Ultrafast drying varnish for repairing car and preparation method of ultrafast drying varnish

A technology for varnishes and automobiles, applied in the direction of coating, etc., can solve the problems of long surface drying and solid drying time, low working hours efficiency, slow curing speed, etc., and achieve the effect of short polishing time, improved working hours efficiency and fast drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of super fast drying varnish for car repair, prepared by the following method:

[0024] 1) Preparation of component A: slowly add 12g of xylene, 4.6g of butyl acetate, 4g of propylene glycol methyl ether acetate, 2g of dicarboxylate, 0.2g of EFKA 3777, and 10% butyl acetate of dibutyltin dilaurate in sequence Solution 0.2g and cellulose acetate butyrate modified acrylic resin (acrylic resin synthesized by super-curing mechanism) 77g were stirred for 30 minutes at a rotating speed of 500RPM to make it uniformly mixed;

[0025] 2) Preparation of component B: slowly add 5.75g of butyl acetate (moisture content: 180ppm) and 19.25g of DesmodurN3300 in sequence, and stir at 500RPM for 10 minutes to make it evenly mixed;

[0026] 3) Blending: Mix component A and component B, and stir at 500 RPM for 5 minutes to make them evenly mixed to obtain an ultra-fast-drying varnish for automobile repair.

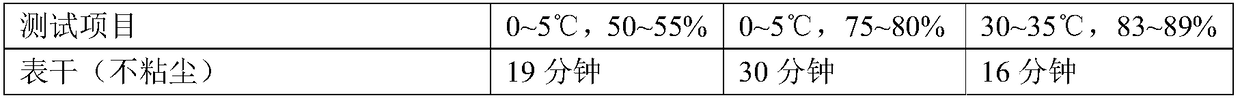

[0027] Testing the properties of the above ultra-fast drying clearcoats f...

Embodiment 2

[0036] A kind of super fast drying varnish for car repair, prepared by the following method:

[0037] 1) Preparation of component A: slowly add xylene 8g, butyl acetate 3g, propylene glycol methyl ether acetate 2g, diformate 1g, EFKA 3777 0.01g, 10% dibutyltin dilaurate in butyl acetate solution 0.01g and 50g of acrylic resin modified by cellulose acetate butyrate (acrylic resin synthesized by supercuring mechanism), stirred for 40 minutes at a rotating speed of 400RPM, to make it evenly mixed;

[0038] 2) Preparation of component B: slowly add 2.7g of butyl acetate (moisture content: 200ppm) and 13.3g of DesmodurN3300 in sequence, and stir at 600RPM for 5 minutes to make it evenly mixed;

[0039] 3) Blending: Mix component A and component B, and stir at 400 RPM for 3 minutes to make them evenly mixed to obtain an ultra-fast-drying varnish for automobile repair.

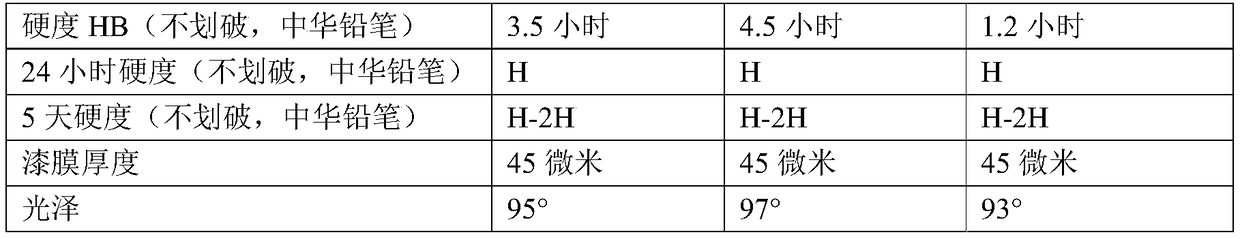

[0040] Testing the properties of the above ultra-fast drying clearcoats for automotive refinishing:

[0041] 1) ...

Embodiment 3

[0049] A kind of super fast drying varnish for car repair, prepared by the following method:

[0050] 1) Preparation of component A: slowly add 16g of xylene, 7g of butyl acetate, 6g of propylene glycol methyl ether acetate, 3g of dicarboxylate, 0.5g of EFKA 3777, and 10% butyl acetate solution of dibutyltin dilaurate in sequence 0.25g and 80g of acrylic resin modified by cellulose acetate butyrate (acrylic resin synthesized by super-curing mechanism), stirred for 20 minutes at a rotating speed of 600RPM to make it evenly mixed;

[0051] 2) Preparation of component B: slowly add 8.58g of butyl acetate and 19.61g of Desmodur N3300 in sequence, and stir at 400RPM for 15 minutes to make it evenly mixed;

[0052] 3) Blending: Mix component A and component B, and stir at 400 RPM for 6 minutes to make them evenly mixed to obtain an ultra-fast-drying varnish for automobile repair.

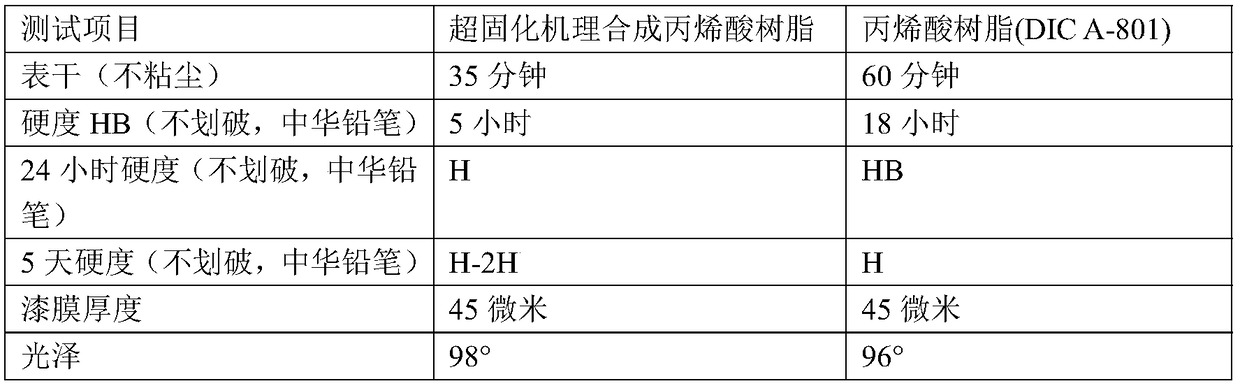

[0053] Testing the properties of the above ultra-fast drying clearcoats for automotive refinishing: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com