Cow heat-stress resistant feed additive

A feed additive and heat stress technology, applied in animal feed, animal feed, application, etc., can solve the problems of poor appetite of dairy cows, harmful stimulation of the body, etc., to improve feed utilization and production performance, reduce the number of somatic cells, No Pollution Cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

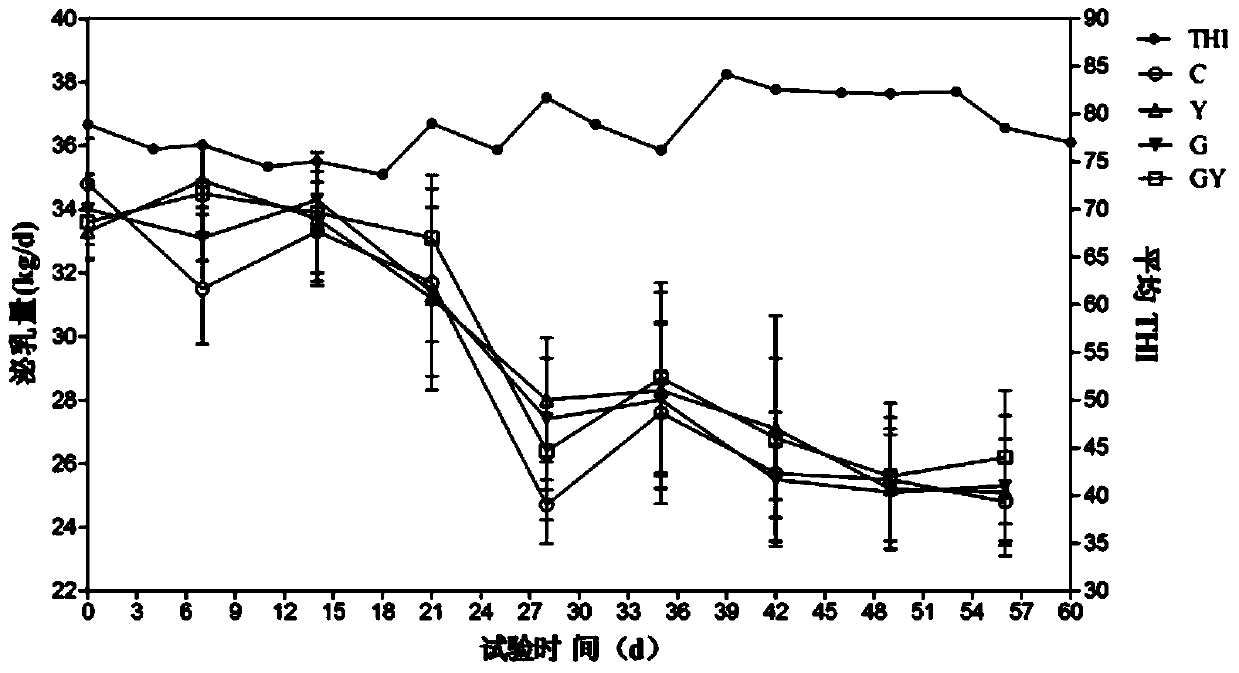

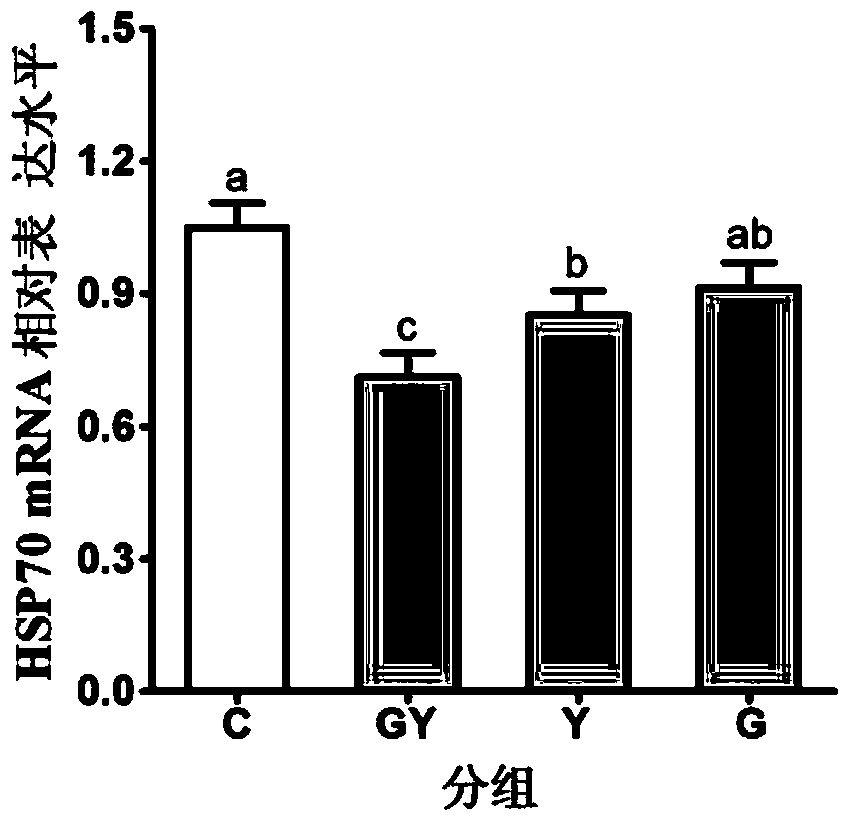

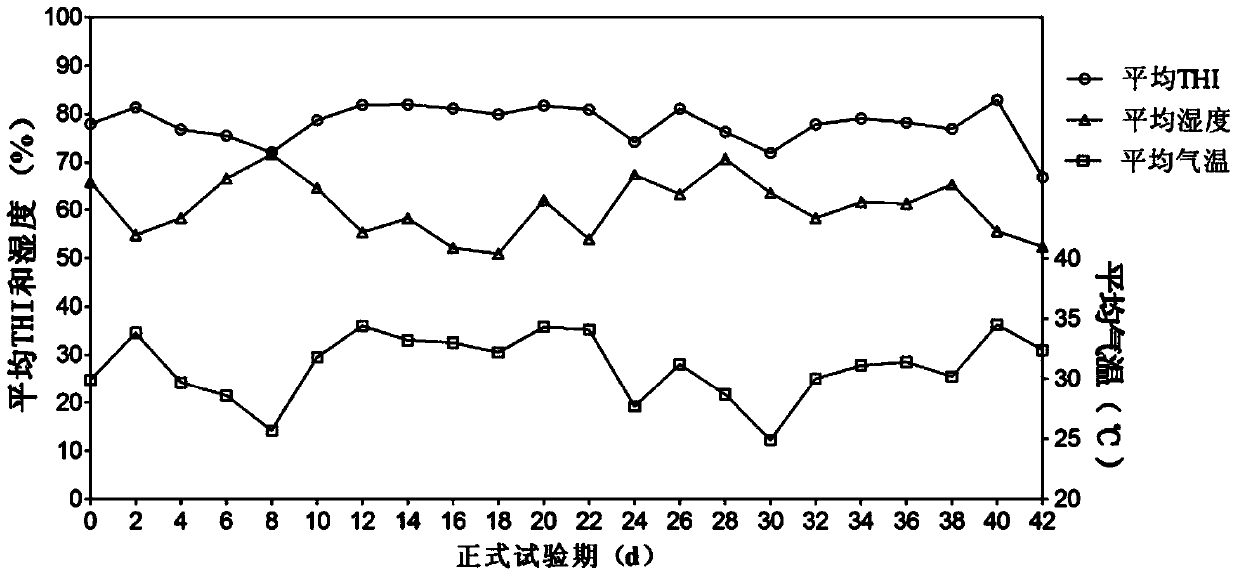

[0033] Example 1 Nanjing dairy farm

[0034] 1. Production of feed additives against heat stress in dairy cows

[0035] 1) Strains:

[0036] Saccharomyces cerevisiae (Sc) NAU‐ZH‐GY1, provided by our laboratory, has been preserved in the General Microbiology Center of China Committee for the Collection of Microbial Cultures, and the culture preservation number is CGMCC No.4551.

[0037] 2) Medium:

[0038] Slope activated medium (YPD): glucose 20g, yeast extract 10g, peptone 20g, agar 20g, water 1L, natural pH, 115°C, high-pressure steam sterilization for 15min, spare;

[0039]Seed culture medium: glucose 28g, yeast extract 14g, peptone 28g, water 1.4L, natural pH, 115°C, high-pressure steam sterilization for 15min, spare;

[0040] Production medium ingredients: glucose 42kg, peptone 280g, urea 420g, corn steep liquor powder 1.4kg, sodium chloride 5.6kg, MgSO 4 ·7H 2 O70g, calcium chloride 14g, thiamine 70g (added separately).

[0041] 3) Activation of strains and acquisi...

Embodiment 2

[0107] Embodiment 2 A dairy farm in Shanghai

[0108] 1. Production of feed additives against heat stress in dairy cows

[0109] 5) Strains:

[0110] Saccharomyces cerevisiae (Sc) NAU‐ZH‐GY1, provided by our laboratory, has been preserved in the General Microbiology Center of China Committee for the Collection of Microbial Cultures, and the culture preservation number is CGMCC No.4551.

[0111] 6) Medium:

[0112] Slope activated medium (YPD): glucose 20g, yeast extract 10g, peptone 20g, agar 20g, water 1L, natural pH, 115°C, high-pressure steam sterilization for 15min, spare;

[0113] Seed medium: glucose 75g, yeast extract 30g, peptone 60g, water 3L, natural pH, 115°C, high-pressure steam sterilization for 15min, spare;

[0114] Production medium ingredients: glucose 49kg, peptone 420g, urea 560g, corn steep liquor powder 1.7kg, sodium chloride 5.6kg, MgSO 4 ·7H 2 O98g, calcium chloride 14g, thiamine 98g (added separately).

[0115] 7) Activation of strains and acquisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com