High-saturation magnetization Z-type hexagonal ferrite powder and preparation method thereof

A hexagonal ferrite, magnetization technology, applied in the direction of inductor/transformer/magnet manufacturing, magnetic objects, magnetic materials, etc., can solve the problem of hexagonal ferrite saturation magnetization is not high enough, limited performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

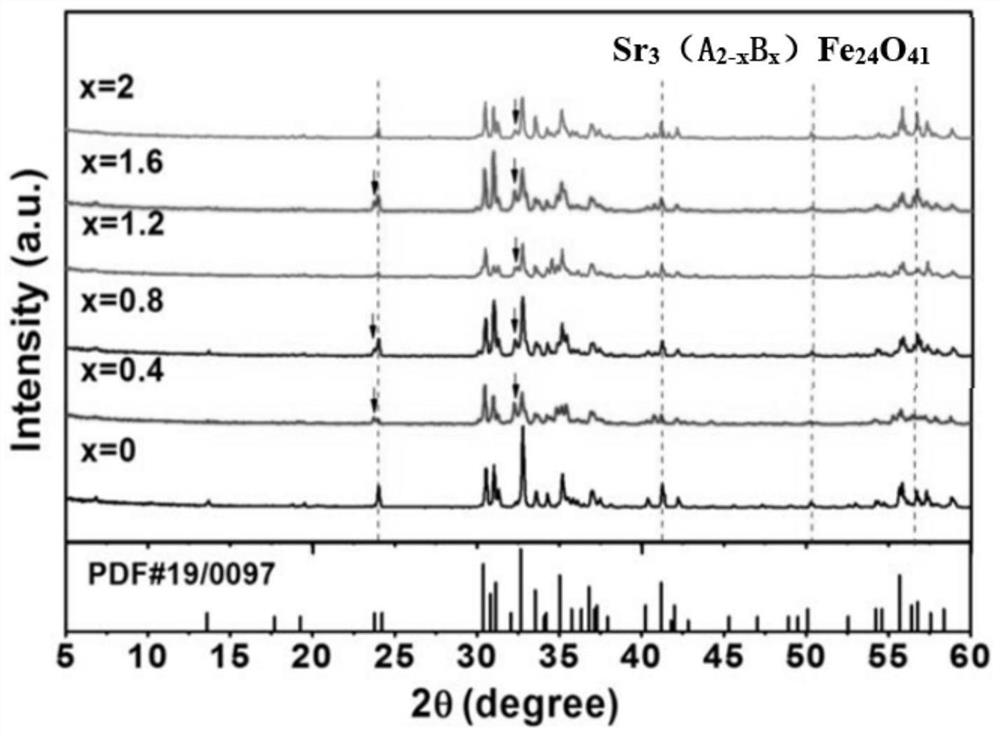

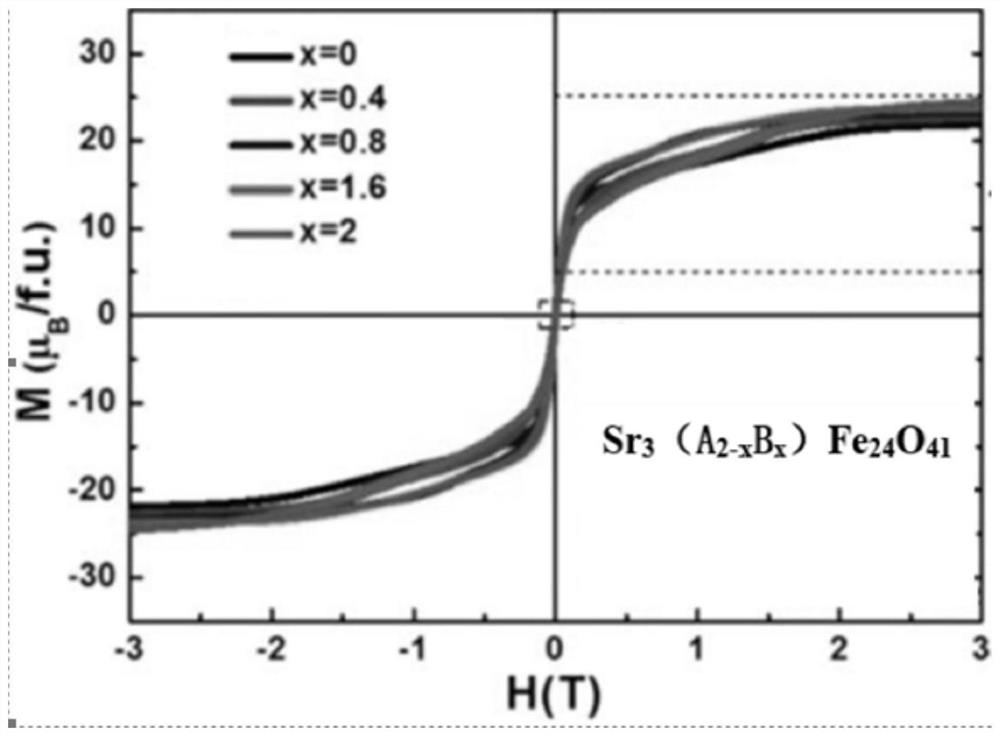

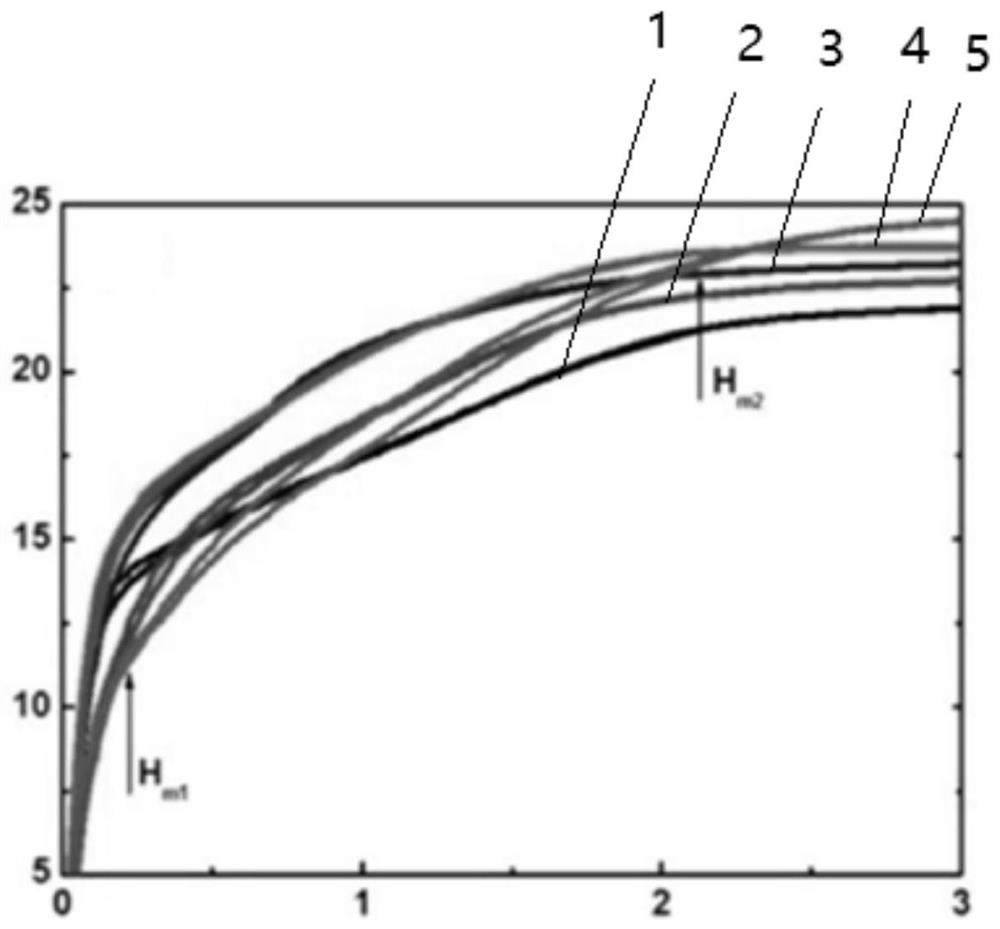

[0025] A high saturation magnetization Z-type hexagonal ferrite powder, the structure of the high saturation magnetization Z-type hexagonal ferrite powder is Sr 3 co 2 Fe 24 o 41 .

[0026] A method for preparing Z-type hexagonal ferrite powder with high saturation magnetization, comprising the following steps:

[0027] (1) with high-purity SrCO 3 、Co 2 o 3 , Fe 2 o 3 The powder is the raw material, and each raw material is weighed according to the atomic molar ratio in the molecular formula;

[0028] (2) Mix the weighed raw materials and place them in a ball mill jar, and add alcohol and ball milling beads into the ball mill jar, then put the ball mill jar on a ball mill for ball milling, after ball milling, a mixed solution is obtained, and the speed of the ball mill is 500 R / min, the ball milling time is 10 hours;

[0029] (3) Put the mixed solution after ball milling into a mortar, put the mortar into a dryer to dry to obtain the first powder, control the drying...

Embodiment 2

[0034] A high saturation magnetization Z-type hexagonal ferrite powder, the structure of the high saturation magnetization Z-type hexagonal ferrite powder is Sr 3 co 1.6 Zn 0.4 Fe 24 o 41 .

[0035] A method for preparing Z-type hexagonal ferrite powder with high saturation magnetization, comprising the following steps:

[0036] (1) with high-purity SrCO 3 、Co 2 o 3 , ZnO, Fe 2 o 3 The powder is the raw material, and each raw material is weighed according to the atomic molar ratio in the molecular formula;

[0037] (2) Mix the weighed raw materials and place them in a ball mill jar, and add alcohol and ball milling beads into the ball mill jar, then put the ball mill jar on a ball mill for ball milling, after ball milling, a mixed solution is obtained, and the speed of the ball mill is 500 R / min, ball milling time is 10h;

[0038] (3) Put the mixed solution after ball milling into a mortar, put the mortar into a dryer to dry to obtain the first powder, control the ...

Embodiment 3

[0043] A high saturation magnetization Z-type hexagonal ferrite powder, the structure of the high saturation magnetization Z-type hexagonal ferrite powder is Sr 3 co 1.2 Zn 0.8 Fe24 o 41 .

[0044] A method for preparing Z-type hexagonal ferrite powder with high saturation magnetization, comprising the following steps:

[0045] (1) with high-purity SrCO 3 、Co 2 o 3 , ZnO, Fe 2 o 3 The powder is the raw material, and each raw material is weighed according to the atomic molar ratio in the molecular formula;

[0046] (2) Mix the weighed raw materials and place them in a ball mill jar, and add alcohol and ball milling beads into the ball mill jar, then put the ball mill jar on a ball mill for ball milling, after ball milling, a mixed solution is obtained, and the speed of the ball mill is 500 R / min, ball milling time is 10h;

[0047] (3) Put the mixed solution after ball milling into a mortar, put the mortar into a dryer to dry to obtain the first powder, control the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com