Coating process capable of lowering VOCs

A coating process and coating technology, which is applied to the device for coating liquid on the surface, coating, etc., can solve the problems of production line failure, long production shutdown time, and heavy transformation workload, etc., and achieve operational energy consumption and material cost Low cost, stable coating quality, and low transformation investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

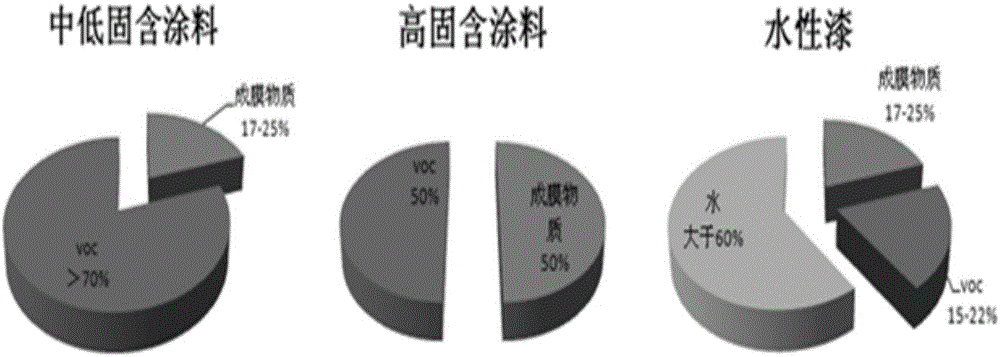

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A coating process for reducing VOCs, specifically:

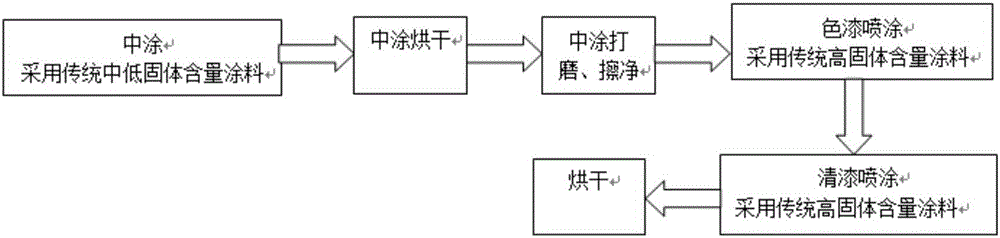

[0030] Traditional process intermediate coating (medium and low solid content coating is used) - intermediate coating drying - intermediate coating grinding and wiping - high solid content paint color paint spraying - high solid content paint varnish spraying - coating drying.

[0031] Paint and varnish spraying equipment parameters are: spraying equipment flow rate 85mL / min; rotary cup speed 56Krpm; spraying voltage 70KV; paint and varnish spray booth environment: temperature 22°C, humidity 60%RH.

Embodiment 2

[0033] A coating process for reducing VOCs, specifically:

[0034] Traditional process intermediate coating (medium and low solid content coating is used) - intermediate coating drying - intermediate coating grinding and wiping - high solid content paint color paint spraying - high solid content paint varnish spraying - coating drying.

[0035] Paint and varnish spraying equipment parameters are: spraying equipment flow rate 95mL / min; rotary cup speed 60Krpm; spraying voltage 70KV; paint and varnish spray booth environment: temperature 25°C, humidity 62-65%RH.

Embodiment 3

[0037] A coating process for reducing VOCs, specifically:

[0038] Traditional process intermediate coating (medium and low solid content coating is used) - intermediate coating drying - intermediate coating grinding and wiping - high solid content paint color paint spraying - high solid content paint varnish spraying - coating drying.

[0039] Paint and varnish spraying equipment parameters are: spraying equipment flow rate 108mL / min; rotary cup speed 64Krpm; spraying voltage 70KV; paint and varnish spray booth environment: temperature 29°C, humidity 70%RH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com