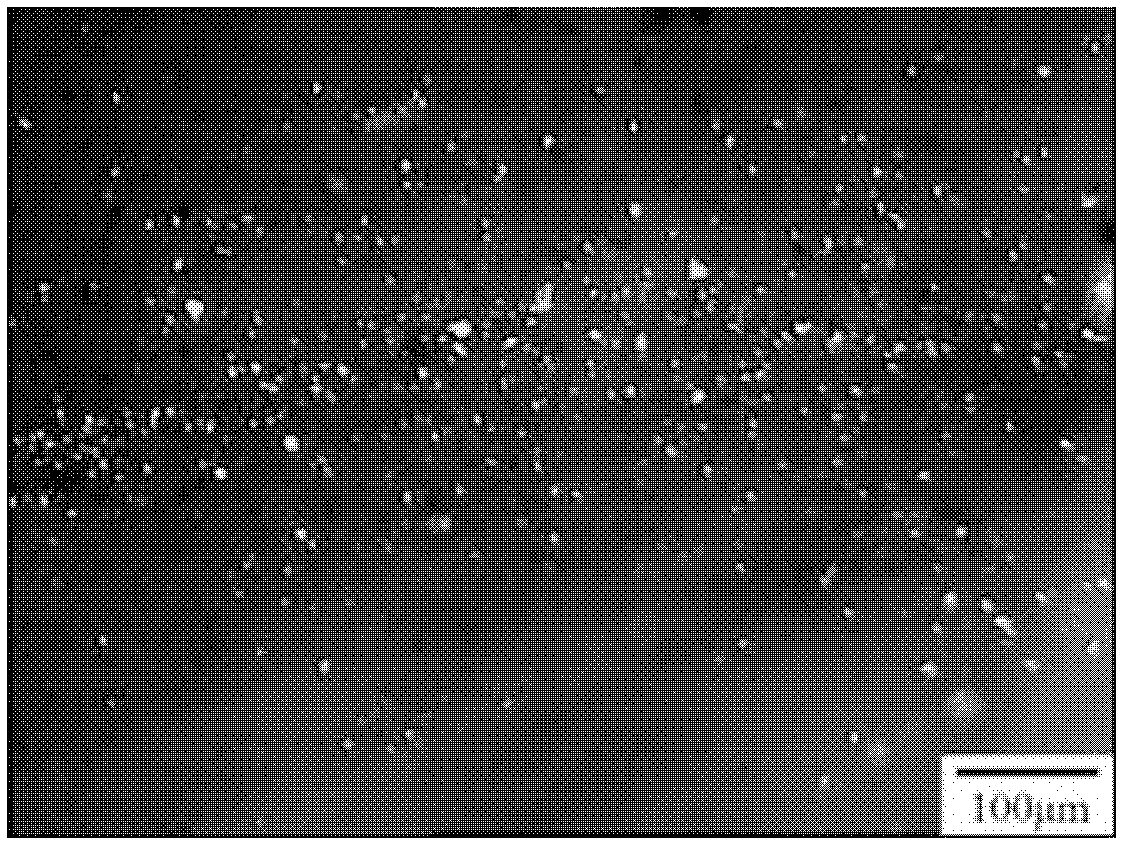

Mixed rare earth sintering permanent magnet and preparation method thereof

ActiveCN104715876AImprove coercive forceReduce extractionPermanent magnetsInductances/transformers/magnets manufactureSintered magnetsRare earth

The present invention provides a mixed rare earth sintered permanent magnet and preparation method thereof. The preparation method of the mixed rare earth sintered permanent magnet prepares the sintered permanent magnet by more than two kinds of alloys. The preparation method of the mixed rare earth sintered permanent magnet of the present invention may produce a sintered magnet with a magnetic energy product such as 2-45 MGOe and optional performance by adjusting proportions of each alloy according to need. A stable main phase of R2Fe14B can be formed by multi-alloy process. Because the permanent magnet is prepared directly by the mixed rare earth, steps of extraction, separation and purification for preparing a single rare earth can be partly saved on one hand, the cost is greatly saved and the environment is protected; the comprehensive utilization of the rare earth resource can be maximized on the other hand.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Process for synthesizing propylene glycol ether

ActiveCN1944365AEasy to separateEliminate the purification processEther preparation from oxiranesEpoxyAlcohol

The present invention discloses process of synthesizing propylene glycol ether. Alcohol, propylene and hydrogen peroxide in the molar ratio of (1-60) to (0.5-10) to 1 are set inside a reactor with catalyst, propylene and hydrogen peroxide produce epoxidation reaction to produce epoxy propane, and the produced epoxy propane and alcohol produce etherification reaction to produce propylene glycol ether. The reaction conditions include reaction temperature of 0-200 deg.c, reaction pressure of 0.5-8.5 MPa, and space velocity of liquid hydrogen peroxide and alcohol of 0.1-65 / hr. The present invention has simple process, environment friendship and propylene glycol ether selectivity up to 90 %.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD +1

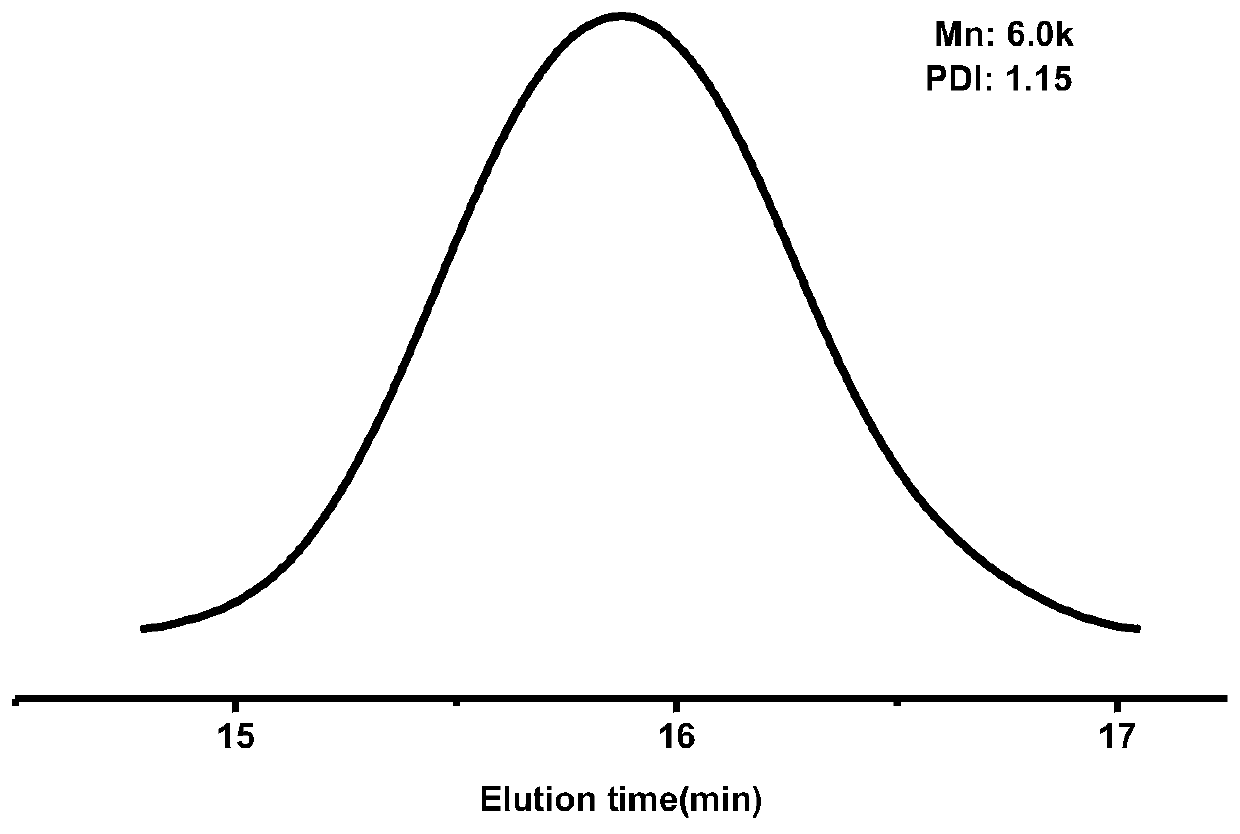

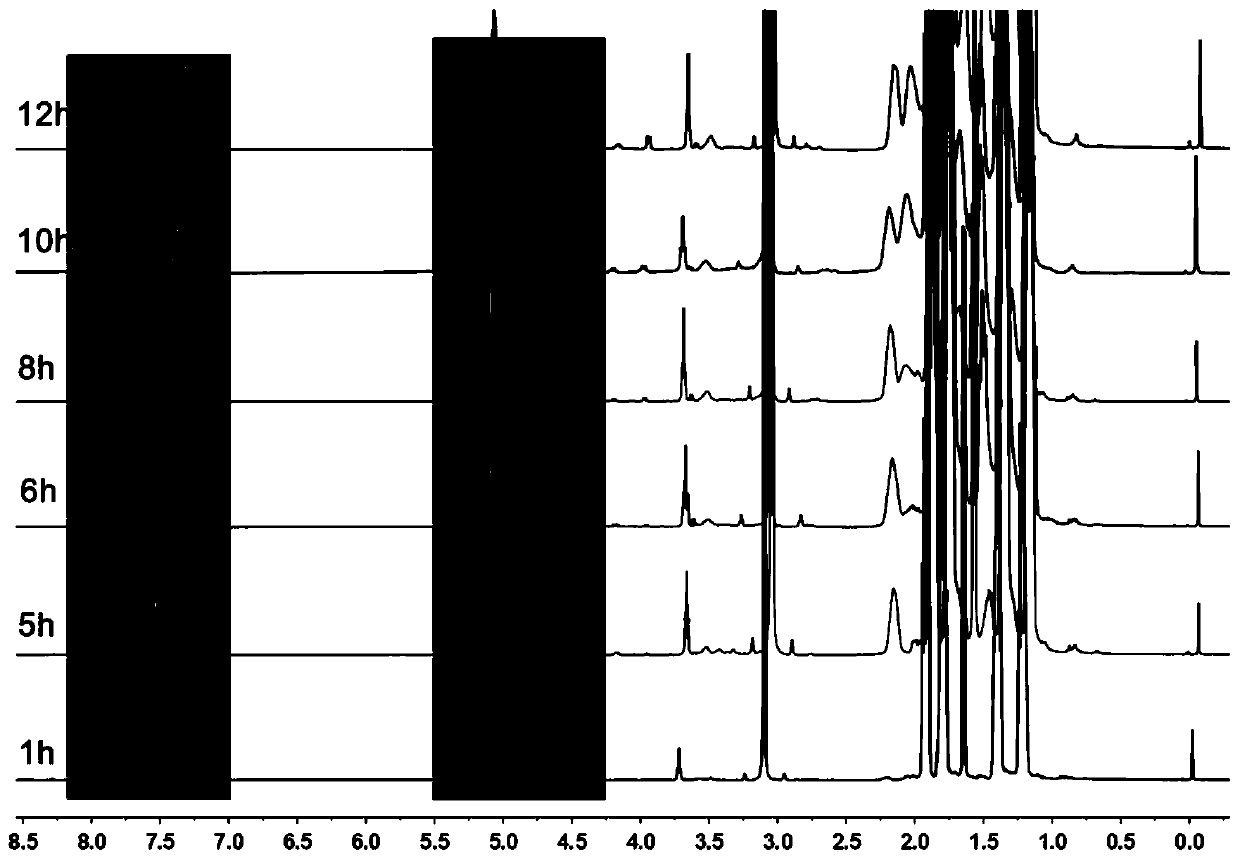

Segmented copolymer with fully-saturated soft segment and crystallizable hard segment and preparation method of segmented copolymer

ActiveCN103122052AEliminate the purification processSave drynessPolymer scienceCationic polymerization

The invention relates to a segmented copolymer with a fully-saturated soft segment and a crystallizable hard segment and a preparation method of the segmented copolymer. A segmented copolymer with a fully-saturated polyisobutene segment as the soft segment and a crystallizable polystyrene or polyalkyl substituted styrene segment as the hard segment is synthesized by combining cationic polymerization of isobutene with cationic steric polymerization of styrene or alkyl substituted styrene cations, wherein as the hard segment has the crystallizability, physical crosslinking points are more stable, not only is a self-enhancement role achieved, but also the softening temperature of the segmented copolymer is effectively improved, and the melting point ranges from 150 DEG C to 210 DEG C; and according to the segmented copolymer, the use temperature is improved by 50-110 DEG C, and the heat resistance, the material size stability and the physical and mechanical properties are also improved.

Owner:BEIJING UNIV OF CHEM TECH

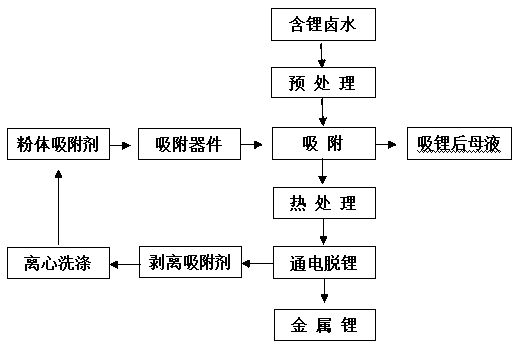

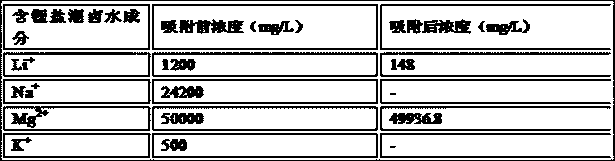

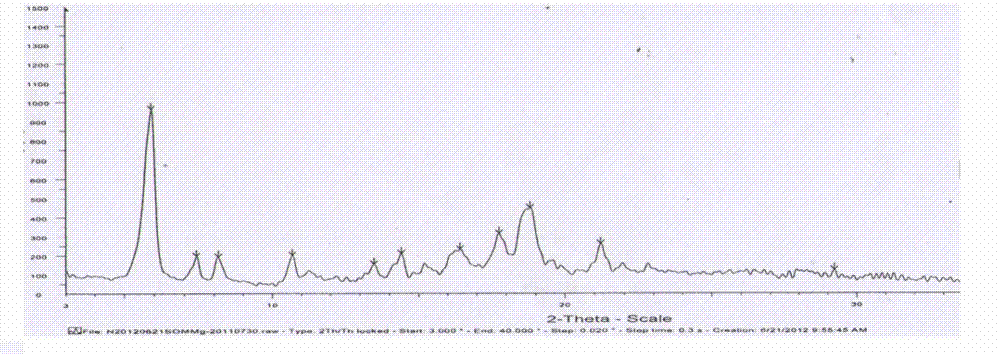

Method for extracting lithium from lithium-containing brine

ActiveCN105506310ARepeated enrichmentEliminate the purification processPhotography auxillary processesProcess efficiency improvementHigh magnesiumPhysical chemistry

The invention discloses a method for extracting lithium from lithium-containing brine. The method comprises the steps that a host material with lithium-insertion activity is used for adsorbing lithium ions in the lithium-containing brine, and according to the lithium ion battery charging principle, lithium is separated out from a cathode of an electrolytic tank under the specific voltage range so as to extract lithium from the lithium-containing brine. By means of the method, a high-purity-grade lithium product can be directly manufactured through the lithium-containing brine, and thus the international competitiveness of domestic lithium products is improved. The extracting method is suitable for purification of lithium in seawater lithium brine, underground lithium brine, salt lake lithium brine and other lithium-containing brine with different components, and the lithium extracting effect of the method is obviously superior to that of traditional technologies for high magnesium-lithium-ratio lithium-containing brine difficult to separate. In addition, the method is short in process, and the main consumable item, namely, the adsorbent of the host material with lithium-insertion activity can be used in a regeneration cycle mode, so that article losses are reduced, and cost is lower.

Owner:李震祺 +1

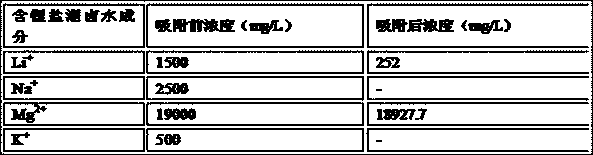

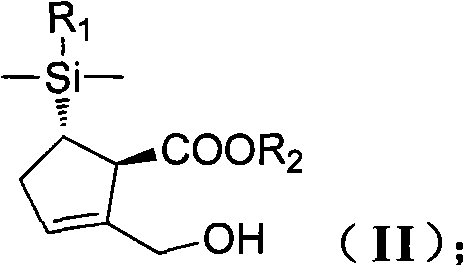

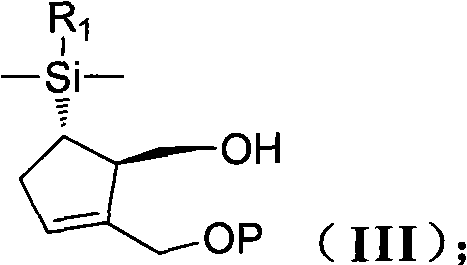

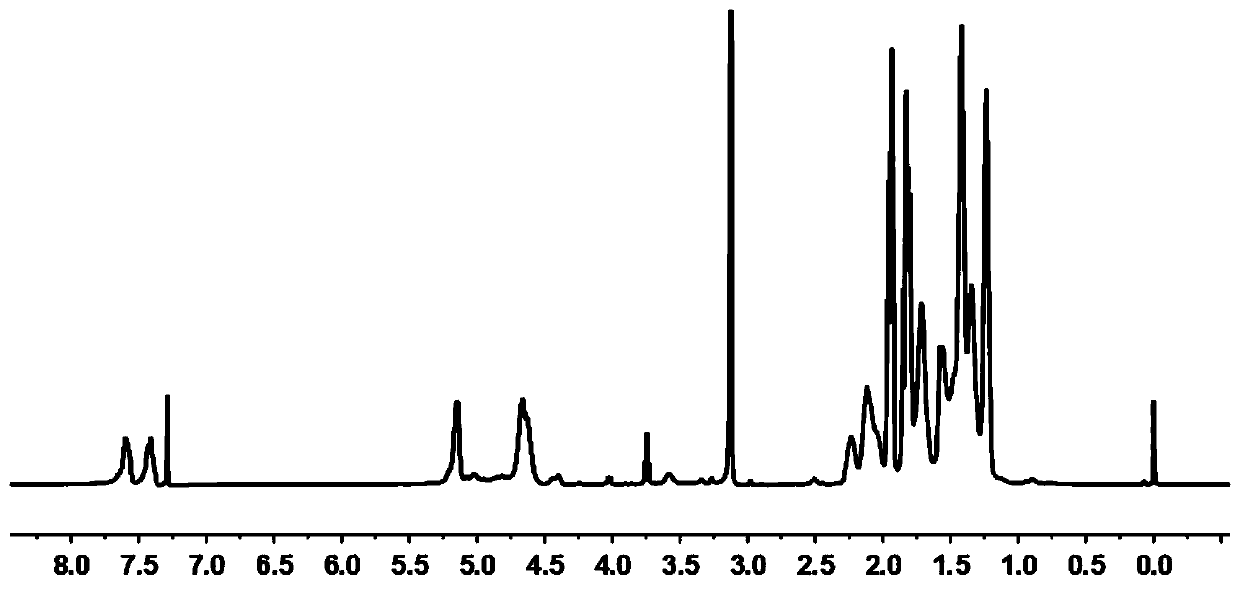

New synthesis process of antiviral drug entecavir

ActiveCN101891741AHigh purityEliminate the purification processOrganic chemistryBulk chemical productionAntiviral drugCombinatorial chemistry

The invention discloses a method for preparing a compound shown as the formula (I), which is characterized by comprising the following steps of: (1) carrying out hydroxyl protection on a compound shown as the formula (II) by using a first hydroxyl protecting group, and then, reacting with hydride to generate a compound shown as the formula (III); (2) carrying out hydroxyl protection on the compound shown as the formula (III) by using a second hydroxyl protecting group, and then, removing the first hydroxyl protecting group to obtain a compound shown as the formula (IV); (3) enabling the compound shown as the formula (IV) to carry out non-corresponding selective epoxidation reaction to generate a compound shown as the formula (V); (4) reacting the compound shown as the formula (V) with thecompound shown as the formula (VI) in a polar aprotic solvent to obtain a compound shown as the formula (VII); and (5) carrying out condensation, desilylation and oxidization on the compound shown asthe formula (VII) to generate the compound shown as the formula (I). In the general formulas of the compounds in each step, R1 is selected from naphthyl or any substituted naphthyl; R2 is selected from alkyl or benzyl of C1-C4; P is selected from hydroxyl protecting groups, such as 2-methoxyl propyl or p-methoxyl benzyl and the like; P' is a hydroxyl protecting group capable of resisting and removing P, such as benzyl; and X is selected from Cl, Br, I or benzyloxyl.

Owner:聊城高新生物技术有限公司

Preparation method of carbon dioxide based block copolymer

The invention belongs to the technical field of polymer synthesis, and more particularly relates to a preparation method of a carbon dioxide-based biodegradable block copolymer. The carbon dioxide-based biodegradable block copolymer is prepared by using a cyclic anhydride monomer, a lactone monomer, an epoxy compound and carbon dioxide as monomers, using an organic Lewis acid and organic Lewis base mixture as a catalyst, and using a terminal hydroxyl compound as an initiator to initiate ring-opening copolymerization of the cyclic anhydride monomer, the lactone monomer, the epoxy compound and the carbon dioxide in one step. The preparation method can effectively utilize the carbon dioxide and convert the carbon dioxide into a practical polymer material. The obtained polymer has no metal residue, and the luster and performance of the polymer can be ensured. One-step feeding is adopted to avoid the problems of complicated steps and purification in the step-by-step synthesis of the block copolymer. Meanwhile, the carbon dioxide-based biodegradable block copolymer has high controllability in molecular weight and block length.

Owner:HUAZHONG UNIV OF SCI & TECH

Carboxyl-containing high-refractive-index hyperbranched polyesteramide and preparation method thereof, as well as application of carboxyl-containing high-refractive-index hyperbranched polyesteramide to plastic modification

The invention provides carboxyl-containing high-refractive-index hyperbranched polyesteramide and a preparation method thereof, as well as application of the carboxyl-containing high-refractive-index hyperbranched polyesteramide to plastic modification, and belongs to the field of hyperbranched polymers. The reaction period can be shortened, the production process can be simplified, the cost can be reduced, and industrial large-scale production can be met. The preparation method comprises the following steps: adding an aromatic polycarboxylic / multi-anhydride monomer and a single amino and single hydroxyl monomer into a reactor, adding a catalyst into the reactor, and performing prepolymerization reaction under the protection of inert gas at the temperature of 80 to 180 DEG C for 0.5 to 48 hours to form a polymeric monomer; and then heating to 120 to 250 DEG C, performing reaction for 0.5 to 120 hours to obtain the carboxyl-containing high-refractive-index hyperbranched polyesteramide. The preparation method provided by the invention can be applied to the industrial production process of the carboxyl-containing high-refractive-index hyperbranched polyesteramide; the prepared carboxyl-containing high-refractive-index hyperbranched polyesteramide can resist the temperature higher than 350 DEG C and is relatively high in refractive index; as an improving agent, the carboxyl-containing high-refractive-index hyperbranched polyesteramide is applied to a plastic system; the mechanical property can be improved without affecting the transparency of the plastic system.

Owner:WEIHAI CY DENDRIMER TECH

Method for producing cyclic adenosine monophosphate by using whole cell biocatalysis

ActiveCN101805770AIncrease chemical potentialConformational stabilityBacteriaMicroorganism based processesPhosphate ionBacterial strain

Owner:NANJING TECH UNIV

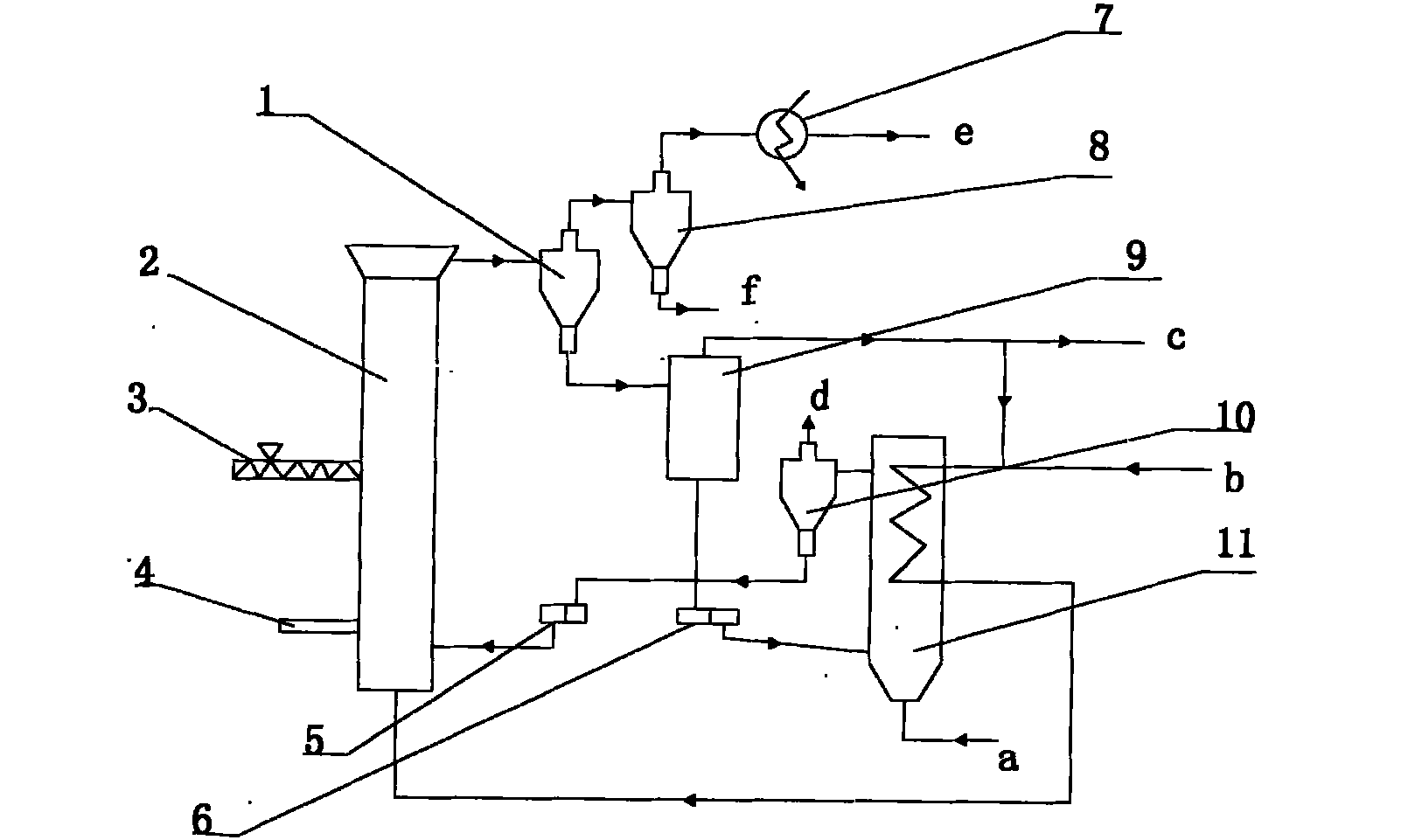

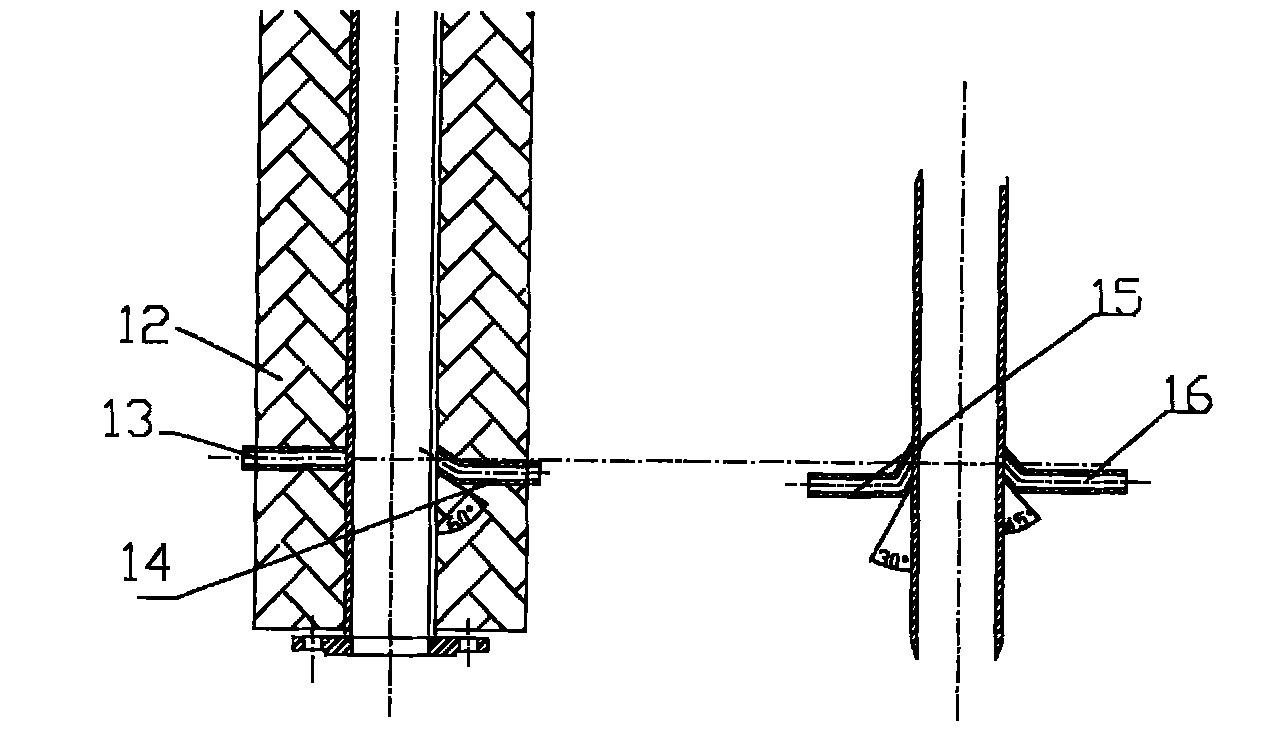

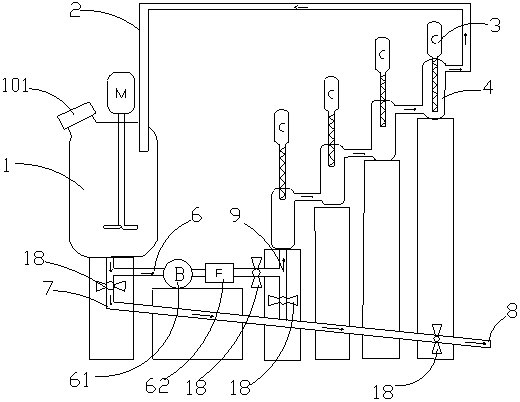

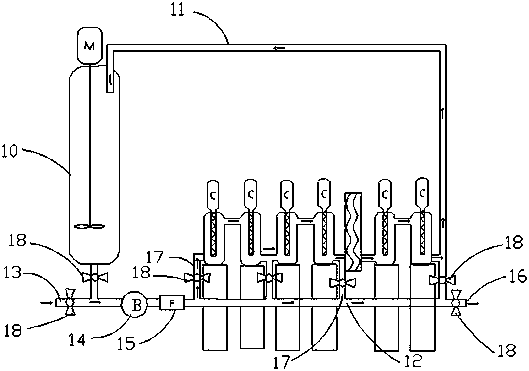

Method and device for preparing synthesis gas by coal particle/oxygen carrier chemical chain

ActiveCN101962575AEliminate the purification processImprove utilization efficiencyEnergy inputGranular/pulverulent flues gasificationSyngasCoal particle

The invention belongs to the technical field of clean and efficient utilization of coal and relates to a novel process and a device for producing synthesis gas by coal, in particular to a method and a device for preparing synthesis gas by a coal particle / oxygen carrier chemical chain. In the method, double chemical chain is used to prepare the synthesis gas, the oxygen carrier undergoes a reduction reaction with the coal particles in an oxygen carrier gasifier and an oxidation reaction with air in an air reactor, and the synthesis gas is prepared by the cycle reaction of the oxygen carrier; the purification of the synthesis gas and the collection of CO2 are completed by using a CaCO3 / CaO chemical chain; in the preparation of the synthesis gas by combined CaSO4 / CaCO3 oxygen chemical chain,the purification and CO2 collection by using the CaCO3 / CaO chemical chain are coupled in the preparation process of the synthesis gas by the oxygen carrier chemical chain; therefore, the preparation of the synthesis gas and the preparation of the two chemical chains for the purification of the synthesis gas and the CO2 collection are processed synchronously. The device has a simple structure and is based on a reliable principle; the energy utilization rate of the device is high; the gas prepared by the device has high quality; and the device causes little environmental pollution.

Owner:水煤浆气化及煤化工国家工程研究中心 +1

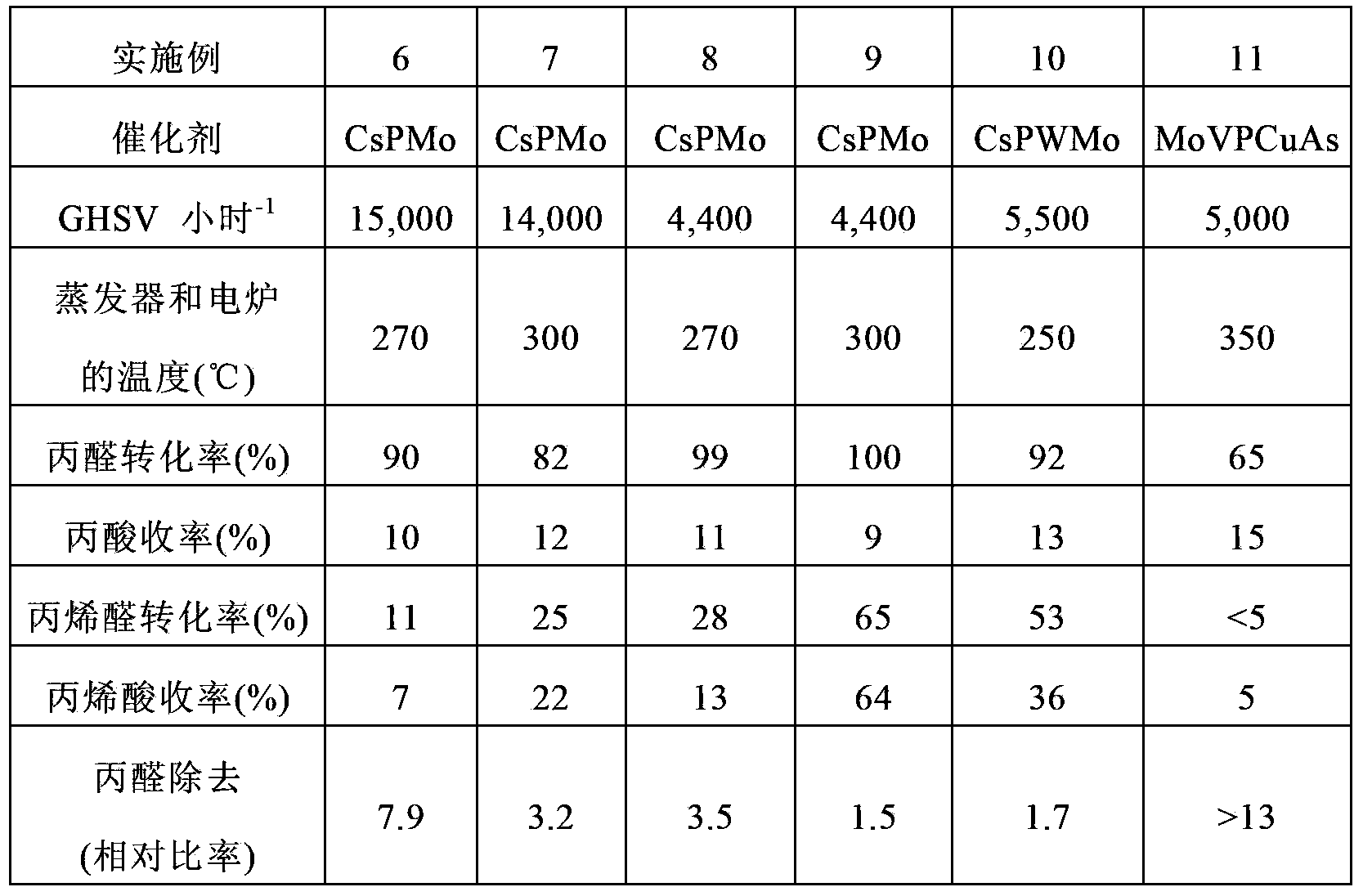

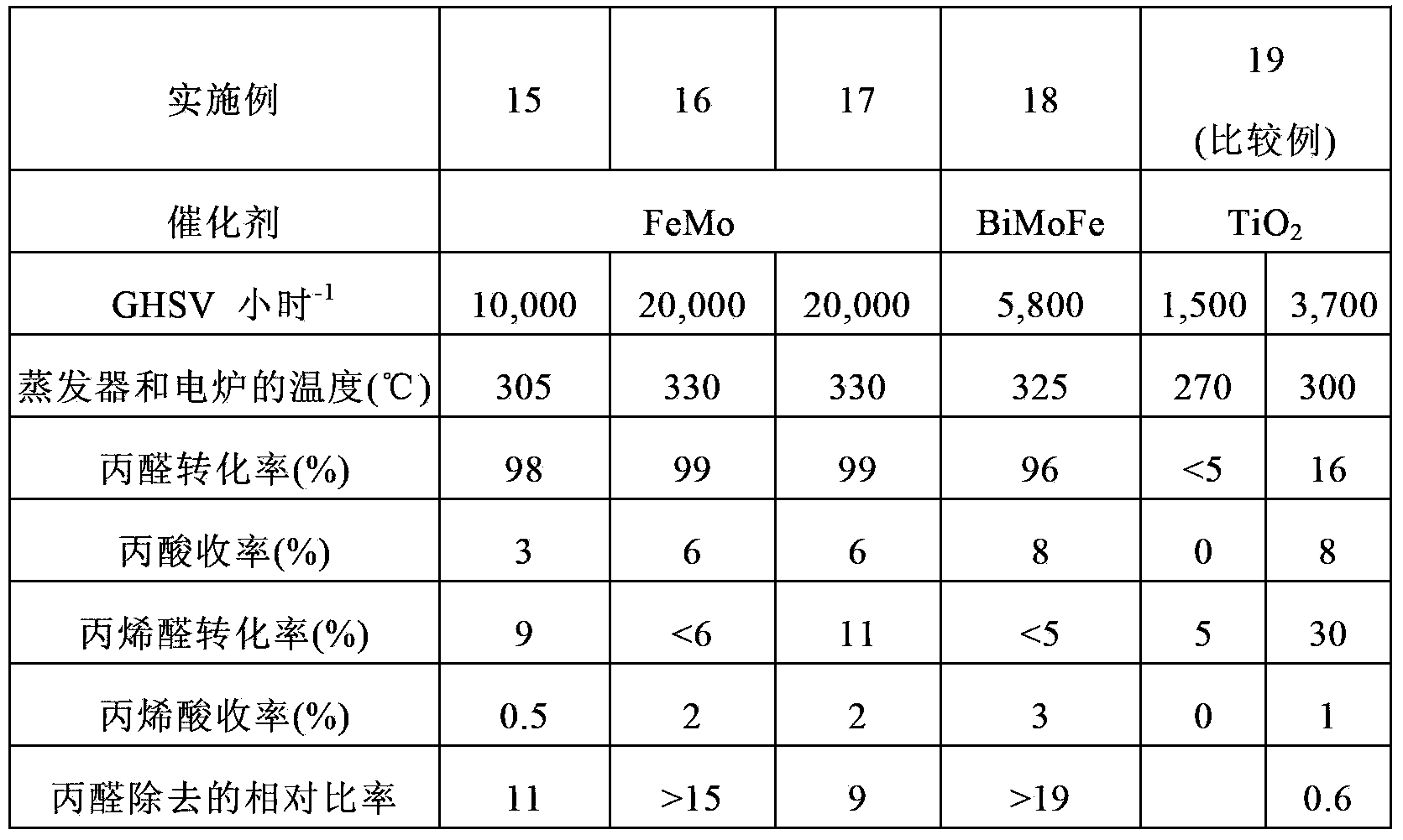

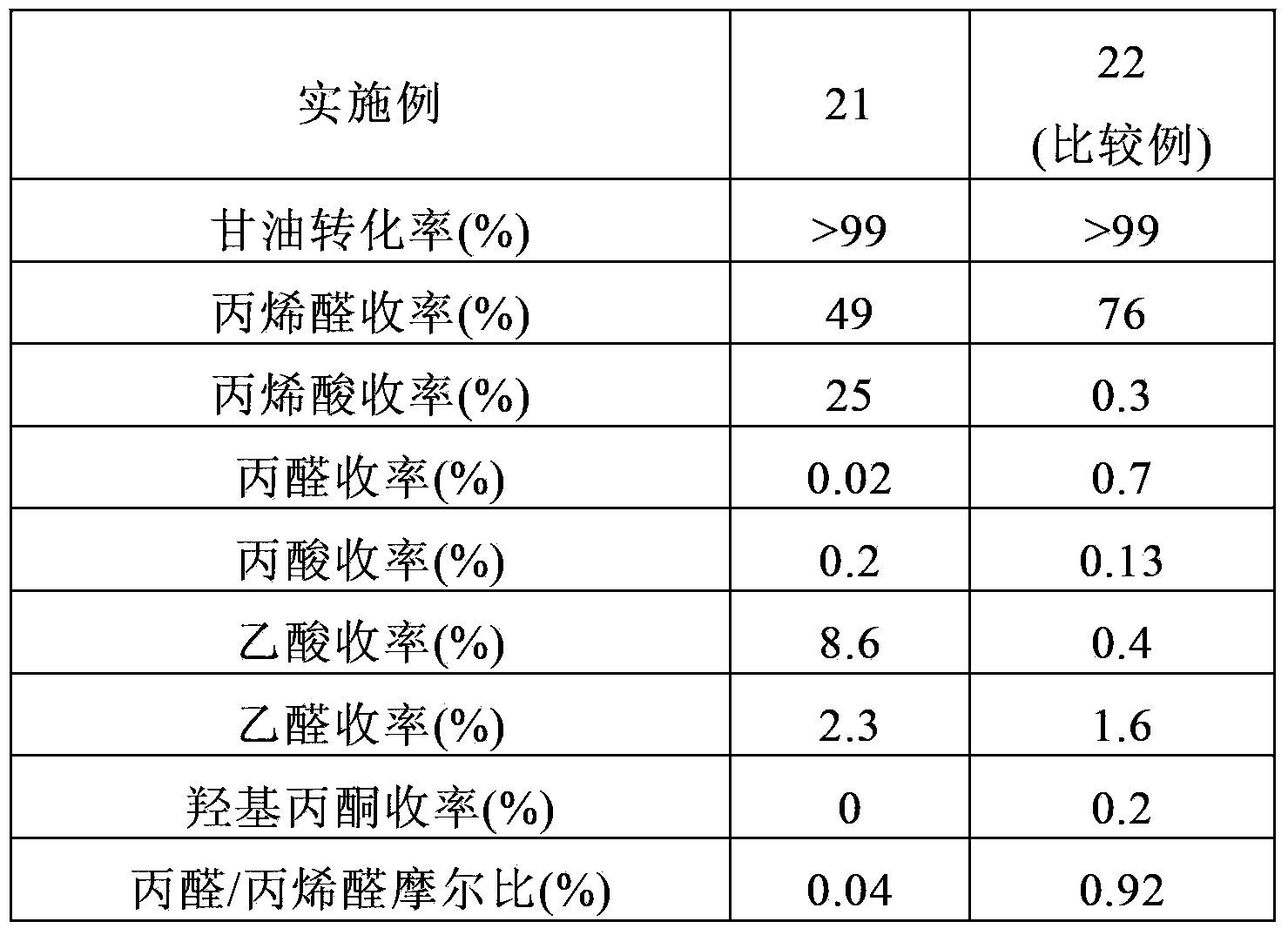

Catalyst for selectively reducing saturated aldehyde, and production method thereof

InactiveCN103648641AReduce propionaldehyde contentImprove qualityCarbonyl compound separation/purificationMetal/metal-oxides/metal-hydroxide catalystsPropanoic acidPtru catalyst

[Problem] To provide a novel catalyst for selectively reducing propionaldehyde from a starting-material acrolein in order to produce an acrolein and / or acrylic acid and / or acrylonitrile and / or methylmercaptopropionaldehyde that has a low-concentration of propionaldehyde and / or propionic acid and / or propionitrile. In particular, to provide a catalyst used to selectively reduce propionaldehyde-containing acrolein. [Solution] A catalyst used for selectively reducing propionaldehyde from propionaldehyde-containing acrolein, said catalyst including Mo as the essential component, and further containing at least one element selected from P, Si, W, Ti, Zr, V, Nb, Ta, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ga, In, Tl, Sn, Ag, As, Ge, B, Bi, La, Ba, Sb, Te, Ce, Pb, Mg, K, Rb, Cs and Al, and preferably from P, Si, W, Ti, Cr, Mn, Fe, Co, Ni, Zn, Sn, Bi, Sb, Ce, Mg, Cs and K.

Owner:NIPPON KAYAKU CO LTD

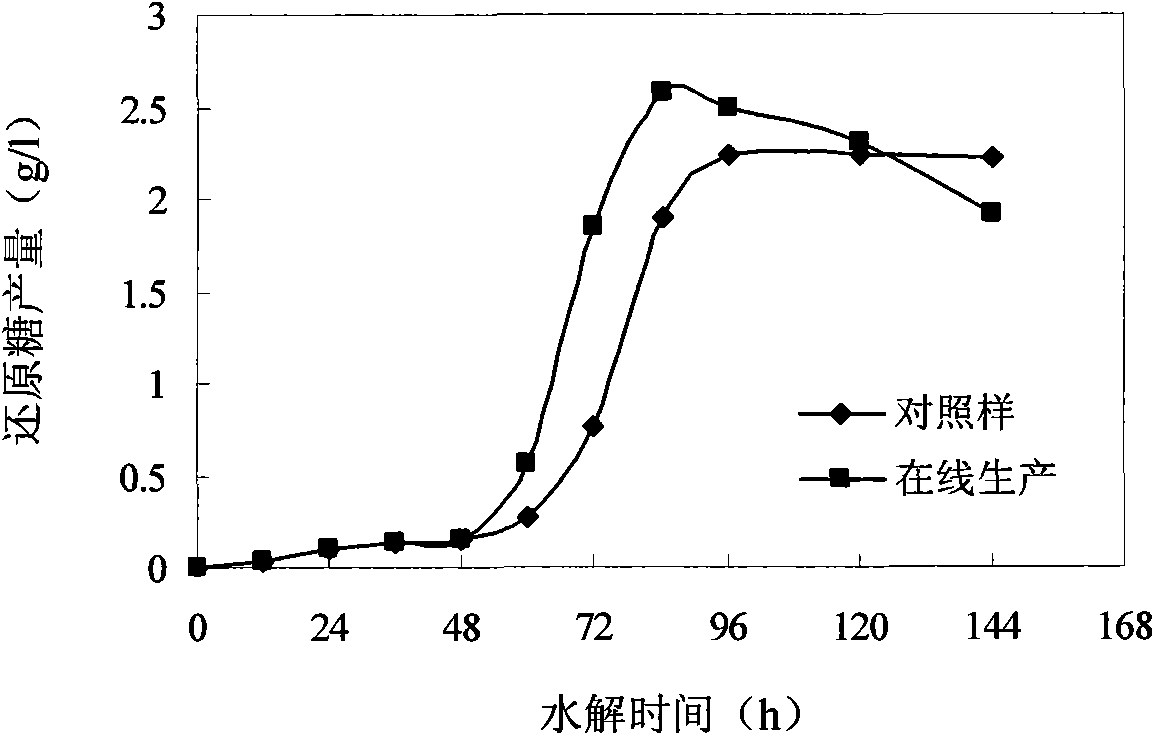

Online production method of rhamnolipid biosurfactant in cellulose hydrolyzation

InactiveCN101538604ARealize online production modeReduce manufacturing costMicroorganism based processesFermentationTrichoderma reeseiPseudomonas aeruginosa

The invention relates to an online production method of rhamnolipid biosurfactant in cellulose hydrolyzation, belonging to the field of biotechnology. Firstly, reaped straws are cleaned, cut and dried to constant weight, and then the cut straws are treated by alkali before cellulose hydrolyzation; secondly, the pretreated straws are cultured with Trichoderma reesei ZM4-F3 in a shaking table for hydrolyzation and sugar production for producing reducing sugar; thirdly, pseudomonas aeruginosa BSZ-07 during logarithmic phase obtained by culture is inoculated into a hydrolyzation system, thus realizing the online production of rhamnolipid biosurfactant and accelerating the hydrolyzation of cellulose. Owing to the addition method of the online production, the complex process of rhamnolipid purification can be saved, thus effectively reducing the production cost of rhamnolipid biosurfactant and being applicable for industrial production. Besides, the addition of rhamnolipid biosurfactant can improve the hydrolyzation efficiency of cellulose effectively.

Owner:SHANGHAI JIAO TONG UNIV

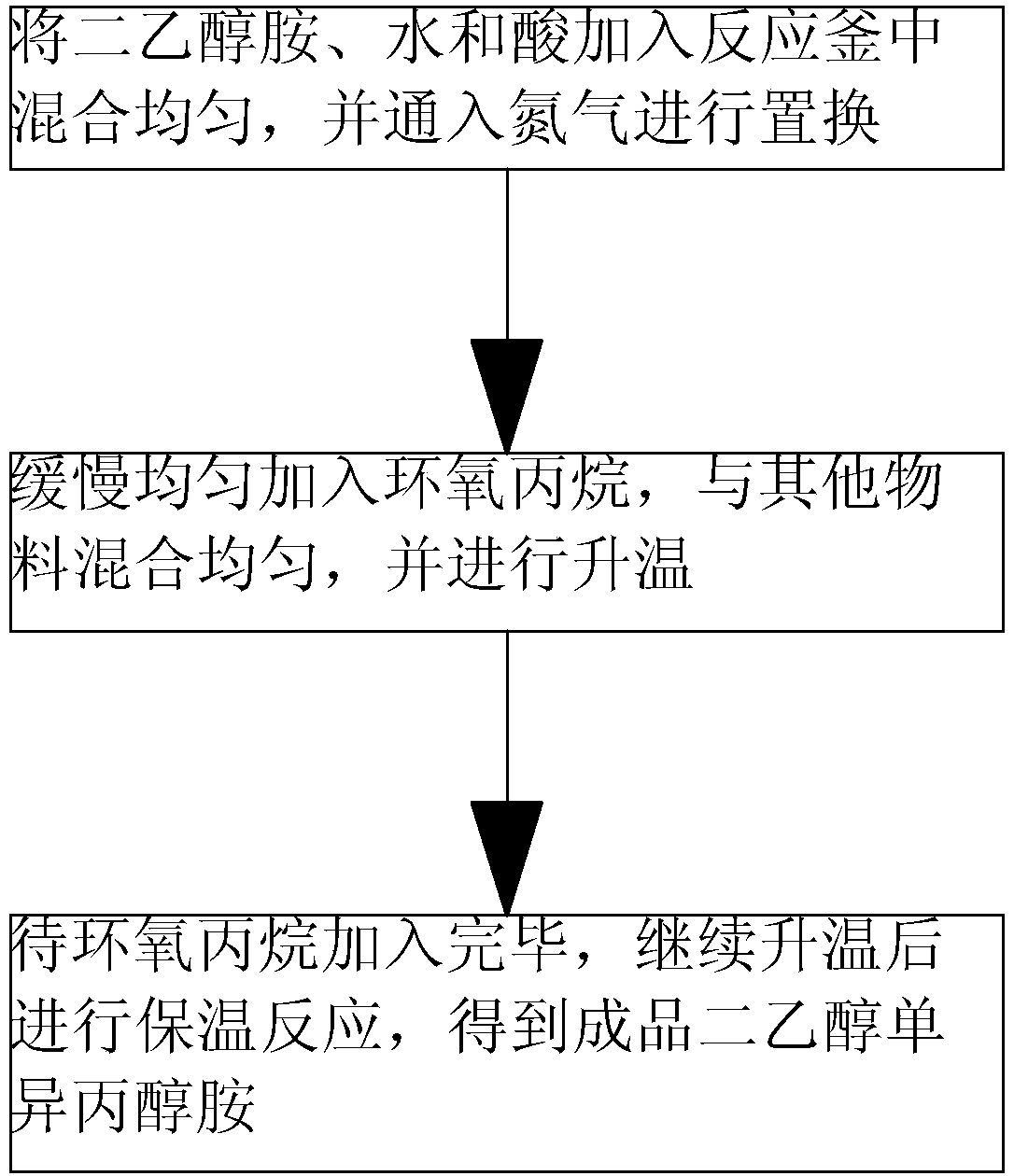

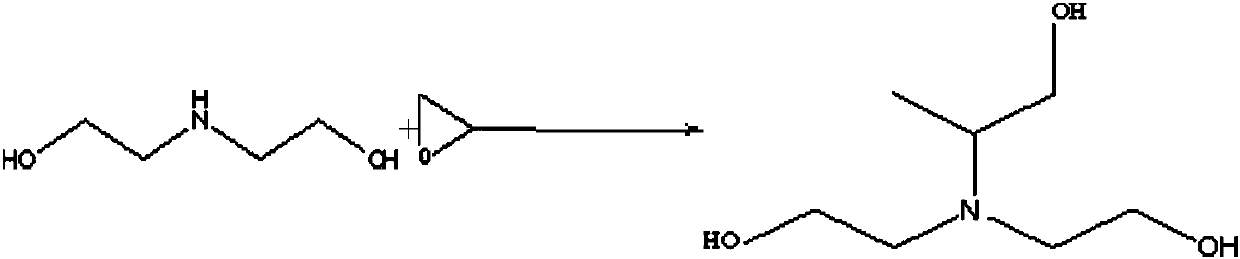

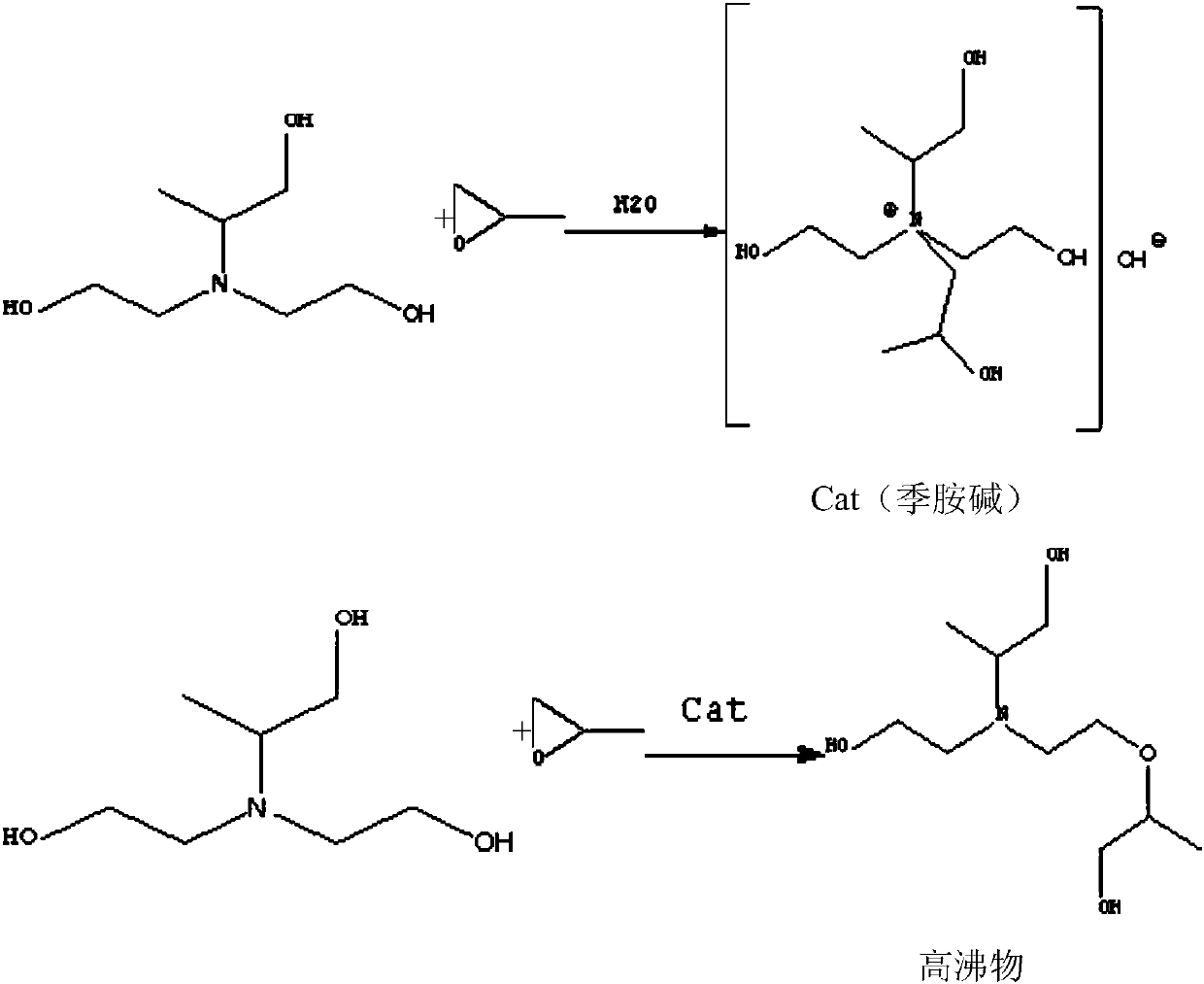

Production method of diethanolisopropanolamine

InactiveCN107556205AInhibits the formation of quaternary amine basesReduce the formation of high boilersOrganic compound preparationAmino-hyroxy compound preparationChemistryQuaternary amine

The invention provides a production method of diethanolisopropanolamine. The method comprises the following steps of S1, adding diethanol amine, water and acid into a reaction kettle; starting a stirring paddle for uniformly mixing each material; S2, in room temperature state, slowly adding epoxy propane; performing continuous stirring so that the epoxy propane and other materials can be uniformlymixed; raising the reaction temperature to 30 to 80 DEG C; S3, after all of the epoxy propane is added, performing heat insulation reaction on the reaction kettle for 30min to obtain a finished product of diethanolisopropanolamine. The diethanolisopropanolamine produced through the reaction of the diethanol amine and the epoxy propane can partially react with the epoxy propane under the water existence condition to produce quaternary amine alkali; the quaternary amine alkali is a strongly basic catalyst and can be used for catalyzing hydroxyls on the diethanolisopropanolamine to continuouslyreact with the epoxy propane to form ester. The acid can fast and effectively achieve the neutralization effect on the quaternary amine alkali in the reaction process; the reaction of the diethanolisopropanolamine in the direction of byproducts of eater is reduced.

Owner:NINGBO YUANLI CHEM

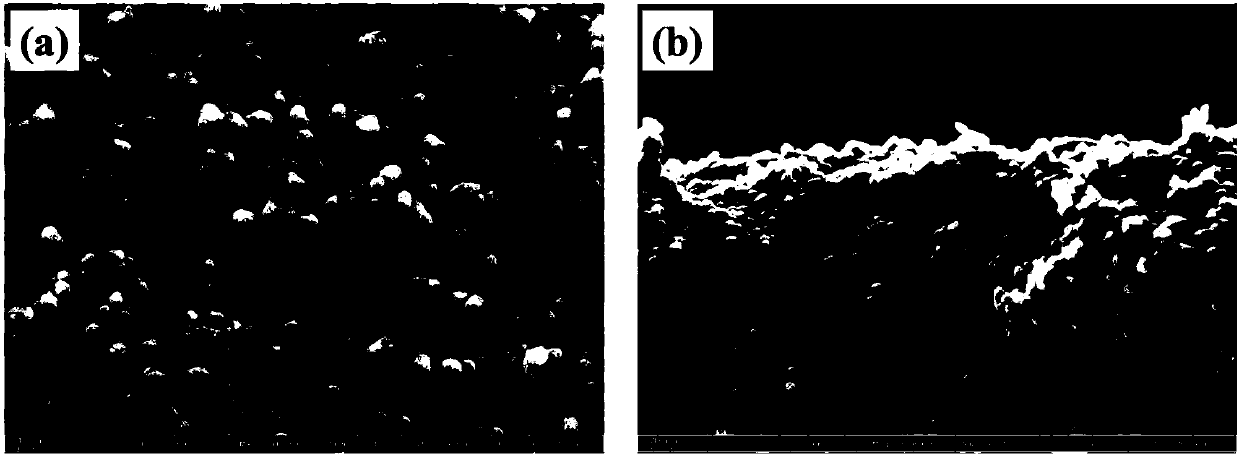

Modified graphene oxide/hyperbranched polymer composite film as well as preparation method and application thereof

ActiveCN107737530AMild reaction conditionsImprove stabilityEther separation/purificationCarbon compoundsComposite filmAlcohol

The invention relates to a modified graphene oxide / hyperbranched polymer composite film as well as a preparation method and application thereof, and belongs to the field of film separation. An in-situpolymerization technology is used for performing decoration modification on the graphene oxide; meanwhile, a graphene oxide and hyperbranched polymer composite material is obtained through the preparation; the composite material is used as film casting liquid to prepare the modified graphene oxide / hyperbranched polymer composite film on a tubular base film under the pressure driving condition. The composite material is used for directly forming the film; the step of purifying and re-dispersing the modified graphene material is omitted; the film forming efficiency is greatly improved. The prepared composite can be used for the separation of methyl tert-butyl ether / methyl alcohol in the pervaporation field; good separation performance and stability can be shown; the potential application prospects are realized.

Owner:BEIJING UNIV OF TECH

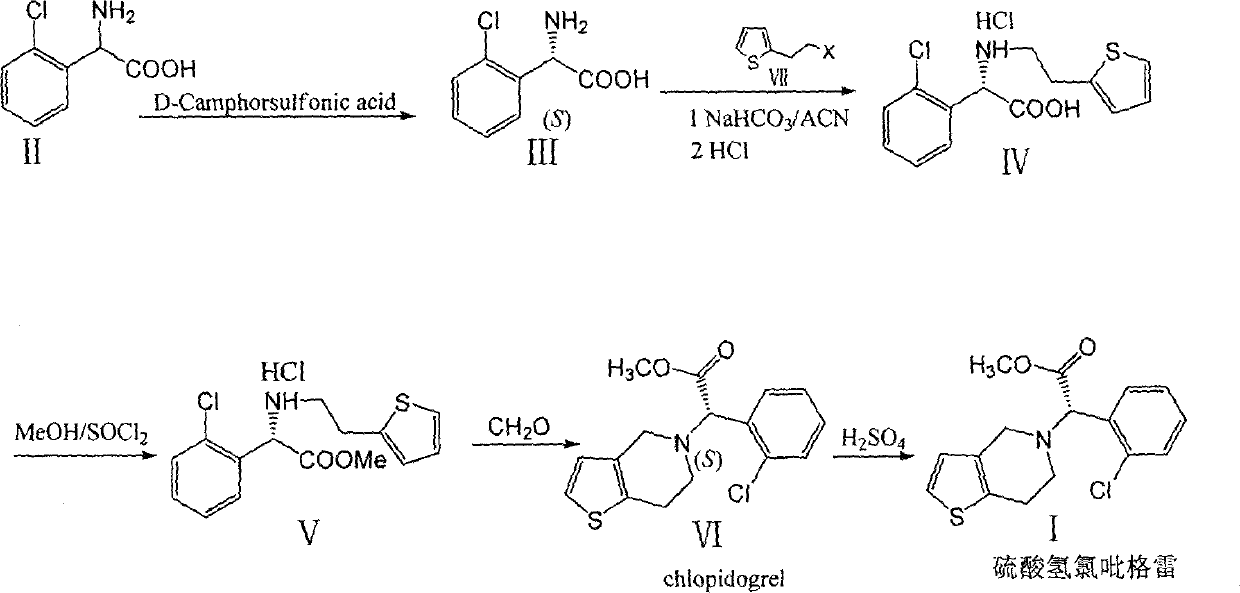

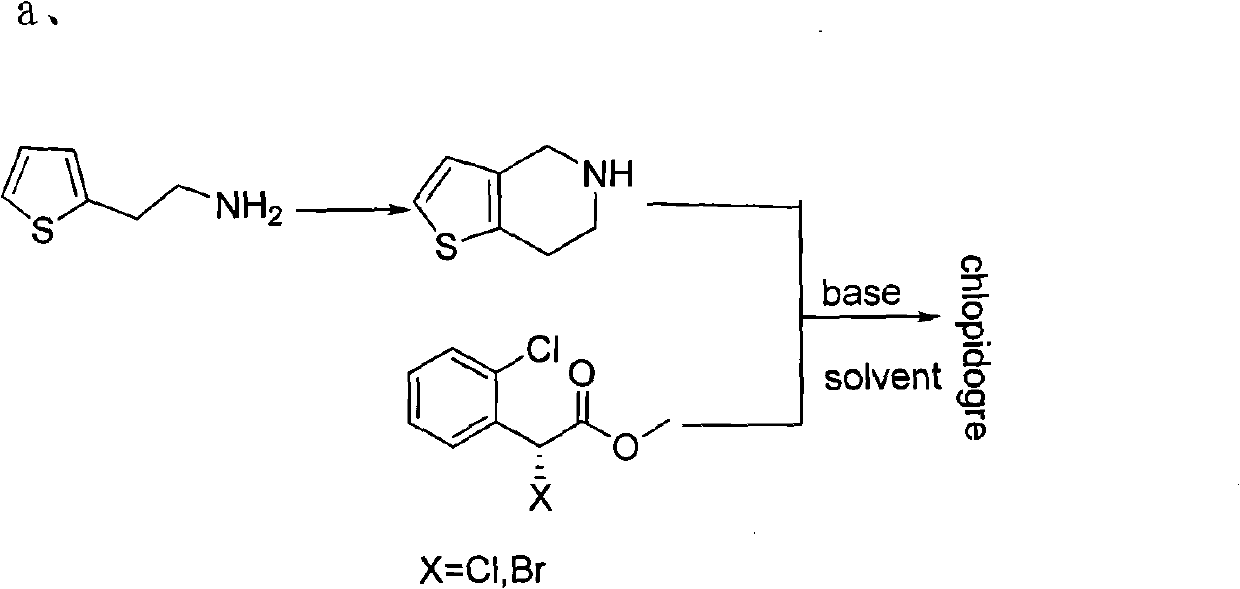

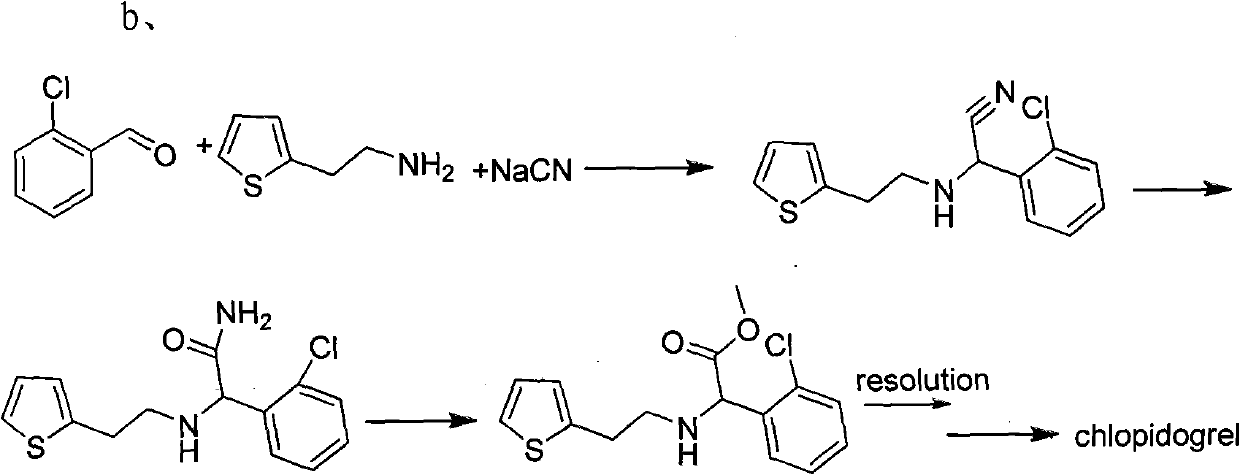

Novel method for preparing clopidogrel and slat thereof

The invention discloses a novel method for preparing a clopidogrel compound, which comprises the following steps: taking a compound shown in Formula (II) as a raw material, obtaining a compound shown in Formula (III) through optical resolution, obtaining a compound shown in Formula (IV) through substitution reaction of the compound shown in Formula (III), further obtaining a compound shown in Formula (V) by acetifying the compound shown in Formula (IV) to be salt, obtaining the final product, i.e. the lopidogrel compound shown in Formula (VI), through Mannich cyclization, and then generating salt by mixing the compound shown in Formula (VI) and sulfuric acid for reaction to obtain the target product (I). The method of the invention for preparing the clopidogrel compound has the advantages of readily available raw materials, low price, mild reaction condition, simple operation and high total yield, and is a novel integrated synthesis method applicable for industrial production of clopidogrel.

Owner:无锡好芳德药业有限公司

Preparation process of bromamine acid

InactiveCN106748913ALess side effectsReasonable designOrganic compound preparationSulfonic acid preparationBromineNitration

The invention discloses a preparation process of bromamine acid. The preparation process is characterized by comprising the following steps of carrying out nitration reaction, reduction reaction, sulfonation reaction and bromination reaction and finally refining to prepare the bromamine acid from anthraquinone; reaction conditions and a process step of adding materials are reasonably designed, so that the generated bromamine acid has high purity and the yield is relatively high.

Owner:TAIZHOU DONGFENG CHEM CO LTD

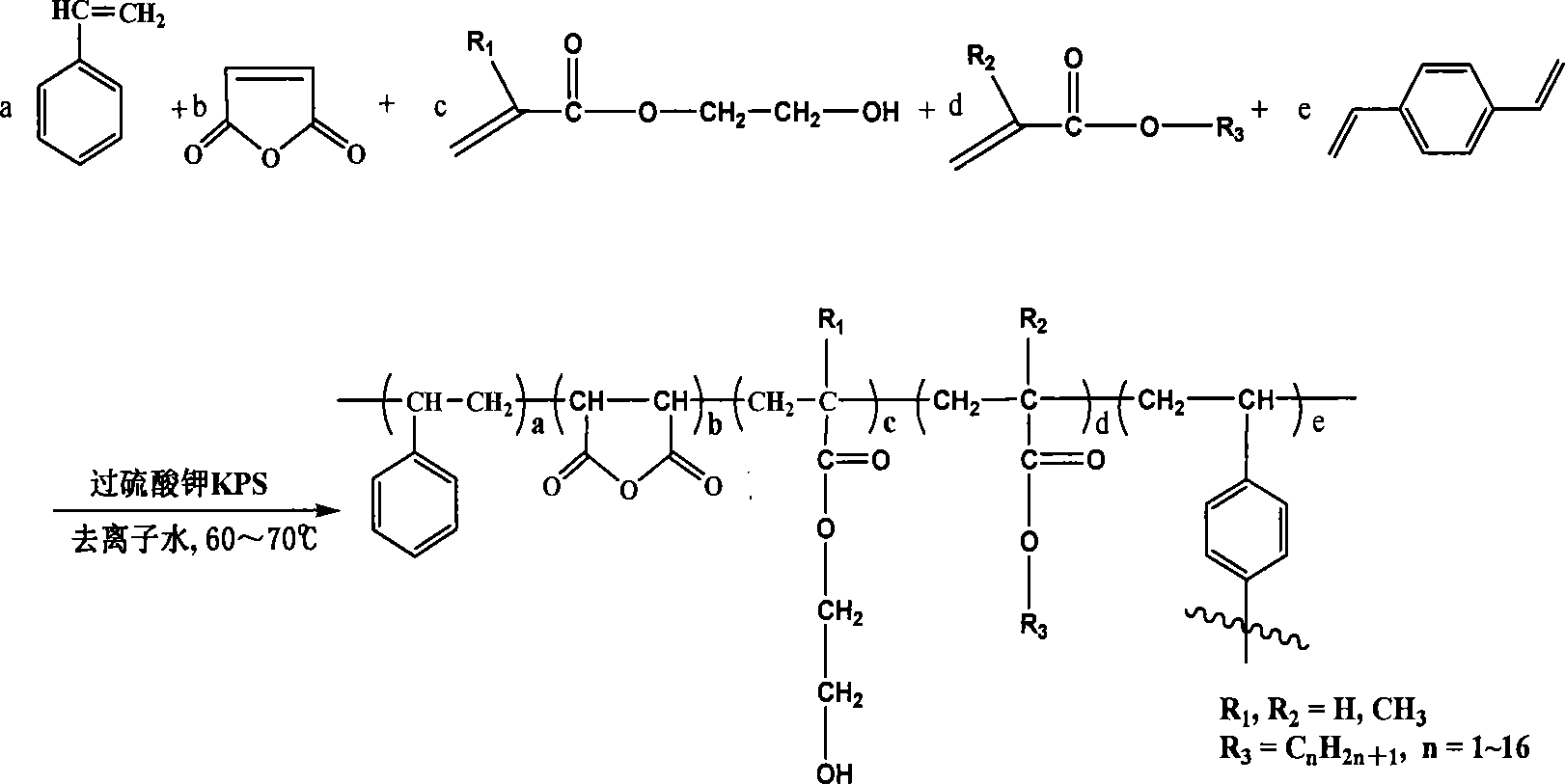

Method for preparing polymer nano micelle by water solution polymerization self-emulsification method

InactiveCN101215353AEliminate the purification processWill not pollutePharmaceutical non-active ingredientsPolymer sciencePotassium peroxodisulfate

The invention relates to a process for preparing polymers nano-micelles with a method of water solution polymerization self-emulsifying method, which belongs to the technical field of high molecule polymerization. The invention utilizes strong alternating polymerization tendency of styrene monomer / maleic anhydride monomer, and / or the participation of (metyl group) 2-hydroxyethyl acrylate and / or the other (metyl group) alkyl acrylate, and / or p-divinyl benzene bifunctional monomer, any emulsifying agent, inorganic salt and organic solvent are not added, crosslinking type or non crosslinking type green and clean polymeric compound namely nano-micelle whose particle diameter can be adjusted and controlled, and distribution is even is directly prepared in water solution through radical polymerization by utilizing potassium peroxodisulfate to be initiating agent, which is directly applied in the loading and releasing of medicament, catalysis, load and the other aspects. The steps of purification and micellization of polymers are omitted by the invention, organic solvent is not brought in, and pollution can not be brought, the operation is simple and convenient, and the production cost is low, polymers nano-micelles which has various sizes, structures and performances can be obtained through adjusting the species, proportion and dosage of initiating agent of hydrophilic / hydrophobic monomer.

Owner:JIANGNAN UNIV

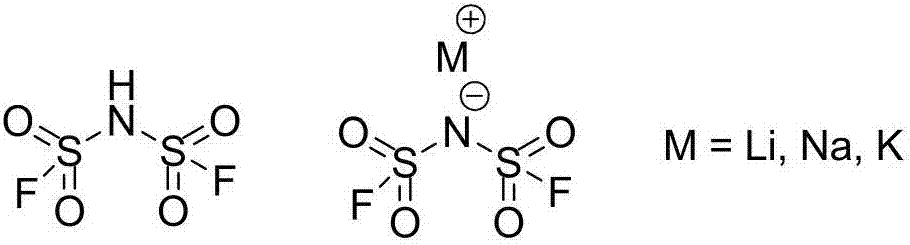

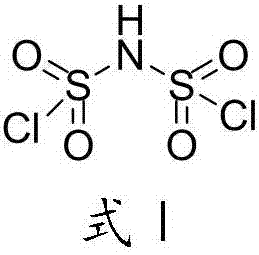

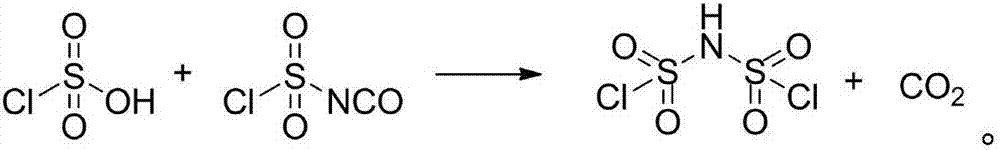

Difluoro-sulfonyl imine preparation method and method for preparing difluoro-sulfonyl imine alkali metal salt by using prepared difluoro-sulfonyl imine

InactiveCN107381522AEasy to controlHigh purityNitrosyl chlorideAmidosulfonic acidChemical industryDistillation

The invention belongs to the technical field of fluorine chemical industry, and especially relates to a difluoro-sulfonyl imine preparation method and a method for preparing difluoro-sulfonyl imine alkali metal salt by using prepared difluoro-sulfonyl imine. The difluoro-sulfonyl imine preparation method comprises the following steps: polystyrene and antimony pentalfluoride are added in a solvent and are subjected to reaction to obtain polystyrene-loaded antimony pentalfluoride, difluoro-sulfonyl imin liquid is added for a reaction, after the reaction is completed, pumping filtration and underpressure distillation are carried out to obtain the difluoro-sulfonyl imin; the method for preparing difluoro-sulfonyl imine alkali metal salt by using the prepared difluoro-sulfonyl imine comprises the following steps: adding difluoro-sulfonyl imine, an alkali metal compound and polystyrene-loaded antimony pentalfluoride in a reaction solvent, reacting the materials for 6-10 h under the reaction temperature of 0-100 DEG C, filtering the materials after the reaction is completed to obtain a difluoro-sulfonyl imine alkali metal salt crude product, and re-crystallizing the difluoro-sulfonyl imine alkali metal salt crude product to obtain a difluoro-sulfonyl imine alkali metal salt fine product. The method has the advantages of controllable reaction, safety, high efficiency, and high yield, and is suitable for industrial production.

Owner:VALIANT CO LTD

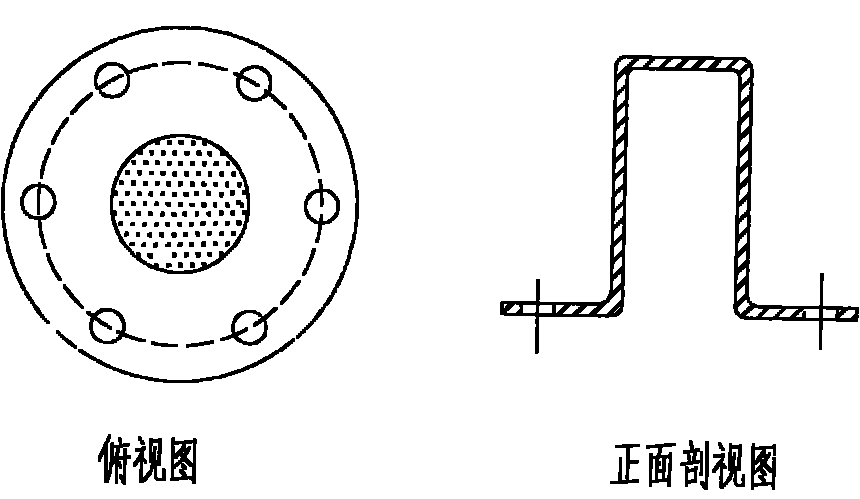

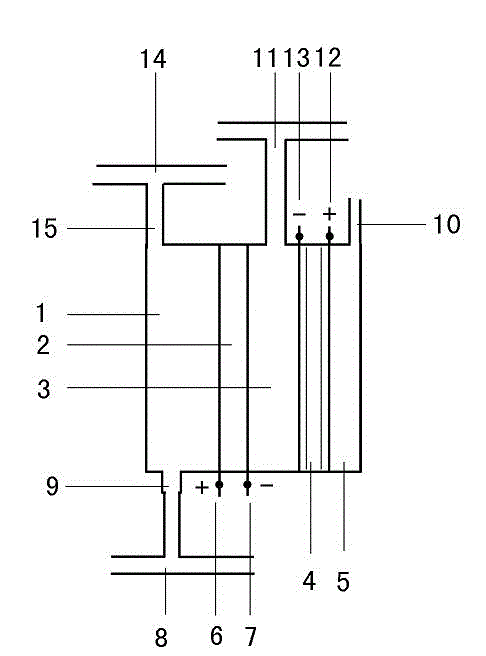

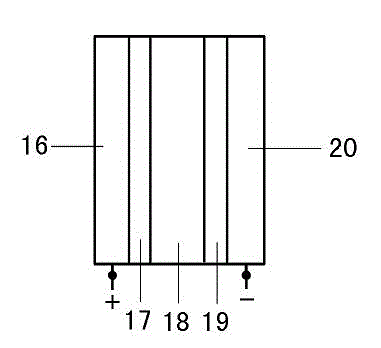

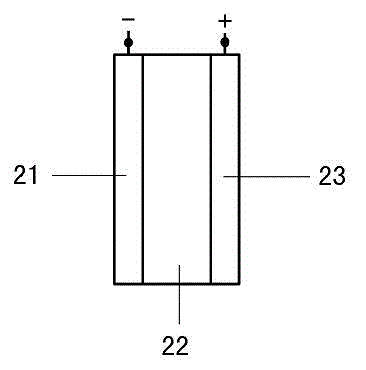

Efficient exchange membrane device for producing hydrogen by electrolyzing water

The invention relates to an efficient exchange membrane device for producing hydrogen by electrolyzing water, belonging to the field of producing hydrogen by electrolyzing water. The device is characterized in that a porous permeable ion component and a common strengthening membrane component are respectively fixed in a box body and separate the box body into a water storage cavity, a hydrogen generation cavity and an oxygen generation cavity; and insulating layers are arranged on the peripheries of the surfaces of the two sides of the porous permeable ion component and the common strengthening membrane component. The device has the advantages that the device has a simple structure, low mass and high transformation efficiency, is safe and reliable, reduces the process difficulty, reduces the cost, can achieve production without more auxiliary equipment, is suitable for various places, has a very extensive market prospect and is an edge tool for achieving hydrogen economy, popularizing hydrogen and widely using hydrogen.

Owner:长春盛举新能源科技有限公司

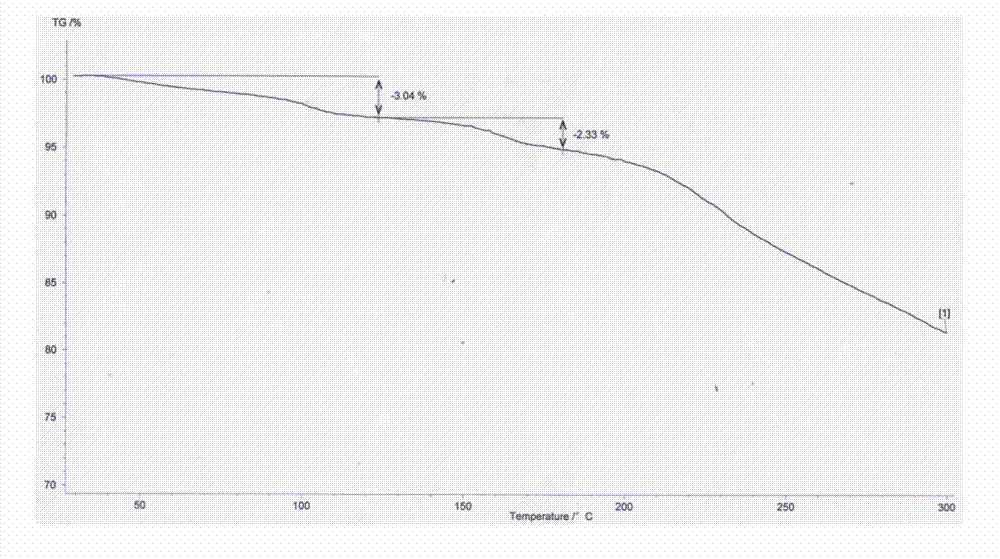

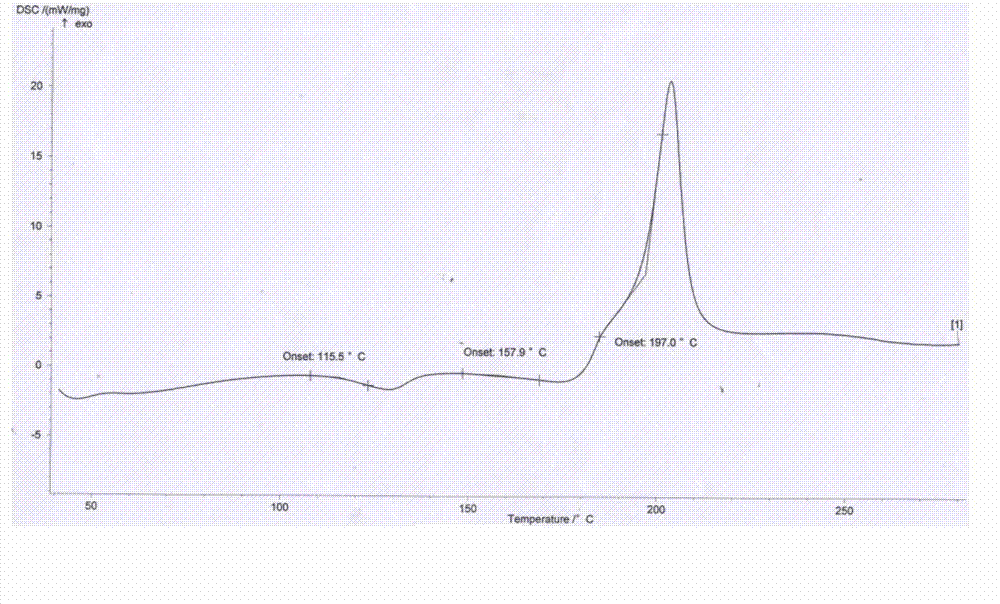

Preparation method of esomeprazole magnesium

The invention relates to a preparation method of esomeprazole magnesium. The method comprises the steps that: esomeprazole is dissolved in an organic solvent; a potassium-containing alkali or salt is subjected to a reaction with esomeprazole, such that esomeprazole potassium is produced; and esomeprazole potassium is subjected to a displacement reaction with a magnesium salt, such that esomeprazole magnesium is prepared. The invention also relates to a refining method of esomeprazole magnesium. With the method provided by the invention, the purity of the prepared esomeprazole magnesium is higher than 99.9%, the yield is higher than 82%, and esomeprazole magnesium has good morphological stability. With the method, requirements by factory pharmacy for purity and yield can be satisfied.

Owner:NANJING YOKO PHARMA

Preparation method and application of primaquine-terminated polyether catalyst prepared through static bed catalytic hydrogenation

InactiveCN106040253AHigh selectivityHigh purityOrganic compound preparationHeterogenous catalyst chemical elementsPolyolHydrogen

The invention discloses a catalyst preparation method for improving selectivity of primaquine-terminated polyether prepared through hydroxyl-terminated polyether static bed catalytic hydrogenation and a method for selectively and continuously producing primaquine-terminated polyether. An Ni-Cu-Cr-MgAl2O4 catalyst is prepared through a coprecipitation method, an original-size catalyst is adopted for producing low molecular weight primaquine-terminated polyether in a static bed reactor, polyether polyol, hydrogen and liquid ammonia are adopted as raw materials, the self-prepared Ni-Cu-Cr-MgAl2O4 catalyst is adopted, the materials are continuously subjected to an ammoniation catalytic reaction through the static bed reactor at the temperature of 180 DEG C to 260 DEG C and the pressure of 4.0 MPa to 8.0 MPa, low molecular weight primaquine-terminated polyether can be obtained through gas-liquid separation, the conversion rate of the obtained primaquine-based polyether product is larger than or equal to 90.0%, and the primaquine selectivity is larger than or equal to 95.0%. The continuous process production technology is adopted, the selectivity of low molecular weight primaquine-terminated polyether can be improved, therefore, product aftertreatment is simplified, the quality of the low molecular weight primaquine-terminated polyether product is improved, and the production efficiency is improved.

Owner:NANJING FORESTRY UNIV

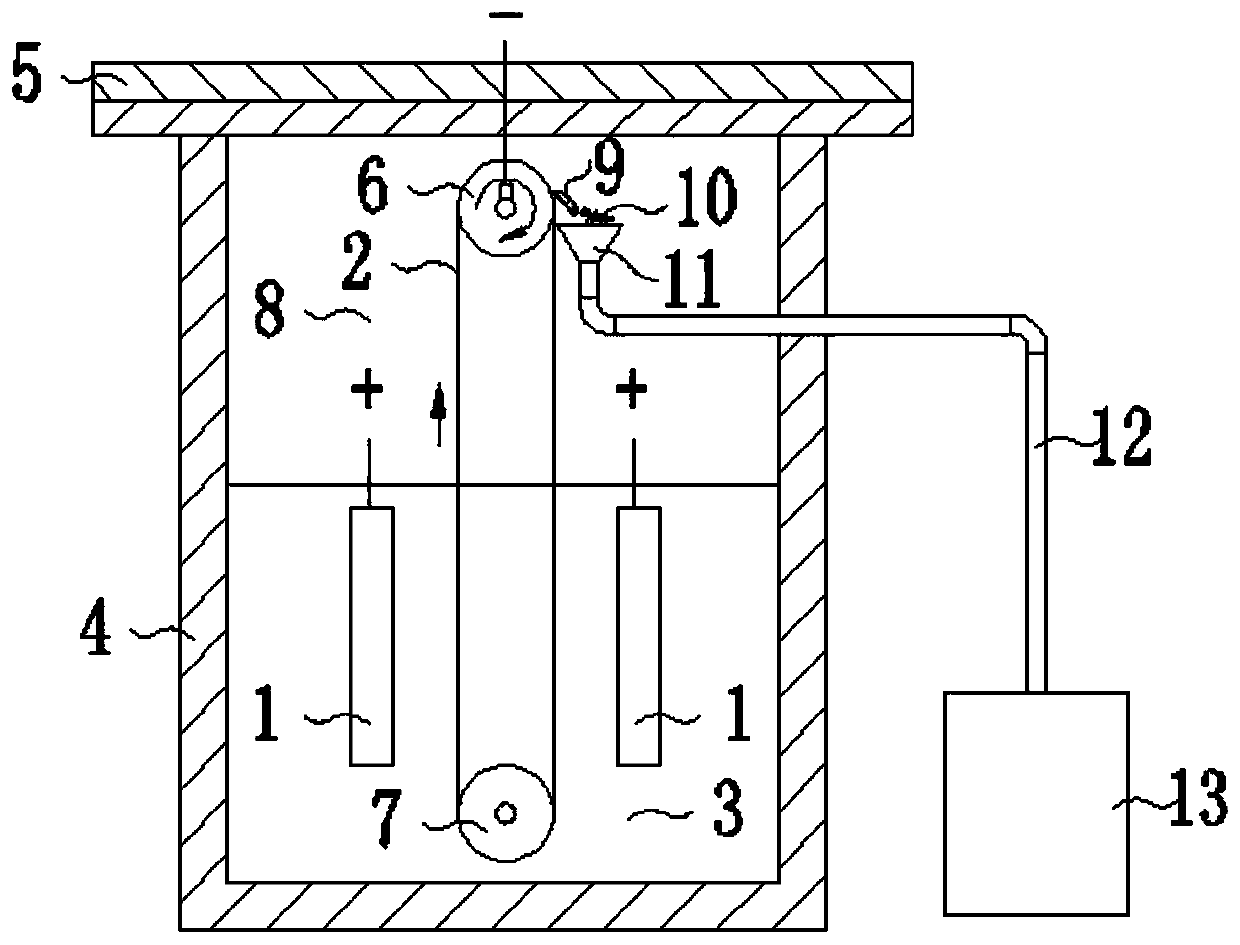

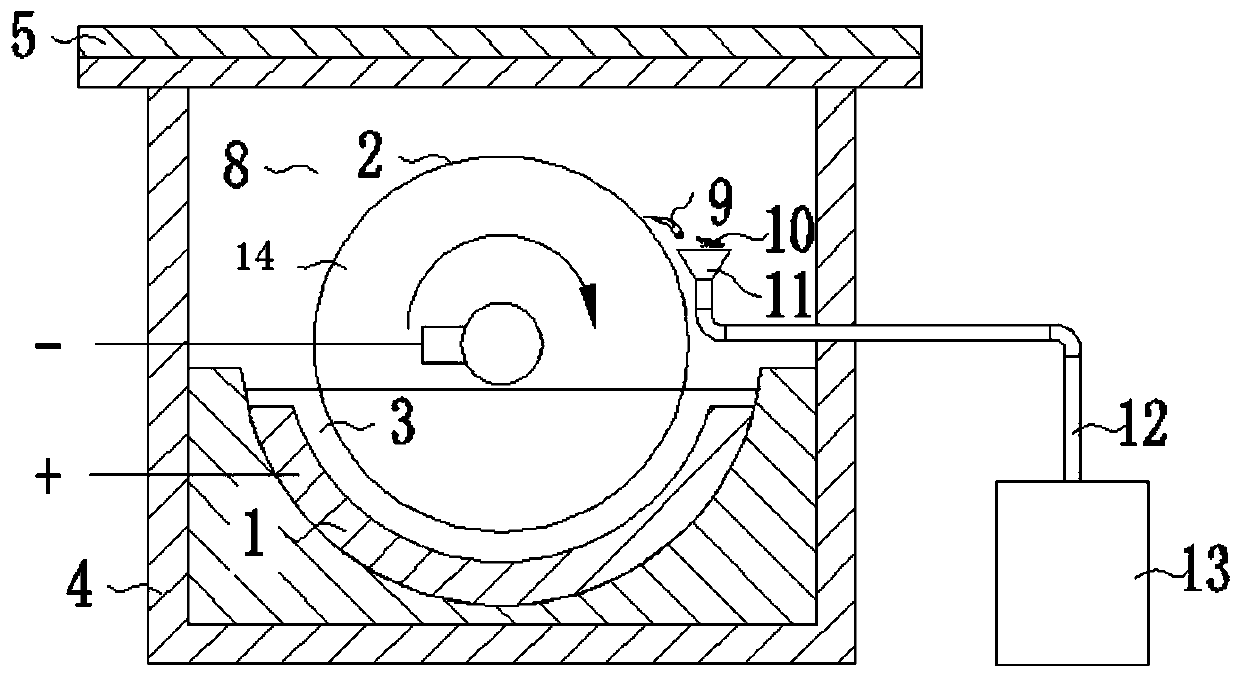

Device and method for preparing high-purity metal titanium powder through continuous electrolysis

ActiveCN109763148ASave smeltingEliminate the purification processElectrodesMolten saltTitanium powder

The invention discloses a device and a method for preparing high-purity metal titanium powder through continuous electrolysis. According to the method, titanium-containing conductive ceramic anodes and a rotary cathode is electrolyzed in a molten salt electrolytic cell, the rotary cathode continuously transfers the metal titanium powder deposited on the surface of the cathode to the surface of molten salt, the metal titanium powder is scraped by a discharging scraping plate, then the metal titanium powder is collected, and then the molten salt is filtered and recycled, the separated metal titanium powder is washed by using a deoxygenization deionized water after being cooled, and finally performing vacuum drying to obtain the prepared metal titanium powder. The device comprises a molten salt electrolysis device, a continuous metal titanium powder collecting device, a filtering device, a cleaning device and a vacuum drying device. According to the device and the method, continuous preparation of the high-purity metal titanium powder is realized, and the average particle size of the prepared metal titanium powder can be adjusted online, the production efficiency is high, the operation is simple, and the product purity is high.

Owner:ZHEJIANG HAIHONG HLDG

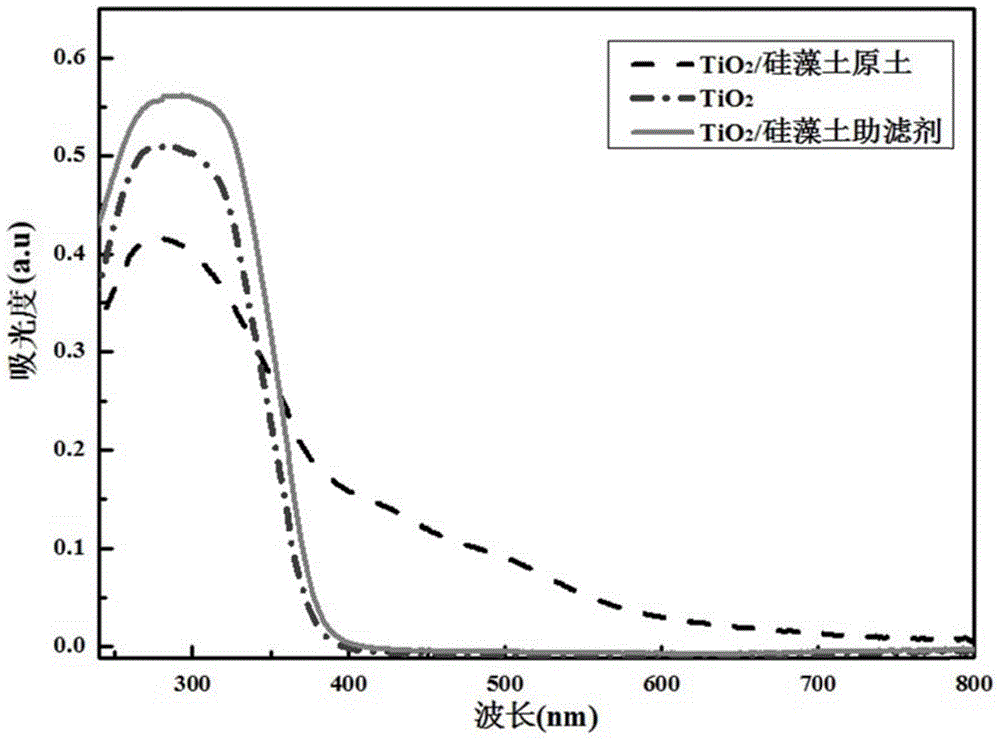

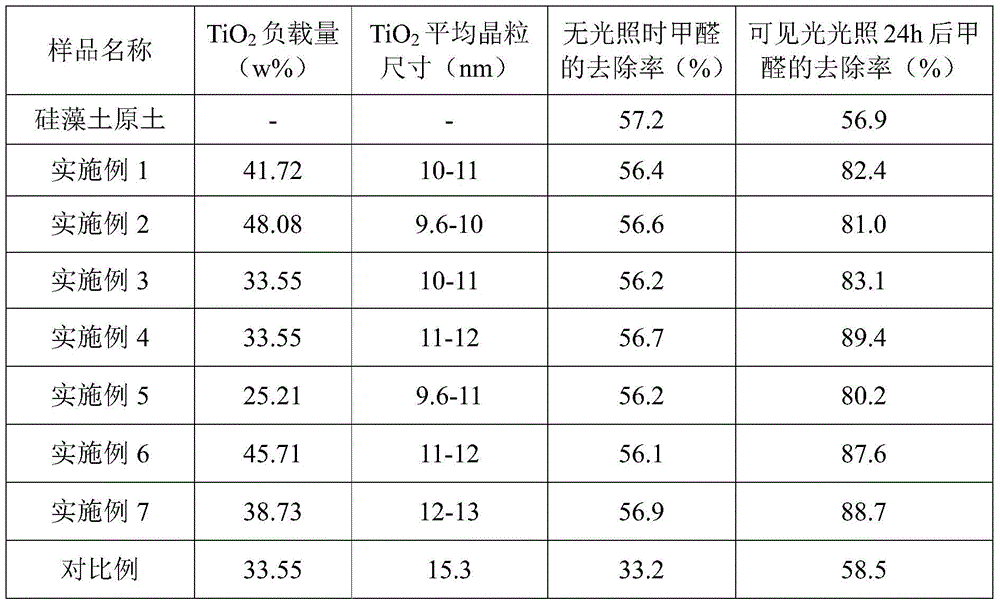

Nano TiO2-diatomite composite photocatalyst and preparation method thereof

ActiveCN105727921APicklingSave the craftPhysical/chemical process catalystsTitanium tetrachlorideAmmonium sulfate

The invention discloses a nano TiO2-diatomite composite photocatalyst and a preparation method thereof. The nano TiO2-diatomite composite photocatalyst is prepared from the following raw materials: raw diatomite, titanium tetrachloride, ammonium sulfate and iron salt, wherein the mass ratio of the raw materials is that the ratio of the raw diatomite to the titanium tetrachloride is 100 to (80-200), and the ratio of the titanium tetrachloride to the ammonium sulfate to the iron salt is 100 to (17-66) to (0-0.7). With the adoption of the composite photocatalyst, the problems in the prior art that the visible light utilization rate of the composite photocatalyst is low and the degradation capability on organic pollutants is low are solved, the visible light utilization rate of the composite photocatalyst is improved, and the degradation capability on the organic pollutants is improved.

Owner:CHINA BUILDING MATERIALS ACAD

Full cell catalyst of intracellular secretory lipase type and its preparing method

The present invention relates to one kind of full cell catalyst with lipase activity and its preparation process. The intracellular lipase secreting full cell catalyst is prepared with the materials including saccharomycetes 0.7-1.2 wt%, diatomite 2.1-3.6 wt%, sodium alginate 2.0-2.3 wt%, calcium dichloride 0.5-0.8 wt%, and pH 7.7 Na2HPO4-NaH2PO4 buffer solution of 92.1-94.7 wt%, with the saccharomycetes to diatomite weight ratio being 1 to 3. The intracellular lipase secreting full cell catalyst is used to replace lipase in producing biological diesel oil, and has simple preparation process, easy product recovery, reusability and low production cost.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Recombination lactic acid bacteria and application thereof

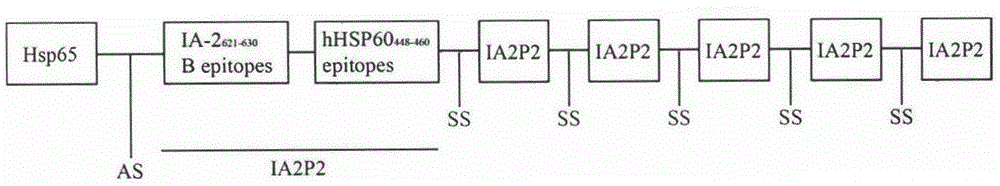

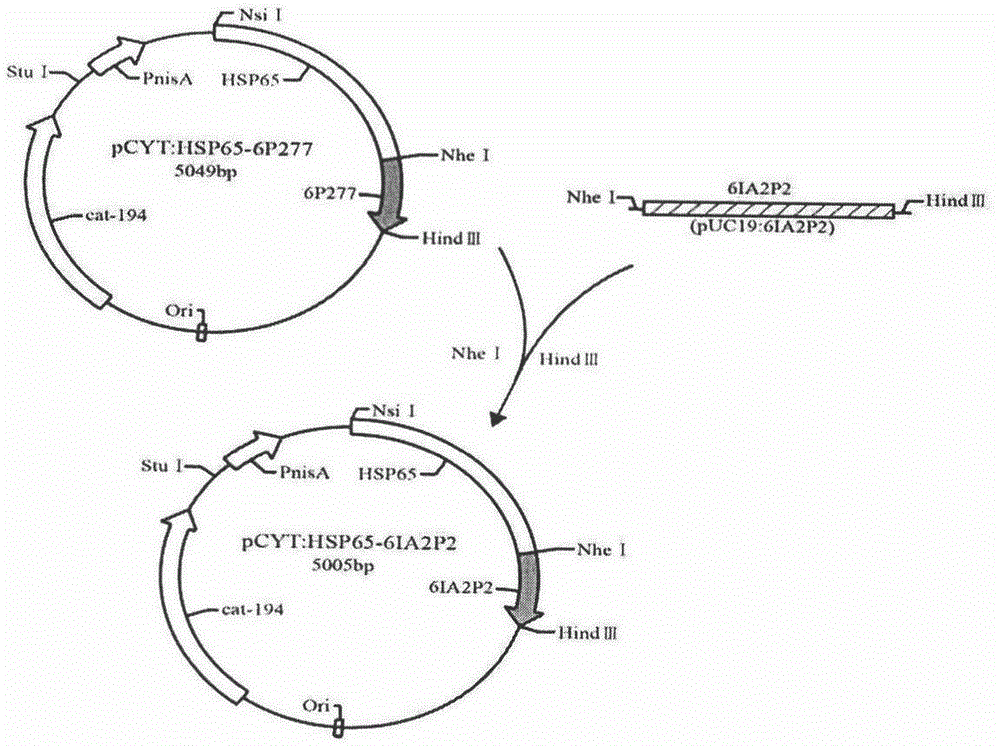

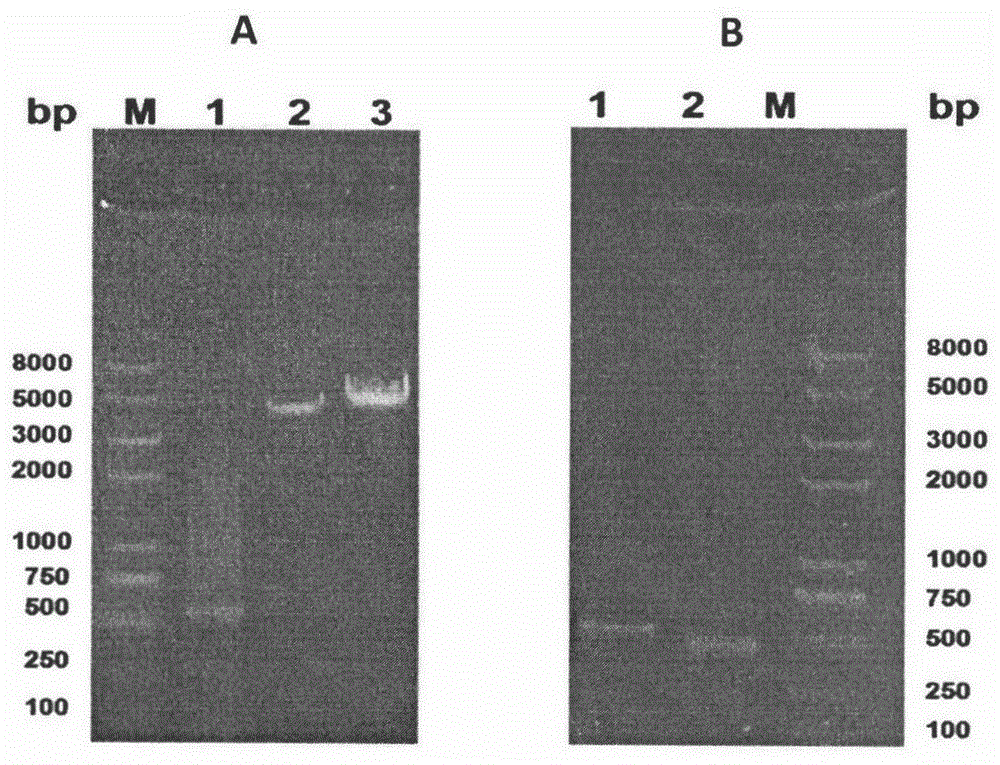

InactiveCN105255800AImproving immunogenicityHigh titerBacterial antigen ingredientsBacteriaWestern blotIn vivo

The invention relates to novel I-type diabetes resisting recombination lactic acid bacteria and application thereof, belongs to the field of biological medicine, and discloses an I-type diabetes resisting vaccine with lactococcus lactics as a carrier and a preparing method and application of I-type diabetes resisting vaccine. A micro genetic technology platform of a laboratory is used, the recombination lactococcus lactics vaccine with lactococcus lactics as the carrier, and the recombination lactococcus lactics vaccine expresses fusion protein HSP65-6IA2P2 after induction. The correct expression of the fusion protein vaccine is detected through Western blot authentication. It is proved through in-vivo animal experiments that the vaccine can remarkably reduce the occurrence of NOD mouse diabetes through an oral administration way, can perform the function of controlling I-type diabetes and has good clinical application prospects on preventing diabetes.

Owner:CHINA PHARM UNIV

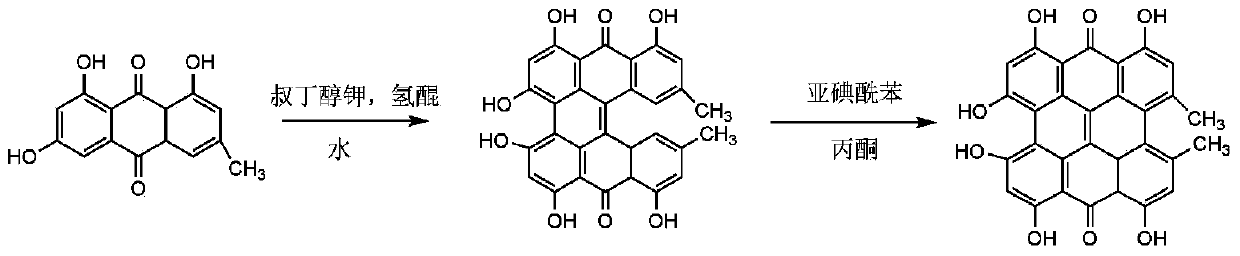

Synthesis method of hypericin

ActiveCN104193610AHigh yieldEliminate the purification processOrganic compound preparationQuinone separation/purificationHypericinSynthesis methods

The invention discloses a synthesis method of hypericin. The synthesis method comprises the following steps of (a) dissolving emodin and tert-butanol salt into water, adding hydroquinone at a protective atmosphere, carrying out microwave irradiation, reacting at the temperature of 90-100 DEG C for 4-6h, then, transferring the product into a sealed vessel, continuing to react at the temperature of 120-140 DEG C for 8-12h, after finishing the reaction, adding an inorganic acid to regulate the pH value of the solution to 3-4, settling, filtering, washing, and drying, thereby obtaining raw hypericin at one step; and (b) dissolving the obtained raw hypericin and iodosobenzene substances into acetone, reacting at the temperature of 45-55 DEG C for 4-8h, filtering after finishing the reaction, collecting filtrate, carrying out evaporative concentration, washing, filtering and recrystallizing to obtain the hypericin. The hypericin obtained by using the synthesis method is high in purity and yield; and the synthesis method is simple in step, environment-friendly, reduced in cost and suitable for industrial production.

Owner:湖南世标健康科技有限公司

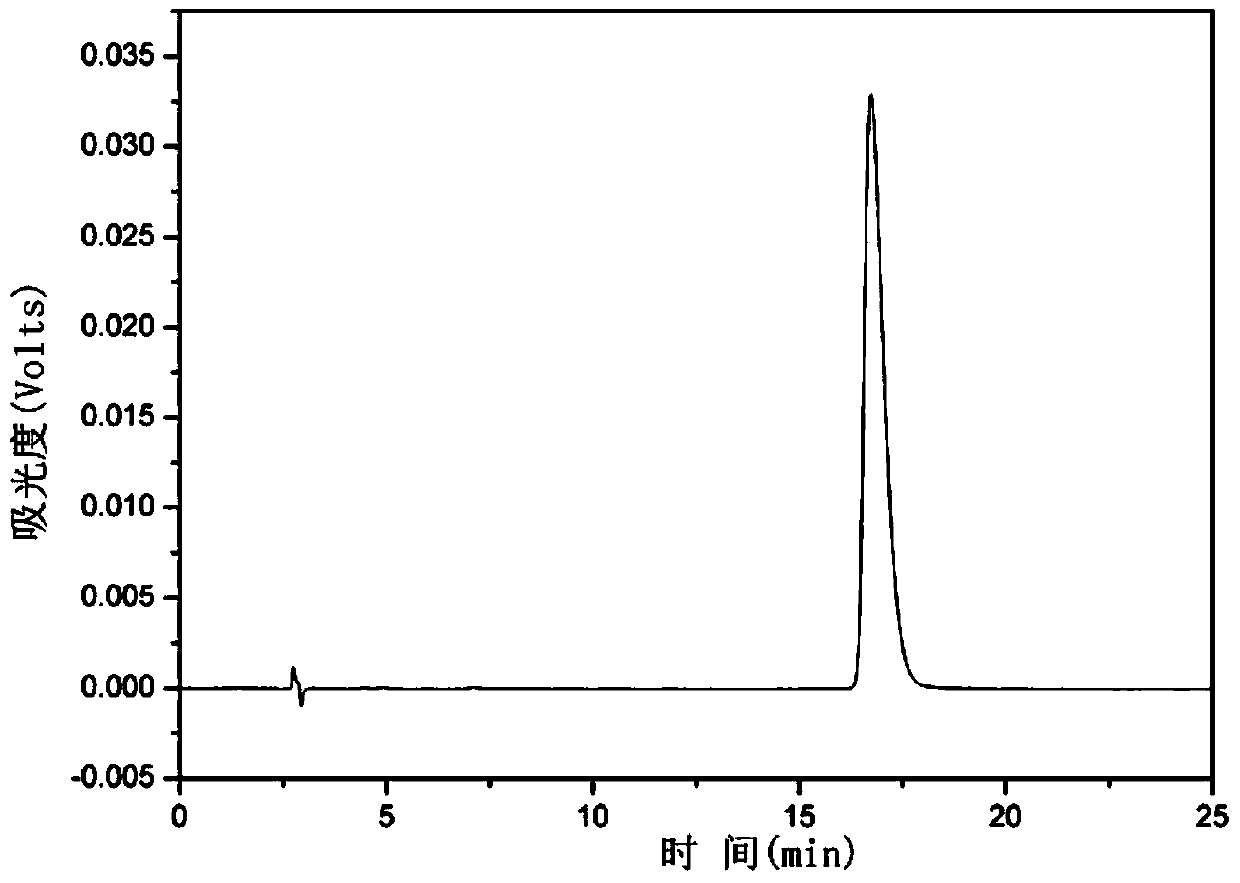

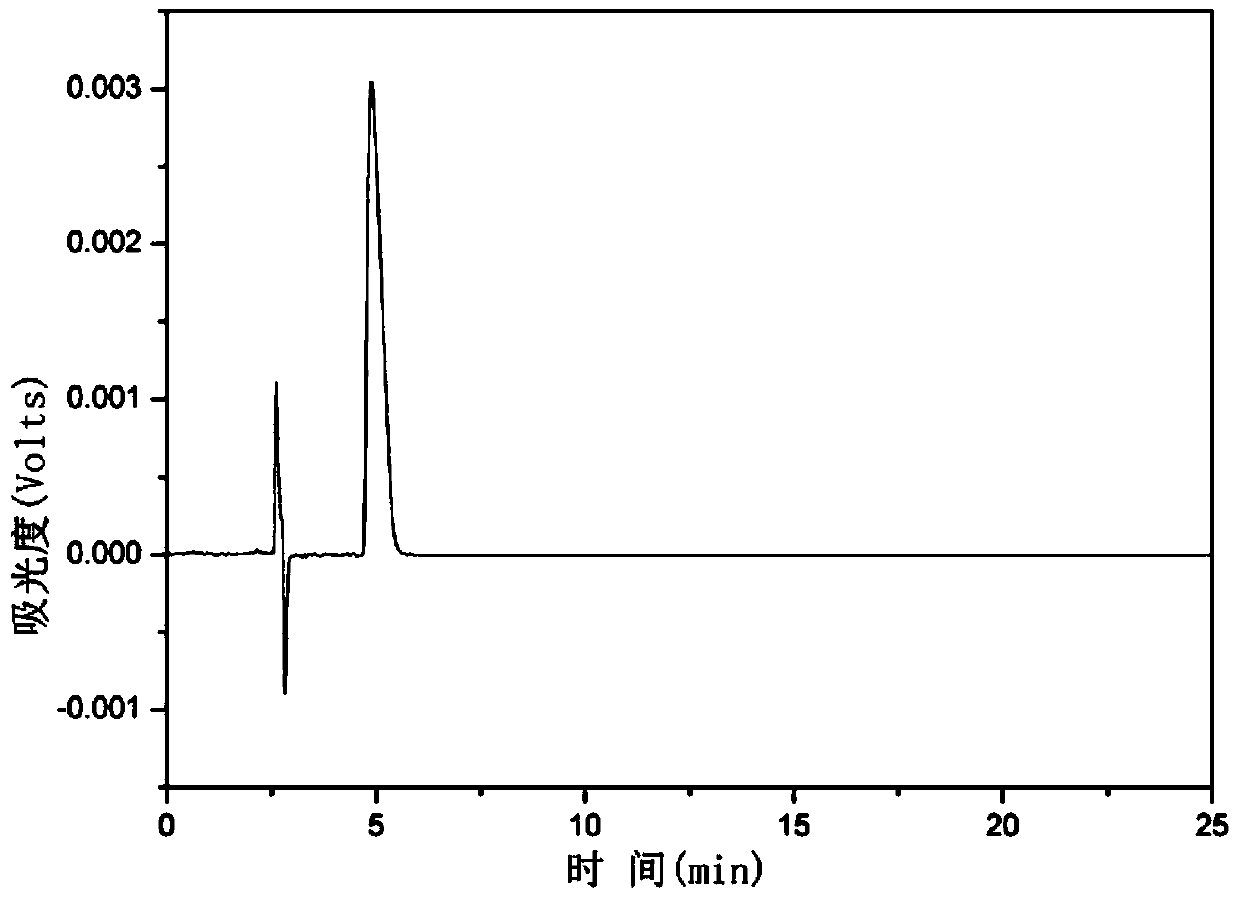

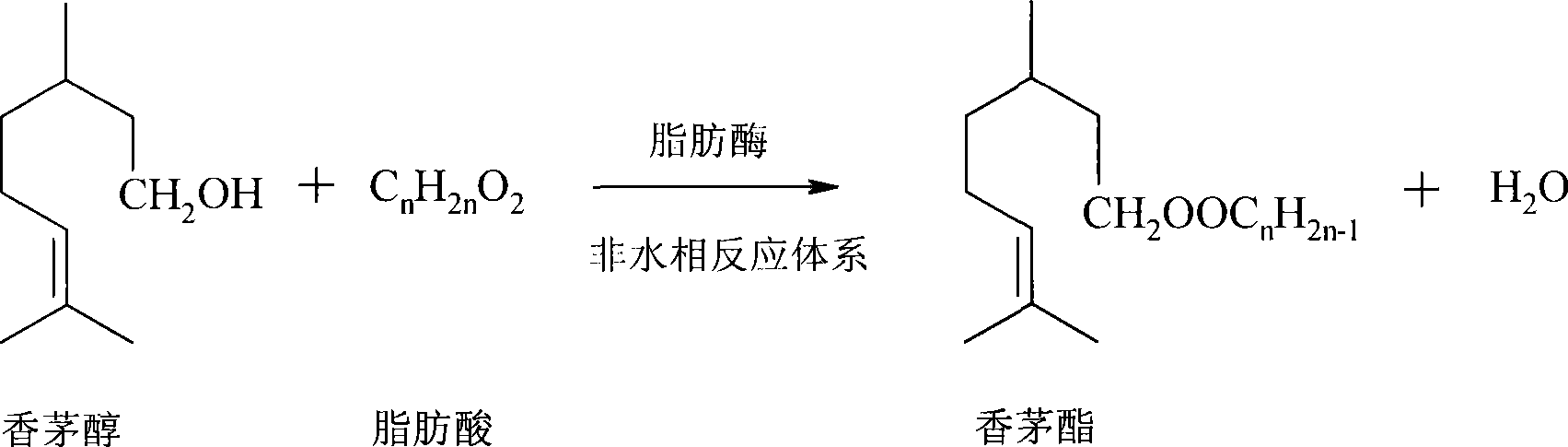

Method for preparing citronellyl by bioconversion in non-aqueous phase system

InactiveCN101457240AHigh selectivityMild reaction conditionsMicroorganism based processesFermentationReaction temperatureControllability

steps: employing an organic phase reaction system when reacted substrate fatty acids are saturation short chain fatty acids with a carbone chain length of C2-C4 and C12 high boiling long chain fatty acids, employing an non-solvent reaction system when reacted substrate fatty acids are saturation middle chain fatty acids with a carbone chain length of C5-C10, conversing and preparing a plurality of citronellyl esters materials by changing the ratio of alcohol to acid and the system water activity methods, obtaining products with a yield of 95 0n a short time. The invention has advantages of novel products, mild reaction temperature and environment friendly, moreover the reaction has selectivity and controllability, the reaction process is easy, the outcomes are easy to separate and the product quality is higher. The method of the invention has positive social benefit and economic value.

Owner:JIANGNAN UNIV

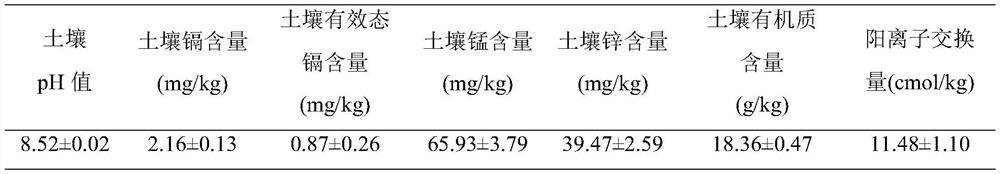

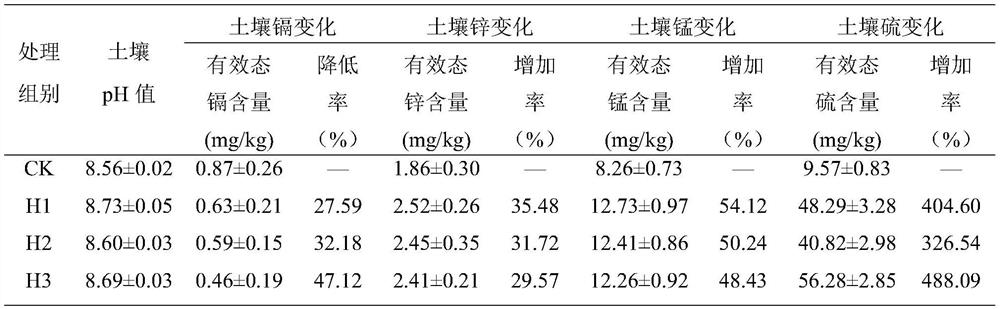

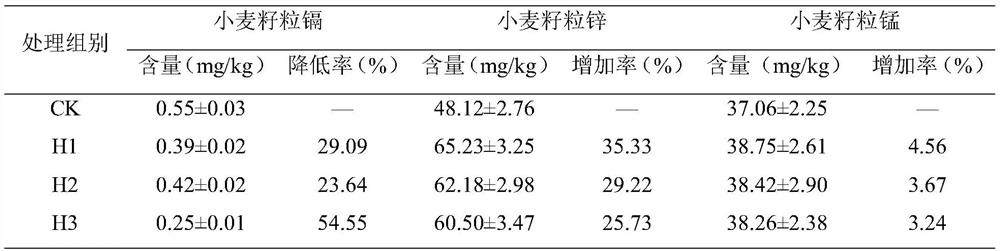

Regulating agent suitable for heavy metal cadmium pollution remediation of alkaline soil, preparation method and application

InactiveCN113234445AWide variety of sourcesLow priceCalcareous fertilisersAgriculture tools and machinesSulfate zincSoil science

The invention relates to a regulating agent suitable for heavy metal cadmium pollution remediation of alkaline soil. The regulating agent is prepared from calcined skarn powder, blue iron ore powder, zinc sulfate and manganese salt. The regulating agent is wide in raw material source, low in price, low in application amount, simple in application method, ingenious and reasonable in product formula design, remarkable in regulation and control effect and the like, can be used for efficient remediation of heavy metal cadmium pollution of alkaline soil, can effectively control heavy metal cadmium pollution of alkaline soil in northern China, and guarantees safe production of agricultural products. The regulating agent and the soil polluted by the heavy metal cadmium are directly spread into the alkaline soil polluted by the heavy metal cadmium according to the mass ratio of (1: 200)-(1: 500), the soil is turned over evenly, and then sowing can be conducted.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

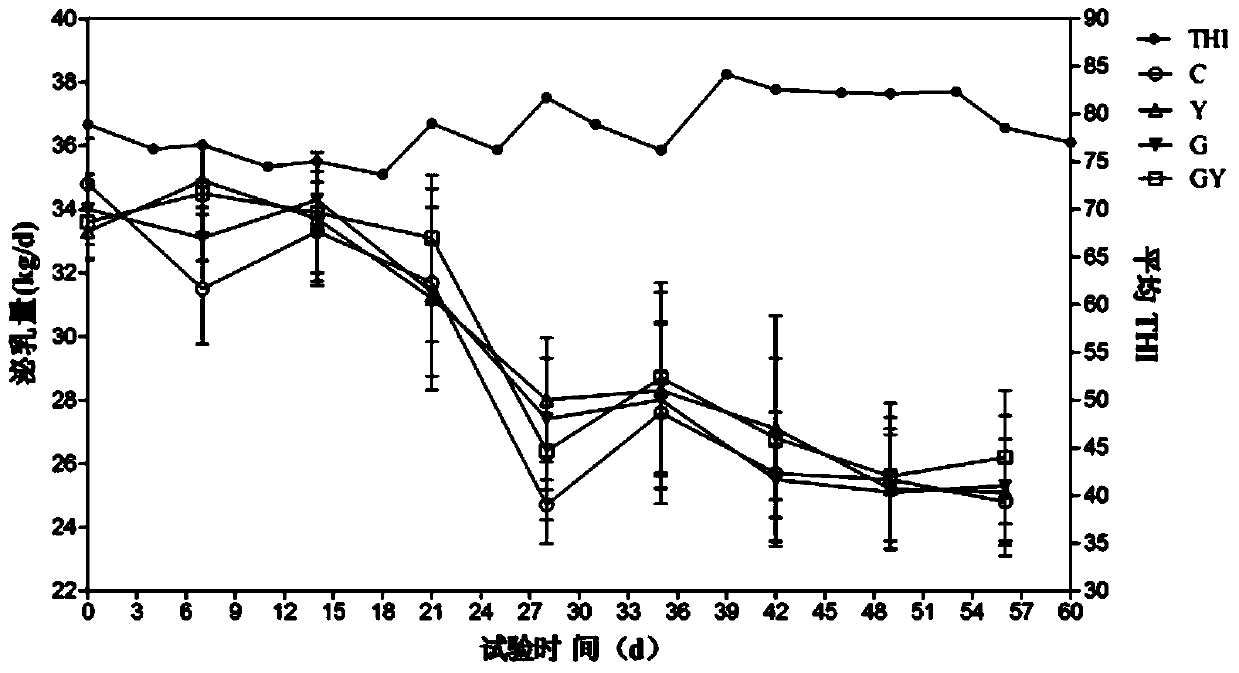

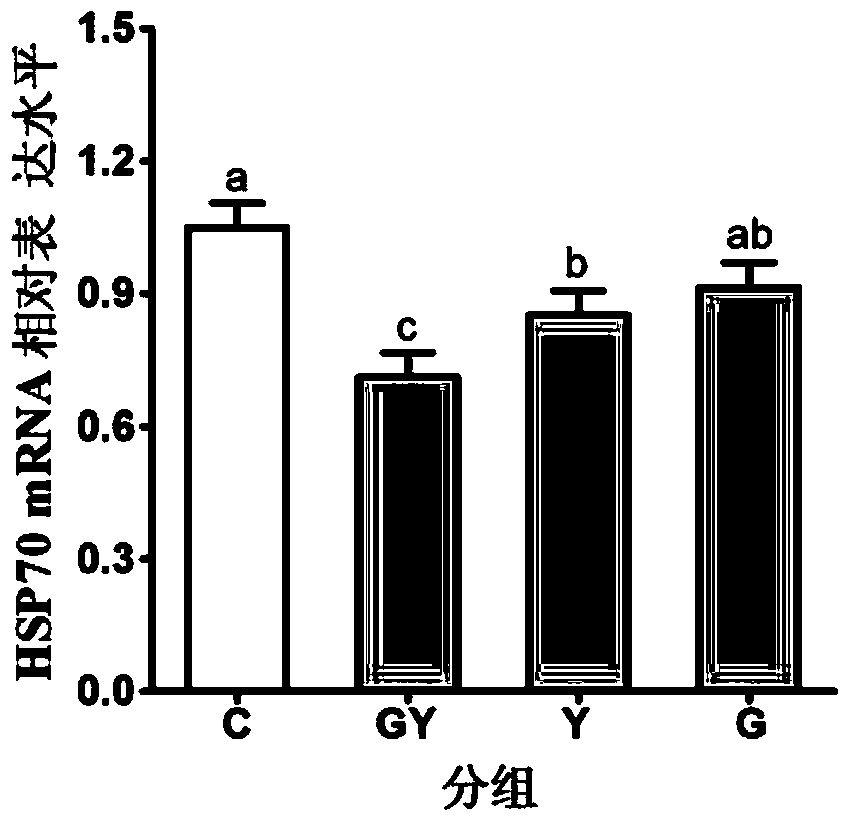

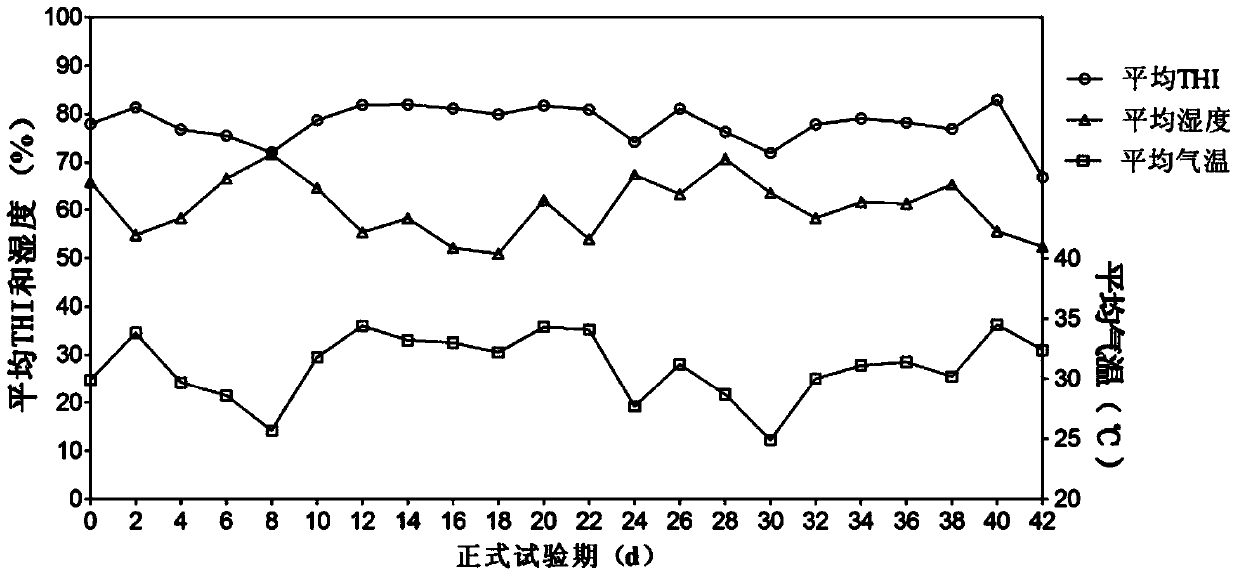

Cow heat-stress resistant feed additive

The invention discloses a cow heat-stress resistant feed additive. Saccharomyces cerevisiae (Sc) NAU-ZH-GY1 is applicable to prepare the cow heat-stress-resistant feed additive. The cow heat-stress-resistant feed additive, which is rich in glycerin, yeast live bacteria and microbial metabolites such as amino acids, vitamins and the like, is produced under the high-permeability condition by employing a continuously feeding manner for fermentation; and the cow heat-stress resistant feed additive is capable of cooperatively perform dual efficacy of glycerin and yeast, and is capable of substantially improving lactation yield, 4% fat corrected milk yield and milk fat percentage of cow under heat-stress condition, improving blood sugar concentration, reducing somatic cell number, concentration of non-esterified fatty acid and concentration of urea nitrogen in milk, supplementing energy for cows, alleviating body weight reduction, enhancing antioxidation capability, reducing HSP70mRNA level and effectively alleviating heat stress of cows.

Owner:NANJING AGRICULTURAL UNIVERSITY

Nano silver loaded graphene silver kettle and preparation method thereof

ActiveCN107752757AImprove performanceIncrease loadCooking-vessel materialsBiocideBoiling pointHardness

The invention relates to the field of graphene composite materials, and discloses a nano silver loaded graphene silver kettle and a preparation method thereof. The preparation method of the nano silver loaded graphene silver kettle comprises the steps that a graphene / silver composite material is adopted as the raw material, a billet made from the graphene / silver composite material is obtained after pretreatment, and the nano silver loaded graphene silver kettle is obtained through manual preparation and mold preparation. Accordingly, on the condition that the performance of the silver kettle is not affected, for the silver kettle prepared through the graphene / silver composite material, the material performance is greatly improved, the Vickers hardness is increased to 100-115 from 25, and the thermal conductivity is increased to 1,000-1,500 Wm<-1>K<-1> from 420 Wm<-1>K<-1>; in addition, the nano silver load is high, the antibacterial effect is better, by means of increasing of the Vickers hardness, the problem that 99.9% silver is soft and difficult to machine is solved, the service life is prolonged, and deformation is not prone to occur; compared with a traditional silver kettle,by means of increasing of the thermal conductivity, the water boiling speed is higher, the boiling point is higher, and the silver kettle is more suitable for tea making.

Owner:郴州博太超细石墨股份有限公司

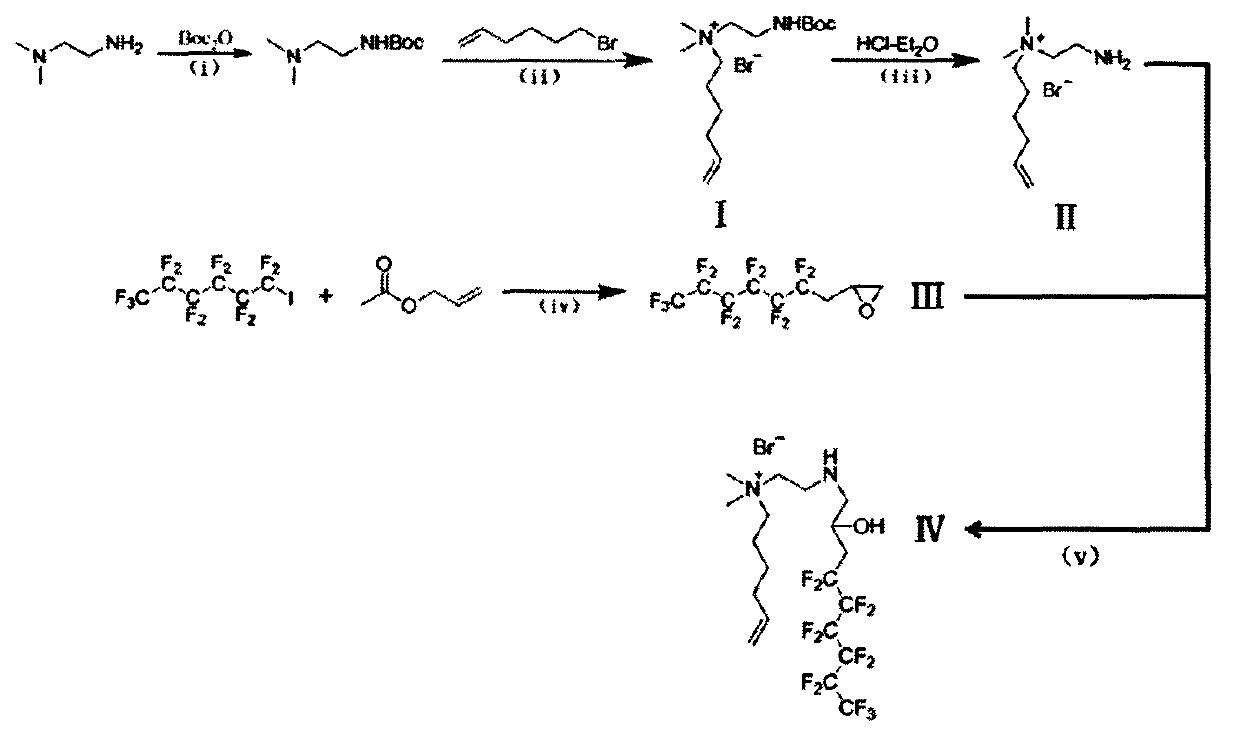

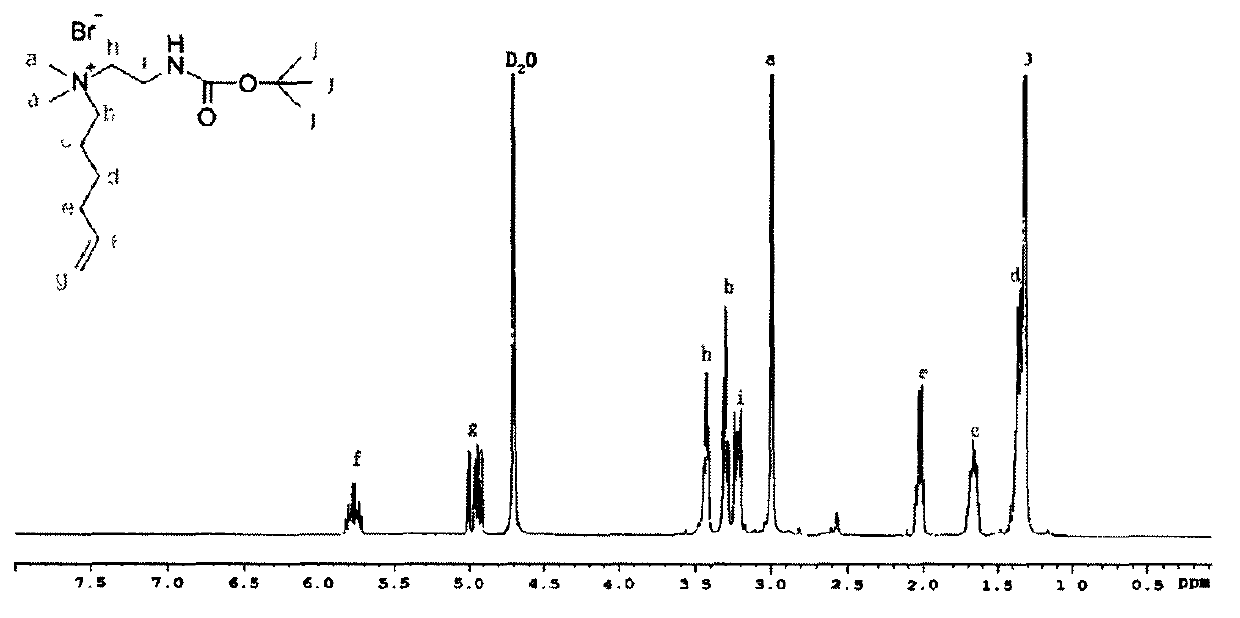

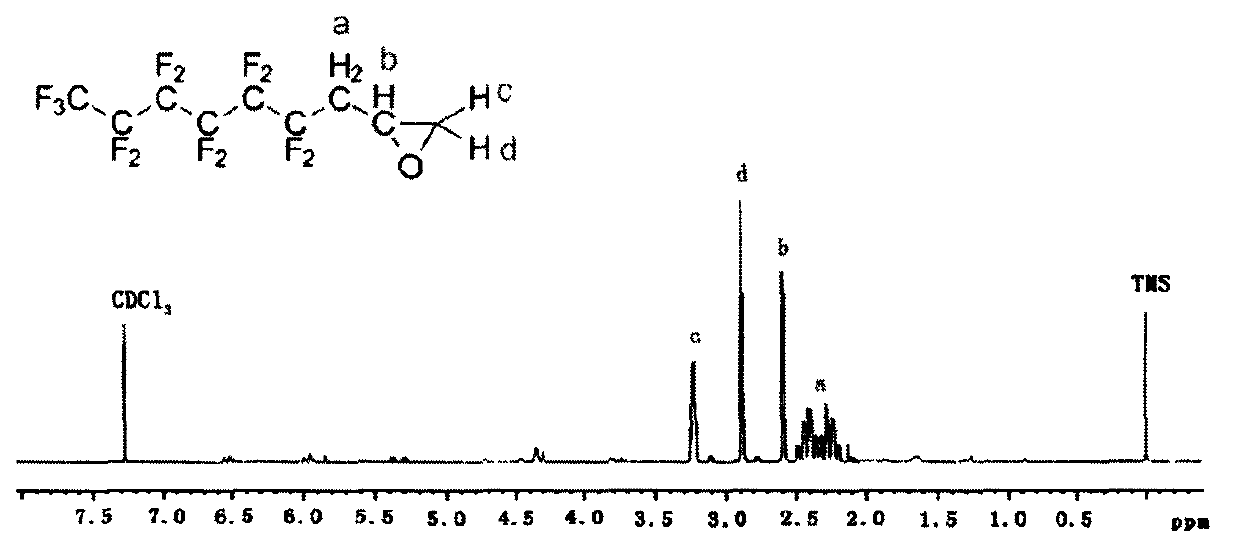

Preparation method of fluorocarbon/hydrocarbon mixed type cation surface active monomer

InactiveCN103214379AEasy to purifyRaw materials are easy to getOrganic compound preparationTransportation and packagingChemical industryHybrid type

The invention provides a preparation method of fluorocarbon / hydrocarbon mixed type cation surface active monomer, and the structural formula is shown in the description. The invention has the advantages of simple synthesis steps and products purification, high yield, safety usage and convenient storage. The fluorine containing surface active monomer can be copolymerized with a plurality of monomers for preparing various functional large molecules, and is widely applied to the fields of oil field exploitation, coating, fire-fighting, printing, electroplate, daily use chemical industry, medicine, etc.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com