Target control method for heating power generation system

A technology of power generation system and control method, which is applied in the direction of heating system, steam centralized heating system, heating method, etc., can solve the problems of unadjustable electric power, loss, and economic loss, etc., so as to keep the heating load constant and improve Stability, increased flexibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

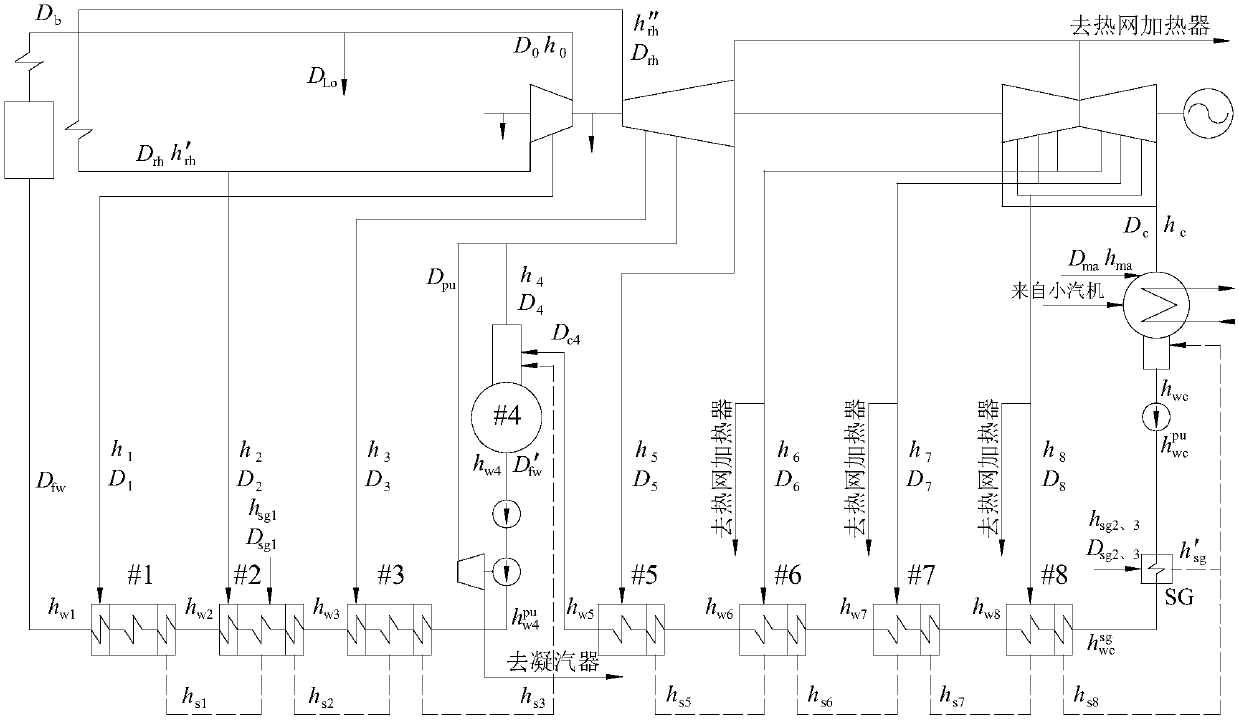

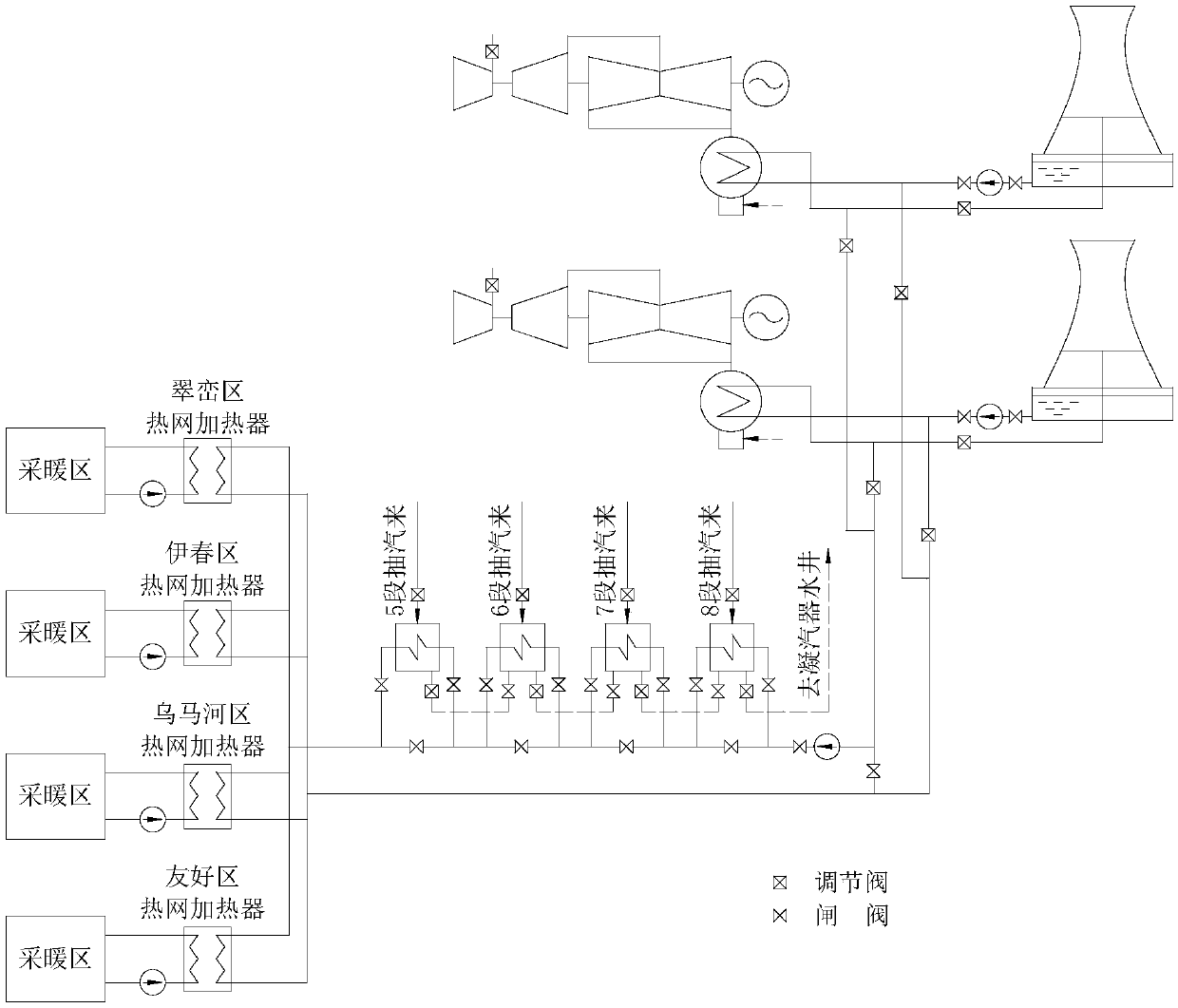

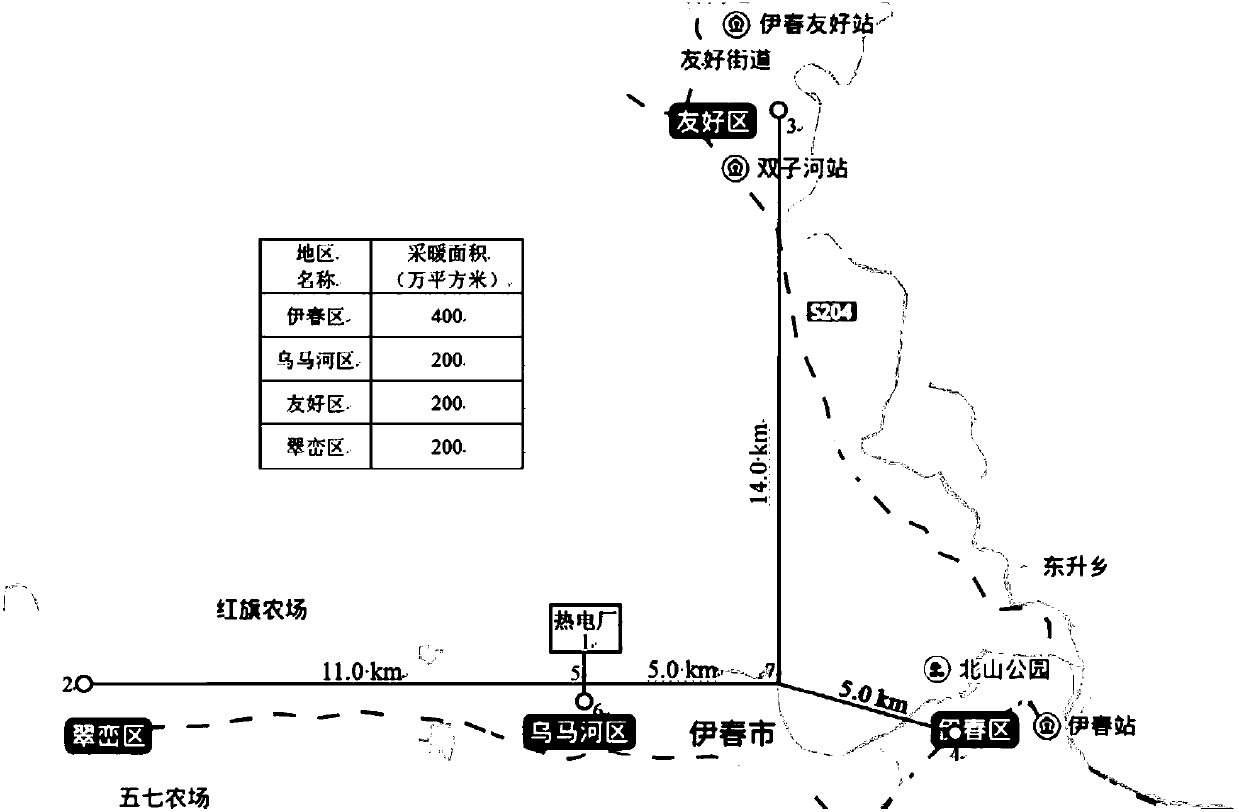

[0075] see Figure 1 to Figure 5 , the present embodiment takes the heating and heating system of the 2×C350-24.2 / 566 / 566 unit currently in service in Heilongjiang Yichun Thermal Power Plant as an example, and simulates the use process, method and effect of the technical solution of the present invention.

[0076] 1.1. Relevant standards and specifications

[0077] (1) Design Code for Heating, Ventilation and Air Conditioning of Civil Buildings (GB 50736-2012)

[0078] (2) Code for Design of Urban Heating Pipeline Network (CJJ34-2010)

[0079] (3) Technical Specifications for Energy Conservation of Urban Heating System (CJJ / T185-2012)

[0080] (4) Standards for Steam Surface Condensers (Eleventh Edition)

[0081] (5) Standard method for thermal calculation of boiler units

[0082] (6) Design guidelines for thermal insulation of equipment and pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com