Automobile carbon fiber / epoxy resin composite exterior decoration transparent coating method

A technology of epoxy resin and composite materials, which is applied in the direction of surface coating liquid devices, coatings, pretreatment surfaces, etc., can solve the problems of not being able to clearly see the carbon fiber texture and loss of aesthetic feeling, and achieve control of coating costs and Coating efficiency, excellent performance indicators, and the effect of realizing production line automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

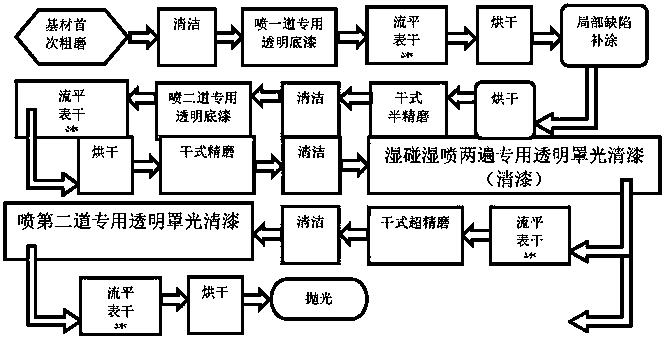

Image

Examples

Embodiment

[0032] Automobile carbon fiber / epoxy resin composite material front hatch is a typical exterior trim part, and its visible surface outer panel is made of carbon fiber / epoxy resin composite material. The transparent coating method used is as follows:

[0033] 1. Substrate pretreatment steps:

[0034] Use P320 sandpaper (product of 3M company, the same below) to apply uniformly and comprehensively and dry roughing the sprayed surface to a matte state, remove the mold release agent on the surface of the part, and do not damage the carbon fiber substrate and make the surface tension The value reaches more than 48 dyne;

[0035] 2. The first primer spraying step

[0036] Use SATA jet 100B F RP spray gun, air spray carbon fiber composite material special transparent primer (model is CF-1000 two-component polyurethane low-temperature primer, the manufacturer is Hunan Xiangjiang Guanxi Paint Co., Ltd.), spraying pressure 0.4MPa, nozzle diameter 1.6mm, spraying speed 0.4~0.5m / s, vertical dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com