Waterborne acrylic amino baking varnish and preparation method thereof

A technology of acrylic amino and acrylic resin, which is applied in the direction of coating, etc., to achieve the effect of high application value, high distinctness of image, and low construction VOCC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the above-mentioned water-based acrylic amino baking varnish provided by the second aspect of the present invention, in a specific embodiment, comprises the following steps:

[0044] Mix the secondary dispersion of hydroxyl-type acrylic resin, amino resin, pH regulator, amino resin co-solvent, defoamer, surfactant ethoxyl acetylene glycol, and stir; preferably, stir at 400-600rpm for 10- 15min;

[0045] Add resin-free water slurry while stirring, and continue stirring; preferably, stir at 400-600rpm for 10-15min;

[0046] Add substrate wetting agent, anti-foaming additive, leveling agent, film-forming additive, acid catalyst while stirring, and continue stirring; preferably, stir at 400-600rpm for 30min until uniform;

[0047] Add a thickener to obtain a product with a viscosity that meets the requirements;

[0048] Wherein, the addition of each raw material is carried out according to certain parts by weight.

[0049] The present invention ...

Embodiment 1

[0053] Preparation of waterborne acrylic amino baking varnish

[0054] (1) The secondary dispersion acrylic resin of 45.5kg is added in the container of suitable size, slowly 2kg pH regulator, 3kg amino resin co-solvent are added and stirred while stirring, 0.1kg organosilicon defoamer, stir (400 -600rpm) 10-15 minutes;

[0055] (2) Slowly add 8.24kg of amino resin while stirring, after adding the amino resin, stir (400-600rpm) for 10-15 minutes;

[0056] (3) Slowly add 34kg of white slurry while stirring, and continue stirring for 30 minutes until uniform;

[0057] (4) Slowly add 0.2kg of substrate wetting agent, 2.4kg of surfactant, 1kg of anti-explosion foam additive, 0.2kg of leveling agent, 0.26kg of acid catalyst, and 3kg of film-forming additive while stirring;

[0058] (5) Test the viscosity, add an appropriate amount of thickener as required, stir (400-600rpm) for 10-15 minutes, filter and pack.

Embodiment 2

[0060] The preparation method of the water-based acrylic amino baking varnish in Example 2 and Example 3 is exactly the same as that of Example 1, except that the weight of the added substances is changed, see Table 1 for details.

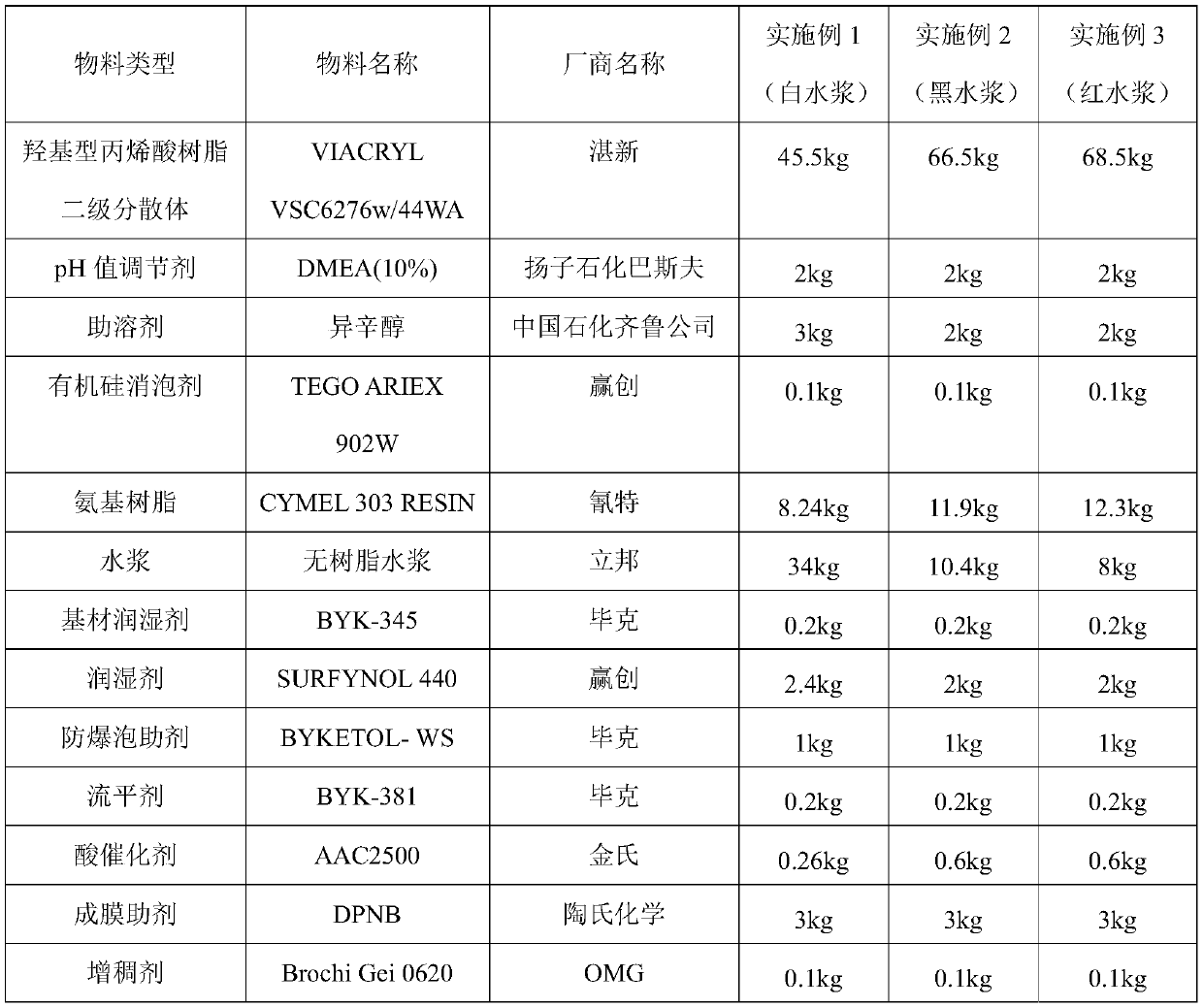

[0061] The component of water-based acrylic amino stoving varnish in table 1 embodiment 1-3

[0062]

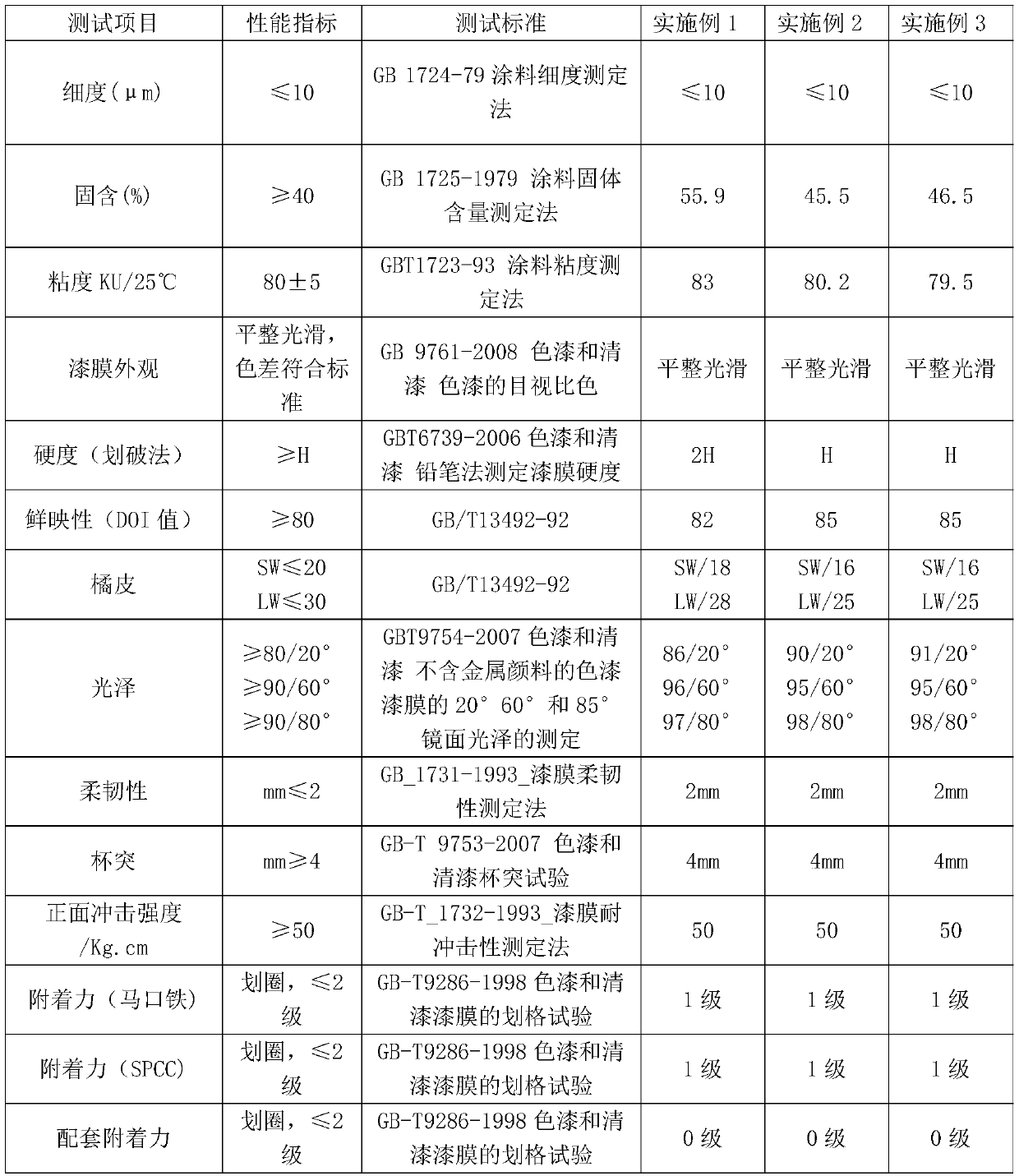

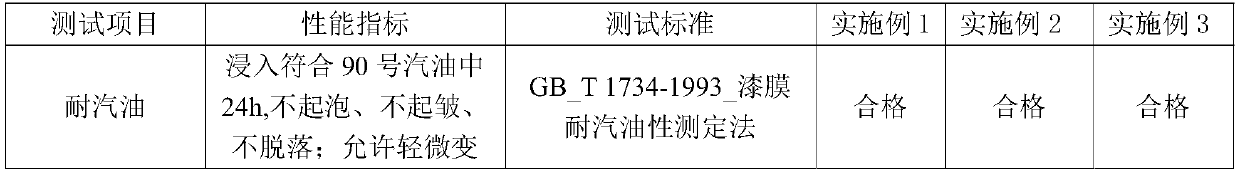

[0063] Dilute the water-based acrylic amino baking varnish prepared in Example 1-3 to 20-25 seconds (coated with -4 viscosity cup, 25°C), wet-on-dry spraying on the gray electrophoretic primer and polished tinplate, (Iwata 101 spray gun, Spraying pressure 0.4MPa, control dry film thickness 20-25μm), leveling for about 10min, and finally bake at 150℃×20min to get the paint film coating applied on light machine. The performance of the obtained paint film coating was tested. The performance of the single coating on the tinplate is shown in Table 2, and the performance of the composite coating on the gray electrophoretic primer is shown in Table 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com