Mixed rare earth sintering permanent magnet and preparation method thereof

A technology of mixed rare earths and mixed rare earth alloys, which is applied in the manufacture of magnetic objects, permanent magnets, inductors/transformers/magnets, etc., can solve problems such as difficulties and adverse effects on magnetic properties, and achieve the effects of protecting the environment and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

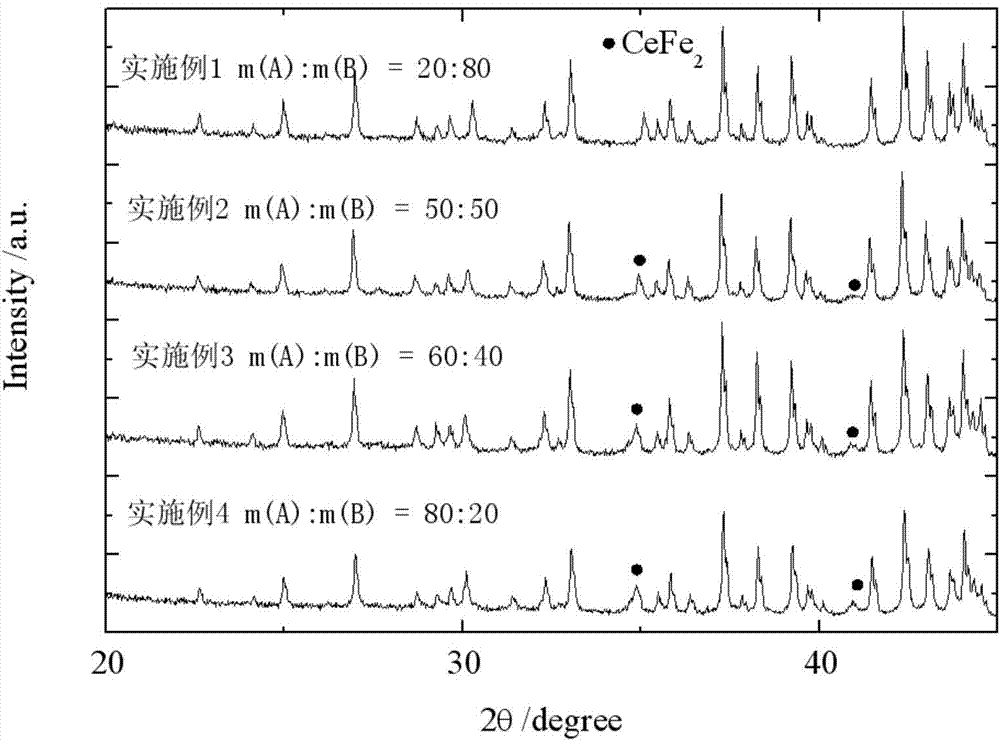

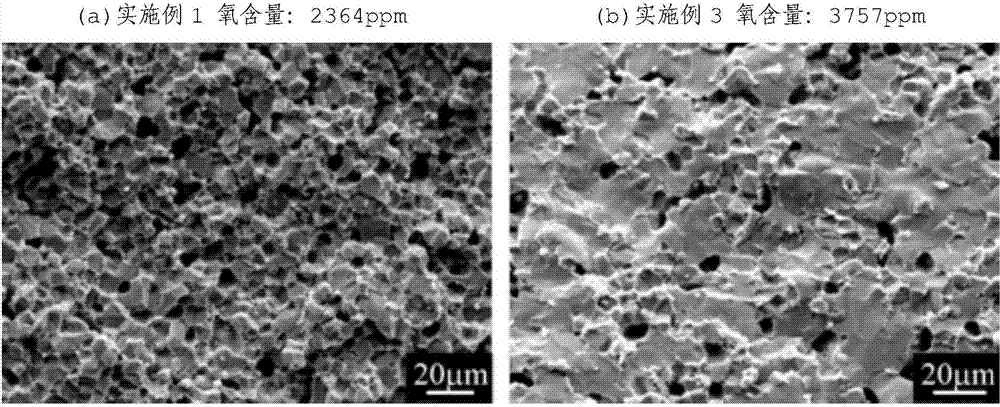

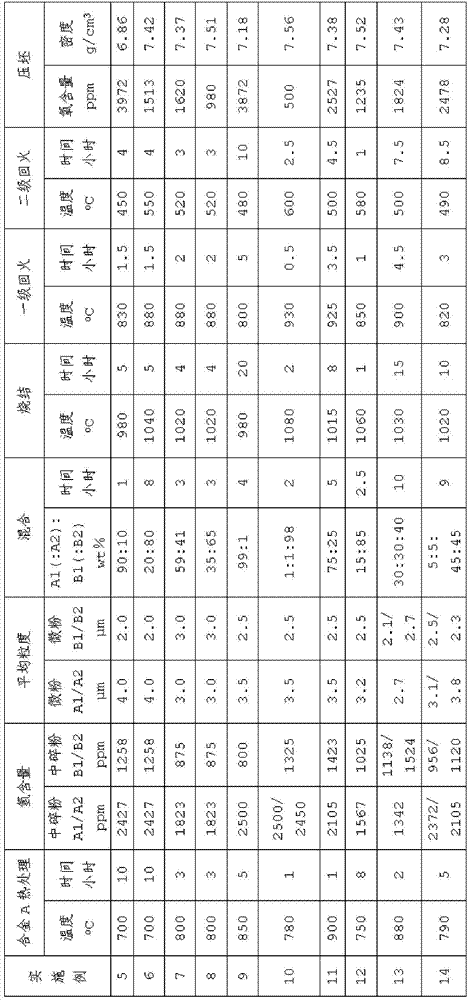

Embodiment 1

[0026] The mass fraction composition of alloy A is:

[0027] MM 32.6 Co 0.5 Cu 0.08 B 1.0 Fe More than MM is a typical mixed rare earth alloy of Baiyun Obo Mine in Baotou. Its composition is La27.1%, Ce51.5%, Pr5.2%, Nd16.2%, Sm less than 0.03%, and the rest are inevitable impurities.

[0028] The mass fraction composition of alloy B is:

[0029] (Pr, Nd) 28.8 Dy 1.8 Co 0.9 (Cu, Al, Nb) 0.5 B 1.0 Fe More than

[0030] The corresponding alloy flake A and alloy flake B are obtained by the quick-setting flake process, and their average thickness is 0.25mm. Then, the alloy flake A was kept at 800°C for 3 hours in a vacuum sintering furnace (vacuum degree 6.5 (Pr, Nd) 23.0 Dy 1.4 Co 0.7 B 1.0 (Cu, Al, Nb) 0.5 Fe More than . The sintered blank magnet is cut, ground to remove the oxide scale, and then the surface is cleaned with alkaline solution to obtain a base magnet of φ8mm×6.5mm, where the 6.5mm direction is the orientation direction.

[0031] Tb(NO 3 ) 3 And Tb-Fe-Al powder mixture,...

Embodiment 2

[0034] The composition of the used alloy A and alloy B and the preparation process of the fine powder are the same as in Example 1. The micropowders A and B were mixed at a ratio of 50:50 for 3 hours. The pressing and sintering process is also the same as in Example 1. The nominal composition of the obtained mixed rare earth permanent magnet sintered blank is MM 16.3 (Pr, Nd) 14.4 Dy 0.9 Co 0.5 B 1.0 (Cu, Al, Nb) 0.5 Fe More than . The sintered blank magnet is cut, ground to remove the oxide scale, and then the surface is cleaned with alkaline solution to obtain a base magnet of φ8mm×6.5mm, where the 6.5mm direction is the orientation direction.

[0035] The grain boundary diffusion method of the magnet and the subsequent tempering process are the same as in Example 1.

Embodiment 3

[0037] The composition of the used alloy A and alloy B and the preparation process of the fine powder are the same as in Example 1. The micropowders A and B were mixed at a ratio of 60:40 for 3 hours. The pressing and sintering process is also the same as in Example 1. The nominal composition of the obtained mixed rare earth permanent magnet sintered blank is MM 19.6 (Pr, Nd) 11.5 Dy 0.7 Co 0.4 B 1.0 (Cu, Al, Nb) 0.5 Fe More than . The sintered blank magnet is cut, ground to remove the oxide scale, and then the surface is cleaned with alkaline solution to obtain a base magnet of φ8mm×6.5mm, where the 6.5mm direction is the orientation direction.

[0038] The grain boundary diffusion method of the magnet and the subsequent tempering process are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com