Patents

Literature

107results about How to "Renovation investment is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving tobacco shred preparing quality stability

InactiveCN108308691ASmall process changesRenovation investment is smallTobacco preparationEngineeringUltimate tensile strength

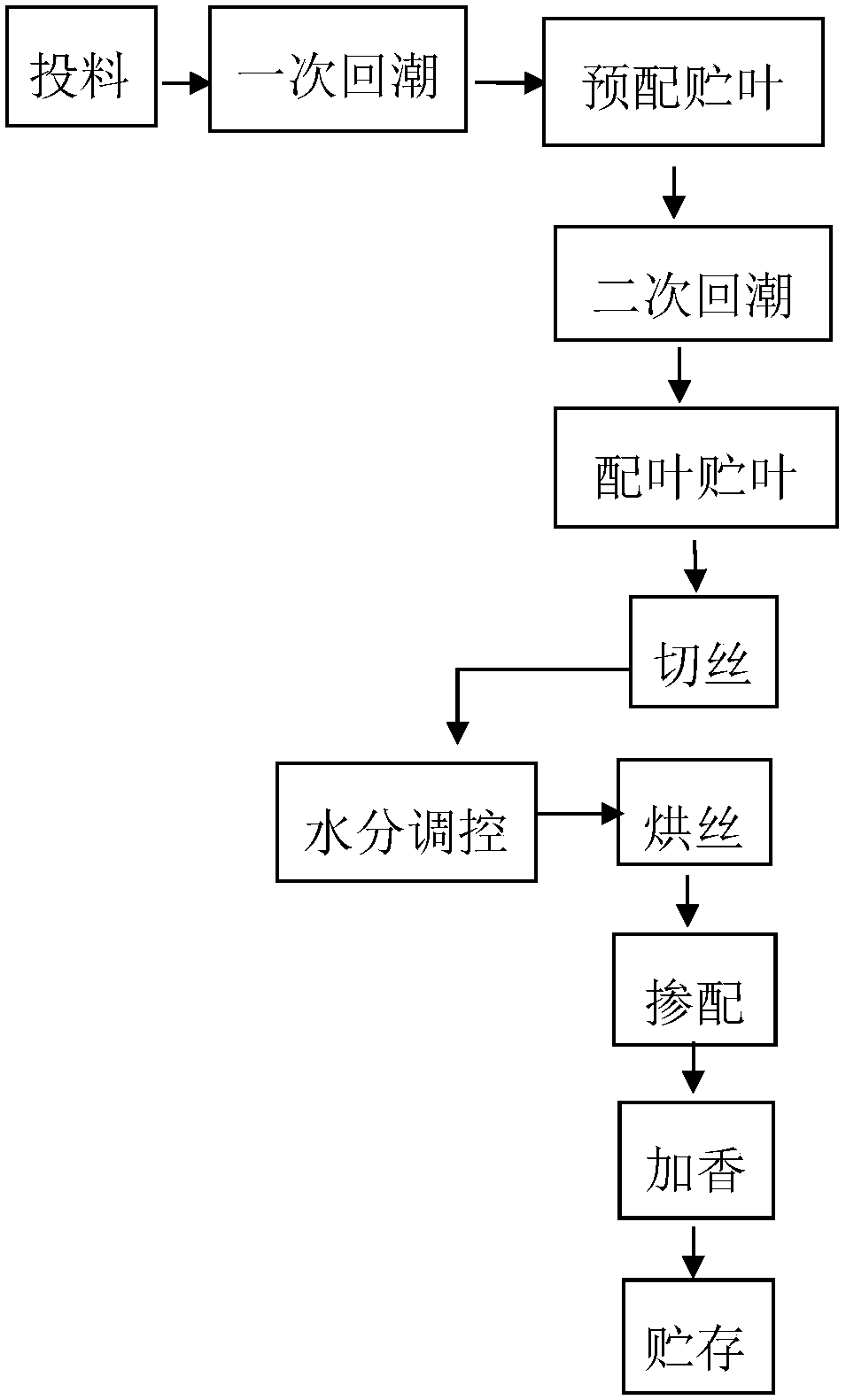

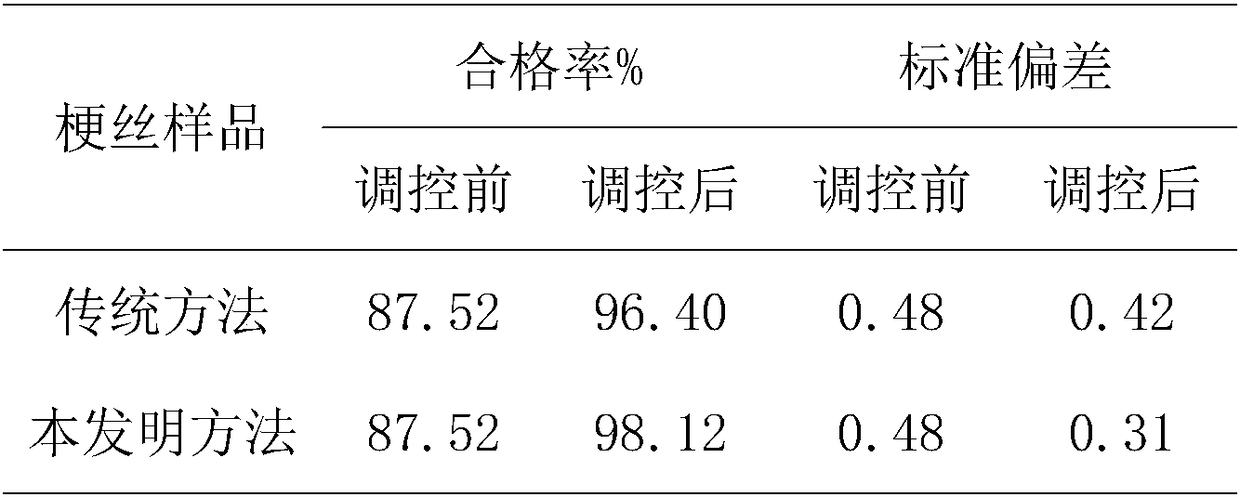

The invention provides a method for improving the tobacco shred preparing quality stability. The method specifically includes the steps of material putting, primary moisture regaining, stored leaf preparing, secondary moisture regaining, stored leaf distributing, shredding, moisture controlling, shred drying, mixing, flavoring and storing. The moisture controlling process is added after shredding,so the problems that due to the long process route, the material process water content is greatly influenced by the environment temperature and humidity and the shred drying inlet water content of different batches fluctuates obviously are solved, the incoming material water content of the shred drying process is stabilized, the stability of the water content of different batches of materials entering the shred drying process is ensured, the shred drying machine outlet material water content meets the processing requirement, and therefore the processing intensity and dewatering amount of theshred drying process of different batches are stabilized, and the stability of the sensory quality of shred drying outlet materials is ensured; compared with other methods, the method has the advantages of being small in technological change, small in refitting investment, capable of saving energy and reducing consumption and free of newly constructing or refitting of a factory.

Owner:HONGTA TOBACCO GRP

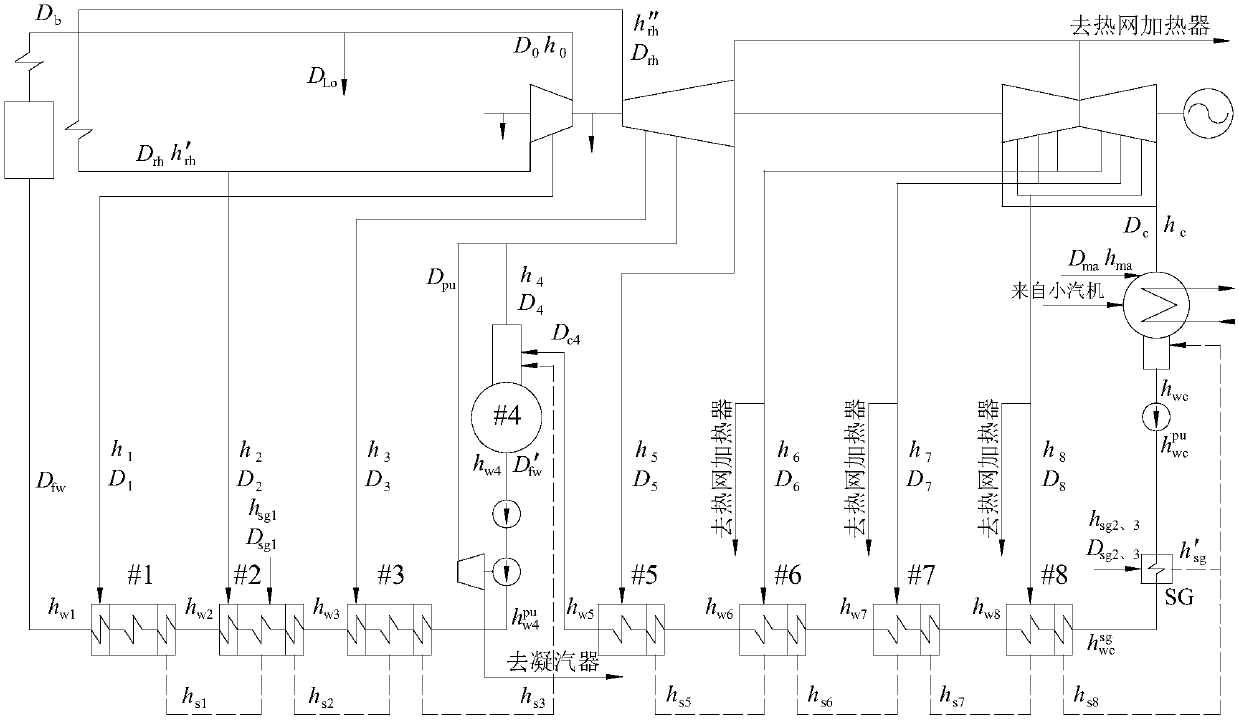

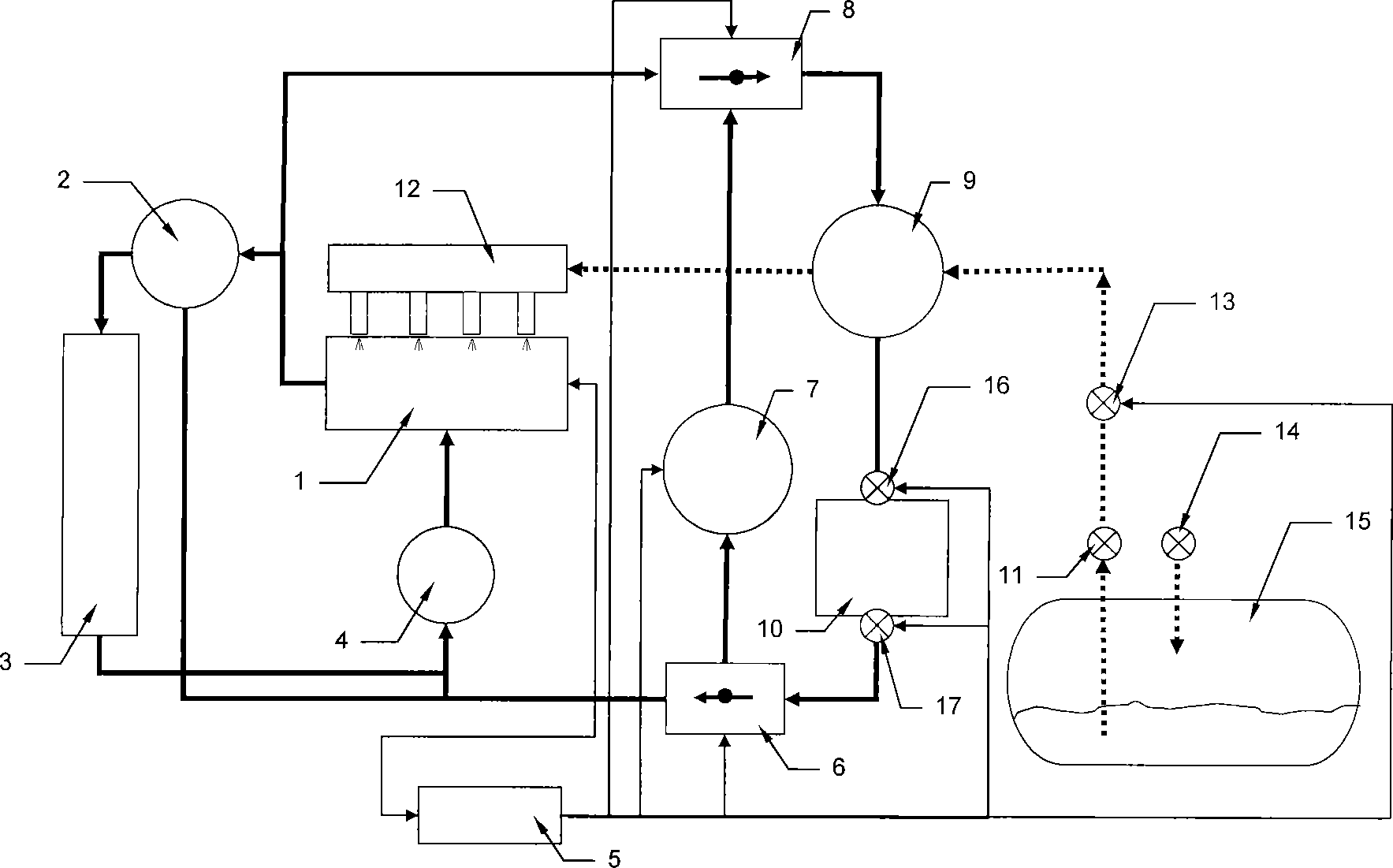

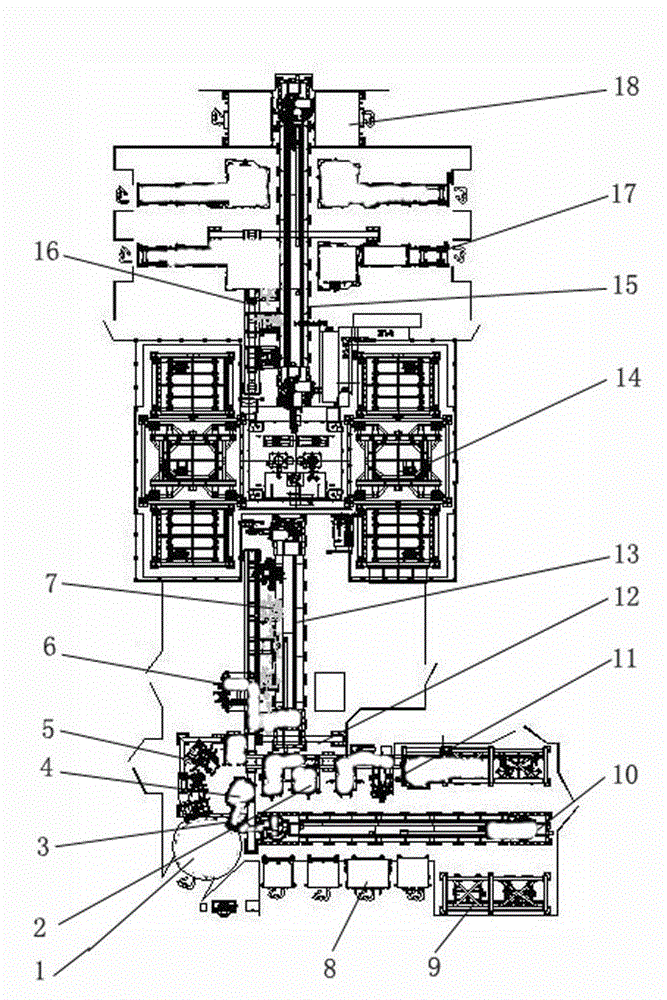

Power station machine furnace integrated cold end comprehensive optimization system

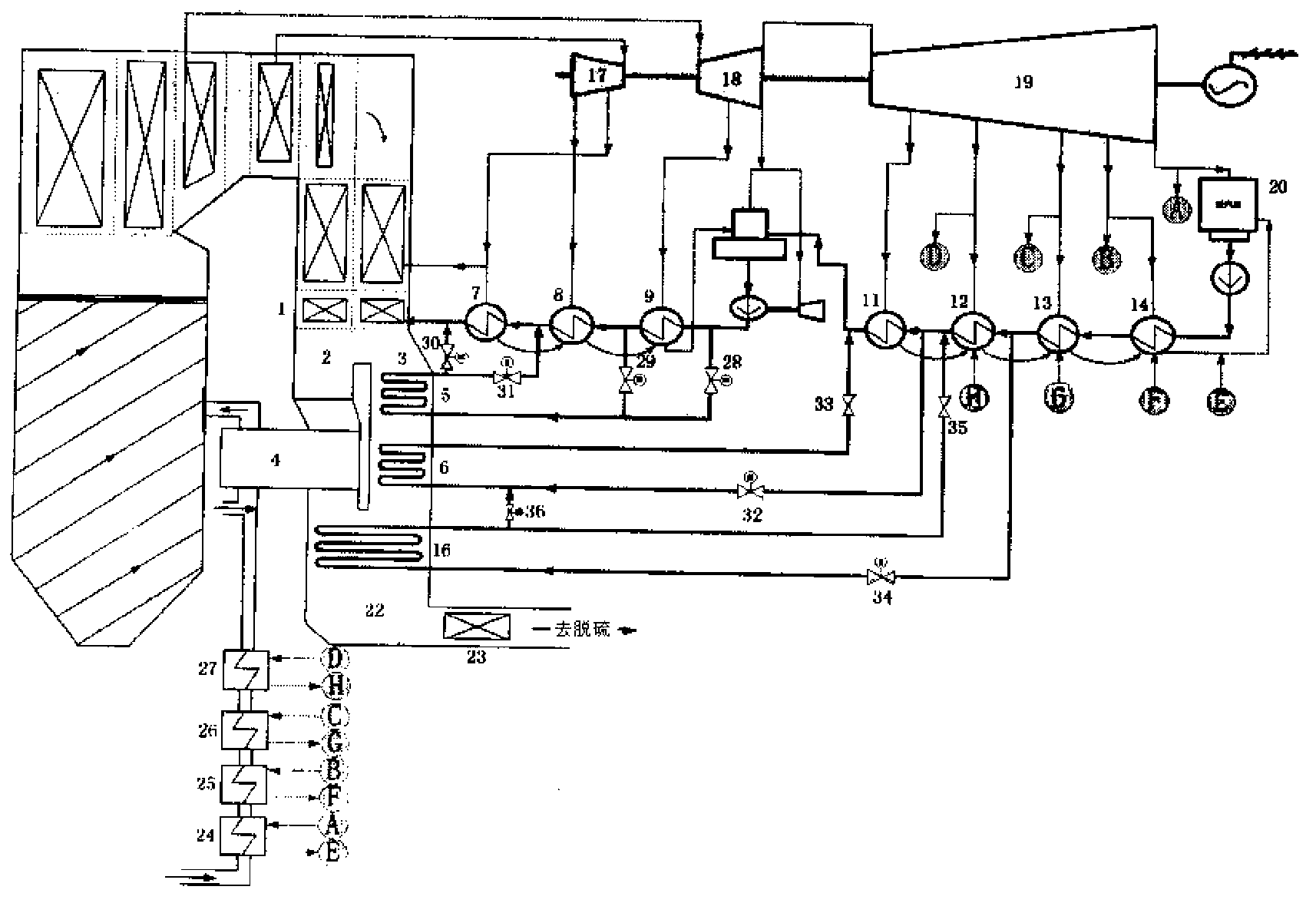

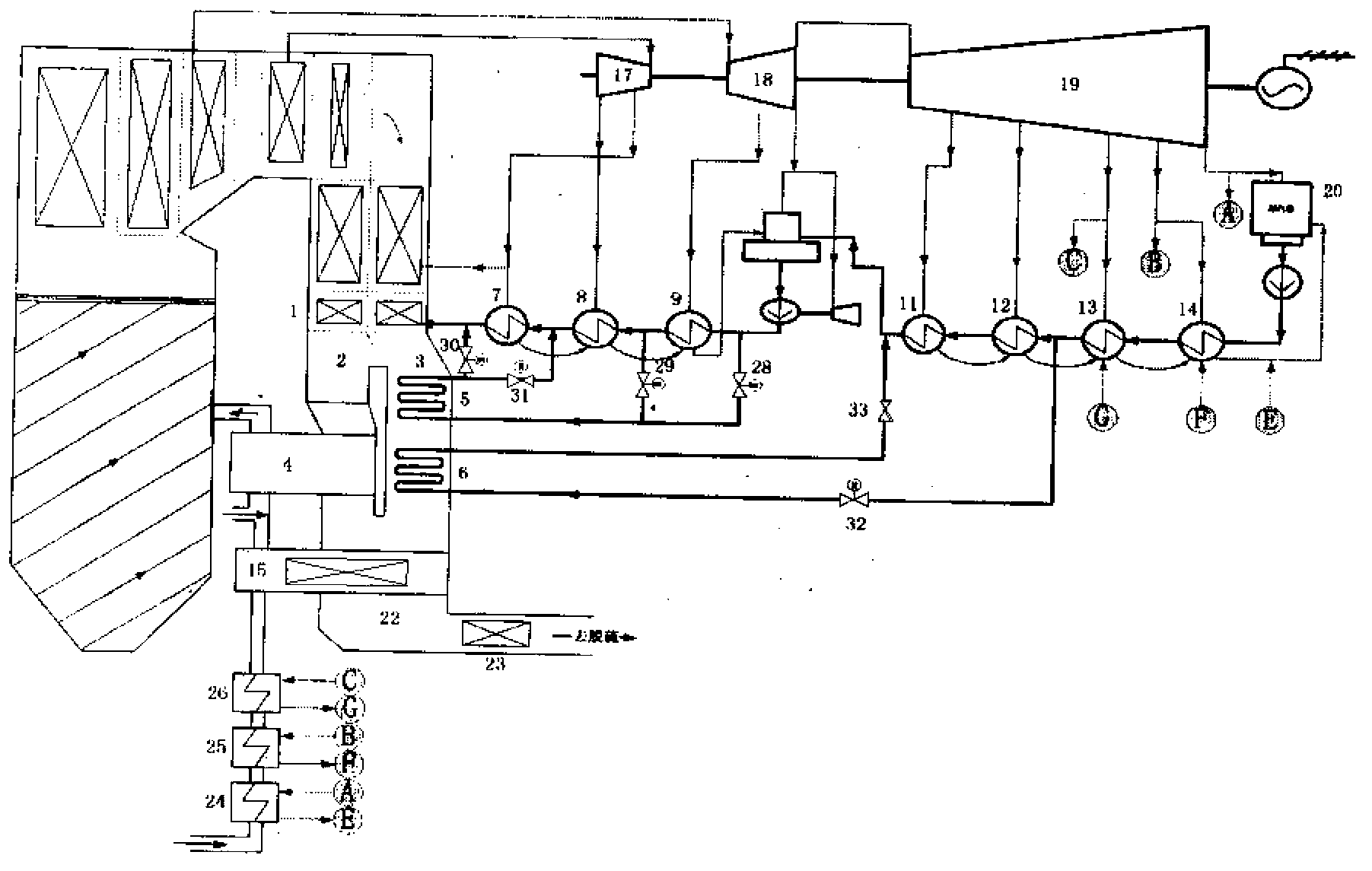

The invention discloses a power station machine furnace integrated cold end comprehensive optimization system which belongs to the field of power station energy saving. The system mainly comprises a steam turbine, a main economizer, a main flue, a bypass flue, a convergence flue, a main air pre-heater, smoke-water heat exchangers, a high pressure heater, a low pressure heater, a deaerator, a smoke-air heater and steam extraction condensed air pre-heaters. Multi-stages of the steam extraction condensed air pre-heaters are serially arranged, sequentially extract a part of exhaust steam of the steam turbine and corresponding low-pressure-stage extraction steam and preheat cold air stage by stage; and the first, second and third stage smoke-water heat exchangers are used for heating feeding water and condensed water, and high-pressure extraction steam of the steam turbine is replaced. According to the machine furnace integrated cold end comprehensive optimization system, by means of efficient waste-heat utilization, low-pressure extraction steam is used for heating air, and the high-pressure extraction steam for backheating is saved so that unit output power is obviously increased, deep energy saving and consumption reduction of the coal-fired power generation unit are achieved, the problem of low-temperature corrosion on a heated surface during waste-heat utilization is solved, and economical benefits are remarkable.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

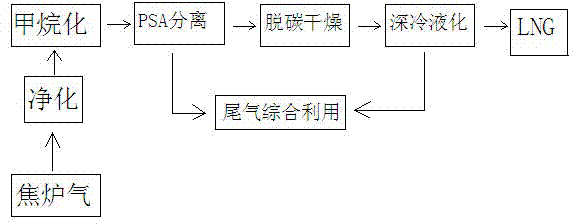

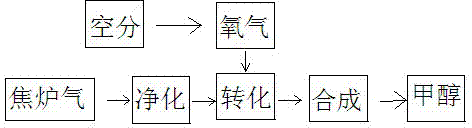

Method of combined production of methanol and liquefied natural gas in coking plant

InactiveCN104119975ASimple processEasy to operateHydrogen separationOrganic compound preparationSyngasThermodynamics

The invention belongs to the technical field of comprehensive coke-oven gas utilization, and particularly relates to a method of combined production of methanol and liquefied natural gas (LNG) in a coking plant. Coke-oven gas is subjected to temperature swing adsorption (TSA), desulphurization, vacuum pressure swing adsorption (VPSA), and other purifying treatment, and is subjected to cryogenic liquidation separation to obtain a liquefied natural gas (LNG) product. The main component of the non-liquefied part is (CO+H2), and is adopted as methanol synthesis gas used for producing methanol, wherein the insufficient carbon component based on the H2is supplied by continuous oxygen-rich gas production from chopped coke having a size of 7-24 mm by a normal-pressure gasifier. The method achieves direct utilization of CH4 that is one of the main components of the coke-oven gas, the (CO+H2) are directly used for methanol synthesis, and the insufficient carbon source is supplied by a normal-pressure gasifier adopting the chopped coke produced by the coking plant as a gas production raw material, and therefore intermolecular conversion and other main energy-consumption sections and high-investment devices are reduced, the whole process is simplified, the comprehensive energy consumption for producing the methanol and the liquefied natural gas (LNG) is low, the whole economic benefit of coking enterprises is increased, and the investment is saved.

Owner:COAL BRANCH YANZHOU MINING GRP

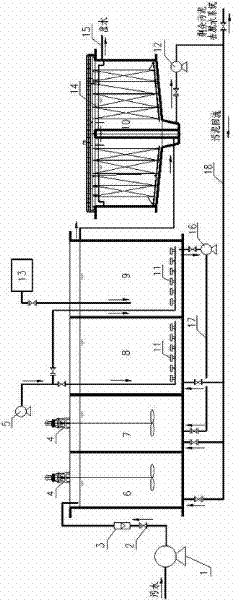

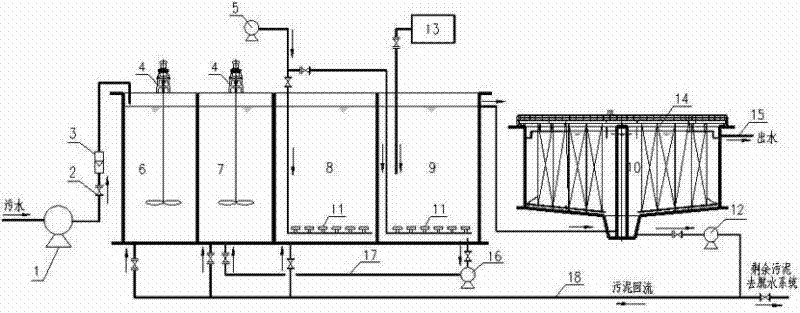

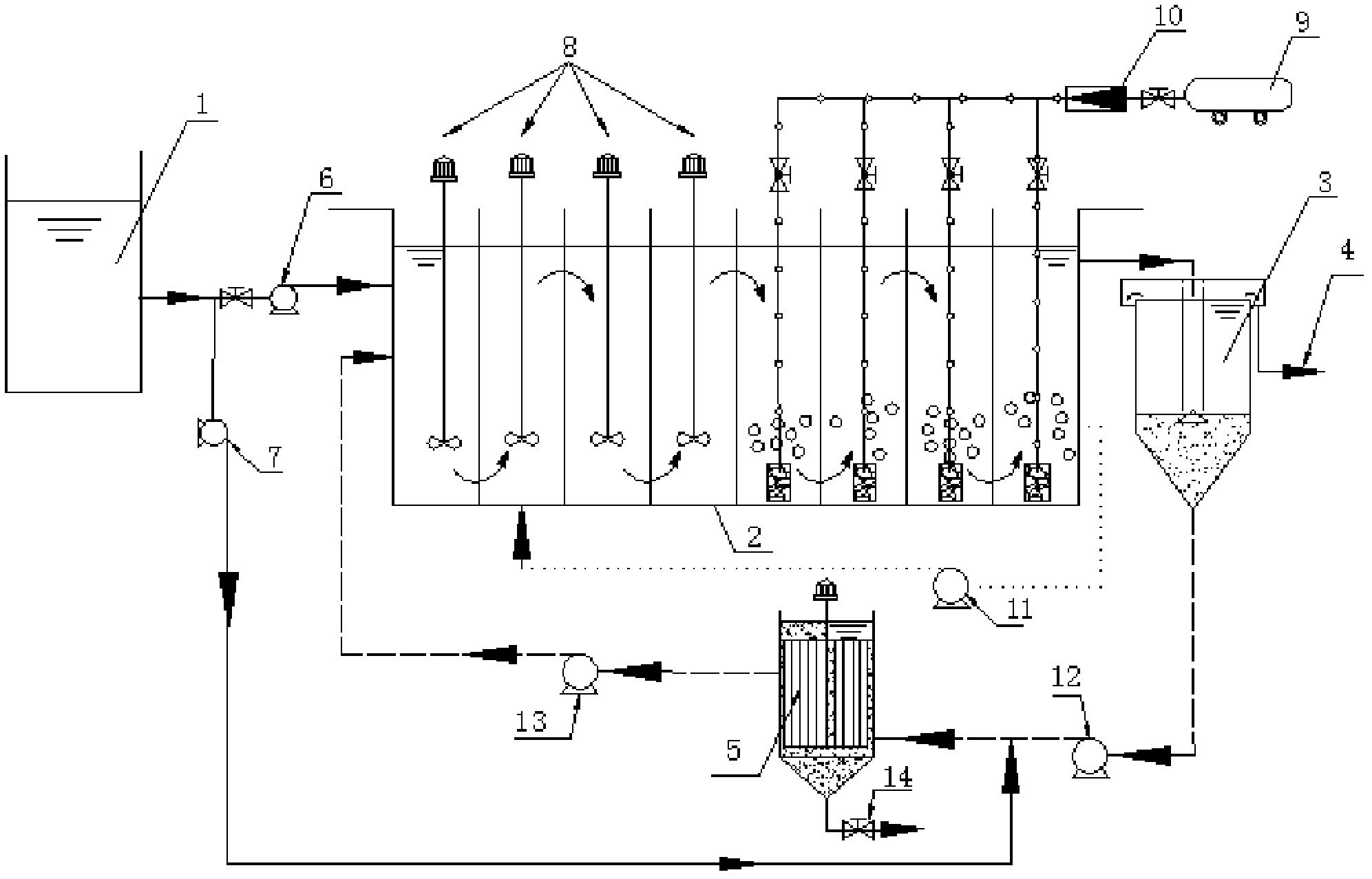

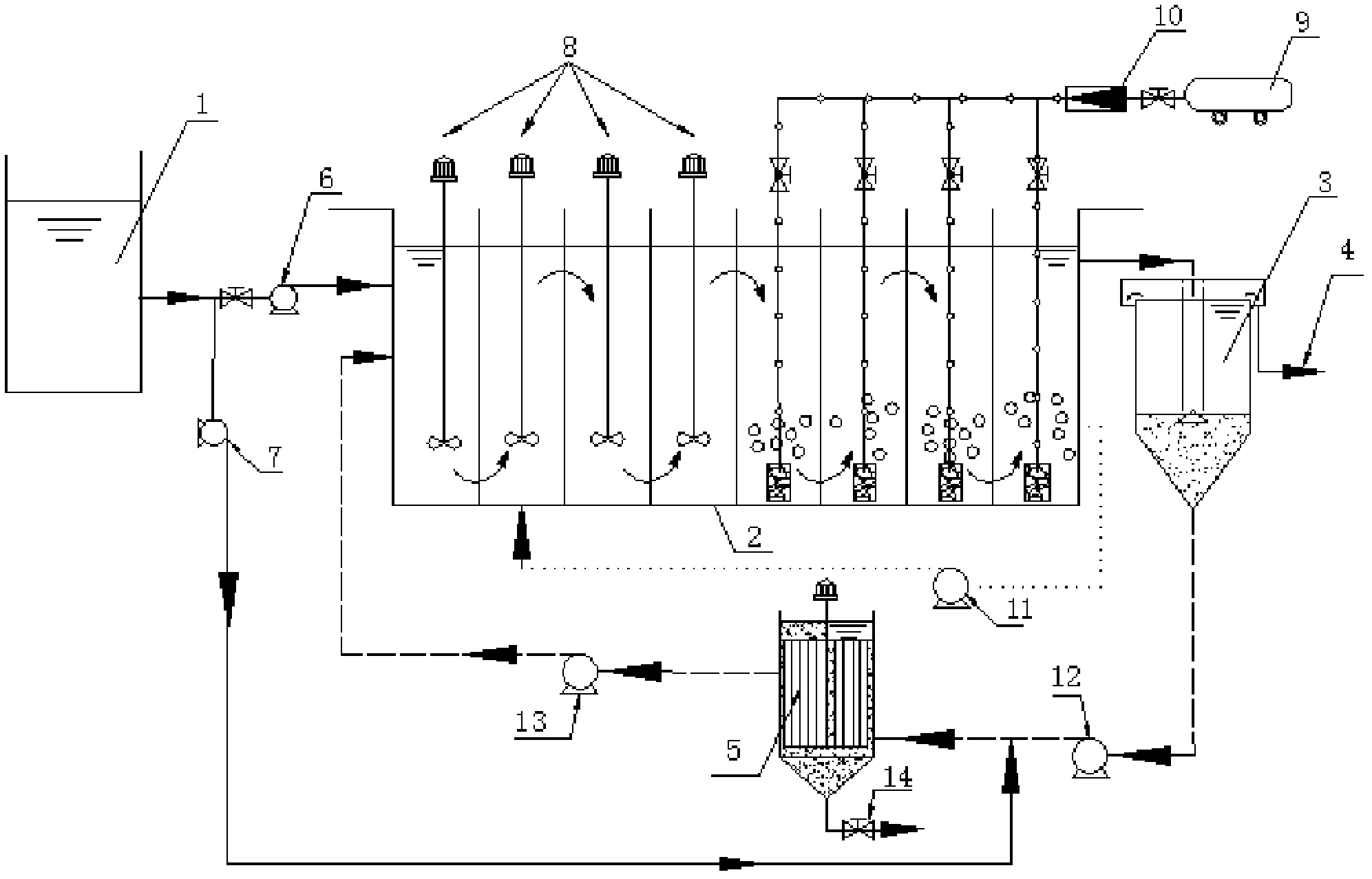

System and process for sludge in situ decrement enhanced by utilizing metazoan and application of process

InactiveCN102372405AProcess structure is compactEasy to operate and manageSludge processingSustainable biological treatmentSequencing batch reactorSewage

The invention discloses a system and a process for sludge in situ decrement enhanced by utilizing metazoan and application of the process. The system comprises an anaerobic zone, an anoxic zone, an oxic zone, a metazoan growing zone and a secondary sedimentation zone. A biochemical system can perform in situ decrement through arranging the metazoan growing zone in the sewage treatment process; and cultivated and domesticated metazoan is continuously added in the metazoan growing zone to enhance organism predation, thereby achieving the purpose of sludge in situ decrement and realizing sludge decrement effect of 50-80% of activated sludge. The process of activated sludge in situ decrement with an efficient biological method is suitable for any activated sludge methods and deformation technologies thereof, such as A<2> / O (anaerobic-anoxic / oxic), A / O (anoxic / oxic), SBR (sequencing batch reactor), MSBR (modified sequencing batch reactor), CASS (cyclic activated sludge System), oxidation ditch, MBR (membrane bio-reactor) and the like, can also be used for a biological treatment technology having a biological carrier, can be used for sludge decrement of a newly-built sewage treatment engineering and can also be used for transformation of a built engineering with extremely low transformation cost.

Owner:浙江环科环境研究院有限公司

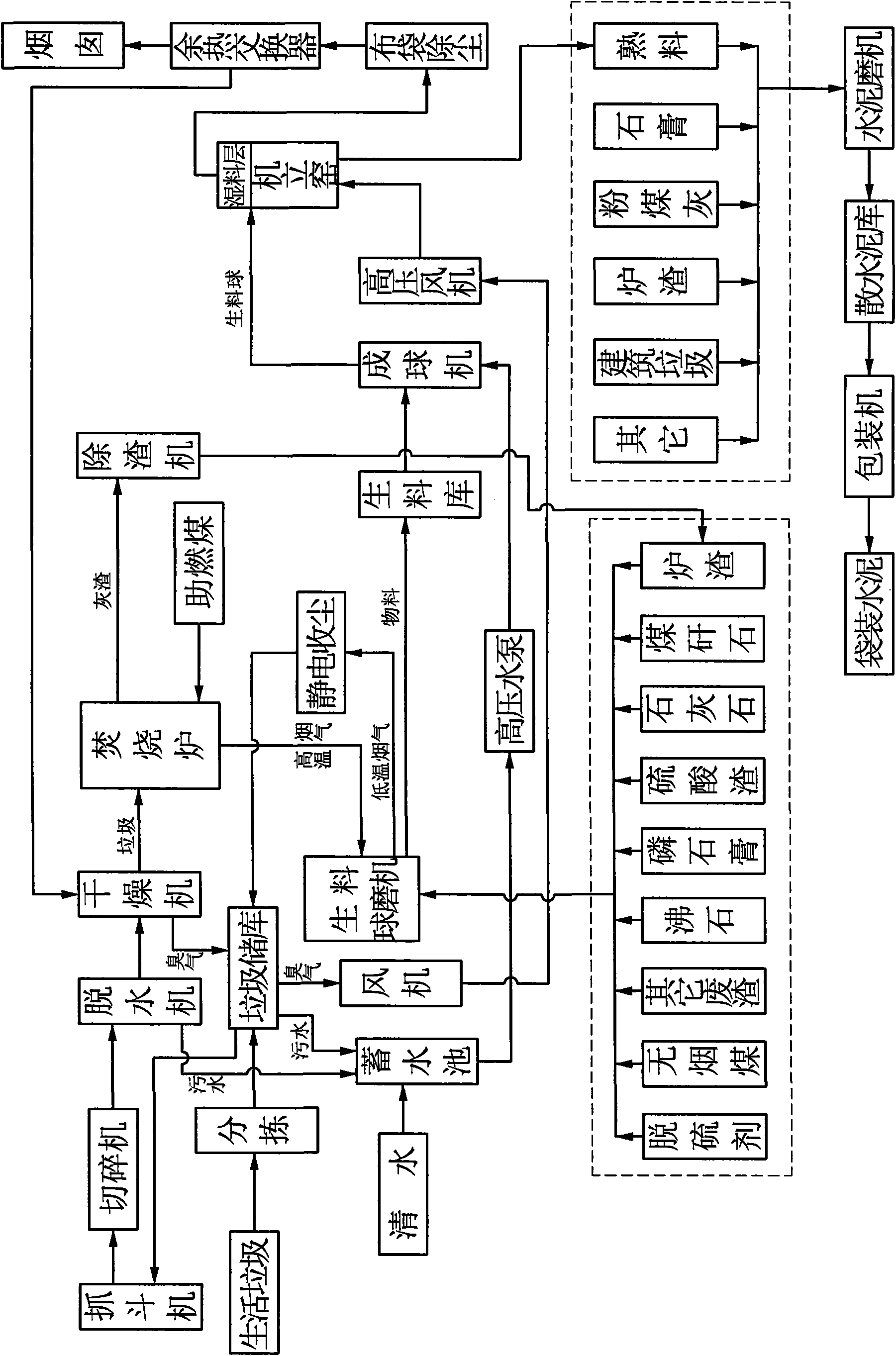

Method for processing municipal solid waste by using shaft kiln cement production line

The invention relates to a method for processing municipal solid waste by using a shaft kiln cement production line. The method comprises the following steps: (1) collecting, separating and warehousing; (2) cutting up, dehydrating and leachate treatment; (3) drying tail gas treatment; (4) burning smoke treatment; (5) slag utilization, raw material ball grinder tail gas treatment; (6) high temperature calcining and tail gas dedusting. The method uses specific conditions of the shaft kiln cement production technology for effectively using heat energy, leachate, slag and the like in the household garbage processing course; simultaneously, all matters generated in the garbage processing course (including taste) are completely dispelled in a high temperature kiln; the method has the advantages of little investment on device reformation, low garbage treatment cost, high waste solid utilization rate, complete garbage treatment and the like, thus truly achieving requirements of minimization, recycling and harmless of the garbage treatment.

Owner:郭涵

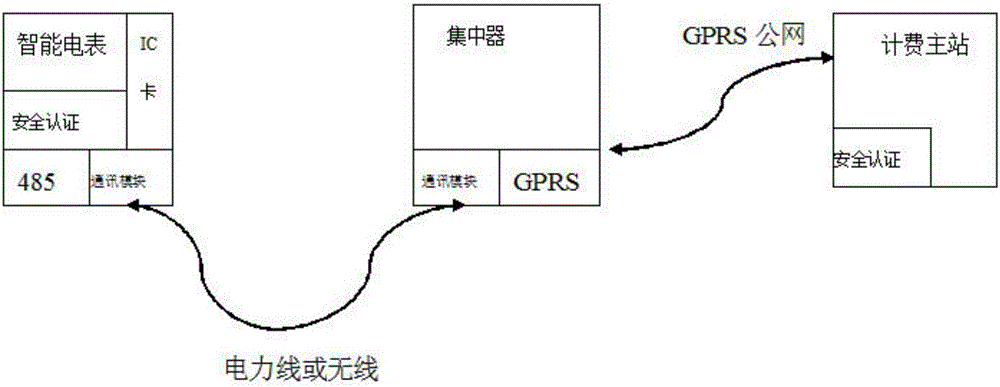

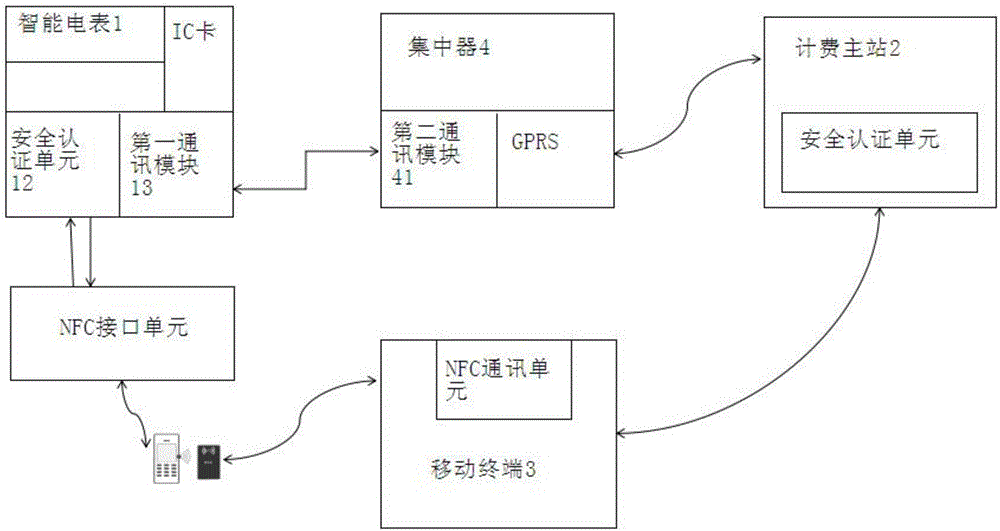

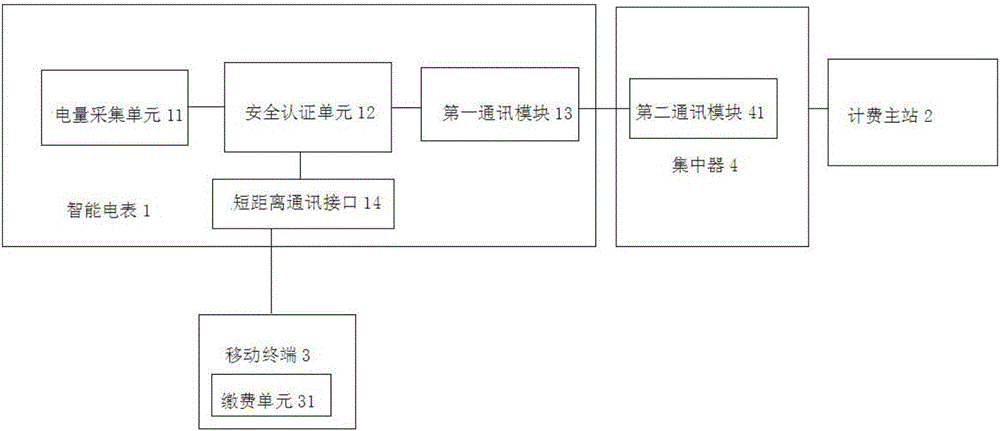

Electricity charge payment method based on non-contact communication, payment channel and payment system

InactiveCN106529936AThe payment process is convenient and fastReliable communicationPayment architecturePrimary stationShortest distance

The invention provides an electricity charge payment method based on non-contact communication, a payment channel and a payment system. The method comprises steps that S1, user identity authentication is accomplished on a mobile terminal by a user, a unique intelligent meter code belonging to the user is acquired, and a network communication channel is established through utilizing the network of the mobile terminal and a charging main station; S2, the mobile terminal is made to realize short distance contact with the intelligent meter by the user, a short distance communication channel between the mobile terminal and the intelligent meter is established, and payment is initiated to the charging main station through the mobile terminal; S3, the payment information of the user is received by the charging main station, and payment of the intelligent meter is directly carried out through the short distance communication channel established between the mobile terminal and the intelligent meter. The method is advantaged in that payment can be accomplished through the non-contact short distance communication channel by utilizing a self-contained NFC communication function of a handset and the intelligent meter, a payment process is made to be convenient and rapid, communication is more reliable and rapid, payment can be rapidly accomplished, and disadvantages of payment in the prior art are solved.

Owner:BEIJING BRON S&T

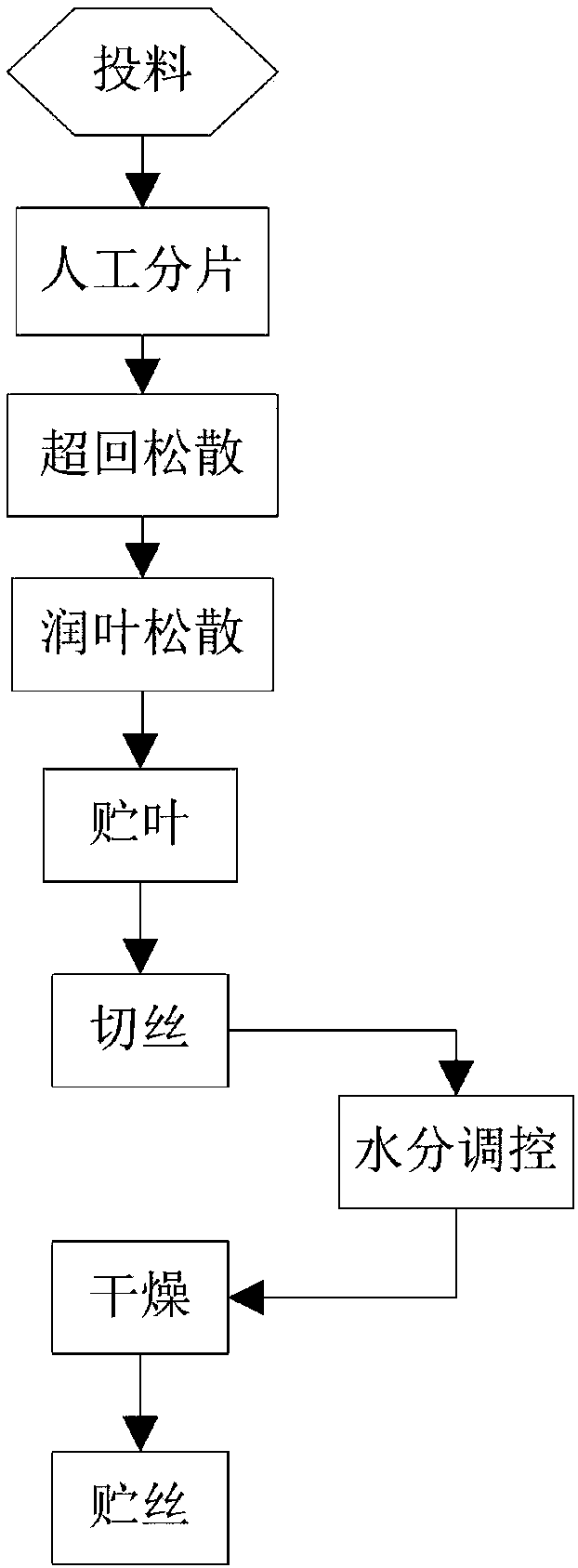

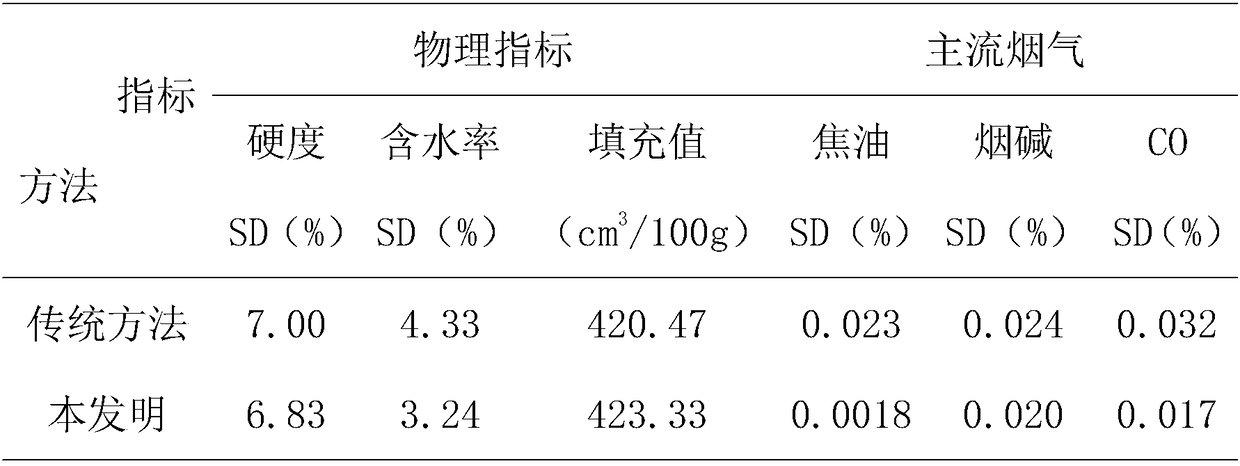

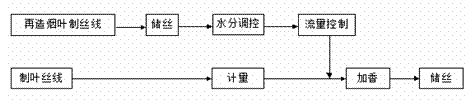

Method for improving tobacco shred making quality of reconstituted tobacco

InactiveCN108185504AImprove sensory qualityImprove processing strength and stabilityTobacco preparationMoisture absorptionEngineering

The invention provides a method for improving the tobacco shred making quality of reconstituted tobacco. The method comprises the specific steps of putting, manual fragmentation, super-return loosening, tobacco moistening and feeding, tobacco storage, shredding, moisture regulation and control, drying and tobacco shred storage. The process of moisture regulation and control is added, and the problems are solved that the technological path is long, the reconstituted tobacco has special moisture absorption performance, the water content in the material process is excessively influenced by the temperature and humanity of the environment, and accordingly the water content of batch-to-batch drying inlets is obviously fluctuated; the water content of shredded materials is stable, the stability of batch-to-batch moisture of the materials which enter the drying process is guaranteed, the water content of materials of drying outlets meets the processing requirement, the stability of the processing intensity and dewatering amount in the batch-to-batch tobacco shred drying process is achieved, and the stability of the smoking quality of the reconstituted tobacco shreds of tobacco shred dryingoutlets is guaranteed. Compared with other methods, the method has the advantages that the technological path is less changed, the reconstitution investment is low, the energy is saved, the consumption is lowered, and meanwhile workshops do not need to be newly built or rebuilt.

Owner:HONGTA TOBACCO GRP

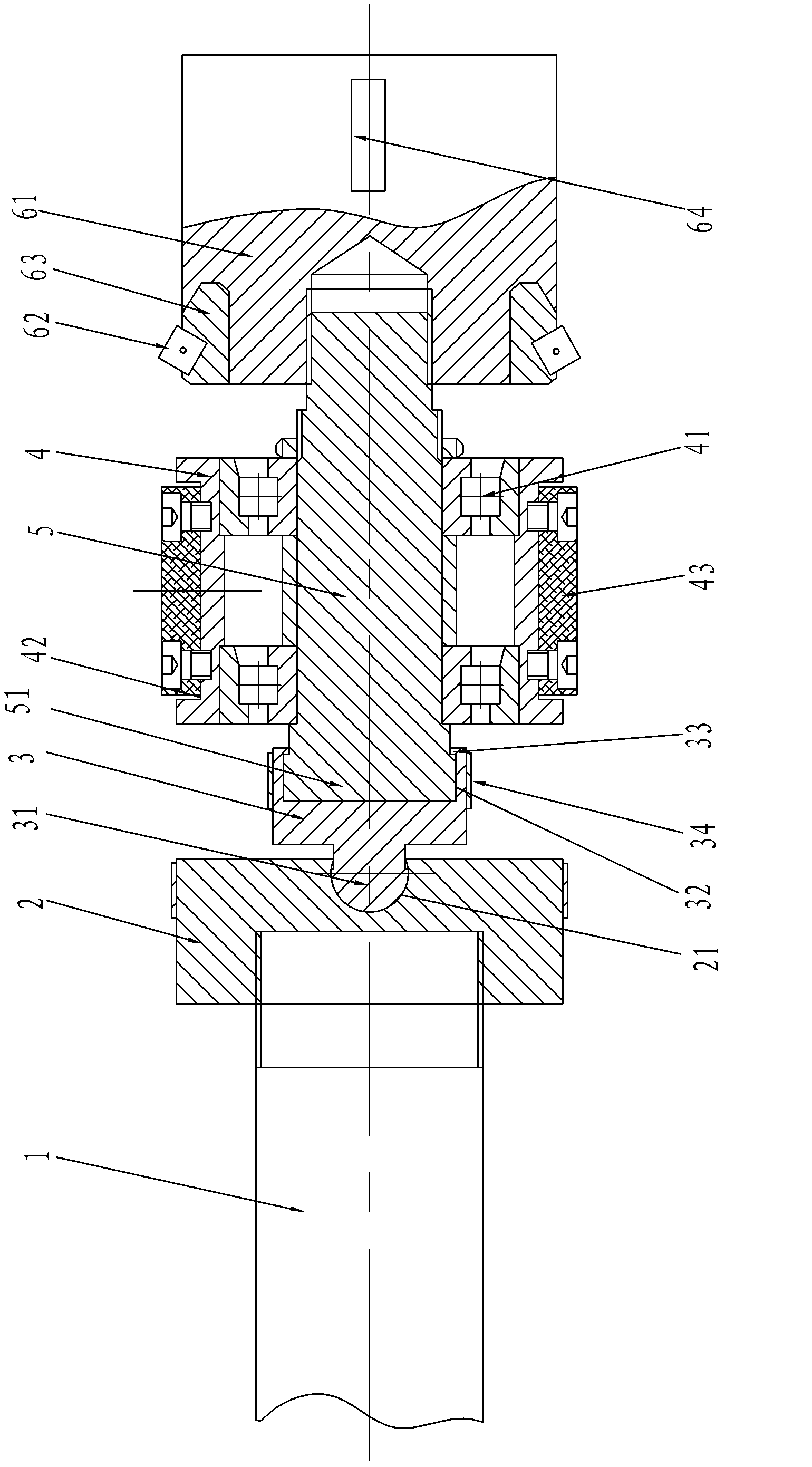

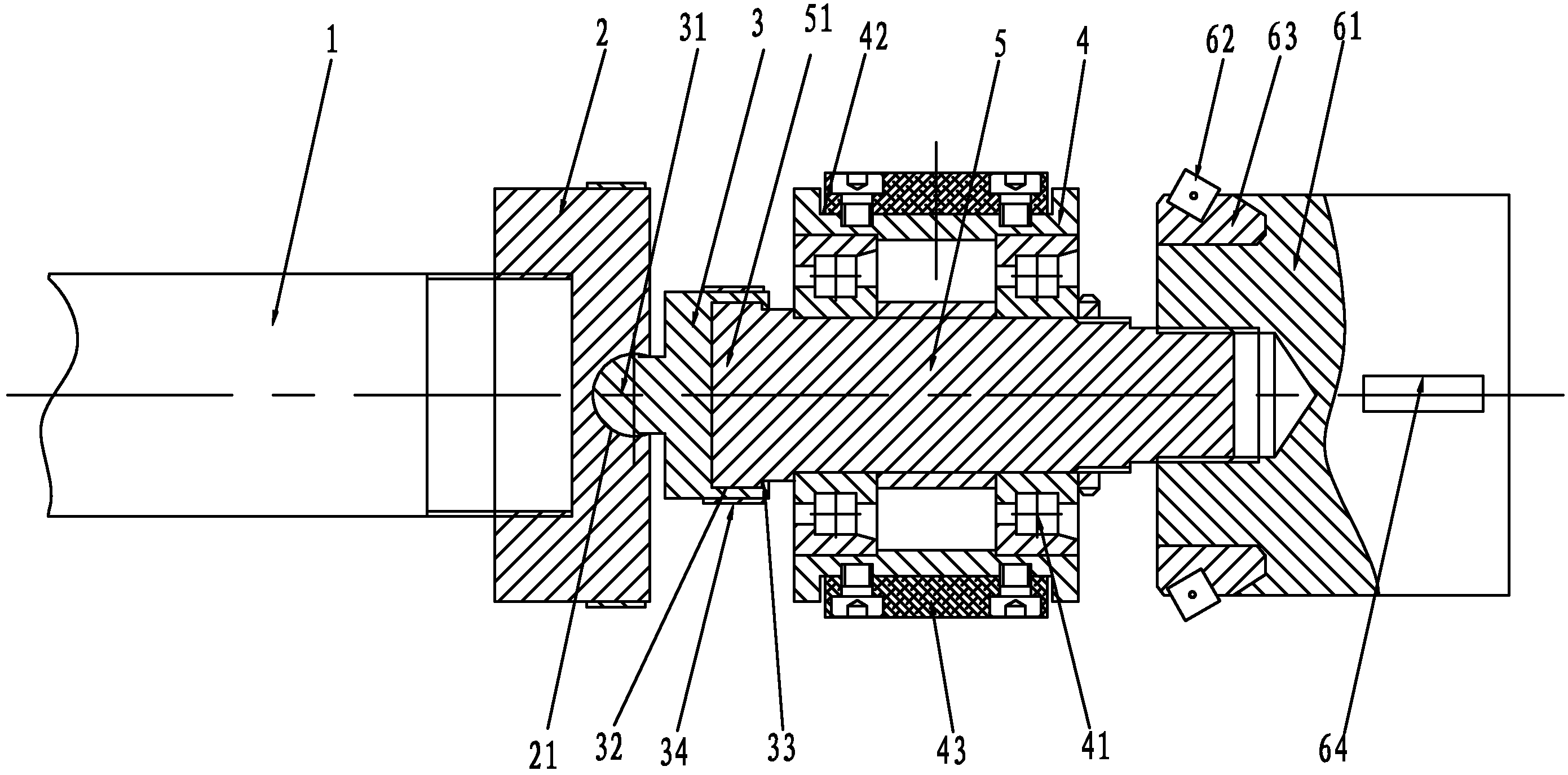

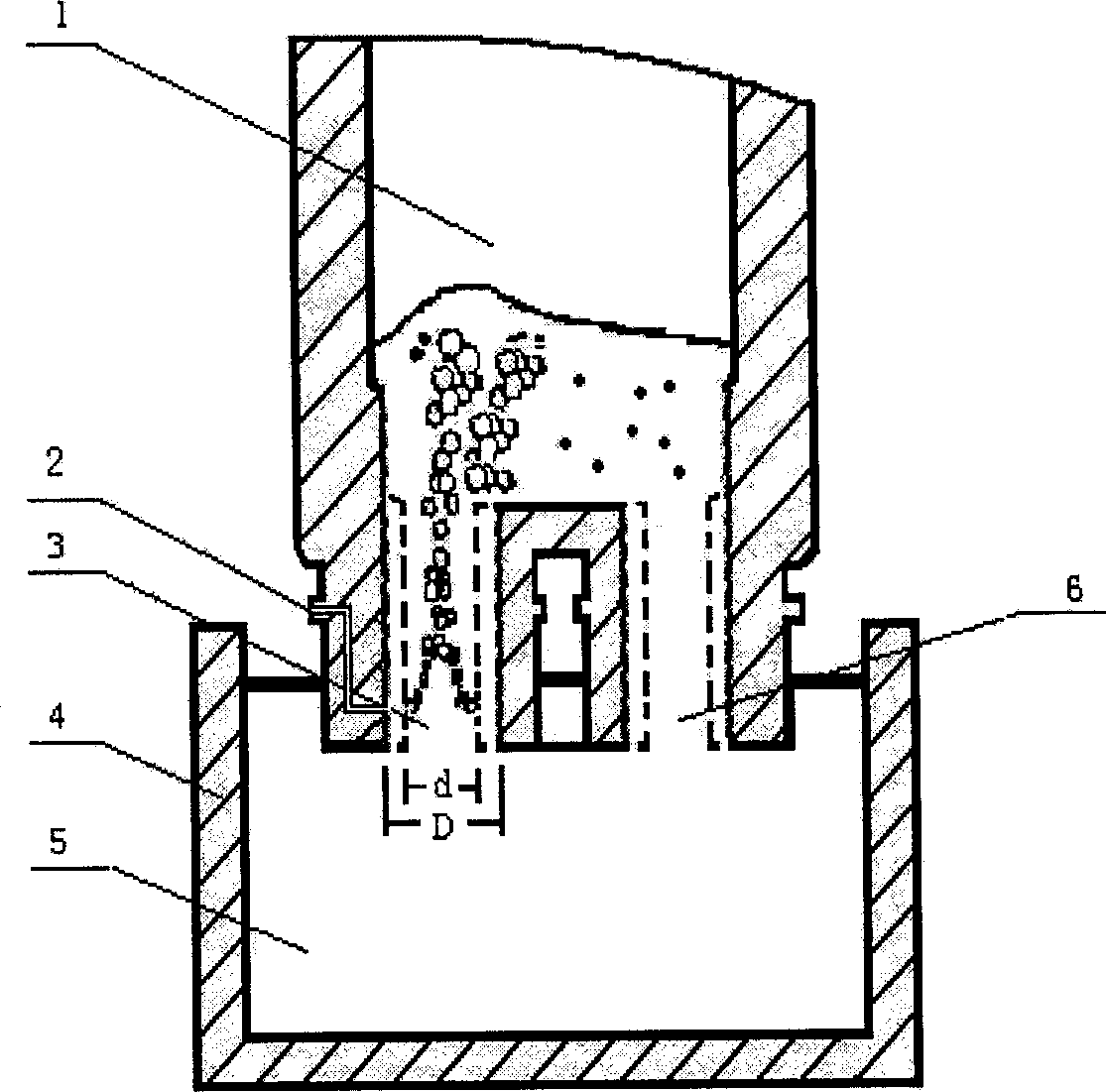

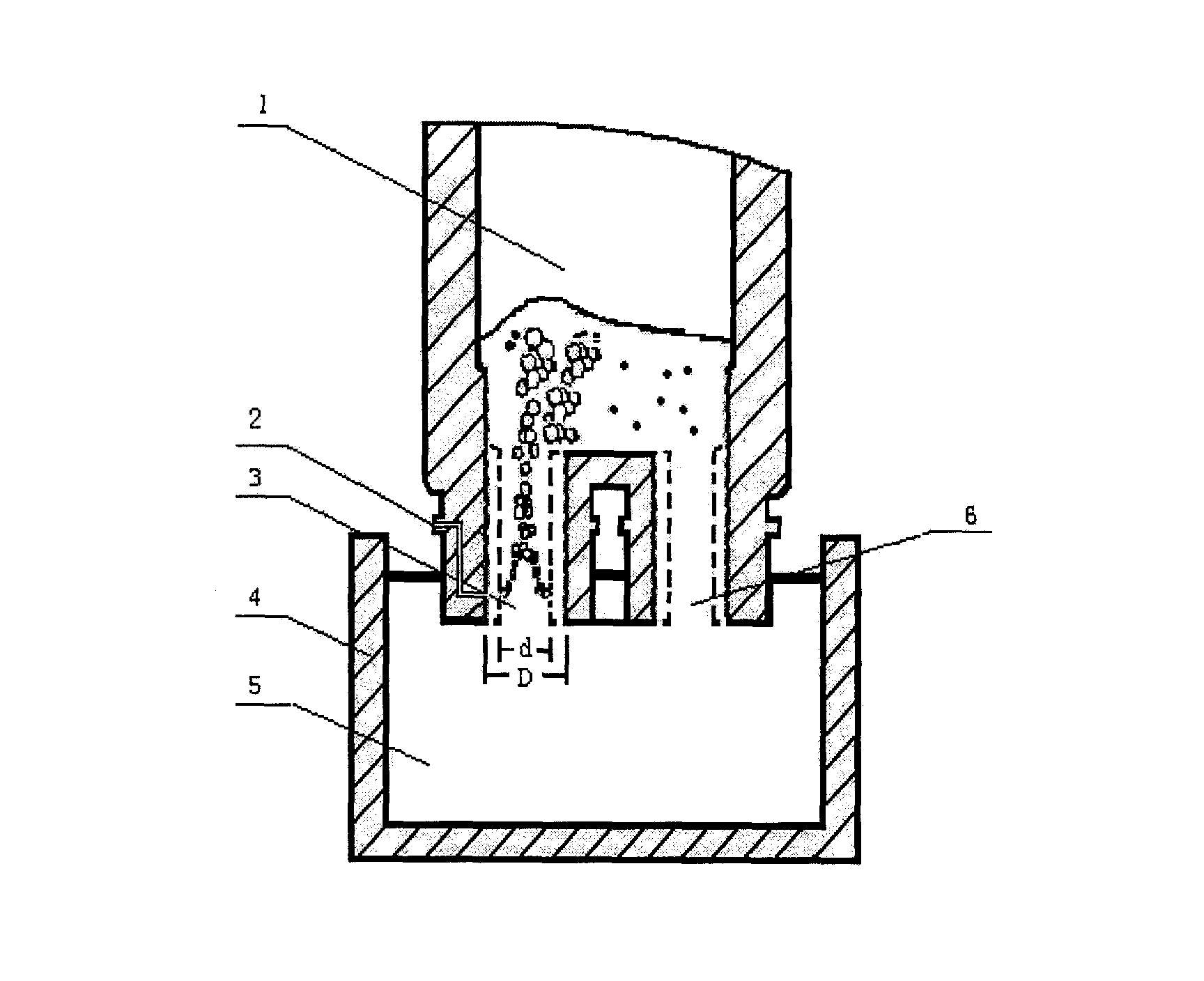

Floating boring head for processing inner surface of bent tube billets

InactiveCN102601402AAdaptive CurvatureGuaranteed Wall Thickness Error RangeBoring headsEngineeringMechanical engineering

The invention discloses a floating boring head for processing inner surface of bent tube billets, wherein one end of a boring bar connector is connected with a boring bar while the other end thereof is flexibly connected with a universal connection block; the other end of the universal connection block is connected with a support shaft; a guide mould is installed on the support shaft through a bearing; a boring cutter mechanism comprises a cutterhead and a boring cutter; the other end of the support shaft is fixedly connected with the cutterhead; and two boring cutters are symmetrically fixed by the central line on the cutterhead. In the floating boring head, as the other end of the boring rod connector is flexibly connected with the universal connection block, the guide mould can vertically and transversely move relative to the boring bar in the tube billet and adapts curvature of the tube billets effectively; moreover, the guide mould and the boring cutter mechanism are in a rigid connection manner; thus, the guide mould can transfer the curvature of the tube billets to the boring cutters well so as to ensure wall thickness uniformity of the processed tube billets, realize high processing efficiency, wide processing range, and small equipment upgrading investment and not influence the processing performance of the original boring lathe after transformations.

Owner:XINXING DUCTILE IRON PIPES CO LTD

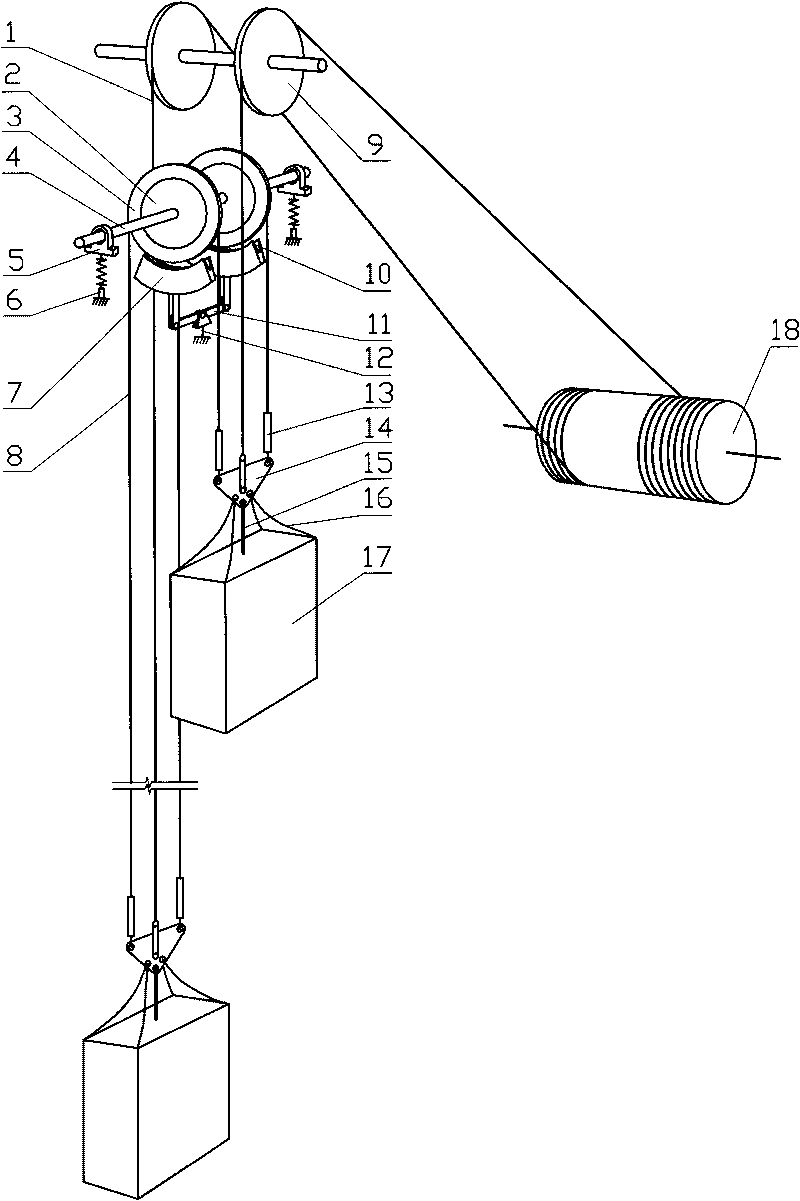

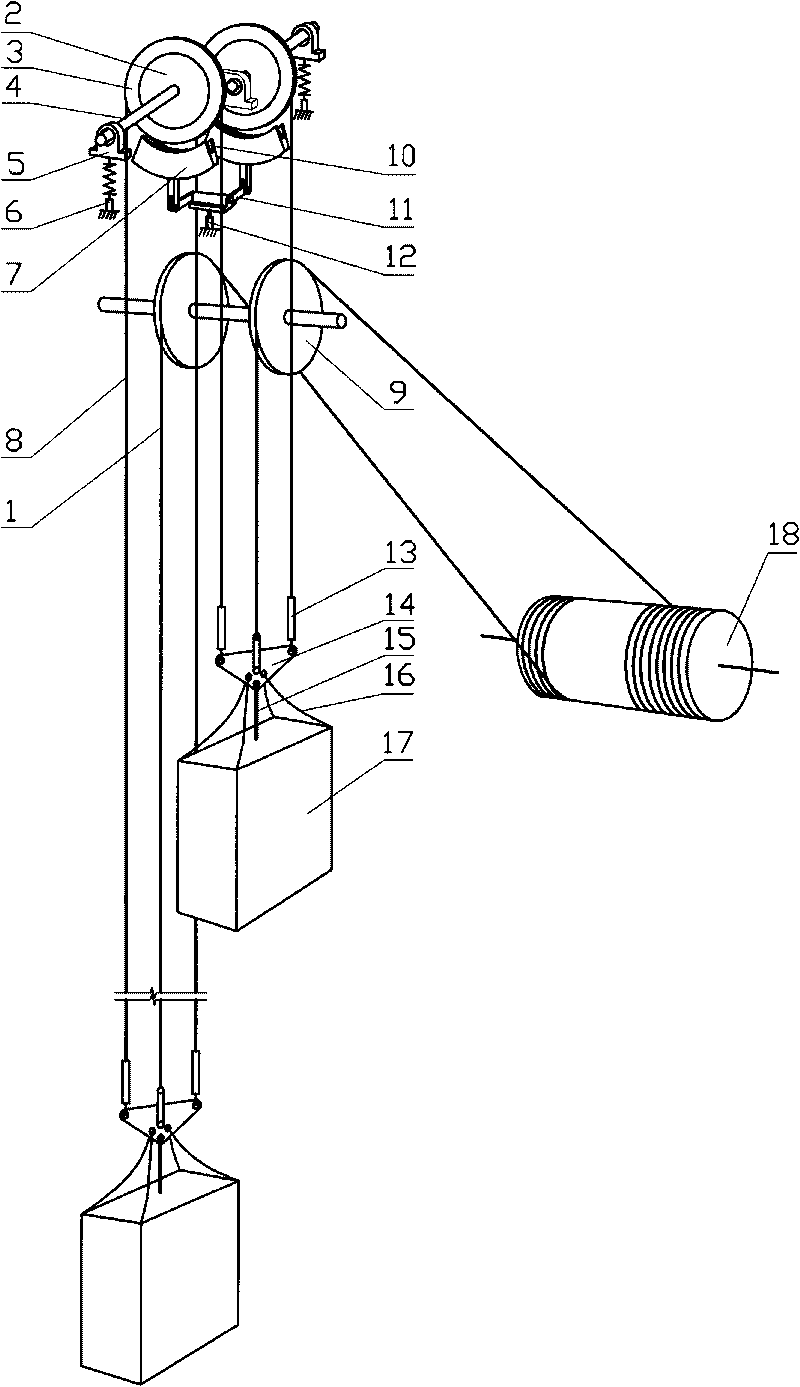

Mine single-rope hoisting balance wheel brake rope anti-case-crashing device

InactiveCN101723219ASolve the problem that the anti-fall device does not workLow investment costElevatorsMine liftsMine safetyFall prevention

The invention aims to provide a mine single-rope hoisting balance wheel brake rope anti-case-crashing device and relates to the technical field of mine safety devices. A hoisting container is connected with another hoisting balance container through more than two brake ropes and more than two corresponding balance wheels; each balance wheel is arranged on a balance wheel axle; the balance wheel axle is arranged on an elastic bearing device through a bearing; the wheel edge of the balance wheel is provided with a friction brake surface; a damper brake is arranged below the balance wheel; and an idle stroke distance exists in the upward direction and the downward direction of the damper brake and the friction brake surface of the balance wheel. The device not only keeps the advantage of the less investment cost of single-rope hoisting, but also has the safety property of multi-rope falling prevention protection, can completely solve the problems that a falling protector cannot be actuated when rope breaking case crashing or rope sliding case crashing happen in a traditional falling protector system, buffer brake force is uncertain, and the buffer brake force is difficult to be accurately calibrated in an use site, and has the advantages of strong safety and reliability and wide application range.

Owner:河北省安全生产监督管理局安全科学技术中心

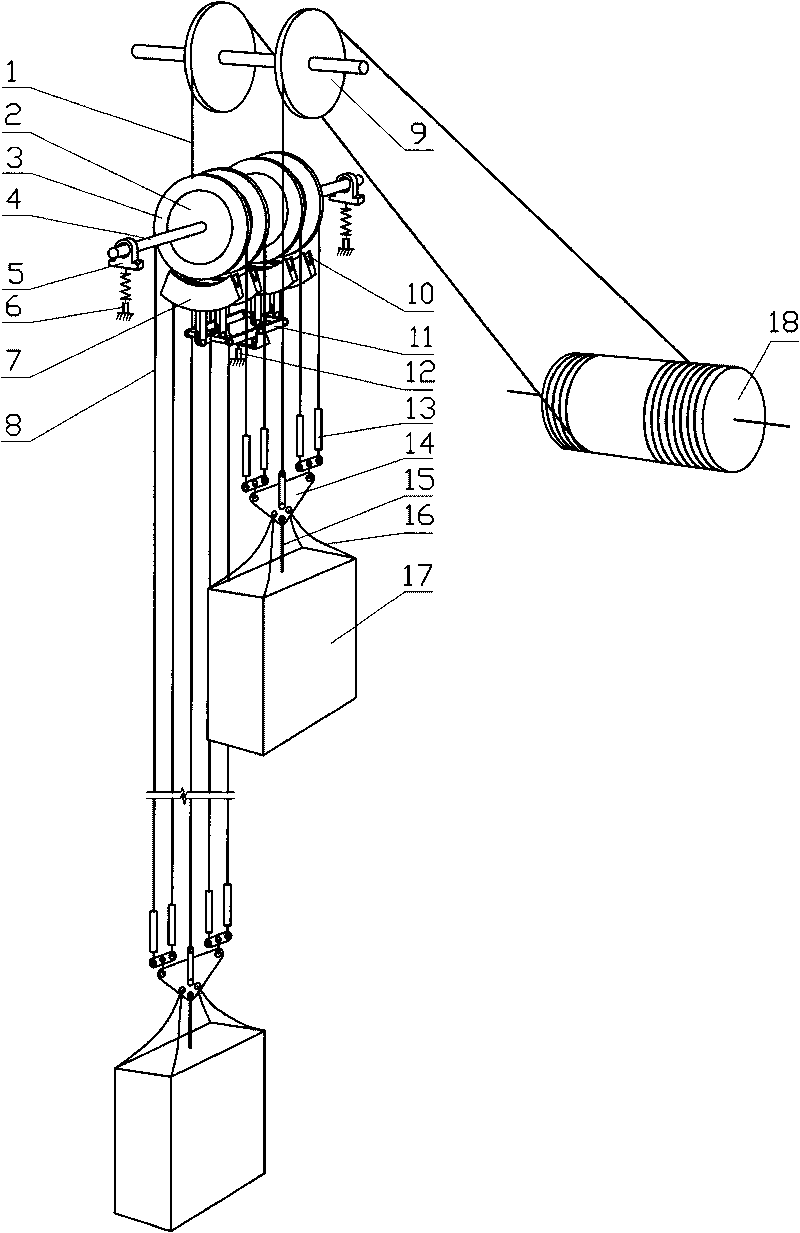

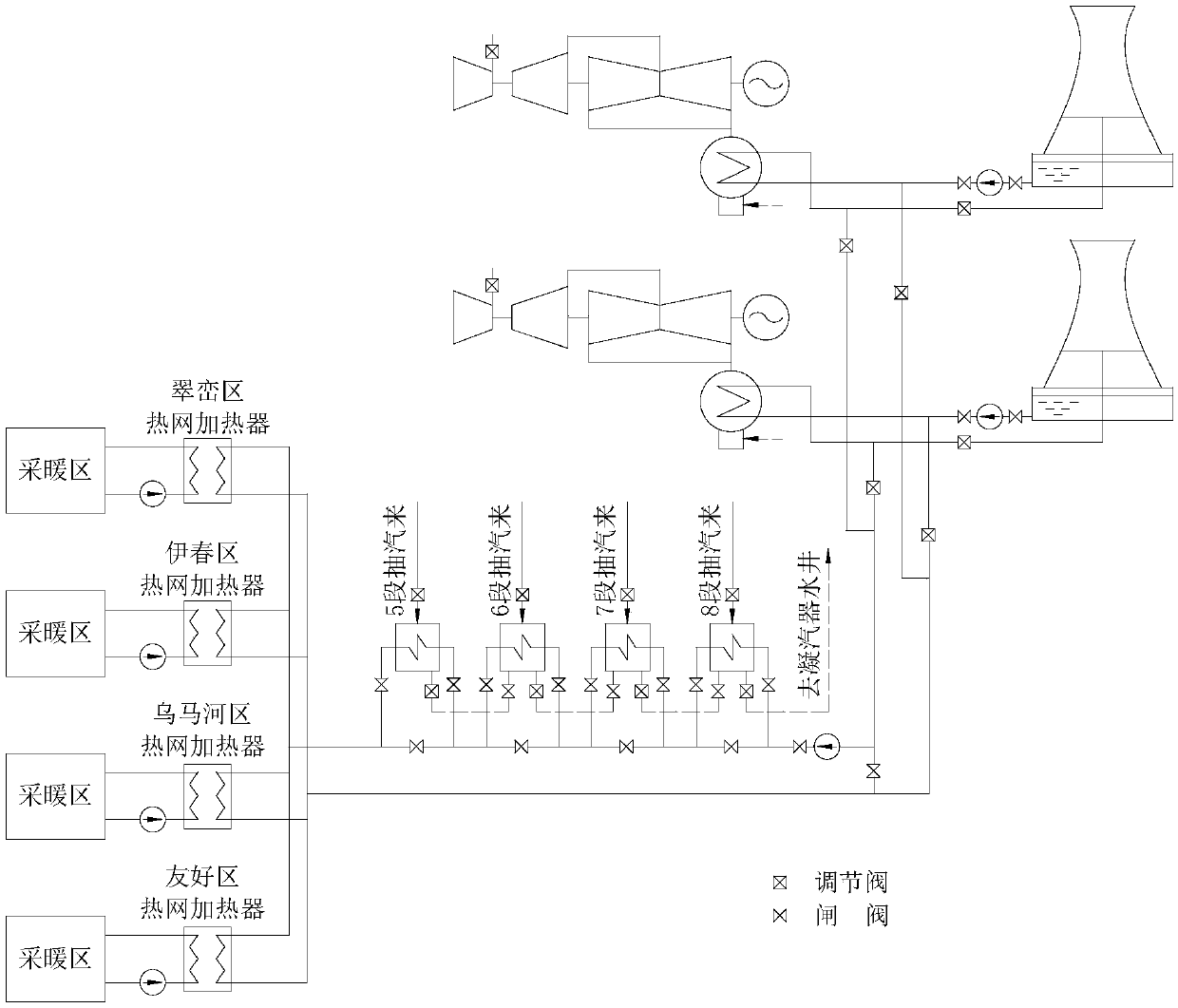

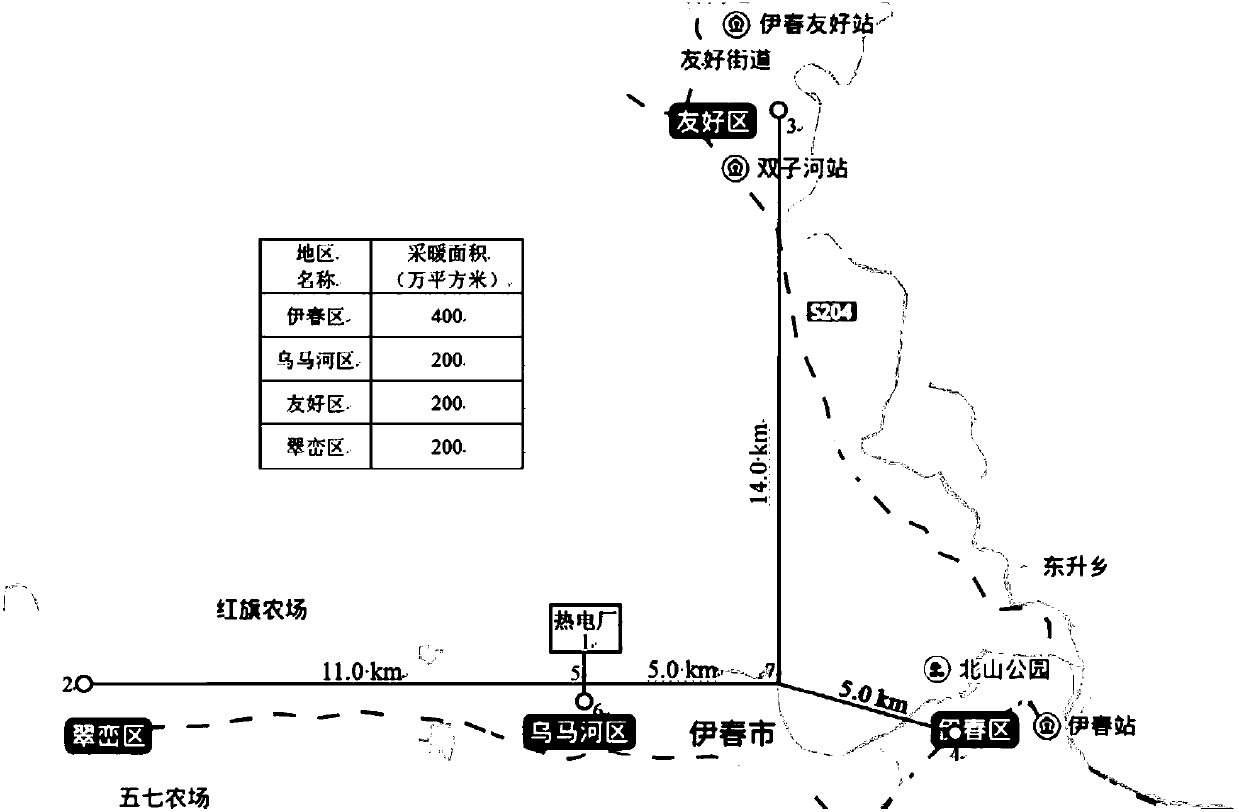

Target control method for heating power generation system

InactiveCN108119940AIncrease flexibilityImprove stabilityLighting and heating apparatusCentral heating componentsMathematical modelHigh energy

The invention provides a target control method for a heating power generation system. The target control method is suitable for various models and capacities of condensing steam turbines used for heating in all heating areas and safely realizes zero cold source heat loss in the heating of steam turbine condenser circulating water within the normal exhaust temperature range on the premise of not needing to reconstruct a steam turbine body, and the method has the beneficial effects that the effects of saving energy, saving the funds and shortening the construction period are realized for enterprises, the environment is protected, and the haze is reduced. During the heating of the circulating water, a unit can also participate in the peak shaving of a power grid and make the power grid operate more safely and stably. The heating radius of a hot water network exceeds the heating radius generated by means of the prior art and can reach 120-150 km. Meanwhile, a mathematic model is established to solve the operating parameter target values with the golden section algorithm, and the control with the highest energy supply efficiency as the target is achieved. The solution to the target values is more accurate, and scientific control measures are used to ensure the optimized, safe and reliable operation of the heating power generation system.

Owner:NORTHEAST DIANLI UNIVERSITY

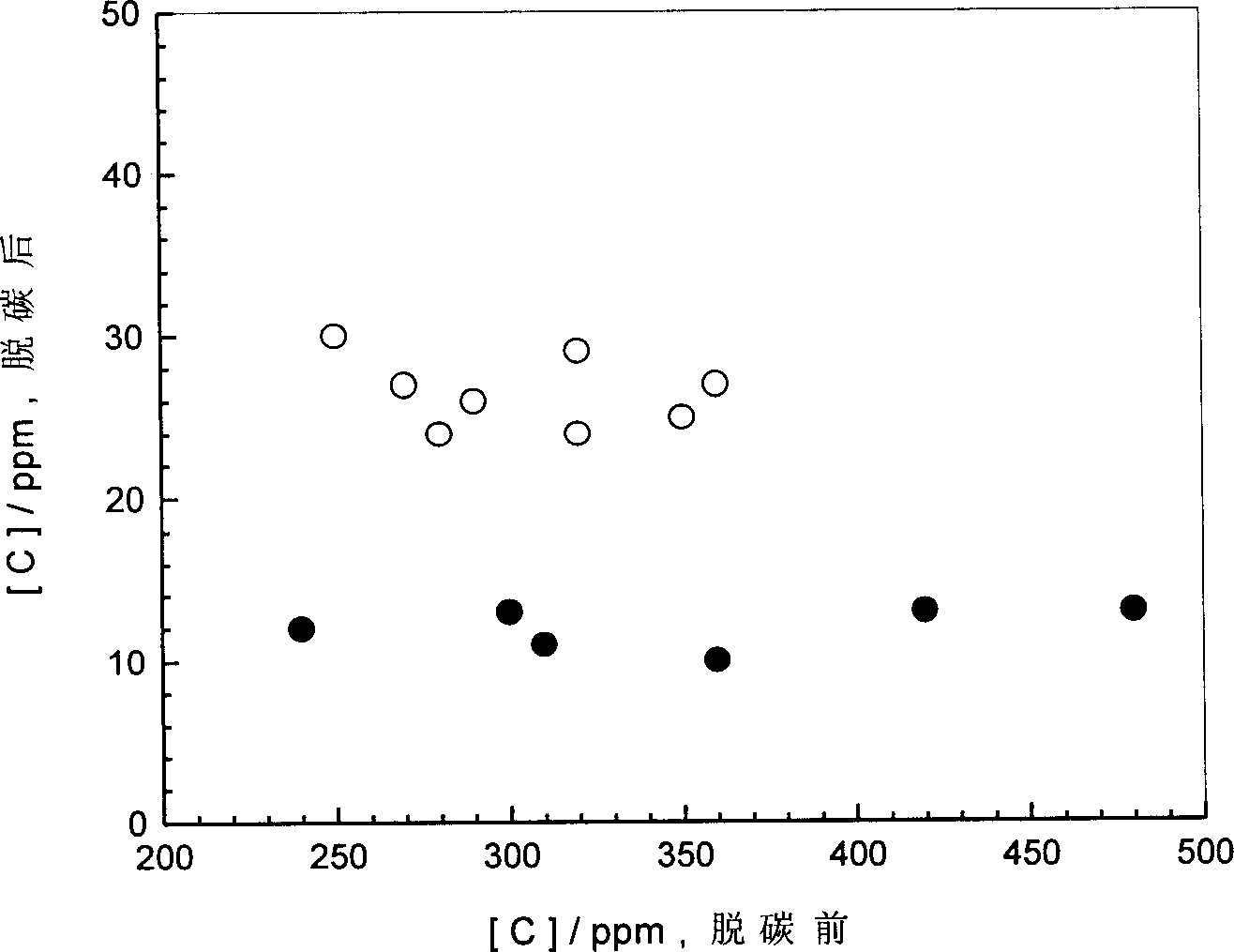

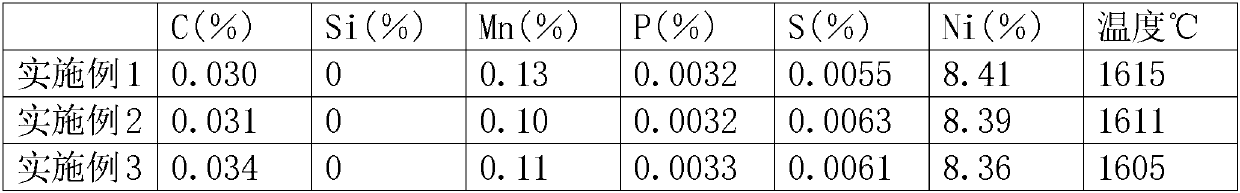

Method of producing super low carbon steel using vacuum degassing

InactiveCN1410559AAvoid damageSolve the problem that the decarburization ability increases with the erosion of the inner diameter of the insertion tubeMetallurgyVacuum level

A process for preparing ultralow-carbon steel by vacuum degassing features that the argon flow and the vacuum level are dependent on the service age of the furnace, that is, for the initial 20 batches, the argon flow is matched with inner diameter of insertion-in tube, and for the following batch whose decarbonizing time is longer than 5 min, the argon flow is increased by more than 20%. Before decarbonizing the molten steel, the vacuum chamber is depressurized in advance. Within 0-10 min after beginning decarbonization, the depressurizing speed is increased.

Owner:武钢集团有限公司

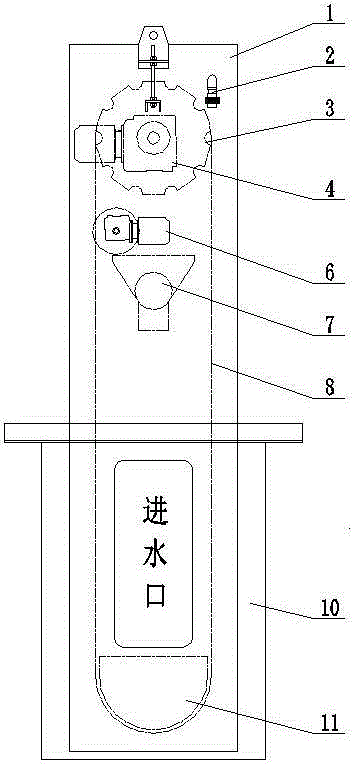

Inner flow feeding type silk screen grating cleaner

InactiveCN105169792AEfficient removalCompact structureMoving filtering element filtersGratingEngineering

The invention relates to an inner flow feeding type silk screen grating cleaner which comprises a driving device, a rack, a transmission chain group, a washing brush, a washing system, a slag collection slot and a guide wheel. The inner flow feeding type silk screen grating cleaner is characterized by further comprising a filtering screen assembly, wherein the transmission chain group mainly comprises a chain plate, a pin shaft and a rolling wheel; the pin shaft is in a hollow structure; the filtering screen assembly comprises a collection plate, a screen plate frame, an upper sealing head, a hinged chain shaft, a filtering screen and a lower sealing head; the filtering screen is formed in a manner that a stainless steel screen is connected to a round stainless steel silk screen frame. The cleaner has the characteristics of being compact in structure, reliable, durable, easy to operate, low in equipment transformation investment, low in treatment expense, low in energy consumption, capable of achieving continuous work and effectively replacing common grating device in an existing sewage treatment plants, and the like.

Owner:江阴天汇环保设备有限公司

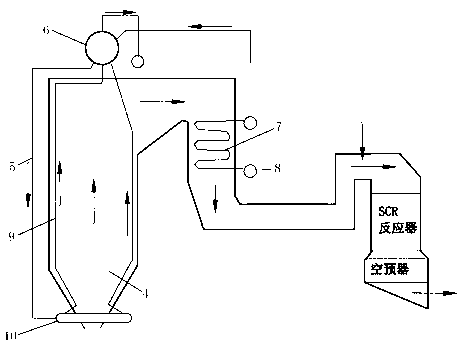

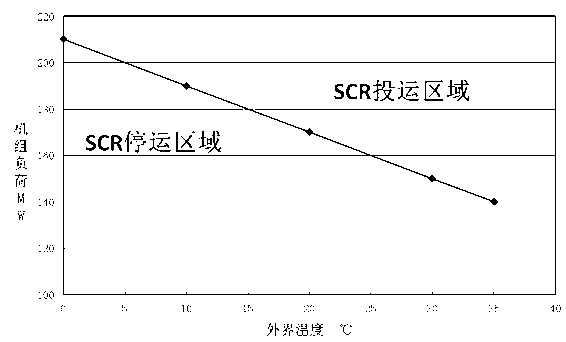

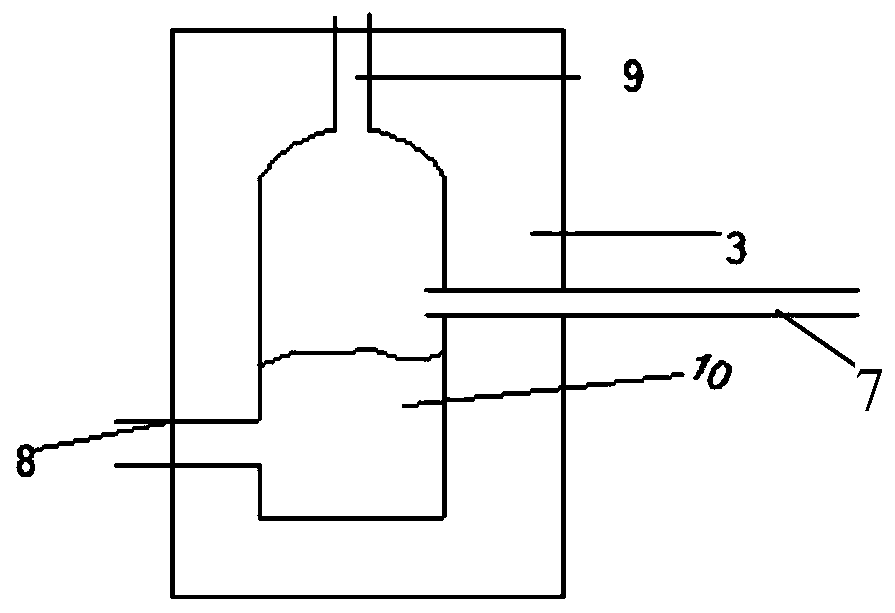

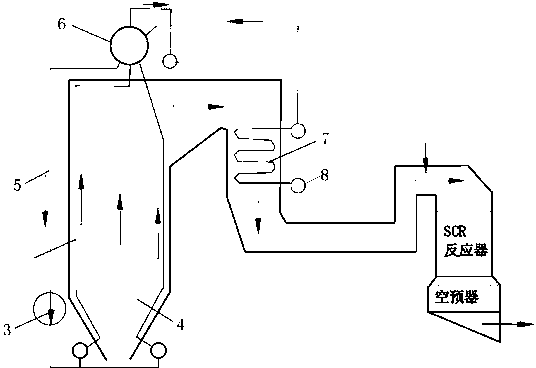

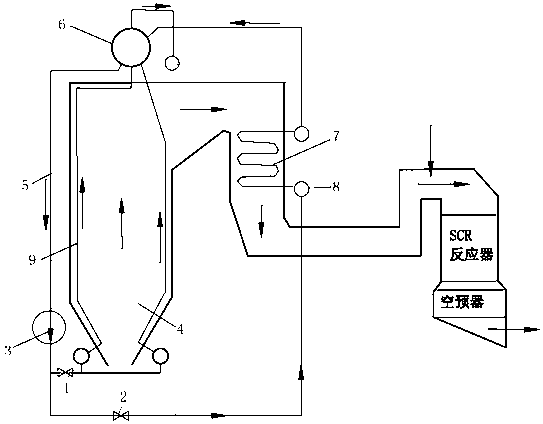

Natural circulating drum boiler with smoke temperature rising system

InactiveCN103343959AIncrease temperatureSmall temperature differenceFeed-water heatersUltra high pressureEngineering

The invention relates to a natural circulating drum boiler with a smoke temperature rising system. The natural circulation drum boiler comprises a boiler body, a steam drum, a coal economizer, an SCR reactor, an air pre-heater and the smoke temperature rising system. A downcomer of the steam drum is connected with a low water drum of the boiler body. The temperature rising system is composed of a water pump, a switch valve and an electric adjusting valve. The low water drum of the boiler body is connected with an inlet pipe of the water pump through the switch valve, and an outlet pipe of the water pump is connected with a water feeding inlet pipe of the coal economizer in parallel through the electric adjusting valve. A check valve is connected between an outlet of the water pump and the electric adjusting valve. The smoke temperature rising system is applicable to subcritical and ultra-high pressure natural circulation drum boilers, the SCR reactor can be made to run normally under the conditions / condition of low loads and / or low atmosphere temperature, and therefore the smoke emission quality of the subcritical and ultrahigh pressure natural circulation drum boilers under the conditions / condition of the low loads and / or the low atmosphere temperature can reach national standards.

Owner:上海上电电力工程有限公司

Device and method for strengthening A2/O denitrification

ActiveCN102583897AGuaranteed uptimeSolve floatingMultistage water/sewage treatmentMunicipal sewagePhysics

The invention discloses a device for strengthening A2 / O denitrification. The anaerobic region of the AAO device and a sludge denitrification pond are connected, the aerobic region of the AAO device is connected with a settling pond, and the sludge denitrification pond is connected with the anaerobic region of the AAO device. The settling and sludge storage functions of the settling pond are separated through technological adjustment, the functions of the original sludge concentration pond are expanded, the original sludge concentration pond is upgraded into the sludge denitrification pond, the overall performance of the sewage treatment system is enhanced, the energy-saving stable and efficient denitrification and dephosphorization of the combined system are realized under the condition of not adding structures, and a theoretical basis and technical support are provided for the upgrading and reconstruction of a municipal sewage treatment plant.

Owner:BEIJING UNIV OF TECH

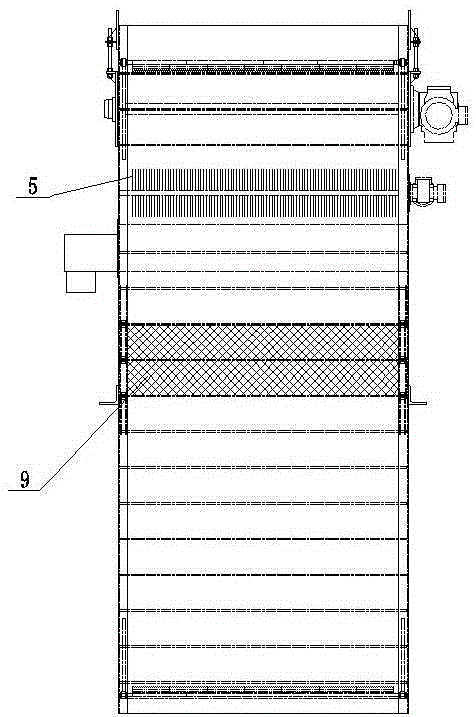

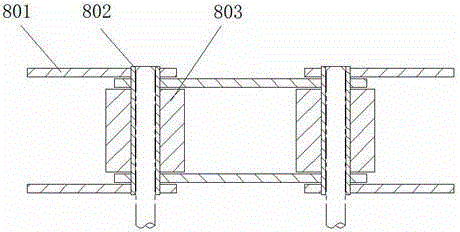

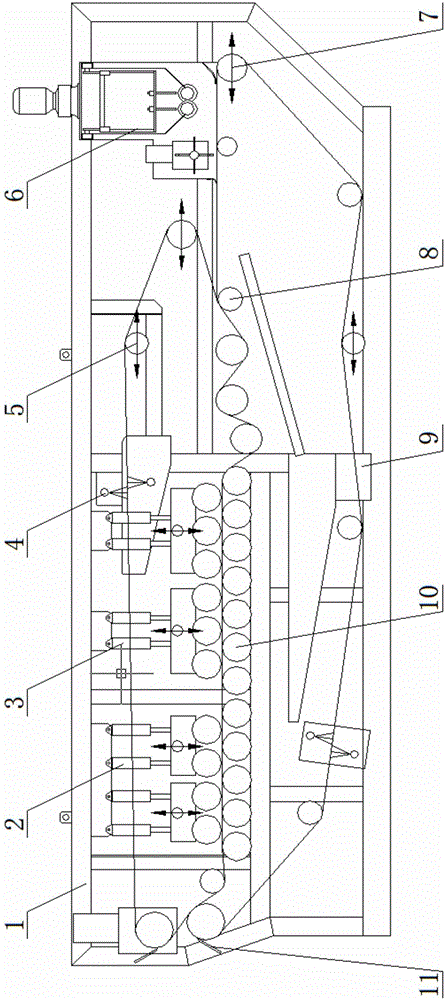

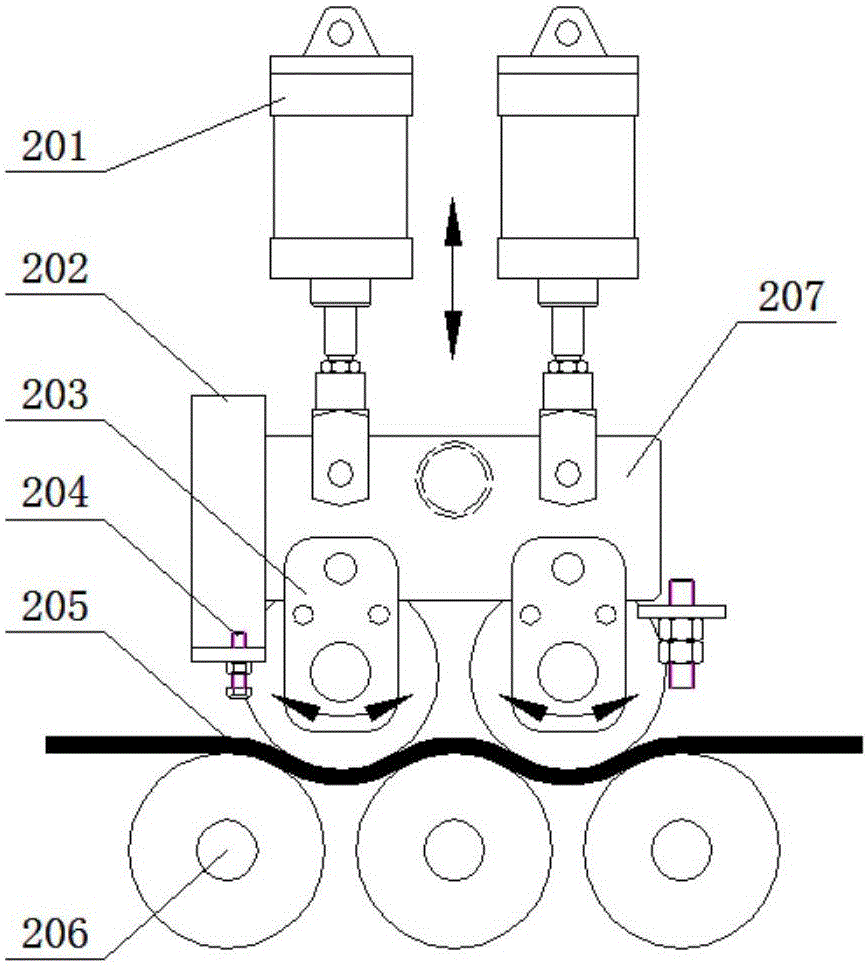

Belt filter press for sludge dehydration

ActiveCN105107251ACompact structureEasy to operateMoving filtering element filtersSludgeControl system

The invention discloses a belt filter press for sludge dehydration. The belt filter press comprises an upper filter belt, a lower filter belt, a frame, a pressing area, a rinsing device, a rectification and protection device, a synchronous tensioning device, a transmission and unloading device, an electric connection box, a pneumatic control system, and a uniform material distributing device (6), wherein the pressing area comprises a pre-pressing arrangement area (8), a low-pressure pressing area (3) and a high-pressure pressing area (2); the lower filter belt is connected with the upper filter belt in the pre-pressing arrangement area (8) after passing through the uniform material distributing device (6), and then the upper and lower filter belts pass through the low-pressure pressing area (3) and the high-pressure pressing area (2), and are separated from the transmission and unloading device. The belt filter press is novel high-pressure belt press dehydration equipment for deep dehydration of sludge of which the moisture content is about 80 percent, is compact in structure, reliable and durable, and can be effectively butted with the conventional equipment of a belt (concentration) filter press, a centrifugal machine and the like in a sewage treatment plant.

Owner:WUXI KINGHOPE ENVIRONMENTAL ENG CO LTD

Corn germ pretreatment processing technology to eliminate mycotoxin in corn oil

ActiveCN106010771AReduce or even eliminate mycotoxinsImprove hygiene qualityFatty-oils/fats refiningFatty-oils/fats productionOzone SterilizationFungal Toxins

A corn germ pretreatment processing technology to eliminate mycotoxin in corn oil includes ozone fumigation of the corn germ, cleaning, impurity removal, modulation and softening, rolling, and alkali puffing. The ozone fumigation treatment is carried out in a closed chamber at a temperature of 5 DEG to 50 DEG C; ozone is introduced when the moisture content of corn germ is 7%-25% for ozone sterilization and mycotoxin pre-degradation for 0.5-48 h, wherein the ozone concentration is 5-50ppm. The alkali puffing is as below: adding alkali lye or steam with concentration of 5%-30% into the corn germ before corn puffing treatment or in the puffing process, wherein the addition amount is calculated by the content of mycotoxin in corn germ and the acid value of corn oil. The corn oil prepared from corn germ contains mycotoxins, such as aflatoxin B1 (AFB1) and zearalenone (ZEN), less than the national limit standard. The final product has the characteristics of low mycotoxin content, small acid value, light color, and little loss in refining.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Automobile color coating process

The invention discloses an automobile color coating process. The coating process comprises the steps of ED coating, floating coat coating, BC1 metal-color paint layer coating, BC2 transparent color paint layer coating and varnish coating. According to the coating process, the light transmission principle is utilized to improve the red color chroma and the angle-dependent color change degree, so that the red charm degree is increased; an automobile coating line does not need to be changed in a large range, by adding one color paint can, the red color chroma can be greatly higher than that of the existing colors, and the 15-degree chroma of the red color adopting the coating process can reach 90-100 while the 15-degree chroma of the mainstream red color in the market is 50-70. According to the coating process, the existing water-based advanced processes 3C1B and 3C2B are combined so that the energy-saving and environment-friendly effects can be effectively carried out.

Owner:湖南湘江关西涂料有限公司

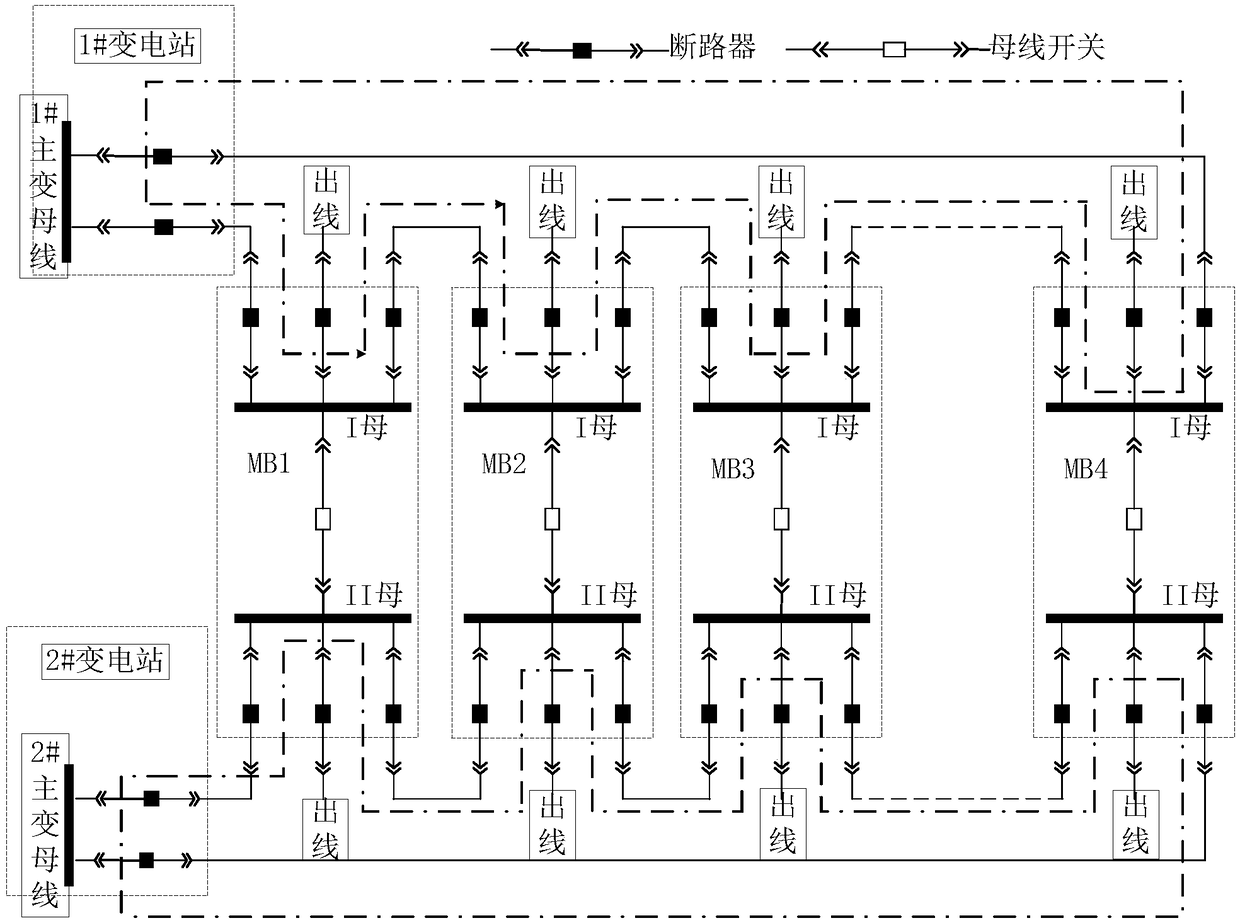

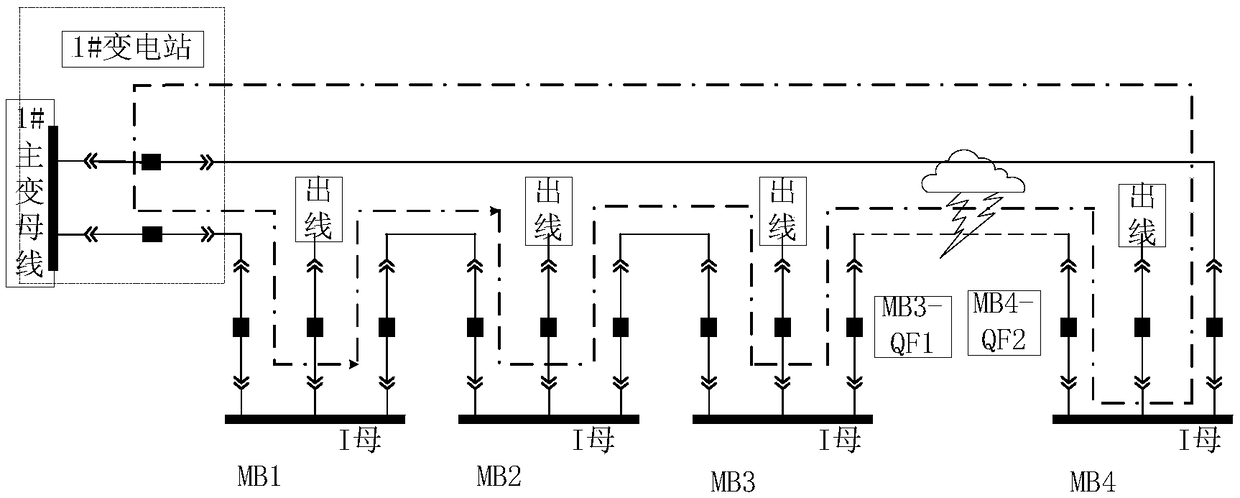

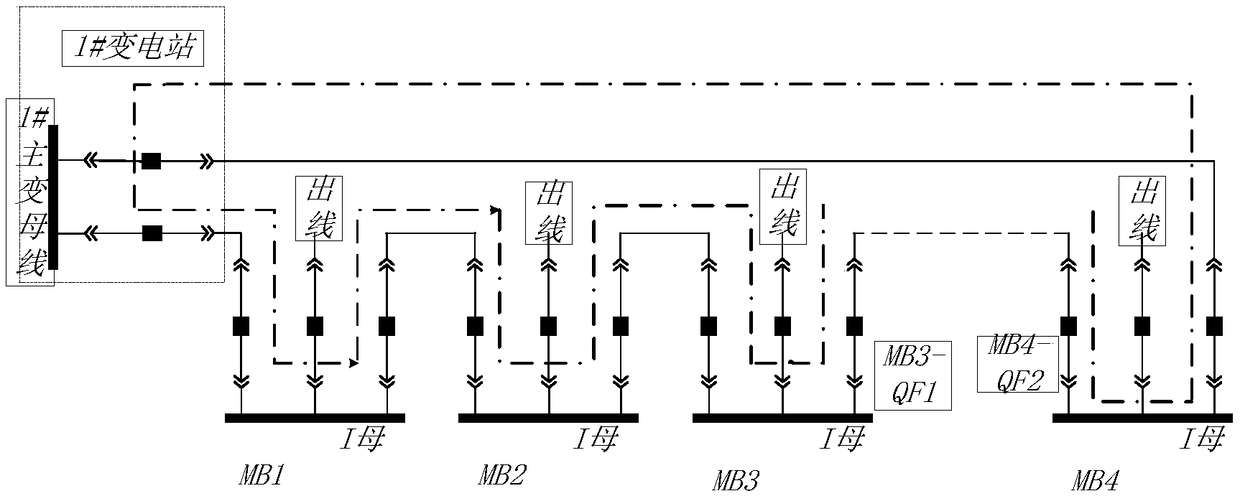

Ring differential protection method and device for distribution network

InactiveCN109193590AImprove reliabilityIncreased sensitivityEmergency protective circuit arrangementsCircuit breakerDifferential protection

The invention discloses a ring differential protection method and device for distribution network, which relates to the technical field of power network. The ring differential DTU device is arranged on a distribution station in a substation, and each DTU device is ring-connected through a gigabit optical fiber. The voltage and current data are sampled by a DTU device, and then a message is formedand sent out; Each DTU device sends the sampled value of the tie line and its own state information through the optical fiber ring network, and simultaneously receives the sampled value and the stateinformation of the equipment subscribed by the DTU device. When the launching fault occurs between two substations, the differential algorithm is used to trigger the differential action, and the circuit breaker of the two substations is disconnected and the fault is removed. A DTU device is use for collecting real-time data of whole line and establishing relay protection by utilizing line currentdifferential protection. That invention has the advantages of high reliability, fast operation speed, high sensitivity and good selectivity, thereby reducing power-off area and shortening power-off time.

Owner:NANJING FENGDAO POWER TECH

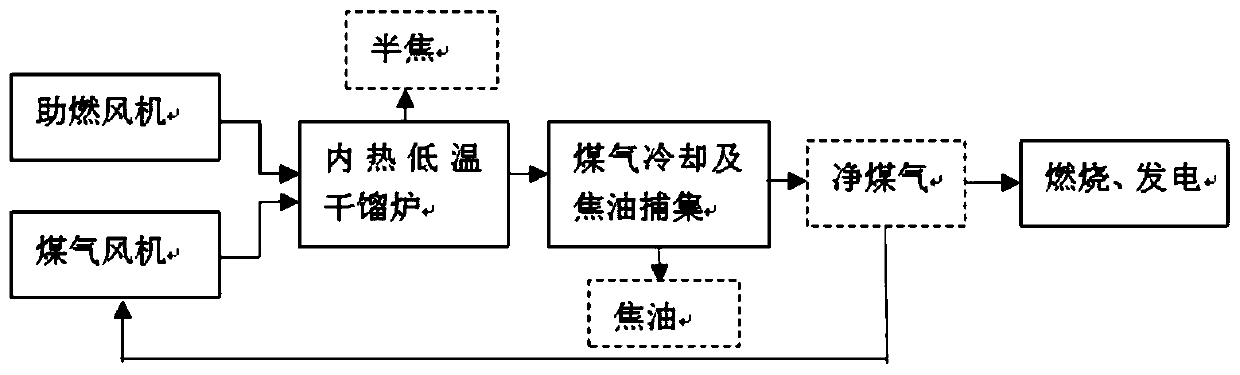

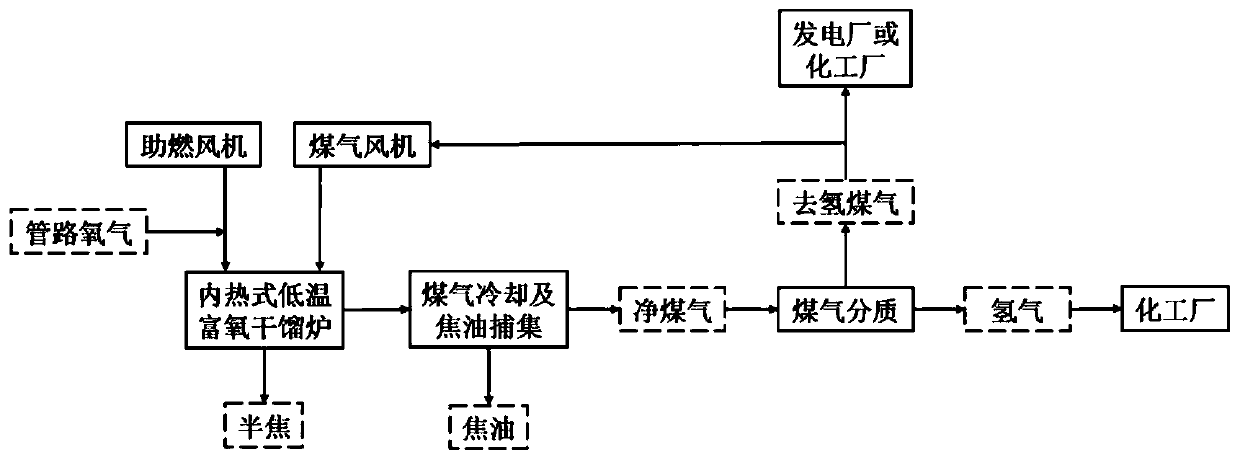

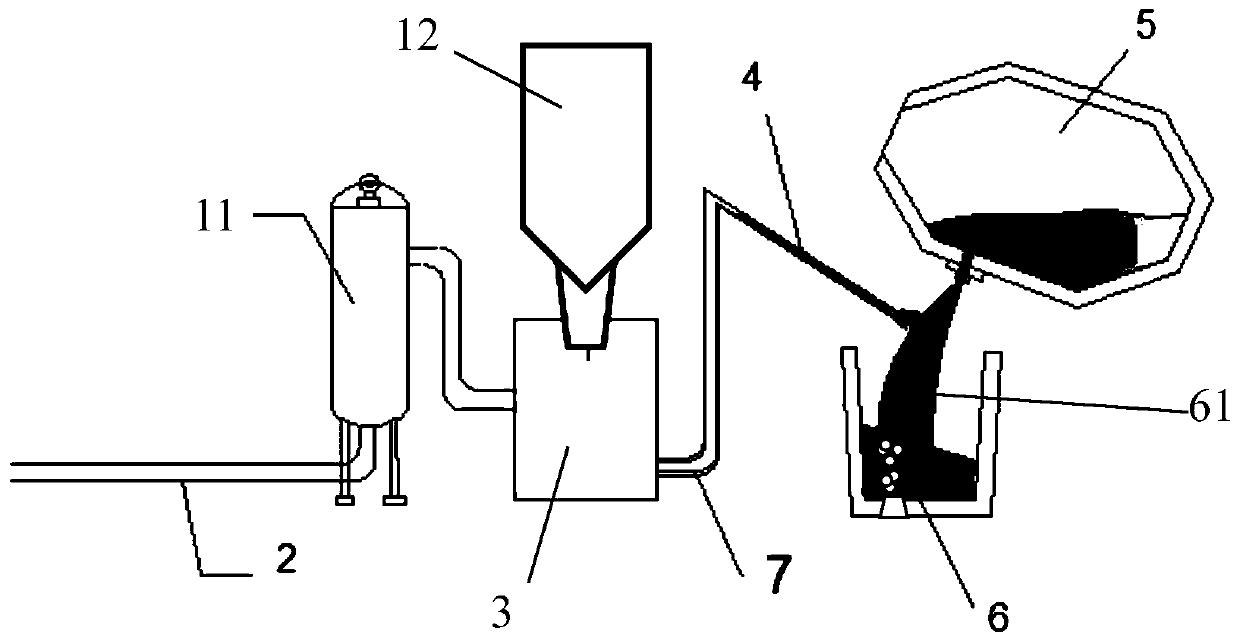

Internal heating type low-temperature oxygen-enriched destructive coal distillation process and system for quality-divided returned coal gas

ActiveCN111187632AAchieving long-term operationQuality improvementSpecial form destructive distillationThermodynamicsProcess engineering

The invention discloses an internal heating type low-temperature oxygen-enriched destructive coal distillation process and system for quality-divided returned coal gas. The process comprises the following steps: introducing dehydrogenated coal gas, air and oxygen into an internal heating type low-temperature destructive coal distillation furnace; mixing the air and the oxygen to form oxygen-enriched combustion-supporting gas; and subjecting the dehydrogenized coal gas and the oxygen-enriched combustion-supporting gas to oxygen-enriched combustion in the internal heating type low-temperature destructive coal distillation furnace, wherein the volume fraction of oxygen in the oxygen-enriched combustion-supporting gas is greater than or equal to 30%. A step of acquiring the dehydrogenated coalgas comprises the following sub-steps: carrying out coal gas cooling and tar trapping on coal gas generated by the internal heating type low-temperature destructive coal distillation furnace to obtain purified coal gas; separating and removing hydrogen in the purified gas so as to obtain the dehydrogenated gas. According to the invention, the flame length and the flame temperature of a flame pathcan better meet the requirements of a low-temperature destructive distillation process, the influence of too high combustion speed of oxygen-enriched destructive distillation high-hydrogen-content coal gas is reduced, the long-period operation of an oxygen-enriched destructive distillation process device and the stable quality of dry distillation products are realized, and the high-added-value gradient utilization of the coal gas can be realized.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Single-fuel liquified-petroleum-gas automobile cold-state starting heat-insulation preheating system

InactiveCN101025131ASpeed up evaporationReliable startInternal combustion piston enginesFuel supply apparatusControl systemControl line

The invention relates to the automobile and engine cold starting technique, especially relating to an automobile cold starting heat-preservation preheating system adopting single fuel liquefied petroleum gas, comprising the original engine cooling system, preheating small circulating system and preheating control system, characterized in that: the preheating small circulating system is connected in parallel in the original engine cooling system and comprises evaporator, heat preservation jar and an electric water pump, where the heat preservation jar is connected in series in the cooling liquid loop behind the evaporator and the inlet and outlet of the heat preservation jar are equipped with electromagnetic valves, the inlet and outlet where the cold starting preheating system and the original engine cooling system are connected in parallel are respectively equipped with change valves, the electric water pump is installed between the two change valves and the control unit is connected through control lines with the engine, electromagnetic valves, change valves and electric water pump.

Owner:JILIN UNIV

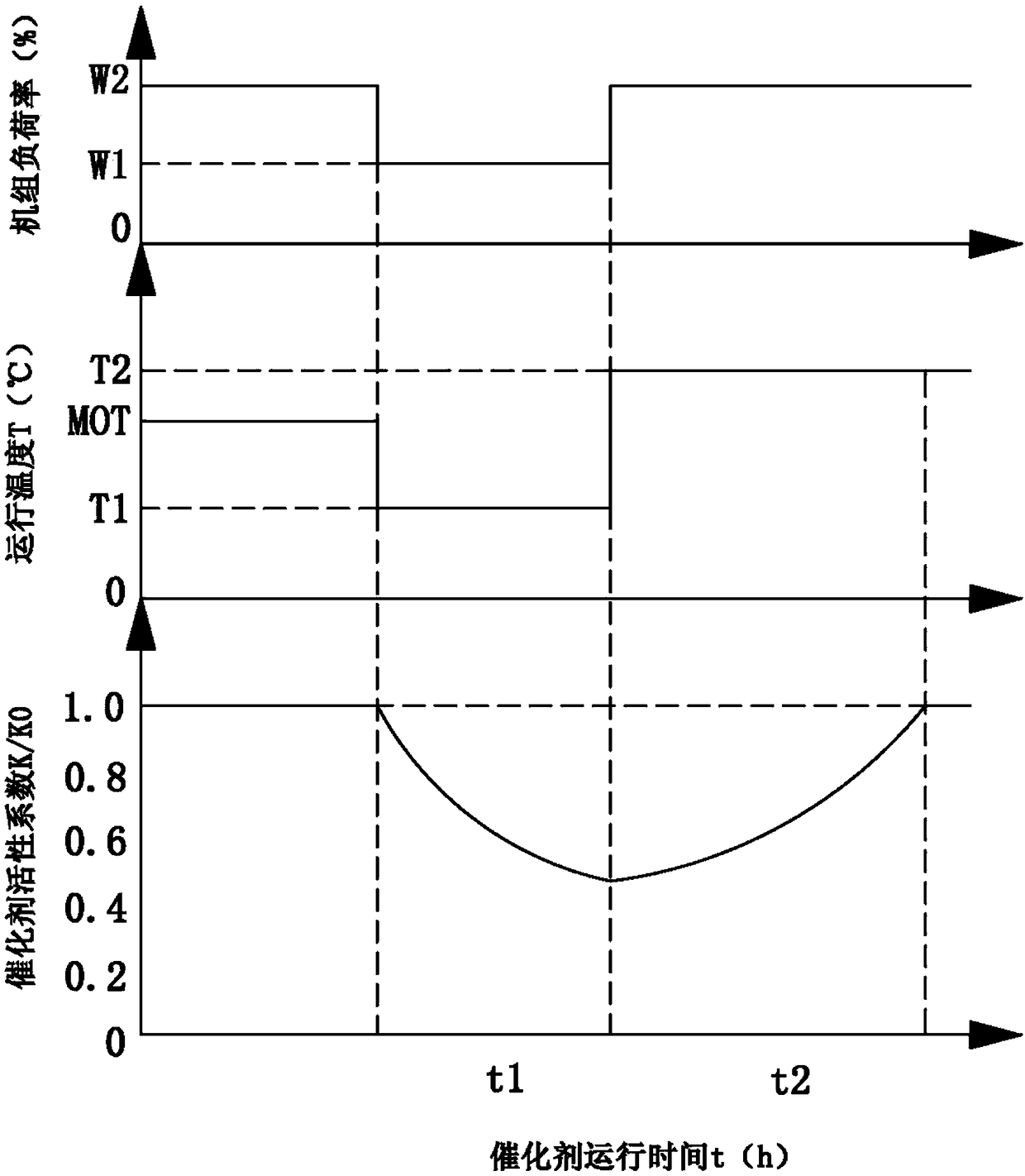

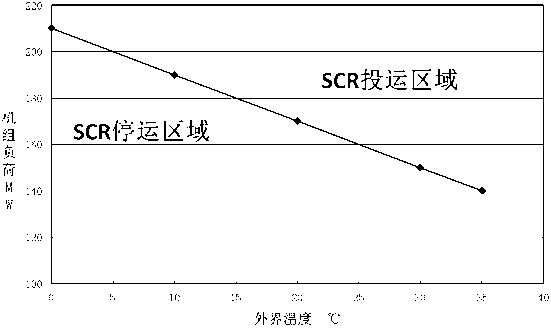

Method for widening SCR denitration low-load operation potential based on ammonium bisulfate poisoning recovery characteristics of catalyst

ActiveCN109433011AReduce operational riskRenovation investment is smallDispersed particle separationEngineeringAmmonium bisulfate

The invention relates to a method for widening SCR denitration low-load operation potential based on ammonium bisulfate poisoning recovery characteristics of a catalyst. The method includes determining the lowest continuous ammonia injection temperature of the catalyst; enabling the catalyst to continuously operate at the temperature T1, wherein T1 is lower than the lowest continuous ammonia injection temperature, the continuous operation time is t1, the unit load corresponding to T1 is W1; and after the continuous operation time of the catalyst at the temperature T1 exceeds t1, enabling the operation temperature of the catalyst to be increased to T2 for continuous operation, wherein T2 is not lower than the minimum continuous ammonia injection temperature, the continuous operation time ist2, the unit load corresponding to T2 is W2, and the difference value between W1 and W2 is the percentage or potential that the SCR denitration low-load operation of the unit can be widened. The method does not need to preform temperature raising transformation on on-site equipment, fully utilizes the low-load adaptability of the catalyst to realize the wide-load operation of the denitration system, reduces transformation investment, avoids the shutdown from affecting the power generation of the unit, and reduces the risk of affecting the normal operation of the unit due to the equipment transformation.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

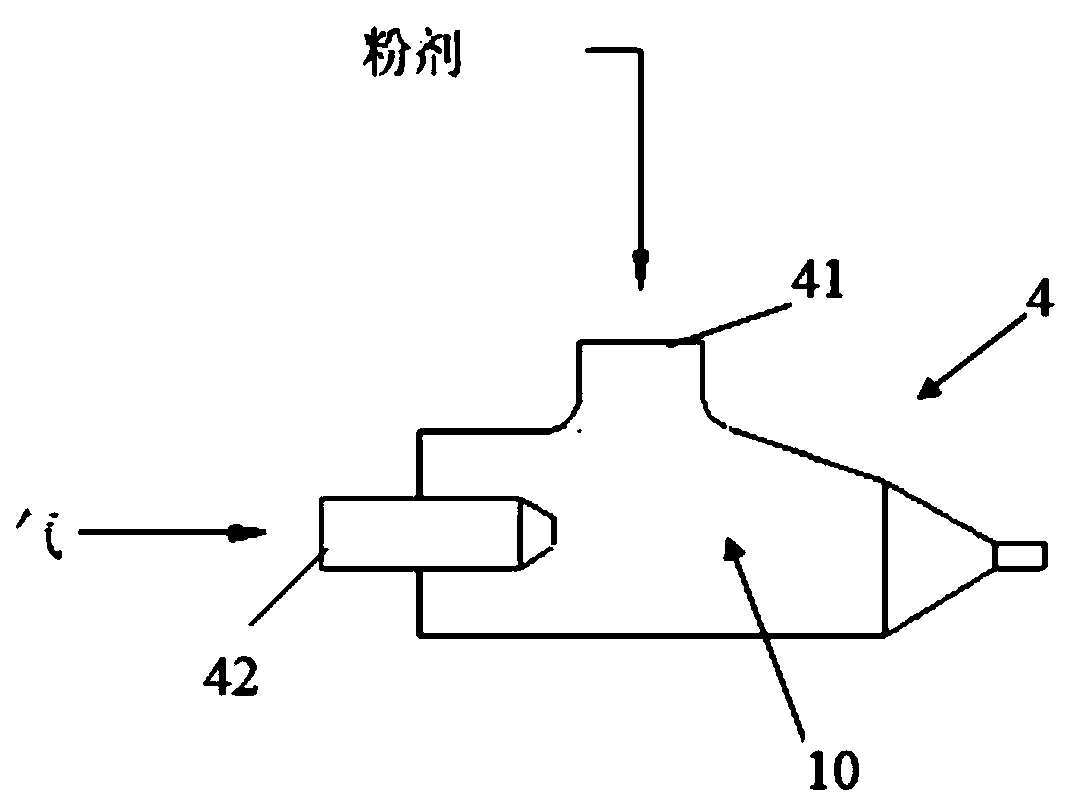

Converter tapping injection refining desulfurization method and device

The invention provides a converter tapping injection refining desulfurization method and device. In the converter tapping process, with Ar (or N2) as powder spraying carrier gas, a spraying gun injects powdery desulfurization agents to molten steel streams in the tapping process, so that the powdery desulfurization agents are fed in a ladle with the molten steel streams; and the full mixing is realized under the effect of bottom blowing argon stirring of the ladle, so that the contact specific surface area of the powdery desulfurization agents and molten steel is increased, the inter-phase mass transfer speed and the molten steel desulfurization reaction speed are accelerated, the effective utilization efficiency of the powdery desulfurization agents is improved, the desulfurization refining production takt is accelerated, and the continuous stable efficient refining is realized. The defects in a traditional desulfurization process can be overcome; and the quick and efficient smeltingcan be realized. The powdery desulfurization agents can be replaced by carbon powder, desulfurization powder agents, desulfurization powder agents or alloy powder agents; and the multifunctional refining can be realized. The device and the method are not only suitable for molten steel desulfurization refining processes, but also suitable for other refining processes.

Owner:NORTHEASTERN UNIV

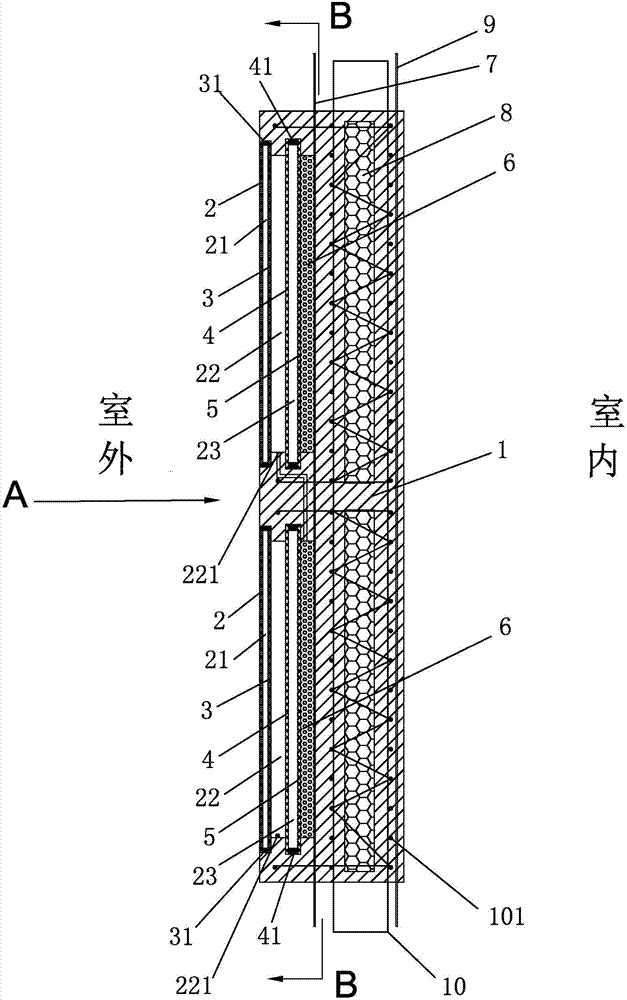

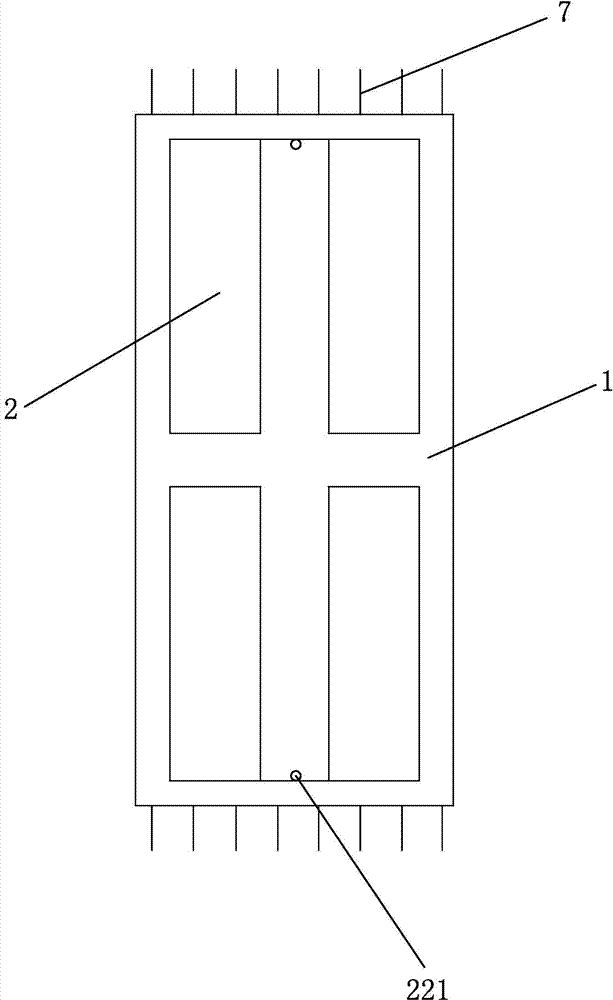

Prefabricated capillary energy-storage heat-dissipation wall

ActiveCN104294958ARenovation investment is smallEven distribution of water flowDispersed particle filtrationWallsElectricityThermal insulation

The invention relates to a prefabricated capillary energy-storage heat-dissipation wall. The prefabricated capillary energy-storage heat-dissipation wall comprises a concrete wall, the concrete wall is sequentially provided with a first tempered glass layer, a second tempered glass layer, a first-stage dedusting filter screen, a second-stage dedusting filter screen, an air adsorption layer, a passive heat source ground heating capillary pipe net, thermal insulation materials and a wall body capillary pipe net from outside to inside. The periphery of the first tempered glass layer and the periphery of the second tempered glass layer are sealed through first sealing glue to form a closed first air layer, a closed second air layer is formed between the first-stage dedusting filter screen and the second tempered glass layer, the periphery of the first-stage dedusting filter screen and the periphery of the second-stage dedusting filter screen are sealed through second sealing glue to form a closed third air layer, the second-stage dedusting filter screen is in close contact with the air adsorption layer, and the capillary pipe nets are in close contact with the air adsorption layer. The prefabricated capillary energy-storage heat-dissipation wall is convenient to install and use and low in cost, strong air and noise pollution can be avoided, the electricity consumption is small, and energy is saved.

Owner:安徽中宝建材科技有限公司

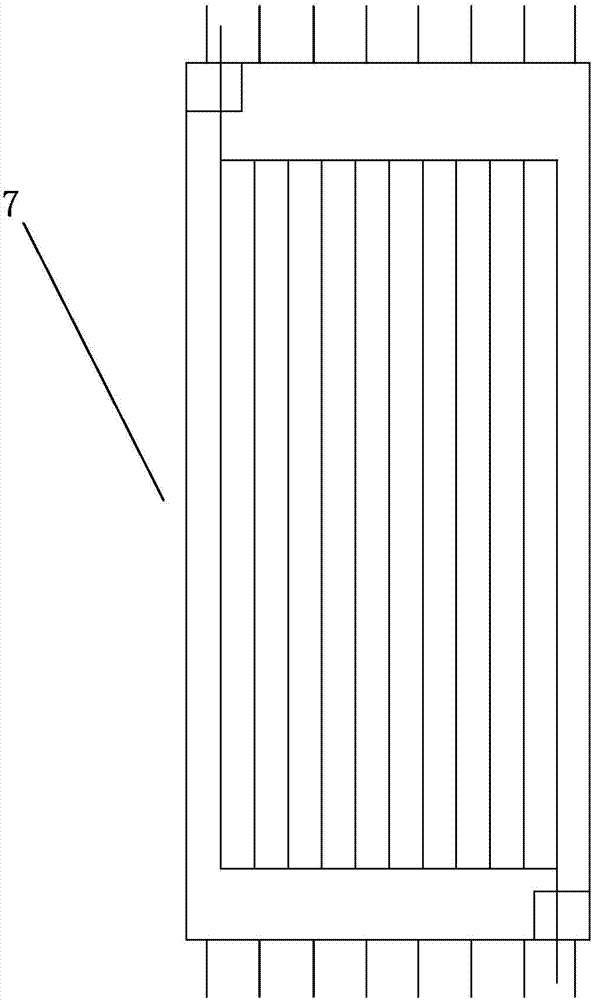

Method for improving reconstituted cut tobacco blending accuracy

ActiveCN104770846ALess investmentShort construction periodTobacco preparationProduction lineEngineering

The invention discloses a method for improving reconstituted cut tobacco blending accuracy. On a cigarette shredding production line, prepared reconstituted cut tobacco end products are subject to a moisture adjust and control procedure to be humidified or dried to enable the moisture content of reconstituted cut tobacco to be basically the same as cut tobacco, and then the humidified or dried reconstituted cut tobacco end products are blended with the cut tobacco according to the formula ratio. By adoption of the method, the content of reconstituted cut tobacco dry matters blended in each batch conforms to the formula demand, fluctuation of the reconstituted cut tobacco blending ratios between different batches is reduced, accordingly, the reconstituted cut tobacco blending accuracy is improved, and influence on the product quality from change of the moisture content of reconstituted cut tobacco is reduced. Compared with other methods, the method provided by the invention has the advantages that the process change is small, the changing investment is low, new workshops or rebuilding of workshops are not needed and the energy consumption is low.

Owner:CHINA TOBACCO YUNNAN IND

Production line used for gluing and edge covering of automobile door cover

ActiveCN104668322ACompact layoutSmall footprintLiquid surface applicatorsMetal-working feeding devicesProduction lineButt joint

The invention discloses a production line used for gluing and edge covering of an automobile door cover. The production line comprises a gluing production line and an edge covering production line which are in mutual butt joint, wherein the gluing production line comprises a combining platform; one side of the combining platform is provided with an inner plate tetrahedron rotating platform, a glue gun, a six-axis fixed robot and an inner plate gripper storing frame; the other side of the combining platform is provided with an outer plate positioning platform, a combining platform switching storage region, an outer plate seven-axis robot and an outer plate gripper storing frame; the edge covering production line sequentially comprises a special pre-edge-covering machine, a pressing machine and a special inner edge covering machine; a buckling gripper storing frame and a buckling seven-axis robot are arranged between the special pre-edge-covering machine and the pressing machine; an assembly seven-axis robot and an assembly gripper storage frame are arranged between the pressing machine and the special inner edge covering machine; the special pre-edge-covering machine is located behind the combining platform. The production line has the beneficial effects that gluing and edge covering processes of a plurality of types of automobile door covers are automatically finished by the machine; the quality of the product is stable and reliable, the automation degree is high and the commonality is strong.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

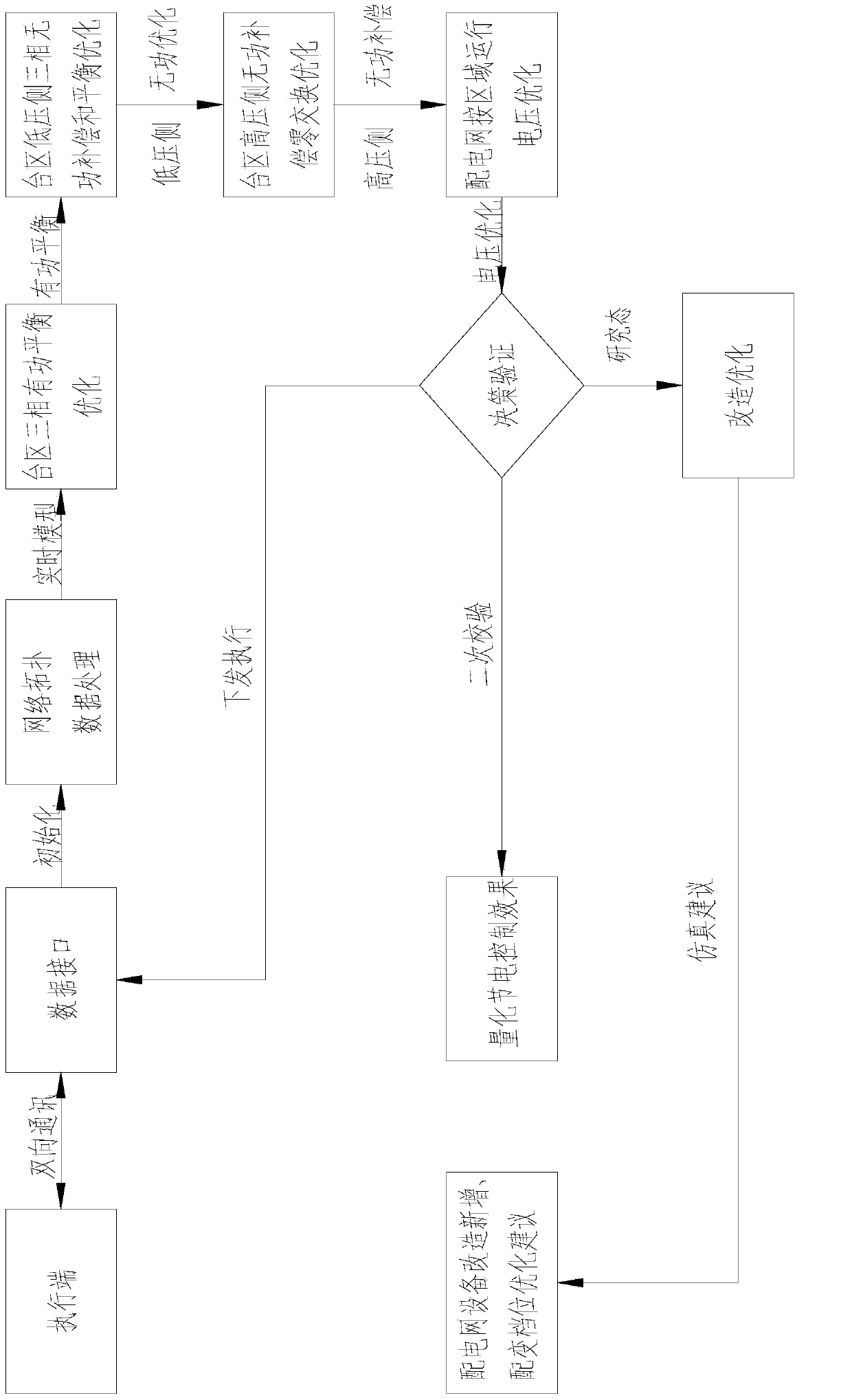

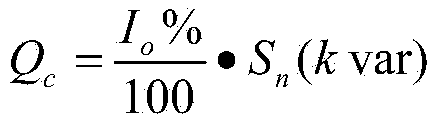

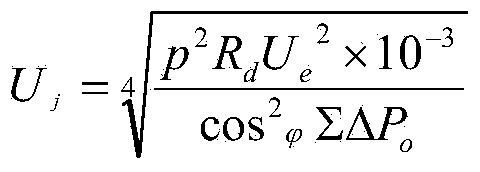

Electricity-saving method for medium and low voltage distribution network

ActiveCN103746394AReduce investmentImprove controllabilityPolyphase network asymmetry elimination/reductionReactive power adjustment/elimination/compensationElectricityThird party

The invention relates to the field of grid control, in particular to an electricity-saving method for a medium and low voltage distribution network. The invention provides the electricity-saving method for the medium and low voltage distribution network. The invention adopts a systematic thinking to save electricity for the medium and low voltage distribution network, and has the advantages of strong controllability, high reliability, easy operation, high practicability and the like. The invention adopts a content electricity-saving method, investment in the distribution network is not increased, reformation investment is small, and systematic and huge electricity saving is realized based on the existing communication network and a third-party system. The invention considers the communication compatibility of master station software, satisfies different kinds of distribution network equipment, the connection communication of the third-party system and the analytic interaction of specifications with different standards, and realizes the largest applicability and usability of application.

Owner:STATE GRID CORP OF CHINA +3

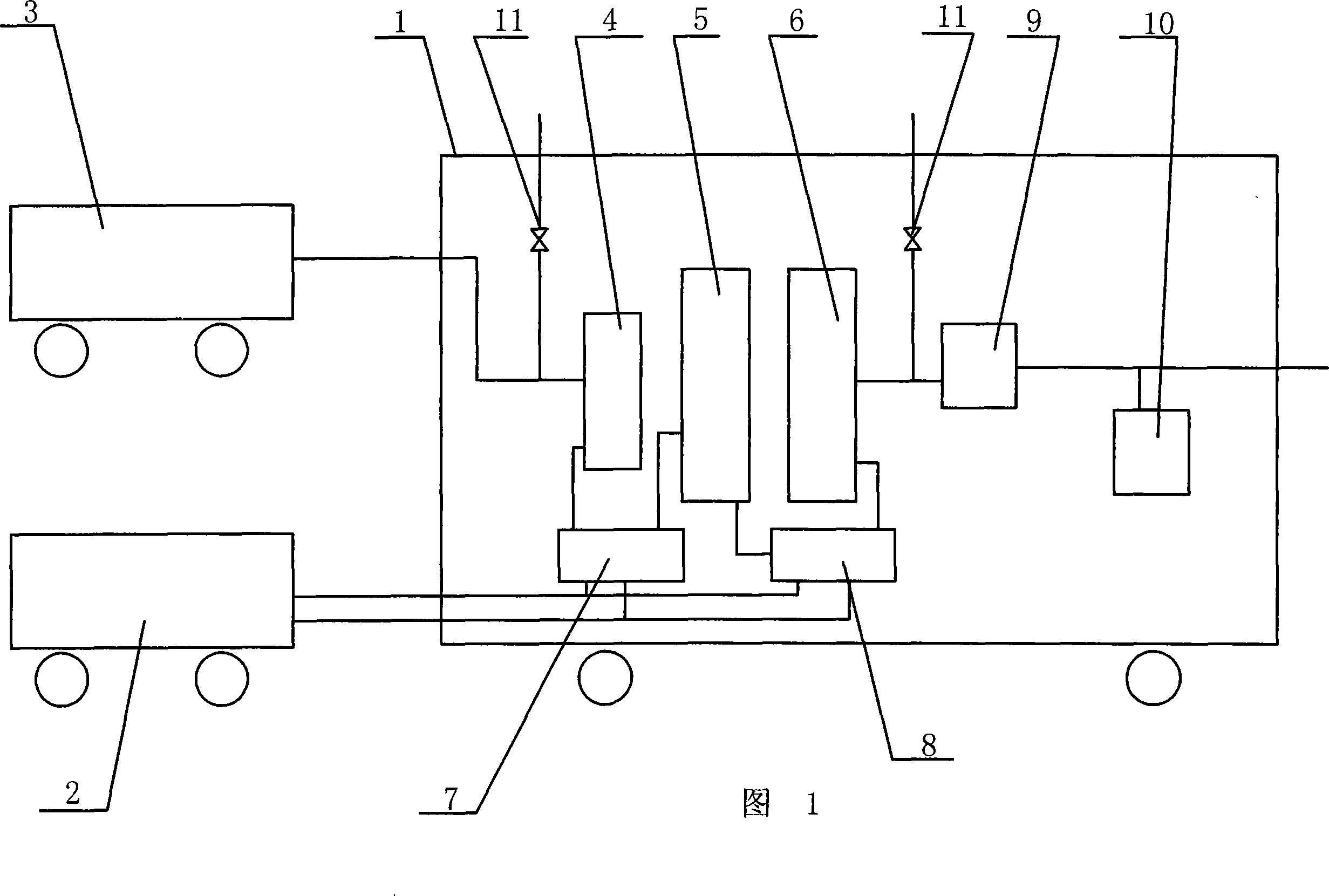

Movable emergency peak regulation gas supplying device

InactiveCN101078464ALess investmentGuaranteed uninterrupted gas supplyPipeline systemsCompressed natural gasEngineering

The invention relates to a movable emergency peak-regulation air feeder for solving problems in background technologies mainly. It is characterized in that a filter (4) is set in a skid-mounted vehicle (1); the filter (4) is connected with a first-order heat exchanger (7) by pipes; the first-order heat exchanger (7) is connected with a first-order pressure regulator (5) by pipes; the first pressure regulator (5) is connected with a second-order heat exchanger (8); the second-order heat exchanger (8) is connected with a second-order pressure regulator (6) by pipes; the second-order pressure regulator (6) is connected with a metering instrument (9); the metering instrument (9) is connected with the user gas pipe network by pipes; the filter is connected with a compressed gas truck (3) by pipes; air inlet pipes and air outlet pipes of the first-order heat exchanger (7) and the second-order heat exchanger (8) are connected with air inlet pipes and air outlet pipes of boiler truck (2) by pipes respectively. The movable emergency peak-regulation air feeder is provided with no-need stopping gas, safety and reliability, flexibility and small investment.

Owner:DAQING PETROLEUM ADMINISTRATION

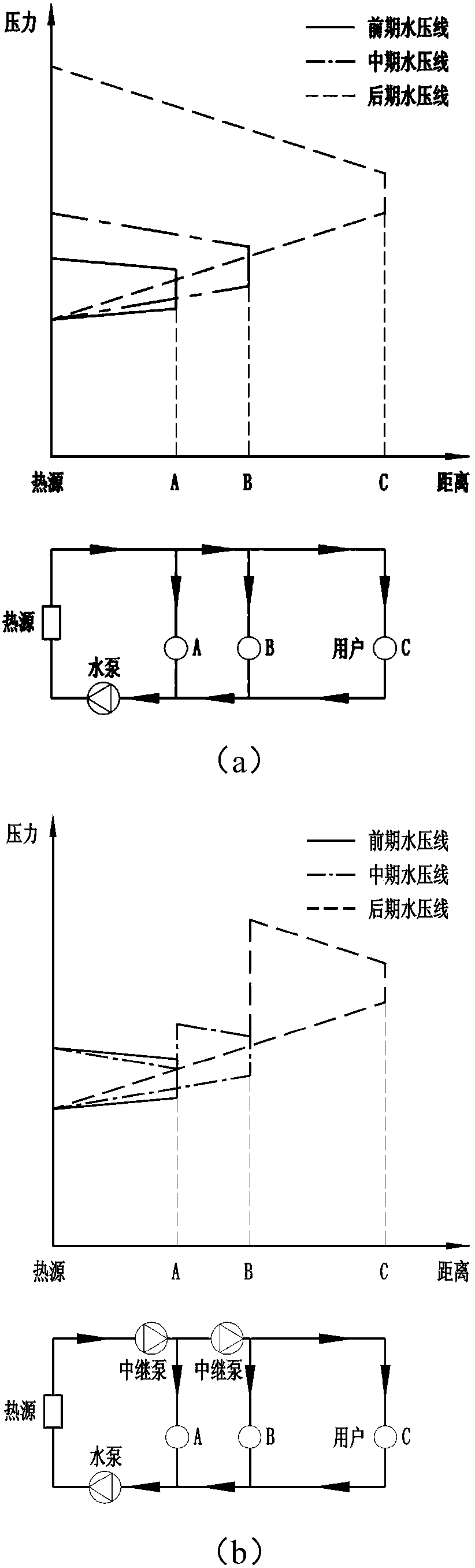

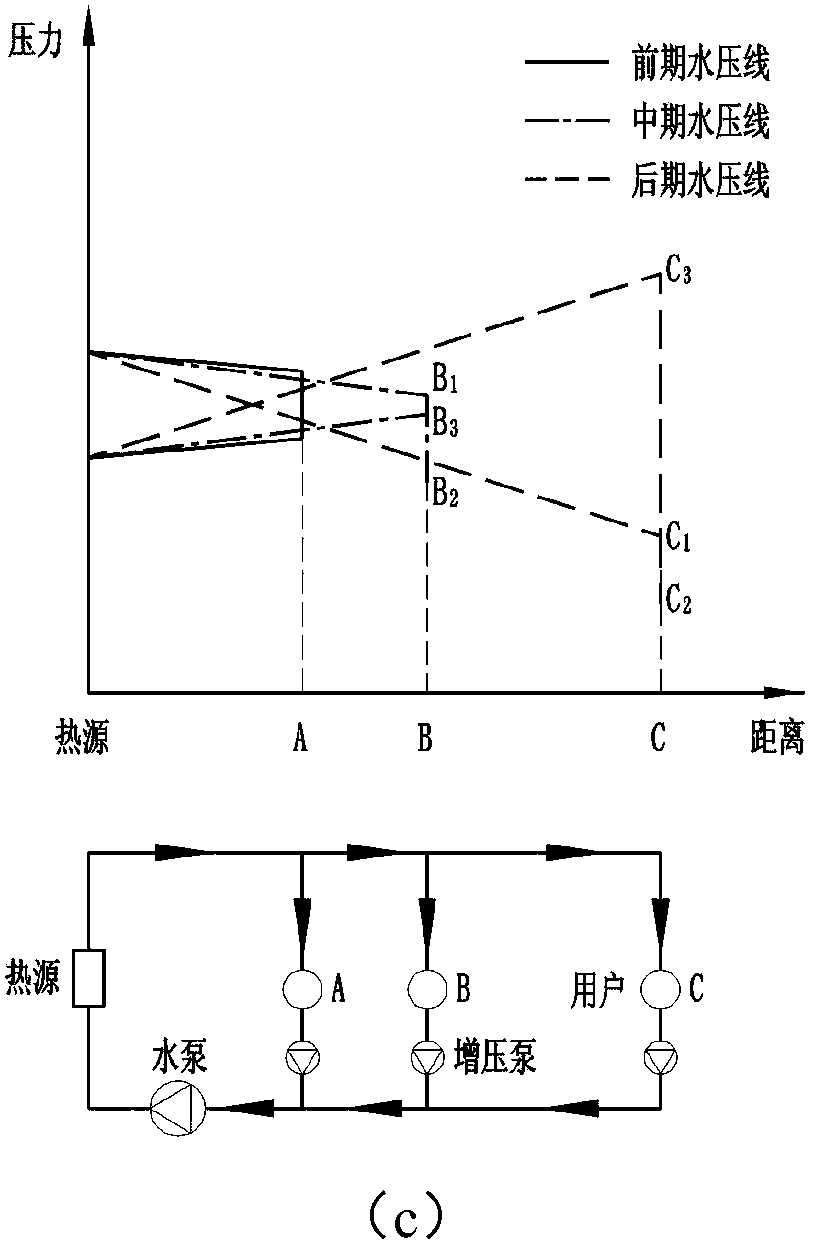

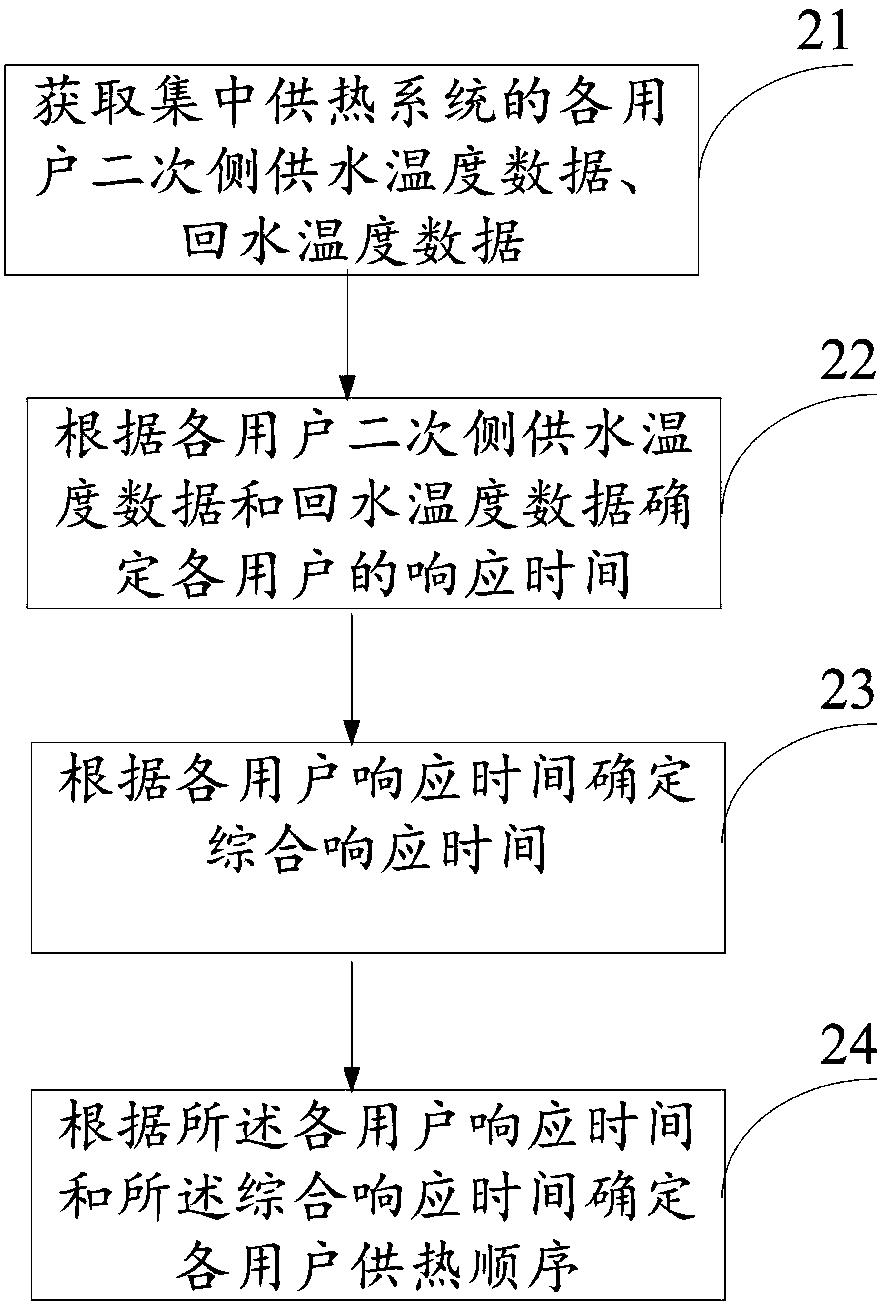

Centralized heating method and system

ActiveCN108087943AReduce operating pressureLow running costLighting and heating apparatusSpace heating and ventilation detailsProcess engineeringResponse type

The invention discloses a centralized heating method and system. The method comprises the steps that secondary side water supply temperature data and return water temperature data of users of the centralized heating system are obtained firstly; according to the secondary side water supply temperature data and return water temperature data of the users, response time of the users is determined; comprehensive response time is determined according to the response time of the users; and finally the heating sequence of the users is determined according to the response time of the users and the comprehensive response time. The heating sequence of the users is determined according to the response time of the users, the number of heating users in the same time period is reasonably set, accordingly, centralized heating pipeline operation pressure is reduced, improvement investment is reduced, and the operation cost is reduced.

Owner:CHANGAN UNIV

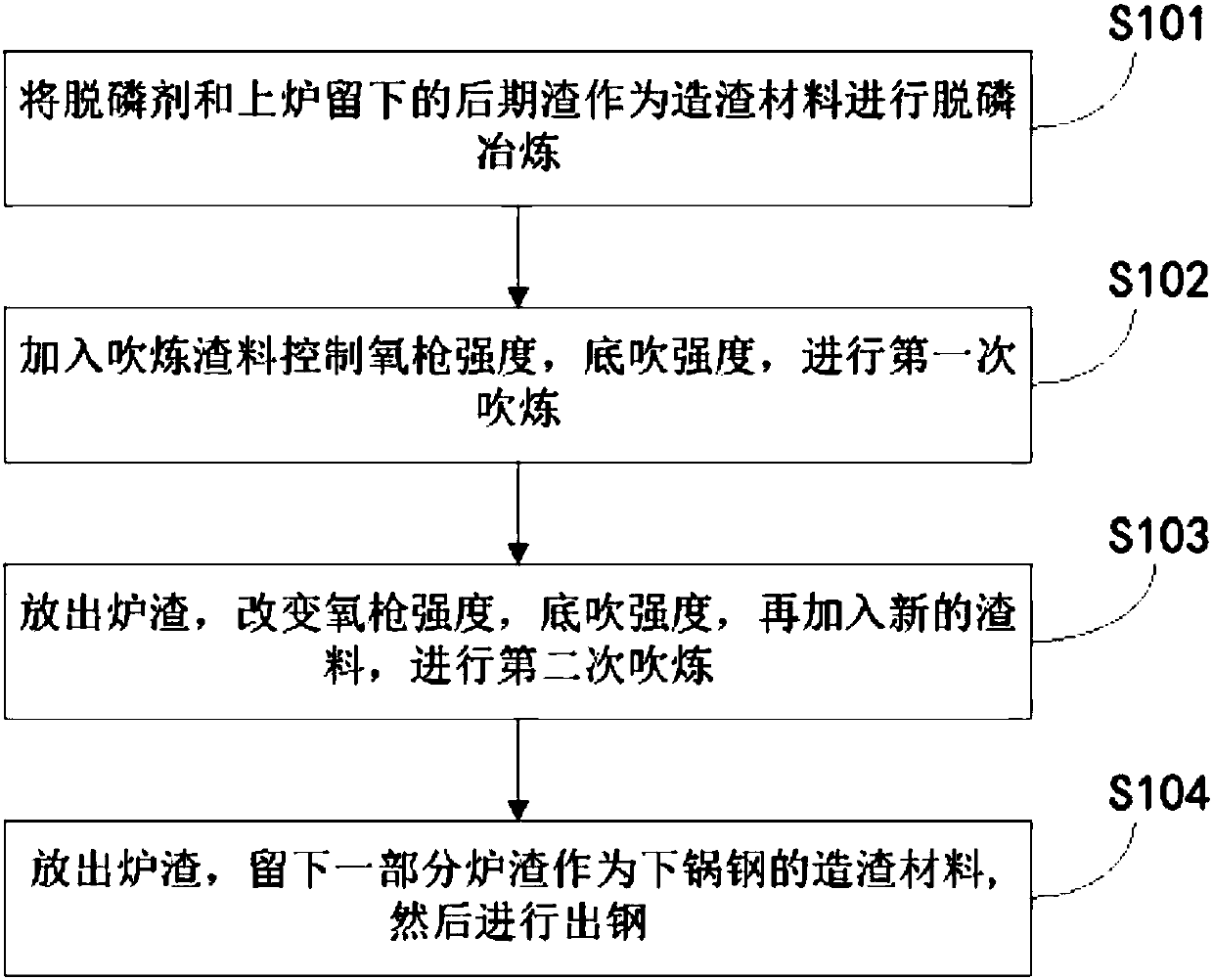

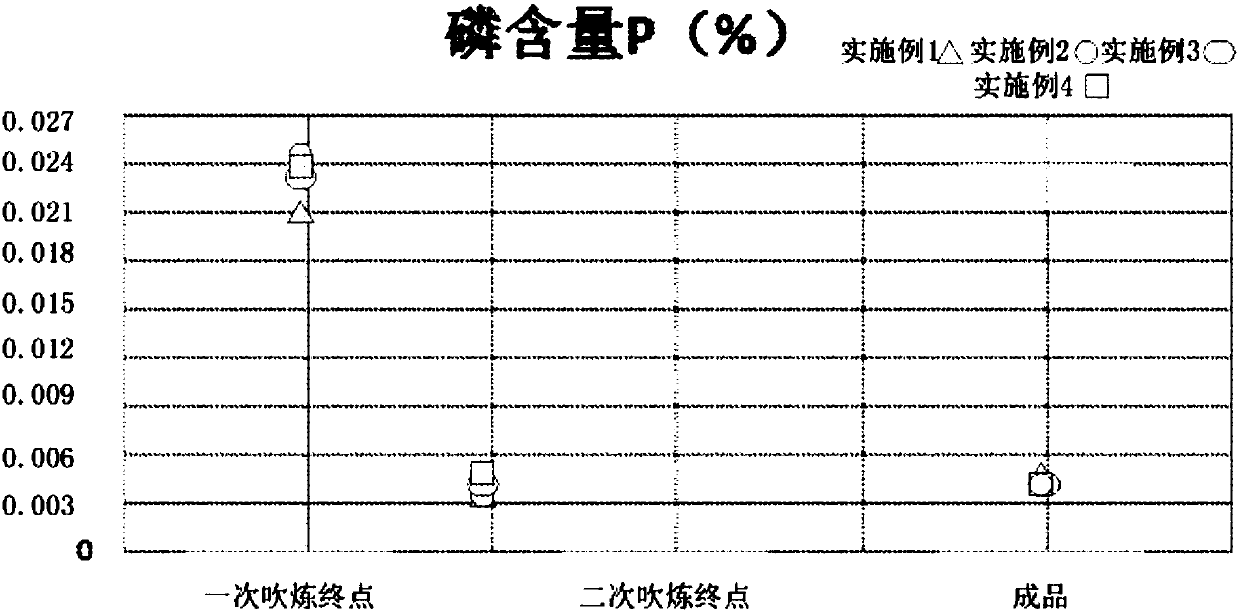

Ultra-low phosphorus steel smelting method

InactiveCN107557533ASolve the problem that the continuous production of ultra-low phosphorus steel cannot be realizedLow costManufacturing convertersProcess efficiency improvementAlkalinitySlag

The invention discloses an ultra-low phosphorus steel smelting method. Dephosphorizing pretreatment is conducted firstly, and then operation is conducted through a double slag method. A dephosphorization period and a blowing period are included. According to the dephosphorization period, a dephosphorization agent and pre-slag left by a previous converter serve as slagging materials to be subjectedto dephosphorization smelting, and alkali converter slag is obtained; according to the blowing period, primary blowing is conducted, specifically, the oxygen flow rate during primary blowing is appropriately decreased, the converter bottom blowing strength is larger than or equal to 0.045 Nm<3> / (t.min), the oxygen-supplying blowing time is 6-7 min, after primary blowing is completed, converter slag is discharged, and then new slag is added to be slagged again; and the final converter slag alkalinity of secondary blowing is controlled to be 3.5-4.5, the content of FeO is 18-25%, the content ofMgO is 8-10%, the final temperature is 1600-1630 DEG C, the content of final C is 0.03-0.06%, a special slag-stopping plug is adopted before steel taping, after 3 / 4 steel taping is conducted, a slag-stopping awl is additionally arranged, and 40-60% of later-period slag which is generated after secondary blowing is finished is left to serve as a slagging material of later converter steel. Throughthe technology, the converter final P can be stably controlled to be 0.005% or below.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

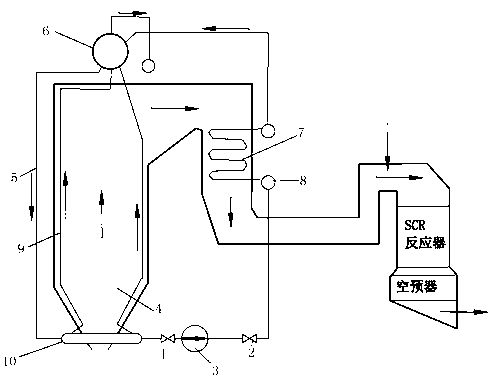

Forced circulation drum boiler with smoke temperature rising system

InactiveCN103343953AIncrease temperatureSmall temperature differenceForced-flow steam boilerThermodynamicsBoiler furnace

The invention relates to a forced circulation drum boiler with a smoke temperature rising system. The forced circulation boiler comprises a boiler body, a steam drum, a boiler water pump, a coal economizer, an SCR reactor and an air pre-heater. An inlet of the boiler water pump is connected with the steam drum through a downcomer, an outlet of the boiler water pump is divided into two routes, one route is connected with a low water drum of the boiler body through an electric adjusting valve, and the other route is connected with a water feeding inlet pipe of the coal economizer through a second electric adjusting valve. The low water drum is connected with the steam drum through the water wall inside a boiler hearth. The smoke temperature rising system is applicable to subcritical and ultrahigh pressure forced circulation drum boilers, the SCR reactor can be made to run normally under the conditions / condition of low loads and / or low atmosphere temperature, and therefore the smoke emission quality of the subcritical and ultrahigh pressure forced circulation drum boilers under the conditions / condition of the low loads and / or the low atmosphere temperature can reach national standards.

Owner:上海上电电力工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com