High-solid-content high-gloss quick-drying water-soluble hydroxy acrylic resin and preparation method thereof

A hydroxyacrylic, quick-drying technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of waterborne hydroxyacrylic resins such as insufficient gloss and fullness, large pollution, and poor dryness, so as to improve the board surface effect and increase Compatibility, improvement of hardness and dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

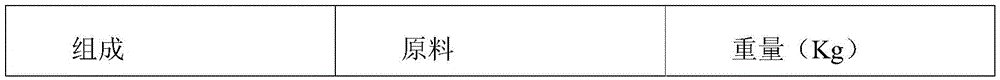

[0042]A kind of water-soluble hydroxyl acrylic resin preparation step of high solid high light quick-drying property comprises as follows:

[0043] 1) Put material A into the reactor, heat up to reflux, seal the reactor, and continue to heat up to 135±2°C;

[0044] 2) Use a flow pump to evenly add material B dropwise at a constant speed, and the common dropwise addition time is 6 hours;

[0045] 3) After the dropwise addition, the constant temperature reaction was carried out for 4 hours;

[0046] 4) Use a flow pump to add C material, and then keep warm for 3 hours;

[0047] 5) Remove 490Kg of 70% solvent under reduced pressure and increase temperature, then lower the temperature to below 80°C, add material D neutralizing agent to neutralize evenly, so that the pH value is 7-8;

[0048] 6) Add material E to dilute with deionized water, disperse evenly, filter and pack.

[0049] Main technical indicators of a water-soluble hydroxyacrylic resin with high solidity, high light ...

specific Embodiment 2

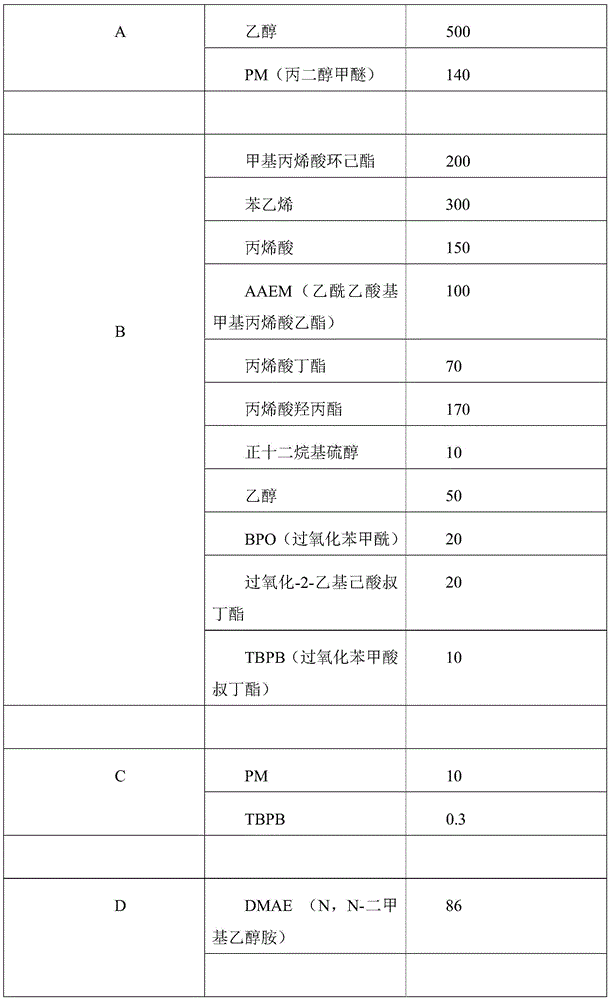

[0060] A kind of water-soluble hydroxyl acrylic resin preparation step of high solid high light quick-drying property comprises as follows:

[0061] 1) Put material A into the reactor, heat up to reflux, seal the reactor, and continue to heat up to 140±2°C;

[0062] 2) Use a flow pump to evenly add material B dropwise at a constant speed, and the common dropwise addition time is 5 hours;

[0063] 3) After the dropwise addition, the constant temperature reaction was carried out for 3 hours;

[0064] 4) Use a flow pump to add C material, and then keep warm for 3.5 hours;

[0065] 5) Remove 475Kg of 60% solvent under reduced pressure and increase temperature, then lower the temperature to below 80°C, add material D neutralizing agent to neutralize evenly, so that the pH value is 7-8;

[0066] 6) Add material E to dilute with deionized water, disperse evenly, filter and pack.

[0067] Main technical indicators of a water-soluble hydroxyacrylic resin with high solidity, high lig...

specific Embodiment 3

[0078] A kind of water-soluble hydroxyl acrylic resin preparation step of high solid high light quick-drying property comprises as follows:

[0079] 1) Put material A into the reactor, heat up to reflux, seal the reactor, and continue to heat up to 130±2°C;

[0080] 2) Use a flow pump to evenly add material B dropwise at a constant speed, and the common dropwise addition time is 6 hours;

[0081] 3) After the dropwise addition, the constant temperature reaction was carried out for 3 hours;

[0082] 4) Use a flow pump to add material C, and then keep warm for 4 hours;

[0083] 5) Remove 740Kg of 80% solvent under reduced pressure and increase temperature, then lower the temperature to below 80°C, add material D neutralizing agent to neutralize evenly, so that the pH value is 7-8;

[0084] 6) Add material E co-solvent and deionized water to dilute, disperse evenly, filter and pack.

[0085] Main technical indicators of a water-soluble hydroxyacrylic resin with high solidity, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com