Patents

Literature

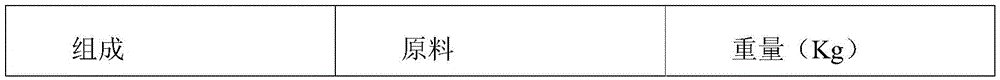

156 results about "2-HYDROXYETHYL ACRYLATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the same test, 3 volunteer controls were negative to 2-hydroxyethyl acrylate. ... 2-hydroxyethyl acrylate penetrates both latex and vinyl gloves and elicits irritant/allergic reactions on the patient and irritant reactions on a control.

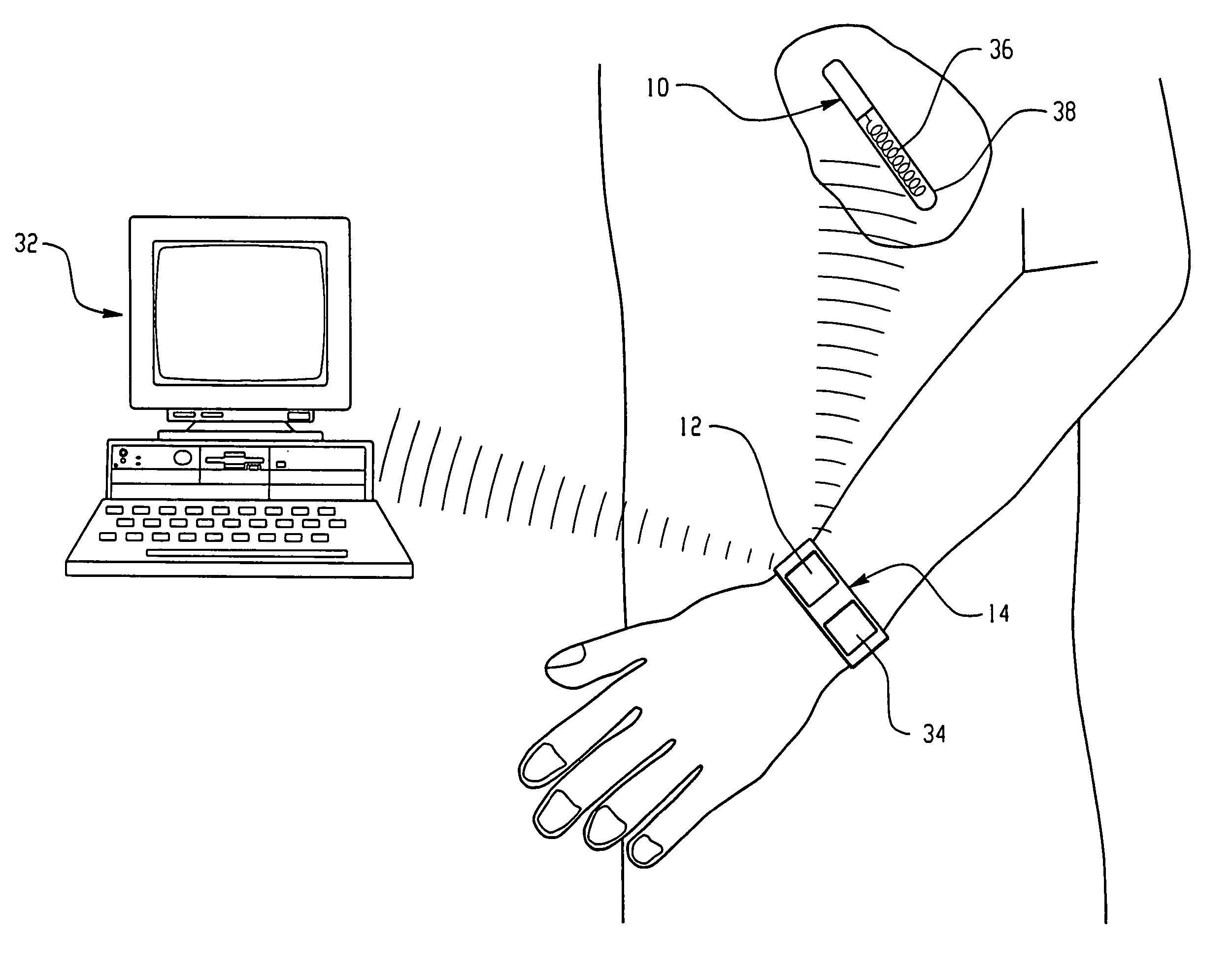

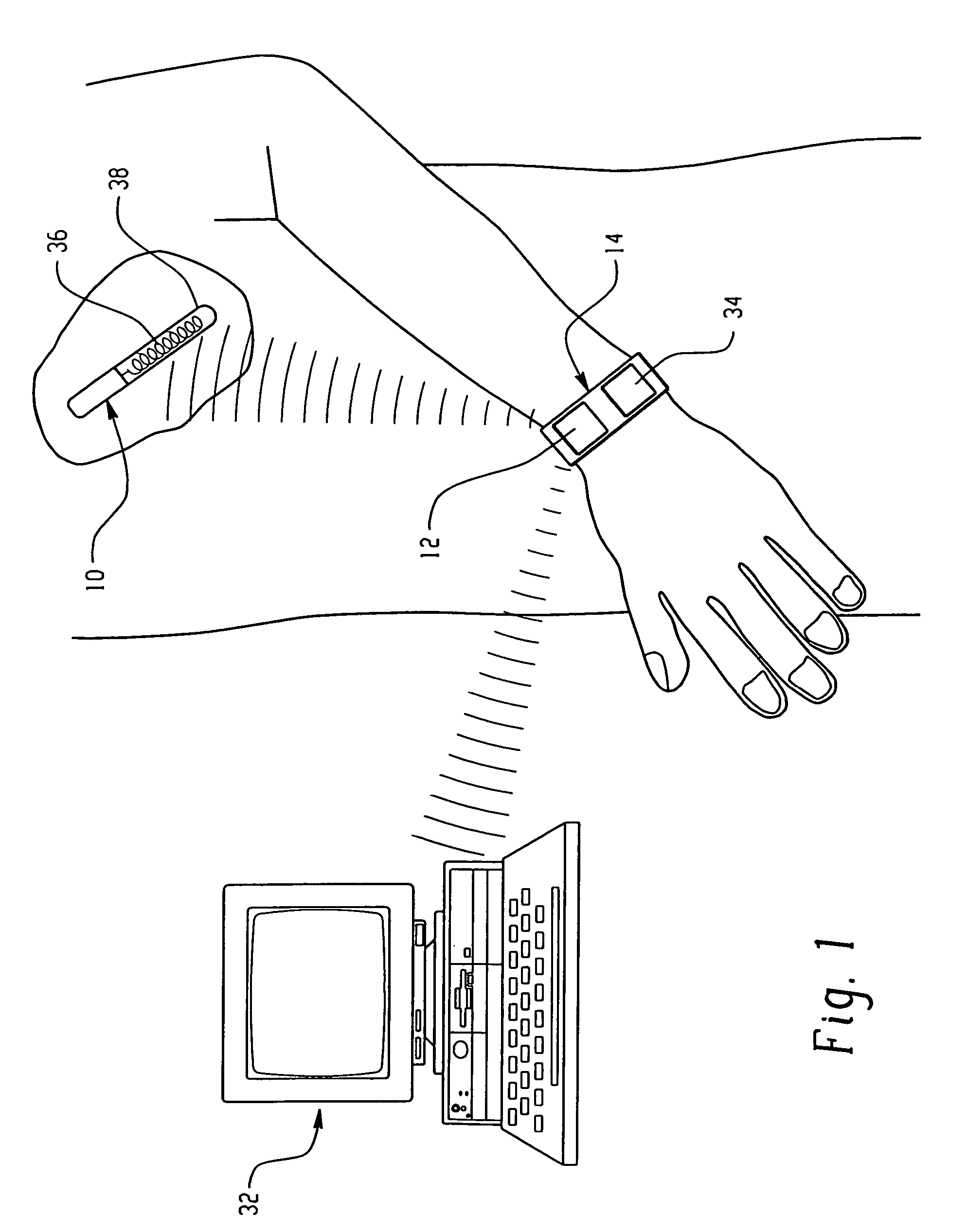

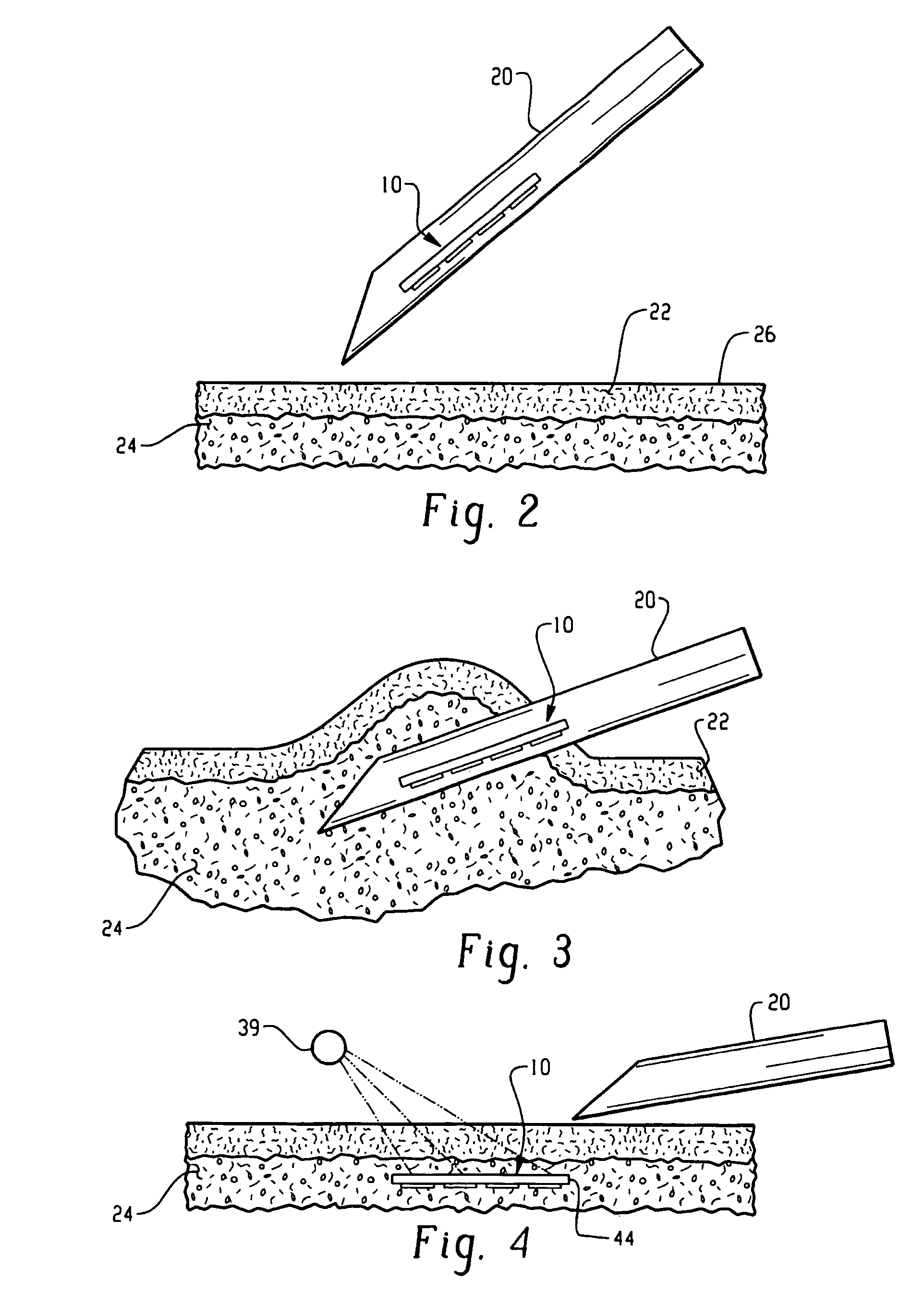

Sensor system

InactiveUS7964390B2Bioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteSensor system

A sensor probe suited for implanting into the skin of a person includes a sensor body which may be formed from a polymer which includes 2-hydroxyethyl methacrylate (HEMA). A sensing system is supported by the body. The sensing system exhibits a detectable change when the probe is exposed to the analyte in the fluid. The sensing system may include an enzyme capable of catalyzing a reaction of the analyte to form a reaction product and a dye system which absorbs in the infrared region of the spectrum in response to the reaction product.

Owner:CASE WESTERN RESERVE UNIV

Method of preparing watersoluble polyurethane adhesive

InactiveCN101508879AGood flexibilitySmall smellPolyureas/polyurethane adhesivesPolyurethane adhesiveEmulsion

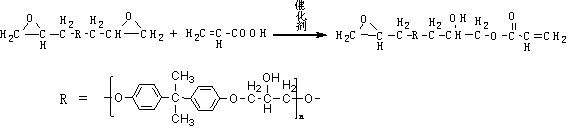

The invention discloses a preparation method of a waterborne polyurethane adhesive, comprising the following steps: evenly mixing vulcabond and polyglycols, adding in proper amount of catalyst, and reacting so as to obtain polyurethane prepolymer; reacting by adding in hydrophilic chain extender and crosslinking agent, adding 2-hydroxyethyl acrylate into the reaction system so as to obtain polyurethane, terminal group of which is double bond; reducing temperature, neutralizing and emusifying by adding in water under high-speed cutting so as to obtain polyurethane emulsion; and heating up, adding vinyl monomer into the emulsion, and polymerizing initiated by water-soluble initiator so as to obtain the modified waterborne polyurethane emulsion. The invention can completely eliminate the harmful effect to the application and the environment protection of the polyurethane emulsion product caused by small molecular emulsifier and organic solvent. The invention can make full use of combination property through the copolymerization modification between the polyurethane and polyacrylic ester.

Owner:SHAANXI UNIV OF SCI & TECH

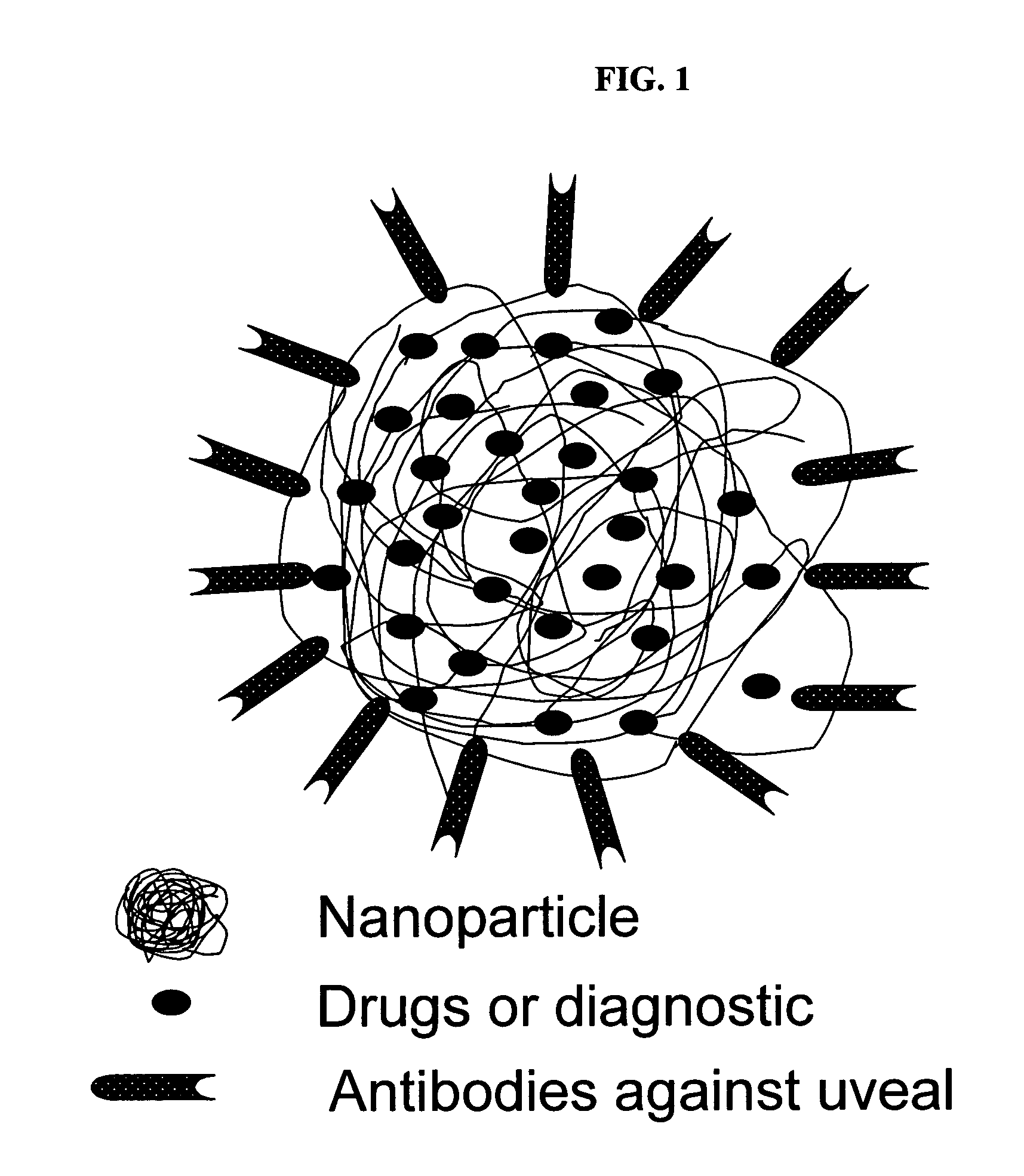

Functionalized particles

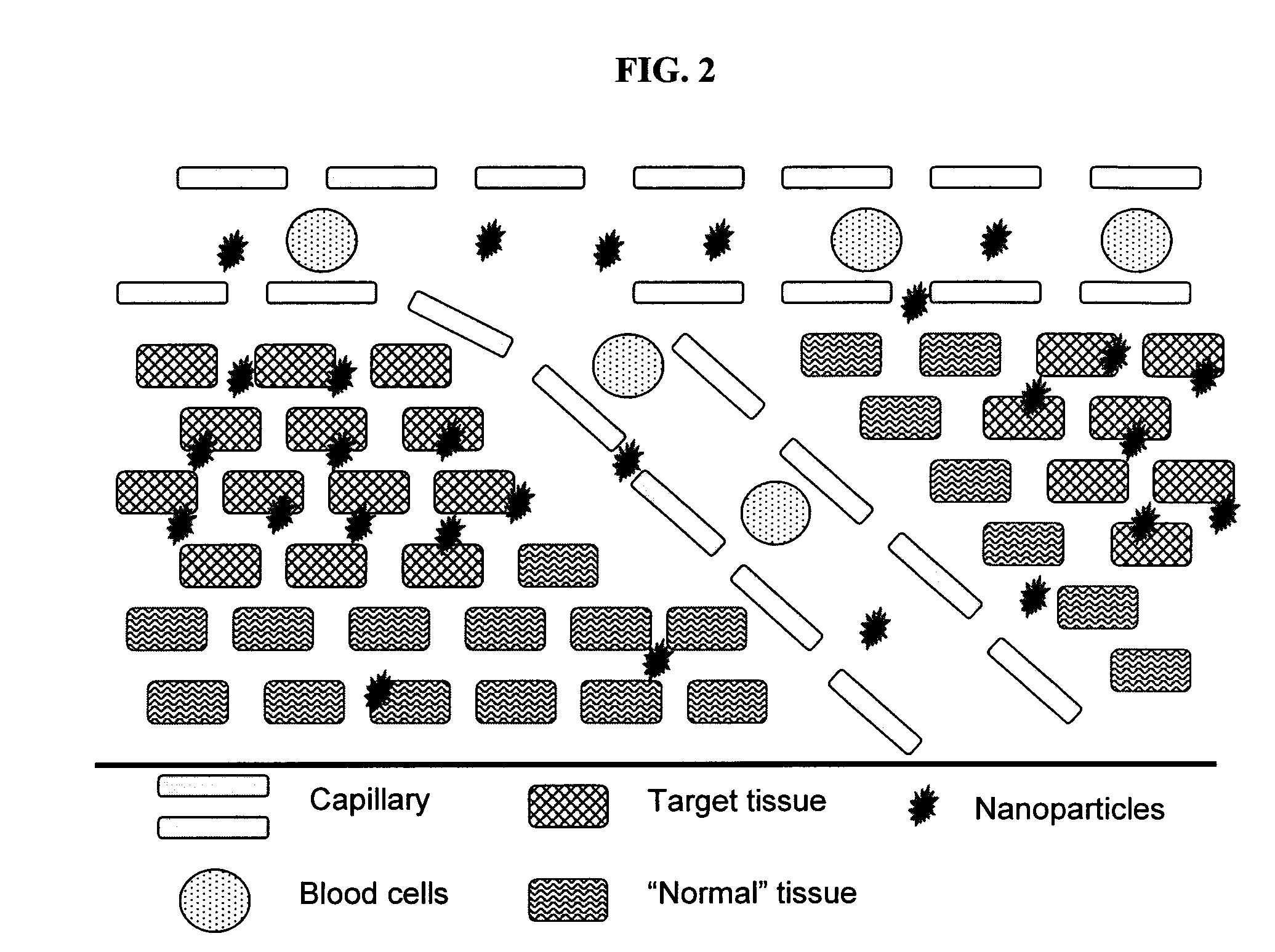

InactiveUS20050084456A1Safe and effectiveSafely and selectivelyPowder deliveryMicroencapsulation basedPhysiologic BarrierMethyl group

The present invention provides functionalized particles and methods for delivering said particles capable of crossing a physiologic barrier and exerting an effect. In one embodiment, the present invention provides a method of delivering a particle to a mammal comprising the steps of contacting a functionalized particle with a tag and introducing the functionalized and tagged particle to a mammal, wherein the functionalized portion of the particle is selected from the group consisting of acrylic acid, 2-hydroxyethyl acrylate, 2-acrylamido-2-methyl-1-propanesulfonic acid, allylamine, carboxyl group, hydroxyl group, sulfonic group, aldehyde and amine group. The particle is a biodegradable or nodegradable polymer and less than 1.0 mm in diameter.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

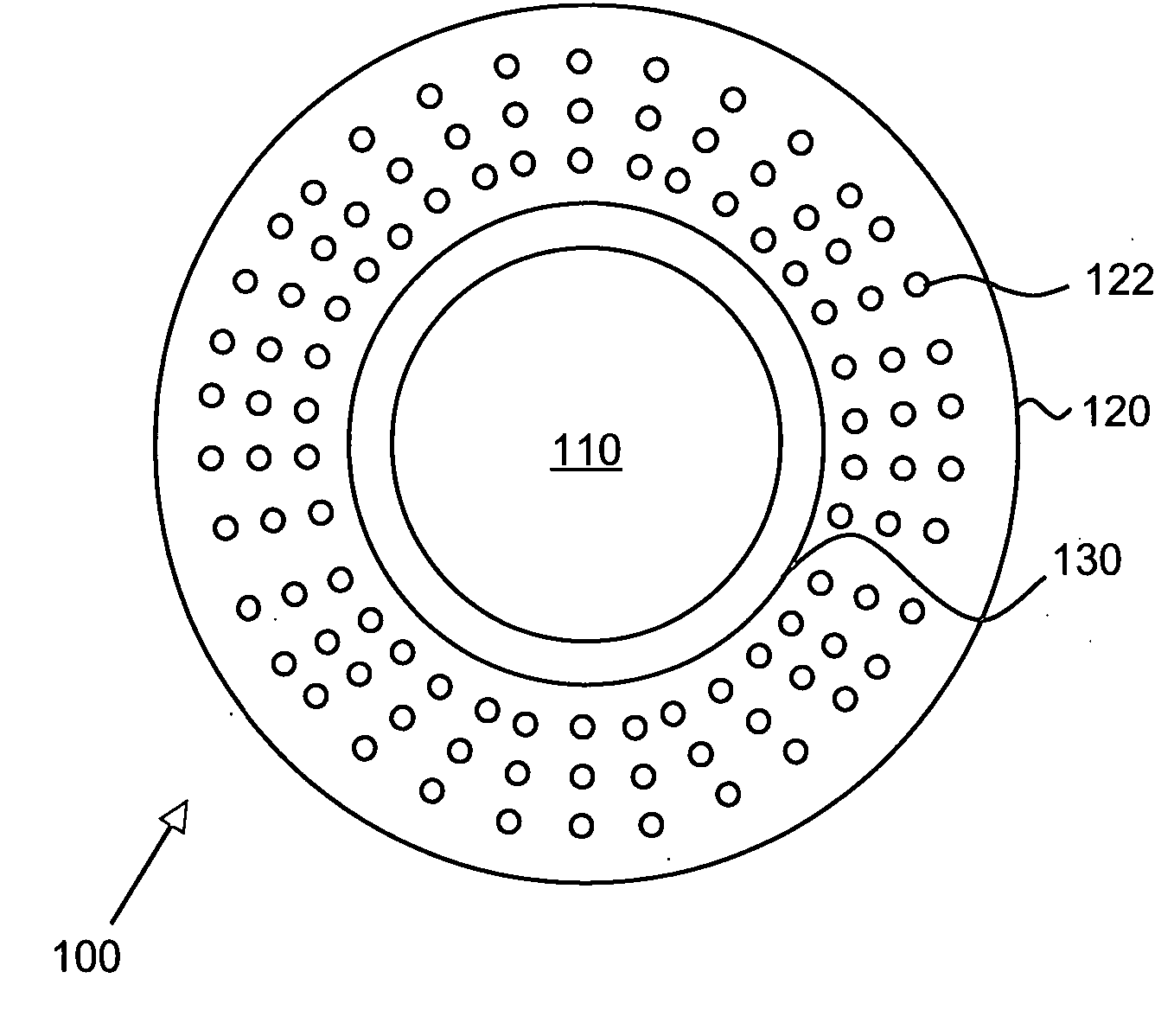

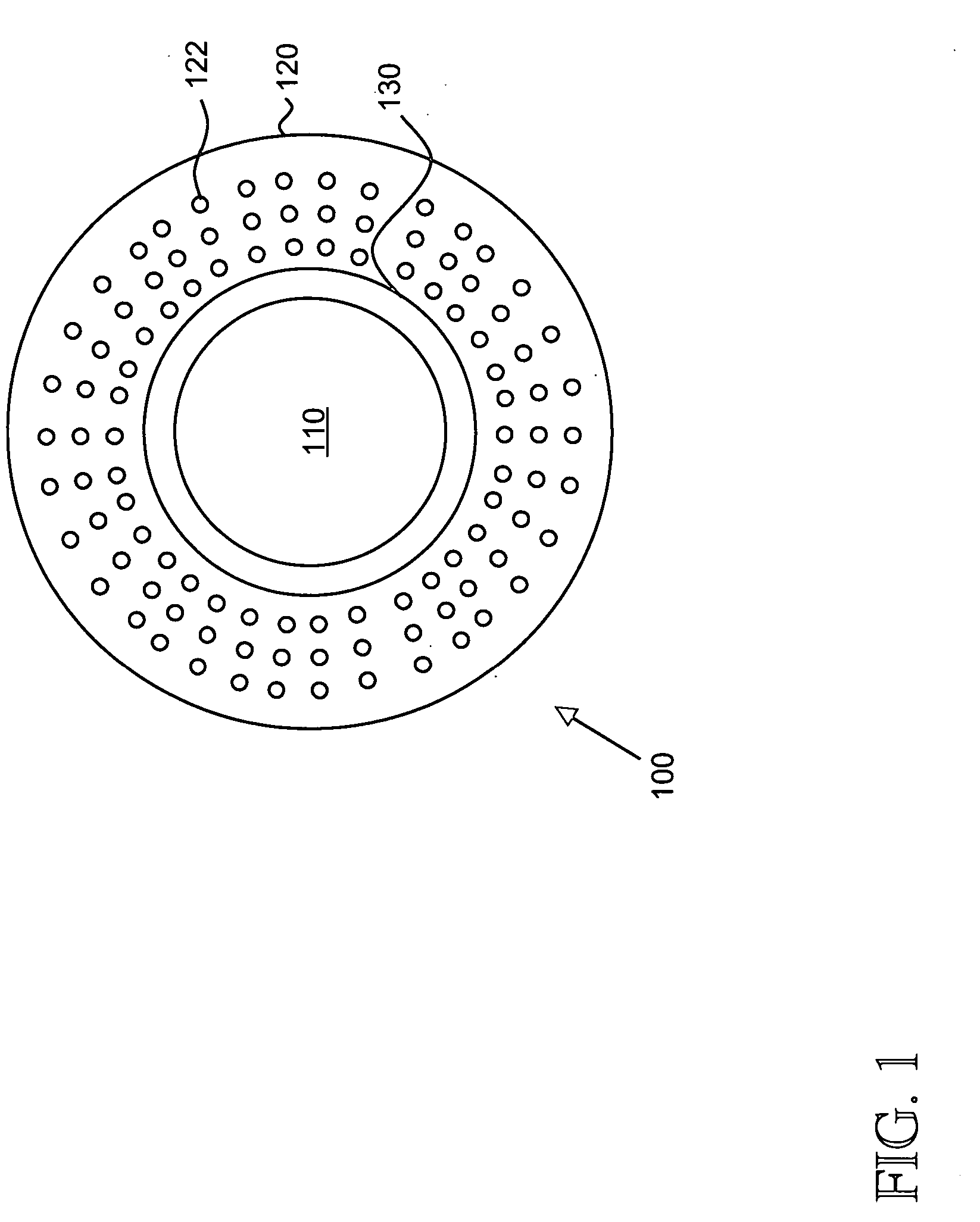

Artificial cornea

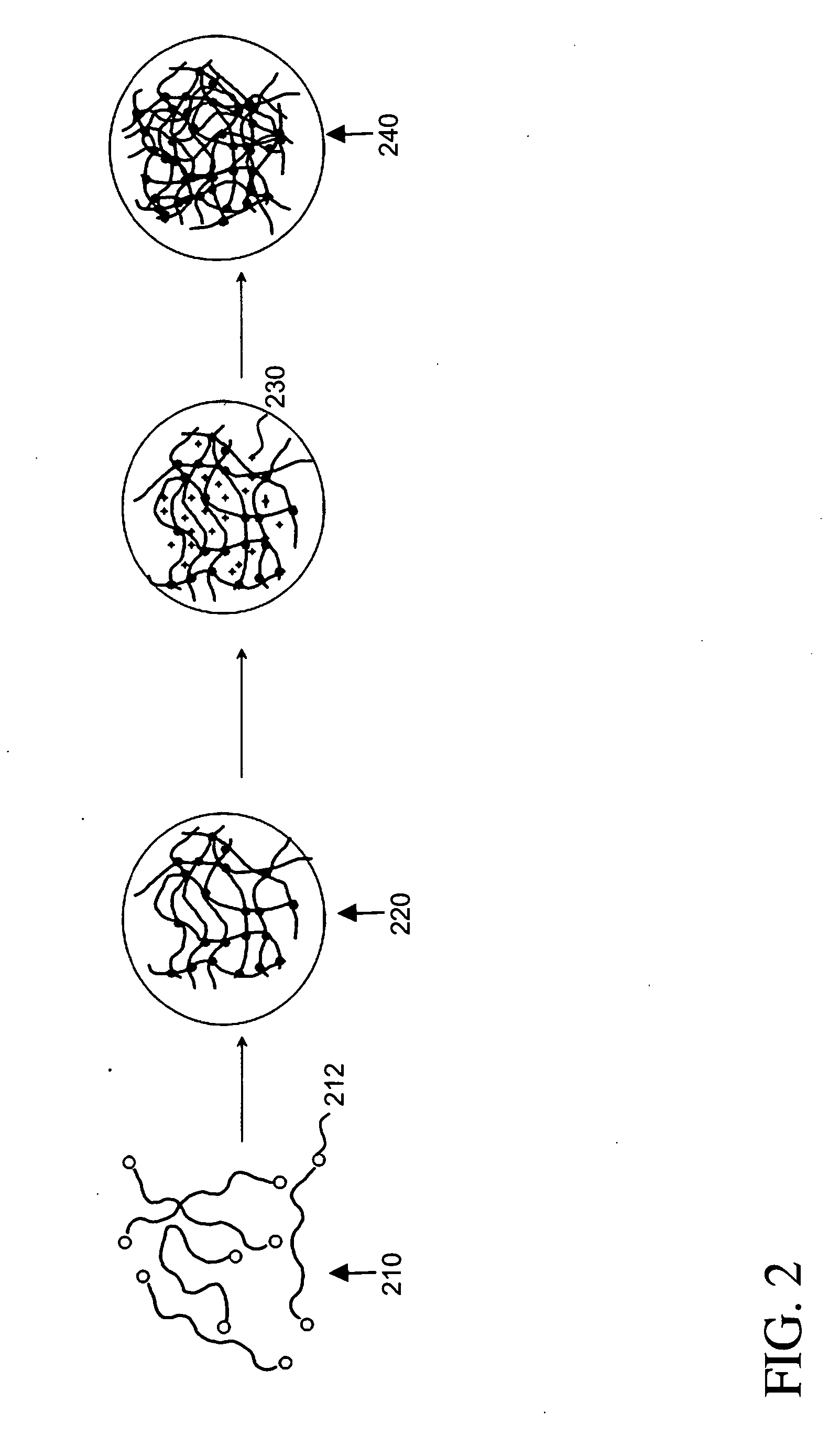

The present invention provides an artificial corneal implant having an optically clear central core and a porous, hydrophilic, biocompatible skirt peripheral to the central core. In one embodiment, the central core is made of an interpenetrating double network hydrogel and the skirt is made of poly(2-hydroxyethyl acrylate) (PHEA). In another embodiment, both the central core and the skirt are made of interpenetrating double network hydrogels. The artificial corneal implant may also have an interdiffusion zone in which the skirt component is interpenetrated with the core component, or vice versa. In a preferred embodiment, biomolecules are linked to the skirt, central core or both. These biomolecules may be any type of biomolecule, but are preferably biomolecules that support epithelial and / or fibroblast cell survival and growth. Preferably, the biomolecules are linked in a spatially selective manner. The present invention also provides a method of making an artificial corneal implant using photolithography.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

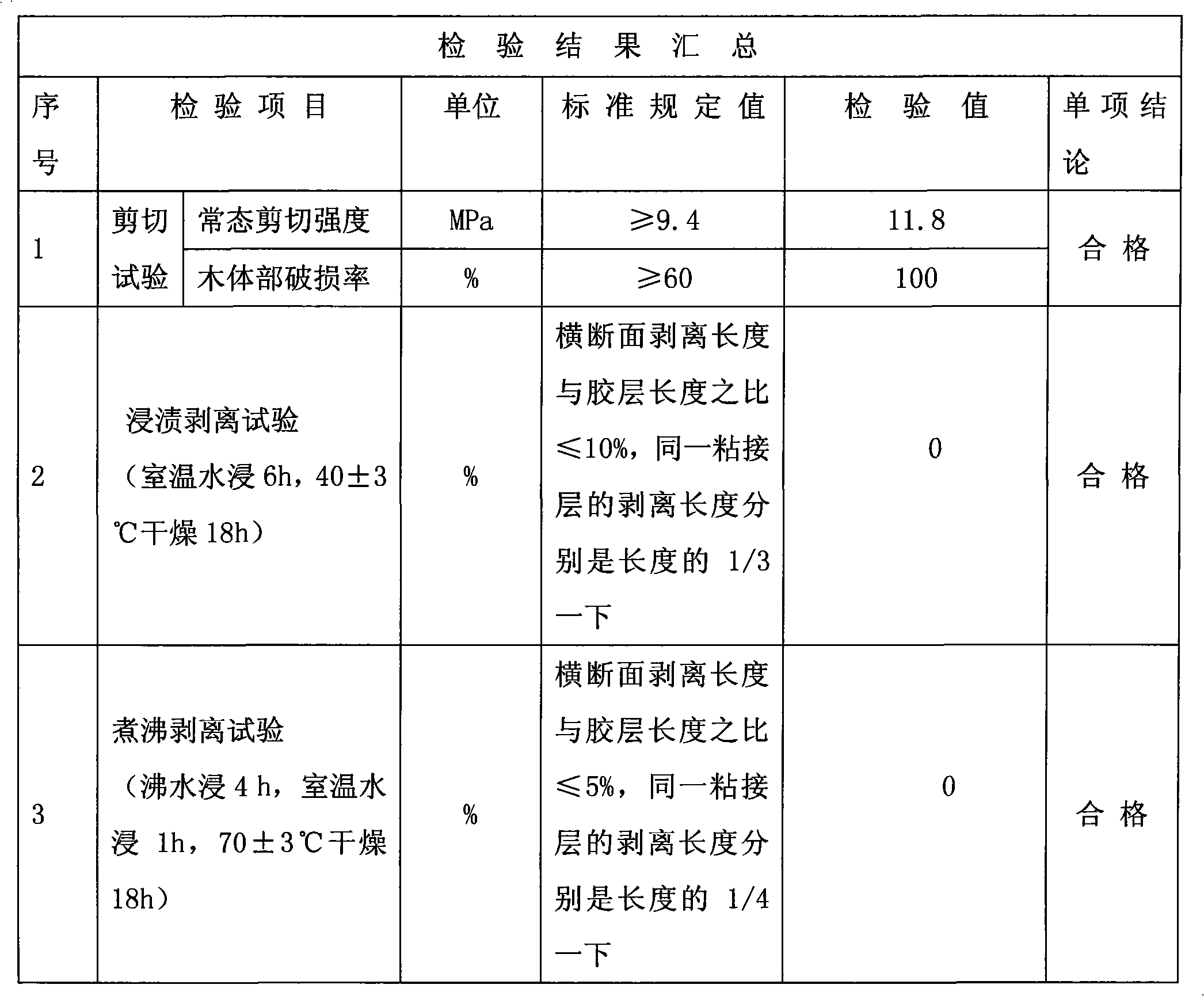

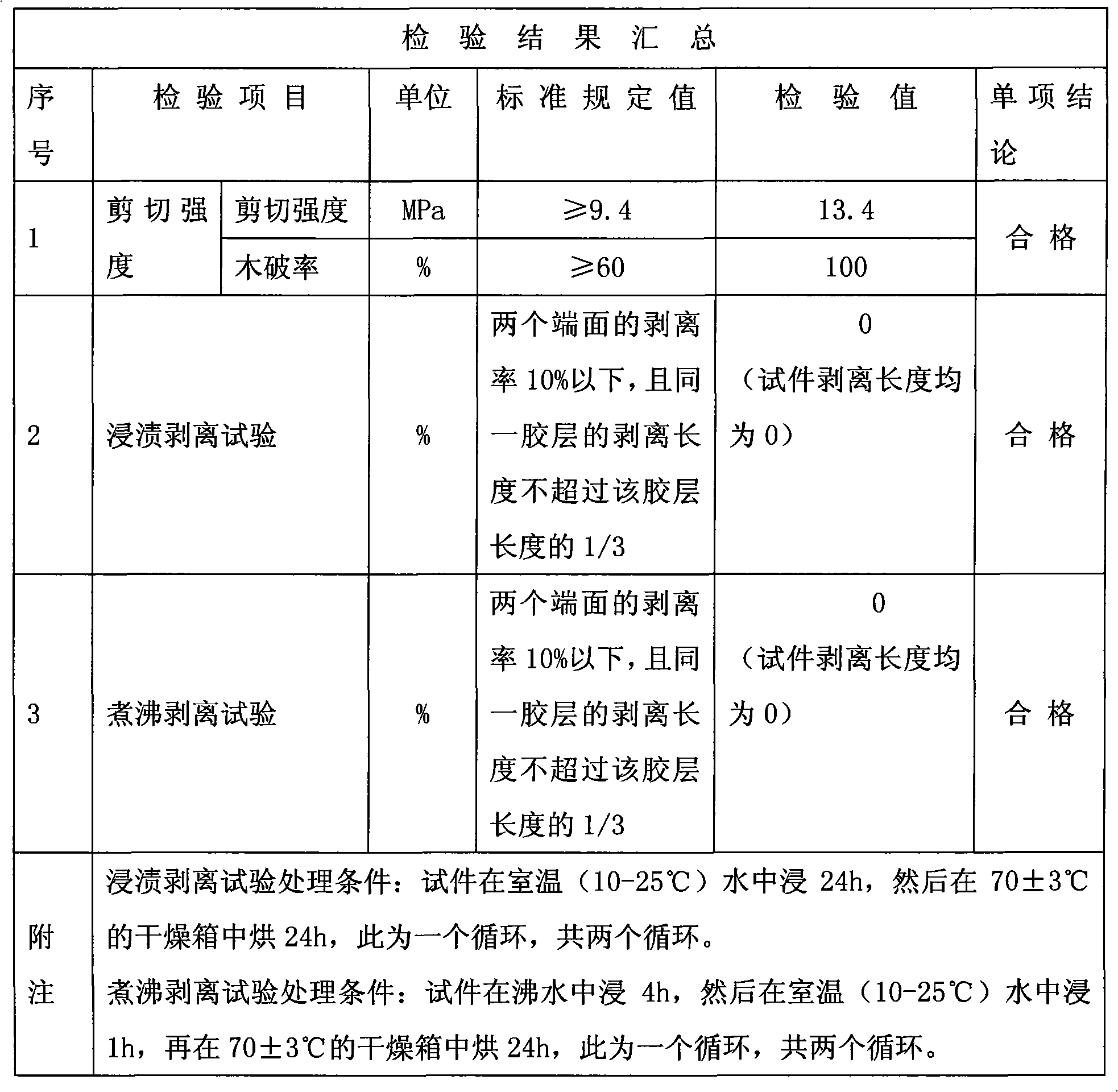

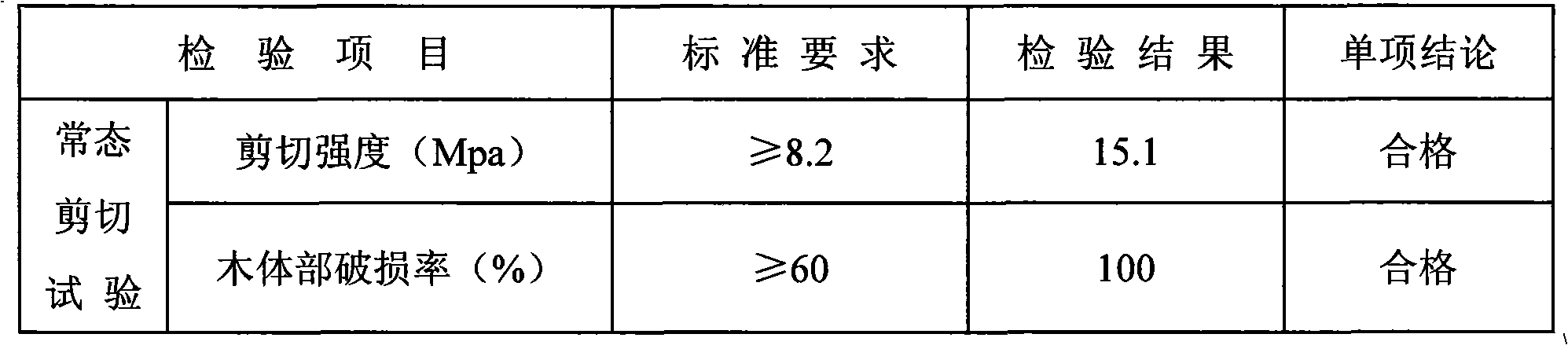

Integrated material wood-splicing adhesive and preparation method thereof

ActiveCN101565593AHigh hardnessIncrease temperatureMonocarboxylic acid ester polymer adhesivesPolymer scienceAdhesive

The invention provides an integrated material wood-splicing adhesive, which is characterized in that the integrated material wood-splicing adhesive is prepared by the following components by weight portions: 100 weight portions of main agent and 13-17 weight portions of cross linking agent modified polyisocyanate, wherein the main agent is prepared by the following raw materials by weight: 3-5% of polyvinyl alcohol, 21.4-38.92% of vinyl acetate, 1-3% of crylic acid, 5-10% of butyl acrylate, 1-3% of methacrylic acid, 0.9-1.1% of 2-hydroxyethyl acrylate, 1-2% of emulsifier OP-10, 1-2% of sodium dodecyl sulfate, 0.08-0.2% of ammonium persulfate, 0.1-0.3% of pH regulator and 48-52% of deionized water. The integrated material wood-splicing adhesive has the advantages of high adhesion strength, good water resistance, and no organic solvent and formaldehyde.

Owner:顶立新材料科技股份有限公司

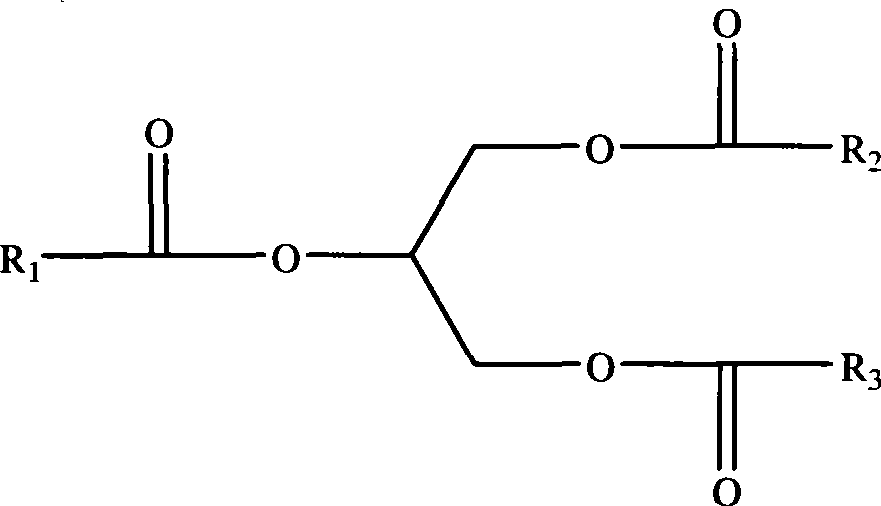

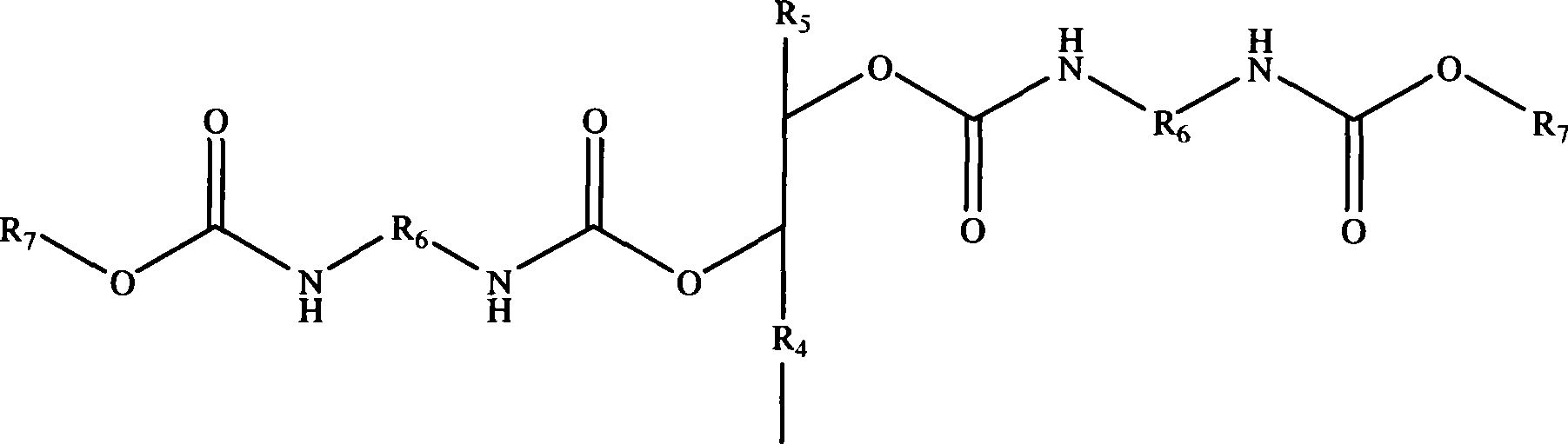

Vegetable oil based polyurethane acrylic ester, preparing process and use thereof

InactiveCN101497684AWide variety of sourcesEasy to makePolyurea/polyurethane coatingsSurface treatment compositionsAlkaneVegetable oil

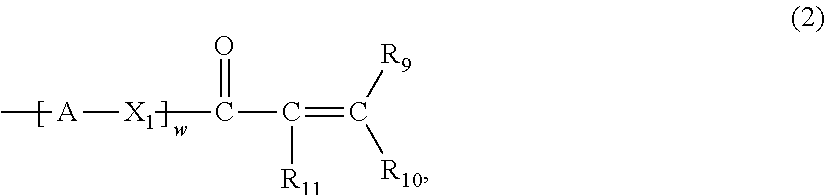

The invention relates to vegetable oil based polyurethane acrylic ester, belonging to the field of photosensitive polymer material. The vegetable oil based polyurethane acrylic ester is characterized in that the general chemical formula is Formula I, wherein R1, R2 and R3 are respectively chosen from alkane of C1-C18, at least one of the alkane is chosen from Formula II, R4 and R5 are respectively chosen from alkane of C1-C16, R6 is diphenyl methane-4,4'-diisocyanate, or hexamethylene diisocyanate, or isophorone diisocyanate or residue of 2,4-toluene diisocyanate with two isocyanate functional group removed, and R7 is 2-hydroxyethyl acrylate, or hydroxypropyl acrylate, or residue of pentaerythritol triacrylate with hydroxy functional group removed.

Owner:天津市天骄辐射固化材料有限公司

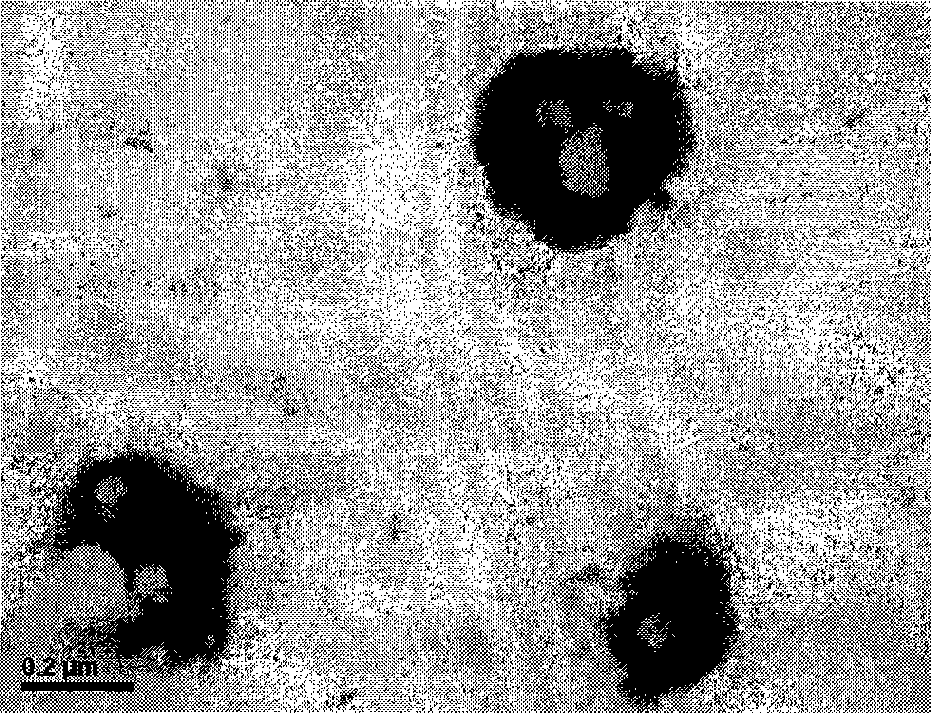

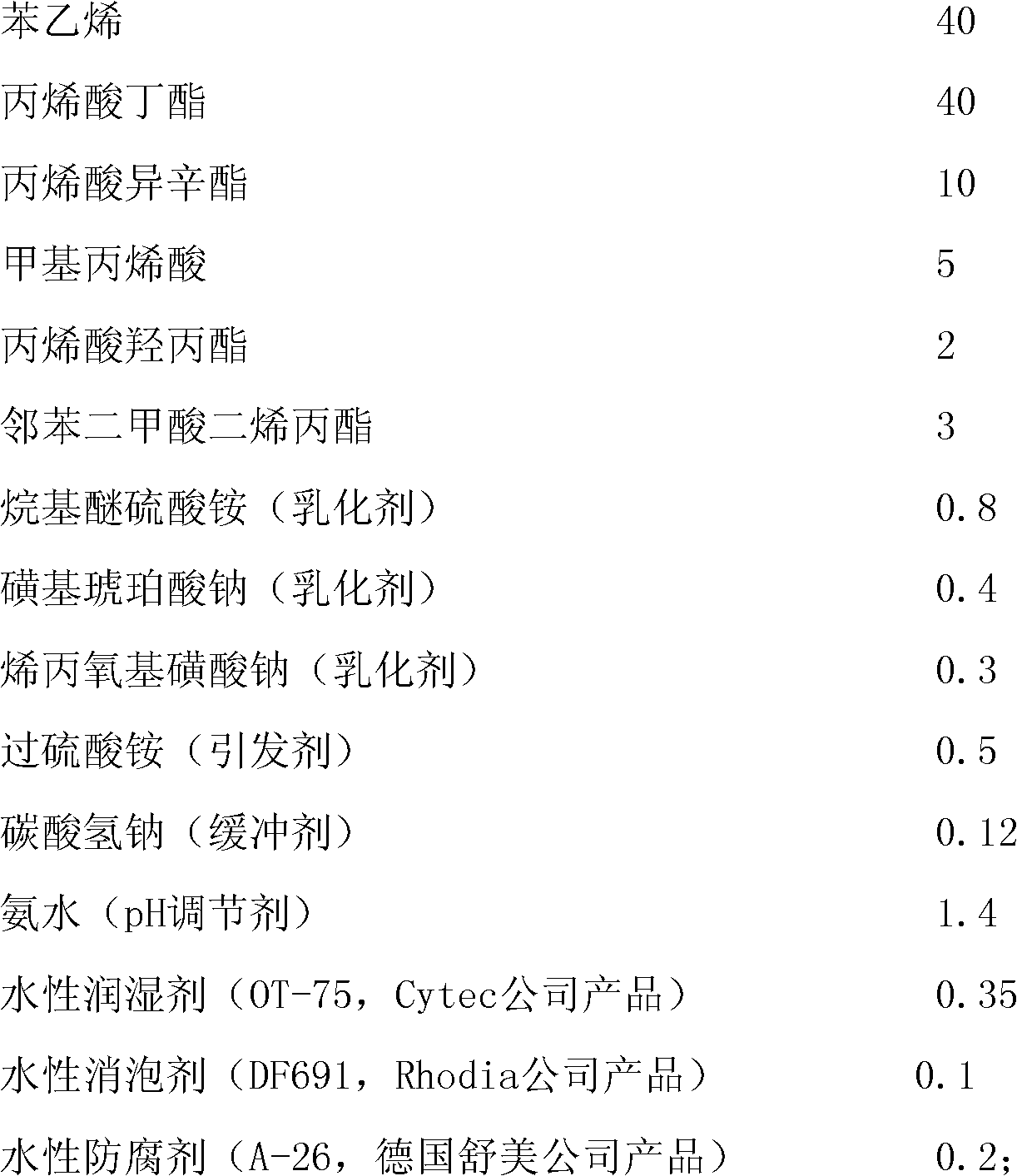

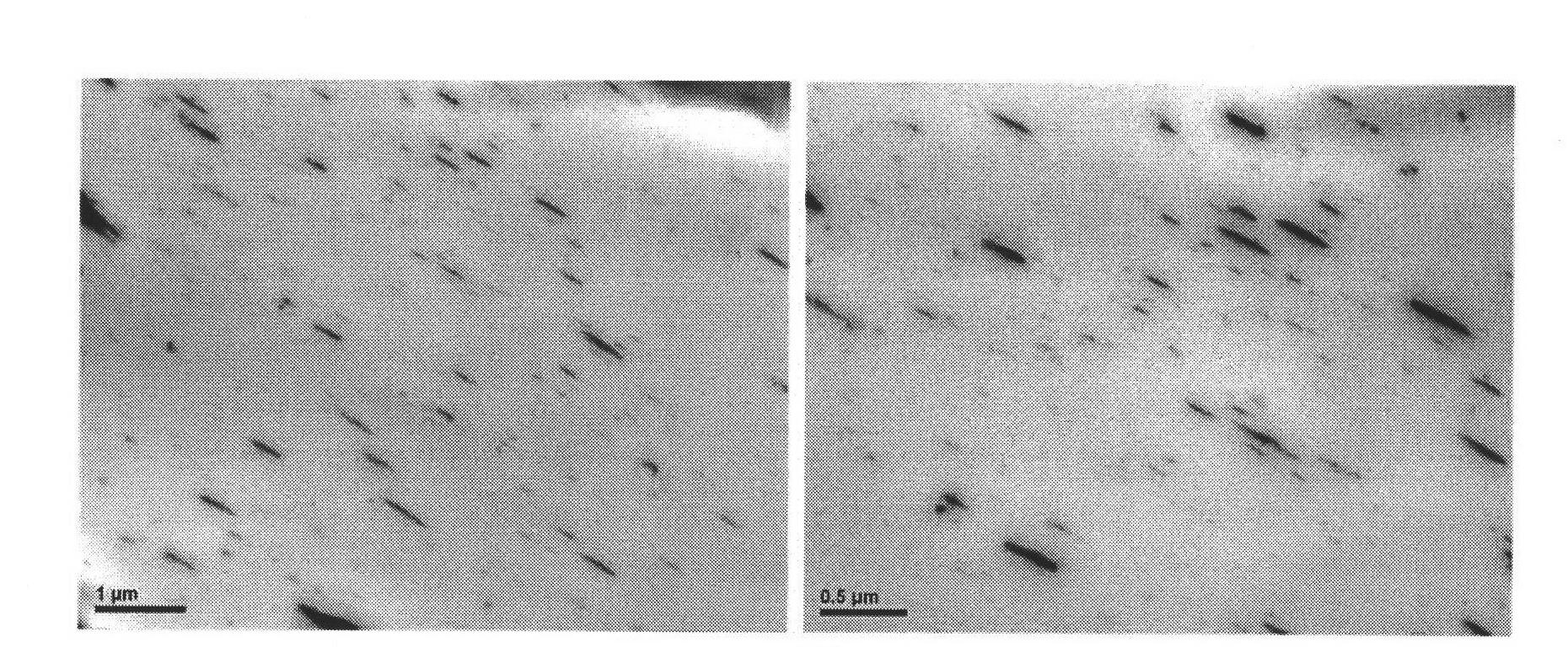

Core-shell type paint dyeing and printing adhesive agent emulsion and preparation method thereof

InactiveCN101368342AImprove bonding fastnessImprove stabilityDyeing processPotassium persulfatePolymer science

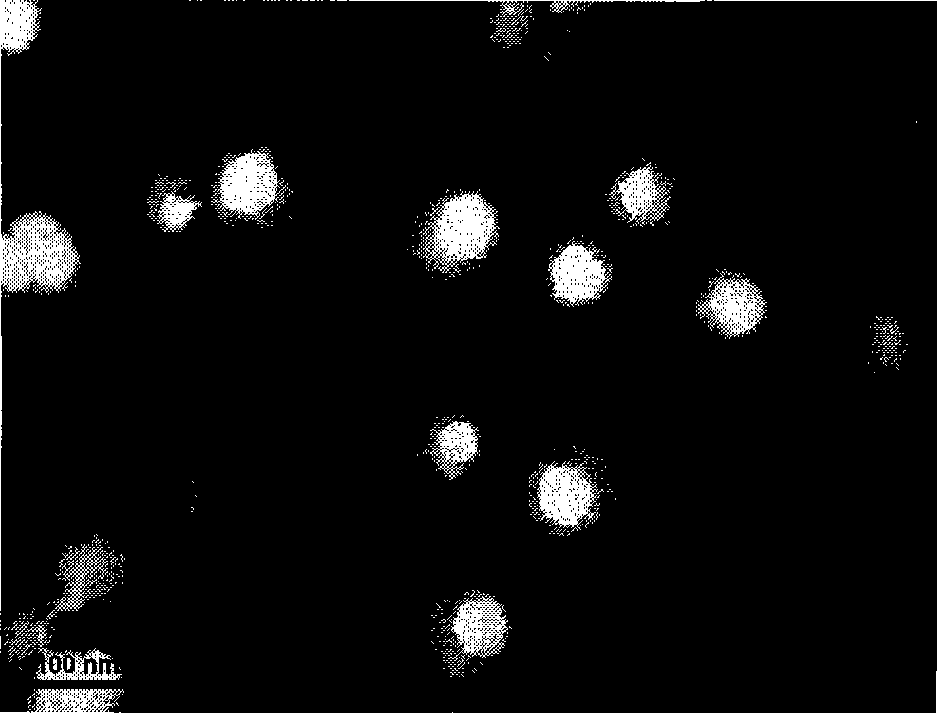

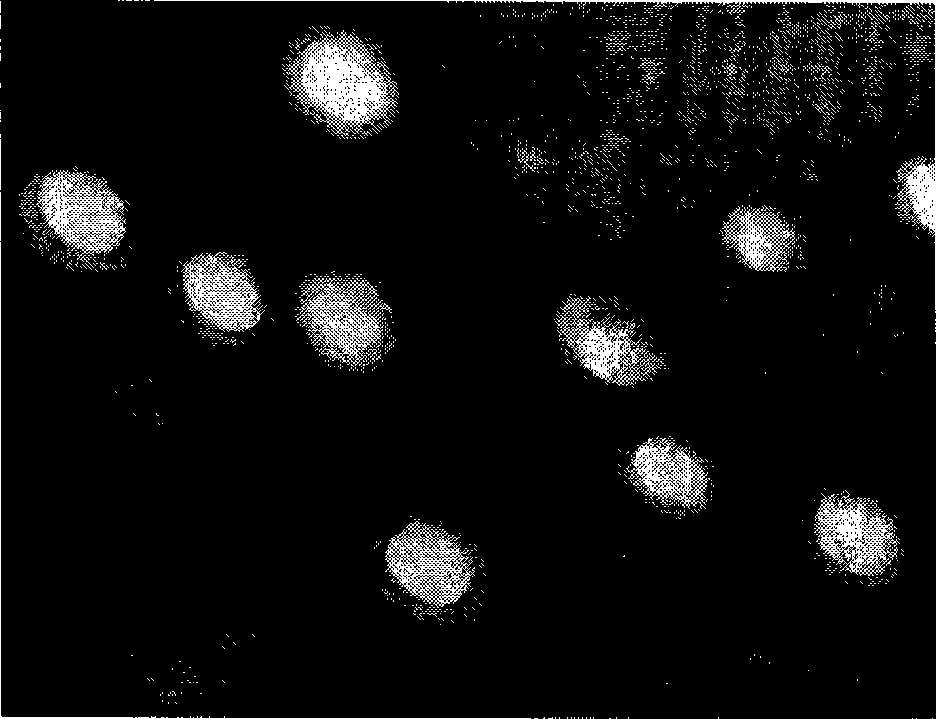

The invention discloses a method for preparing core-shell emulsion type adhesive which is modified by hydroxyl-terminated acrylic ester and is used in fabric printing and dyeing processes. The adhesive is prepared through the following steps: soft monomers copolymerize with crosslinking monomers and portions of hard monomers to produce core-shell particles; then a small portion of soft monomers and a large portion of crosslinking monomers copolymerize with hard monomers to coat the surface of the core layer, thus obtaining a shell layer and forming stable core-shell type emulsion. One or the mixture of two or more from 2-hydroxyethyl acrylate, hydroxypropyl acrylate, hydrobutyl acrylate and hydrohexyl acrylate is taken as a portion of soft monomers and crosslinking monomers; one or the mixture of two or more from hydroxylmethyl methacrylic acid, 2-hydroxyethyl acrylate methacrylic acid and hydroxypropyl methacrylic acid is taken as a portion of hard monomers and crosslinking monomers; one from butyl acrylate, ethyl acrylate and 2 ethylhexyl acrylate is taken as main soft monomers; one or the mixture of two or more from methyl methacrylate, crylic acid, cinnamene, acrylonitrile and methacrylic acid is taken as the hard monomers; surfactant sodium dodecyl sulfate, sodium dodecyl benzene sulfonate and octyl phenol polyethylene glycol are taken as emulsifying agent; potassium persulfate or ammonium persulfate is taken as initiator; and the copolymer emulsion is produced through emulsion copolymerization. Observed by transmission electron microscopy, the particles of the emulsion have visible core-shell structure and are even in distribution; the emulsion is stable, absolutely has no formaldehyde release both during the machining and using processes; the emulsion can be used both for pigment printing and for pigment dyeing.

Owner:JIANGNAN UNIV

Water-based polyurethane composite emulsion and preparation method thereof

ActiveCN102838713ASpeed up evaporationLower glass transition temperatureGraft polymer adhesivesWater basedPolyester

The invention discloses a water-based polyurethane composite emulsion and a preparation method thereof. The preparation method is characterized by comprising the following steps: by using acetone or butanone and acrylic monomer as solvents, polymerizing diisocyanate (HDI), isophorone diisocyanate (IPDI), mixed polyester polyalcohol, dihydroxymethylpropionic acid, 1,4-butanediol, trimethylolpropane monoene propyl ether, 2-hydroxypropyl acrylate and 2-hydroxyethyl acrylate to obtain carboxylic polyurethane; neutralizing with tertiary amine, and removing the solvents to obtain a self-emulsified double-bond-containing water-based polyurethane anionic emulsion; and by using the emulsion as a seed, adding acrylate monomer and a right amount interpenetrating-network crosslinking agent monomer to carry out pre-emulsification, and carrying out seed emulsion polymerization to obtain the composite emulsion in an interpenetrating network structure. The invention has the advantages of energy saving, environmental protection, high early bonding force, safe and reliable technique and stable product quality.

Owner:广东多正树脂科技有限公司

Polymers

ActiveUS8404783B2Organic compound preparationCarboxylic acid esters preparationHydrophilic monomerGlycidyl methacrylate

The invention relates to novel crosslinkable copolymers which are obtainable by (a) copolymerizing at least two different hydrophilic monomers selected from the group consisting of N,N-dimethyl acrylamide (DMA), 2-hydroxyethyl acrylate (HEA), glycidyl methacrylate (GMA), N-vinylpyrrolidone (NVP), acrylic acid (AA) and a C1-C4-alkoxy polyethylene glycol (meth)acrylate having a weight average molecular weight of from 200 to 1500, and at least one crosslinker comprising two or more ethylenically unsaturated double bonds in the presence of a chain transfer agent having a functional group; and (b) reacting one or more functional groups of the resulting copolymer with an organic compound having an ethylenically unsaturated group.

Owner:ALCON INC

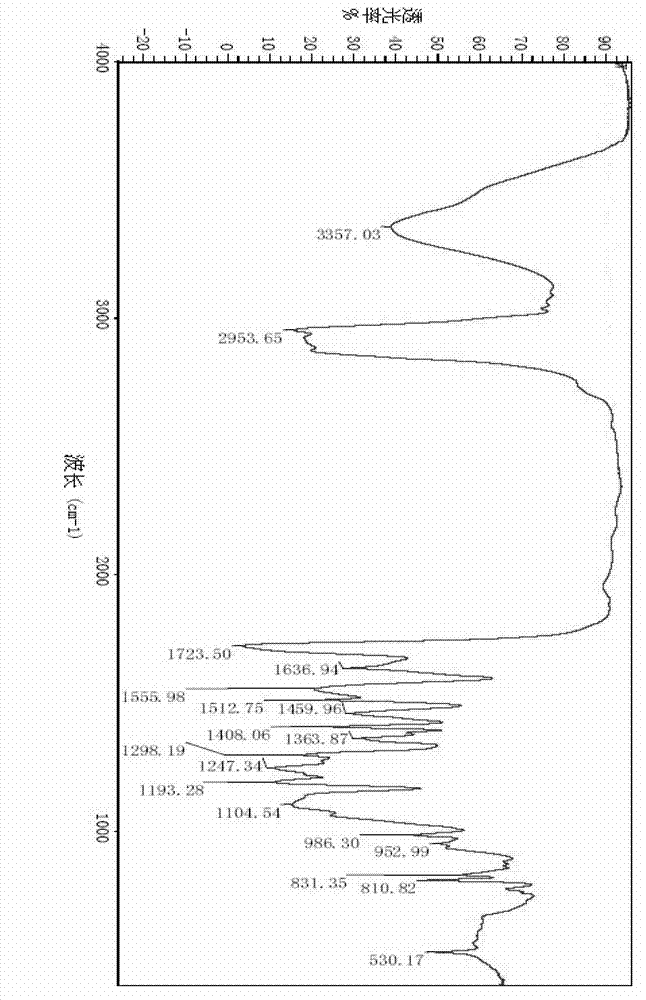

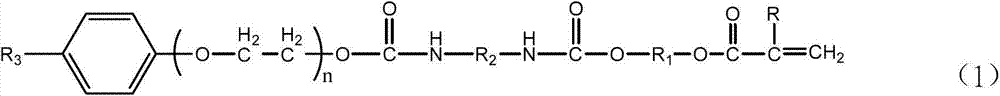

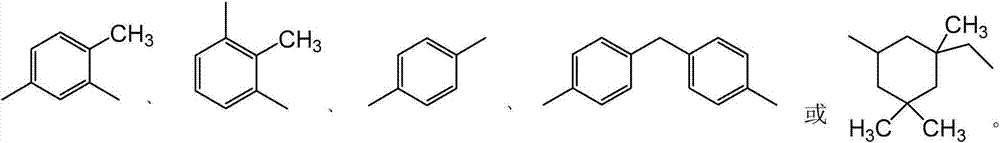

Urethane acrylate low polymer and preparation method and application thereof

ActiveCN103193678AReduce viscosityLow functionalityCarbamic acid derivatives preparationOrganic compound preparationAlkylphenolUrethane acrylate

The invention discloses a urethane acrylate low polymer and a preparation method and an application thereof. The urethane acrylate low polymer is prepared through the reaction of monofunctional alkylphenol ethoxylates and diisocyanate and the end capping by using 2-hydroxyethyl acrylate. The preparation method comprises step of: dropwise adding diisocyanate into the monofunctional alkylphenol ethoxylates at 40-60 DEG C to react on a heat insulating condition, thus obtaining a semi-addition product; and cooling the semi-addition product to 30-40 DEG C, dropwise adding a uniform mixture of hydroxyalkyl acrylate or methyl hydroxyalkyl acrylate and a polymerization inhibitor into a reactant, reacting for 15-30 minutes on a heat insulating condition, dropwise adding a catalyst and continuously reacting for 40-60 minutes, then heating to 50-60 DEG C and keeping the reaction, thus obtaining the urethane acrylate low polymer. Long soft segments are introduced into a molecular structure and have monofunctional degrees, and molecular chains can freely rotate, so that resin can have excellent softness and extremely low viscosity; and moreover, the structure contains benzene rings, so that molecules do not lose rigidity.

Owner:CHANGXING PHOTOELECTRIC MATERIAL +1

High-solid-content high-gloss quick-drying water-soluble hydroxy acrylic resin and preparation method thereof

The invention discloses a high-solid-content high-gloss quick-drying water-soluble hydroxy acrylic resin and a preparation method thereof. The monomers in the monomer-phase solution B is composed of 0-35 wt% of methyl methacrylate, 20-50 wt% of styrene or toluene isoborneol acrylate and toluene cyclohexyl acrylate; 5-15 wt% of methyl acrylate or butyl acrylate or methyl acrylate and butyl acrylate mixture, 5-15 wt% of functional monomer, 15-20 wt% of 2-hydroxyethyl acrylate or 2-hydroxypropyl acrylate, 8-15 wt% of acrylic acid or methacrylic acid and 1-2 wt% of chain-transfer agent. The invention aims to provide a high-solid-content high-gloss quick-drying water-soluble hydroxy acrylic resin, thereby solving the problem of high pollution in the traditional solvent-type hydroxy acrylic resin and the problem that a great amount of organic solvent is needed for dilution when the paint prepared from high-solid-content hydroxy polyacrylate is sprayed, and overcoming the defects of insufficient gloss and fullness and poor drying property in the water-based hydroxy acrylic resin. The invention also discloses a preparation method of the water-soluble hydroxy acrylic resin.

Owner:广东波特科技股份有限公司

Heat-resistant strippable micro-viscous pressure-sensitive adhesive film and preparation thereof

InactiveCN101275059AEasy to operateSatisfy processabilityFilm/foil adhesivesEster polymer adhesivesToluene diisocyanateViscous pressure

The present invention provides a heat resistance peeling mild adhesive pressure sensitive adhesive film for electronic manufacturing industry or package industry, and its manufacturing method, 2-ethylhexyl acrylate, methacrylic acid 2-ethylhexyl acrylate, butyl acrylate, methyl methacrylate and 2-hydroxyethyl acrylate copolymer liquid cement are prepared by solution polymerization process, then a coating composition is prepared by adding a toluene diisocyanate crosslinking agent, the mild adhesive pressure sensitive adhesive film is obtained by coating and drying, the peeling strength of the mild adhesive pressure sensitive adhesive film, the polyimide film and the pet film is above 300g / 25mm, the peeling strength after ageing 1 hour also keeps above 37g / 25mm, the any residual does not retain after peeling, the mild adhesive pressure sensitive adhesive film has mild adhesive ability under the high temperature 180 DEG C, 90 DEG C and the acid-base environment, having a convenient operation, being directly peeled.

Owner:SHENZHEN DANBOND TECH

Biologically-bactericidal acrylic resin and novel marine antifouling paint composition prepared from resin

ActiveCN105949382AImprove adhesionAntibacterial and antifouling effectAntifouling/underwater paintsRosin coatingsThiolButyl acetate

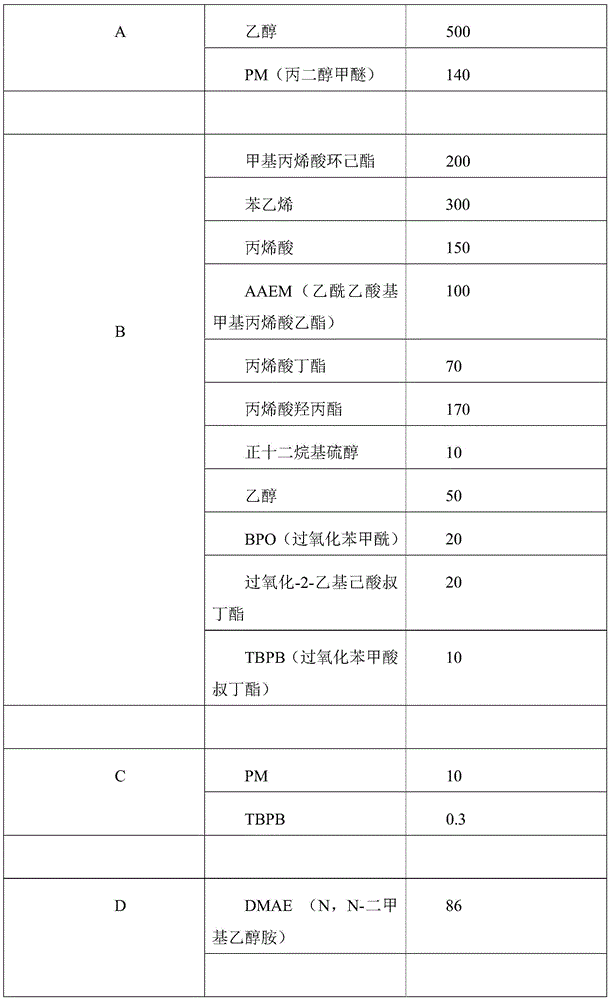

The invention relates to an antifouling paint, particularly a biologically-bactericidal acrylic resin and a novel marine antifouling paint composition prepared from the resin. The biologically-bactericidal acrylic resin is prepared from the following raw materials in percentage by mass: 0.35-0.45% of azodiisobutyronitrile, 0.38-0.48% of azodiisovaleronitrile, 0.49-1.2% of dodecamercaptan, 47-50% of butyl acetate, 2.3-3.6% of 2-hydroxyethyl acrylate, 9-10% of trichlorophenyl acrylate, 24-28% of butyl acrylate and 10-13% of isoborneol acrylate. The formula system is free of copper or tin, and thus, is a novel environment-friendly biologically-bactericidal antifouling paint.

Owner:ZHEJIANG MARINE DEV RES INST

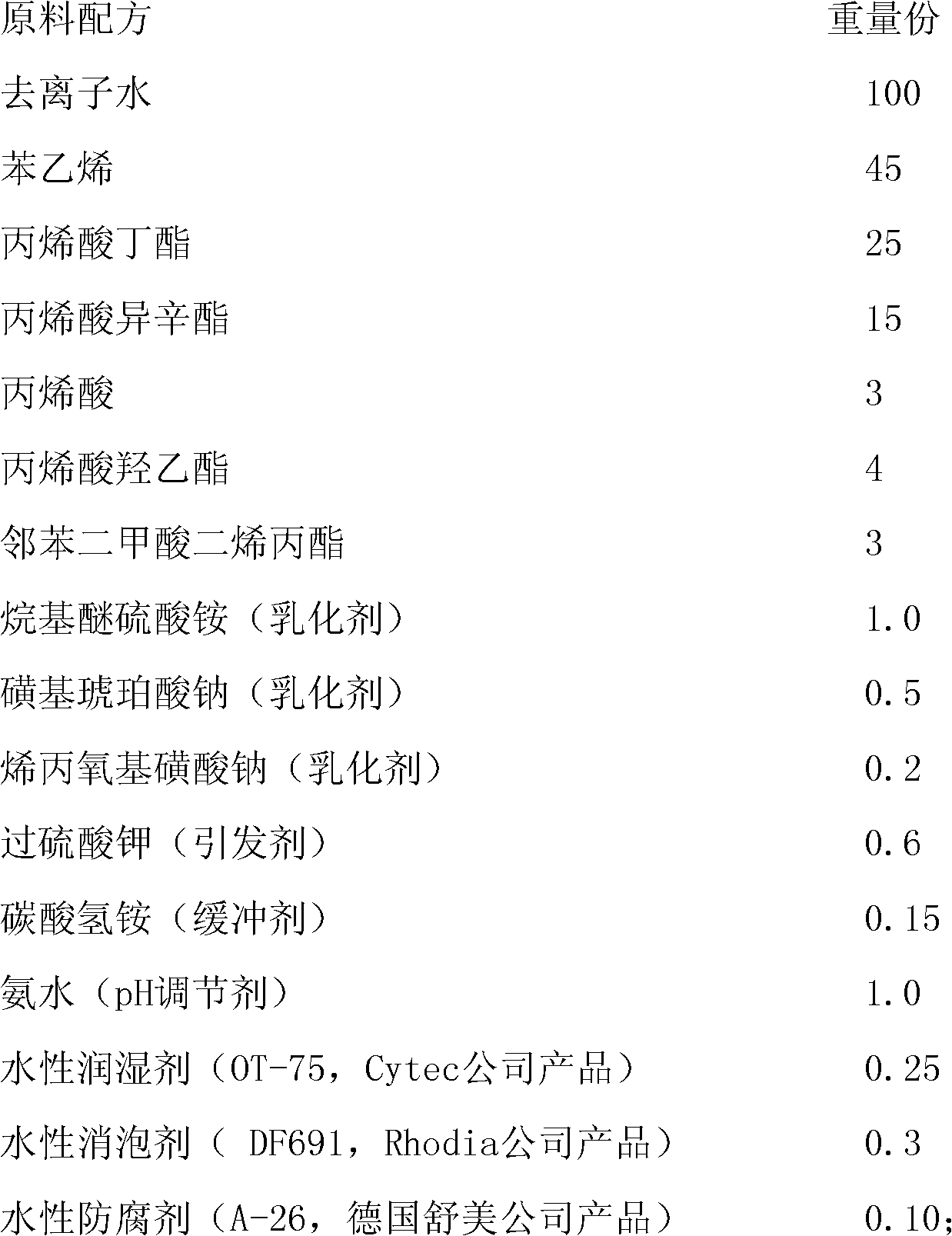

Water-based dry-type complex film adhesive and preparation method thereof

ActiveCN102134463AReduce the amount addedReduce contentHydrocarbon polymer adhesivesIsooctyl acrylateWater based

The invention discloses a water-based dry-type complex film adhesive and a preparation method thereof, belonging to the field of preparation of adhesive. The preparation method of the complex film adhesive comprises the following steps: by using monomers, an emulsifier, an initiator, a buffering agent, deionized water, a pH regulator and water-based assistants as raw materials, emulsifying, carrying out seed reaction and polymerization reaction, and compounding to obtain the complex film adhesive of which the solid content is 45-55%, wherein the monomers comprise a hard monomer, soft monomers and functional monomers; the hard monomer is styrene; the soft monomers comprise butyl acrylate and 2-ethylhexyl acrylate; the functional monomers comprise acrylic acid or methacrylic acid, 2-hydroxyethyl acrylate or 2-hydroxypropyl acrylate, and diallyl phthalate; and the emulsifier comprises ammonium alkyl ether sulfate, sodium sulfosuccinate and sodium allyloxysulfonate in a weight ratio of 2:1:(0.4-0.8). The complex film adhesive has the advantages of high bonding strength, favorable affinity and covering performance for ink, and environment protection since the content of VOCs (volatile organic compounds) is lowered.

Owner:NANTONG GAOMENG NEW MATERIAL

Hydrophobic masking tape and preparation method thereof

ActiveCN103173157ANo pollution in the processCapable of outdoor useFilm/foil adhesivesOrganic non-macromolecular adhesiveSodium bicarbonateEmulsion

The invention provides a hydrophobic masking tape and a preparation method thereof. The hydrophobic masking tape comprises a masking tape layer and an adhesive layer which is coated on the surface of the masking tape layer, wherein the adhesive formula of the adhesive layer comprises the following components in parts by weight: 200-300 parts of butyl acrylate, 100-200 parts of 2-ethylhexyl acrylate, 2-10 parts of acrylic acid, 2-10 parts of 2-hydroxyethyl acrylate, 30-60 parts of styrene-acrylic emulsion, 5-10 parts of sodium benzene sulfonate, 300-500 parts of water, 2-7 parts of ammonium persulfate and 0.1-0.5 part of sodium bicarbonate. A hydrophobic adhesive is adopted in a preparation process to remove the conventional organic solvent, and the masking tape is subjected to ultraviolet pretreatment, so that the produced masking tape is pollution-free and environment-friendly and has an outdoor use function.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

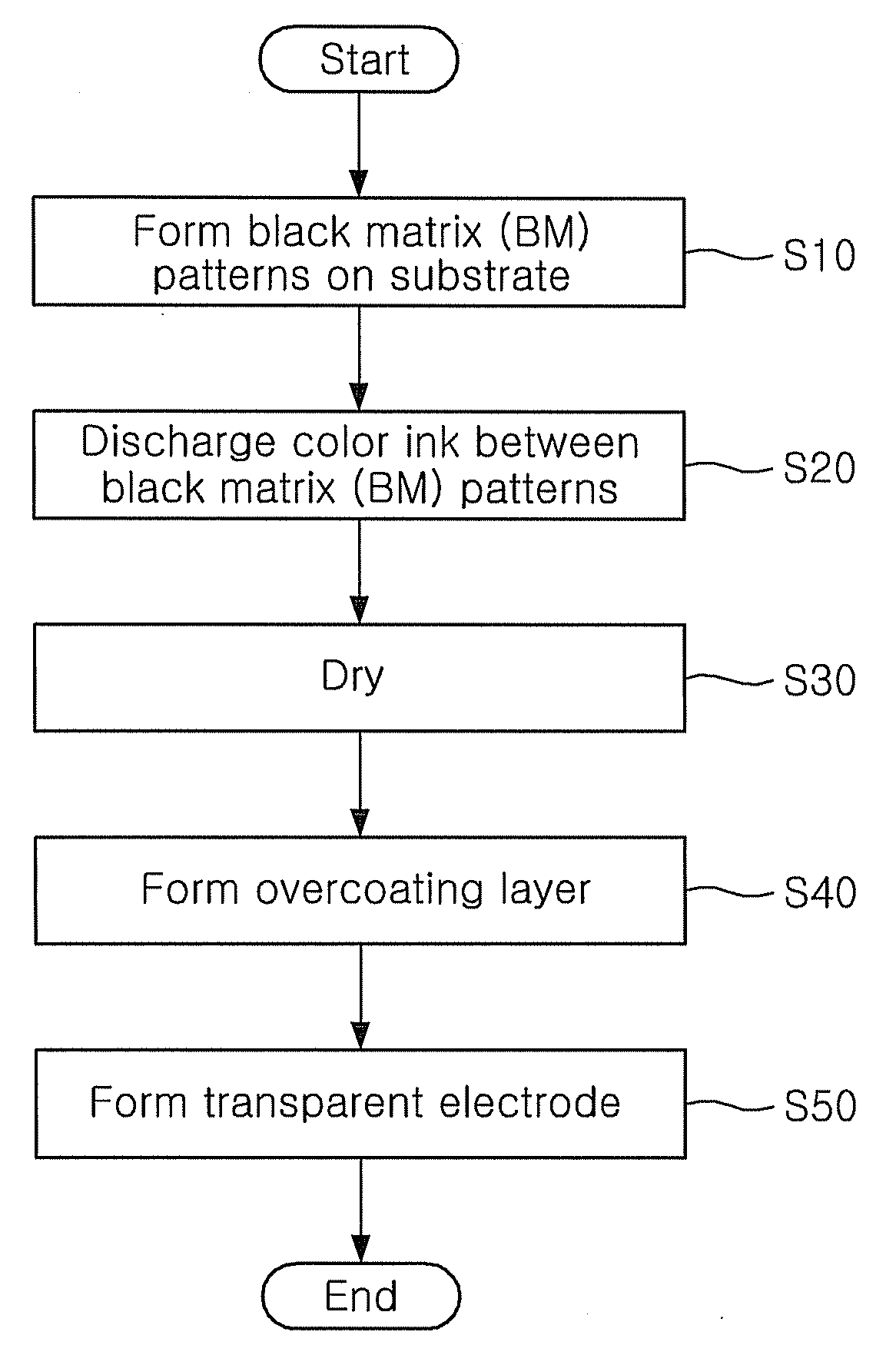

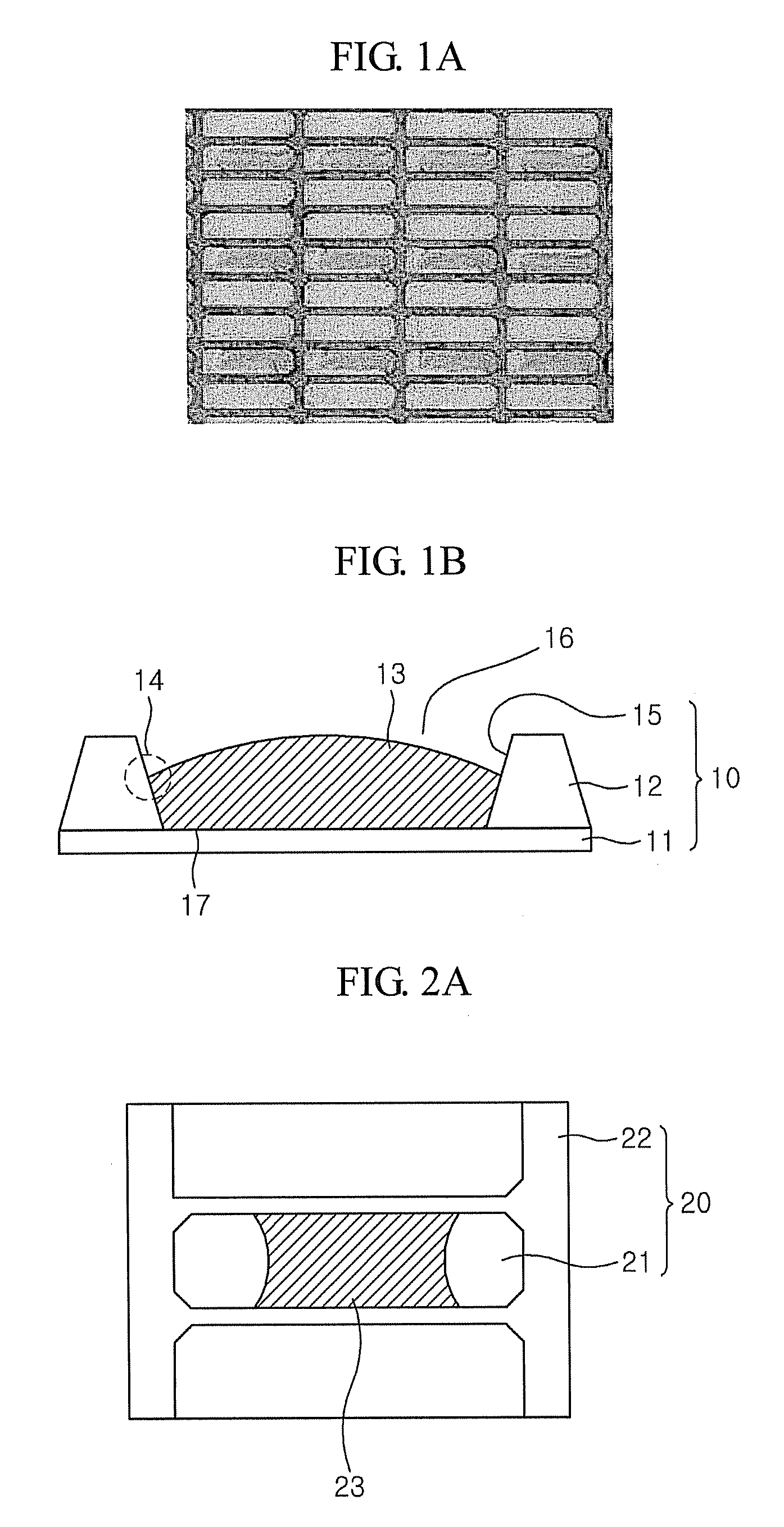

Ink for color filter, method of fabricating color filter using the ink, and color filter fabricated by the method

ActiveUS20070182795A1Improve color uniformityImprove reliabilityLiquid surface applicatorsMeasurement apparatus componentsPolymer scienceEthyl ester

The present invention provides an ink for a color filter comprising a polymer binder, a crosslinking monomer, a solvent, a pigment, and a polymerization initiator. The polymer binder comprises acrylate or methacrylate including a hydroxy group. The polymer binder may comprise 2-hydroxyethyl acrylate or 2-hydroxyethyl methacrylate.

Owner:DONGJIN SEMICHEM CO LTD +1

Polyether carboxylic acid water reducer and preparation method thereof

The invention provides a polyether carboxylic acid water reducer and a preparation method thereof. The water reducer is prepared from the following components: polypropylene alcohol ether, maleic anhydride, sodium methylallyl sulfonate, acrylamide, 2-hydroxyethyl acrylate, initiator and water.

Owner:马清浩

Polycarboxylic-acid water reducing agent synthesized at normal temperature, and preparation method and application method thereof

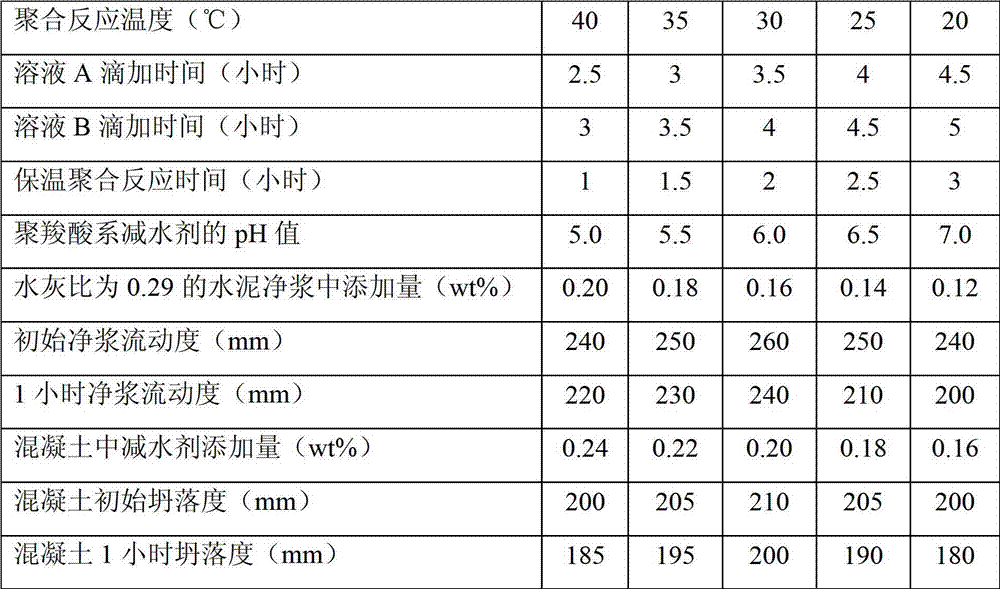

The invention discloses a polycarboxylic-acid water reducing agent synthesized at normal temperature, and a preparation method and application method thereof. The polycarboxylic-acid water reducing agent is prepared from the following components in parts by weight:100 parts of unsaturated polyether DD-424, 9-13 parts of acrylic acid, 0-4 parts of methacrylic acid, 0-2 parts of sodium allylsulfonate, 0-2 parts of sodium methylallyl sulfonate, 0.2-1 part of oxydol, 0.2-1 part of ammonium persulfate, 0.2-0.6 part of L-ascorbic acid, 0-0.8 part of thioglycolic acid, 0-0.8 part of mercaptopropionic acid, 0-0.4 part of 2-hydroxyethyl acrylate, 4-6 parts of sodium hydroxide and 182-185 parts of water. At most one of the methacrylic acid, sodium allylsulfonate and sodium methylallyl sulfonate is 0 part; and at most one of the thioglycolic acid, mercaptopropionic acid and 2-hydroxyethyl acrylate is 0 part. The product disclosed by the invention has the advantages of excellent properties, high water reducing rate and favorable slump retention; and the method is simple and convenient to operate, has the advantages of low energy consumption and no discharge of three wastes, and is beneficial to application to large-scale production.

Owner:SHANGHAI DONGDA CHEM

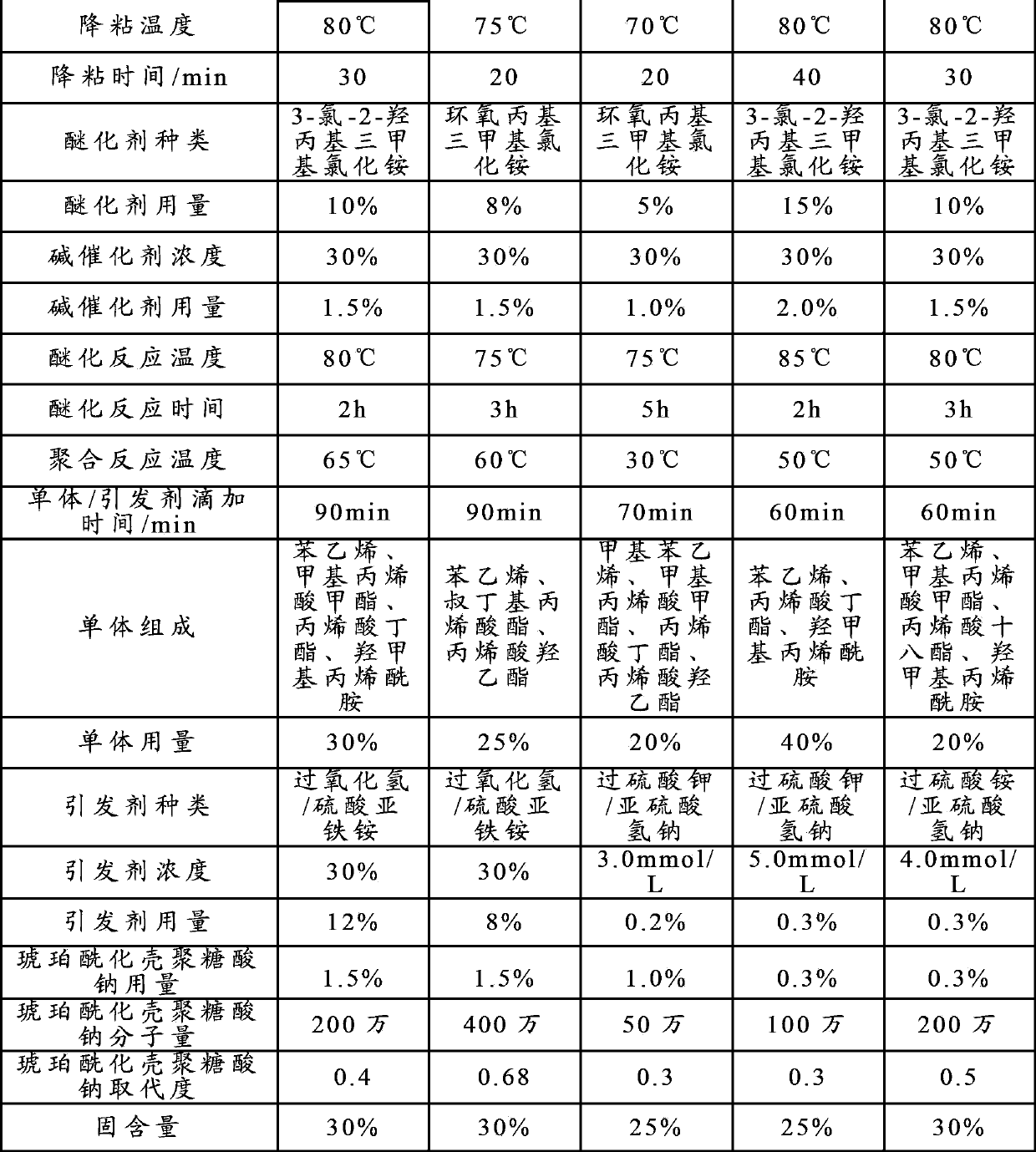

Surface sizing agent and preparation method thereof, sizing liquid and sizing paper

ActiveCN103866618ALow priceImprove water resistanceWater-repelling agents additionCross-linkMethyl acrylate

The invention relates to a surface sizing agent, which contains a polymer of cationic starch grafted monomers and succinylated chitosan sodium, wherein the cationic starch grafted monomers comprise three monomers such as a hard monomer, a soft monomer and a cross-linking monomer, the hard monomer is a mixture comprising one or a plurality of materials selected from styrene, methyl styrene, methyl methacrylate and methyl acrylate, the soft monomer is a mixture comprising one or a plurality of materials selected from n-butyl acrylate, tert-butyl acrylate and octadecyl acrylate, and the cross-linking monomer is a mixture comprising one or two materials selected from 2-hydroxyethyl acrylate and methylol acrylamide. The present invention further provides a preparation method for the surface sizing agent, a sizing liquid containing the surface sizing agent, and sizing paper prepared by applying the sizing liquid containing the surface sizing agent to carry out sizing. The surface sizing agent has characteristics of low price, green environmental protection and good use effect.

Owner:GOLD EAST PAPER JIANGSU

High-solid-content finishing oil-based acrylic resin for automobiles and preparation method thereof

The invention discloses a high-solid-content finishing oil-based acrylic resin for automobiles and a preparation method thereof, which belong to the field of automobile paints and solve the problems of low solid content, high viscosity, poor solubility and the like in the existing acrylic resin paint. The resin contains acrylic acid, styrene, butyl acrylate, hydroxyethyl methacrylate, methyl methacrylate, methacrylic acid, butyl methacrylate, 2-ethylhexyl acrylate, n-dodecyl mercaptan, lauryl methacrylate, isoborneol methacrylate, 2-hydroxyethyl acrylate, 2-hydroxypropyl acrylate, 100# solvent oil, di-tert-pentyl peroxide, glycidol tert-carboxylate and a resin reactive diluent. The solid content can reach 90%. The acrylic resin has the advantages of favorable dilution property and low viscosity. The self-made reactive diluent can greatly enhance the water resistance and acid resistance of the paint. The construction solid content of the resin is nearly 70%. The acrylic resin greatly lowers the discharge of VOC (volatile organic compound), and is environment-friendly and practical.

Owner:安徽优科新材料科技有限公司

High-efficiency ceramic water reducing agent and preparation method thereof

The invention provides a high-efficiency ceramic water reducing agent and a preparation method thereof. The high-efficiency ceramic water reducing agent comprises the following components by weight percent: 35 to 60 polyoxyalkylene, 0 to 10 methacrylic acid or maleic anhydride, 0 to 20 methacrylic acid, 0 to 10 sodium allyl sulfonate, 0 to 20 2-hydroxyethyl acrylate, 1.0 to 3.0 potassium persulfate, 0.5 to 1.0 hydroquinone and 1.0 to 2.0 p-toluenesulfonic acid, and the weight percent of the components is not zero. The high-efficiency ceramic water reducing agent can greatly reduce the water content of slurry after being added into ceramic pulp and satisfies fluidity needed by ceramic production. The high-efficiency ceramic water reducing agent is added into a glaze material, the glaze material has good fluidity and proper viscocity under a lower water-content condition, greatly reduces a glaze cutting phenomenon, and the like and increases product quality. The high-efficiency ceramic water reducing agent has good universality and can be suitable for various clay mineral materials.

Owner:HANSHAN NORMAL UNIV

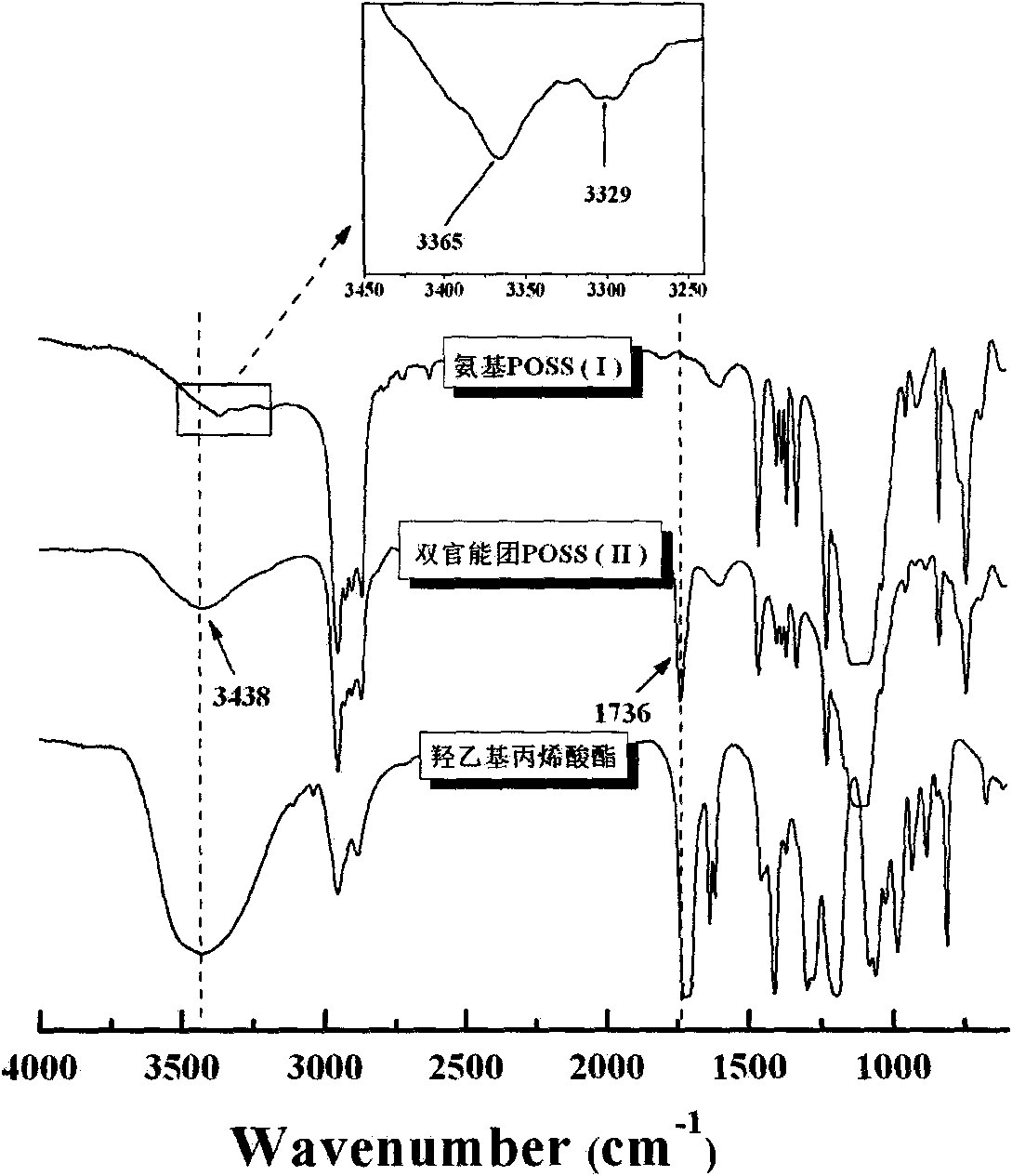

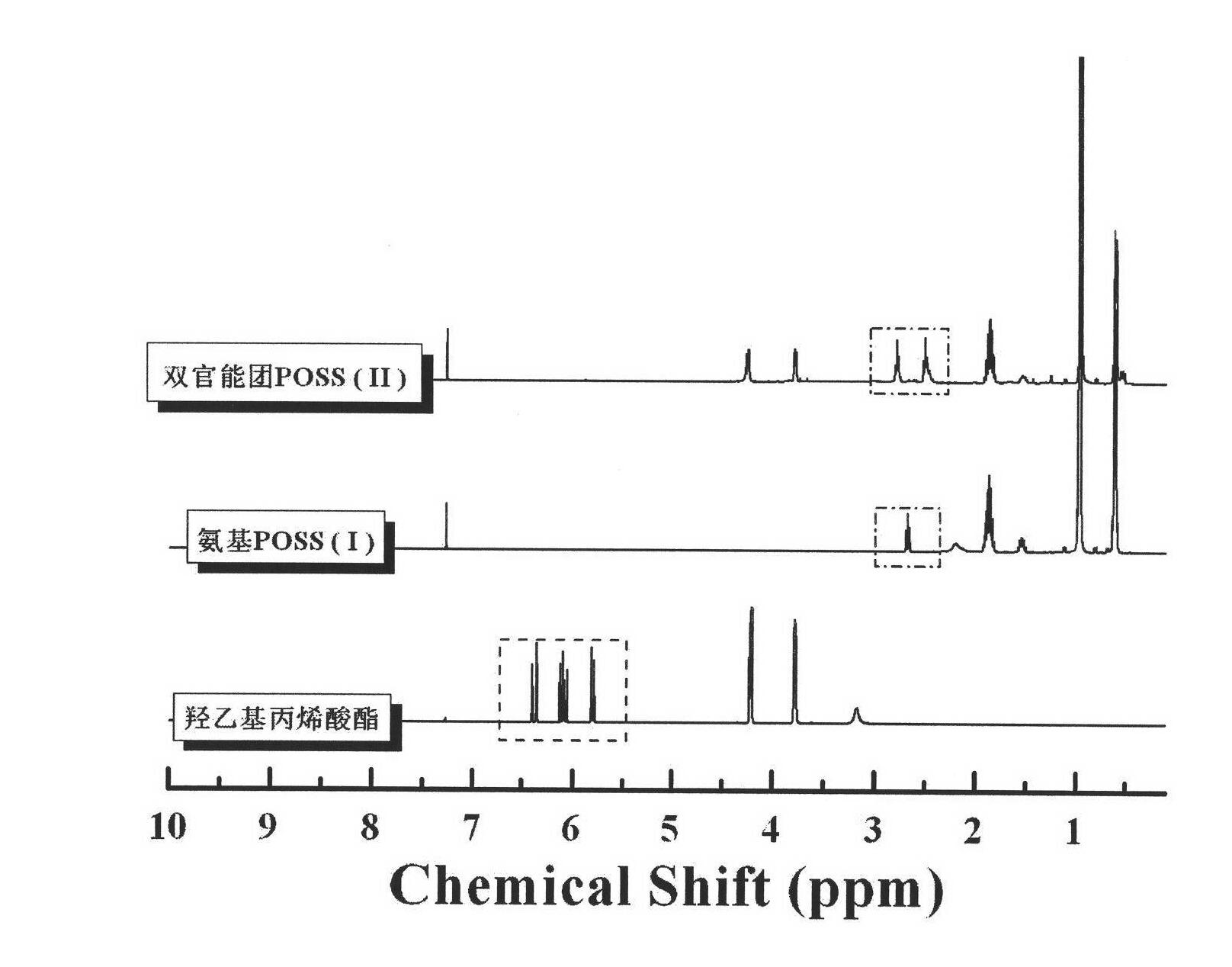

Method for preparing degradable organic-inorganic nanometer hybrid material containing POSS (Polyhedral Oligomeric Silsesquioxanes)

The invention discloses a method for preparing a degradable organic-inorganic nanometer hybrid material containing POSS (Polyhedral Oligomeric Silsesquioxanes), comprising the following steps of: (1) firstly, preparing a difunctional POSS derivative (II) by carrying out the addition reaction of amino POSS (I) and 2-hydroxyethyl acrylate through Michael; and (2) secondly, forming an etherified product by carrying out the esterification reaction of aromatic dibasic acid and aliphatic dihydric alcohol and preparing the degradable organic-inorganic nanometer hybrid material containing the difunctional POSS through the melt polycondensation reaction of the difunctional POSS derivative (II) and aliphatic chydroxy oligomer with the etherified product. The preparation method has the advantages of uniform dispersion and difficult agglomeration of POSS in the hybrid material during preparation, effective improvement on the performances of degradable copolyester composite material, simple operation and high yield.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Pressure-sensitive adhesive composition for optical members and pressure-sensitive adhesive tape for optical members

ActiveCN102791817AImprove reliabilityHigh temperature and high reliabilityPolarising elementsEster polymer adhesivesPolymer scienceHydrogen

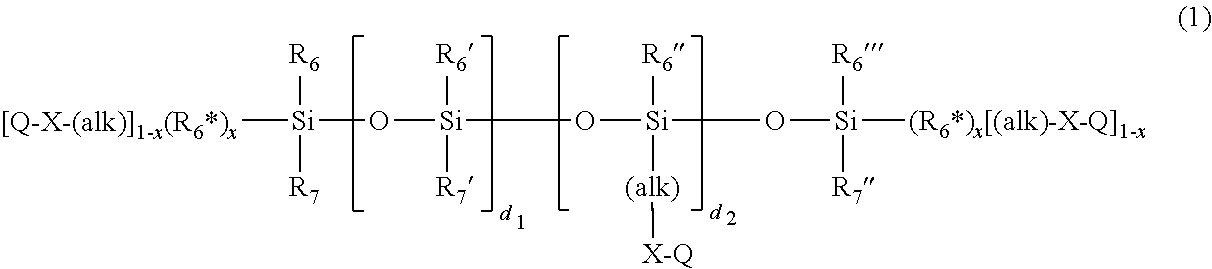

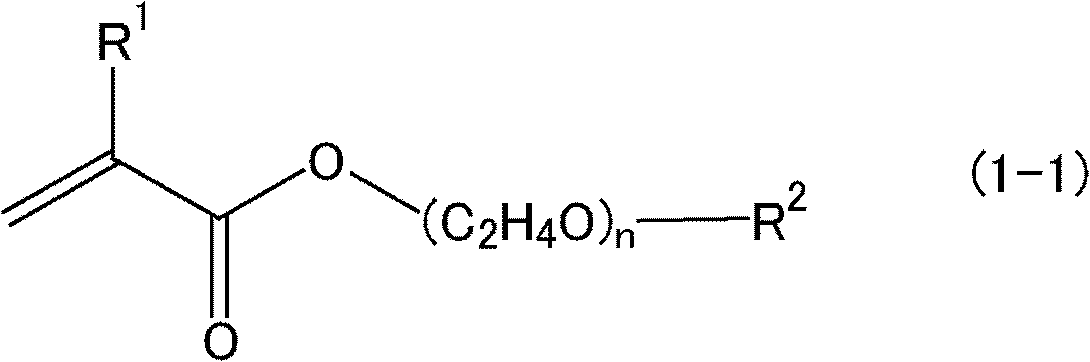

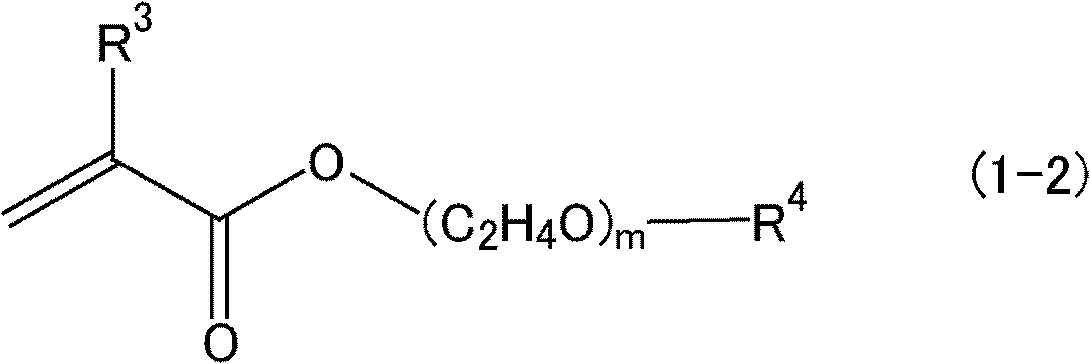

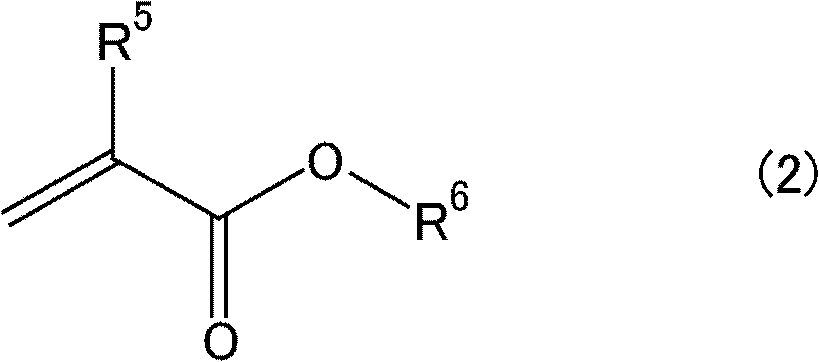

Provided is a pressure-sensitive adhesive composition for optical members which is protected from whitening under high -temperature and high-humidity conditions and which can ensure high reliability. Also provided is a pressure-sensitive adhesive tape for optical members, which is produced using the pressure-sensitive adhesive composition. The pressure -sensitive adhesive composition for optical members comprises an acrylic copolymer obtained by polymerizing a mixed monomer which contains 1 to 25wt% of 2-hydroxyethyl acrylate, 1 to 25wt% of N-vinylpyrrolidone, 0.5 to 30wt% of a monomer having a structure represented by general formula (1-1), or 0.1 to 30wt% of a monomer having a structure represented by general formula (1-2). In general formula (1-1), R1 is hydrogen or methyl; R2 is hydrogen or alkyl having less than 3 carbon atoms; and n is an integer of 8 to 45. In general formula (1-2), R3 is hydrogen or methyl; R4 is alkyl having 3 to 30 carbon atoms; and m is an integer of 8 to 45.

Owner:SEKISUI CHEM CO LTD

Preparation method of water-based nitrocellulose emulsion and nitrocellulose film

The invention relates to a preparation method of a water-based nitrocellulose emulsion and a nitrocellulose film. The preparation method comprises the following steps: adding 2-hydroxyethyl acrylate, acrylic acid, butanone and azodiisobutyronitrile into a reactor, and carrying out free-radical polymerization reaction at 50-90 DEG C for 2-3 hours; after the reaction finishes, adding dibutyltin dilaurate and isophorone diisocyanate in a nitrogen protective atmosphere, carrying out thermostatic reaction at 25-65 DEG C for 1-2 hours, heating to 70-95 DEG C, adding a nitrocellulose butanone solution, and keeping the temperature to react for 2-3 hours; and cooling, regulating the pH value of the obtained reaction system to 8-9, adding deionized water, and dispersing uniformly to obtain the water-based nitrocellulose emulsion. The water-based nitrocellulose emulsion prepared by the preparation method is subjected to running film formation to obtain the nitrocellulose film. The water-based nitrocellulose emulsion has the advantages of favorable water dispersibility, favorable storage stability, high film flexibility, high adhesive force, high water resistance and high yellowing resistance.

Owner:SHAANXI UNIV OF SCI & TECH

Pressure-sensitive adhesive emulsion, preparation method and high-holding protective film prepared from pressure-sensitive adhesive emulsion

ActiveCN103467650AImprove cohesionIncrease stickinessNon-macromolecular adhesive additivesFilm/foil adhesivesIsooctyl acrylateTectorial membrane

The invention discloses a pressure-sensitive adhesive emulsion. The pressure-sensitive adhesive emulsion is prepared from a component A and a component B, wherein the component A is acrylate used for adhesive power of the pressure-sensitive adhesive and has side chain alkyl carbon atoms of 4-8 and is a mixture of 50-85 parts by weight of butyl acrylate and 2-20 parts by weight of 2-ethylhexyl acrylate; the component B is a rigid monomer compound for enhancing the cohesive force of the pressure-sensitive adhesive and is a mixture of two or more of 1-15 parts by weight of methyl methacrylate, 1-15 parts by weight of vinyl acetate, 2-5 parts by weight of 2-hydroxyethyl acrylate and 0.5-2 parts by weight of acrylic acid. The pressure-sensitive adhesive emulsion provided by the invention is capable of guaranteeing good initial adhesion and high holding power under good peeling strength.

Owner:潍坊胜达科技股份有限公司

Formaldehyde-free color-fixing agent and preparation method of color-fixing agent

InactiveCN104452366AImprove wear resistanceImprove mechanical propertiesDyeing processEnvironmental resistancePersulfate

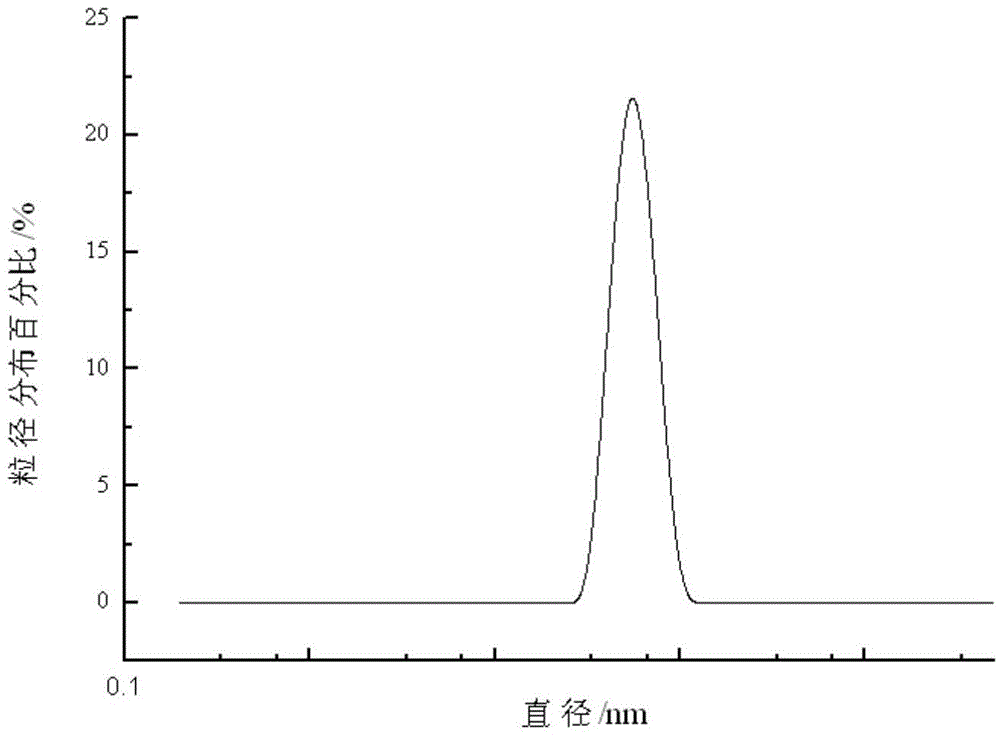

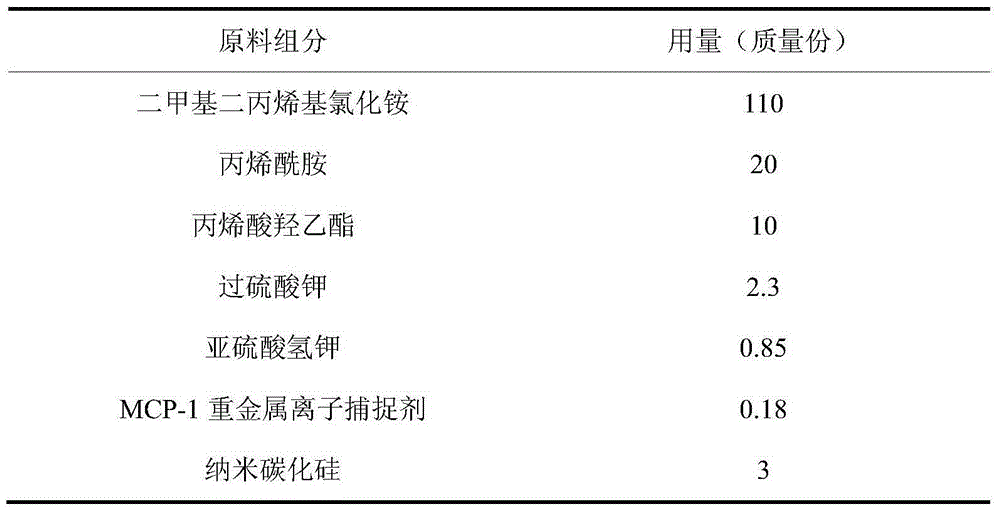

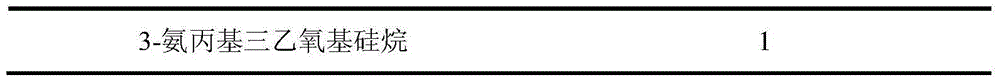

The invention discloses a formaldehyde-free color-fixing agent and a preparation method of the color-fixing agent. The formaldehyde-free color-fixing agent comprises the following raw materials in parts by weight: 90-110 parts of dimethyl diallyl ammonium chloride, 12-20 parts of acrylamide, 6-10 parts of 2-hydroxyethyl acrylate, 1.6-2.3 parts of peroxysulphate, 0.45-0.85 part of hydrosulphite, 0.10-0.18 parts of a heavy metal ion capture agent, 0.8-3 parts of nano silicon carbide, 0.2-1 part of a siloxane coupling agent and the balance of water. A siloxane coupling agent is used for carrying out surface modification on the nano silicon carbide to obtain the modified nano disilicon; the abrasion resistance and the mechanical property of the color-fixing agent can be remarkably improved; dimethyl diallyl ammonium chloride is used as a main monomer and is used for carrying out solution copolymerization together with water-soluble acrylamide and 2-hydroxyethyl acrylate to prepare a cationic quaternary ammonium salt polymer, so that the prepared color-fixing agent is environmentally friendly, safe and strong in color-fixing effect.

Owner:TAICANG YUNTONG BIOCHEM ENG

Epoxy modified water-soluble acrylic resin, and preparation method and application thereof

The invention discloses an epoxy modified water-soluble acrylic resin, and a preparation method and application thereof. The preparation method of the epoxy modified water-soluble acrylic resin comprises the following steps: adding organic solvent, methyl methacrylate, butyl acrylate, methacrylic acid, 2-hydroxyethyl acrylate, chain-transfer agent and initiator into a reaction kettle, and heating to react; and adding organic solvent, methyl methacrylate, butyl acrylate, unsaturated double-bond terminated epoxy resin, methacrylic acid, 2-hydroxyethyl acrylate, chain-transfer agent and initiator into a dropwise addition tank, uniformly stirring, dropwisely adding into the reaction kettle, keeping the temperature, cooling, and adding an amine neutralizer for neutralization, thereby obtaining the epoxy modified water-soluble acrylic resin. The epoxy resin is introduced to the chain segment of the water-soluble acrylic resin by chemical modification, so that the epoxy modified water-soluble acrylic resin has better comprehensive properties, and better satisfies the requirements of customers.

Owner:GUANGDONG YINYANG ENVIRONMENT FRIENDLY NEW MATERIALS CO LTD

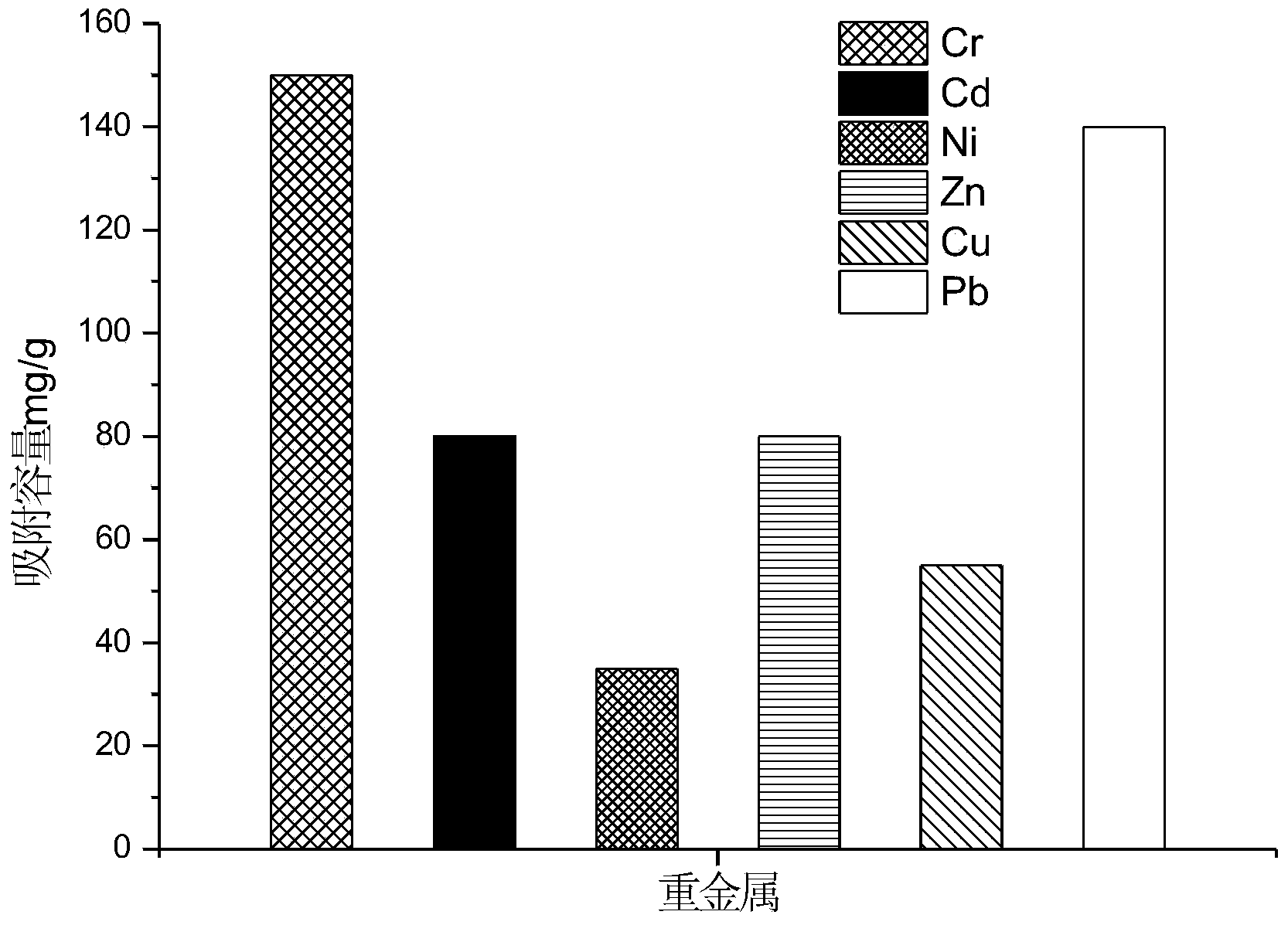

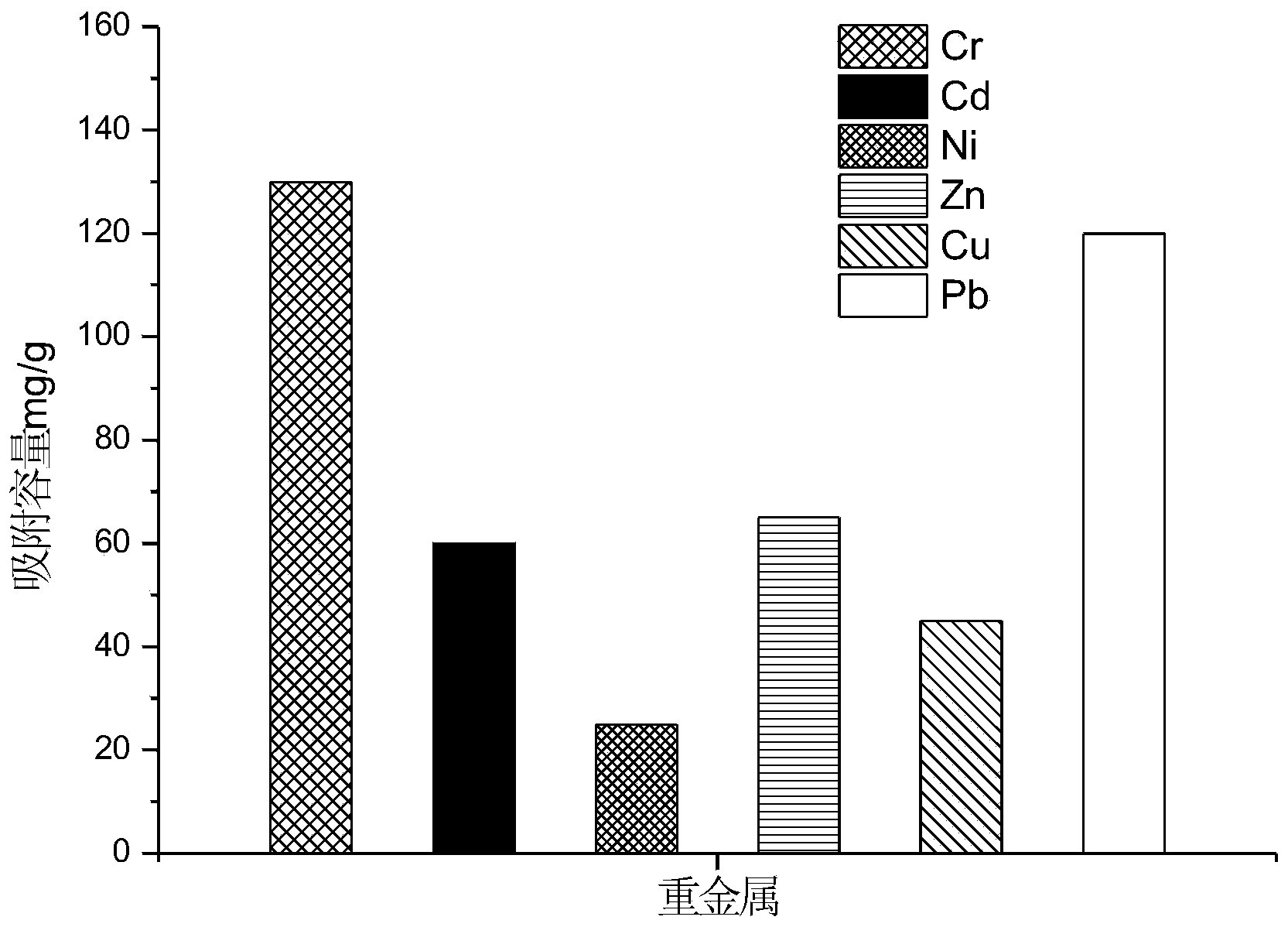

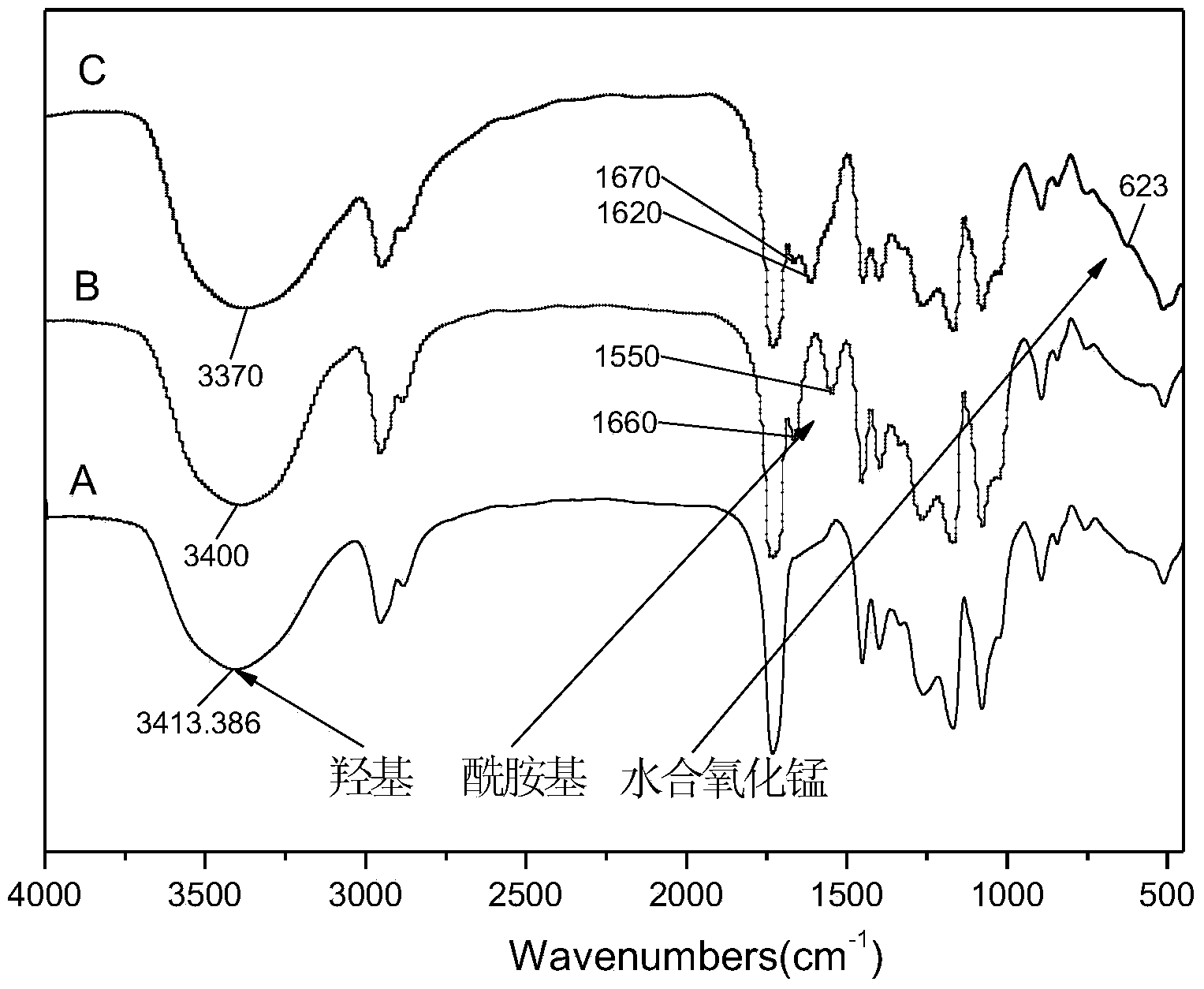

Preparation method and application of composite hydrogel provided with amide group and hydroxyl group and loaded with nano manganese oxide hydrate

InactiveCN104292388AEasy to retouchImprove adsorption capacityWater/sewage treatment by sorptionHydration reactionShielding gas

The invention relates to a preparation method and an application of composite hydrogel provided with an amide group and a hydroxyl group and loaded with nano manganese oxide hydrate. The preparation method comprises the following steps: uniformly mixing 2-hydroxyethyl acrylate, N-hydroxymethyl acrylamide and distilled water to obtain polymer hydrogel by virtue of radiation polymerization; by taking the polymer hydrogel as a template, loading nano manganese oxide hydrate in situ, wherein a molar ratio of 2-hydroxyethyl acrylate to the N-hydroxymethyl acrylamide monomer is (1-9) to (9-1), a polymerization temperature is (-)63 DEG C-(-)95 DEG C, the irradiation polymerization is performed by an aqueous solution of 2-hydroxyethyl acrylate and N-hydroxymethyl acrylamide in the presence of a protective gas, and a method for loading nano manganese oxide hydrate is an oxidization reduction reaction in-situ precipitation method. The composite hydrogel is applied to adsorbing heavy metal ions in wastewater, and capable of effectively removing heavy metals; and moreover, the composite hydrogel has relatively high mechanical strength and a long service life.

Owner:NANJING UNIV

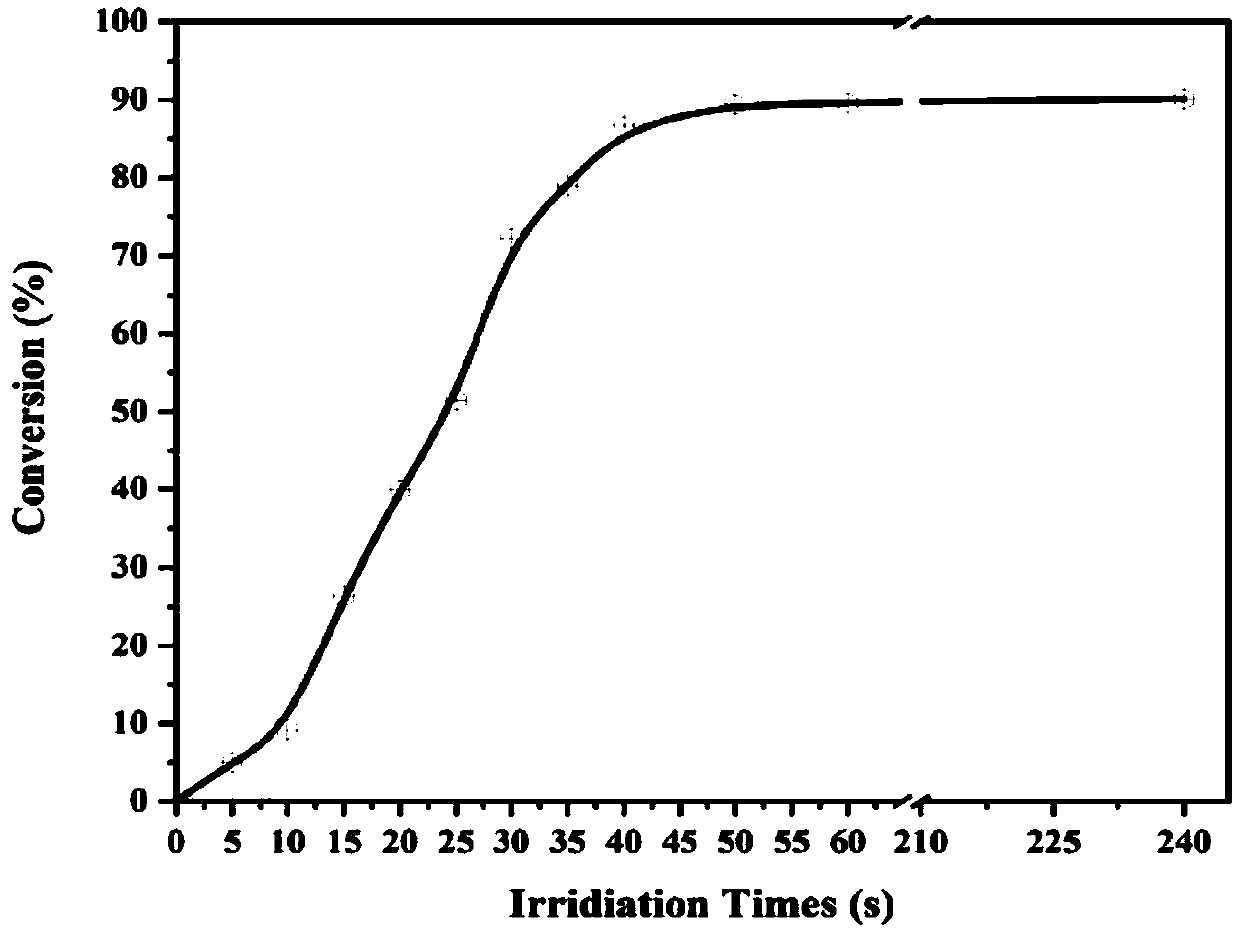

Method for preparing photosensitive ceramic precursor for manufacturing ceramic products by additive manufacturing technology

The invention discloses a method for preparing a photosensitive ceramic precursor for manufacturing ceramic products by an additive manufacturing technology; the method comprises the following steps:carrying out hydrolysis reaction of (chloromethyl)methyldichlorosilane with dichloromethylvinylsilane to obtain linear polysiloxane, then carrying out end-capping reaction of dimethylvinylchlorosilanewith linear polysiloxane, and carrying out reaction of the end-capped polysiloxane with 2-hydroxyethyl acrylate and triethylamine to obtain the photosensitive ceramic precursor. The UV-curable polysiloxane ceramic precursor is prepared, and the obtained photosensitive ceramic precursor can achieve 80% of double-bond conversion rate when being irradiated by ultraviolet light for 30 s and 90% of double-bond conversion rate when being irradiated by ultraviolet light for 40 s with the addition of a suitable initiator. The photosensitive ceramic precursor has quite high-efficiency photocuring performance. With the photosensitive ceramic precursor as the raw material, the stereolithography technology is used for additive manufacturing, and the cured product with regular appearance is obtained and has bright and clean appearance and high strength.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Rubber used for solid tyres and a preparing method thereof

InactiveCN107099064AGood molding effectImprove wear resistanceSpecial tyresPolymer scienceAntioxidant

Rubber used for solid tyres and a preparing method thereof are disclosed. The rubber includes natural rubber, butadiene-acrylonitrile rubber, polybutadiene, 2-hydroxyethyl acrylate, graphene, nanometer titanium dioxide, stearic acid, an antioxidant, a vulcanizing agent, a coupling agent and a filler. The method includes adding polymer into an internal mixer, plastifying the polymer, then adding the graphene, the 2-hydroxyethyl acrylate and the silane coupling agent, blending the mixture, then adding the rest components in order, and discharging the rubber after blending is finished to obtain the rubber used for solid tyres. The rubber has good shaping effects, and has good using properties such as wear resistance, corrosion resistance and weatherability. The rubber is used for preparing the solid tyres and provides a guarantee for automobile using safety.

Owner:明光速耐德实心轮胎有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com