Automobile finishing varnish containing water dispersible acrylic ester and preparation method thereof

A technology of acrylate and varnish coatings, which is applied in the field of automotive varnish coatings and its preparation, and can solve problems such as lack of decorative performance for automotive exterior coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

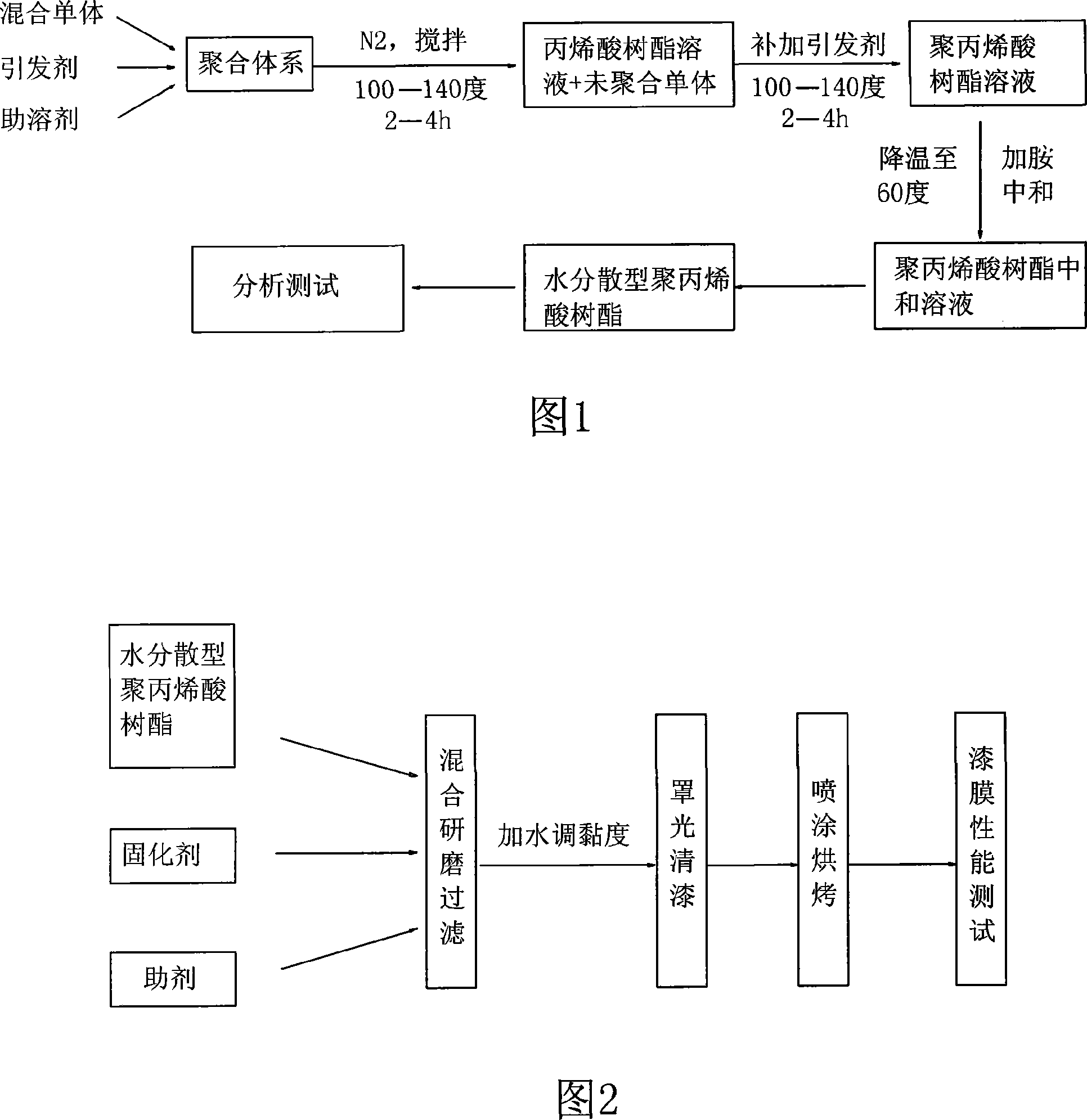

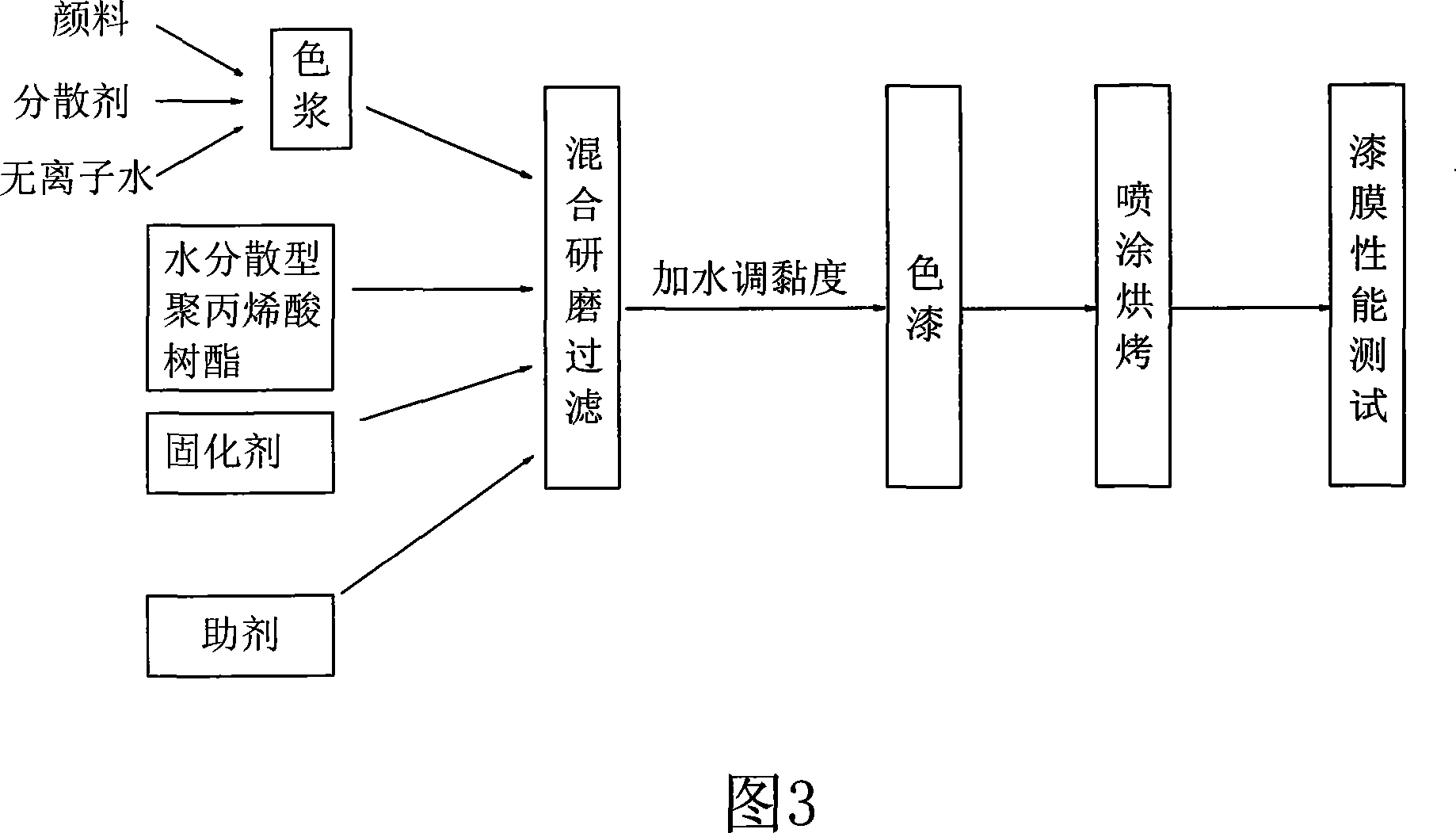

Method used

Image

Examples

Embodiment 1

[0039] The feeding formula of synthetic acrylic resin is shown in Table 4.

[0040] The feeding formula of table 4 embodiment 1 synthetic acrylic resin

[0041]

project

Formula number and dosage / mass fraction

1

2

3

4

Propylene Glycol Monomethyl Ether (PGME)

Methyl methacrylate (MMA)

Styrene (S)

Butyl Acrylate (BA)

Isobornyl Methacrylate (IBOMA)

Hydroxyethyl Methacrylate (HEMA)

Acrylic (AA)

Initiator

Azobisisobutyronitrile (AIBN)

Molecular weight regulator

dodecanethiol

Additional initiator solution

AIBN

PGME

25

15

30

20

35

0

10

5

1

0.8

0.4

10

25

15

26

16

35

8

10

5

1

0.8

0.4

10

...

Embodiment 2

[0053] The feeding formula of synthetic acrylic resin is shown in Table 7.

[0054] The feeding formula of table 7 embodiment 2 synthetic acrylic resin

[0055]

project

Formula number and dosage / mass fraction

5

6

7

8

solvent

Propylene Glycol Monomethyl Ether (PGME)

Methyl methacrylate (MMA)

Styrene (S)

Isooctyl Acrylate (2-EHA)

Benzyl methacrylate (BNMA)

Hydroxyethyl Methacrylate (HEMA)

Acrylic (AA)

Initiator

Azobisisobutyronitrile (AIBN)

Molecular weight regulator

dodecanethiol

Additional initiator solution

AIBN

PGME

25

15

26.5

14.5

35

8

10

6

1

1

0.4

10

25

15

22

12

40

10

10

6

1

1

0.4

10

25

15 ...

Embodiment 3

[0067] The feeding formula of synthetic acrylic resin is shown in Table 10.

[0068] The feeding formula of table 10 embodiment 3 synthetic acrylic resins

[0069]

project

Formula number and dosage / mass fraction

9

10

11

solvent

Propylene Glycol Monomethyl Ether (PGME)

Glycidyl tert-carbonate (E10P)

Methyl methacrylate (MMA)

Styrene (S)

Butyl Acrylate (BA)

Hydroxyethyl Acrylate (HEA)

Acrylic (AA)

Initiator

Di-t-amyl peroxide

Add initiator and monomer for the first time

Acrylic (AA)

Di-t-amyl peroxide

Second addition of initiator solution

Di-t-amyl peroxide

Propylene Glycol Monomethyl Ether (PGME)

10

30

23.5

20

9

4

9

2.4

4.5

0.1

0.5

10

30

15

23.5

20

18.5

14

4.5

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com