Acrylic acid modified vinyl organic silicon resin and preparation method thereof

A technology of vinyl silicone and acrylic acid, which is applied in coatings, anti-corrosion coatings, paints containing biocides, etc. It can solve the problems of reduced adhesion, insufficient mechanical strength, low silicon content and long-term pollution resistance, and achieves non-volatile High component content, graffiti resistance, stain resistance, and high image clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

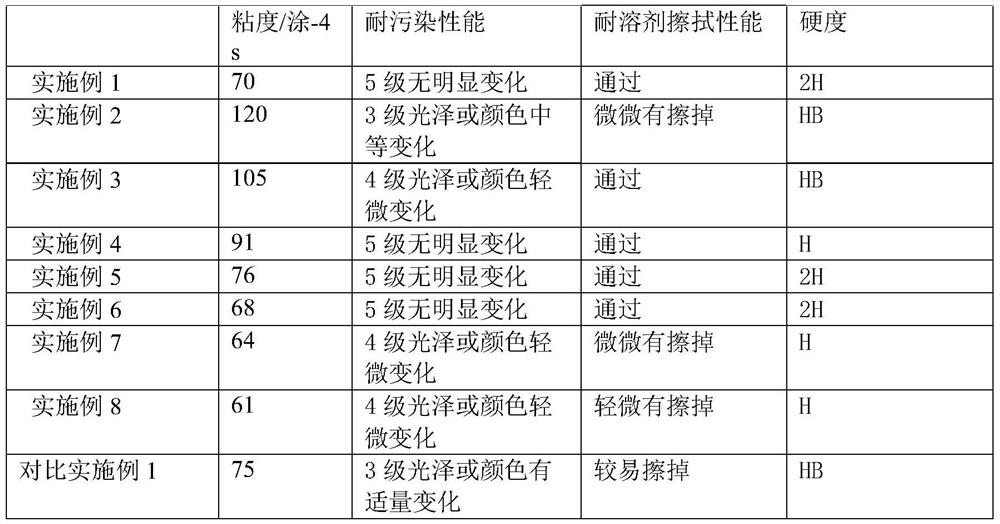

Examples

Embodiment 1

[0018] 162 parts of vinyl silicone oligomer, 2.4 parts of acrylic acid, 127.2 parts of hydroxybutyl acrylate, 86.4 parts of butyl acrylate, 96 parts of isooctyl acrylate, 168 parts of styrene, 2.4 parts of di-tert-butyl peroxide, 3- 5.6 parts of mercapto-1-propanol, 222 parts of xylene, and 222 parts of butyl acetate.

[0019] (1) Preparation of vinyl silicone oligomer

[0020] 120 parts of monomethyltrichlorosilane (M1), 80 parts of dimethyldichlorosilane (M2), 80 parts of monophenyltrichlorosilane (P1), 120 parts of diphenyldichlorosilane (P2), methyl 120 parts of vinyl dichlorosilane are fully mixed in proportion and then added to 600 parts of xylene, 1200 parts of butanol and 600 parts of water are added, the hydrolysis temperature is controlled at 5°C, the hydrolysis is completed in 5 hours, washed with water to pH ≈ 7, and decompressed. Solvent yields silicone oligomers.

[0021] (2) 16.2 parts of vinyl silicone oligomer, 0.24 parts of acrylic acid, 12.72 parts of hydr...

Embodiment 2

[0028] 24 parts of vinyl silicone oligomer, 2.4 parts of acrylic acid, 127.2 parts of hydroxybutyl acrylate, 86.4 parts of butyl acrylate, 96 parts of isooctyl acrylate, 168 parts of styrene, 2.4 parts of di-tert-butyl peroxide, 3- 5.6 parts of mercapto-1-propanol, 222 parts of xylene, and 222 parts of butyl acetate.

[0029] The preparation method is the same as in Example 1.

Embodiment 3

[0031] 50 parts of vinyl silicone oligomer, 2.4 parts of acrylic acid, 127.2 parts of hydroxybutyl acrylate, 86.4 parts of butyl acrylate, 96 parts of isooctyl acrylate, 168 parts of styrene, 2.4 parts of di-tert-butyl peroxide, 3- 5.6 parts of mercapto-1-propanol, 222 parts of xylene, and 222 parts of butyl acetate.

[0032] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com