Method for preparing polymer nano micelle by water solution polymerization self-emulsification method

An aqueous solution polymerization and nano-micelle technology, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems of drug or human injury, low concentration, etc., and achieve good results, easy operation, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

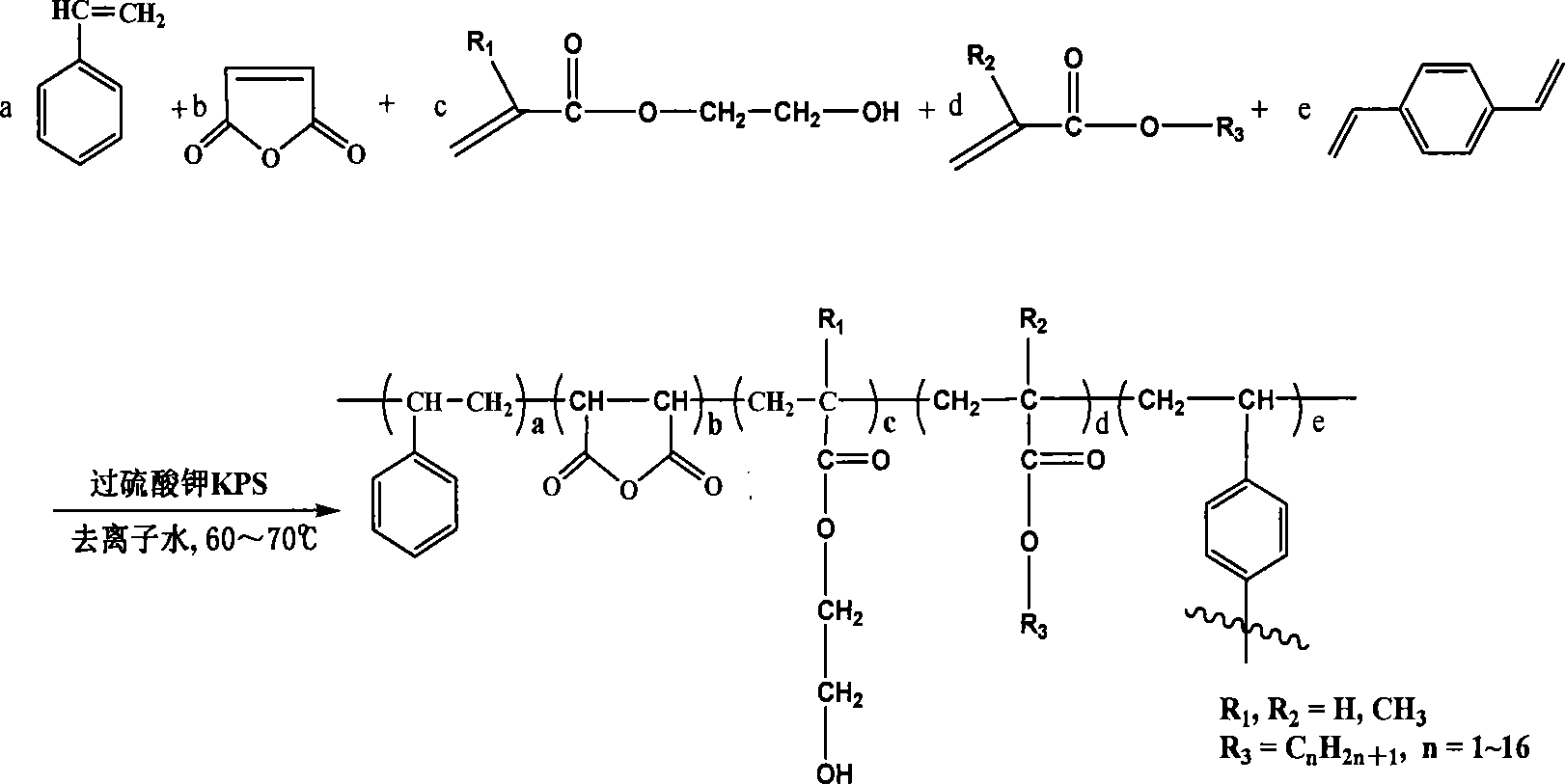

Method used

Image

Examples

Embodiment 1

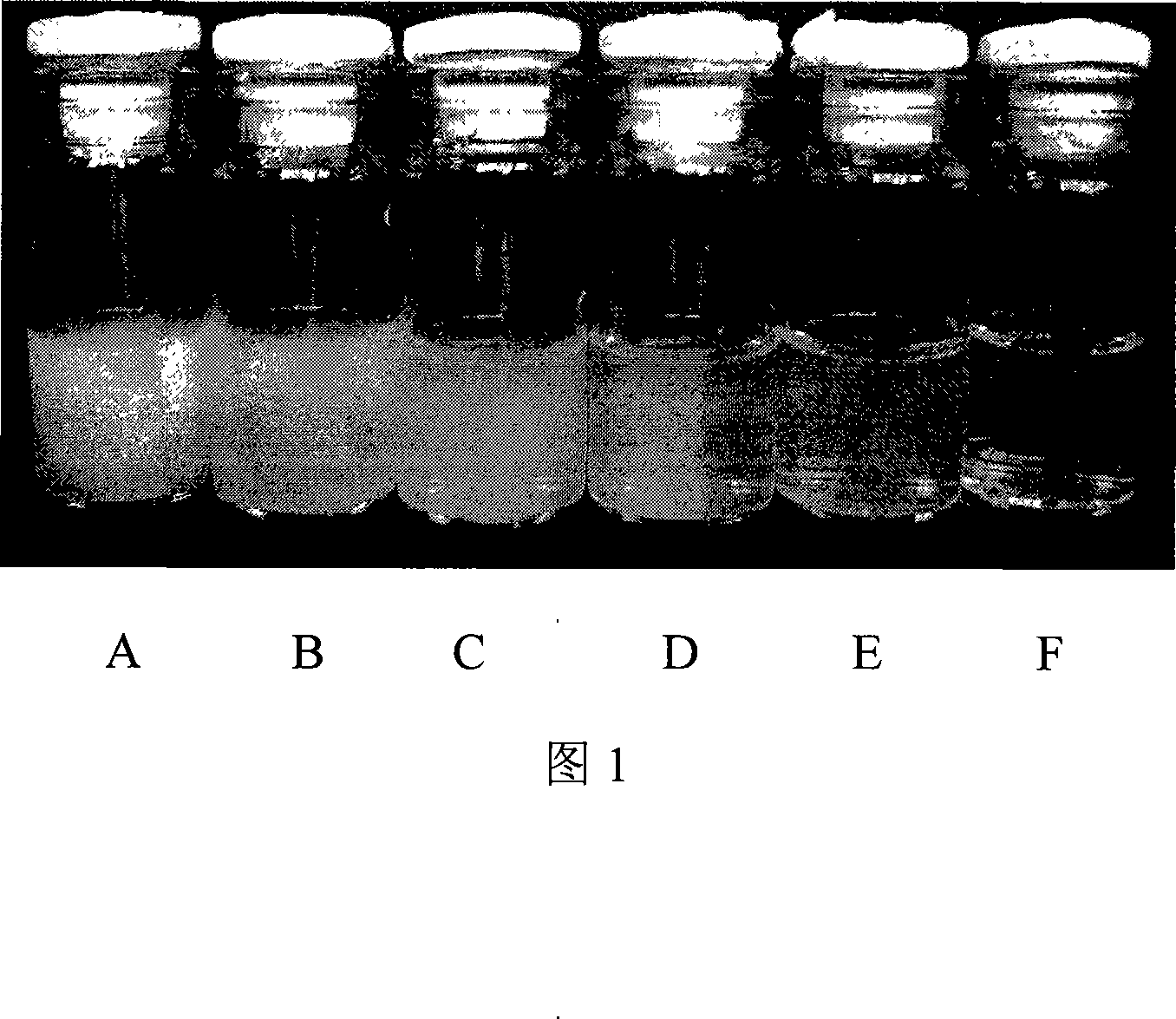

[0023] Embodiment 1. styrene / maleic anhydride mol ratio is 1.5: 1, and adding butyl acrylate (accounting for 5% of all monomer molar consumptions) is the 3rd monomer, with potassium persulfate as initiator (consumption is unit 2% of the total moles of the monomer), with deionized water as the reaction solvent, and the weight percentage of the monomer in the aqueous solution was 15%, and reacted at 60° C. for 20 hours to ensure that all the monomers were completely reacted. Its polymer micelle solution is shown in accompanying drawing 1-A.

Embodiment 2

[0024] Embodiment 2. styrene / maleic anhydride mol ratio is 1.5: 1, and add hydroxyethyl acrylate (accounting for 10% of all monomer molar consumption), butyl acrylate (accounting for all monomer molar consumption 10%), P-divinylbenzene (accounting for 1.5% of the molar amount of all monomers) is a crosslinking agent, potassium persulfate is used as an initiator (the amount is 1.5% of the total molar amount of monomers), and deionized water is used as a reaction solvent, and The weight percent of the monomers in the aqueous solution was 30%, and the reaction was carried out at 60° C. for 20 hours to ensure that all the monomers were completely reacted. Its polymer micelle solution is shown in accompanying drawing 1-B.

Embodiment 3

[0025] Embodiment 3. styrene / maleic anhydride mol ratio is 1.5: 1, and adding hydroxyethyl acrylate (accounting for 10% of all monomer molar consumption) is the third monomer, with potassium persulfate as initiator (consumption is 1% of the total moles of the monomers), with deionized water as the reaction solvent, and the weight percentage of the monomers in the aqueous solution was 25%, and reacted at 60° C. for 20 hours to ensure that all the monomers were completely reacted. Its polymer micelle solution is shown in accompanying drawing 1-C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com