Patents

Literature

36results about How to "High distinctness of image" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

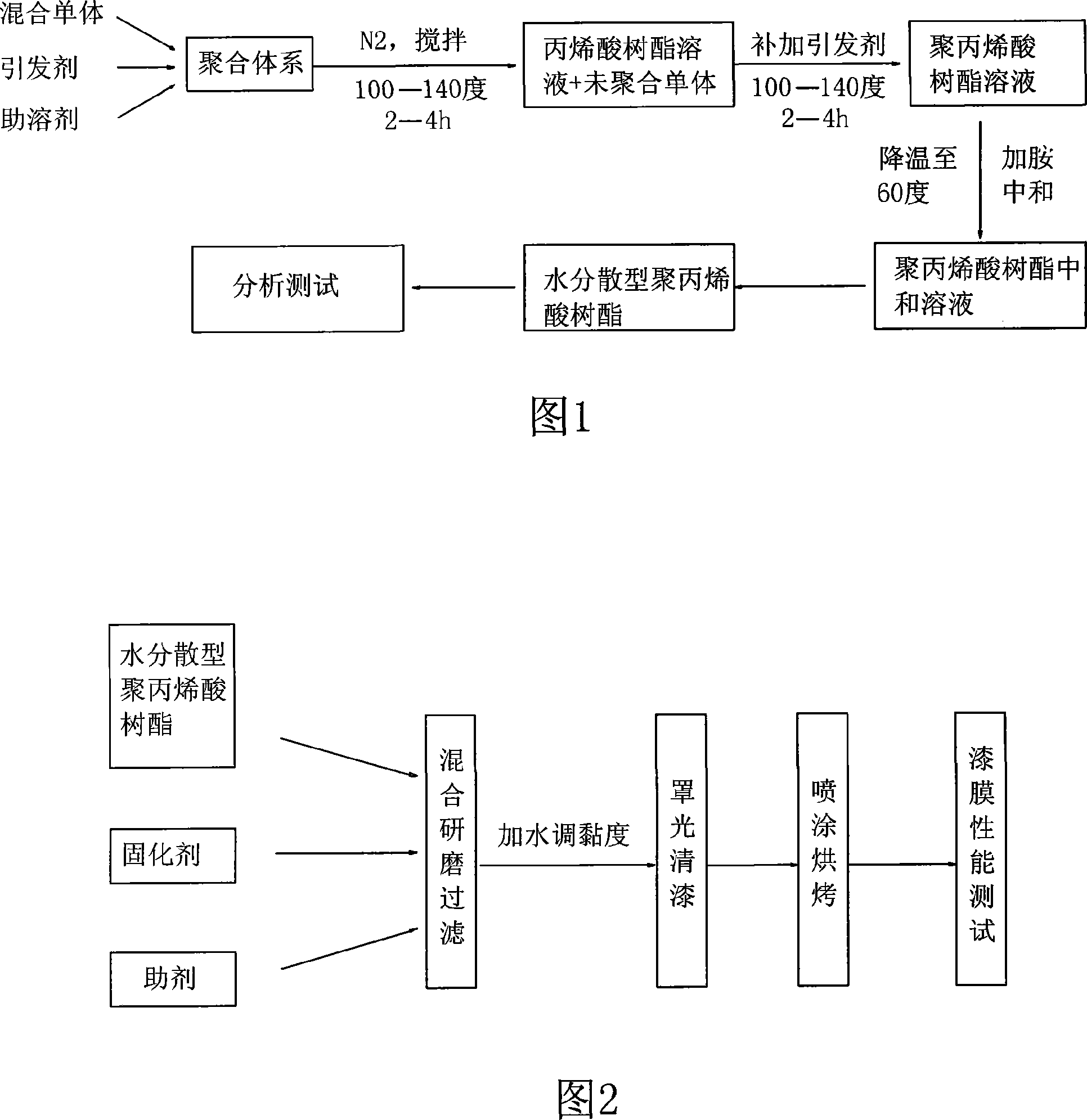

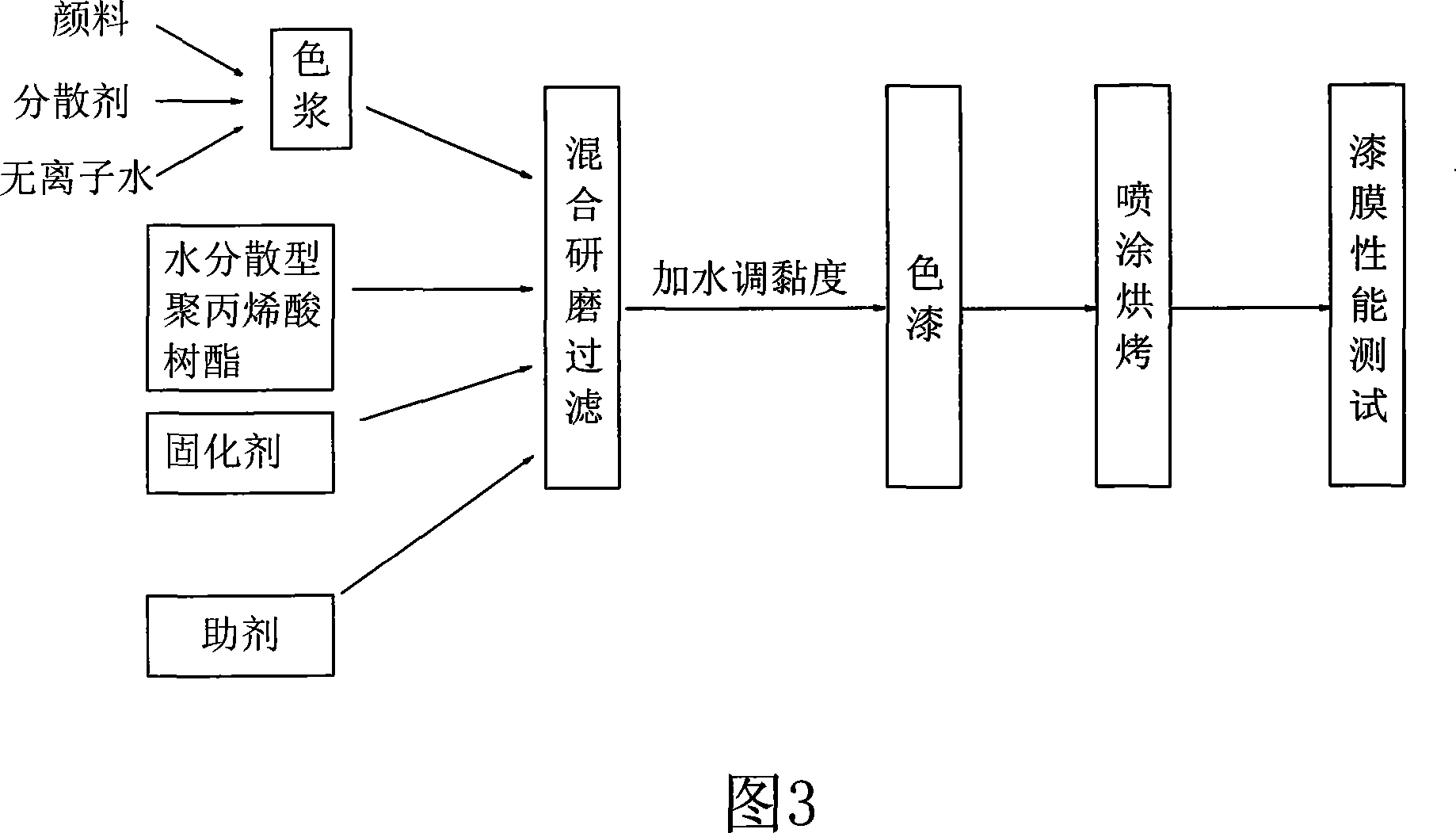

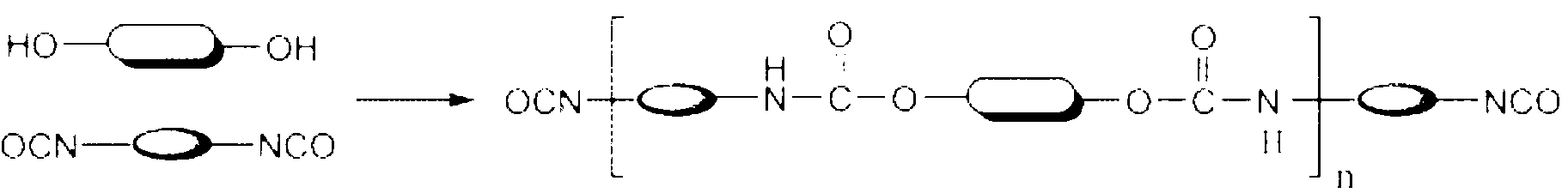

Automobile finishing varnish containing water dispersible acrylic ester and preparation method thereof

ActiveCN101081957AHigh glossHigh distinctness of imageLiquid surface applicatorsCoatingsWater dispersiblePolymer science

The present invention discloses water dispersed automobile finishing varnish of polyacrylate and its preparation process. The water dispersed automobile finishing varnish is mixture of water dispersed polyacrylate, water dispersed curing agent amino resin and closed polyisocyanate. The polyacrylate is water dispersoid prepared with the mixture of five components, and through the first radical initiator initiated polymerization in mixed solvent to obtain polyacrylate resin and the subsequent neutralization with neutralizer. The water dispersed automobile finishing varnish after being sprayed and cured forms varnish film possessing high glossiness, high brightness, high hardness, high impact resistance, high weather resistance, high compactness and fast adhesion to the base material.

Owner:GUANGDONG YATU CHEM +1

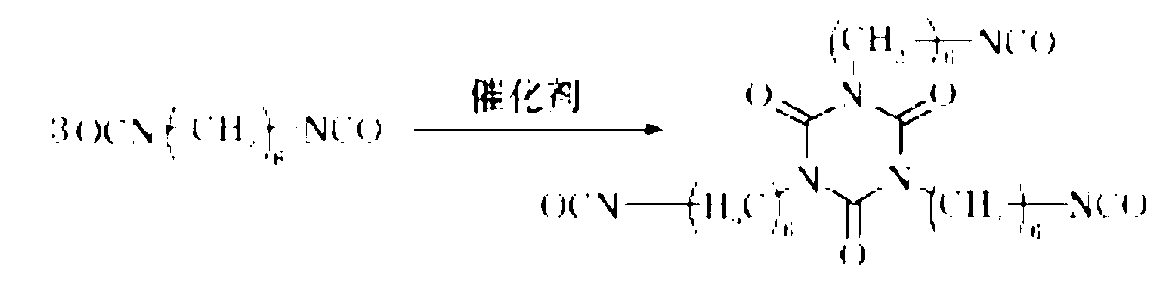

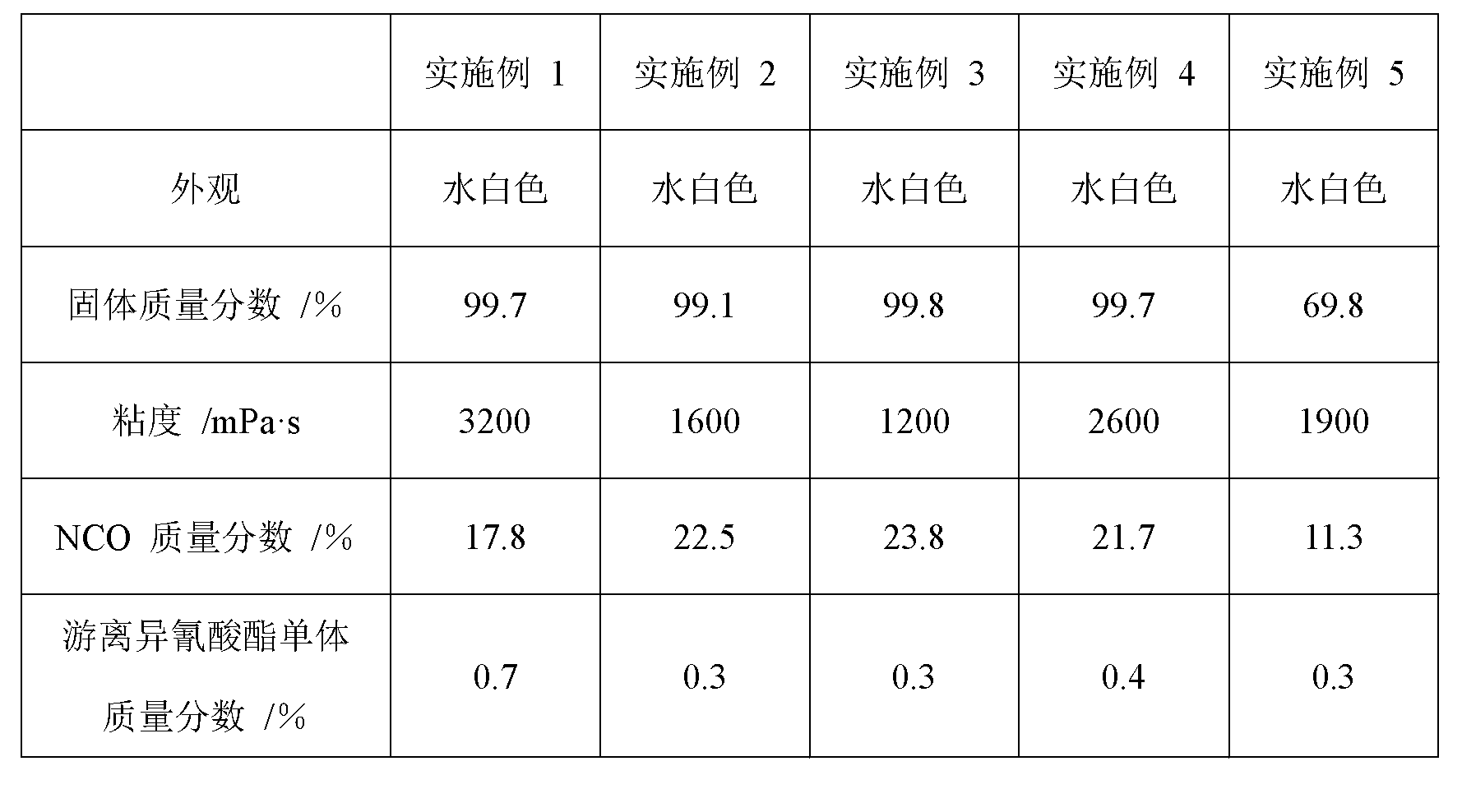

Polyurethane curing agent with low free isocyanate monomer and preparation method thereof

InactiveCN103224605AAdd one step polymerization reactionLow free HDI contentPolyurea/polyurethane coatingsPolymer scienceMeth-

The present invention relates to a polyurethane curing agent with low free isocyanate monomer and a preparation method thereof. The polyurethane curing agent comprises the raw materials in weight percentage as following: 80 - 88 parts of hexamethylene diisocyanate monomer; 12 - 20 parts of polyhydric alcohol; 0.1-0.5 part of catalyst; and 0.1-1.0 part of terminating agent. The invention adopts a two-step chemical conversion reaction, namely, adds one step of polymerization reaction based on one-step addition reaction to remove free isocyanate monomer by a trimer method so as to obtain the 100% solid content, wherein the NCO content is between 21 and 22 %, and the free HDI content is between 0.1 and 1.0 %. According to the present invention, the preparation process of polyurethane curing agent is simplified without post-processing . The polyurethane curing agent of the invention is matched with hydroxyl acrylic resin and polyester resin etc., and the paint film will not be yellowed, and has excellent light resistance, weathering resistance, chemical resistance and gorgeous gloss.

Owner:HUBEI TRASION CHEM IND CO LTD

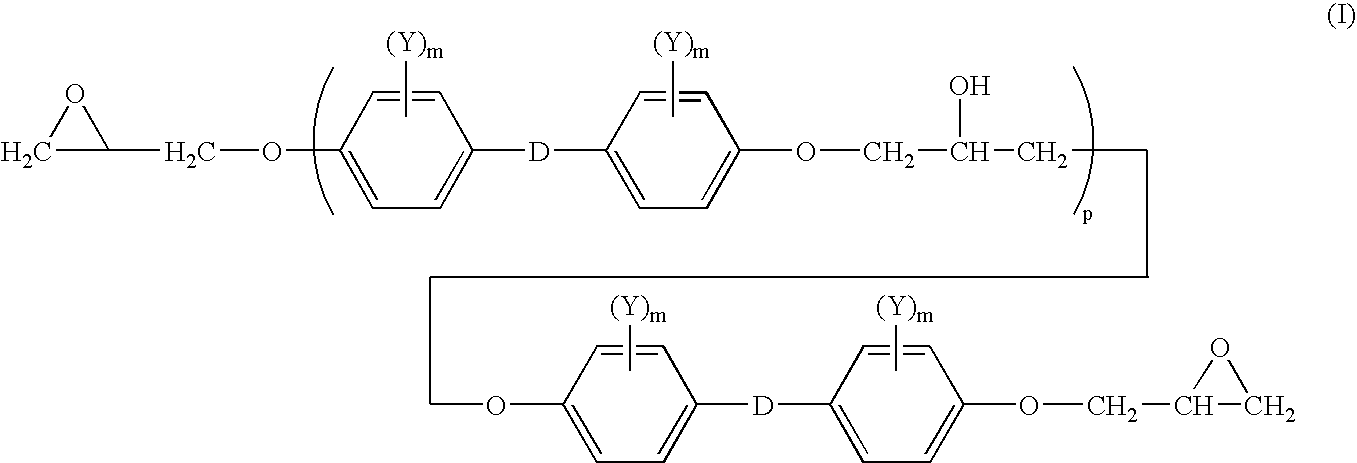

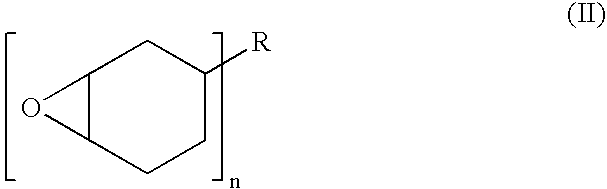

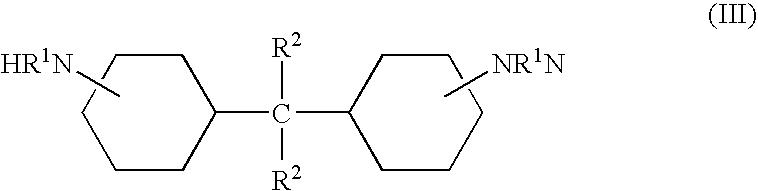

Process for Preparing Composites Using Epoxy Resin Formulations

InactiveUS20080308972A1High distinctness of imageImprove surface qualityCeramic shaping apparatusCoatingsEpoxyAlkane

The invention is a process for making reinforced composites using an epoxy resin composition. The epoxy resin compositions are hardened using a gem-di(cyclohexylamine)-substituted alkane as a hardener and a tertiary amine compound, a heat-activated catalyst, or a mixture thereof as an accelerator. This epoxy resin composition has a long open time, and then cures rapidly in a mold in the presence of a reinforcement. These cure characteristics make the composition well suited for use in manufacturing processes such as resin transfer molding (RTM), vacuum-assisted resin transfer molding (VARTM), Seeman Composites Resin Infusion Molding Process (SCRIMP) and reaction injection molding (RIM).

Owner:DOW GLOBAL TECH LLC

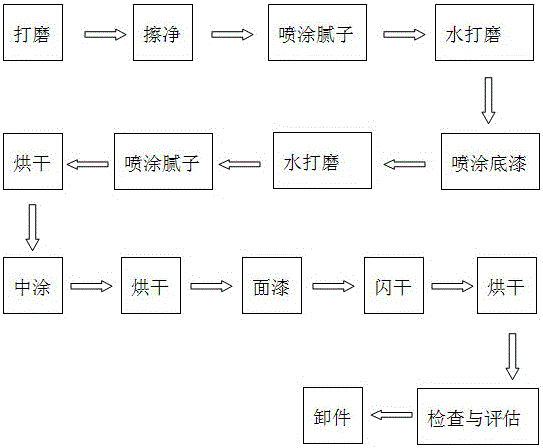

Paint spraying process for automobile carbon fiber composite material

InactiveCN106622909ASolve the difficulties in the coating of highly decorative auto partsSolve the difficulties of paintingPretreated surfacesCoatingsFiberCoated surface

The invention relates to a paint spraying process for an automobile carbon fiber composite material. The paint spraying process is characterized by comprising the following steps that a carbon fiber workpiece needing to be painted is polished, putty is sprayed at the normal temperature, after the surface of a putty layer is dried, water polishing treatment is conducted aiming at coating surface defects after the putty is sprayed, thus, the coating surface is flat and smooth visually, primer is sprayed at the normal temperature, local water polishing treatment is conducted aiming at coating surface defects after the primer is sprayed, and the coating surface is flat and smooth visually; for a primer layer, if a few of scratches, particles, shrinkage cavities or pinholes exist, secondary normal-temperature putty spraying is conducted; otherwise, a floating coat is sprayed directly and then is dried, finish paint is sprayed, after finish paint spraying is conducted, the immediate drying temperature is 18-35 DEG C, the relative humidity RH is 40%-70%, the time is 7-10 min, the drying temperature is 130-150 DEG C after the finish paint is sprayed, and the heat preservation time is 20 + / - 2 min; and whether the surface of the workpiece is flat, smooth and free of shrinkage cavity is inspected, and the surface has a flashing effect. By means of the paint spraying process for the high-decoration and high-performance automobile part made of the carbon fiber composite material, the technical problems of paint spraying processes are solved.

Owner:CHINA FIRST AUTOMOBILE

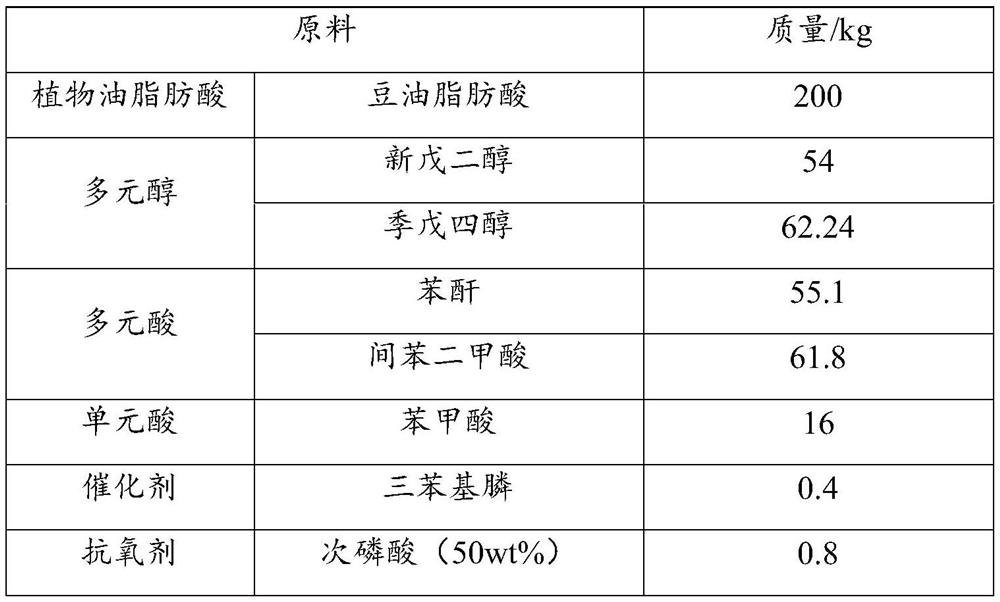

Alkyd resin for amino baking paint and preparation method thereof

The invention discloses alkyd resin for amino baking paint and a preparation method thereof. The alkyd resin for amino baking paint is prepared from the following components: 10 to 15 parts of dry or half-dry vegetable oil acid, 10 to 15 parts of triatomic alcohol with side chains, 5 to 10 parts of dihydric alcohol with side chains, 20 to 30 parts of phthalic anhydride, 1 to 3 parts of adipic acid, 0.05 to 0.2 part of esterification catalyst, 1 to 5 parts of dimethylbenzene, and 30 to 40 parts of organic solvent. The compositions and the proportions of the raw materials are screened through a lot of experiments, the component proportion is scientific and reasonable, and the alkyd resin for the amino baking paint has good flexibility, shock resistance, rigidity and weather resistance, and is wide in application range. The preparation method of the alkyd resin for amino baking paint is low in production cost, high in preparation efficiency, reasonable in whole process design, strong in operability and easy to implement.

Owner:江苏三木化工股份有限公司

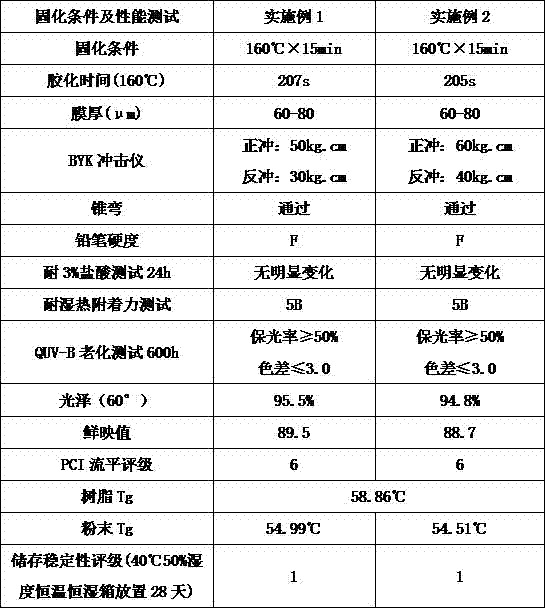

Environment-friendly HAA low-temperature-curing high-Tg high-toughness high-leveling ultra-weatherability powder coating

InactiveCN107033754AGood storage stabilityHigh distinctness of imagePowdery paintsPolyester coatingsWaxAntioxidant

The invention discloses an environment-friendly HAA low-temperature-curing high-Tg high-toughness high-leveling ultra-weatherability powder coating which comprises, by mass, 60-70% of carboxyl polyester resin, 4.5-5.0% of HAA curing agent, 0.8-1.2% of leveling agent, 0.5-1.0% of degassing agent, 0.3-0.5% of antioxidant, 0.5-1.0% of brightener, 0.5-0.8% of dispersion aid, 0.5-0.8% of degassed wax, 0-4% of toughener and25-28% of weatherable pigment. The powder coating does not contain TGIC, is nontoxic, environment-friendly, low in curing temperature (160 DEG CX15min), high in storage stability, excellent in mechanical performance and high in distinctness of image, glossiness and leveling property, has good performance in resisting chemicals and resisting damp and heat and excellent ultra-weatherability and belongs to real environment-friendly energy-saving powder coatings.

Owner:ZHEJIANG HUACAI NEW MATERIAL CO LTD

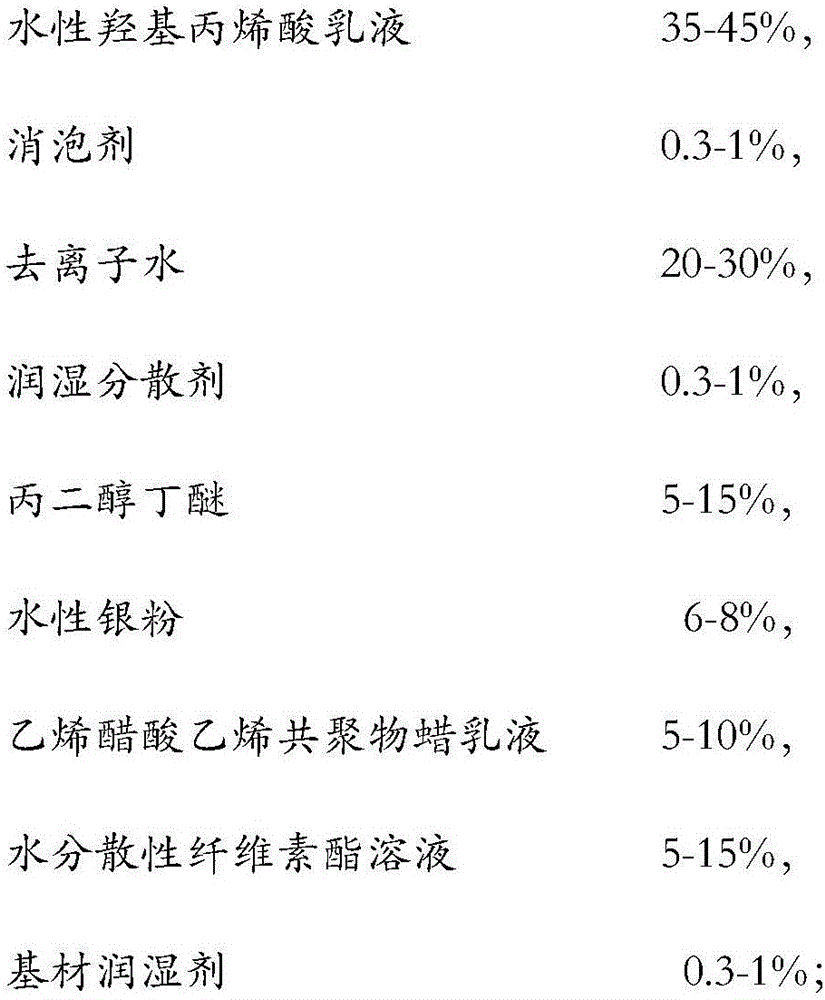

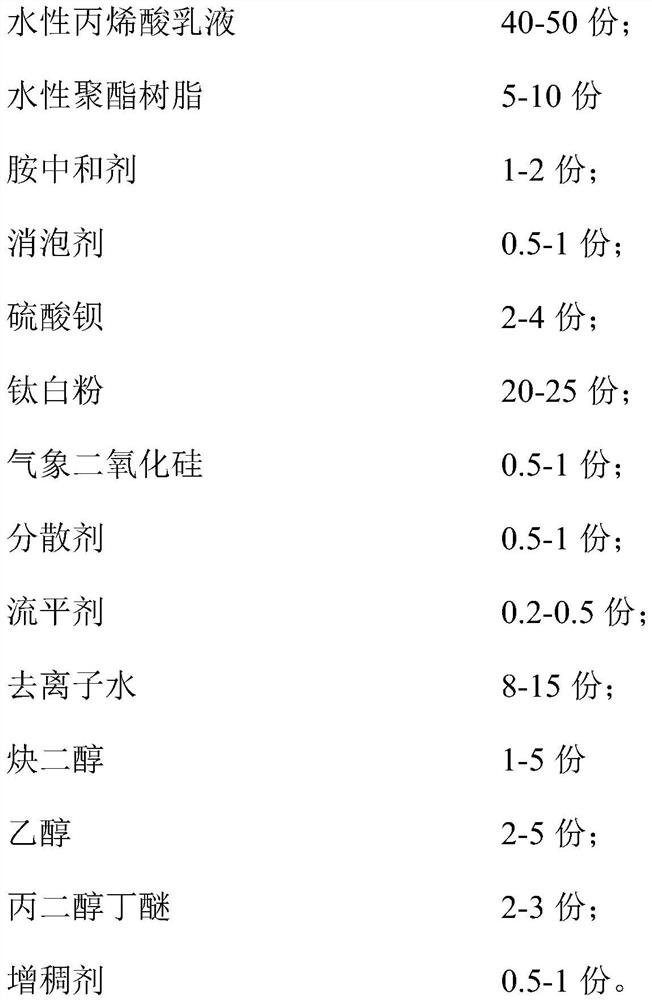

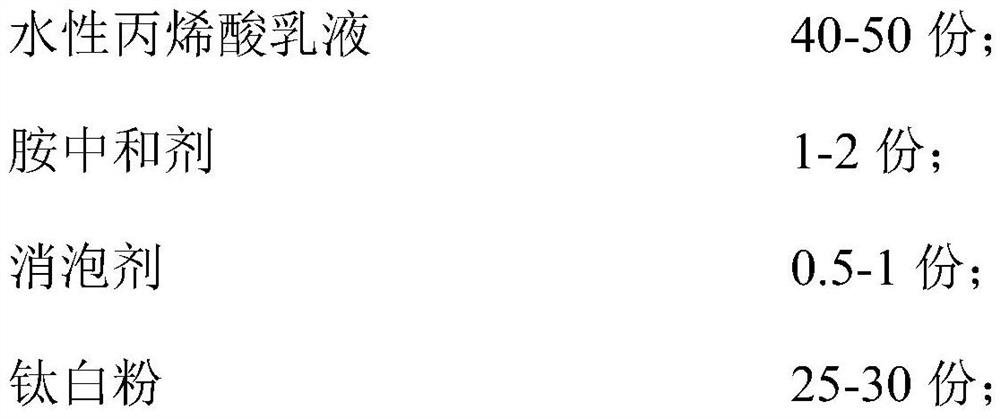

Aqueous acrylic polyurethane aluminum powder paint and preparation method thereof

InactiveCN106590379AReduce pollutionFast dryingPolyurea/polyurethane coatingsCellulosePROPYLENE GLYCOL BUTYL ETHER

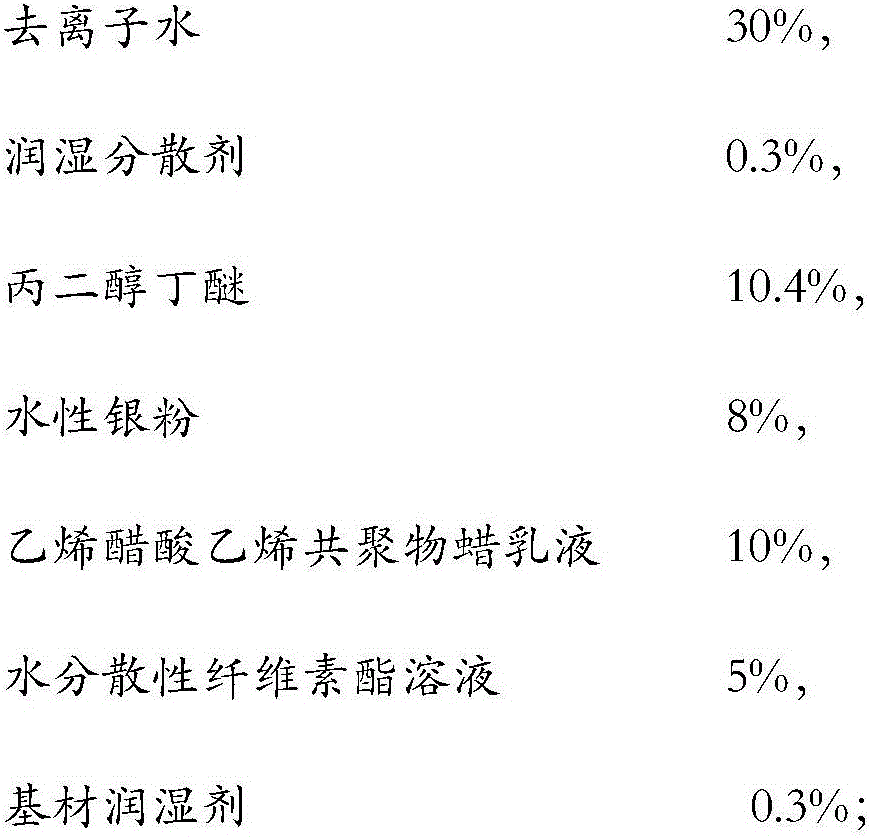

The invention discloses an aqueous acrylic polyurethane aluminum powder paint, which is composed of a component A and a component B, wherein the component A is composed of, by weight, 35-45% of aqueous hydroxyl acrylic emulsion, 0.3-1% of a defoamer, 20-30% of deionized water, 0.3-1% of a wetting dispersant, 5-15% of a propylene glycol butyl ether, 6-8% of aqueous aluminum powder, 5-10% of an ethylene-vinyl acetate copolymer wax emulsion, 5-15% of water-dispersible cellulose ester solution, and 0.3-1% of a base material wetting agent; and the component B is an isocyanate curing agent. The weight ratio of the component A to the component B is 7-9:1. A paint film formed by the aqueous acrylic polyurethane aluminum powder paint is quick to dry, is glossy and has high brightness. Orientation of the aluminum powder is excellent.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Coating preparation method of automobile part

InactiveCN107812685ALower requirementHigh fullnessPretreated surfacesCoatingsColor effectCoating system

The invention discloses a coating preparation method of an automobile part. The coating preparation method comprises the following steps: selecting a plastic electroplating part manufactured by adopting the highlighting nickel process, and enabling the plastic electroplating part to be subjected to seven process steps: pretreatment, primer spraying, primary levelling, colored paint spraying, secondary leveling, baking, and discharging. The coating preparation method of the automobile part has the benefits as follows: through reasonable selection of materials, pretreatment process and the coating system, a diversified color effect is achieved, the prepared coating has a high plumpness, high grade of transparency and highly metallic appearance, the coating effect and color diversity are enriched, the scratch resistant and ageing resistant performances are realized without additionally arranging a protecting coating, the high-performance requirements of the surface coating of the automobile part are met, the long-term usage of the high-cost process of performing paint spraying after vacuum coating is avoided, and the production cost is further reduced.

Owner:SHANGHAI REAL INDAL

Water-based amino baking varnish

Water-based amino baking varnish is prepared from, by mass, the raw materials of aluminum silver paste, silver powder orientation agents, n-butyl alcohol, butyl cellosolve, water-based epoxy modified acrylic acid dispersions, water-based amino, wetting agents, leveling agents, alcohol and water. The water-based amino baking varnish has the properties of excellent adhesive force, weather resistance, impact resistance, chemical resistance, high rigidity, yellowing resistance, image distinctness, high luster and transparency and others.

Owner:安徽传奇新材料有限公司

Water-based air-dry finishing coat

A water-based air-dry finishing coat is prepared form, by mass, water-based epoxy modified acrylic acid dispersions, dispersing agents, F5RK, ethylene glycol butyl ether, water, water-based epoxy modified acrylic acid dispersions, thickening agents, wetting agents, leveling agents and water. The water-based air-dry finishing coat has excellent adhesive force, weather resistance, impact resistance, chemical resistance, high rigidity, yellowing resistance, image distinctness, high luster and transparency and others.

Owner:安徽传奇新材料有限公司

High-glass metal powder coating and preparation method thereof

InactiveCN104263194AReduce floatingLower rankPolyurea/polyurethane coatingsPowdery paintsMetal coatingDry mixing

The invention relates to a high-glass metal powder coating which is prepared from a base material, a floating metal pigment, a powder treatment agent and a functional auxiliary by adopting a dry-mixing method, wherein the base material comprises resin, a curing agent, a flatting agent, filler and pigments and a degassing agent and is prepared by high-speed mixing, melt extrusion and abrasive powder sieving. Then, the product provided by the invention is prepared by adopting a dry-mixing and adhering process with the base material which is added in two steps. By virtue of granular control of a cellulose acetate butyrate material and the two-step dry-mixing process, the appearance effect and the distinctness of a coating are remarkably improved while the dispersing effect of cellulose acetate butyrate and metal pigments is improved and the adhering effect and efficiency of the metal pigments are enhanced, the glossiness of the coating reaches over 50% (60 DEG C), and particularly, the touch pollution resisting capability of the surface of the metal coating is remarkably enhanced. The whole quality of the product is comprehensively enhanced.

Owner:晁兵

Static even-color painting method

InactiveCN102059208AReduce manufacturing costImprove surface qualityLiquid surface applicatorsCoatingsOrganic solventEngineering

The invention discloses a static even-color painting method comprising the following steps of: setting a painting chamber control unit for controlling air speed in a painting chamber; setting a static automatic painting unit for controlling the working state of a static automatic painting gun to ensure that the static automatic painting gun achieves a set painting effect; setting an automatic hanger unit to ensure that workpiece hangers to be painted are reasonably arranged at intervals and the velocity of conveying chains for suspending the hangers are reasonable; and painting workpieces to be painted, hung on the hangers in the painting chamber by using the static automatic painting gun so that paints are attached to the workpieces well by a static effect. The static even-color paintingmethod has the advantages that (1) a paint film has the characteristic of evenness, good leveling property and obviously improved orange-peel phenomenon; (2) the distinctness of image (DOI) and glossiness of the paint film are improved, and a PGD (a unit of the DOI) value can be improved by 0.1-0.3; (3) by adopting static automatic painting, the emission of a volatile organic solvent is effectively reduced to relieve environmental pollution of painting; and (4) the painting efficiency is improved and paint is saved.

Owner:DONGGUAN GUANHUI HARDWARE

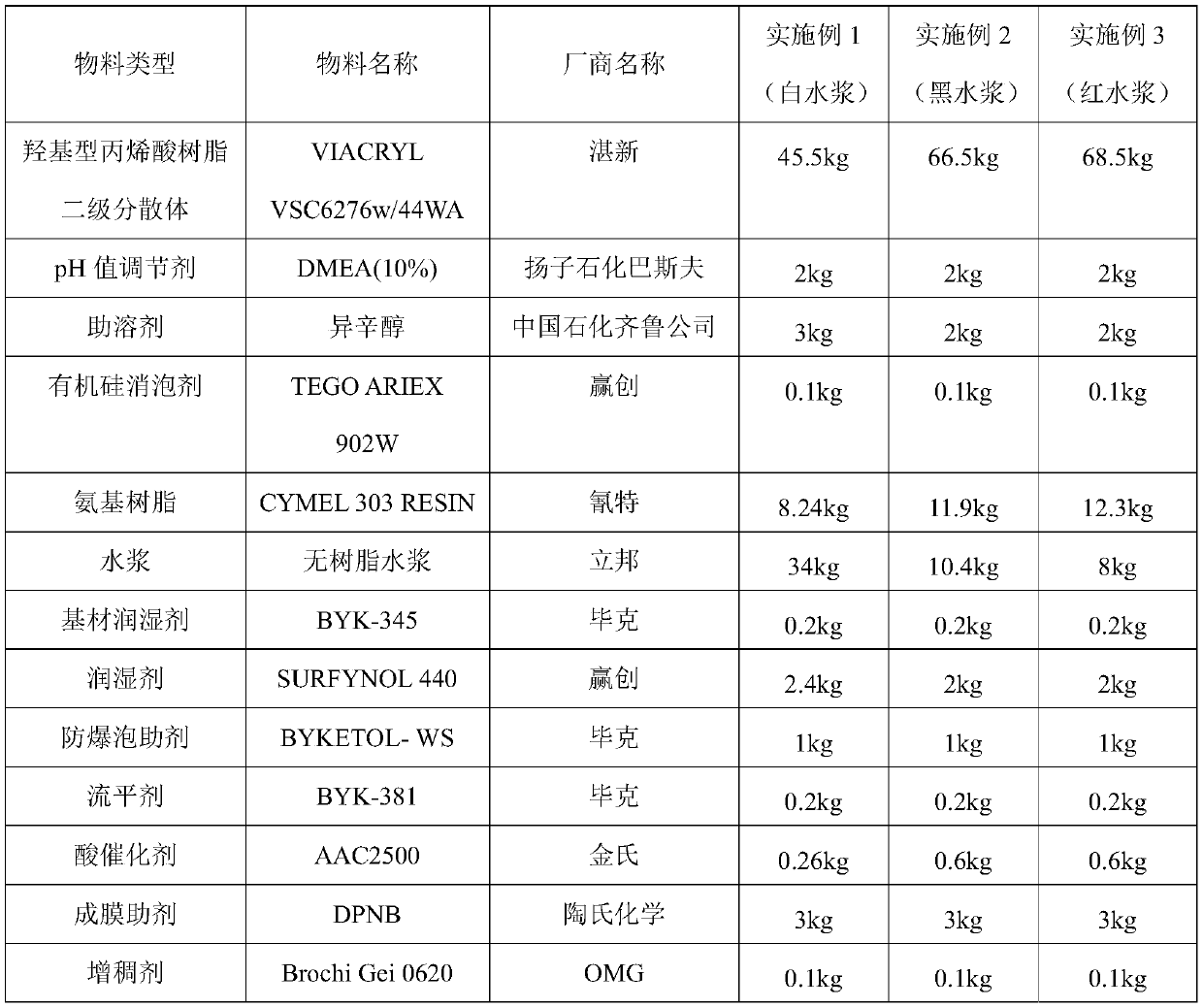

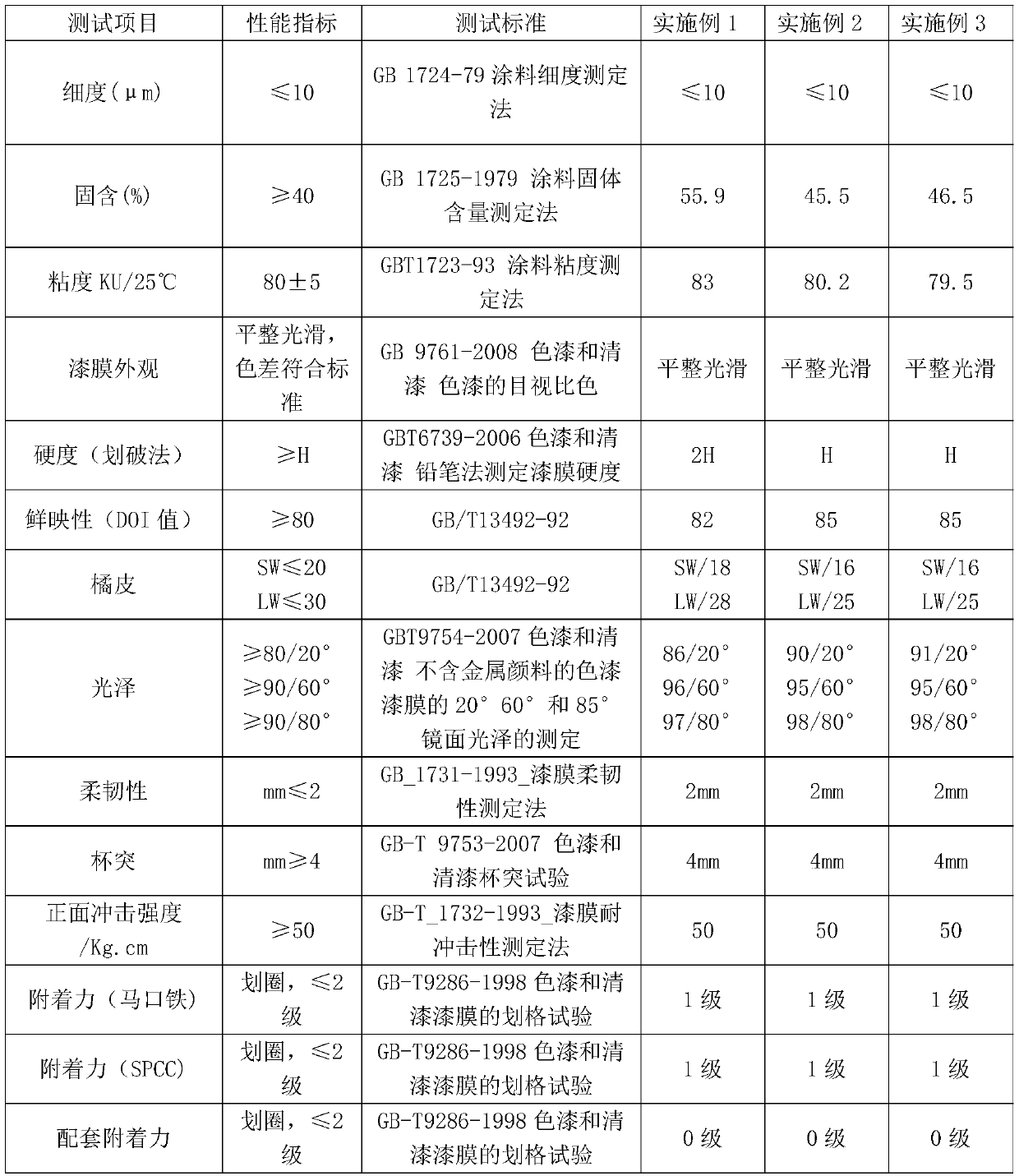

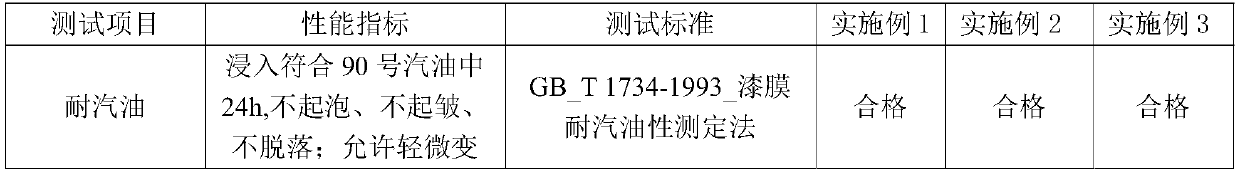

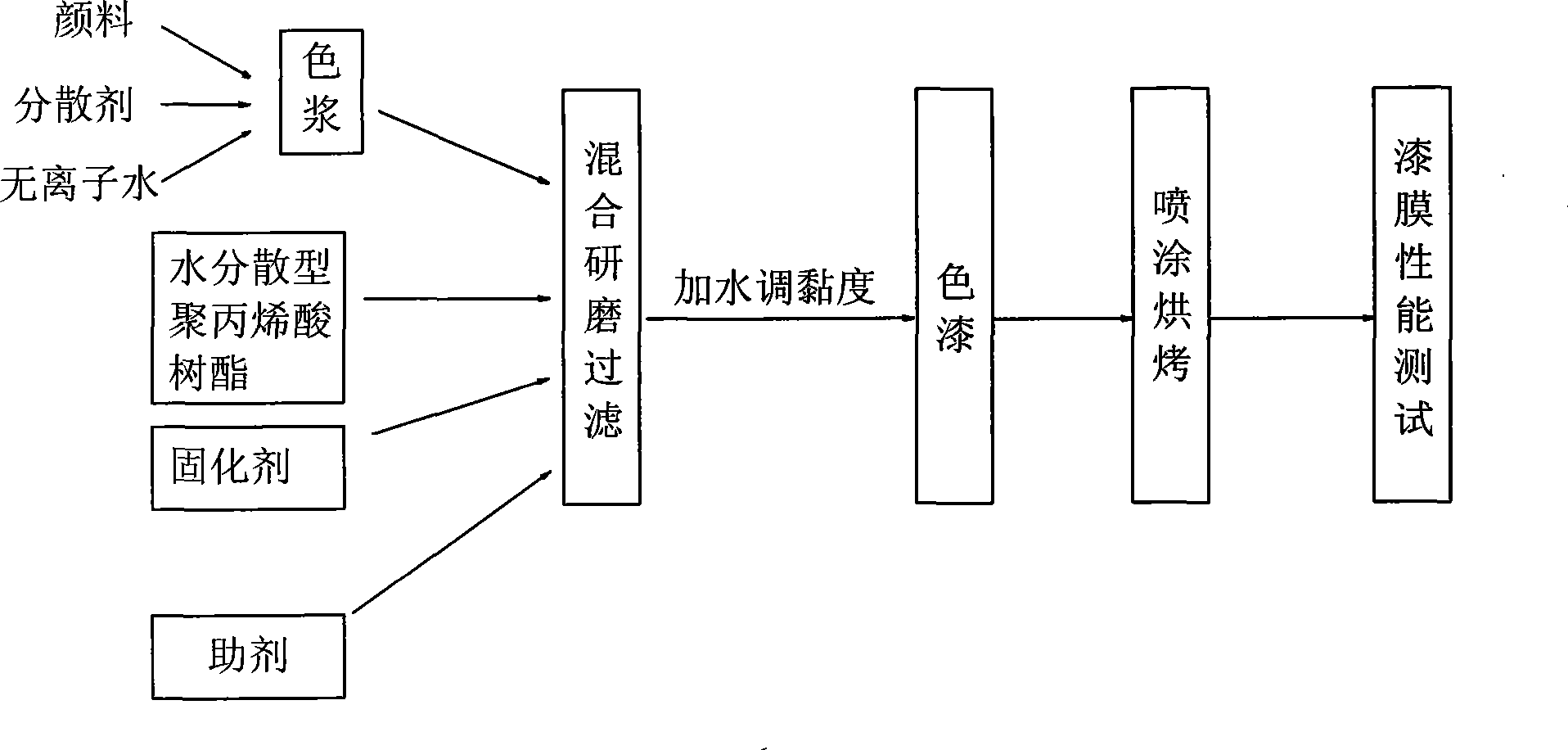

Waterborne acrylic amino baking varnish and preparation method thereof

The invention discloses a waterborne acrylic amino baking varnish, which comprises the following components by weight: 30-60 parts of hydroxyl type acrylic resin secondary dispersoid, 5-15 parts of amino resin, 20-40 parts of resin-free water slurry, 3-6 parts of an amino resin cosolvent, 1-5 parts of a surfactant ethoxyalkynediol, 3-6 parts of a film-forming assistant, 0-1 part of a pH regulator,0-1 part of a defoaming agent, 0-1 part of a base material wetting agent, 0-1 part of a leveling agent, 0-1 part of anti-explosion foaming aid, 0-1 part of an acid catalyst and 0-1 part of a thickener. While having excellent weather resistance, high gloss and high distinctness of image, a paint film prepared from the waterborne acrylic amino baking varnish also has extremely low construction VOCC, and has great application value.

Owner:NIPPON PAINT IND COATINGS SHANGHAI

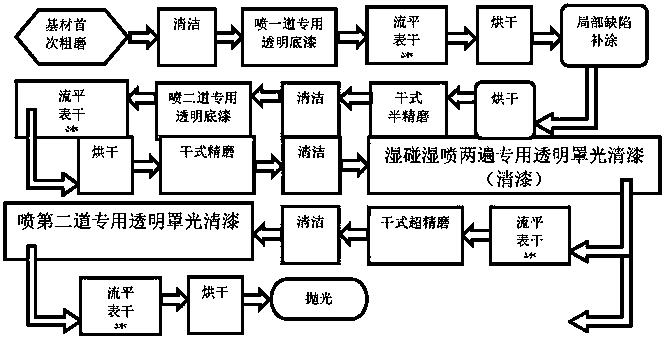

Automobile carbon fiber / epoxy resin composite exterior decoration transparent coating method

InactiveCN108993842AMeet rich individual requirementsIncrease added valuePretreated surfacesCoatingsEpoxyFiber

The invention belongs to the technical field of spraying, and relates to a process method for spraying automobile exterior decorations, in particular to an automobile carbon fiber / epoxy resin composite exterior decoration transparent coating method. Carbon fiber / epoxy resin composite exterior decoration transparent coating is a coating technology that the carbon fiber texture can be clearly seen after the exterior decoration is painted. The selection and use of uvioresistant primers and varnishes can ensure the weatherability of the exterior decoration, meanwhile by use of the low-temperature paint, the coating environment that usually exceeds 170 DEGC for automobiles is not considered, the requirements for equipment are greatly lowered, and the coating cost is reduced; the selection of the mesh number of abrasive paper in each process is verified by a large number of experiments, and it is ensured that the textures of carbon fiber woven fabric base materials show high distinctnessof image (DOI) and adhesive force; and the coating cost and the coating efficiency can be effectively controlled through reasonable combination of two primer processes and two finishing coat processes.

Owner:AVIC COMPOSITES

Low-temperature water-based vehicle body coating as well as preparation method and use method thereof

ActiveCN112708318AStrong adhesionGood weather resistanceLiquid surface applicatorsPolyurea/polyurethane coatingsPolyesterVarnish

The invention provides a low-temperature water-based vehicle body coating as well as a preparation method and a use method thereof. The low-temperature water-based vehicle body coating comprises a low-temperature water-based single-component intermediate coat, a low-temperature water-based single-component colored paint and a low-temperature oily double-component varnish. According to the invention, water-based polyester modified acrylic resin is used as matrix resin of the intermediate coat, so baking temperature is low; the performance of a paint film is equivalent to the performance of a traditional solvent type coating, and the stone impact resistance of the paint film is superior to the stone impact resistance of the solvent type coating; and the distinctness of image and fullness of finish paint are improved, and the decorative effect of the whole vehicle is better.

Owner:WUHU CHUNFENG NEW MATERIAL

High-fullness high-distinctness thermosetting acrylic resin and preparation method thereof

InactiveCN103342783AThe ratio is scientific and reasonableImproves image clarity and fullnessPrepolymerButyl acrylate

The invention discloses a high-fullness high-distinctness thermosetting acrylic resin which is prepared from the following raw materials in parts by weight: 15-25% of prepolymer, 15-25% of styrene, 8-20% of n-butyl acrylate, 5-10% of butyl acrylate, 0.1-0.5% of tert-butyl peroxybenzoate and 25-37% of dimethylbenzene. The high-fullness high-distinctness thermosetting acrylic resin disclosed by the invention is composed of the raw materials selected from abundant experiments according to the optimal proportion, and the component proportion is scientific and reasonable. The property detection result indicates that the thermosetting acrylic resin has the characteristics of high gloss, high hardness, high distinctness, high fullness and the like, and can be widely used in the fields of automobiles, electric appliances, mechanics, architecture and the like.

Owner:无锡市南雅化工有限公司

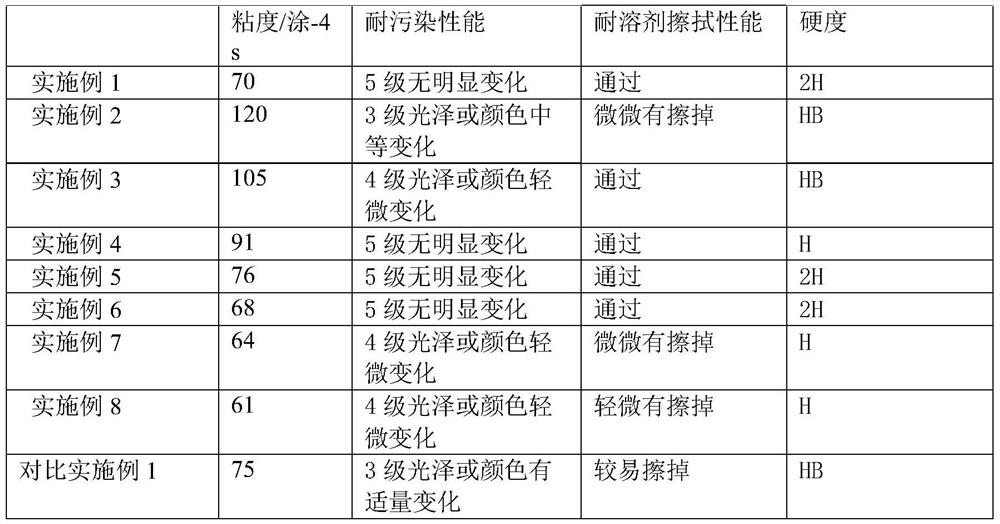

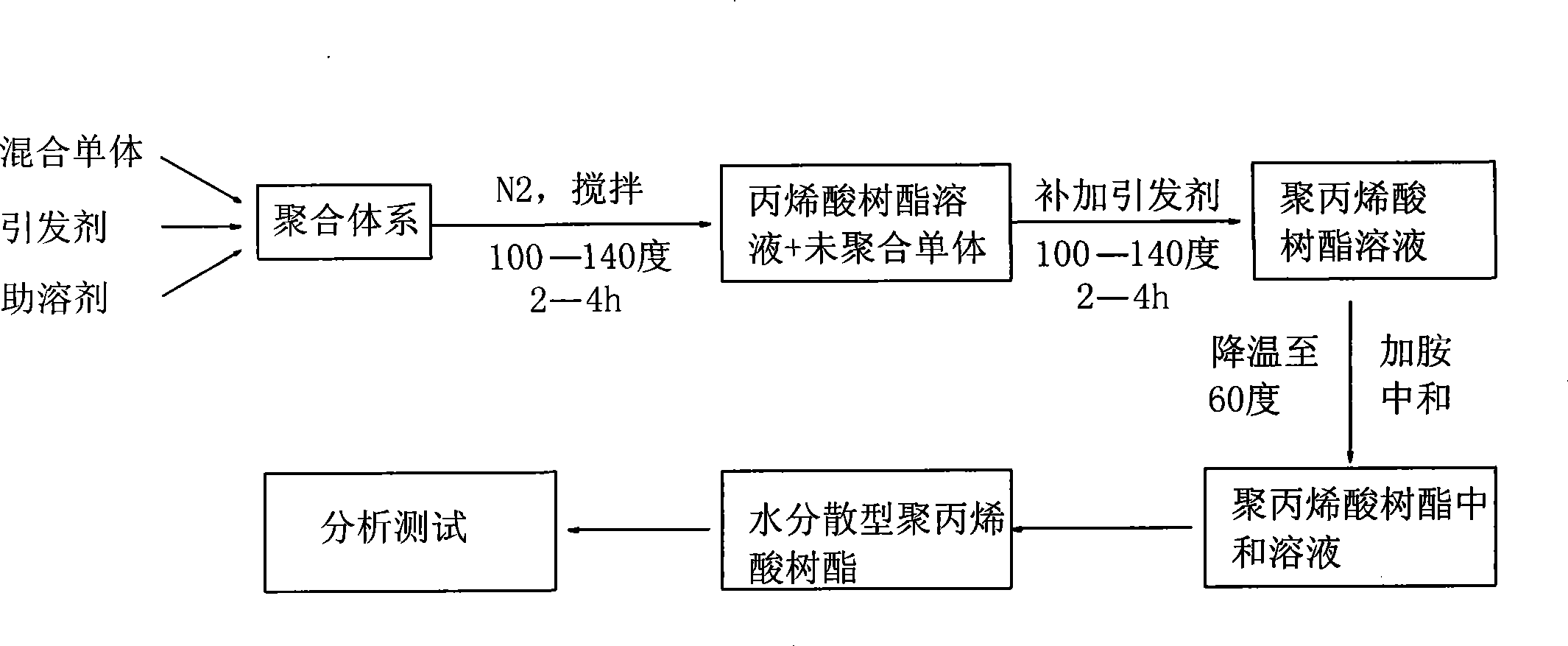

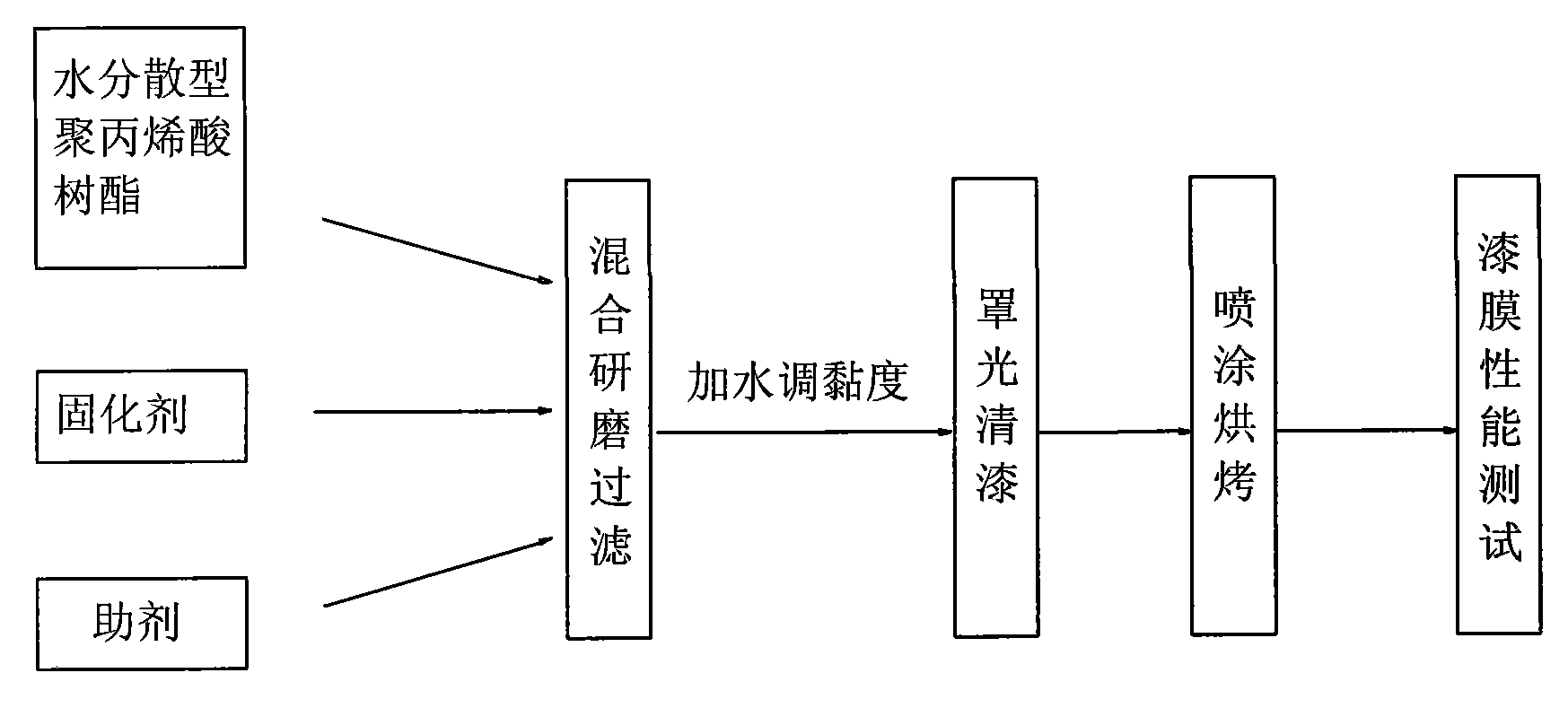

Water-based acrylic resin with high distinctness of image and preparation method thereof

The invention discloses water-based acrylic resin with high distinctness of image. The water-based acrylic resin is prepared from the following raw materials: an acrylic monomer, a styrene monomer, an initiator, a chain transfer agent, a solvent and a mixed solution, wherein the mixed solution is prepared from glycidyl versatate and vinyl versatate in a mass ratio of 2.5: 1. The preparation method comprises the following steps: adding 80% of solvent into a reaction kettle, heating and preserving heat; mixing an acrylic monomer, a styrene monomer, a chain transfer agent and 90% of an initiator, and dropwise adding the mixture into the reaction kettle; dropwise adding a mixed solution composed of glycidyl versatate and vinyl versatate, and carrying out heat preservation; adding the residual solvent and initiator, preserving heat, cooling to 90-95 DEG C, dropwise adding an amine neutralizer solution, dispersing at a high speed, slowly dropwise adding deionized water at 90-95 DEG C, and carrying out reversed-phase emulsification to obtain the water-based acrylic resin. The waterborne acrylic resin provided by the invention can improve the gloss of the resin, reduce the viscosity of the resin, and improve the flexibility, impact resistance and water resistance of a paint film.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

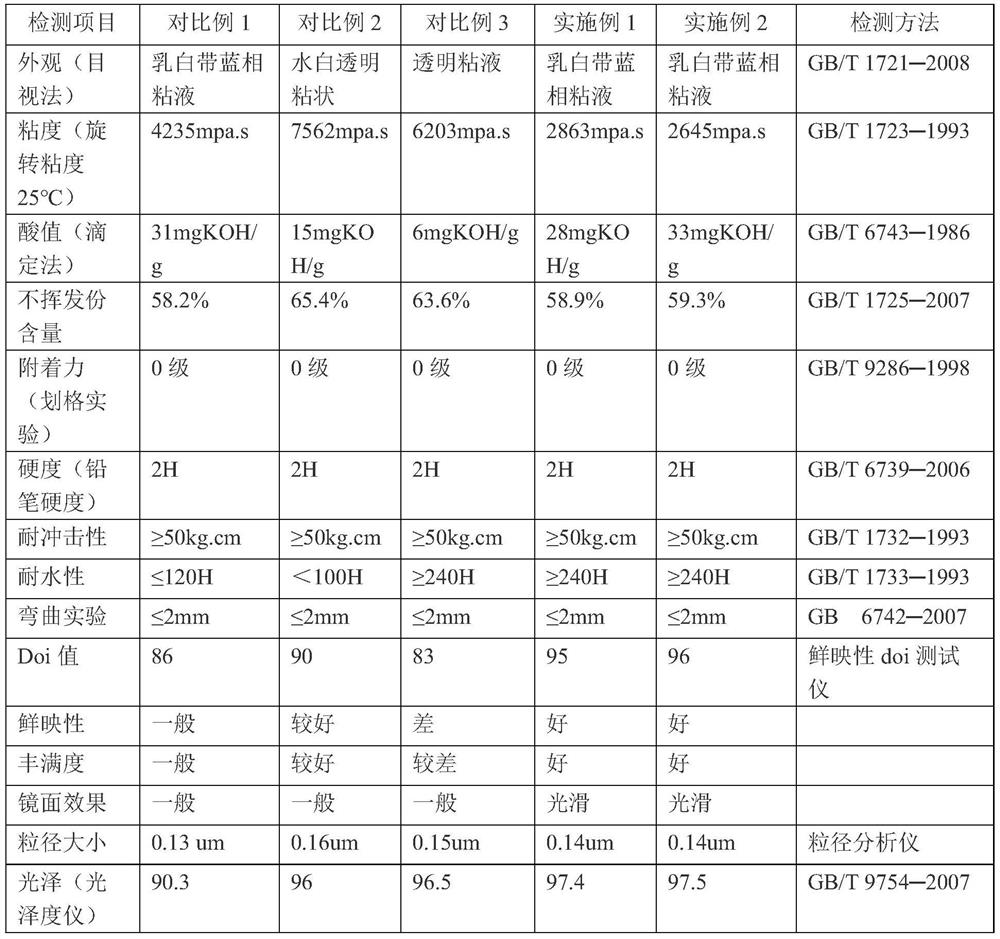

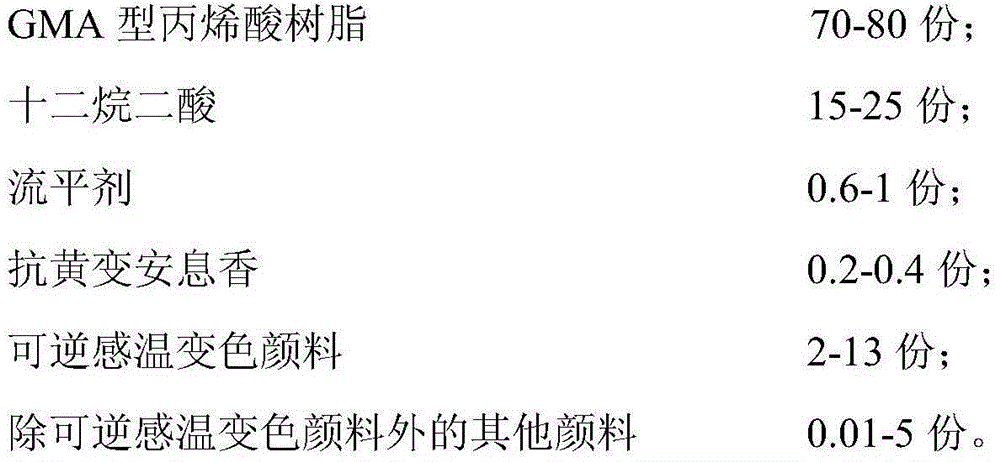

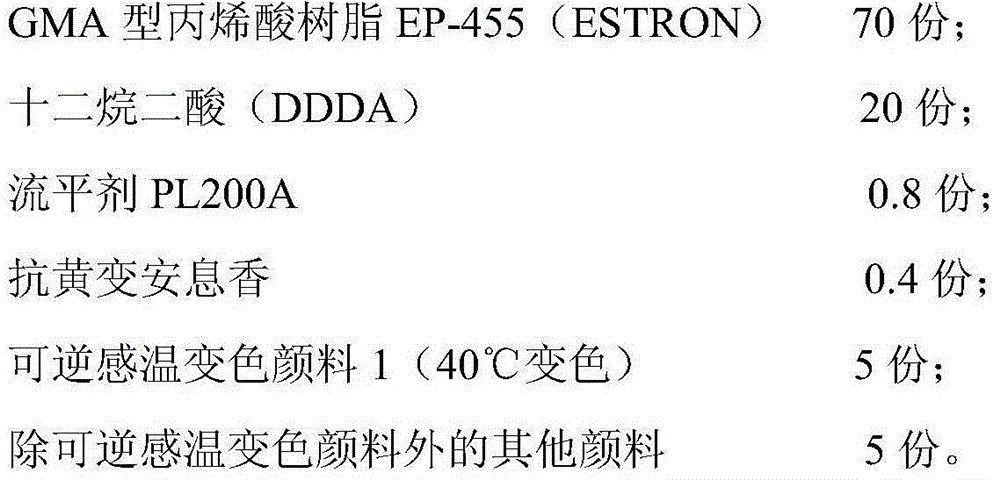

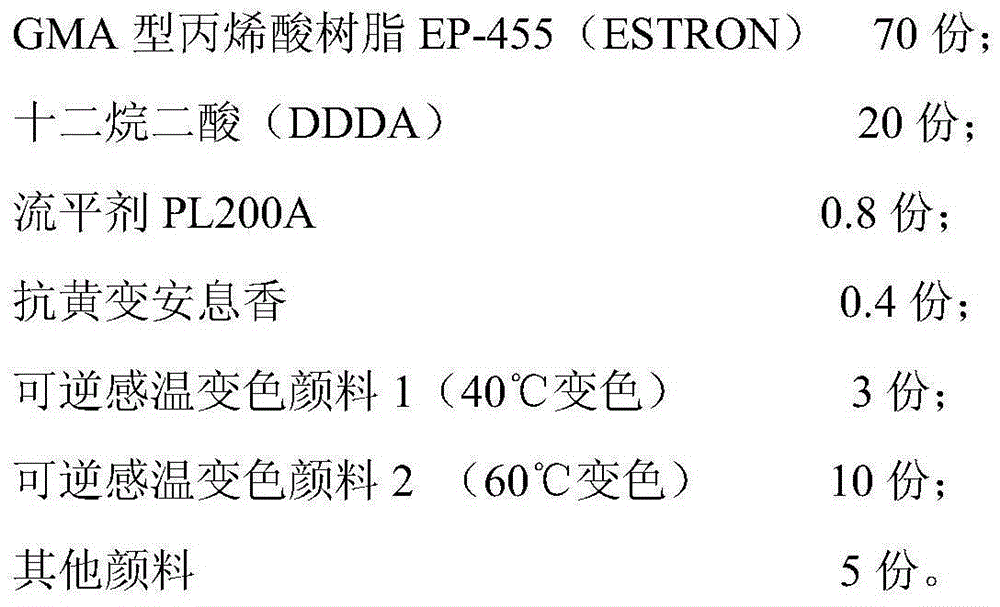

A reversible temperature-indicating powder coating and its preparation method and application method

InactiveCN103614043BGood color retentionLong discoloration lifePowdery paintsThermosensitive paintsGlycidyl methacrylateAcrylic resin

The invention relates to a reversible temperature indicating powder coating, comprising the following components in parts by weight: 70-80 parts of glycidyl methacrylate (GMA) acrylic resin, 15-25 parts of dodecanedioic acid, 0.6-1 part of flatting agent, 0.2-0.4 parts of anti-yellowing benzoin, 2-13 parts of reversible thermochromic pigment and 0.01-5 parts of other pigments except for the reversible thermochromic pigment. The powder coating disclosed by the invention is exquisite in appearance, has the functionality of indicating temperature, displays a specific color at a certain temperature, and achieves instant color change when reaching a color change temperature; the traditional solvent color-change coating is abandoned under the condition that the environmental requirements are gradually increased; a powder coating form free of a solvent to release is adopted, so that the powder coating has higher color retention, is longer in service life, and has excellent decorative property and weather fastness and the hardness reaching 2H-3H; meanwhile, the powder coating can be applied outside, and also can be applied inside; the application range is expanded, and the production cost of an enterprise is reduced.

Owner:TIANJIN XIANGSHENG NEW MATERIALS CO LTD

A kind of high blackness blue phase black finish paint and preparation method thereof

InactiveCN104312399BHigh blacknessHigh blackness blue phasePolyurea/polyurethane coatingsWeather resistanceAcrylic resin

Owner:ZHENGZHOU YUTONG BUS CO LTD

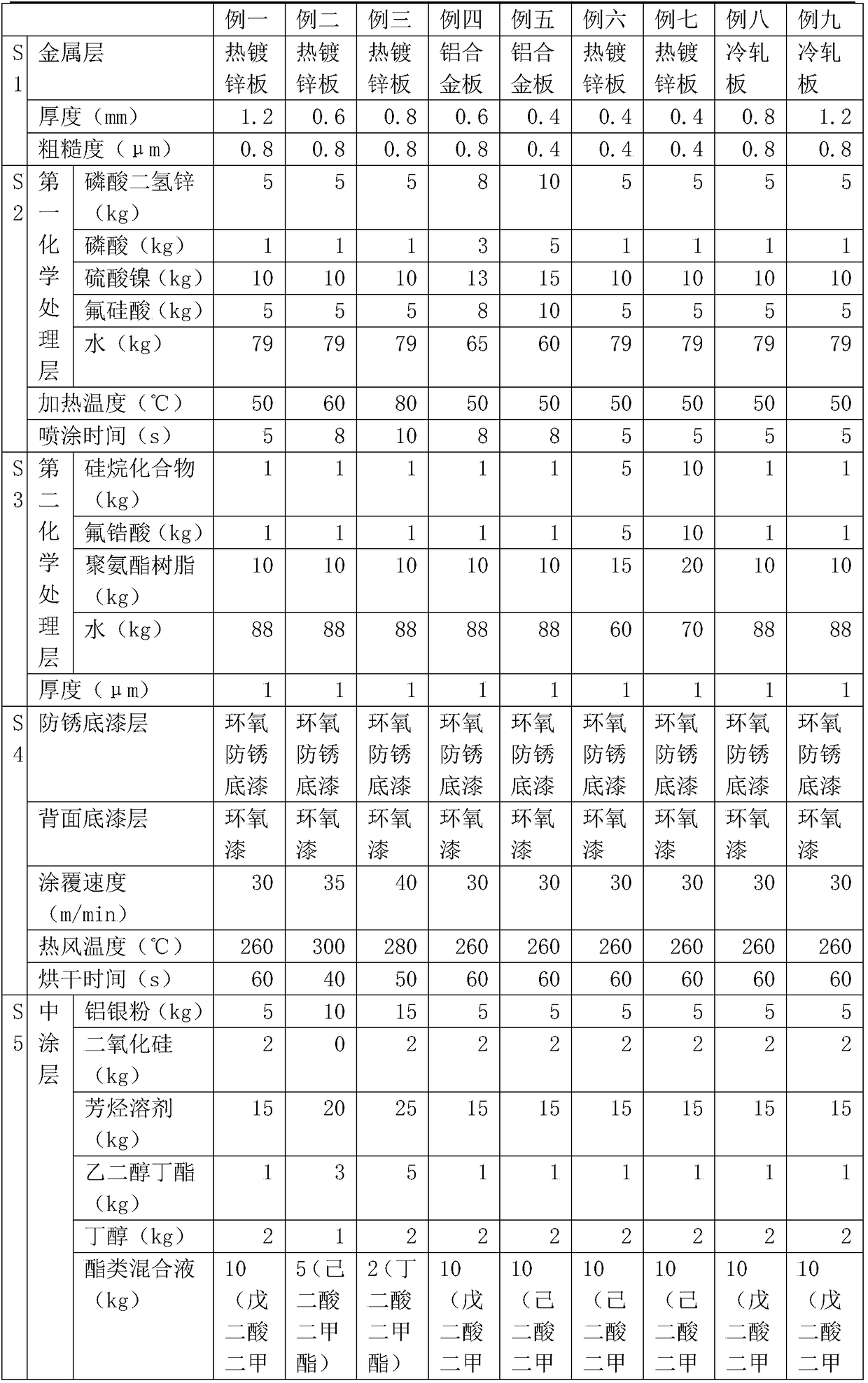

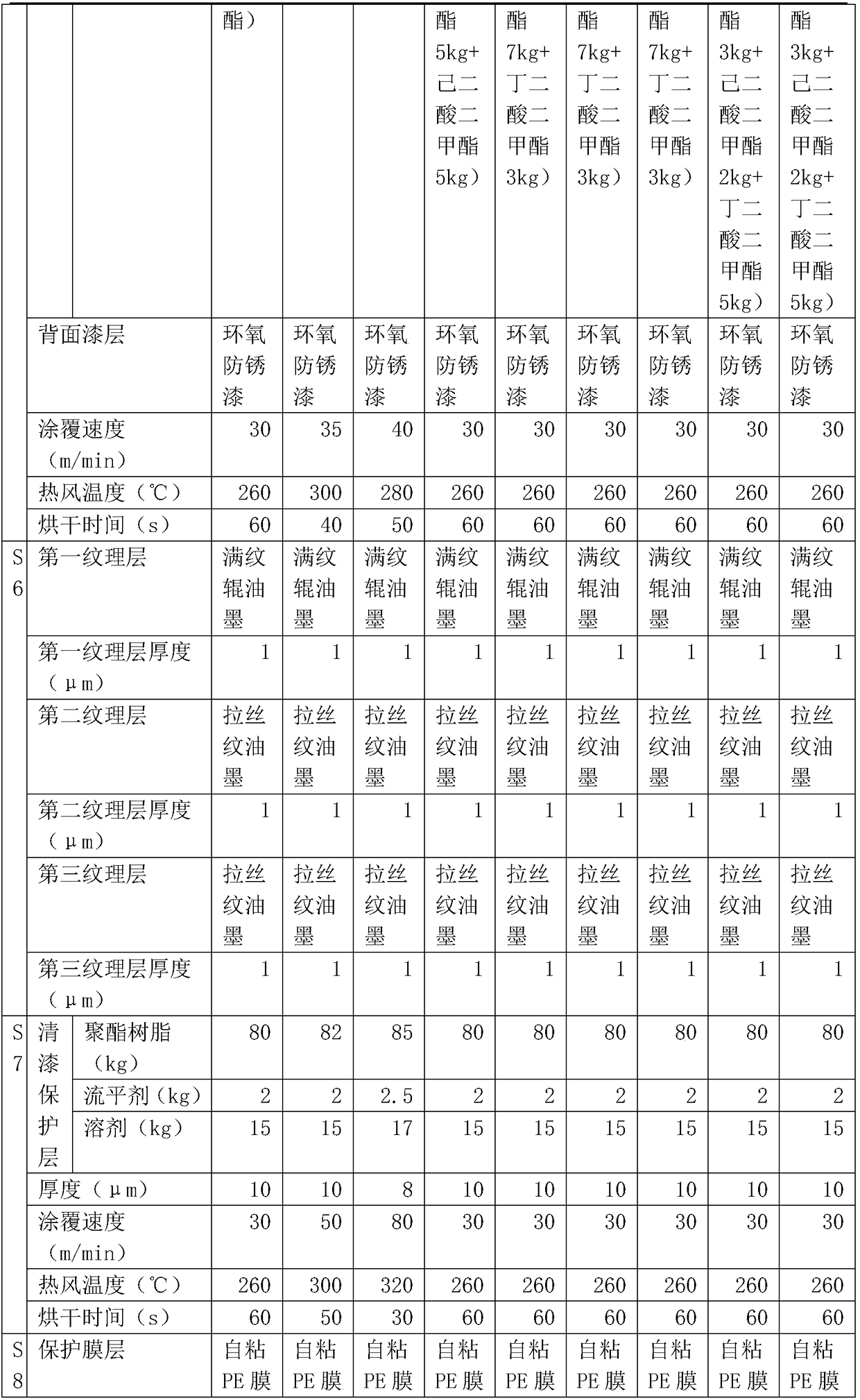

Printed color coated sheet with high distinctness of image and preparation method thereof

PendingCN108359371AImprove adhesionImprove bonding forcePretreated surfacesAnti-corrosive paintsChemical treatmentLacquer

The invention relates to a printed color coated sheet with high distinctness of image and a preparation method thereof. The printed color coated sheet with high distinctness of image mainly comprisesa metal layer; a chemical treatment layer, a floating coat and a varnish protective layer are sequentially arranged on the upper surface of the metal layer from the surface of the metal layer; and a chemical treatment layer and a back paint layer are sequentially arranged on the lower surface of the metal layer from the surface of the metal layer. According to the printed color coated sheet, metallayer pretreatment and metal layer surface chemical treatment are sequentially carried out on the surface of the metal layer, the surface of the metal layer is coated with an anti-corrosive primer layer and a back primer layer, the upper surface of the metal layer is coated with the floating coat, the upper surface of the metal layer is provided with a texture layer through gravure printing, thesurface of the metal layer is coated with the varnish protective layer, and a protective film layer adheres to the upper surface of the metal layer. The printed color coated sheet treated by the process has the advantage of being relatively high in distinctness of image.

Owner:合肥河钢新材料科技有限公司 +1

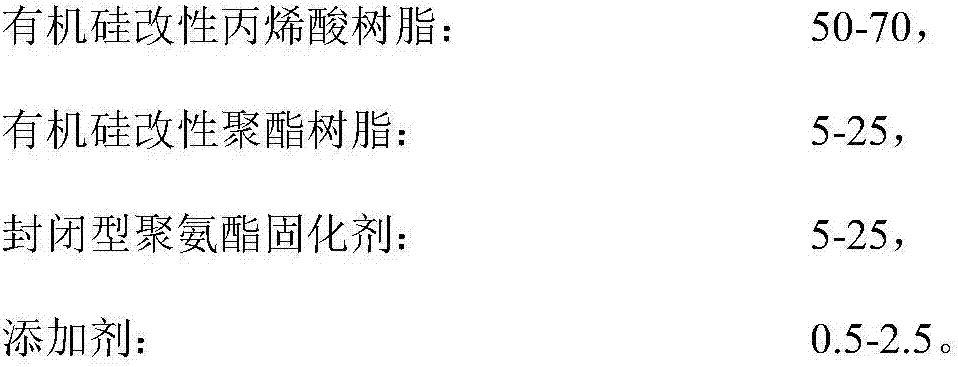

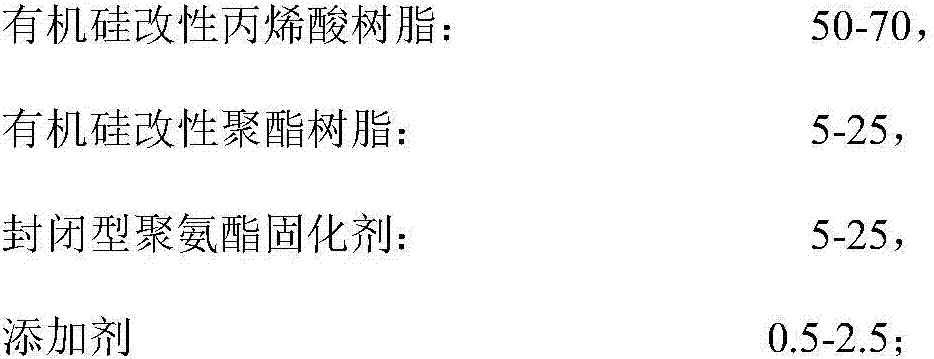

Automatic perspiration-removing varnish

InactiveCN106883712AQuick paintFacilitate assembly line productionAnti-corrosive paintsPolyester coatingsAcrylic resinHigh adhesion

The invention discloses automatic perspiration-removing varnish. The automatic perspiration-removing varnish comprises the following components in percentage by mass: 50 to 70% of silicone modified acrylic resin, 5 to 25% of silicone modified polyester resin, 5 to 25% of a closed polyurethane curing agent and 0.5 to 2.5% of an additive. The automatic perspiration-removing varnish coats the surface of coated color stainless steel, the thickness of the automatic perspiration-removing varnish is 5 to 15 microns, the baking temperature of the automatic perspiration-removing varnish is 195 to 200 DEG C, the baking time of the automatic perspiration-removing varnish is 150 to 180 seconds, and then the automatic perspiration-removing varnish is naturally cooled or subjected to blast cooling after dried. The automatic perspiration-removing varnish disclosed by the invention belongs to baking varnish which has convenient flow line production and quick coating. The automatic perspiration-removing varnish coats the color coated surface of a stainless steel plate to quickly and automatically remove perspiration and show a mirror surface result and removes the perspiration after being naturally aired for 5 seconds. The automatic perspiration-removing varnish disclosed by the invention is easily attached to a coating layer, and is an organic coating which is excellent in gloss and color retention, and outstanding in medium resistance and anti-fouling and anti-perspiration effects, and further has the characteristics of weather resistance, high hardness, high toughness, high adhesion, high distinctness, scratch resistance, fingerprint resistance and medium resistance.

Owner:CHONGQING SANXIA PAINTS CO LTD

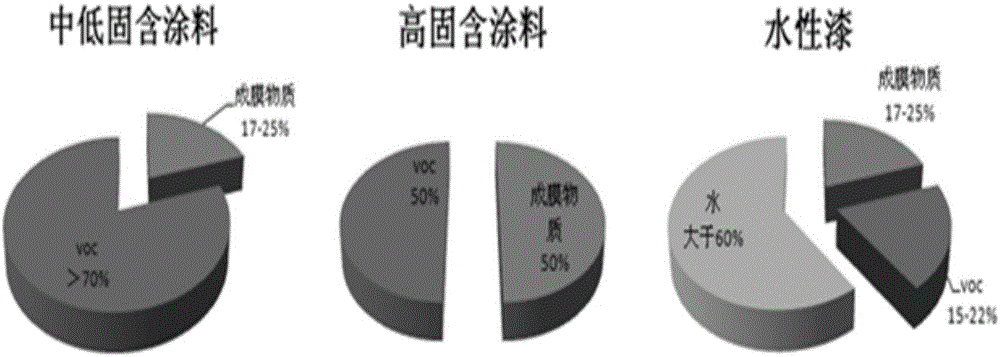

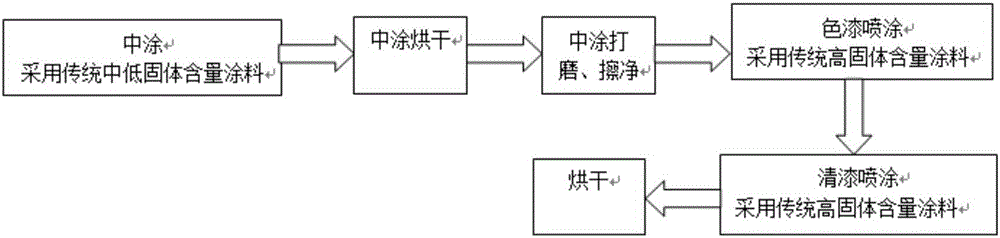

Coating process capable of lowering VOCs

InactiveCN105797943AImprove coating qualityReduce the difficulty of operationLiquid surface applicatorsCoatingsSolventLacquer

The invention discloses a coating process capable of lowering VOCs. The 3C2B coating process is adopted. On a traditional solvent-type coating line, high-solid content paint with low VOCs are used in colored paint and varnish, there is no need to transform a large number of coating lines, and the high-solid content paint requirement can be met only by slight change of a colored paint and varnish feeding system, spraying equipment and spray booth air-conditioning equipment of an original production line. Emission of the VOCs is reduced under the condition of low cost, and the environmental requirement can be met. Furthermore, the quality of coatings is stable and easy to control, difficulty in operation is low, running energy consumption and material cost are low, aftertreatment is simple, change is small, changing investment is low, and generalization performance is high.

Owner:CHERY AUTOMOBILE CO LTD

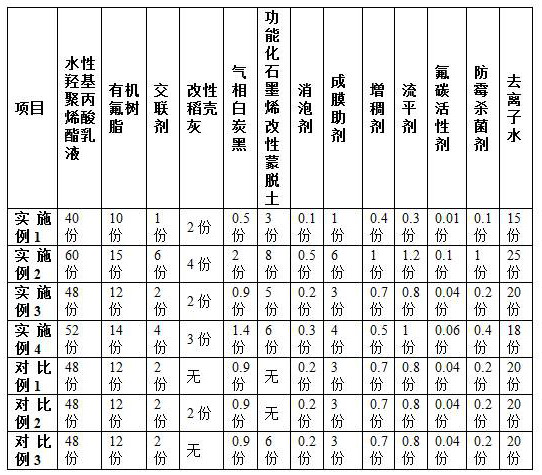

Flame-retardant anti-fouling water-based paint for woodware, and preparation method thereof

InactiveCN112094552AGood film forming stabilityImprove stain resistanceFireproof paintsAntifouling/underwater paintsActive agentCross linker

The invention relates to a flame-retardant anti-fouling water-based paint for woodware, and a preparation method thereof The water-based paint is prepared from, by weight, 40-60 parts of a water-basedhydroxyl polyacrylate emulsion, 10-15 parts of organic fluorine resin, 1-6 parts of a cross-linking agent, 2-4 parts of modified rice hull ash, 0.5-2 part of fumed silica, 3-8 parts of functionalizedgraphene modified montmorillonite, 0.1-0.5 part of an antifoaming agent, 1-6 parts of a coalescing agent, 0.4-1 part of a thickener, 0.3-1.2 parts of a leveling agent, 0.01-0.1 part of a fluorocarbonactivator, 0.1-1 part of a mildew-proof bactericide and 15-25 parts of deionized water. Compared with paints in the prior art, the water-based paint disclosed by the invention has the advantages of strong adhesive force to wood products, and good flame-retardant and heat-insulating effects, and apaint film of the paint has the advantages of high hardness, good abrasion resistance, good weather resistance, good fullness and distinctness of image, good stain resistance, easiness in construction, no pollution to environment and human bodies, no toxicity and no harm, and is green and environment-friendly.

Owner:JIANGXI LONGZHENG SCI & TECH DEV

High-gloss and high-freshness bus finishing paint and preparation method thereof

The invention discloses a high-gloss and high-freshness bus finishing paint. The high-gloss and high-freshness bus finishing paint is composed of a component I and a component II, wherein the component I is composed of, by weight percentage, 50-60% of resin A, 5-10% of resin C, 4-8% of wetting dispersant A, 1-2% of wetting dispersant B, 25-40% of pigments, 10-30% of solvent, 0.5-1% of flatting agent, 0.1-0.3% of defoamer, 0.5-1.5% of light stabilizer and 0.5-1.5% of ultraviolet light absorber; the component II comprises curing agent. The preparation method of the high-gloss and high-freshnessbus finishing paint is simple in process and convenient to operate, effectively improves gloss, freshness and chemical resistance of the high-gloss and high-freshness bus finishing paint, increases degree of mixing of raw materials, controls discharging fineness and improves the quality of finished products.

Owner:郑州双塔涂料有限公司

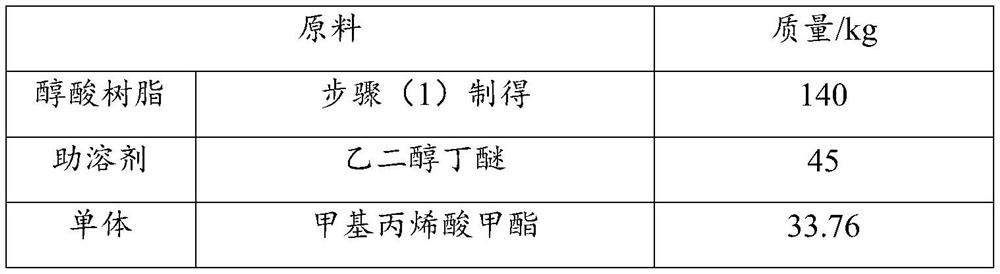

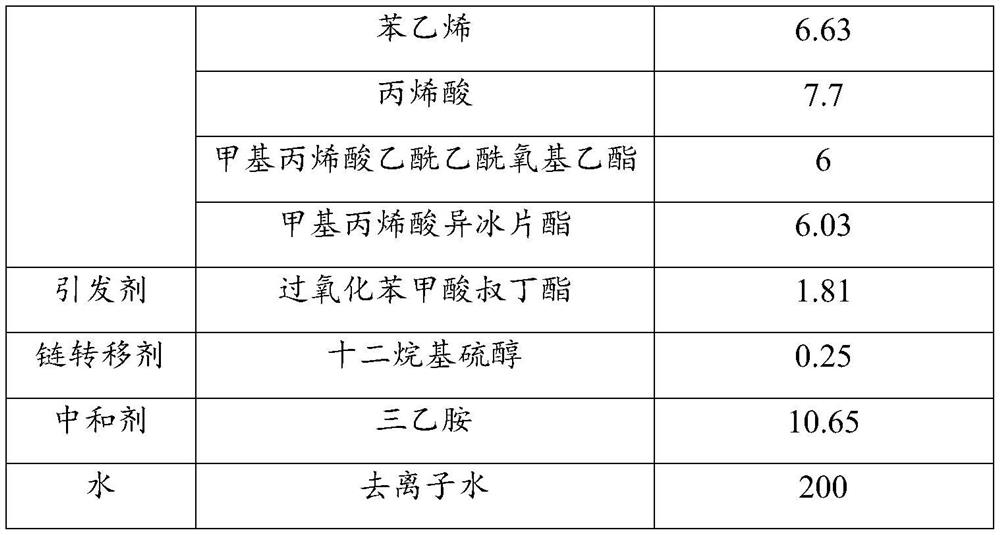

Water-based acrylic acid modified alkyd hybrid resin as well as preparation method, coating and application of water-based acrylic acid modified alkyd hybrid resin

PendingCN114507324AHigh hardnessImproves flexibility and impact strengthCoatingsIsocyanateMethacrylate

The invention relates to the technical field of environment-friendly coatings, in particular to a water-based acrylic acid modified alkyd hybrid resin, a preparation method thereof, a coating and application. The preparation method of the water-based acrylic acid modified alkyd hybrid resin comprises the following steps: preparing alkyd resin, and carrying out copolymerization reaction on the alkyd resin, monomers and the like; neutralizing with a neutralizer, and diluting with water to obtain the water-based acrylic acid modified alkyd hybrid resin with certain solid content; the monomer comprises an acrylic monomer and meets the following conditions: (i) the content of hydroxyl in the acrylic monomer accounts for less than or equal to 1% of the mass of the acrylic monomer; (ii) the monomer further comprises acetoacetoxyethyl methacrylate and / or diacetone acrylamide. After adipic acid dihydrazide or blocked isocyanate is added into the water-based acrylic acid modified alkyd hybrid resin to prepare amino baking paint, a paint film can reach relatively high hardness and impact resistance, and the contradiction that the hardness and the impact resistance of the paint film of the amino baking paint cannot be considered at the same time can be solved.

Owner:江苏富琪森新材料有限公司

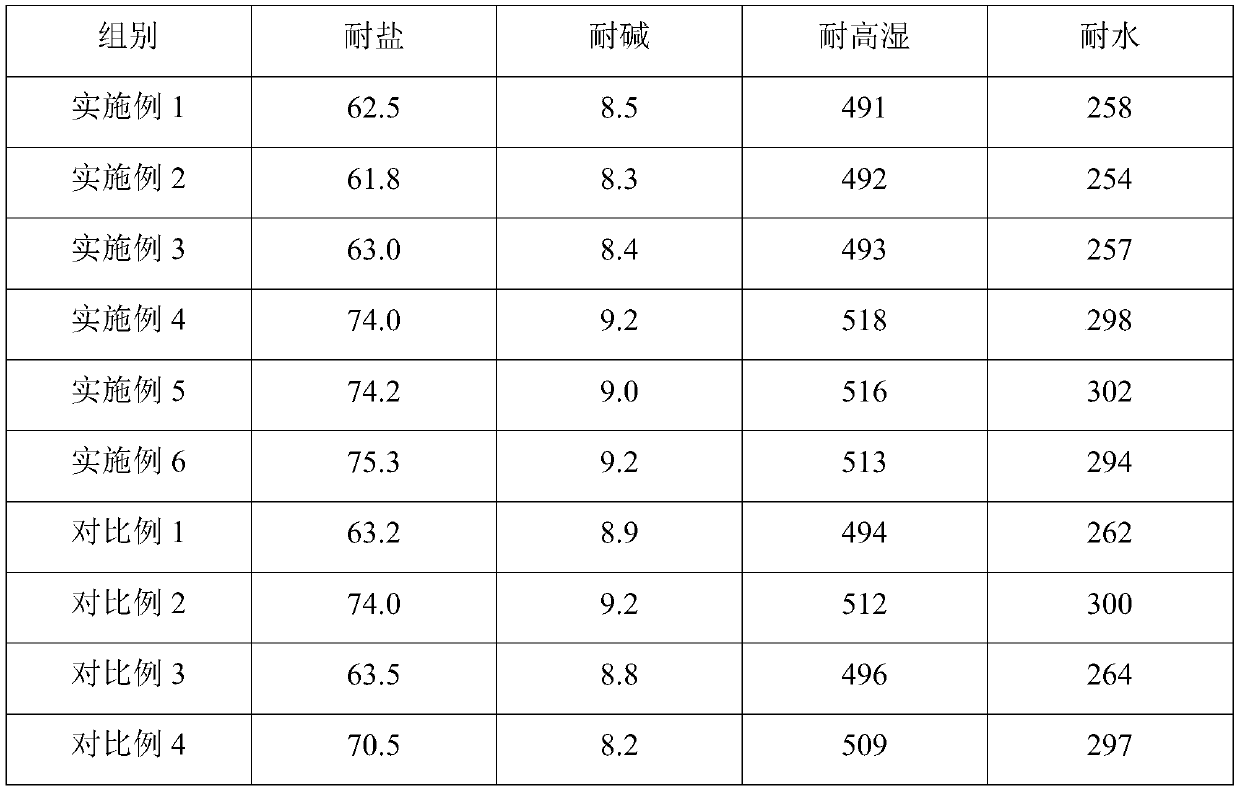

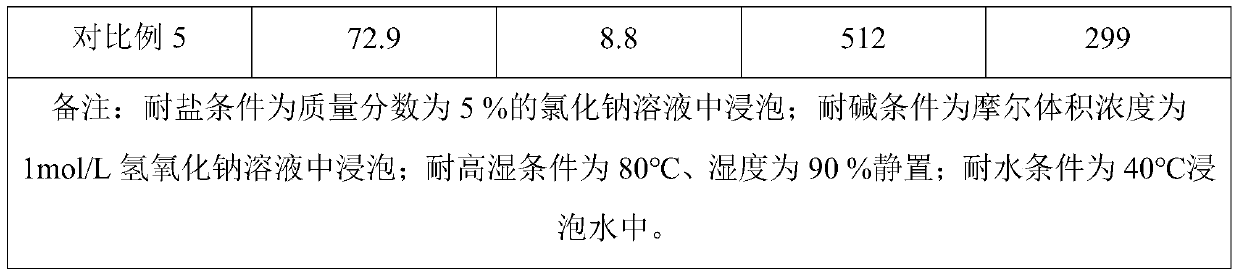

Preparation method of epoxy solution for cathodic electrophoresis of NdFeB magnets

ActiveCN108467662BImprove salt toleranceGood alkali resistancePolyether coatingsPaints for electrolytic applicationsEpoxyElectrophoreses

Owner:廊坊京磁精密材料有限公司

A kind of alkyd resin and preparation method thereof

The invention discloses an alkyd resin, which comprises the following components in terms of mass percentage: 5-25% of cyclohexane 1,2-dicarboxylic acid diisononyl by-product; 20-30% of polyhydric alcohol; 20-35% polybasic acid; 5-20% monobasic acid; 0.01-1% color reducer; 0.01-5% reflux solvent; 10-25% dilution solvent; cyclohexane 1,2-dicarboxylic acid The diisononyl ester by-product comprises 5-15% nonanol by mass percentage, 5-15% nonanoic acid, 25-35% nonyl nonanoate, 25-35% hydroxymethyl dinonyl ester, 5-15% aldol condensate from nonanal, 5-15% high carbon ester from nonanoic acid. The alkyd resin of the invention can effectively utilize the by-products of DINCH, avoid subsequent by-product treatment costs, reduce environmental pollution, and can prepare coatings with high solid content in construction, high gloss and high vividness of image.

Owner:东胜化学(上海)有限公司

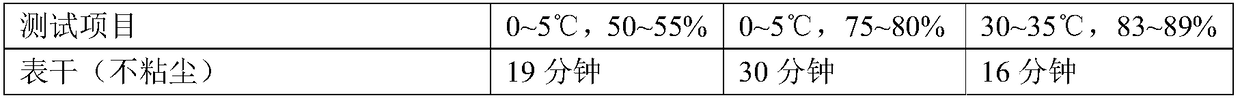

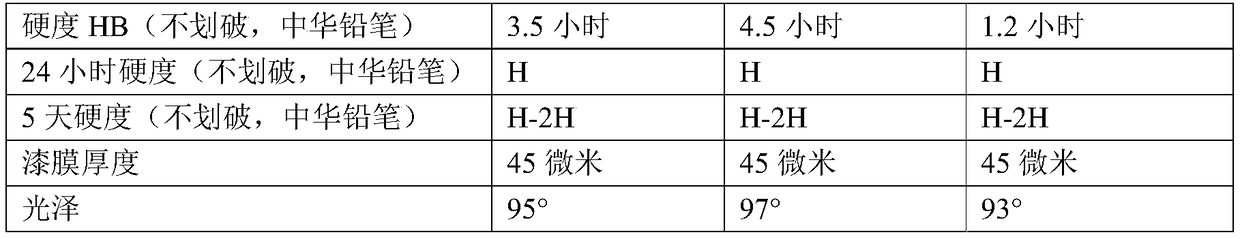

Ultrafast drying varnish for repairing car and preparation method of ultrafast drying varnish

The invention discloses ultrafast drying varnish for repairing a car. The ultrafast drying varnish comprises a component A and a component B in a weight ratio of 4, wherein the component A comprises 50 to 80 parts of cellulose acetate butyrate modified acrylic resin, 0.01 to 0.5 part of flatting agent, 0.01 to 0.5 part of dryness accelerant, and 14 to 32 parts of solvent; and the component B comprises 50 to 80 parts of curing agent and 10 to 35 parts of solvent. The invention also discloses a preparation method of the ultrafast drying varnish for repairing the car. The ultrafast drying varnishhas the advantages that the ultrafast drying varnish has the performances of fast drying, high initial and final hardness, short polishing time, high gloss and distinctness, no chalkiness after the polishing and the like under a high-low-temperature condition, the working efficiency can be significantly improved, and the ultrafast drying varnish can be applied to the car repairing paint and bus paint.

Owner:安庆瑞泰化工有限公司

Acrylic acid modified vinyl organic silicon resin and preparation method thereof

ActiveCN113136013AGraffiti and stain resistanceHigh distinctness of imageAntifouling/underwater paintsPaints with biocidesSilicone resinPropanol

The invention belongs to the technical field of organic synthesis, and particularly discloses acrylic acid modified vinyl organic silicon resin and a preparation method thereof. The invention discloses a high-temperature-resistant adhesive which is prepared from the following components in parts by mass: 24 to 299 parts of vinyl organic silicon oligomer, 2 to 3 parts of acrylic acid, 120 to 130 parts of hydroxybutyl acrylate, 80 to 90 parts of butyl acrylate, 90 to 100 parts of 2-ethylhexyl acrylate, 160 to 170 parts of styrene, 2 to 3 parts of di-tert-butyl peroxide, 5 to 6 parts of 3-mercapto-1-propanol, 220 to 240 parts of xylene, and 210 to 230 parts of butyl acetate. The acrylic acid modified vinyl organic silicon resin is high in non-volatile matter content and low in viscosity, so that coating can be cured at room temperature and can also be heated and cured to form a film, and is widely applied to coating of weather-proof, anti-corrosion and anti-fouling equipment such as automobiles, bridges and engineering machinery.

Owner:CHANGZHOU JIANUO ORGANIC SILICON

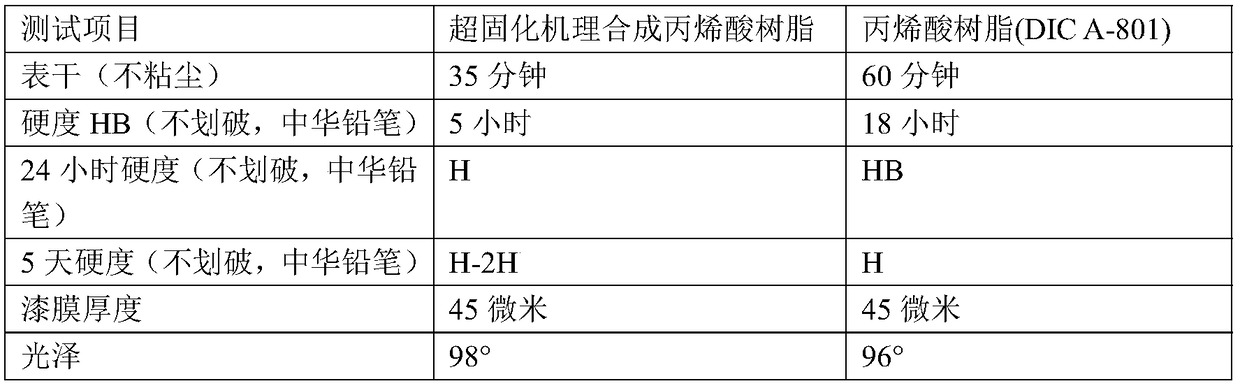

Automobile finishing varnish containing water dispersible acrylic ester and preparation method thereof

ActiveCN101081957BHigh glossHigh distinctness of imageLiquid surface applicatorsCoatingsWater dispersiblePolymer science

The present invention discloses water dispersed automobile finishing varnish of polyacrylate and its preparation process. The water dispersed automobile finishing varnish is mixture of water dispersed polyacrylate, water dispersed curing agent amino resin and closed polyisocyanate. The polyacrylate is water dispersoid prepared with the mixture of five components, and through the first radical initiator initiated polymerization in mixed solvent to obtain polyacrylate resin and the subsequent neutralization with neutralizer. The water dispersed automobile finishing varnish after being sprayed and cured forms varnish film possessing high glossiness, high brightness, high hardness, high impact resistance, high weather resistance, high compactness and fast adhesion to the base material.

Owner:GUANGDONG YATU CHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com