Production process of dendritic polyamidoamine

A technology of polyamidoamine and production process, which is applied in the chemical synthesis process field of dendritic polymers, can solve the problems of toluene residue, restriction of industrial production, and restriction of industrialization, so as to reduce the generation of by-products, reduce the multiple of monomer excess, The effect of reducing the harm to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

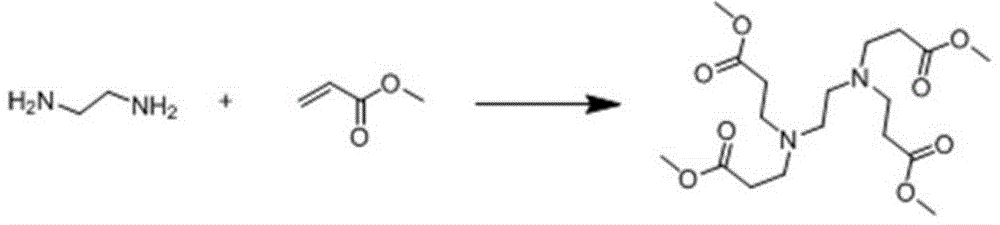

Embodiment 1

[0051] The temperature of the 1 ton reactor is controlled by a low-temperature cooling cycle machine to -5±2°C, and 14Kg of ethylenediamine (EDA) dissolved in 70Kg of methanol is added to the reactor; 112Kg of methyl acrylate is dissolved in 444Kg of methanol, And join it in the reaction kettle and mix with the methanol solution of EDA; Keep this temperature, adopt nitrogen protection and under the mechanical agitation under continuous reaction 24h, then by 200L rotary evaporator under vacuum state, excess solvent and unreacted small molecule In order to remove unreacted small molecules to obtain a product with higher purity, the rotary evaporator with continuous feeding and discharging is used for repeated purification with solvent methanol three times to obtain the G-0.5 generation dendritic polyamidoamine.

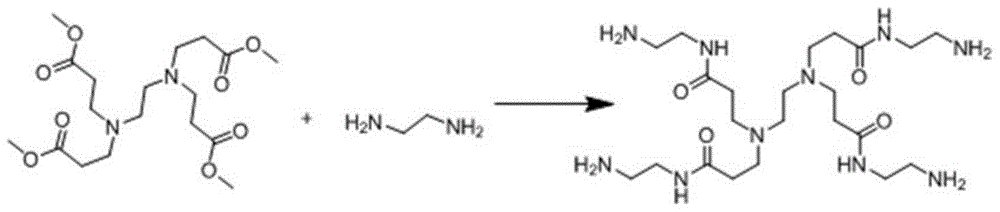

Embodiment 2

[0053]Dissolve 118.2KgEDA in 463Kg of methanol and add it to a 1-ton reactor. The cooling cycle machine precisely controls the temperature to keep it at 0±2°C; then add dropwise 9.8KgG-0.5 dendritic polyamidoamine dissolved in 49Kg of methanol , under nitrogen protection and mechanical stirring; use a low-temperature cooling cycle machine to control the temperature of the reactor at 20±2°C, and stir at a constant temperature for 48 hours. After the reaction is complete, most of the excess methanol and EDA are removed by vacuum distillation, and then the initially purified The crude product is further purified by a rotary evaporator with continuous feed and discharge at 70°C. In order to purify excess unreacted small molecules as much as possible, n-butanol is used as an entrainer for methanol and ethylenediamine. Purified by rotary steaming once, and then washed three times with methanol to finally obtain the G0 generation dendritic polyamidoamine.

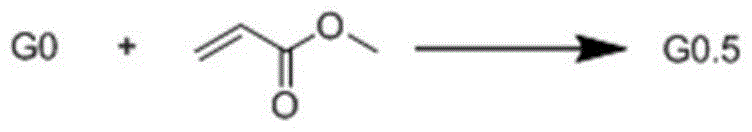

Embodiment 3

[0055] The temperature of the 1 ton reactor is controlled by a low-temperature cooling cycle machine to -5±2°C, 120.5KgMA dissolved in 472Kg of methanol is added to the reactor, and then 7.5KgG0 generation dendrite dissolved in 40Kg of methanol is added dropwise to the reactor Polyamidoamine solution, under the protection of nitrogen and mechanical stirring, the reaction temperature is controlled by a low-temperature cooling cycle machine to 20±2°C, and the reaction is continued for 24 hours. After the reaction is complete, excess methanol and MA are removed by vacuum distillation, and then the preliminary purified crude The product was further purified by a 200L rotary evaporator with continuous feeding and discharging at 60°C. In order to purify the excess unreacted small molecules as much as possible, the product was purified three times with the solvent methanol to obtain the G0.5 generation dendrimer amidoamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com