Preparation method of epoxy solution for cathodic electrophoresis of NdFeB magnets

A technology of cathodic electrophoresis and preparation method, applied in electrophoretic coatings, epoxy resin coatings, polyether coatings, etc., can solve problems such as easy rust, and achieve the effect of small orange peel value, good compatibility and low dry film density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

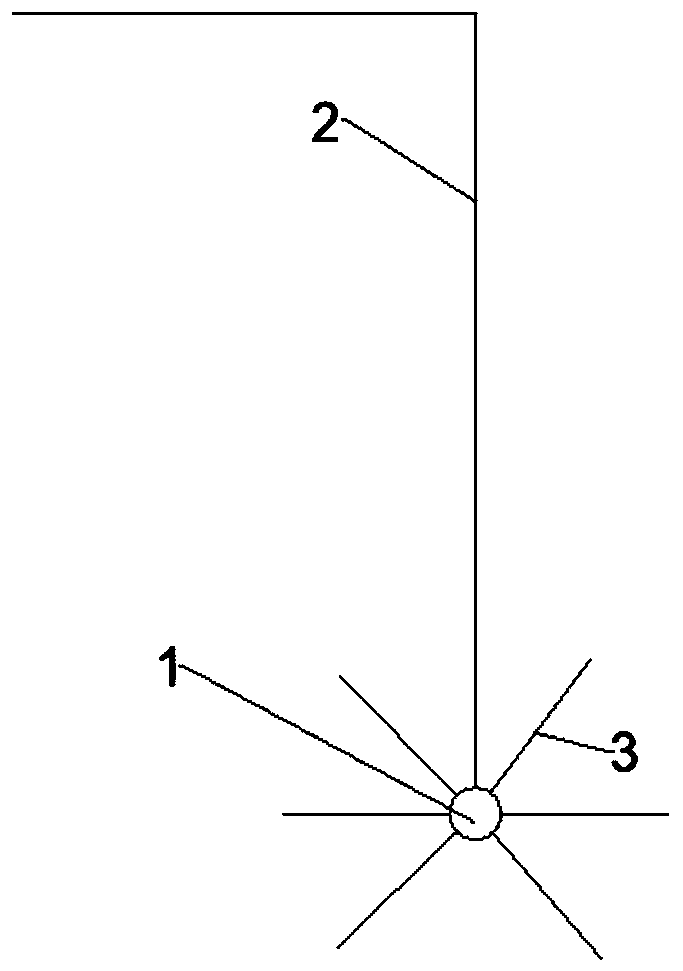

Image

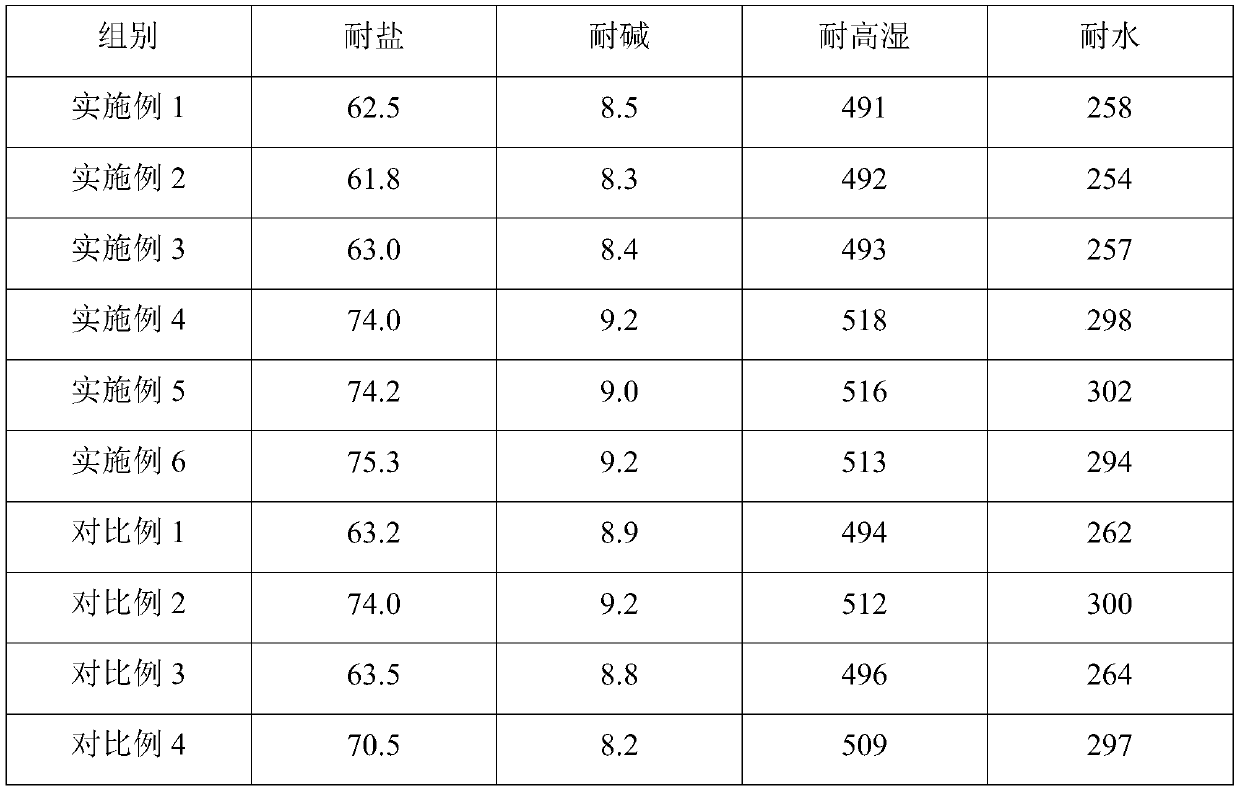

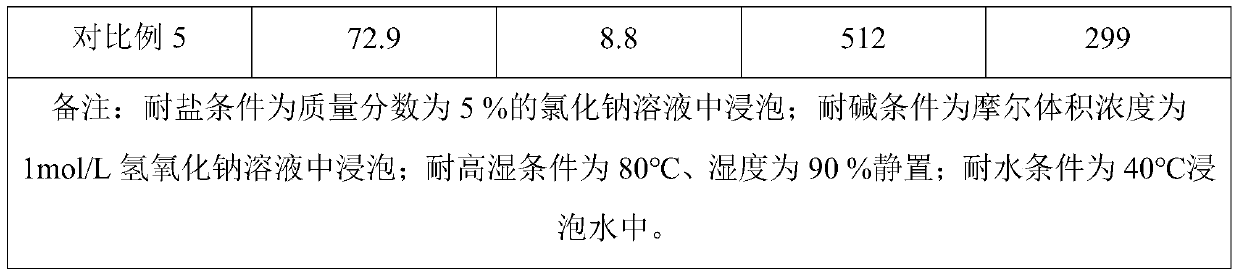

Examples

Embodiment 1

[0031] The epoxy solution preparation method for cathodic electrophoresis of NdFeB magnets comprises: adding pure water, color paste, epoxy resin, and polyether to the tank body of the electrophoresis tank in sequence, circulating and raising the temperature to 30°C, and Continue to circulate for 9 hours under the condition of ℃ to obtain the epoxy solution, wherein, the color paste: epoxy resin: pure water is 1:6:7 by volume, and the volume of polyether is three times that of the color paste, epoxy resin, and pure water. 0.5% of the total volume of the liquid, the time for heating to 30°C is 5h.

Embodiment 2

[0033] The epoxy solution preparation method for cathodic electrophoresis of NdFeB magnets comprises: adding pure water, color paste, epoxy resin, and polyether to the tank body of the electrophoresis tank in sequence, circulating and raising the temperature to 32°C, and heating at 32°C Continue to circulate for 9 hours under the condition of ℃ to obtain the epoxy solution, wherein, the color paste: epoxy resin: pure water is 1:6:8 by volume, and the volume of polyether is three times that of the color paste, epoxy resin, and pure water. 1% of the total volume of the liquid, the time to warm up to 32°C is 6h.

Embodiment 3

[0035] The epoxy solution preparation method for cathodic electrophoresis of NdFeB magnets comprises: adding pure water, color paste, epoxy resin, and polyether to the tank body of the electrophoresis tank in sequence, circulating and raising the temperature to 31°C, and Continue to circulate for 9 hours under the condition of ℃ to obtain epoxy solution, wherein, the color paste: epoxy resin: pure water is 1:6:7.5 by volume, and the volume of polyether is three times that of color paste, epoxy resin, and pure water. 0.8% of the total volume of the liquid, the time for heating to 31°C is 5.5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com