Patents

Literature

557results about "Steam central heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

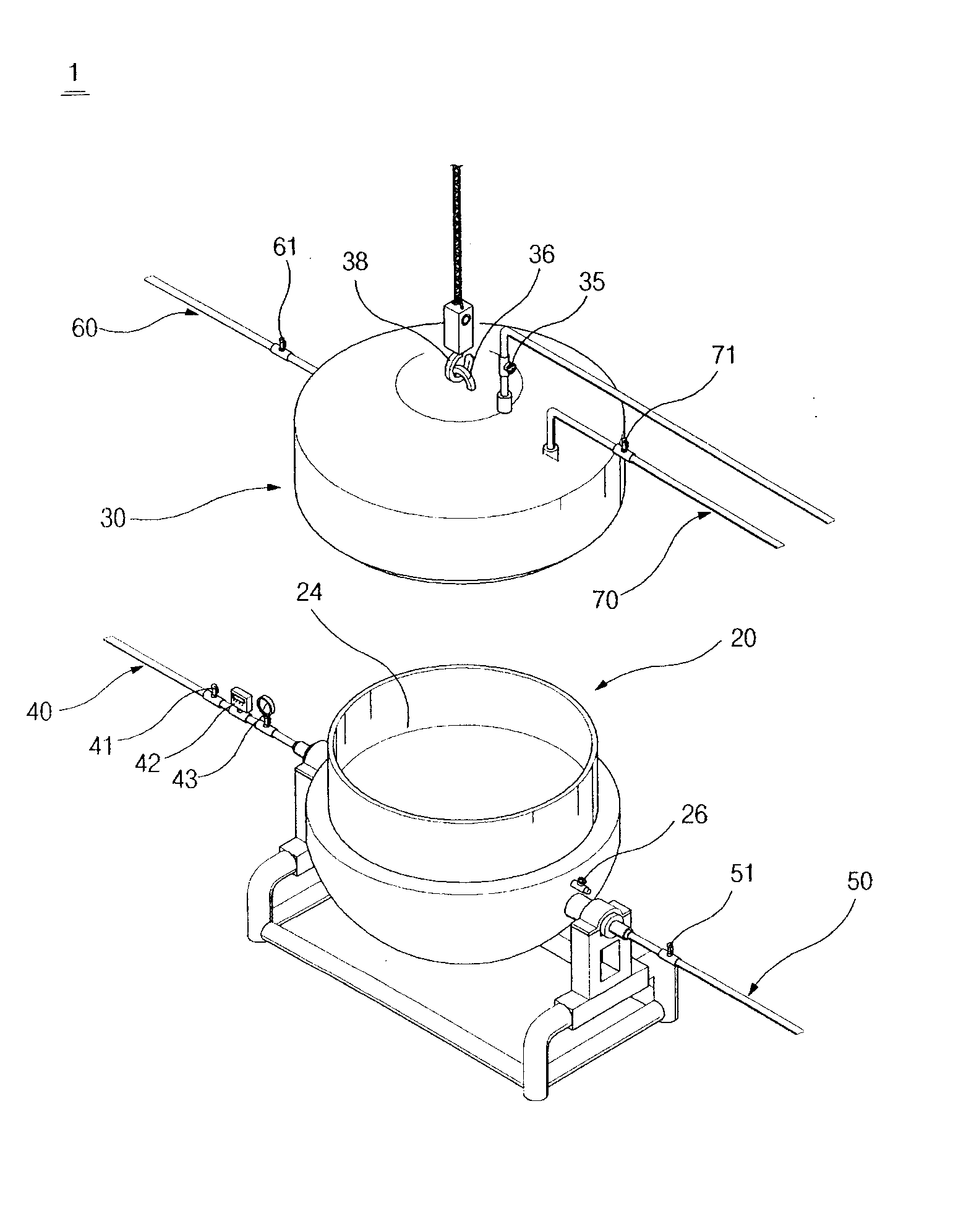

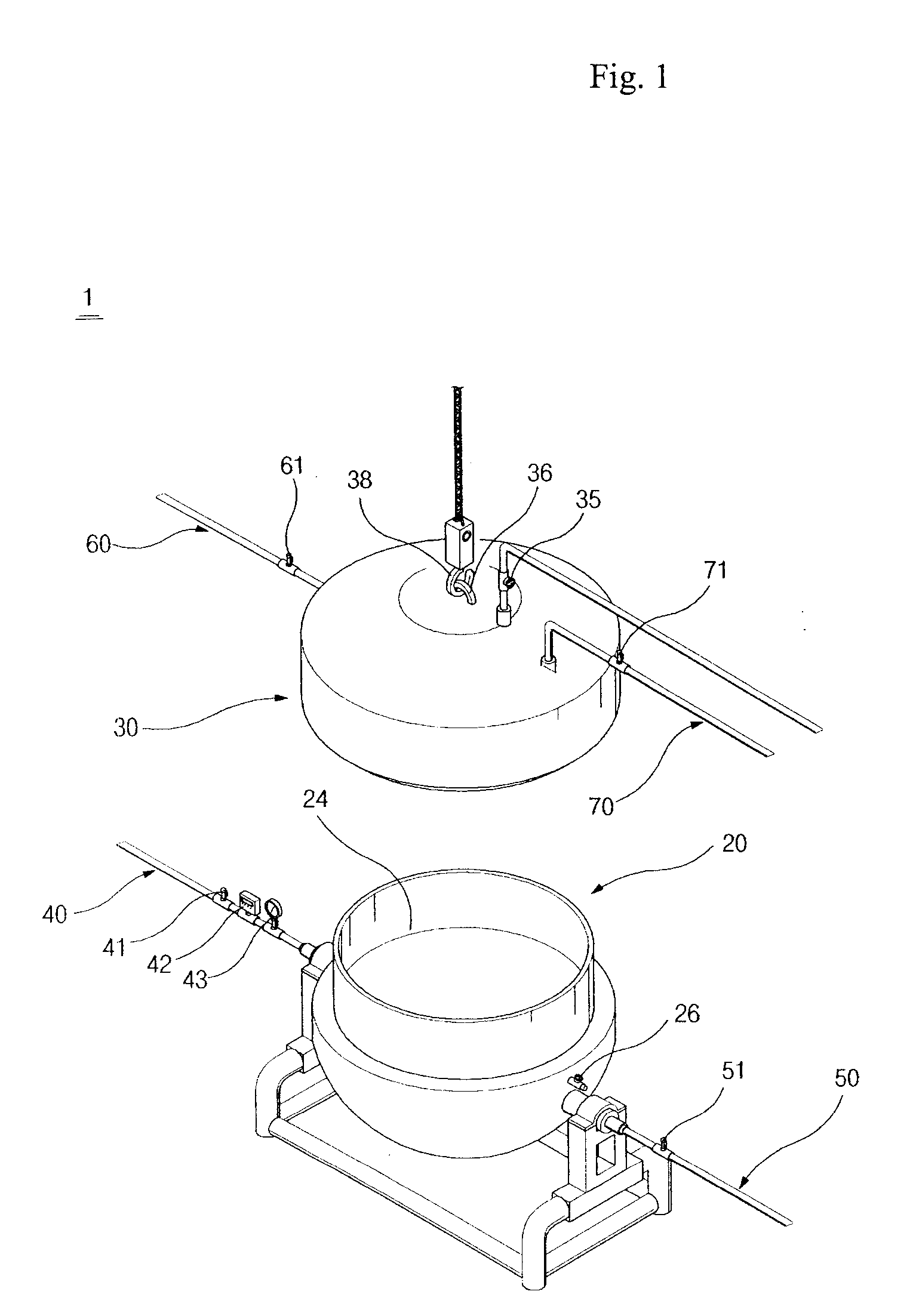

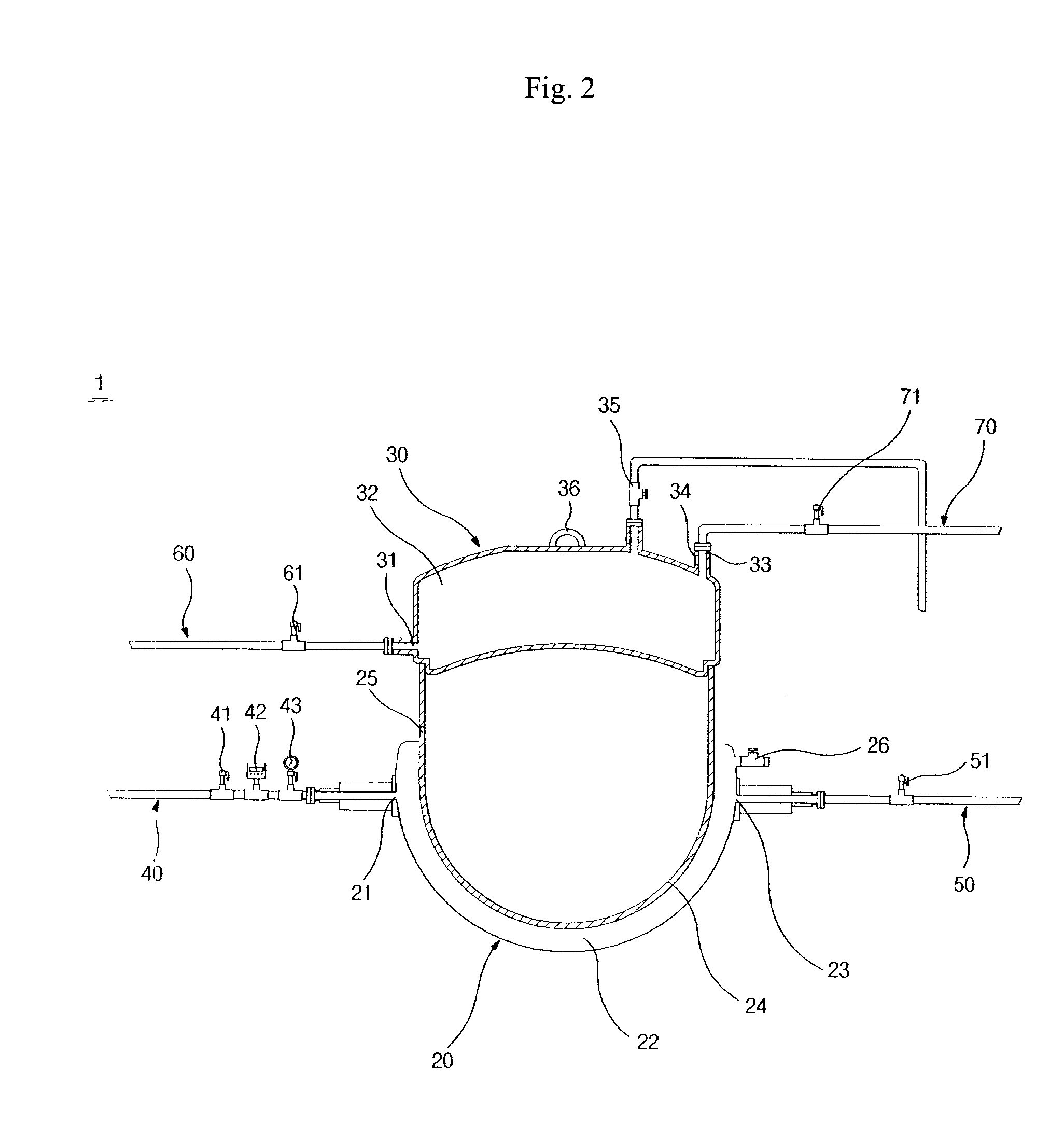

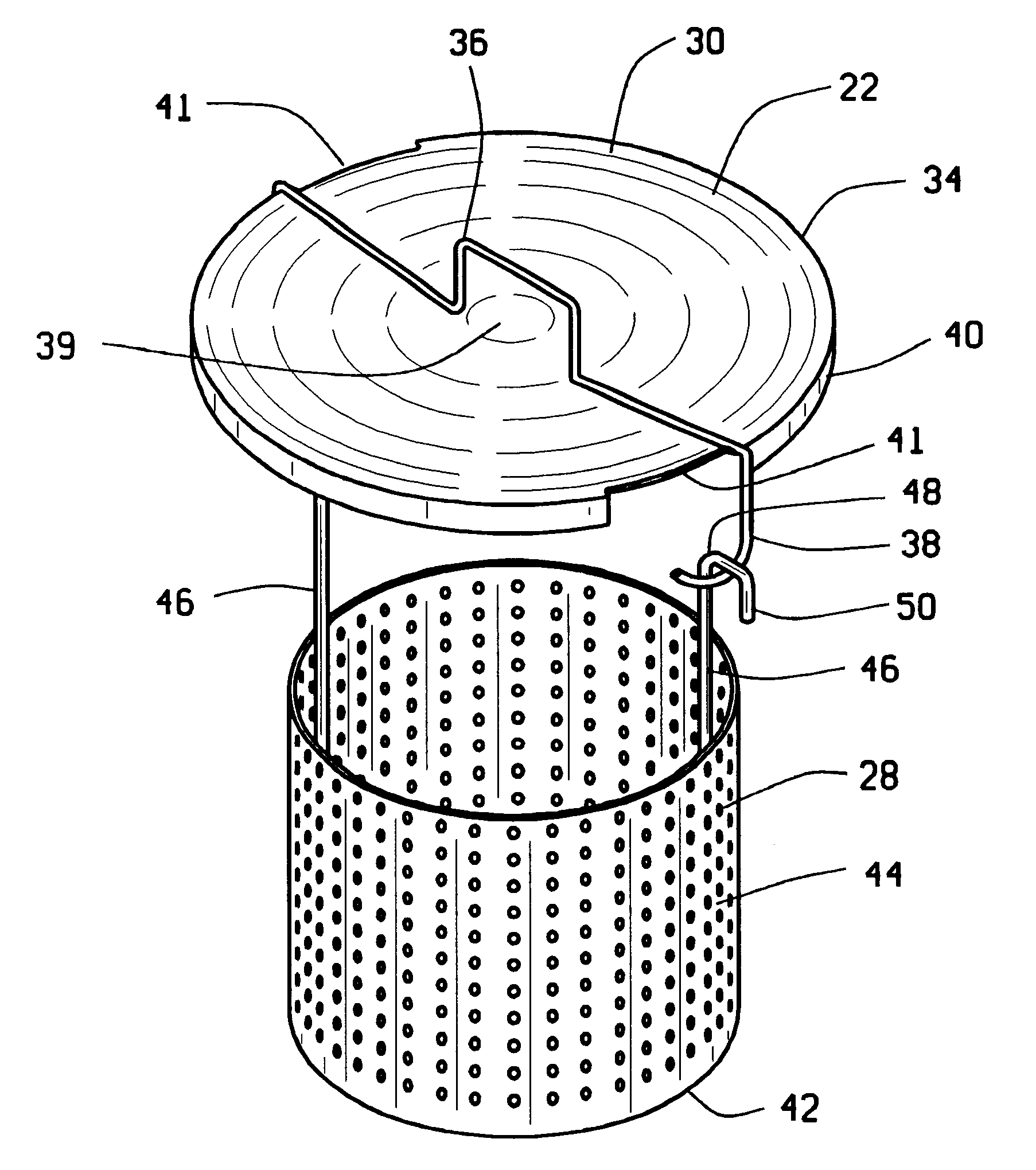

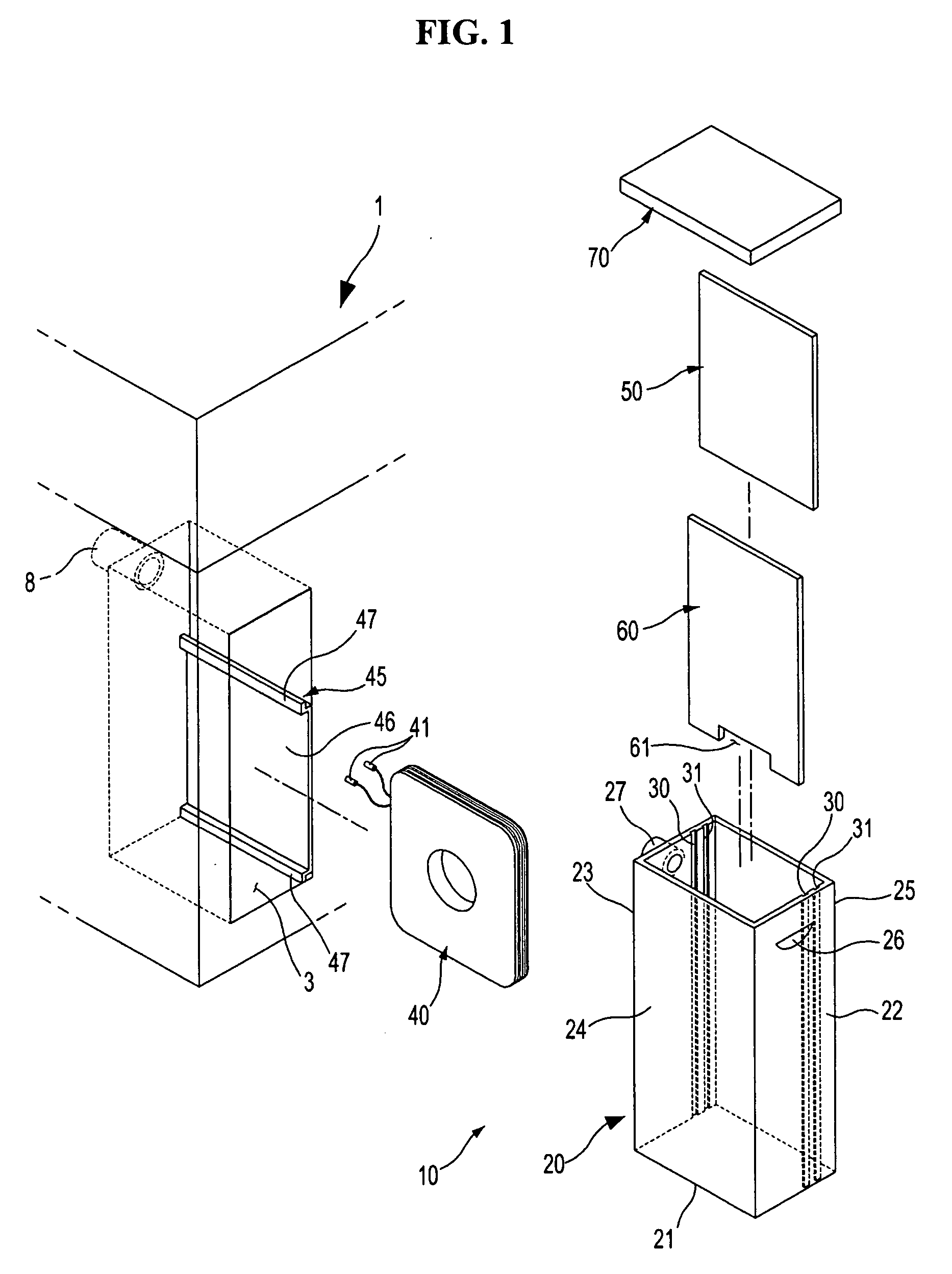

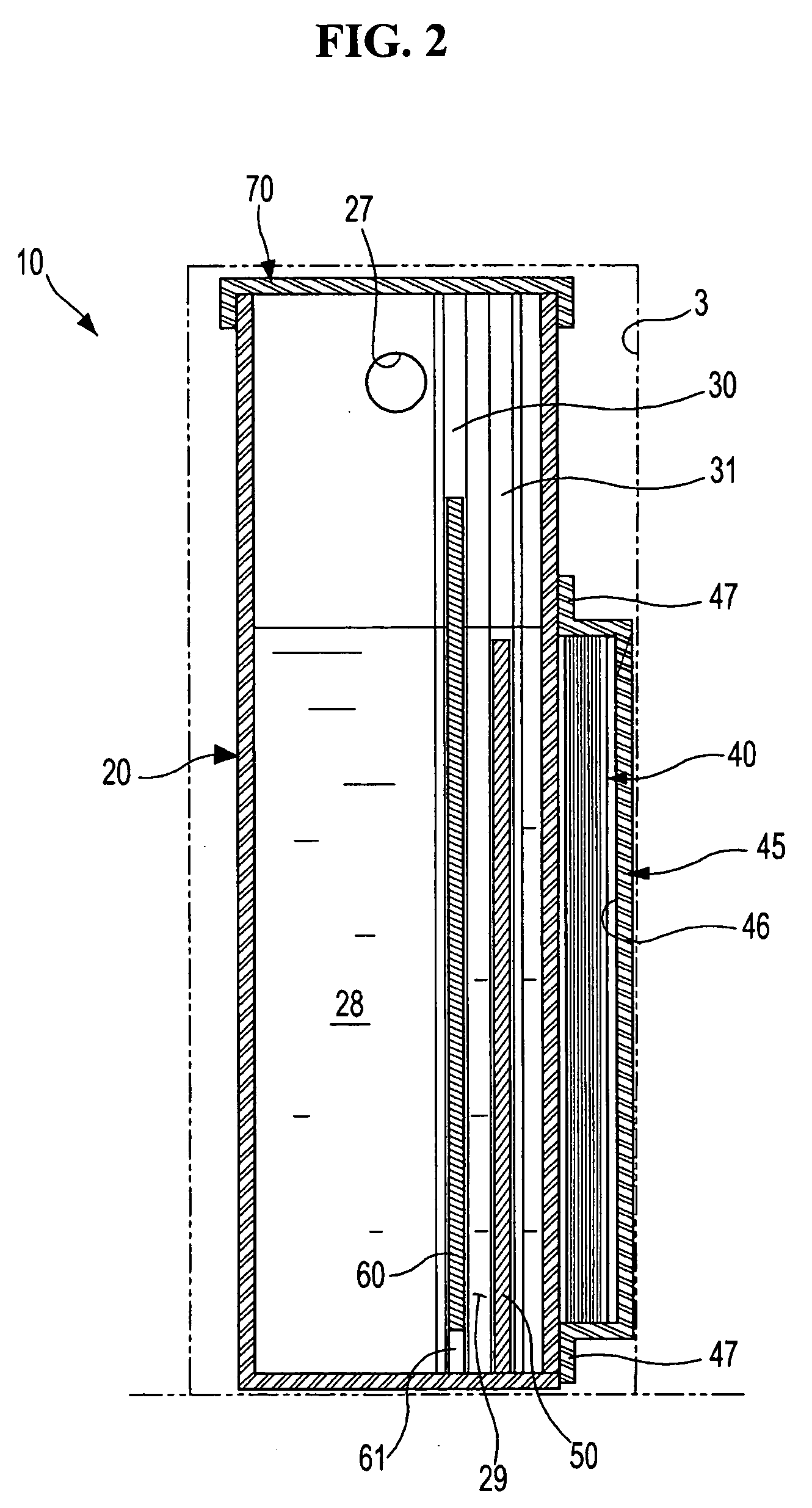

Vapor Heating Type Cooking Apparatus

InactiveUS20070209656A1Avoid stickingImprove the inconvenienceLighting and heating apparatusCooking-vessel lids/coversInterior spaceWater discharge

The present invention relates to a vapor heating type cooking apparatus cooking food materials using high pressure vapor as a heat source. A vapor heating type cooking apparatus includes: a vapor supply section generating the high pressure vapor; a vapor supply pipe and a vapor discharge pipe for introducing and discharging the high pressure vapor; a body section including a vapor introduction opening connected to the vapor supply pipe, an interior space having a dual structure so as to circulate the high pressure vapor in the caldron in which food materials are accommodated, a vapor discharge opening provided between the interior space and the vapor discharge pipe; a cooling water supply pipe and a hot water discharge pipe; a lid section including a cooling water introduction opening connected to the cooling water supply pipe, a storage space having a dual structure, in which the cooling water is temporarily stored, and a hot water discharge opening provided between the storage space and the hot water discharge pipe; and a control section for controlling introduction and discharge of the high pressure vapor, the cooling water, and the hot water.

Owner:LEE WON KI

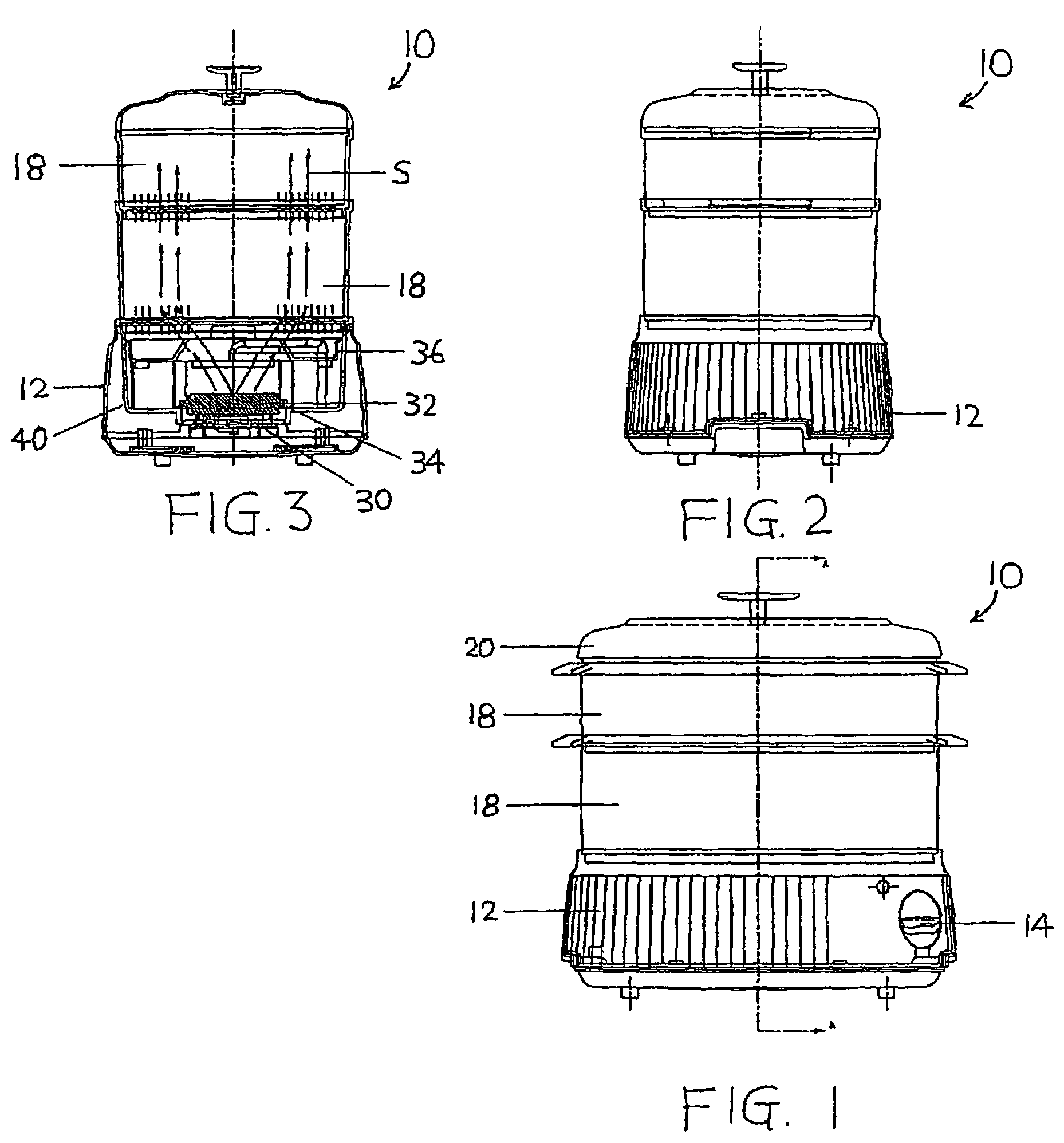

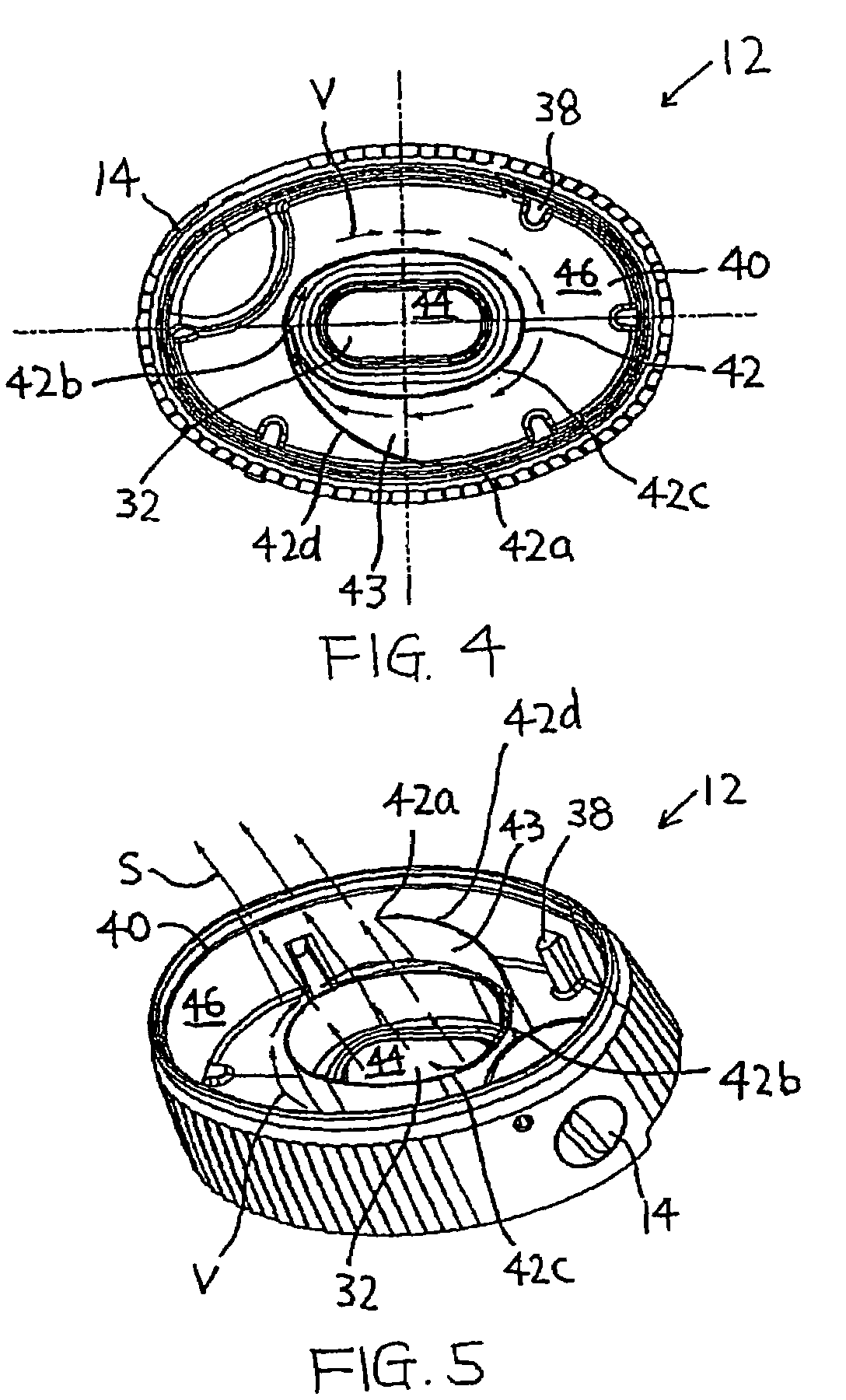

Food cooking apparatus

InactiveUS6269737B1Lighting and heating apparatusWater-bath cooking vesselsMechanical engineeringLiquid content

Owner:EMPIRE COMFORT SYST

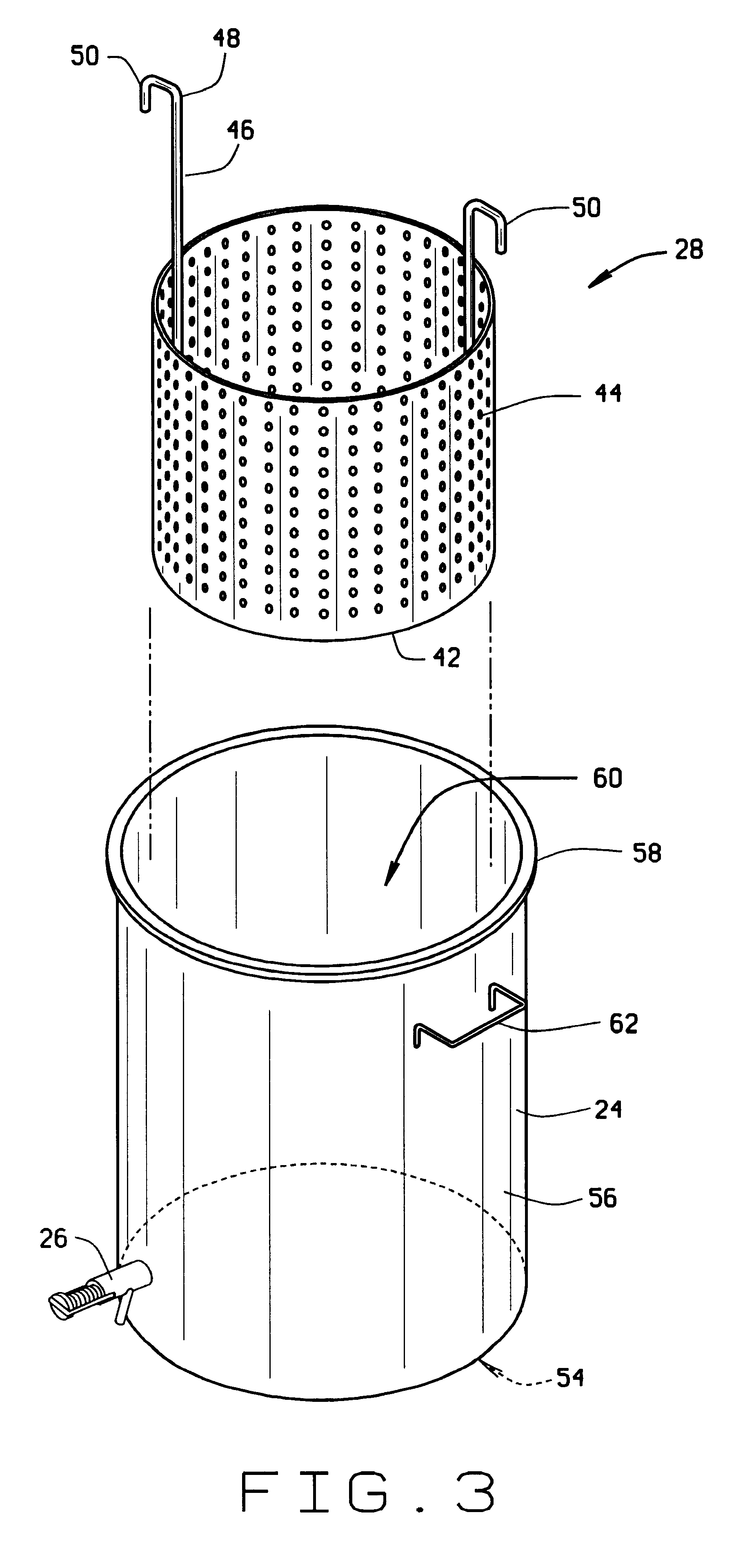

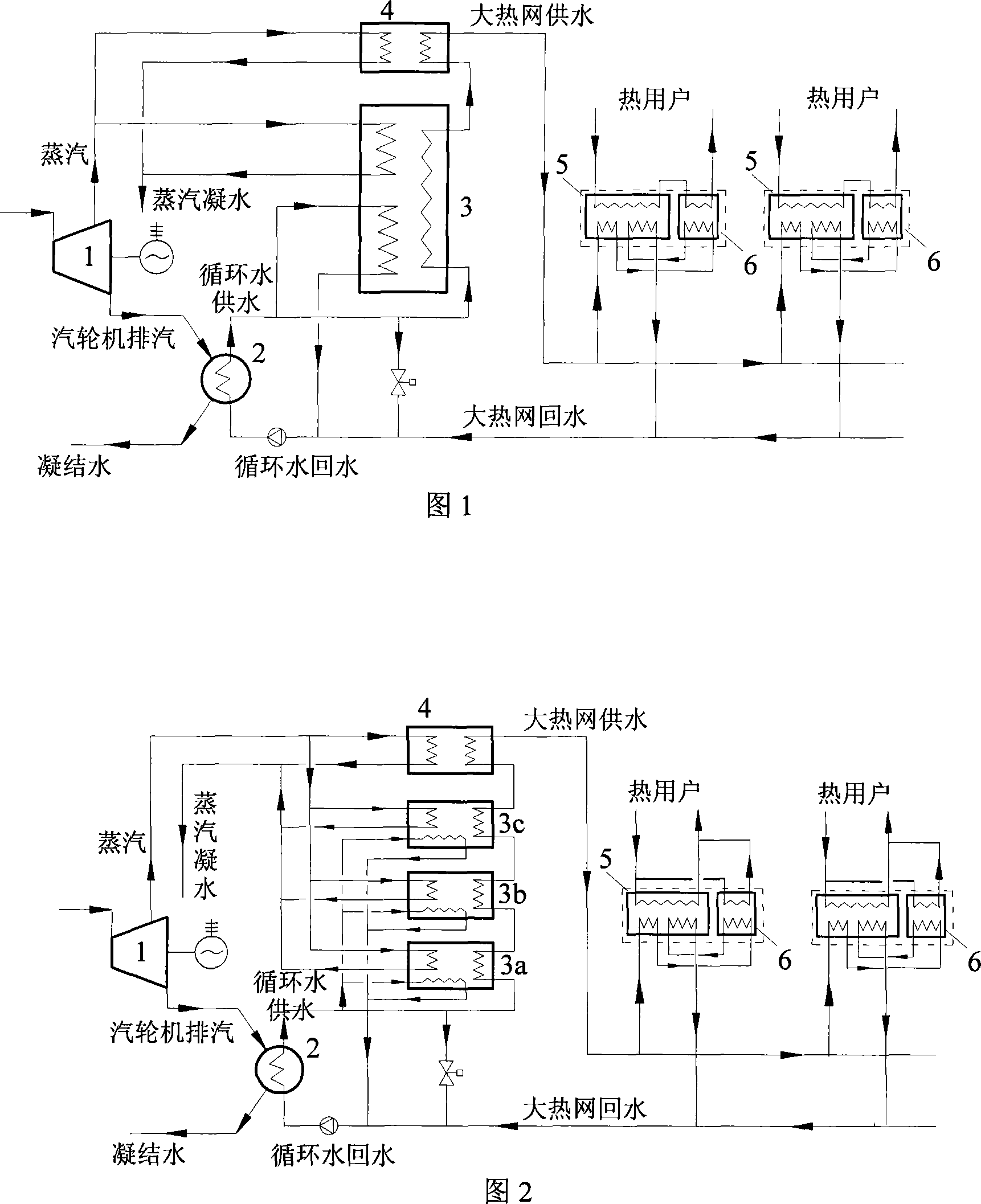

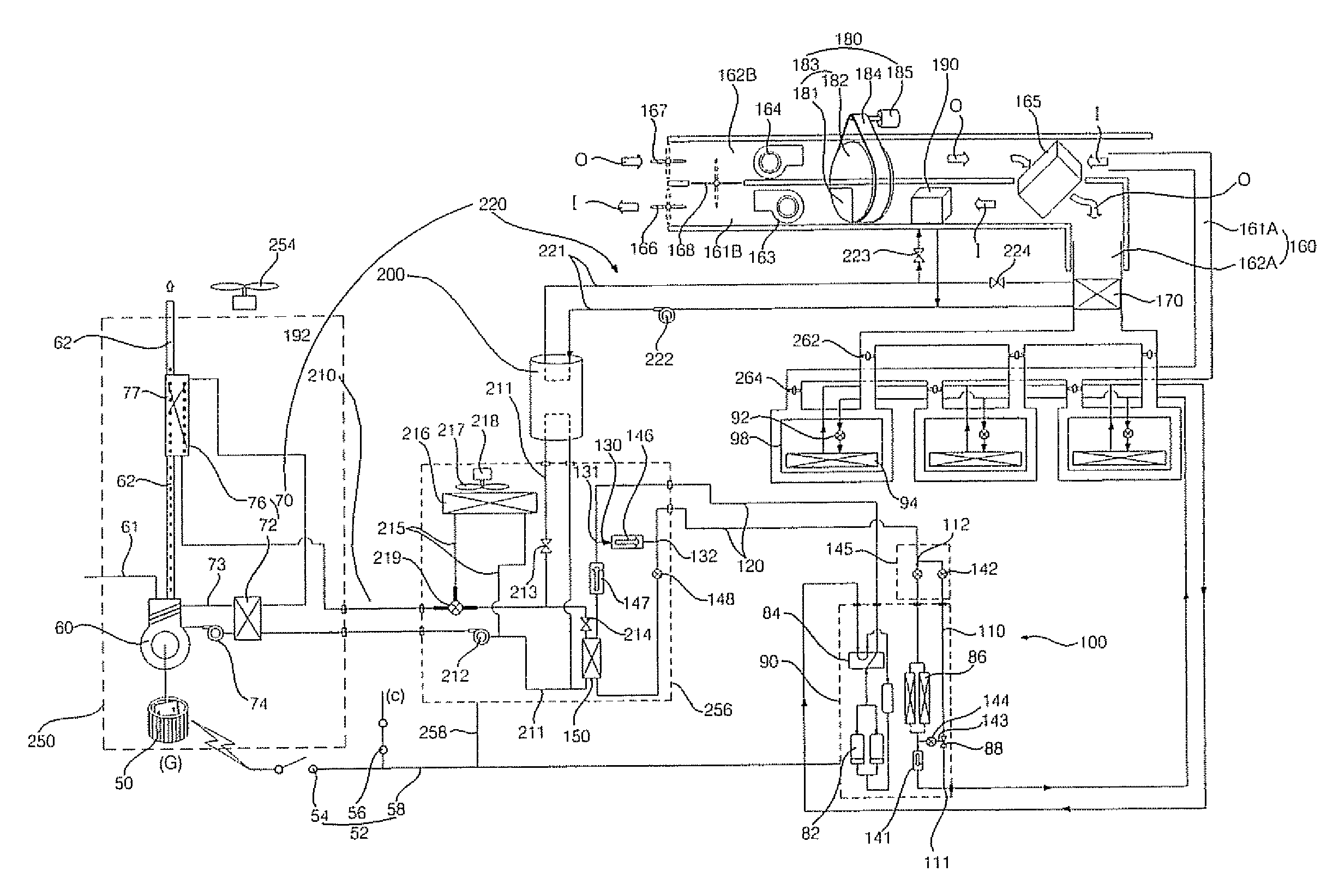

Large temperature-difference central heating system

ActiveCN101231004ALarge heating temperature differenceImprove delivery capacityHeat recovery systemsLighting and heating apparatusElectricityExternal energy

The invention relates to a central heating system with large temperature difference, which belongs to the energy field. The system comprises a steam turbine, a condenser, a steam absorption heat pump, a steam-water heat exchanger, a hot water absorption heat pump, a water-water heat exchanger as well as a connecting pipe and accessories. The invention is characterized in that the temperature difference of the heat net supply is large, and is about one time higher than the conventional heat net operation, thus the transmission capacity of the heat net is greatly increased, and at the same time, no heat preservation and thermal stress compensation problems exist as the backwater temperature of the heating is low, thereby reducing the investment of the backwater pipeline network and the whole pipeline network; the steam turbine is utilized to discharge steam and preheat the backwater of the large heat net, and circulating cooling water is utilized to be taken as the low level heat energy of the absorption heat pumps. The invention has the advantages that the residual heat produced in the electricity generating process of a power plant is recycled to the greatest extent as much as possible, the combination mode of the hot water absorption heat pump and the water-water heat exchanger is adopted at the end to heat the hot water of the secondary heat net supply, and the temperature difference of the supply-water and the backwater of the large heat net are increased, at the same time, the heat net does not need external energy to be the driving force.

Owner:TSINGHUA UNIV +1

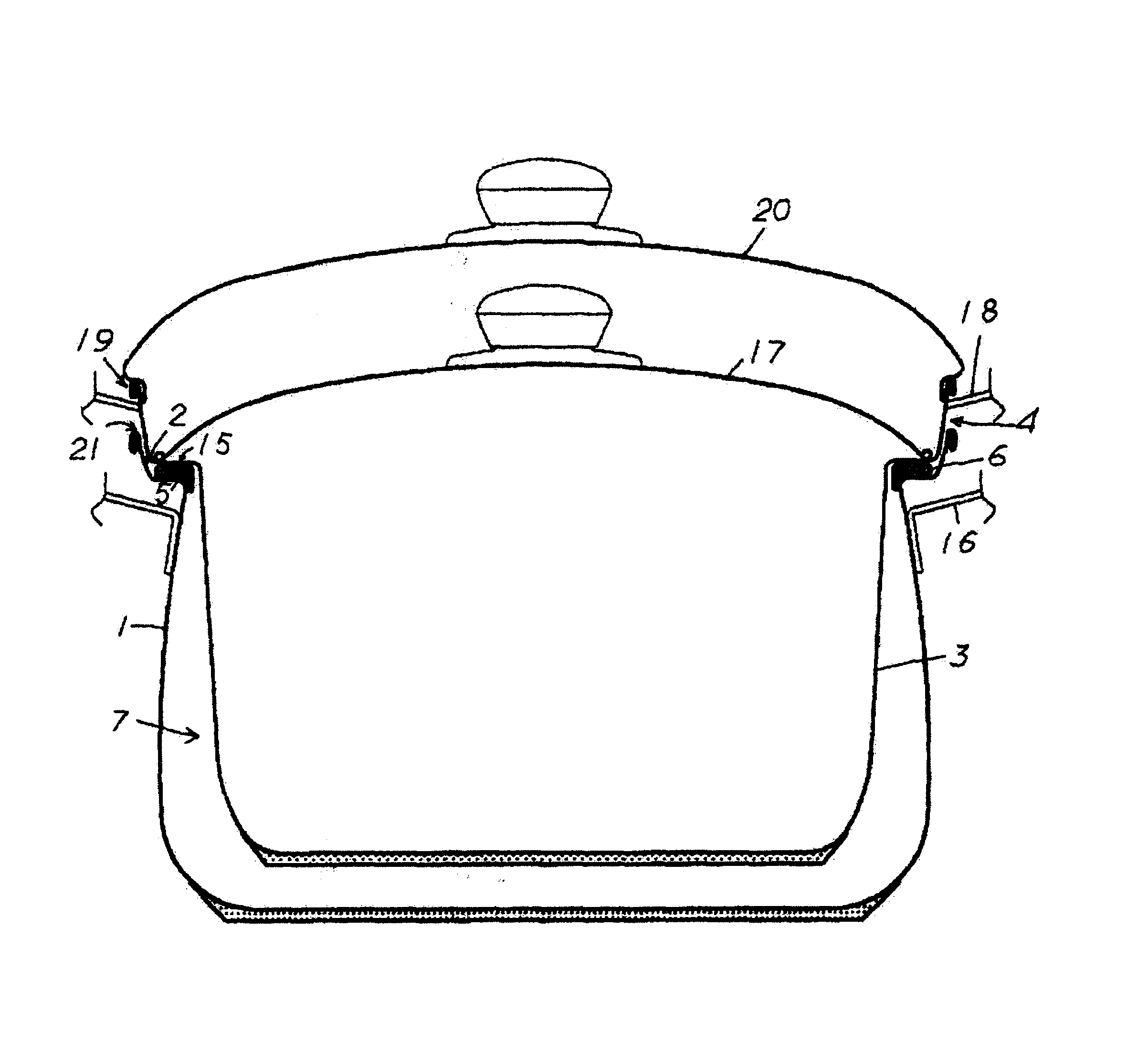

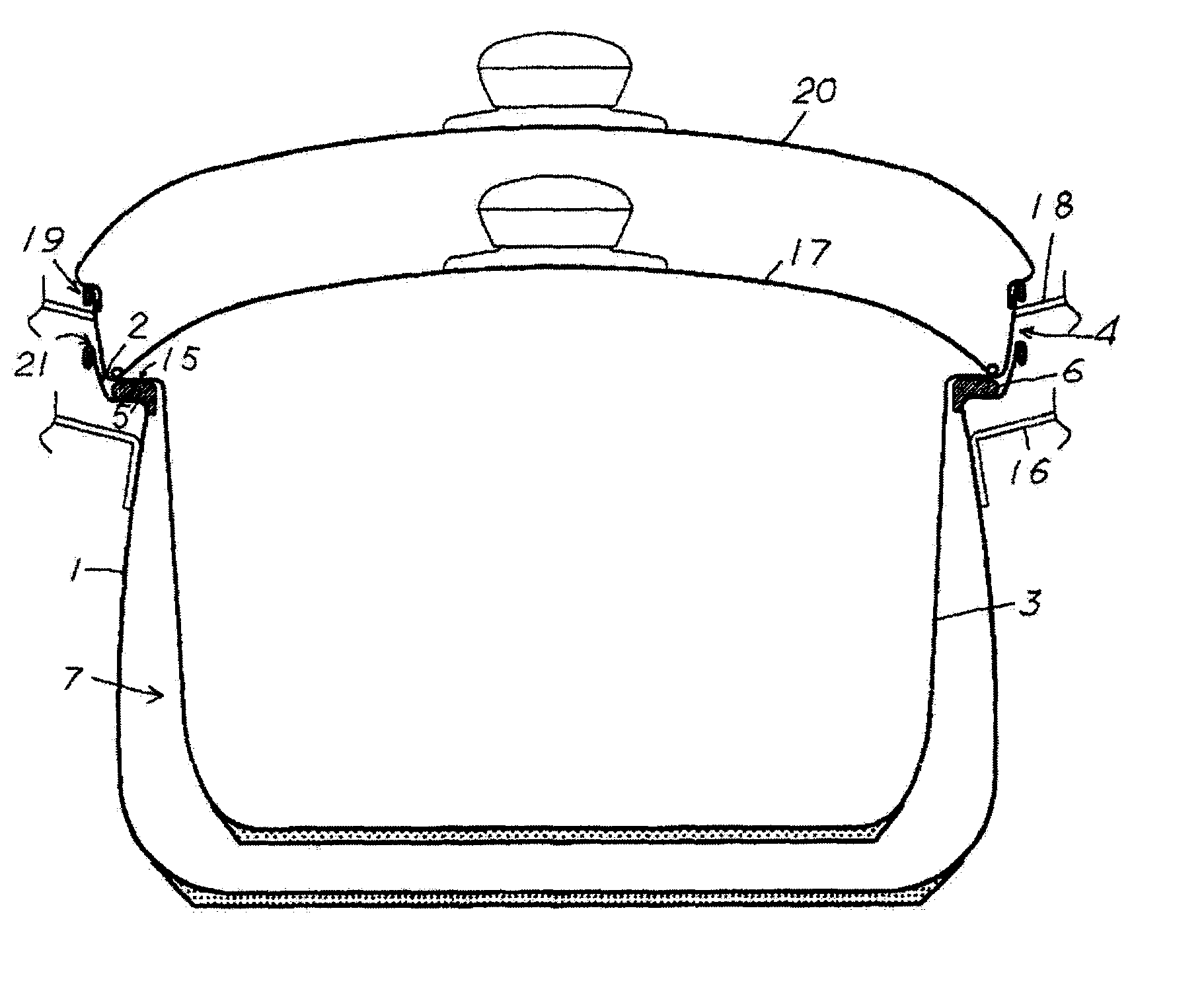

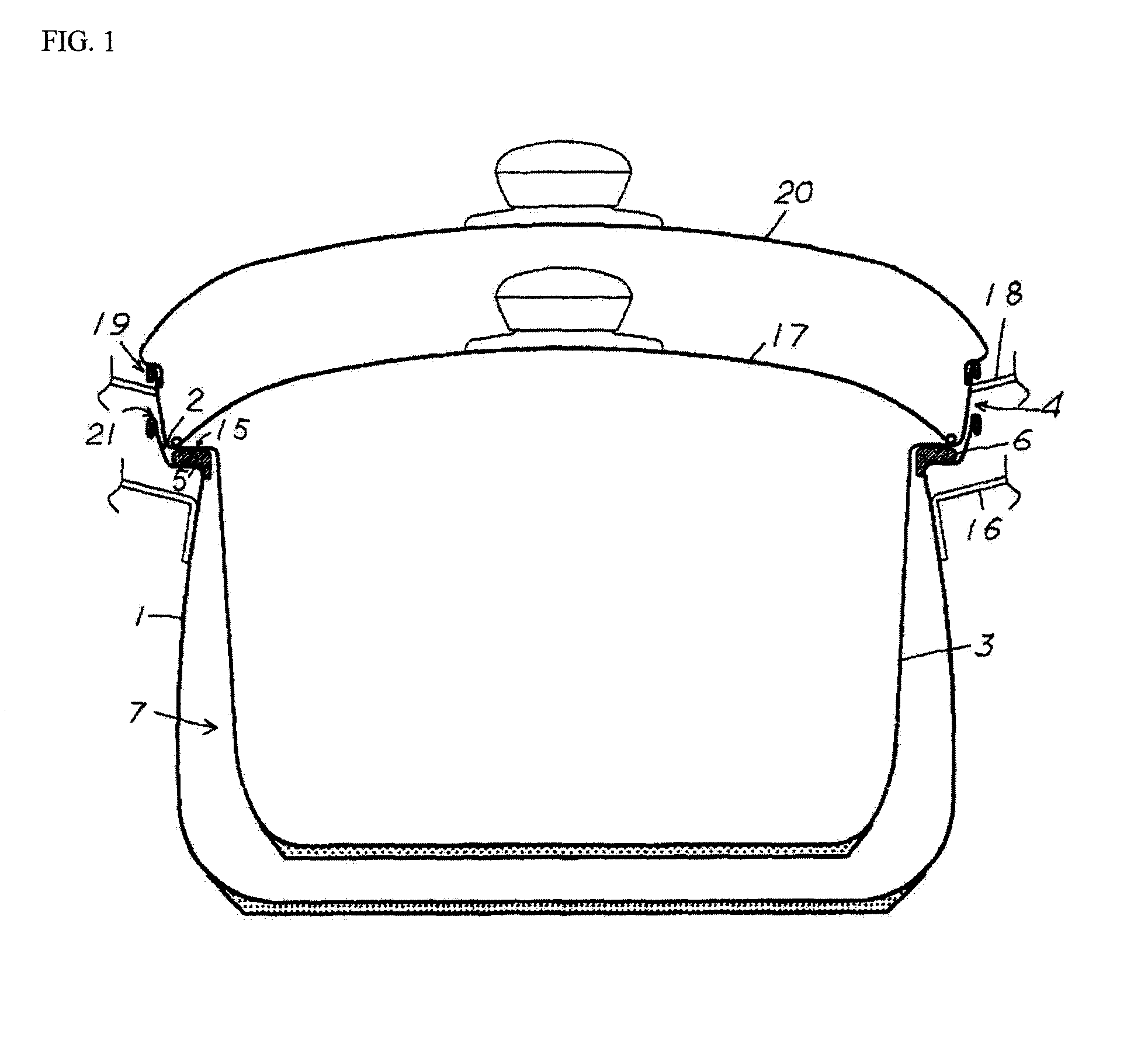

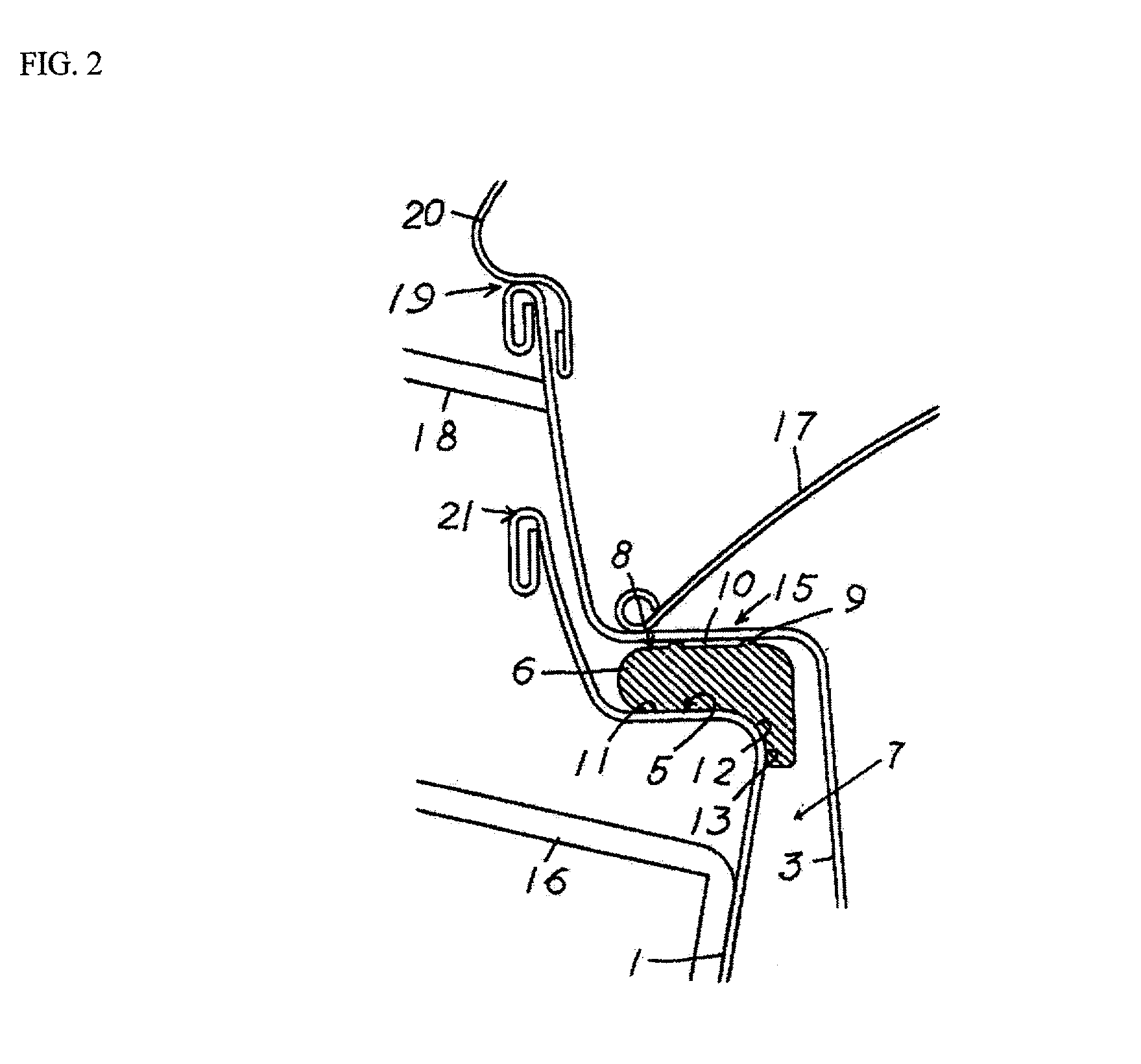

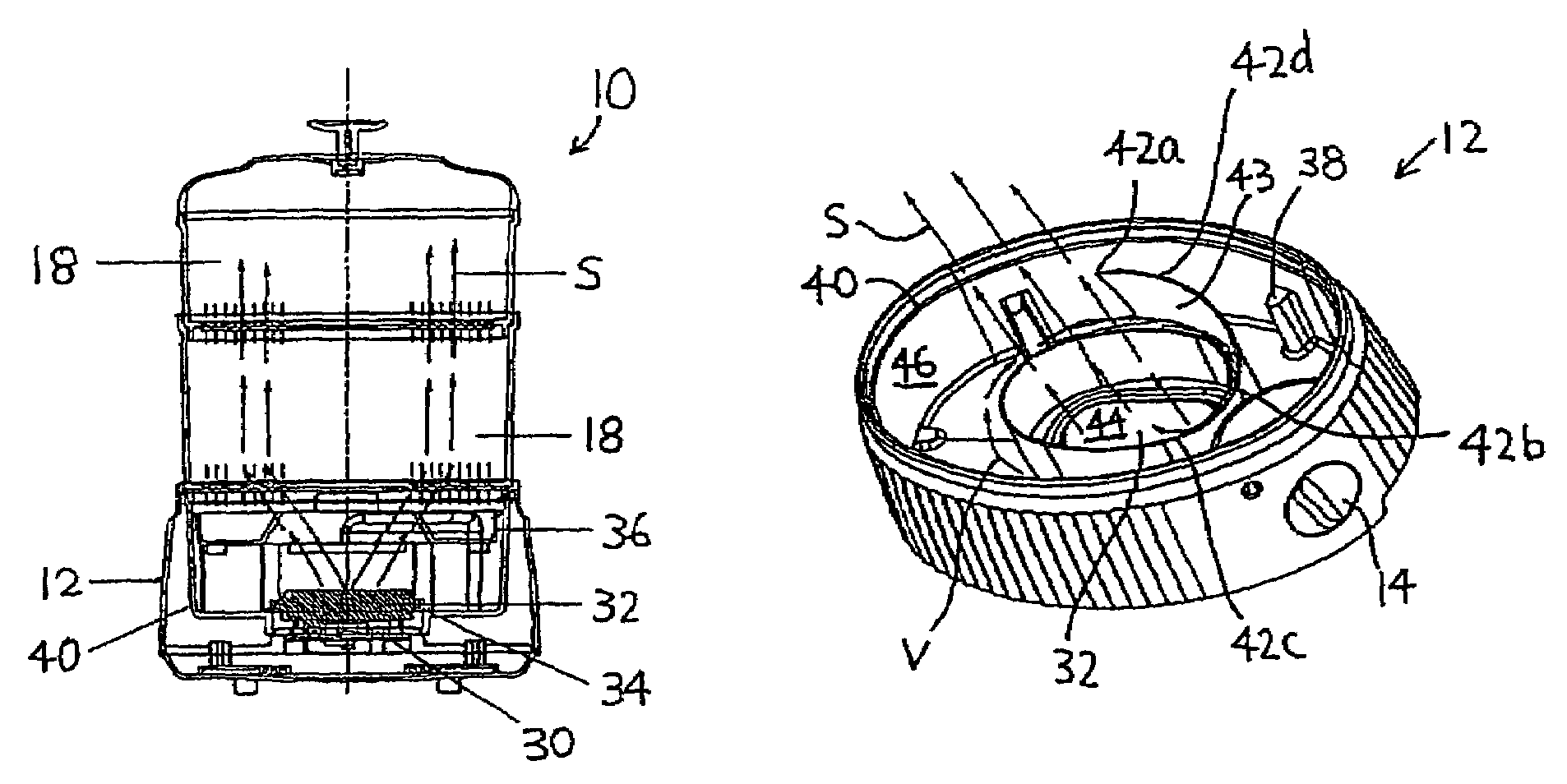

Thermally insulated pot

InactiveUS7086326B2Improve insulation effectImprove sealingWater heating stoves/rangesStove/ranges for heating waterThermal insulationEngineering

A thermally insulated cooking pot consists of an outer pot and an inner pot. The inner pot is suspended within the outer pot by hanging from the top inner circumferential area of the outer pot with its own top outer circumferential area. The space between the inner and outer pots becomes an insulation cavity. The contact point between the two pots is sealed by a pliable packing ring with an L-shaped cross-section, thereby sealing the insulation cavity. This sealed insulation cavity provides excellent thermal insulation. The packing ring contains a plurality of protrusions on the surface that come into contact with the inner pot to prevent the packing ring from sticking to the inner pot. The gap formed between the packing ring protrusions and the inner pot prevents the inner pot from sticking to the packing ring.

Owner:PATERSONS ENTERPRISES

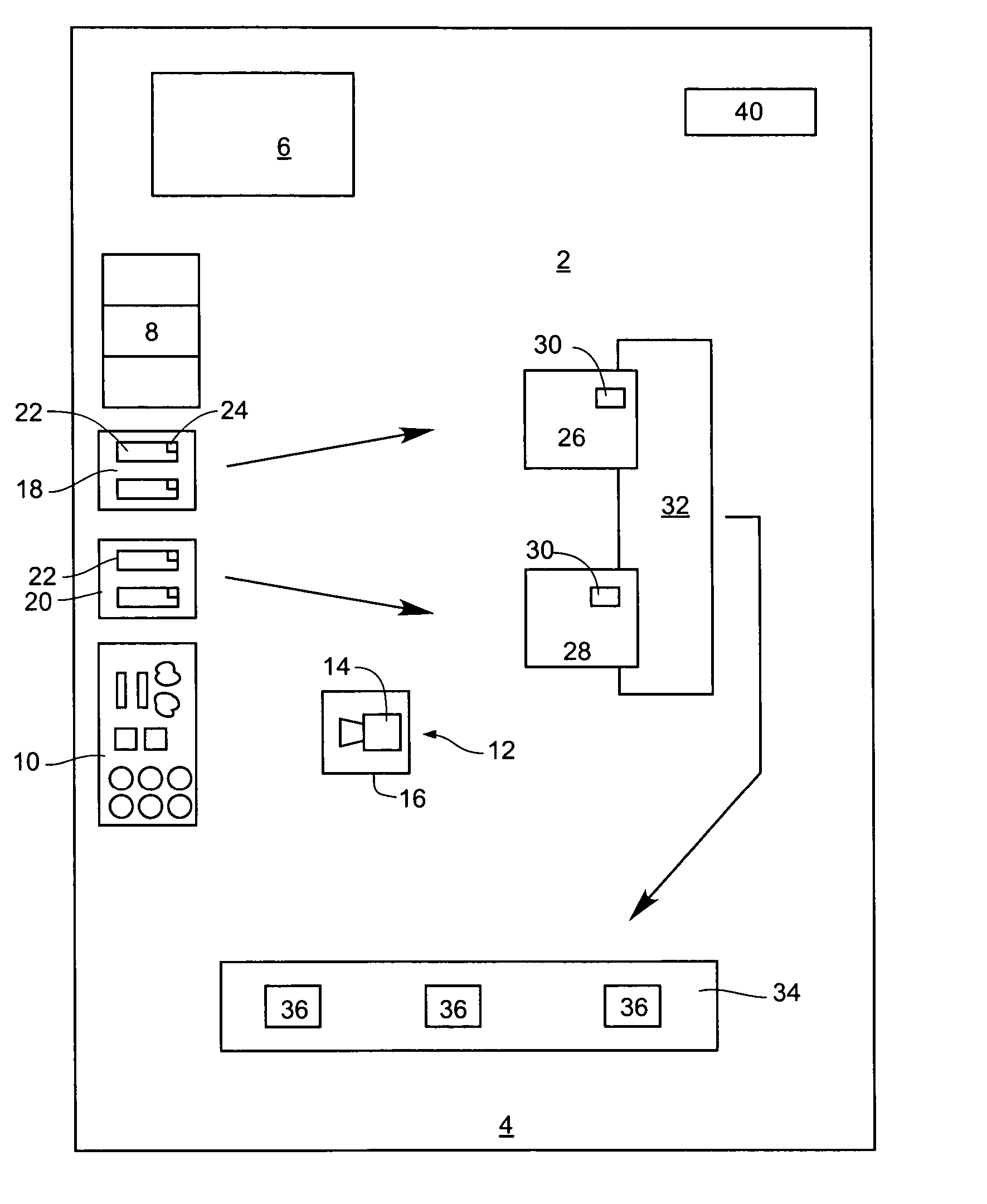

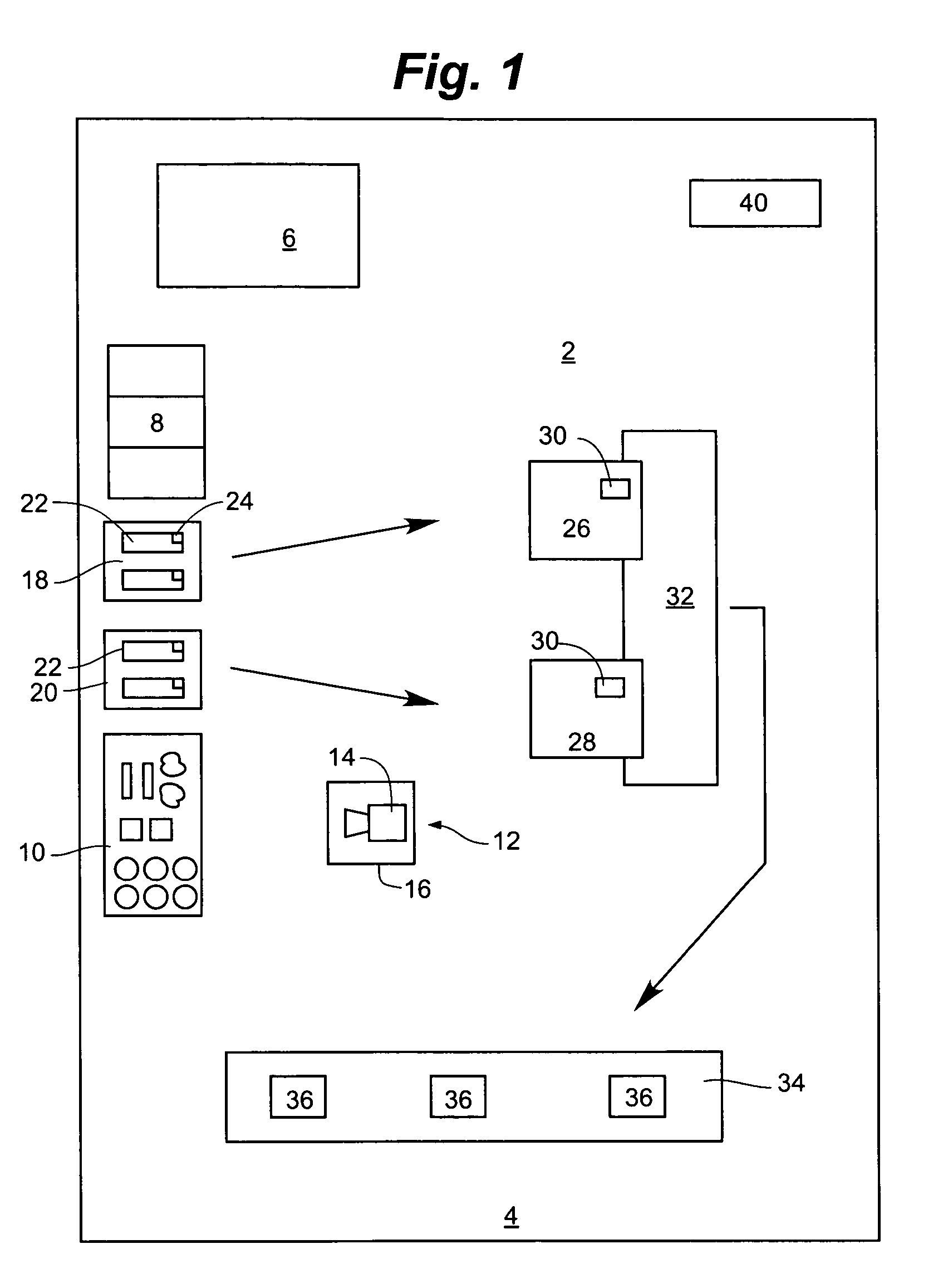

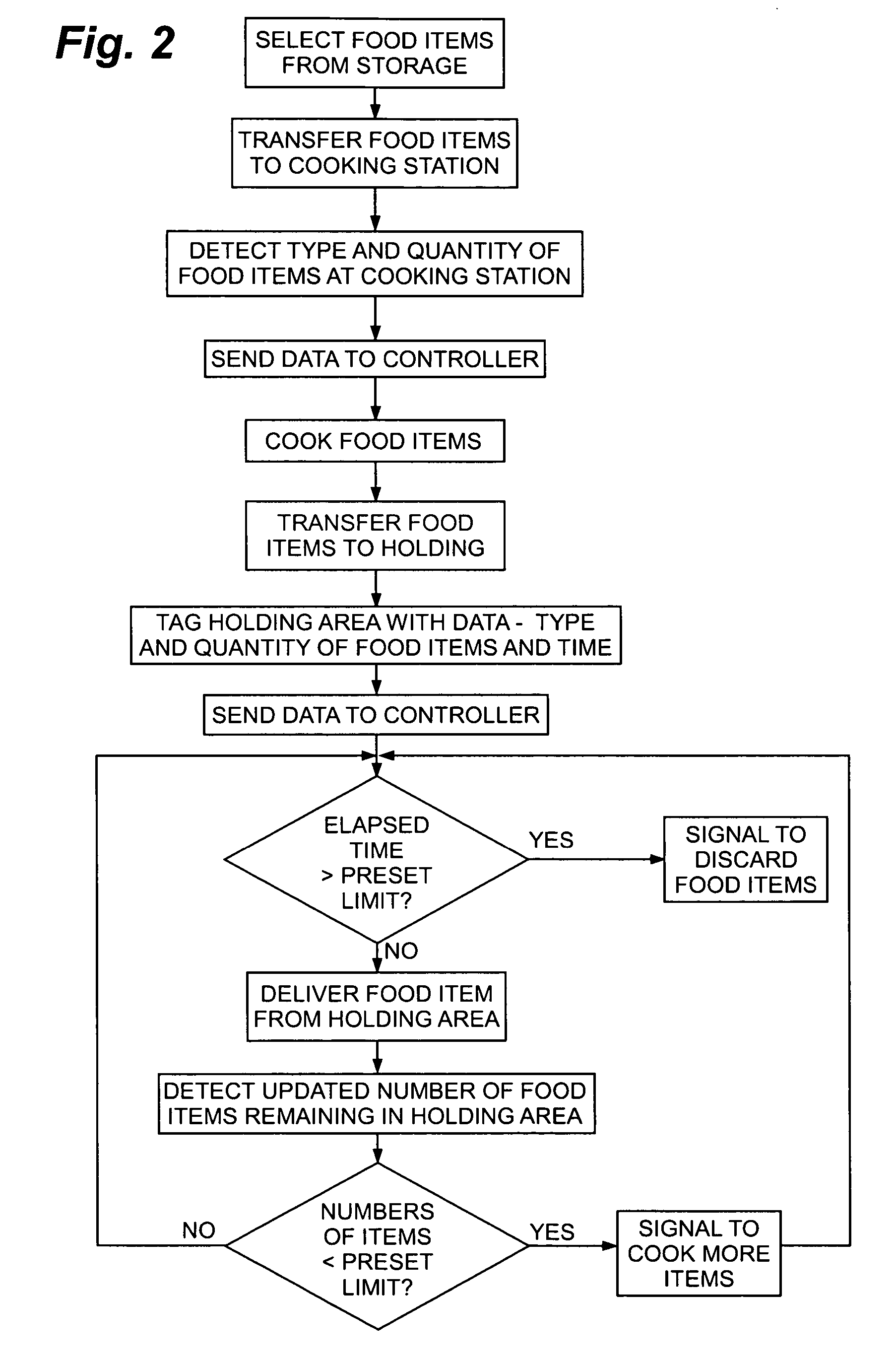

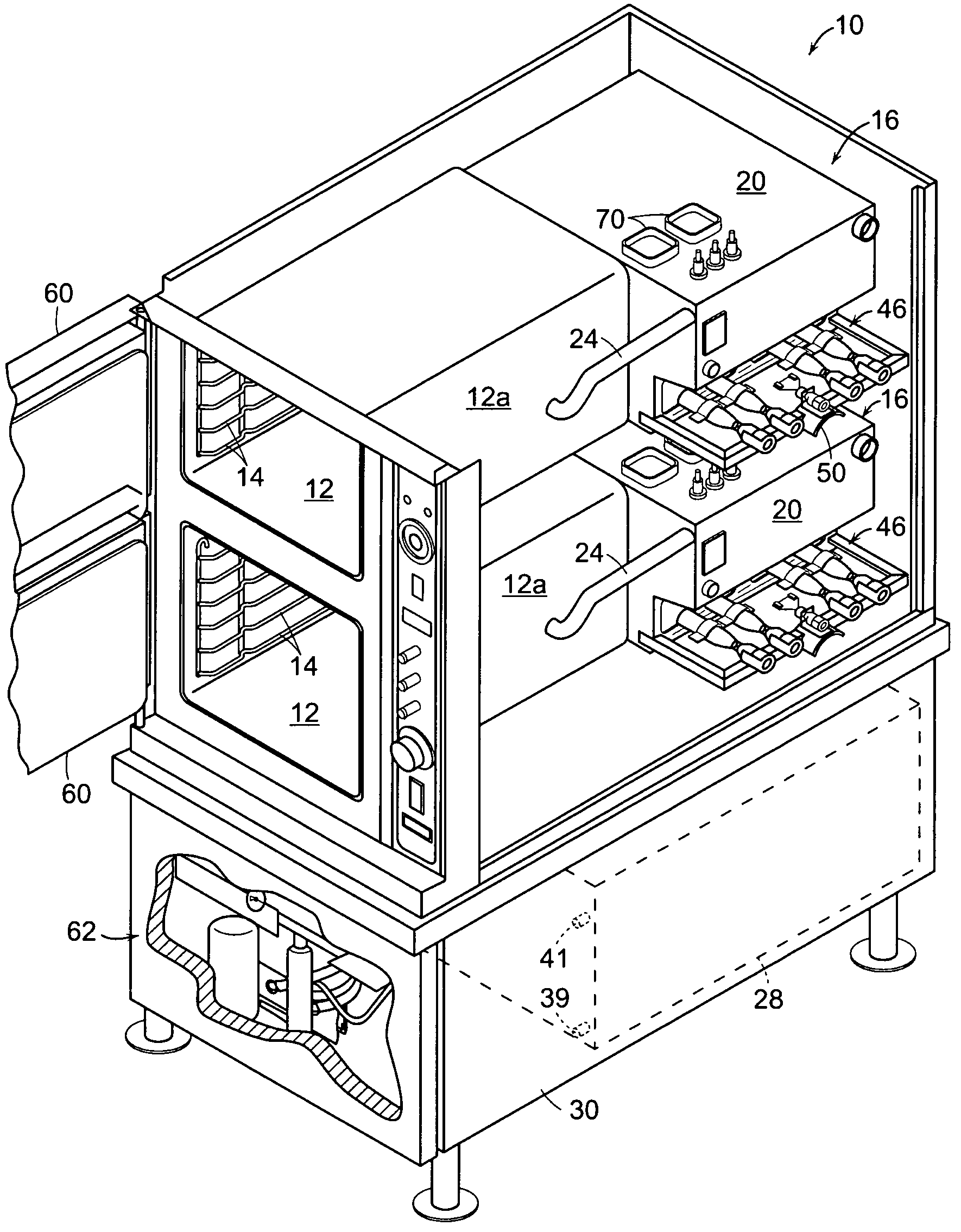

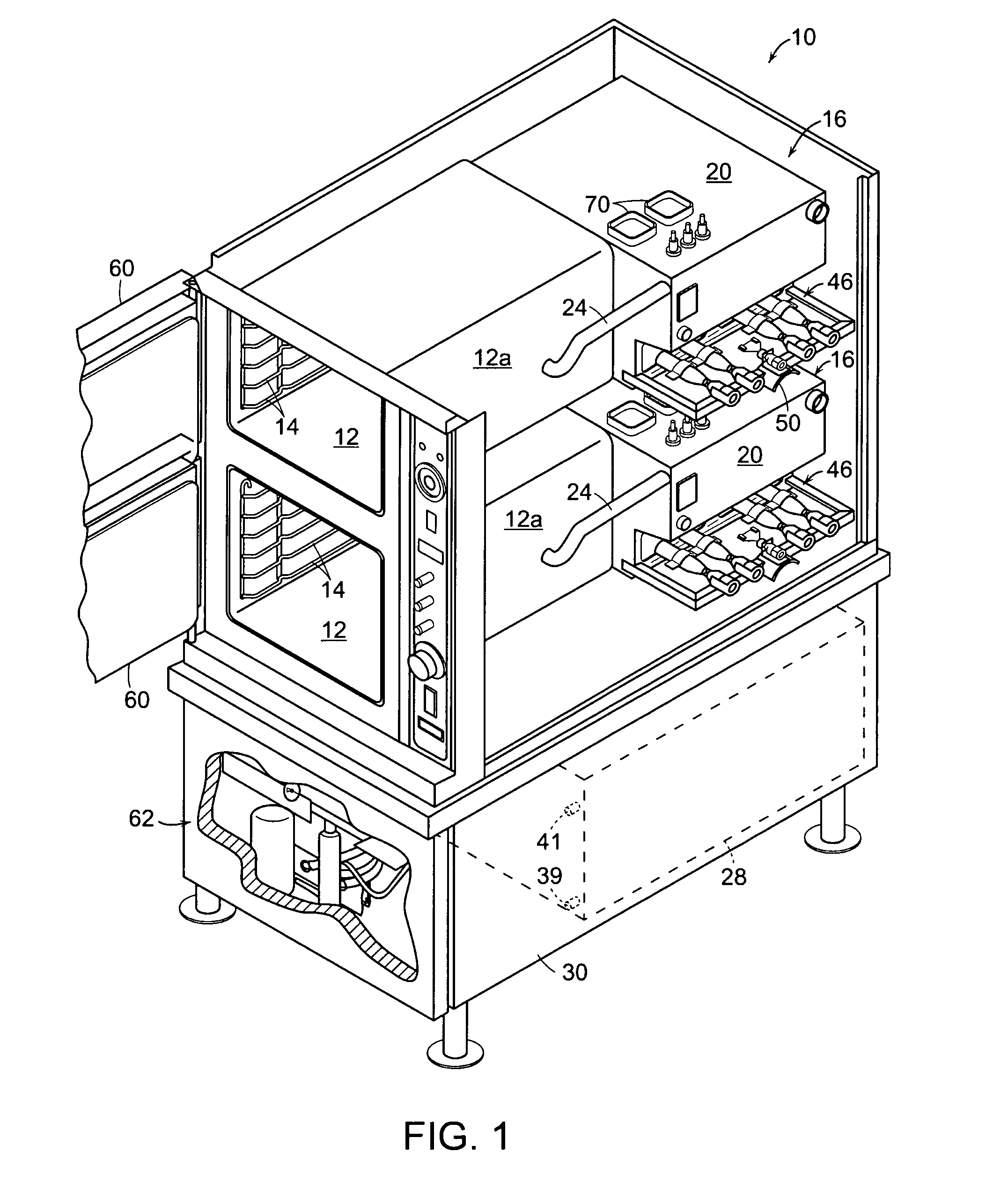

RFID food production, inventory and delivery management system for a restaurant

InactiveUS20070251521A1Data processing applicationsLighting and heating apparatusMachine visionEngineering

A system and method for managing food production, inventory and delivery in a restaurant by automatically monitoring the types and quantities of food types that have been cooked and are in a cooked food holding area. Food holding trays are equipped with radio frequency identification (RFID) tags, and holding cabinets are equipped with RFID interrogators. The type and quantity of food items are determined manually or by machine vision or weighing systems, and the data is stored on the RFID tags and in a controller. The system manages the use of food items on a first-in, first-out basis, alerts operators when the inventory of an item is nearing exhaustion, and alerts operators when food items in the holding area must be discarded. The system manages movable trays of food no matter where in the facility they are located.

Owner:RESTAURANT TECH

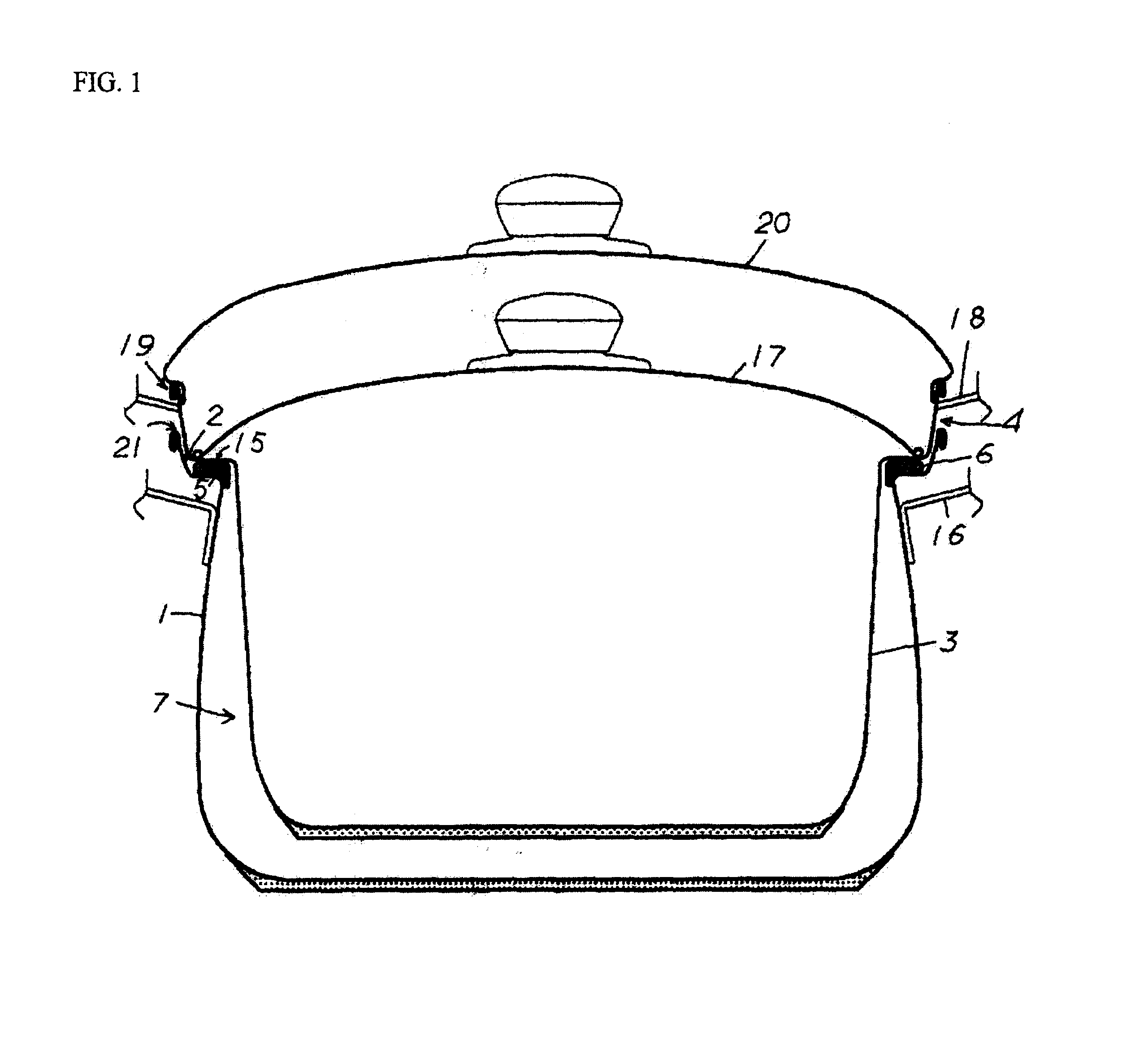

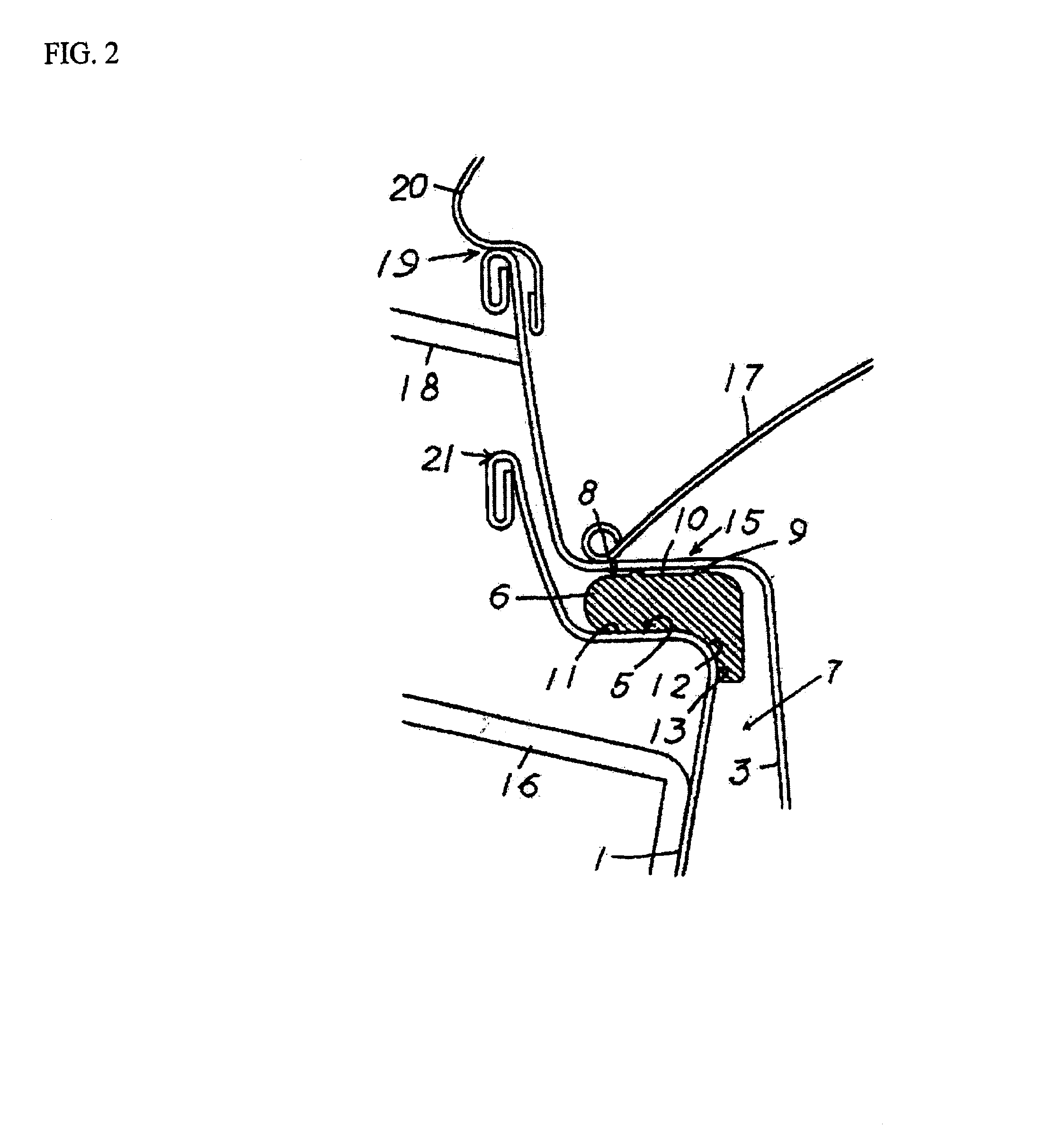

Thermally insulated pot

InactiveUS20020185012A1Multiple-unit cooking vesselsWater heating stoves/rangesThermal insulationEngineering

A thermally insulated cooking pot consists of an outer pot and an inner pot. The inner pot is suspended within the outer pot by hanging from the top inner circumferential area of the outer pot with its own top outer circumferential area. The space between the inner and outer pots becomes an insulation cavity. The contact point between the two pots is sealed by a pliable packing ring with an L-shaped cross-section, thereby sealing the insulation cavity. This sealed insulation cavity provides excellent thermal insulation. The packing ring contains a plurality of protrusions on the surface that come into contact with the inner pot to prevent the packing ring from sticking to the inner pot. The gap formed between the packing ring protrusions and the inner pot prevents the inner pot from sticking to the packing ring.

Owner:PATERSONS ENTERPRISES

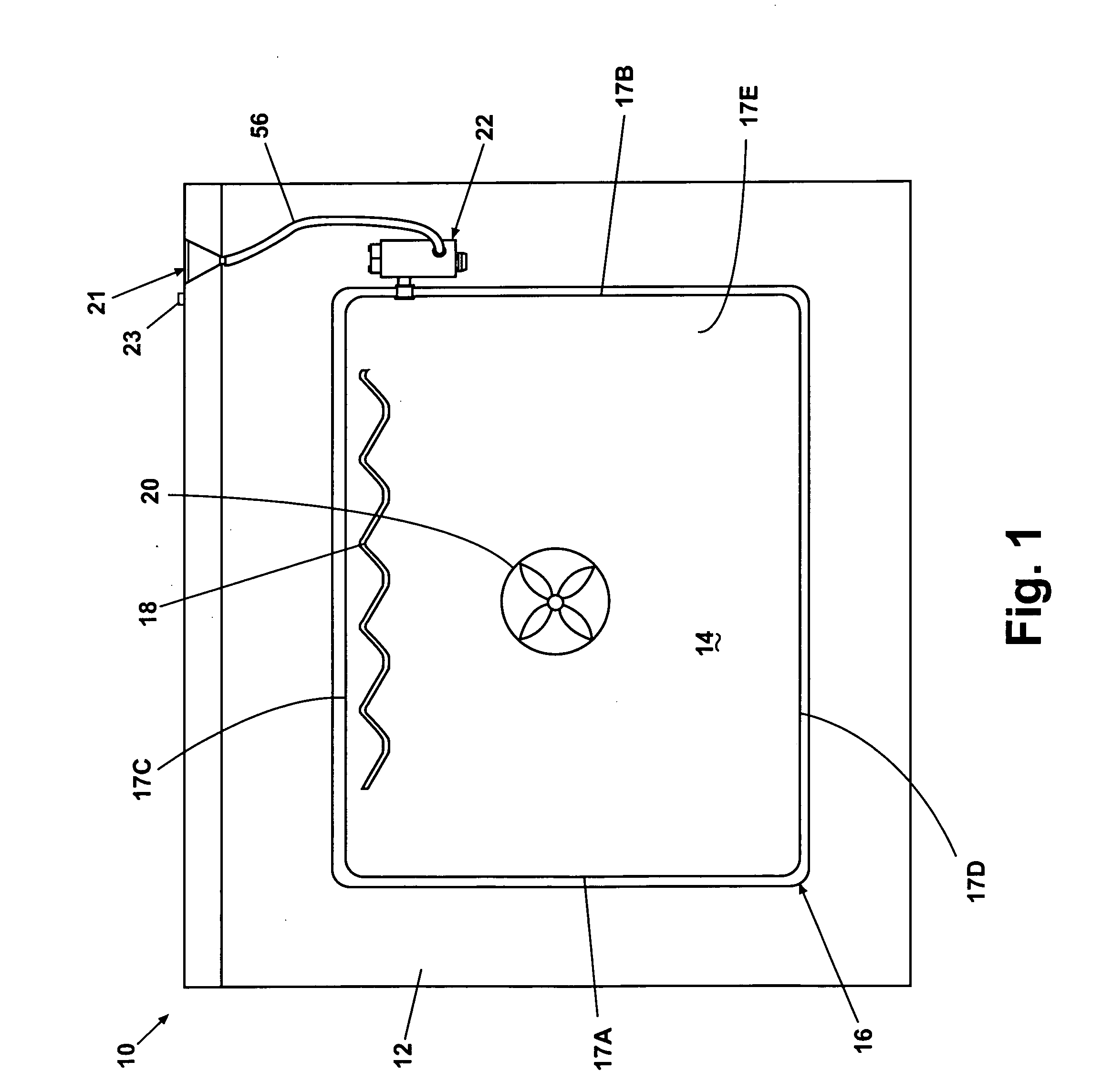

Cooking appliance with steam generator

InactiveUS20080095905A1More energy efficientEnergy efficiencyMilk preservationDough treatmentPulp and paper industryEngineering

Owner:WHIRLPOOL CORP

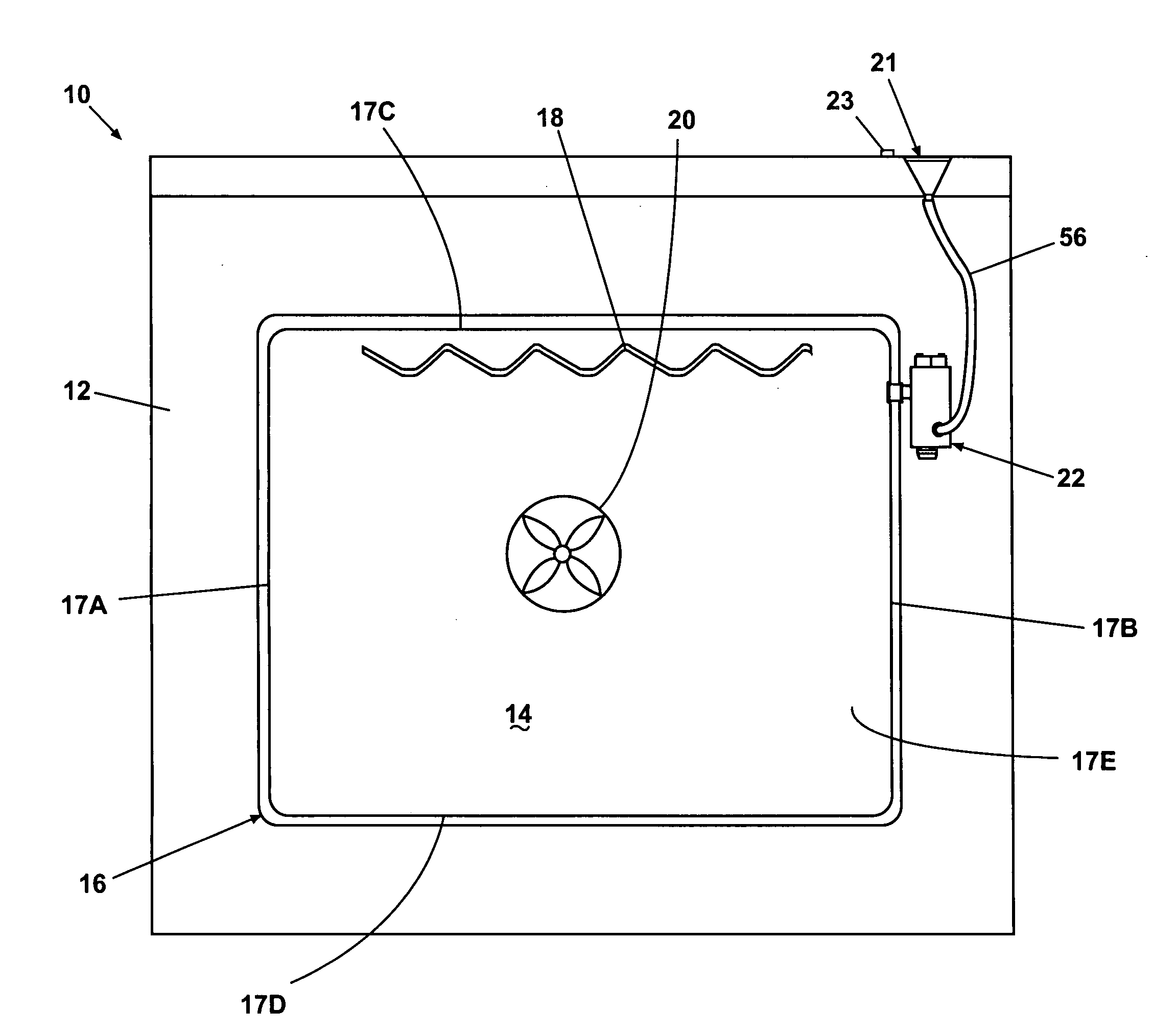

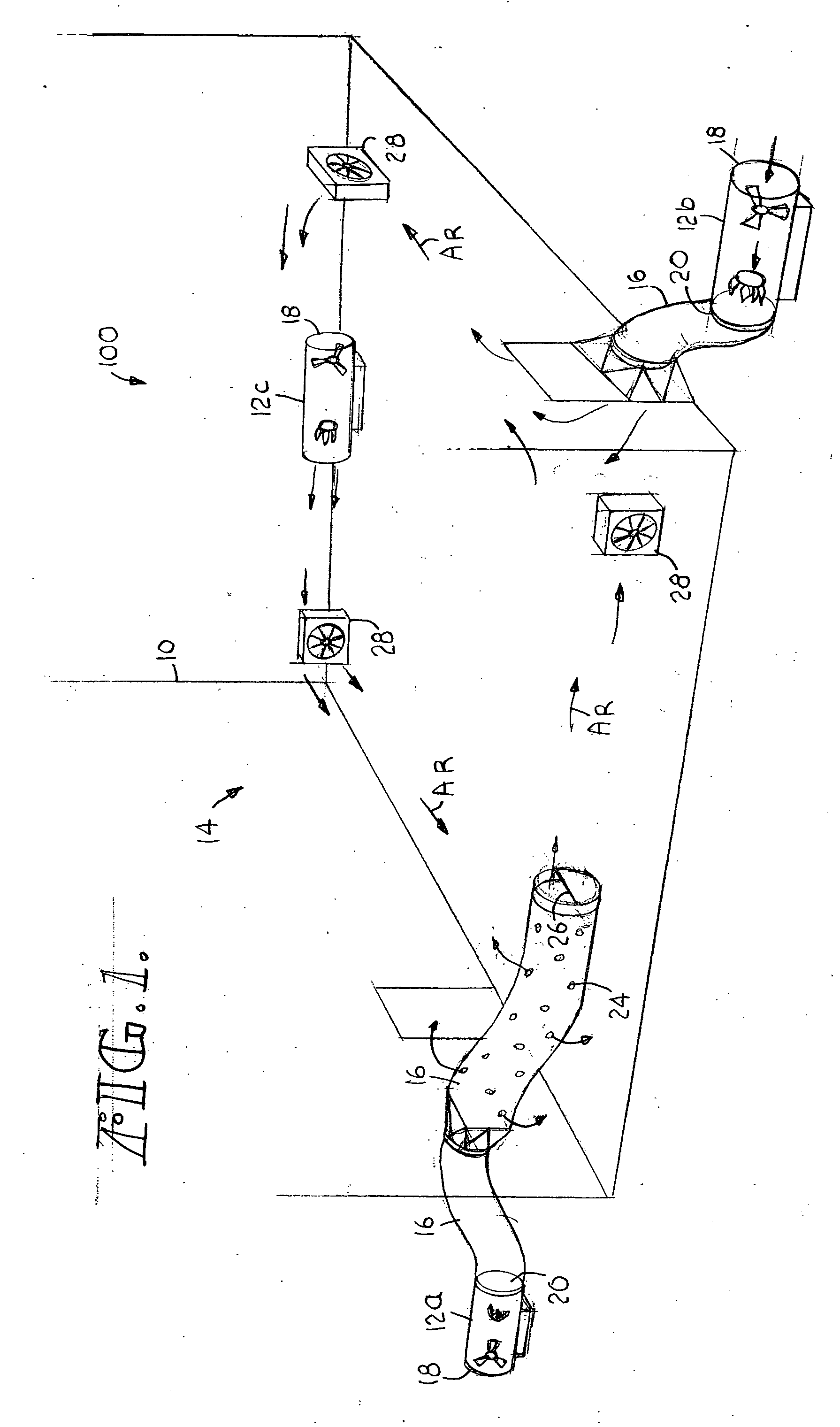

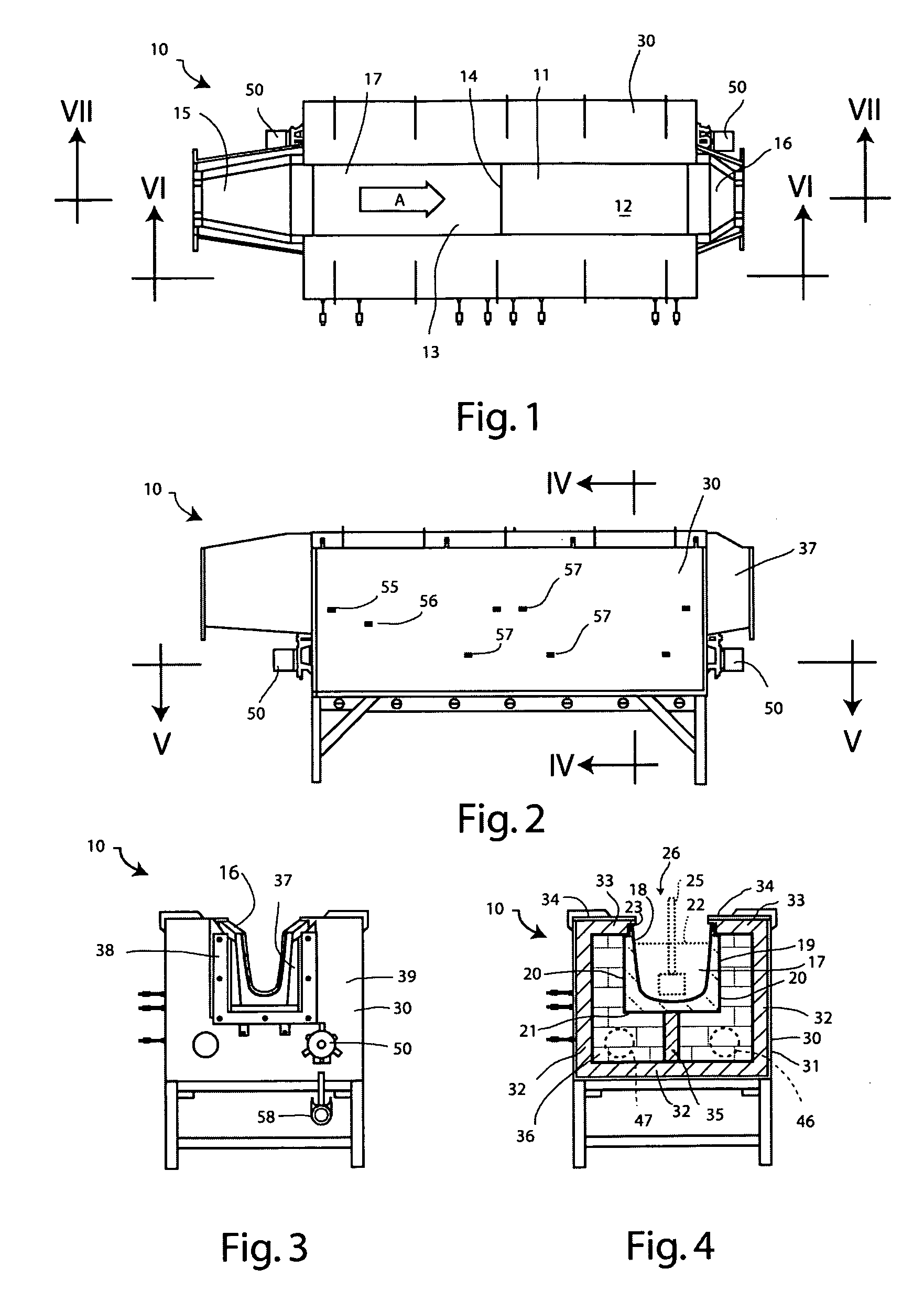

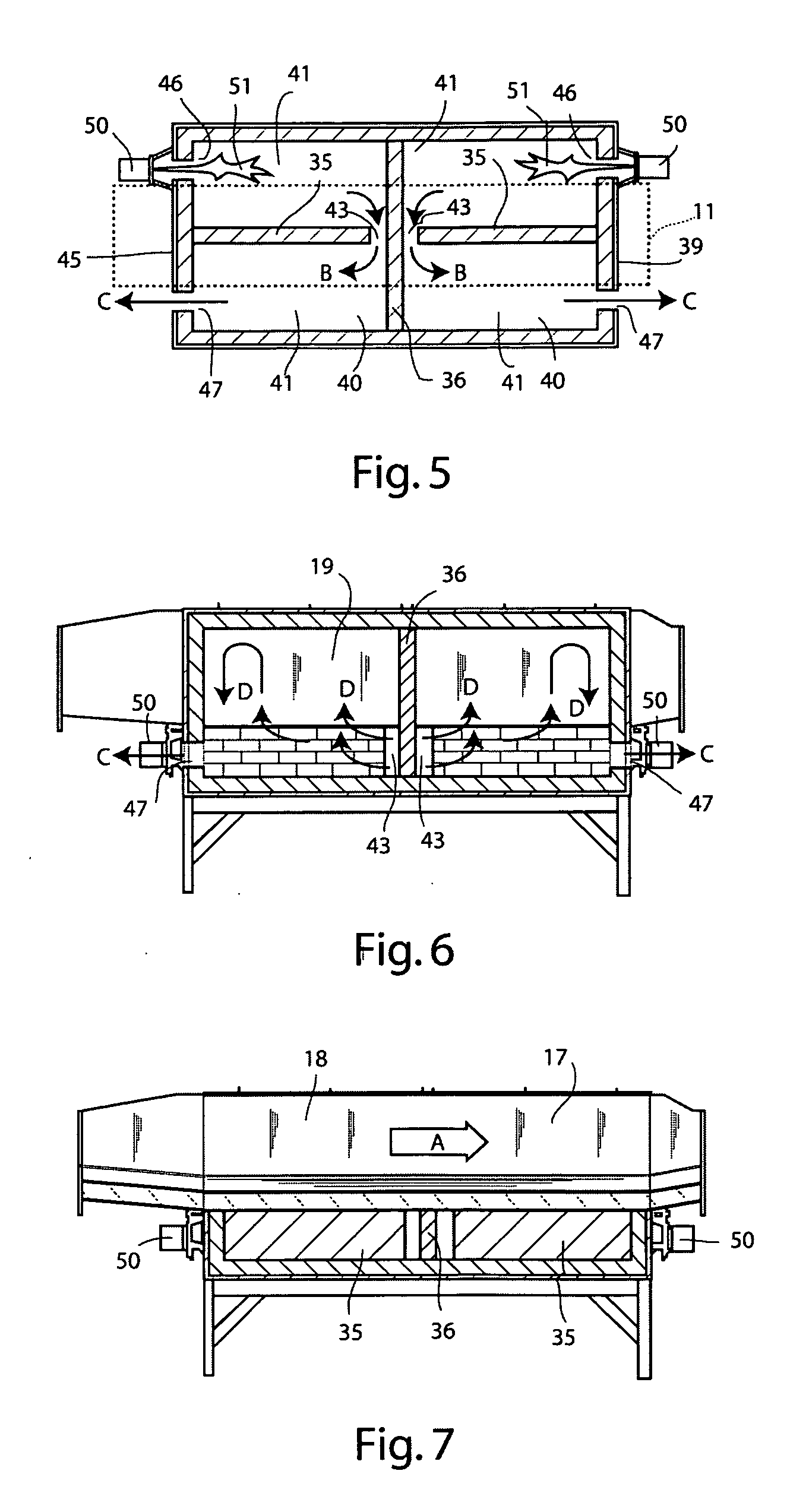

Method of extermination utilizing heated air

InactiveUS20050246942A1Conducive to pest controlUniform temperature distributionHot-air central heatingOther heat production devicesTemperature stratificationEngineering

A method of exterminating organisms is provided utilizing heated circulating air. First, a determination is made as to which enclosed areas of the building or other structure are to undergo extermination. This step defines an application zone. Next, a desired elevated temperature limit is established for heated air that is to be circulated through the application zone. Heaters are provided in airflow communication with the application zone, and circulation fans are positioned throughout the application zone to move the heated air for proper heat distribution. The heaters utilize an amount of recirculated air already present in the application zone to cut down on the amount of energy needed to raise the air temperature within the application zone towards the desired elevated temperature limit, and to eliminate the need for high CFM airflow heaters to achieve air temperature elevation. The temperature at various nodes within the application zone may be monitored to allow personnel to redirect circulating airflow within the application zone to balance out areas of higher air temperature with areas of lower air temperature. The method takes advantage of convection heat transfer to raise the temperature evenly within an application zone, minimizing temperature stratification which could result in ineffective pest extermination and / or damage to equipment and facilities.

Owner:IND FUMIGANT

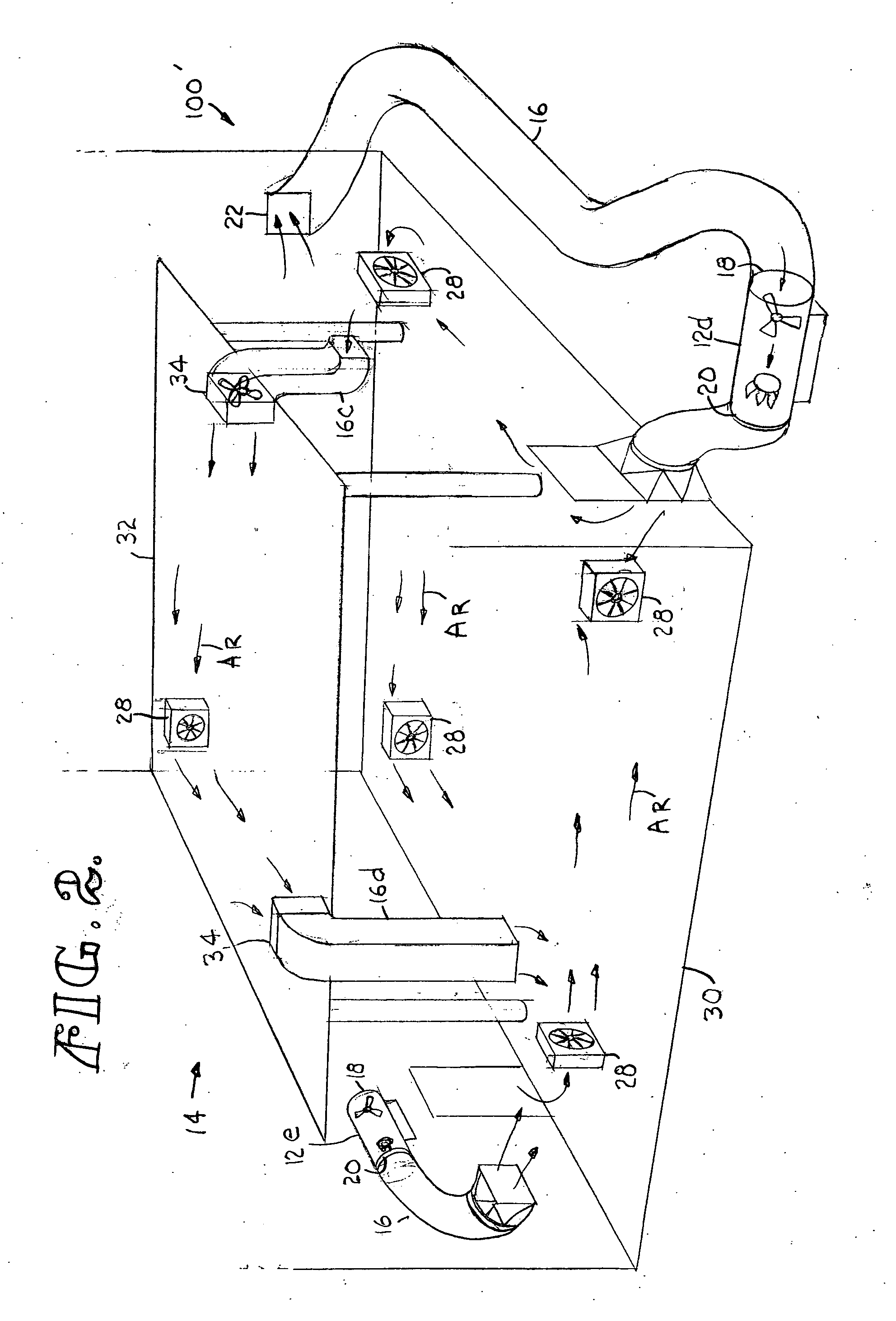

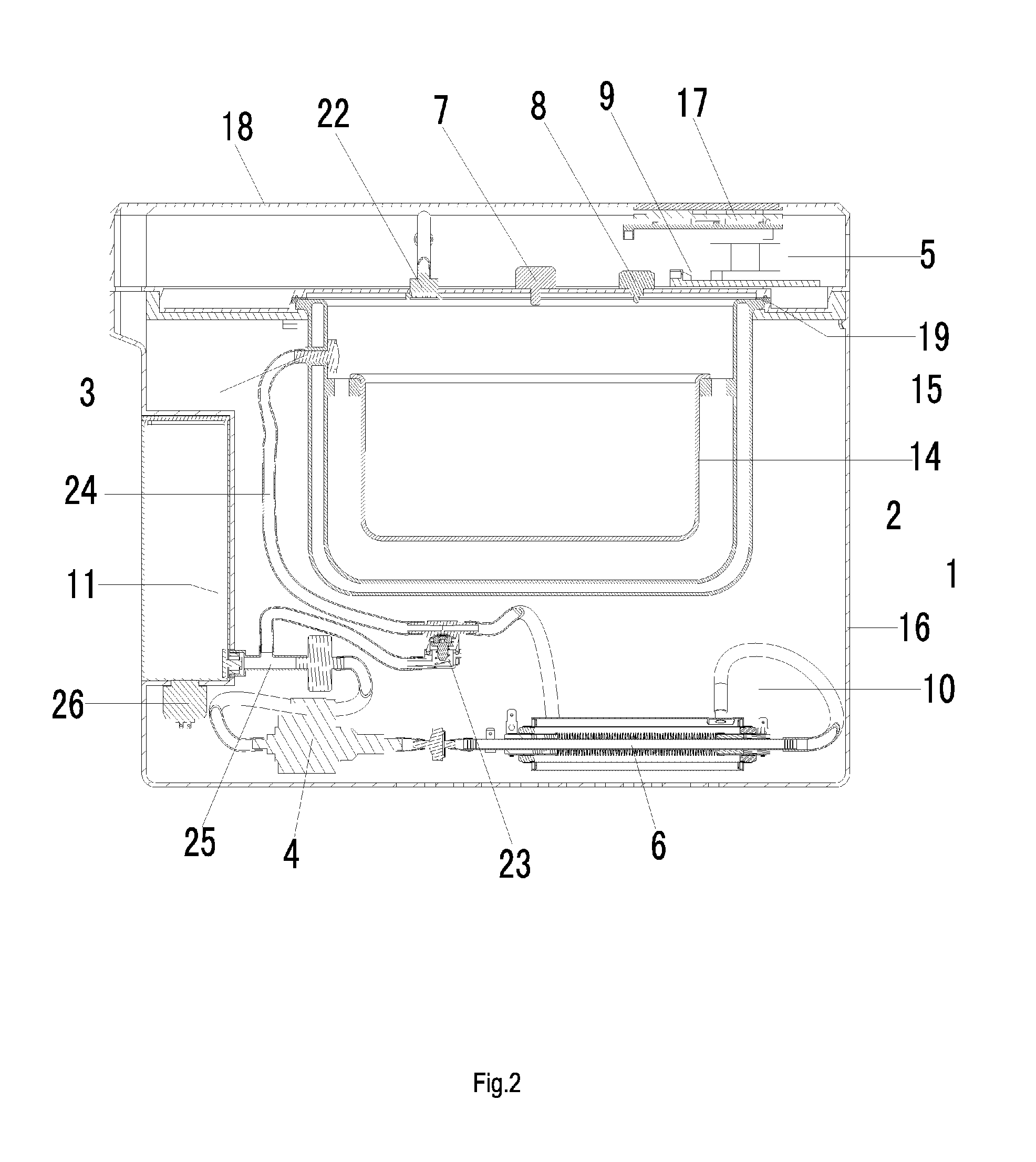

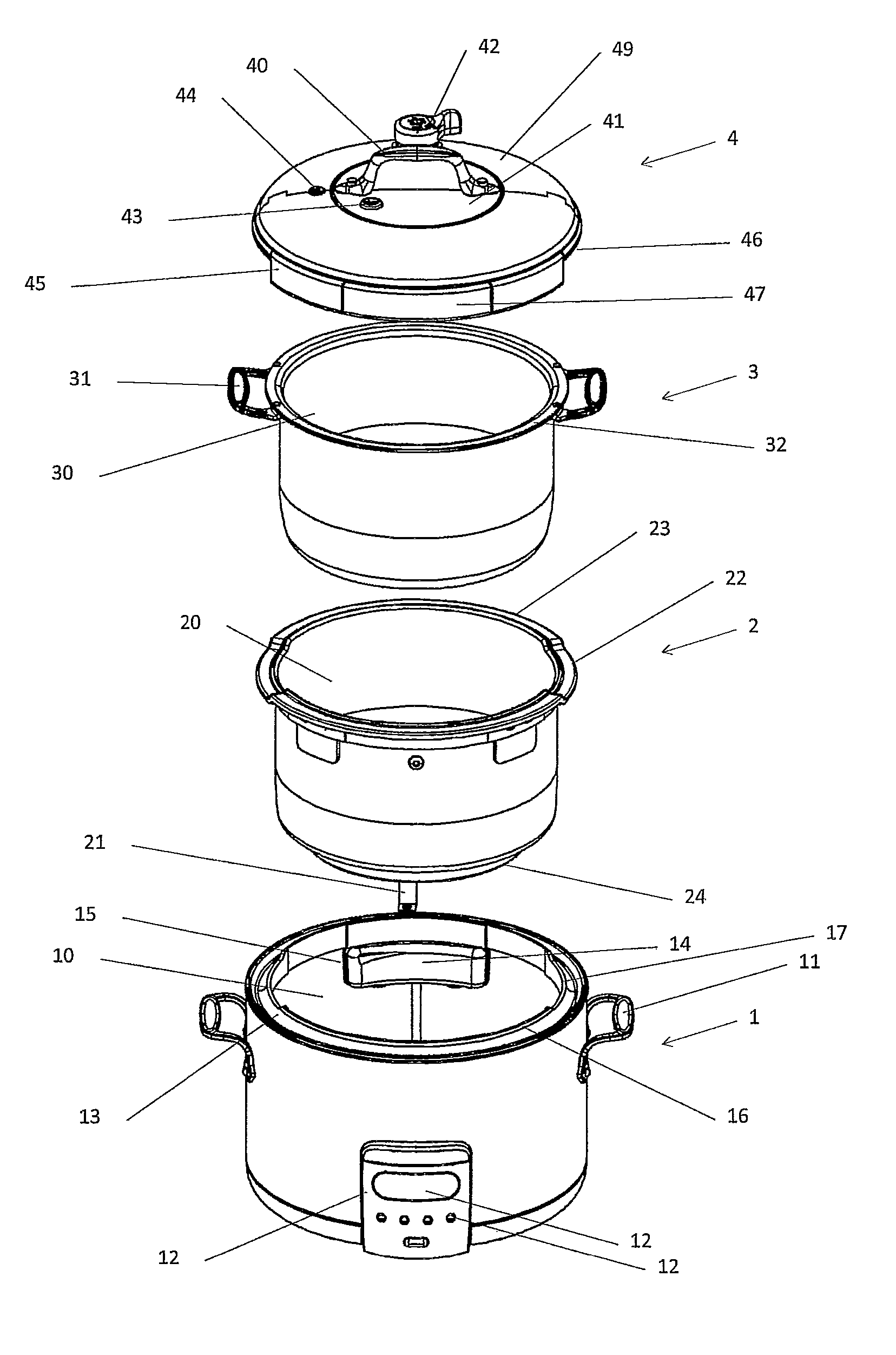

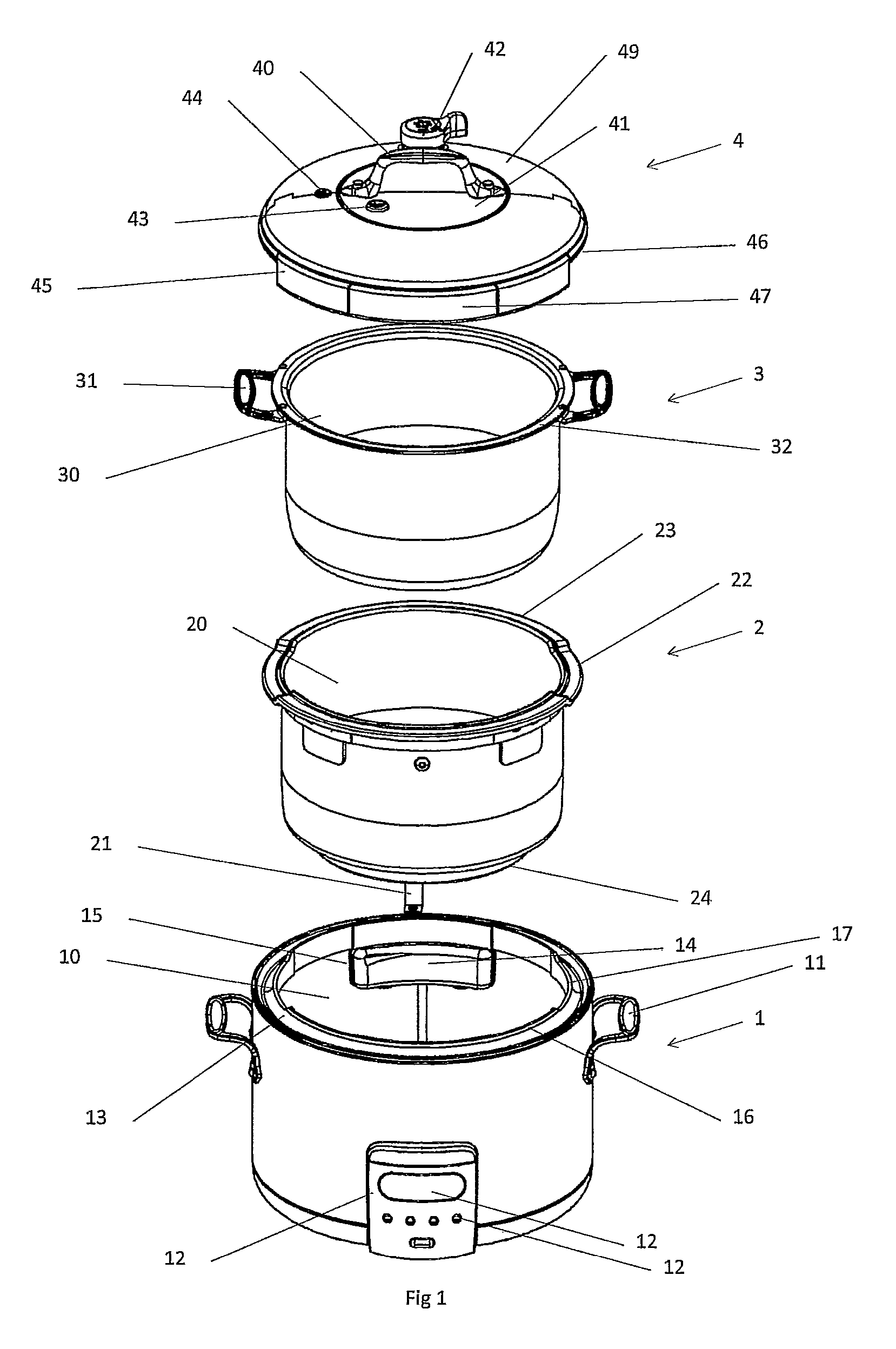

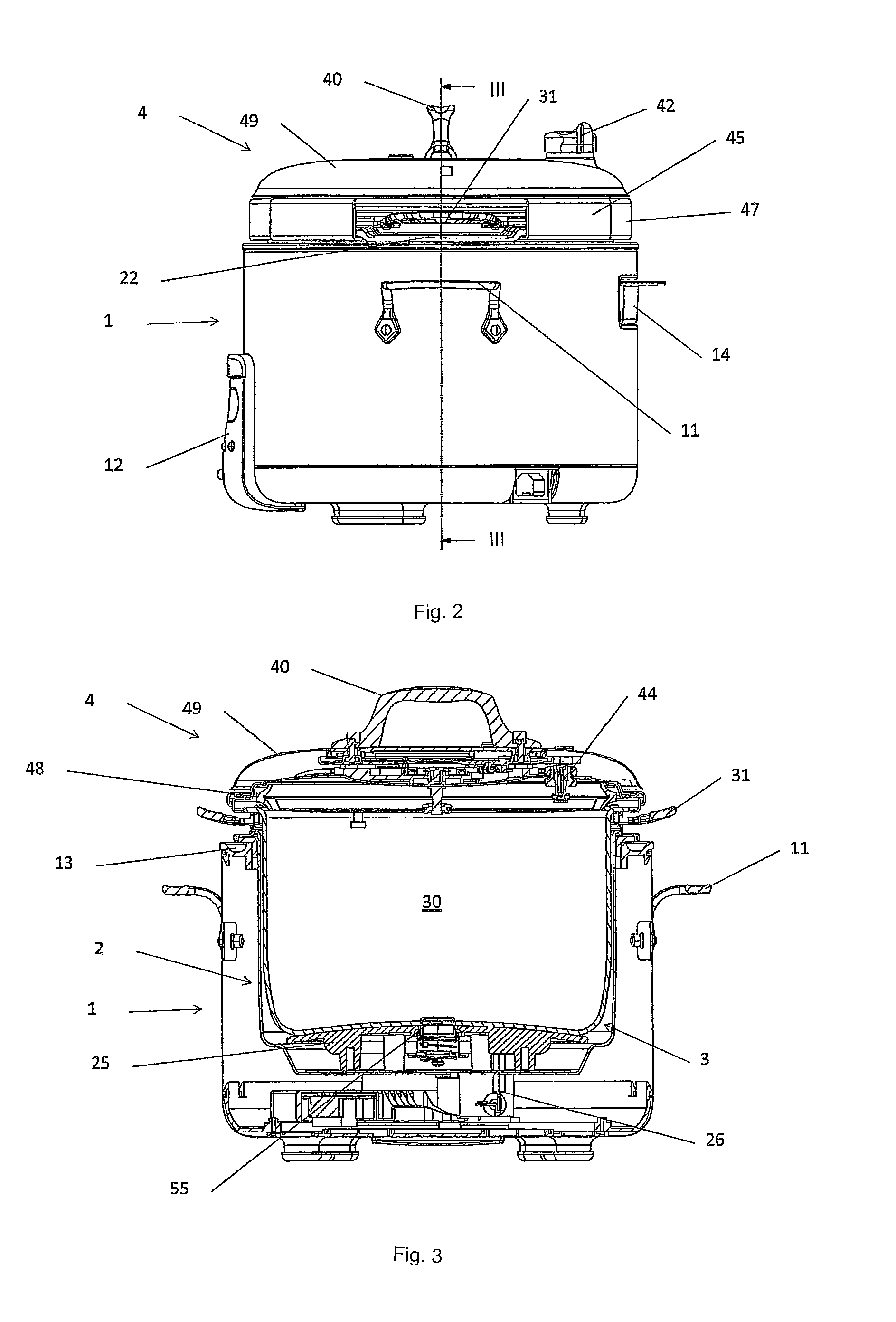

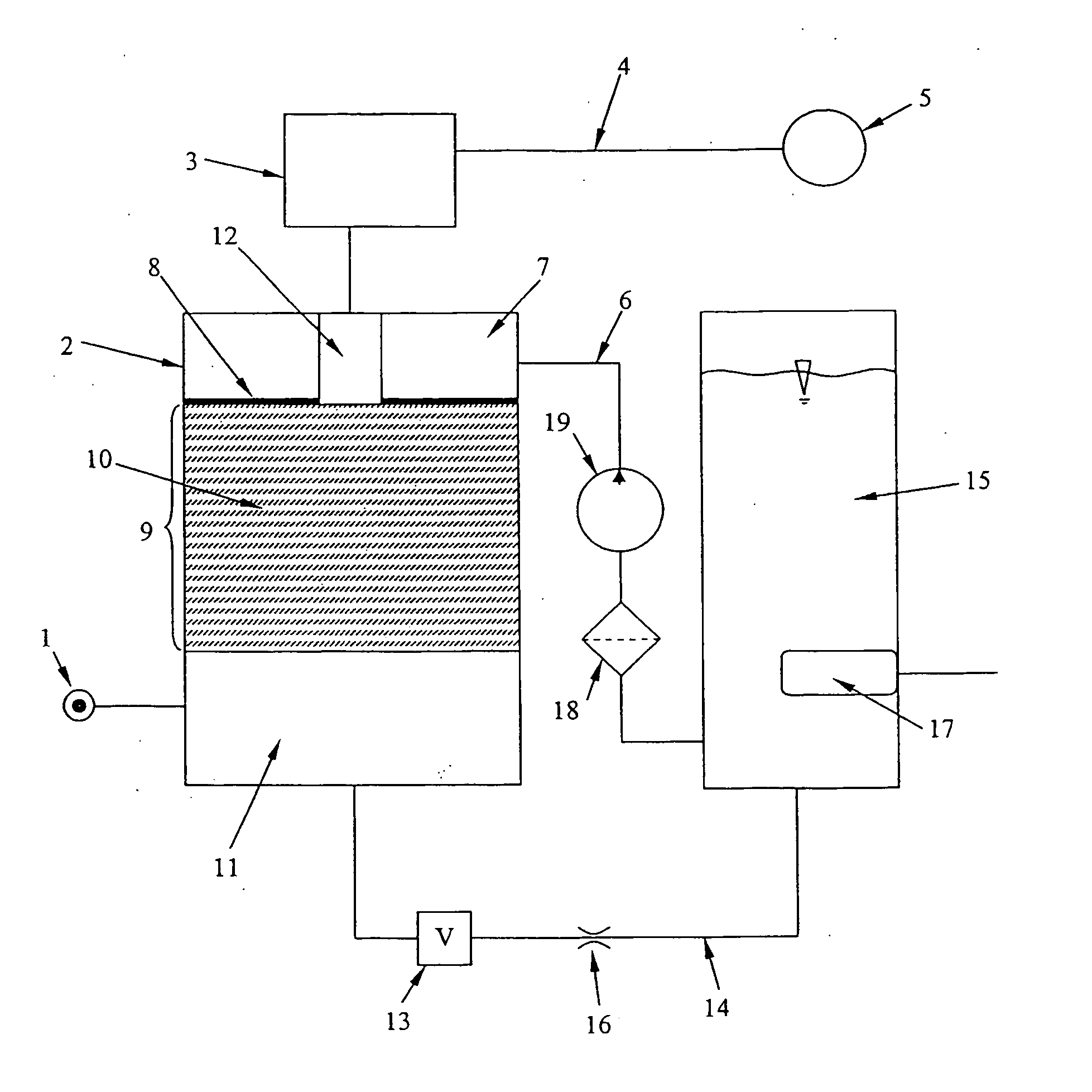

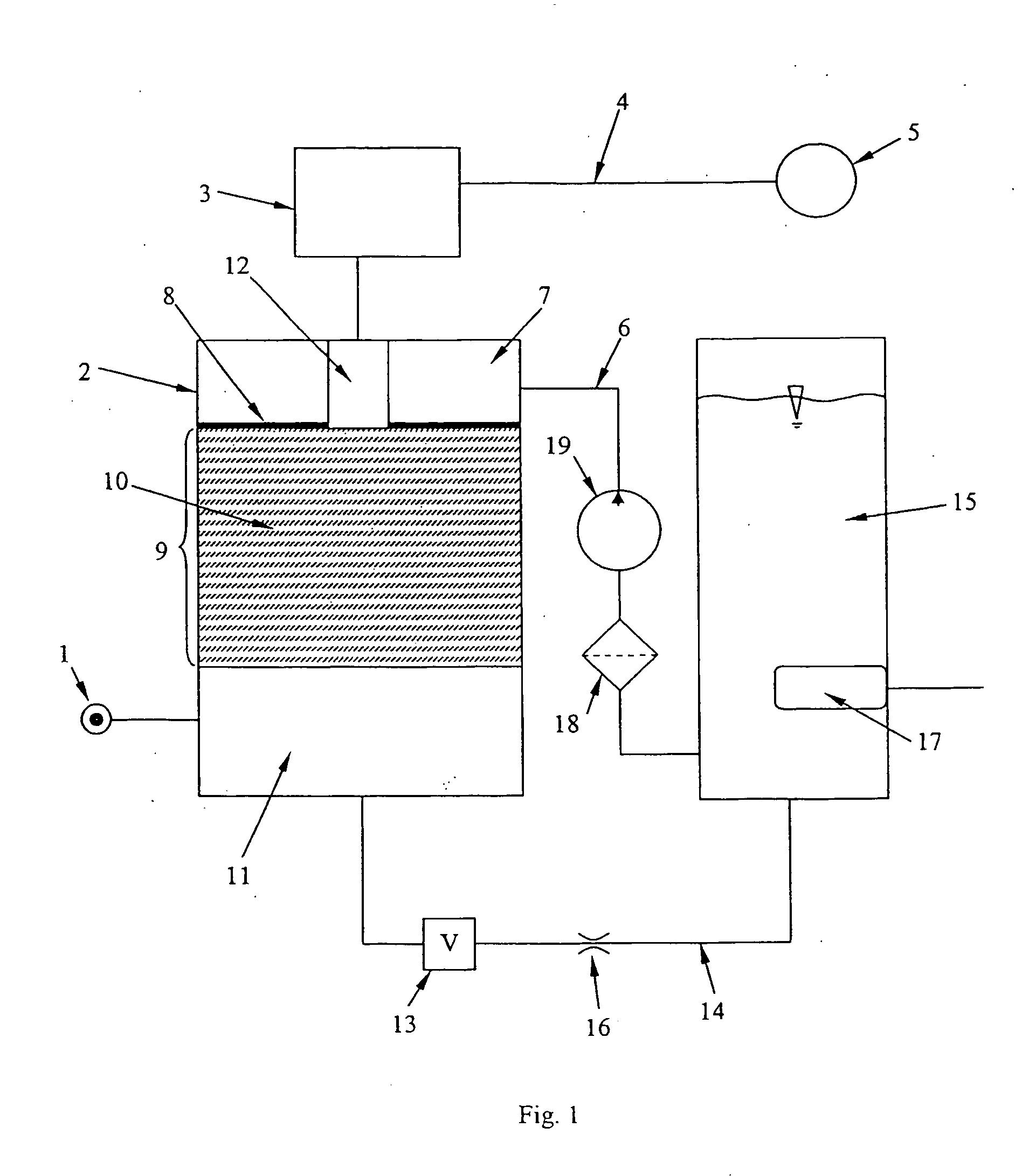

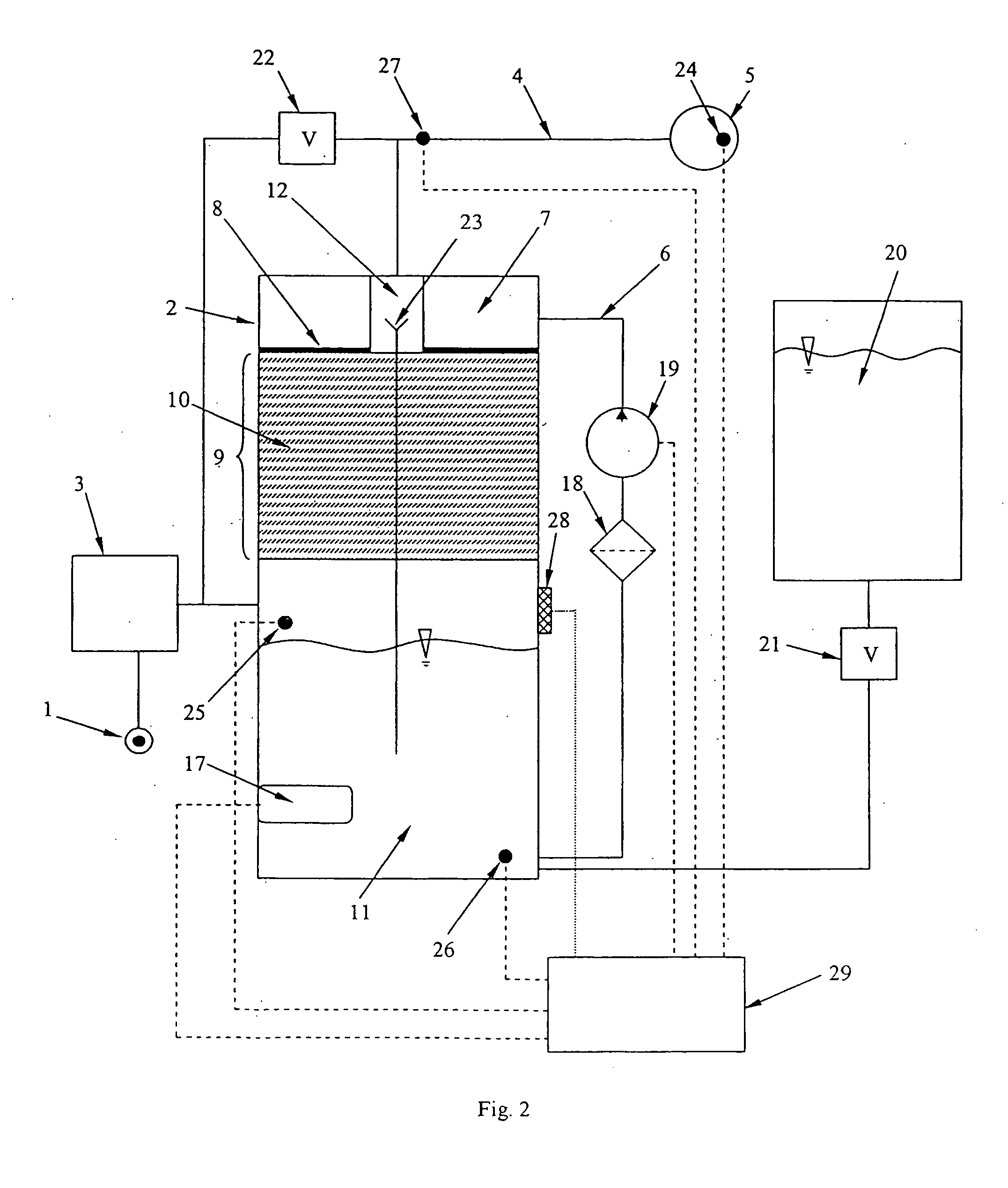

Pressure cooker

A pressure cooker (1) comprises: a pressure vessel (2) for containing items to be cooked; an inlet (3) in a wall of the pressure vessel (2) for receiving steam from a steam source; and a pump (4) for pumping the steam from the steam source into the pressure vessel (2) through the inlet (3), wherein the pump (4) produces a maximum pressure below a maximum safety pressure for the pressure vessel (2).

Owner:TOP ELECTRICAL APPLIANCES IND

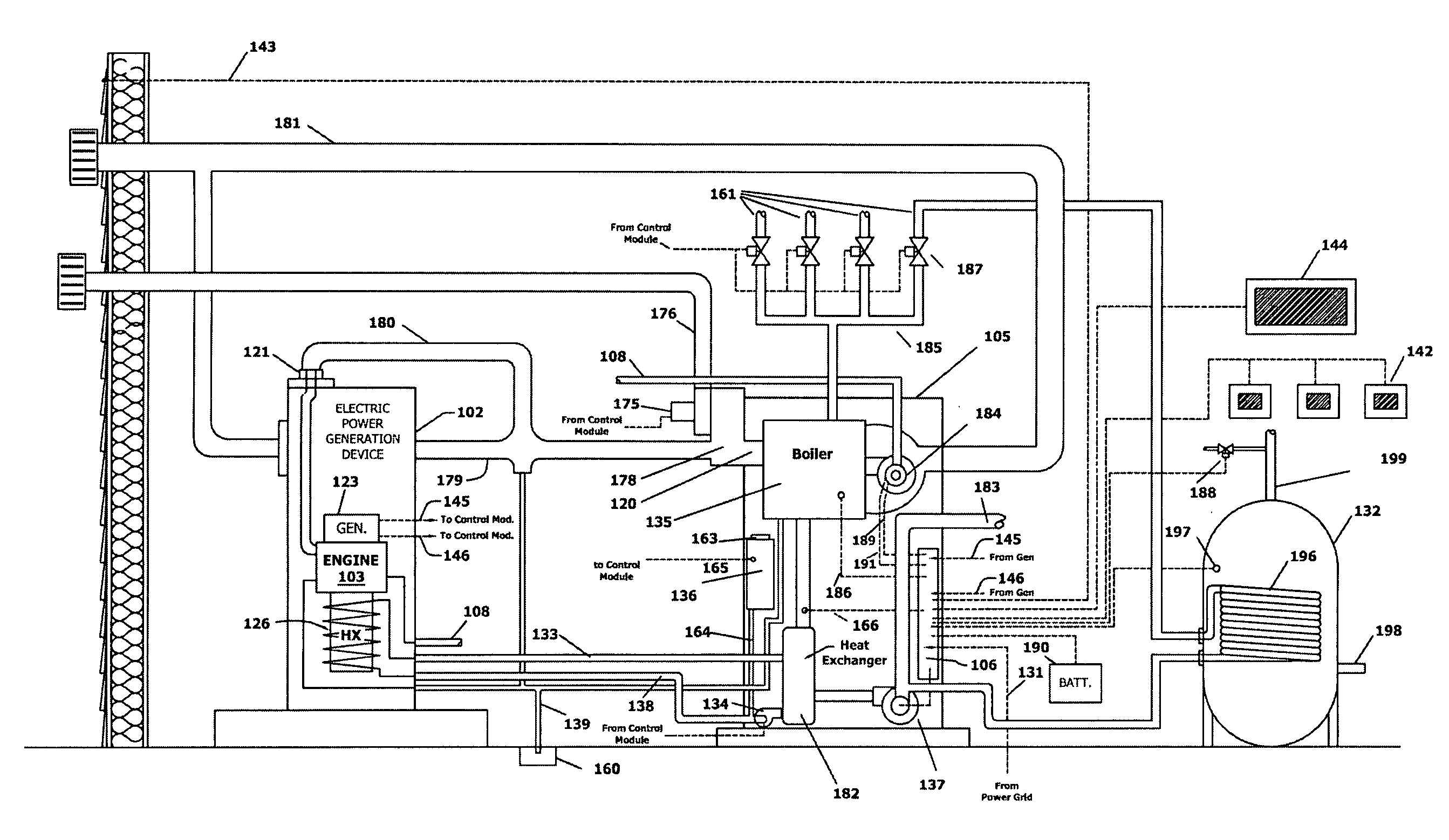

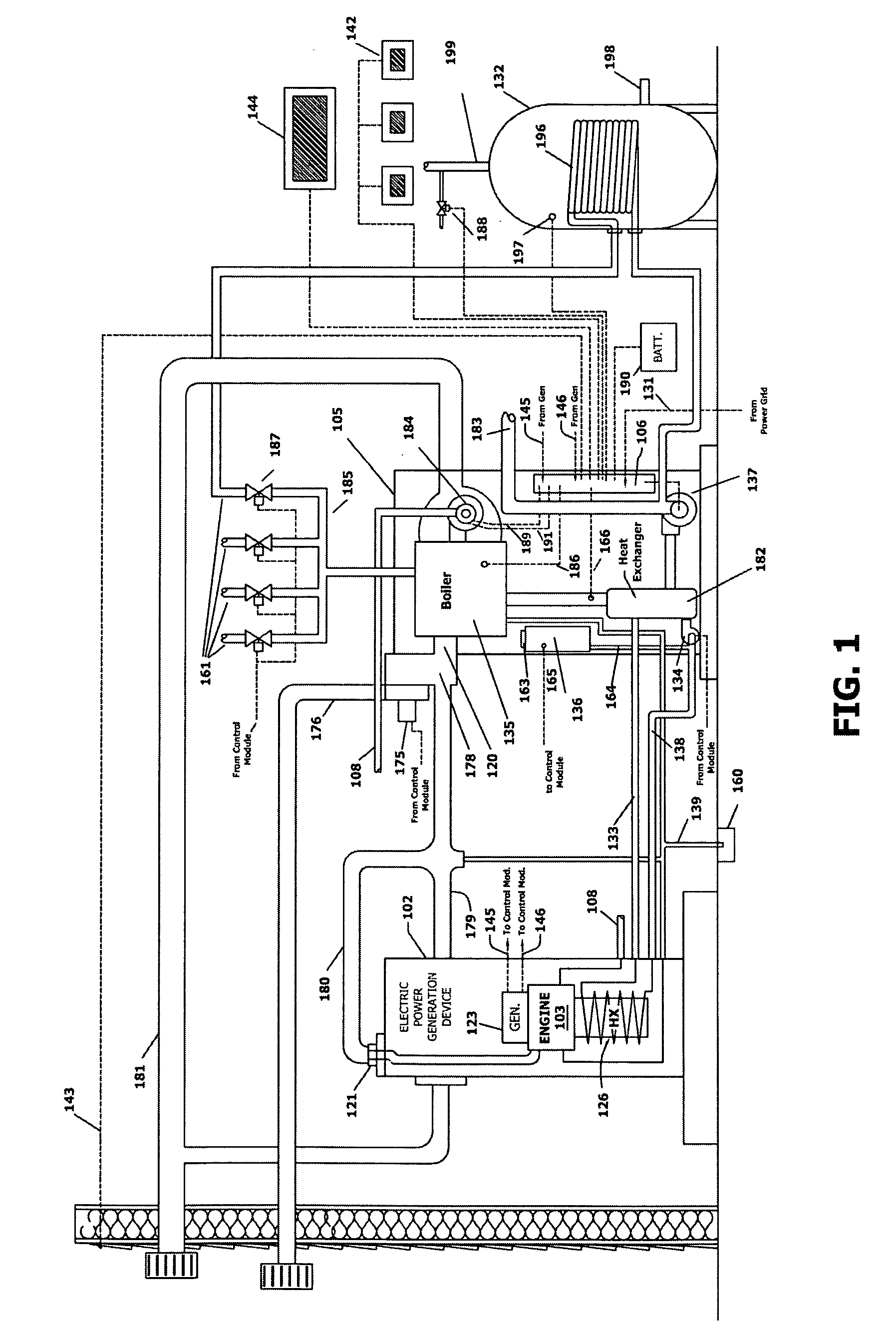

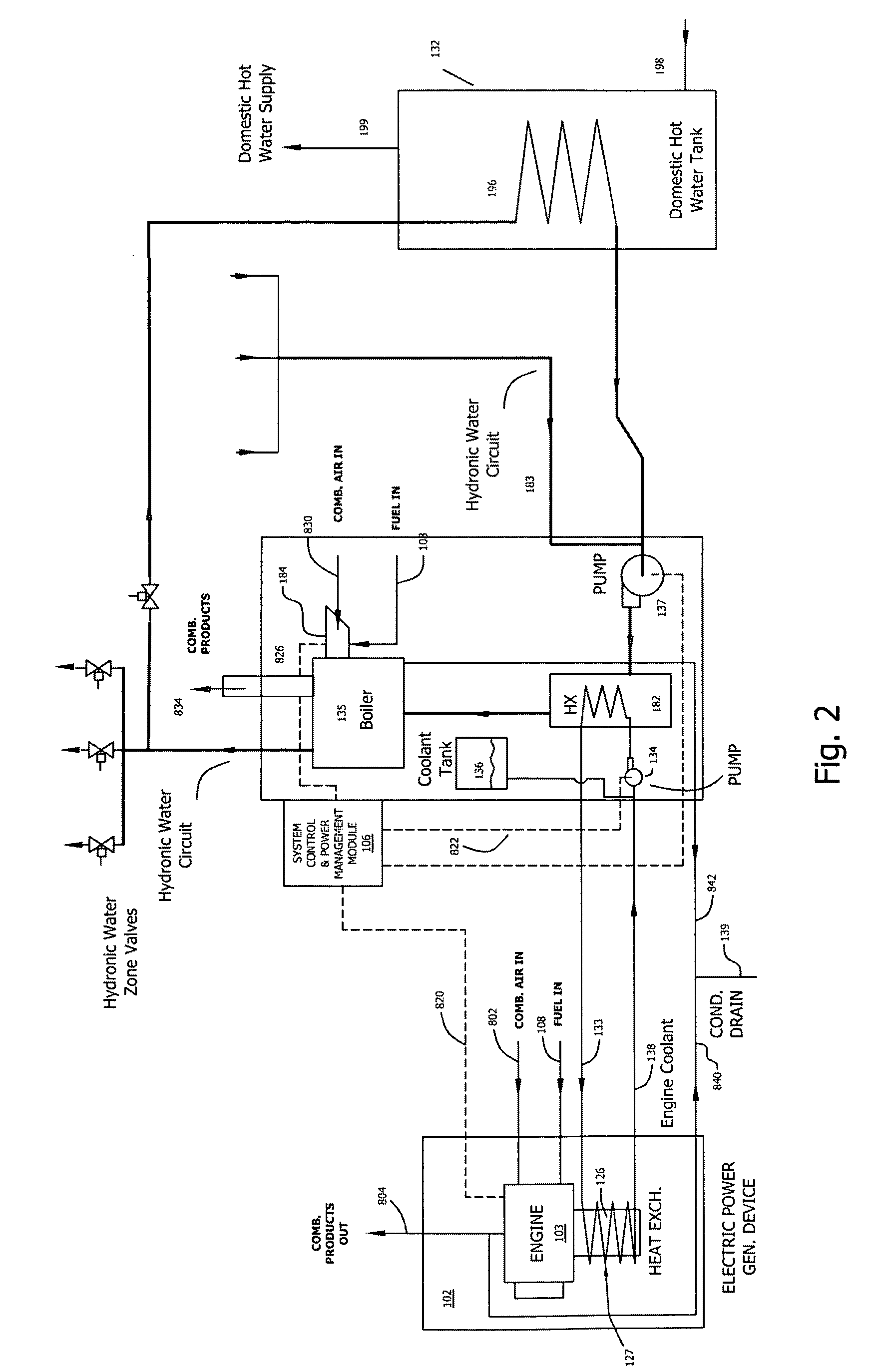

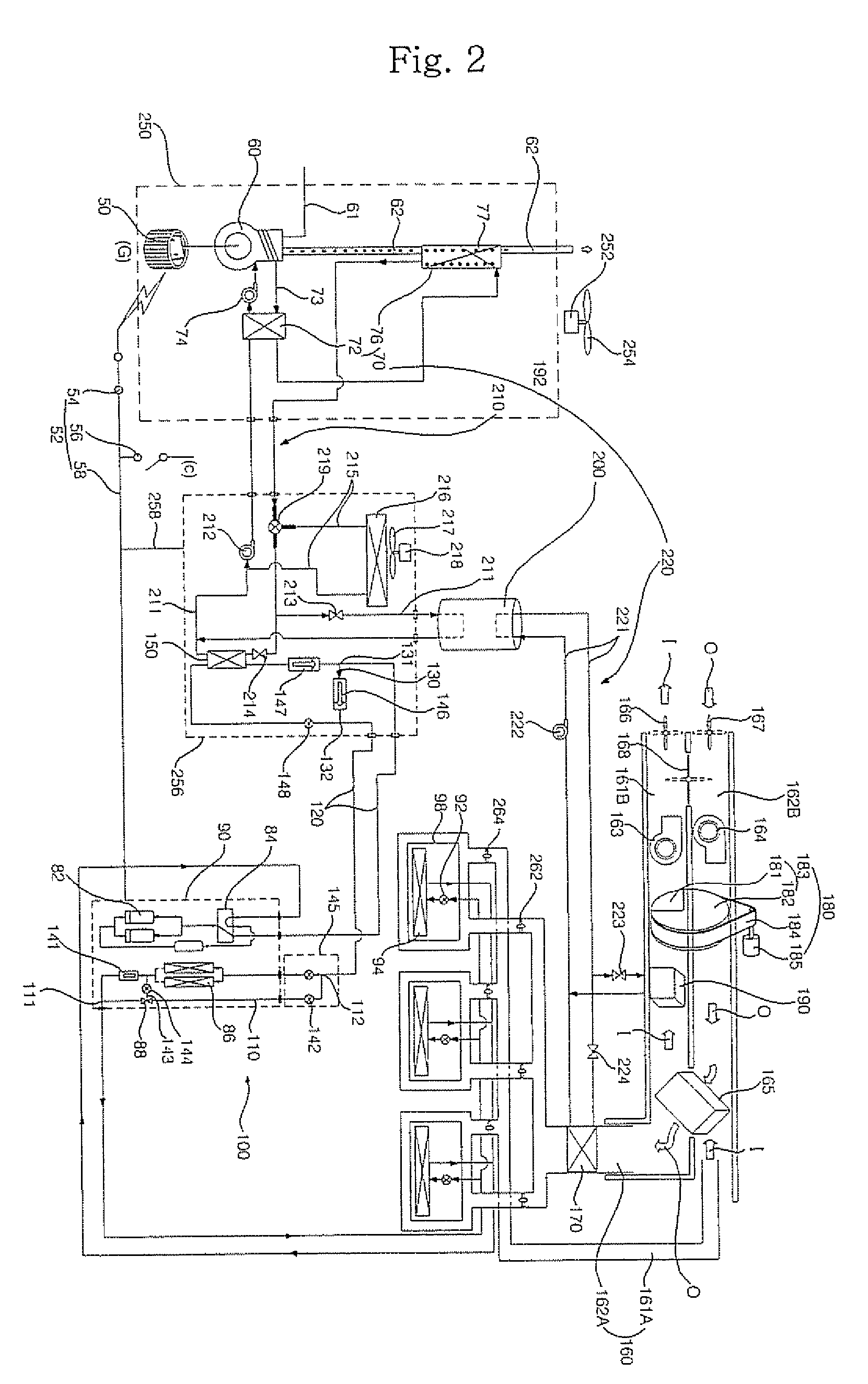

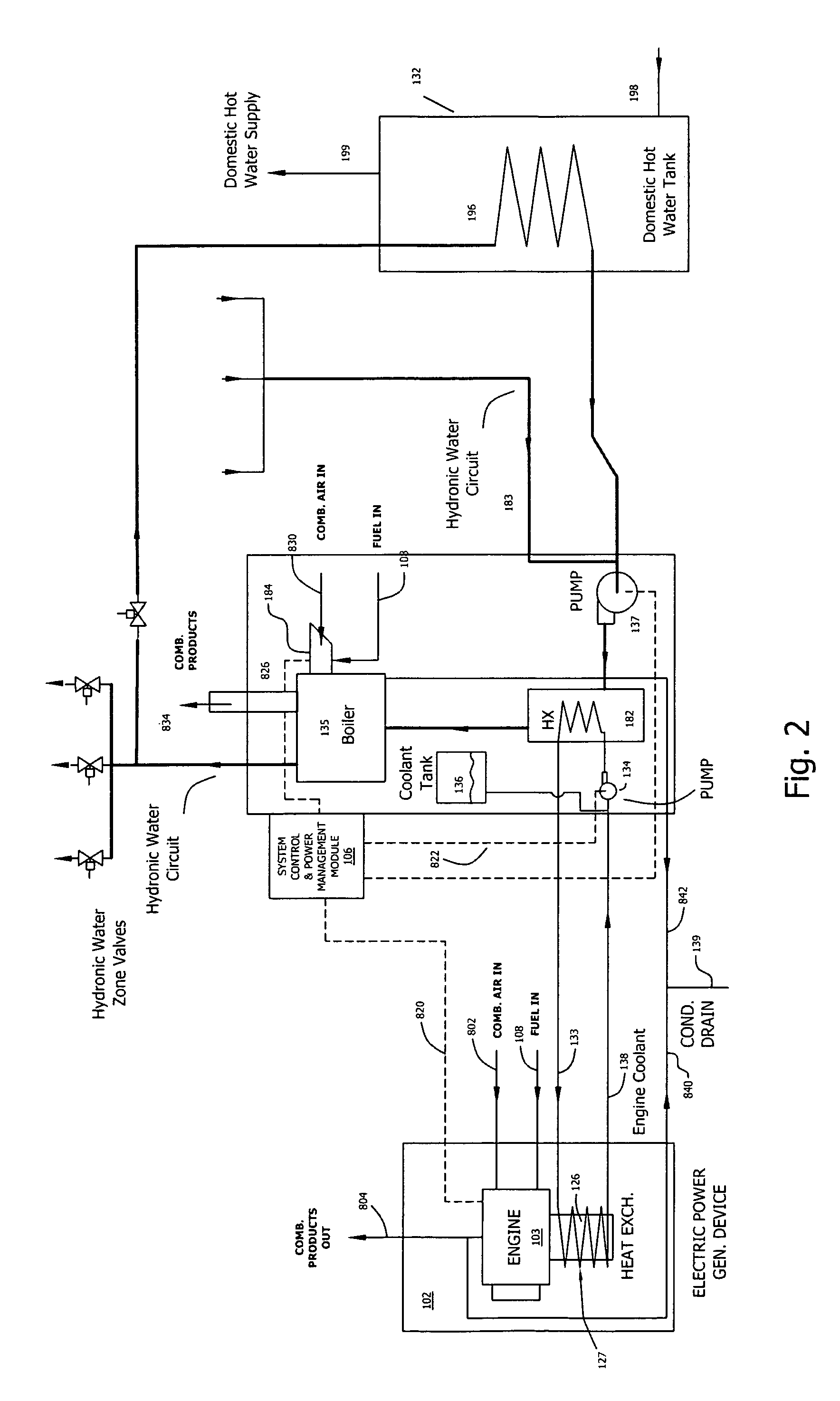

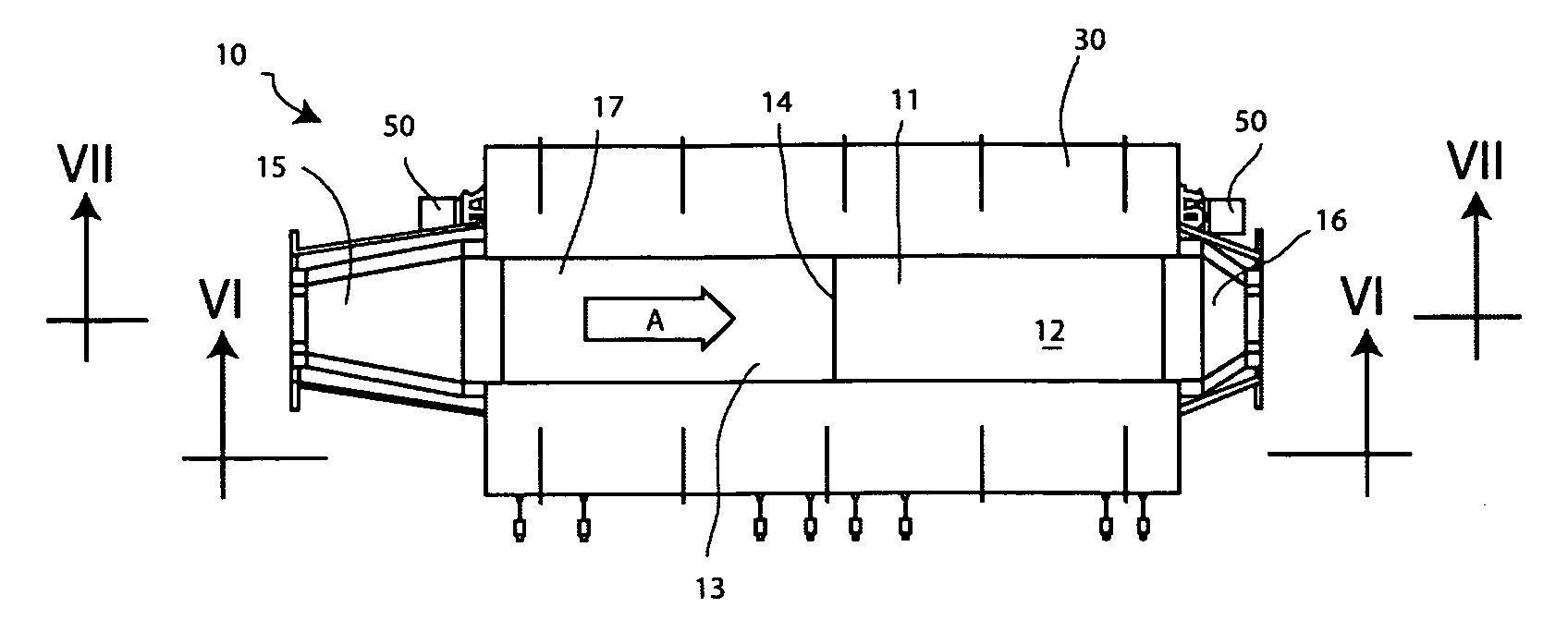

System and method for hydronic space heating with electrical power generation

ActiveUS20050161521A1Easy to useMaximizing run timeInternal combustion piston enginesWaste gas energyCogenerationEngineering

This invention provides a system and method for cogeneration of electric power and building heat that efficiently interfaces a liquid-cooled electric power generator with a multi-zone forced hot water (hydronic) space heating system. The system and method utilizes an electric generator with an electric output capacity (kW) that is near the time-averaged electric power consumption rate for the building and with a heat generation capacity that is useful for meeting building heating needs. This generator is operated as the priority source of heat for the building, but normally only when there is a demand for heat in building, with the intent of running the generator for long periods of time and generating a total amount of electric energy (kWhs) that is significant in comparison to the total electric energy consumption of the building over time. The actual onsite time-variable power demand (kW) is met by a combination of the cogenerated electric power produced on site and quantities of electric power from the public electric power grid or another external power source. Hence, useful electric power is generated on site as a by-product of the required generation of heat for space or water heating. The generator is run at a speed / operating condition that is appropriate to maintaining a long operational life.

Owner:CLIMATE ENERGY

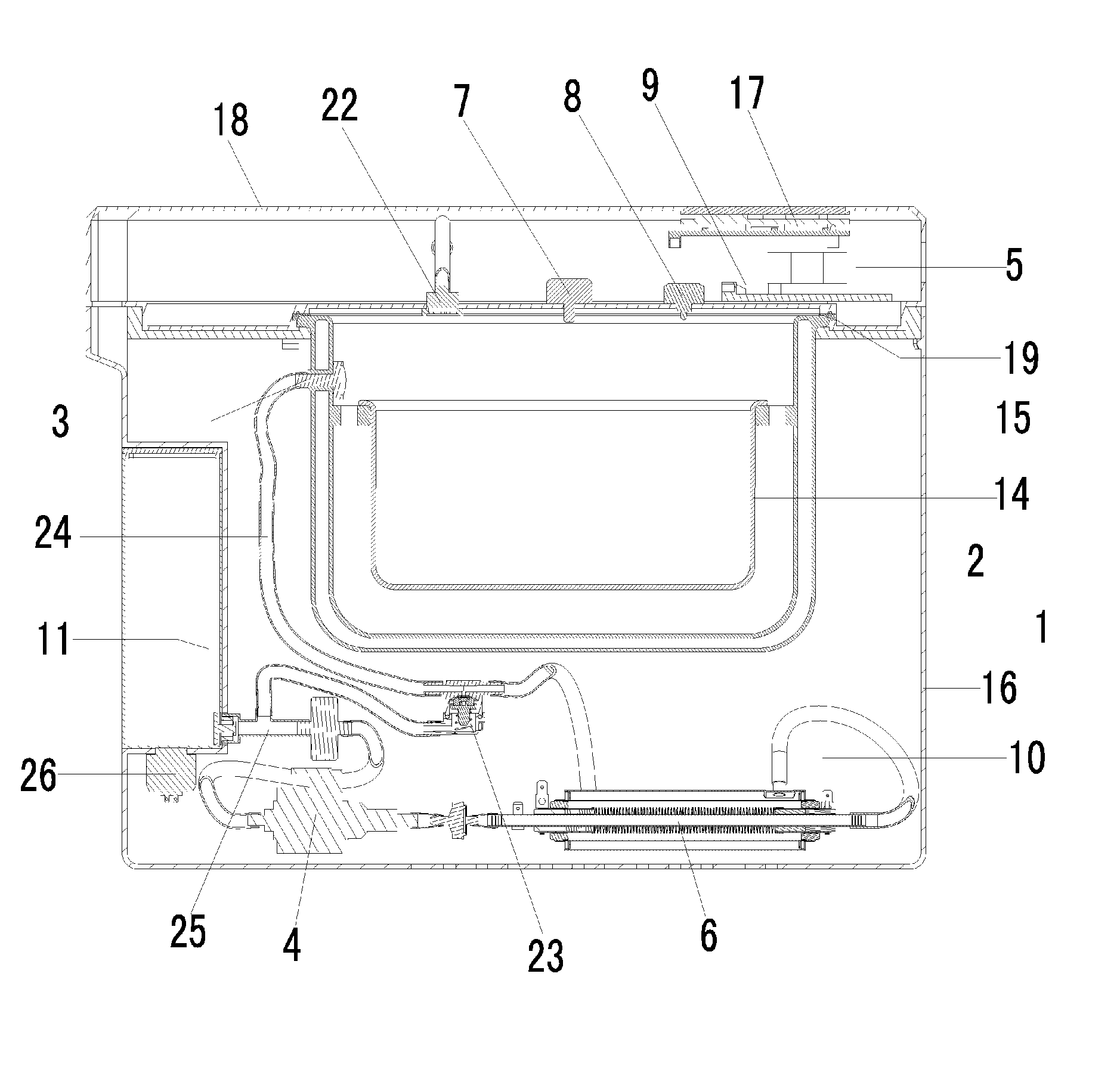

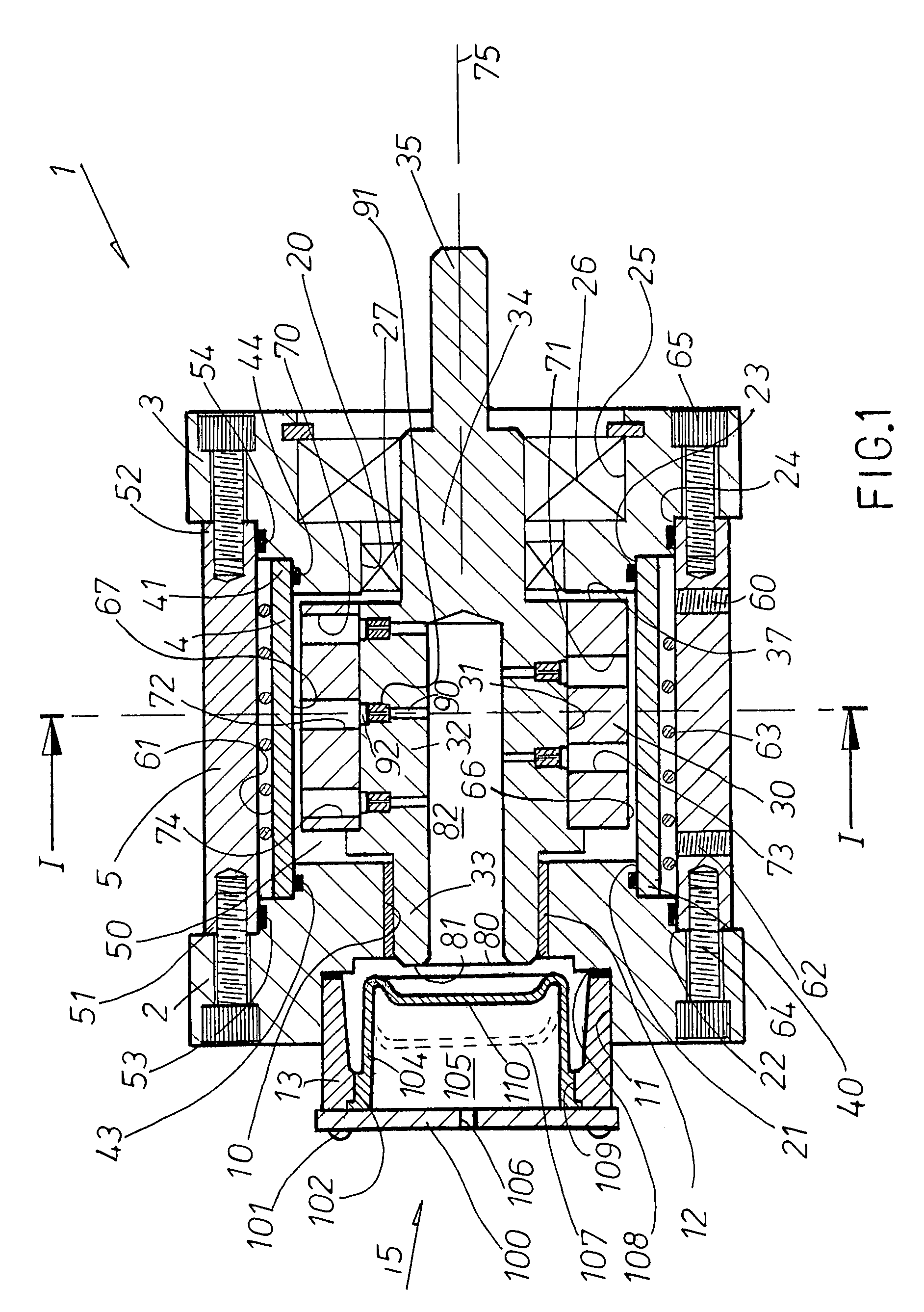

Electrical appliance for cooking food

InactiveUS8546731B2Easy and safe manipulationAvoid burnsRotary drum furnacesWater heating stoves/rangesEngineeringIngested food

An electric appliance for pressure cooking food includes a casing (1) and a lid (4) forming the outer jacket of the appliance, an outer vessel (2) forming the inner chamber of the appliance, a heating element (25) placed in the bottom of the outer vessel (2), a removable inner vessel (3) forming the container (30) for cooking food, wherein the inner vessel (3) includes at least one handhold (31) extending past the periphery of the casing (1).

Owner:SEB SA

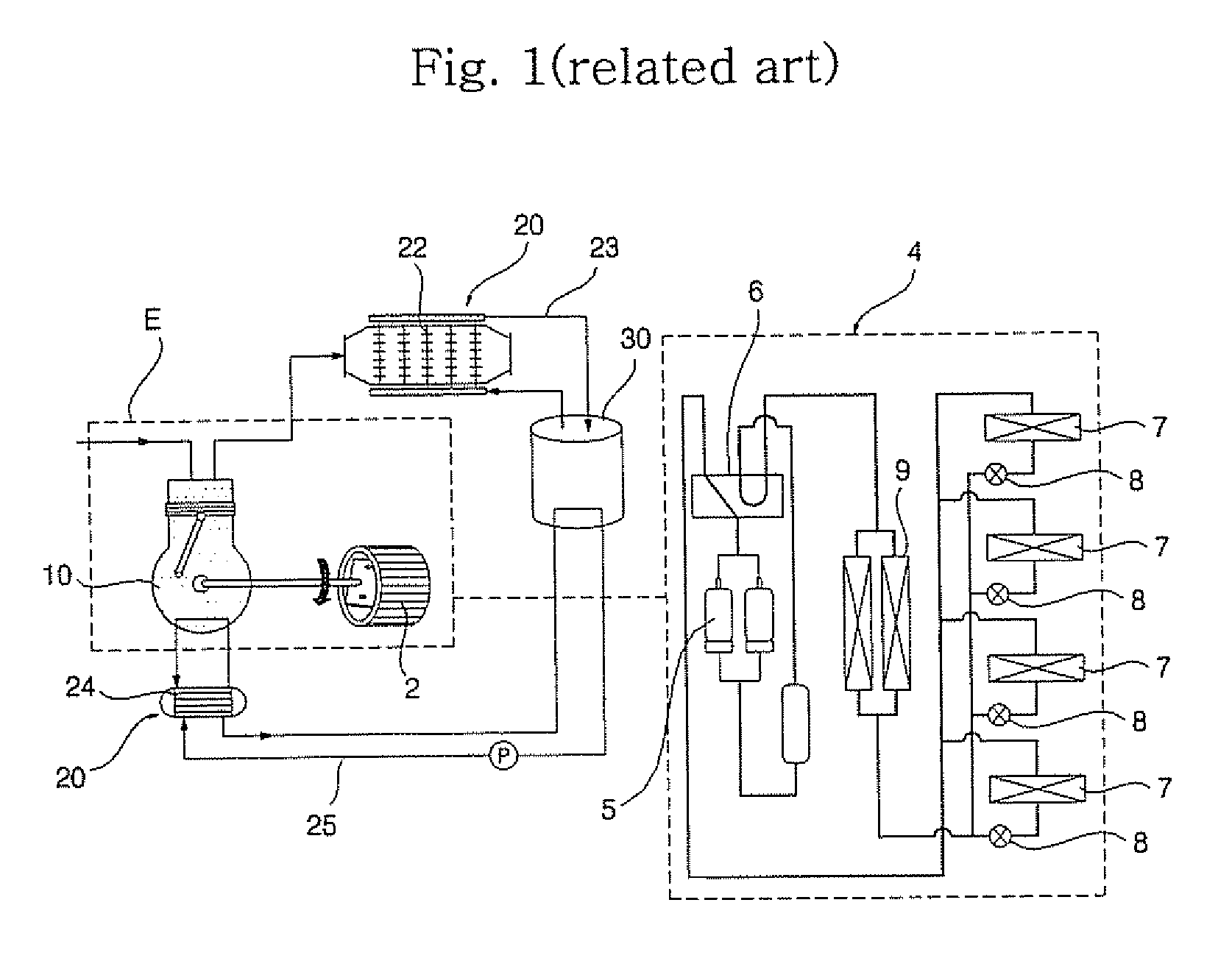

Cogeneration system

InactiveUS20060283967A1Maximum energy efficiencyImprove the heating effectMechanical apparatusHeat pumpsCogenerationProcess engineering

A cogeneration system is disclosed which includes a generator, a drive source for driving the generator, a waste heat supplying heat exchanger for enhancing the heating performance of a heat pump type air conditioner, an auxiliary heating heat exchanger using the waste heat of the drive source as a heat source for heating indoor air, and a regeneration heat supplying heat exchanger using the waste heat of the drive source as a heat source for regenerating a dehumidifier. The cogeneration system can use the waste heat of the drive source for diverse purposes in accordance with the indoor environment, and can have a maximal efficiency.

Owner:LG ELECTRONICS INC

System and method for hydronic space heating with electrical power generation

ActiveUS7284709B2Minimizing starting and stoppingMaximizing run timeInternal combustion piston enginesGas turbine plantsCogenerationElectric generator

This invention provides a system and method for cogeneration of electric power and building heat that efficiently interfaces a liquid-cooled electric power generator with a multi-zone forced hot water (hydronic) space heating system. The system and method utilizes an electric generator with an electric output capacity (kW) that is near the time-averaged electric power consumption rate for the building and with a heat generation capacity that is useful for meeting building heating needs. This generator is operated as the priority source of heat for the building, but normally only when there is a demand for heat in building, with the intent of running the generator for long periods of time and generating a total amount of electric energy (kWhs) that is significant in comparison to the total electric energy consumption of the building over time. The actual onsite time-variable power demand (kW) is met by a combination of the cogenerated electric power produced on site and quantities of electric power from the public electric power grid or another external power source. Hence, useful electric power is generated on site as a by-product of the required generation of heat for space or water heating. The generator is run at a speed / operating condition that is appropriate to maintaining a long operational life.

Owner:CLIMATE ENERGY

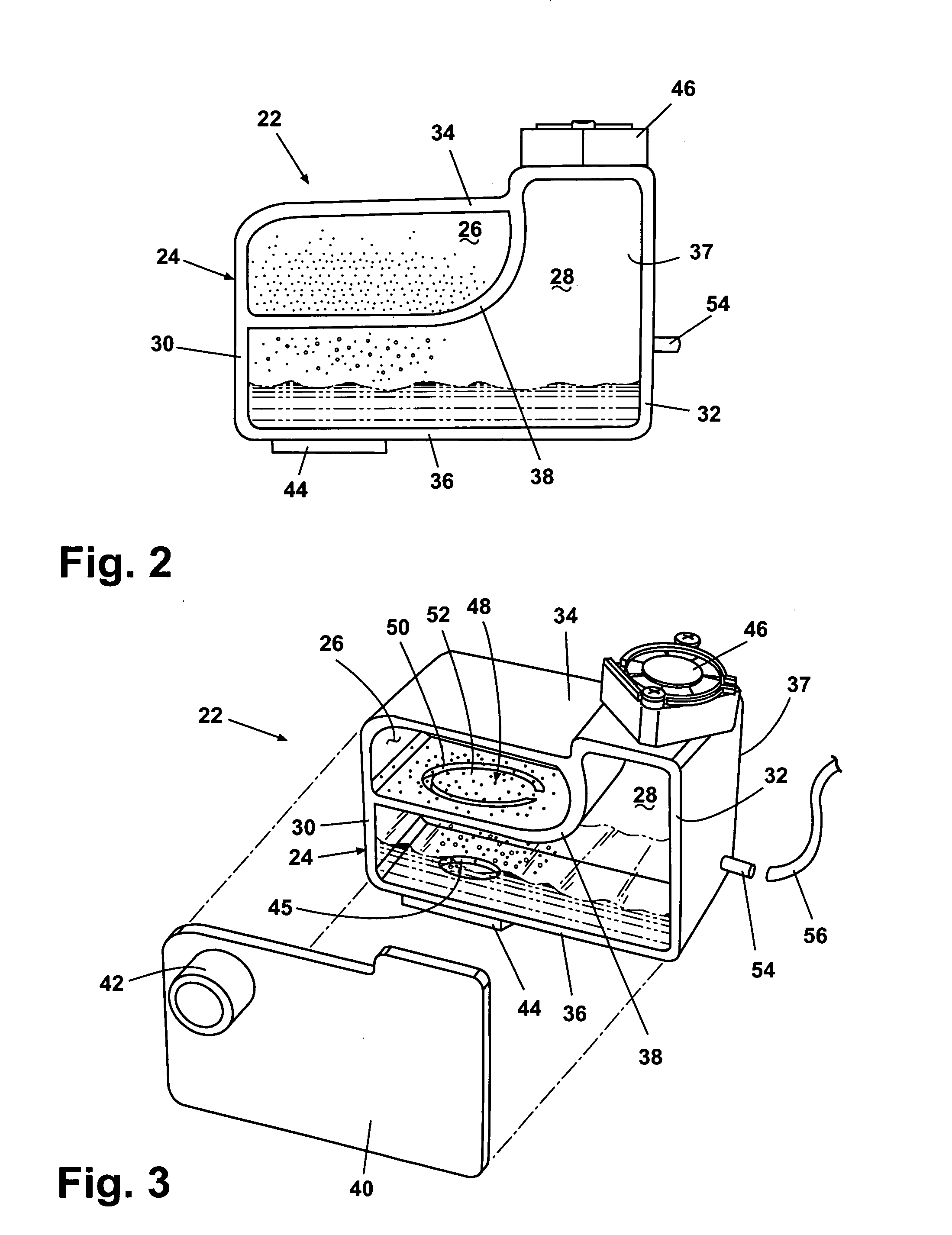

Device and method for tempering and humidifying gas, especially respiratory air

ActiveUS20060151624A1Easy to controlCompact designRespiratorsOther heat production devicesTemperature controlMedicine

Owner:RESMED HUMIDIFICATION TECH

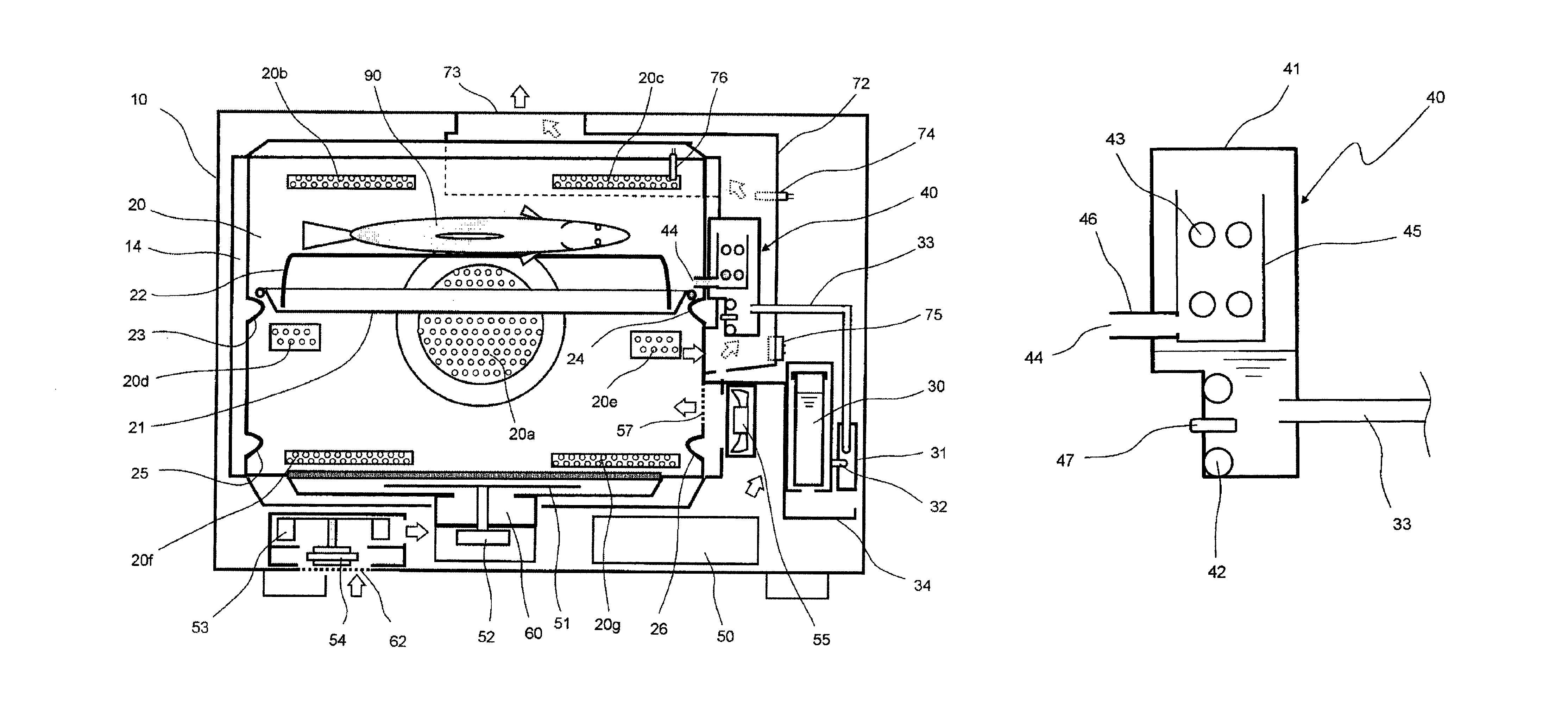

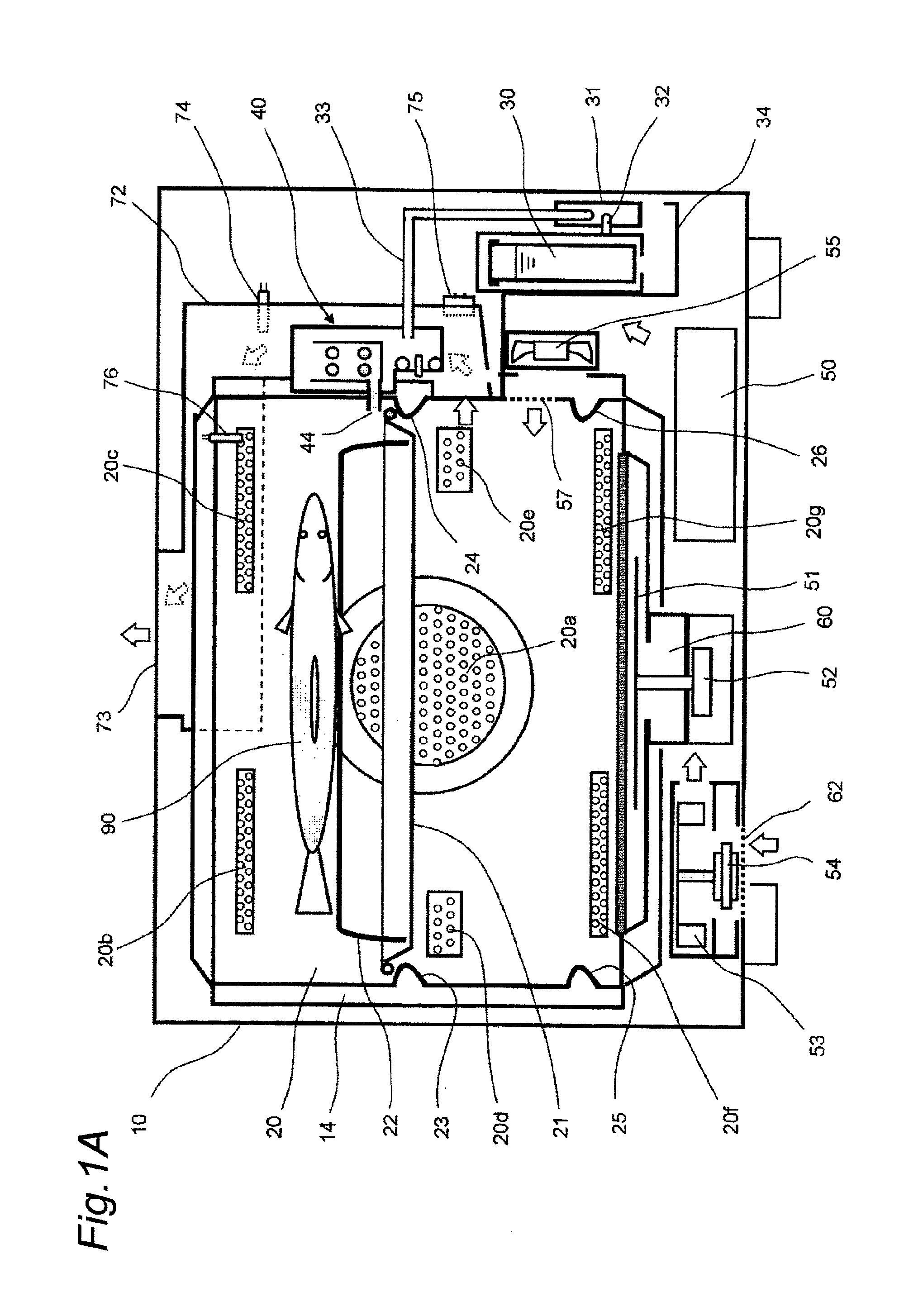

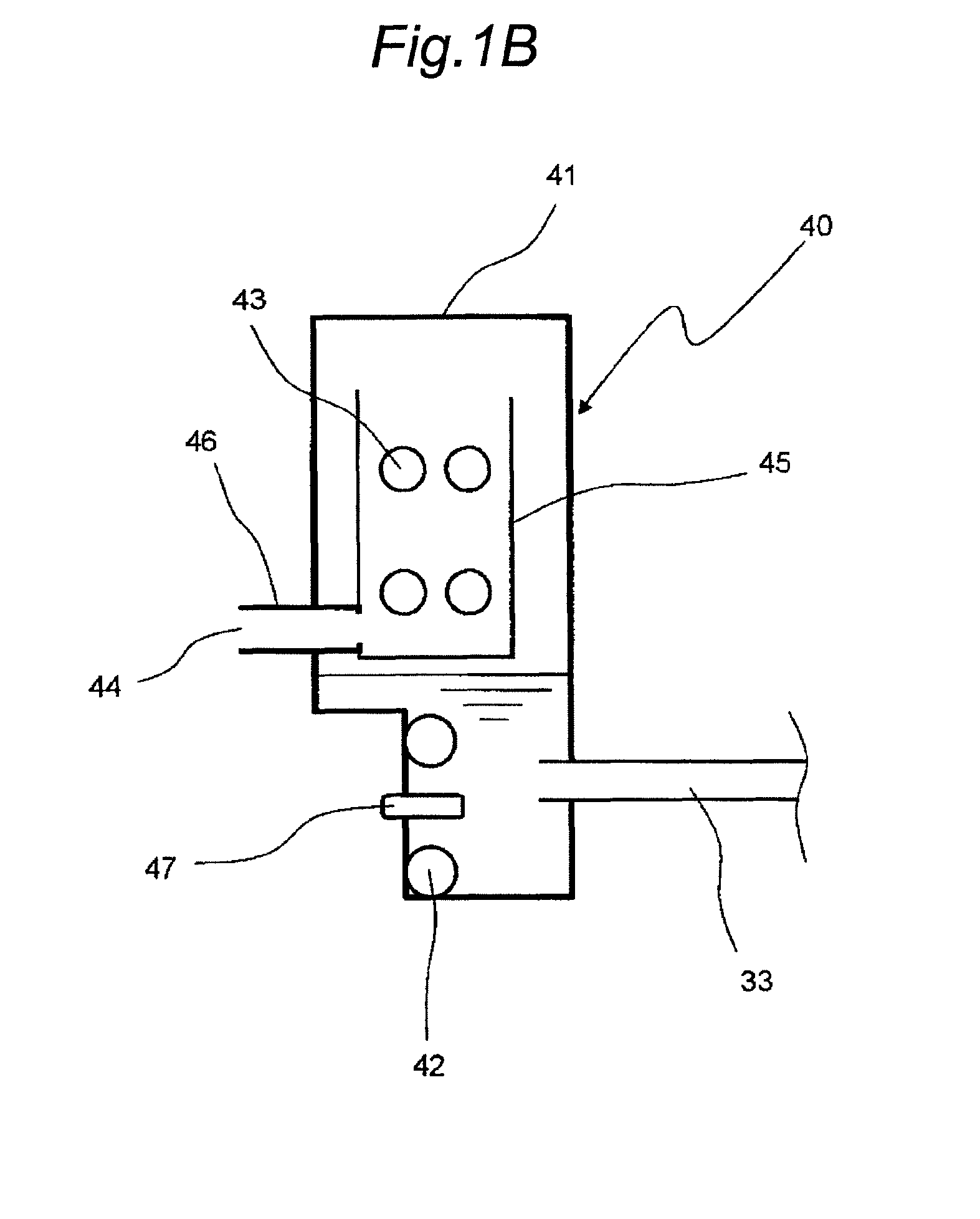

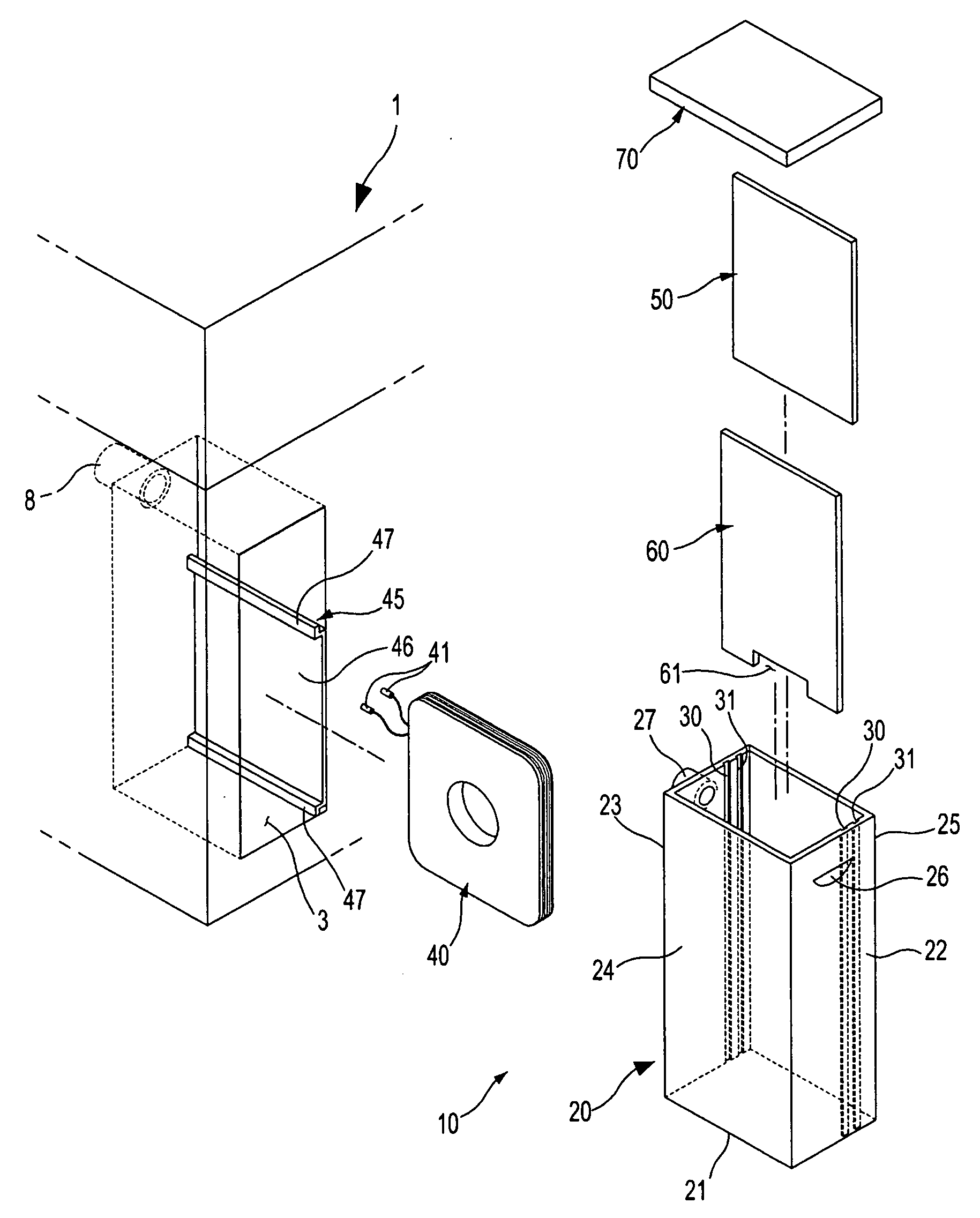

Cooking appliance

ActiveUS8695487B2Simple structureLow costDomestic stoves or rangesBaking ovenEngineeringSteam generation

Disclosed is a cooking appliance provided with: a water tank (30) disposed inside a main case (10); a steam-generation device (40) that generates steam by heating water supplied from the water tank (30); a heating chamber (20) to which steam from the steam-generation device (40) is supplied; an exhaust duct (72), provided inside the main case (10), for expelling exhaust from inside the heating chamber (20) to outside the main case (10); an exhaust temperature sensor (74) that measures the temperature of the exhaust air inside the exhaust duct (72); and a steam-generation decision unit that, upon cooking in which steam is supplied from the steam-generation unit (40) into the heating chamber (20), uses information on a physical quantity (the exhaust temperature measured by the exhaust temperature sensor (74)), which indirectly indicates whether there is water in the steam-generation device (40), to decide whether or not to halt steam generation, including the case in which the water tank (30) is out of water.

Owner:SHARP KK

Steam generating apparatus and oven including the same

InactiveUS20060278630A1Easy to cleanRapidly generate steamGrinding machine componentsDomestic stoves or rangesEngineeringInduction coil

A steam generating apparatus, and an oven including the same. The apparatus includes a water tank adapted to enable convenient cleaning, and is adapted to heat water in the water tank via an induction heating method to generate steam rapidly. The water tank is provided with a steam discharging pipe. The apparatus further includes an induction coil assembly, an induction heating member fitted to the water tank such that it is located near the induction coil assembly, a barrier inserted into the water tank such that only a small amount of water is directly heated by the induction heating member which generates heat by the induction coil assembly, and a cover closing an upper portion of the water tank. The steam discharging pipe is connected with a steam supplying pipe which communicates a cavity with a cooking compartment to supply steam from the apparatus to the cooking compartment.

Owner:SAMSUNG ELECTRONICS CO LTD

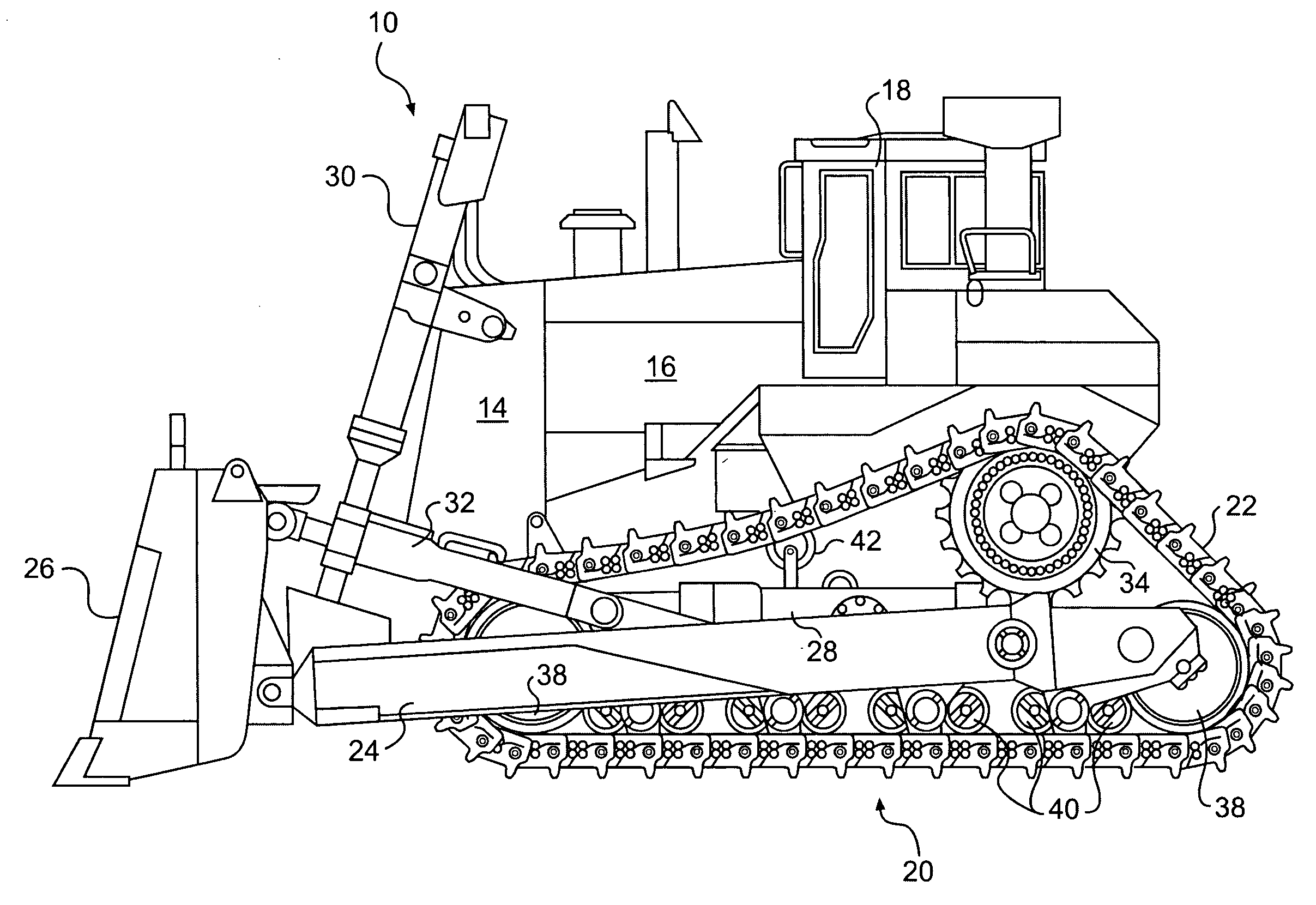

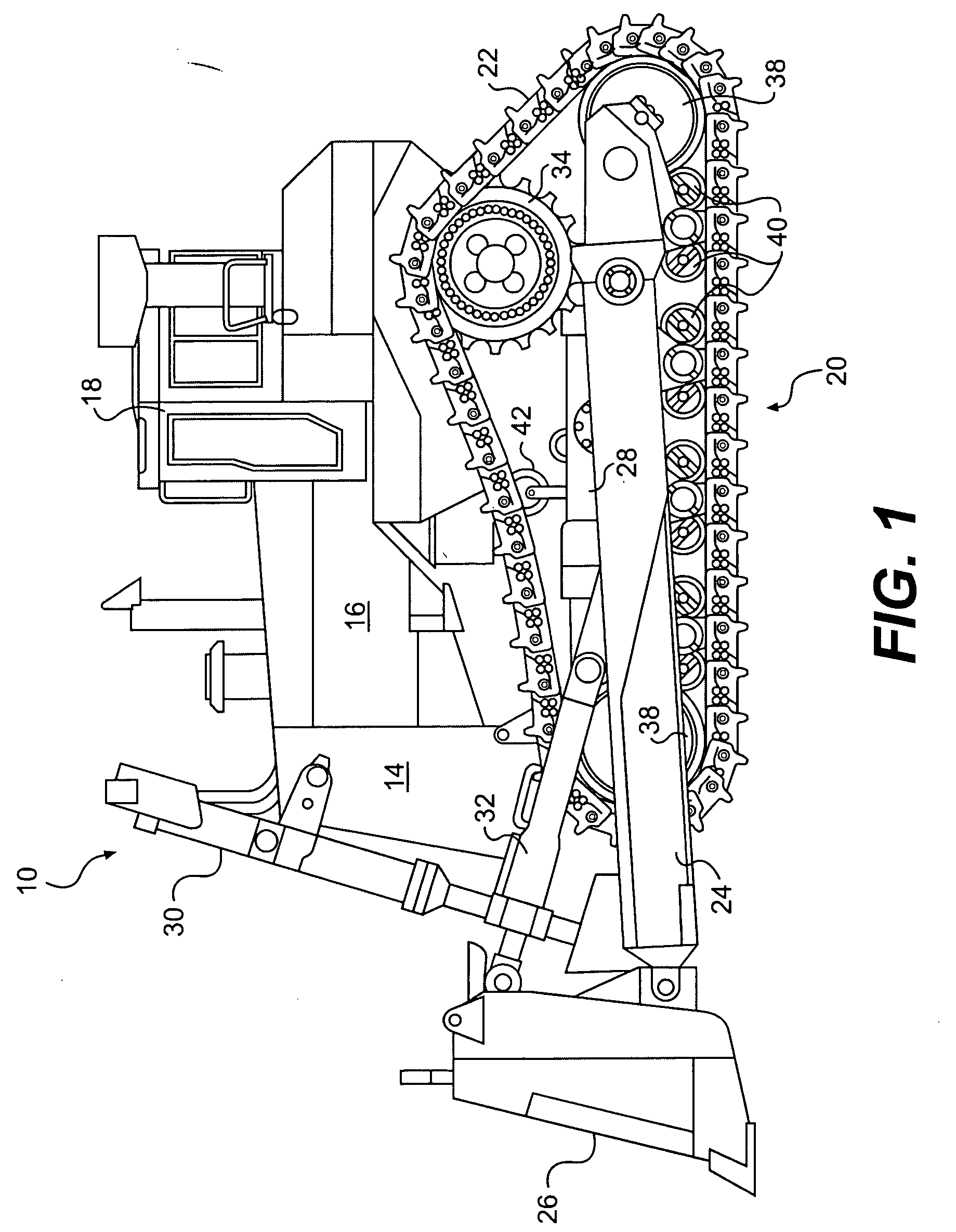

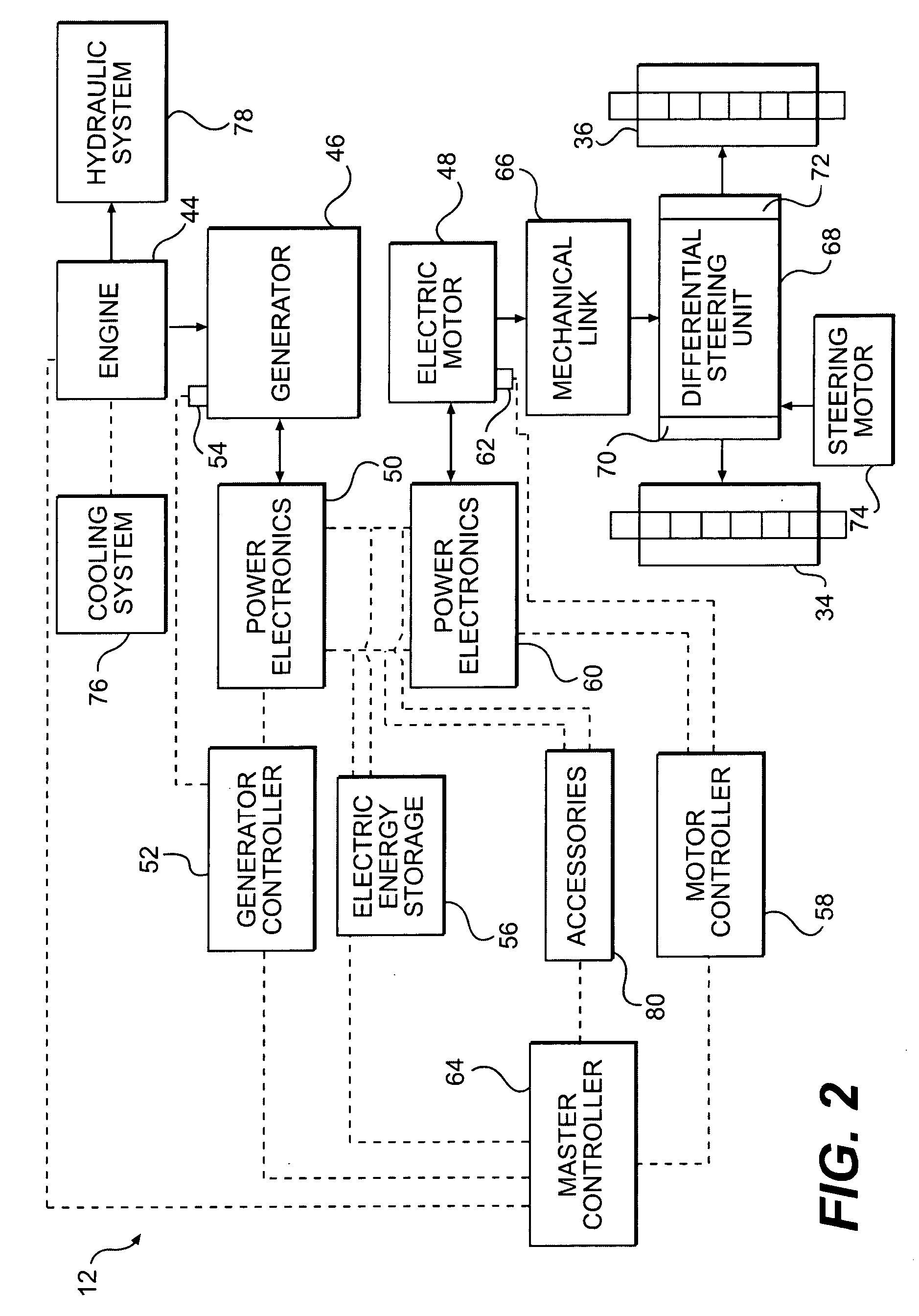

Electric powertrain for work machine

An electric powertrain includes an engine configured to provide mechanical energy and a generator operably coupled to the engine and configured to convert at least a portion of the mechanical energy into electric energy. The electric powertrain further includes at least one electric motor operably coupled to the generator, a plurality of driving members, and at least one power electronics unit configured to control at least one of the engine and the generator. The at least one electric motor is configured to provide torque for the plurality of driving members.

Owner:CATERPILLAR INC

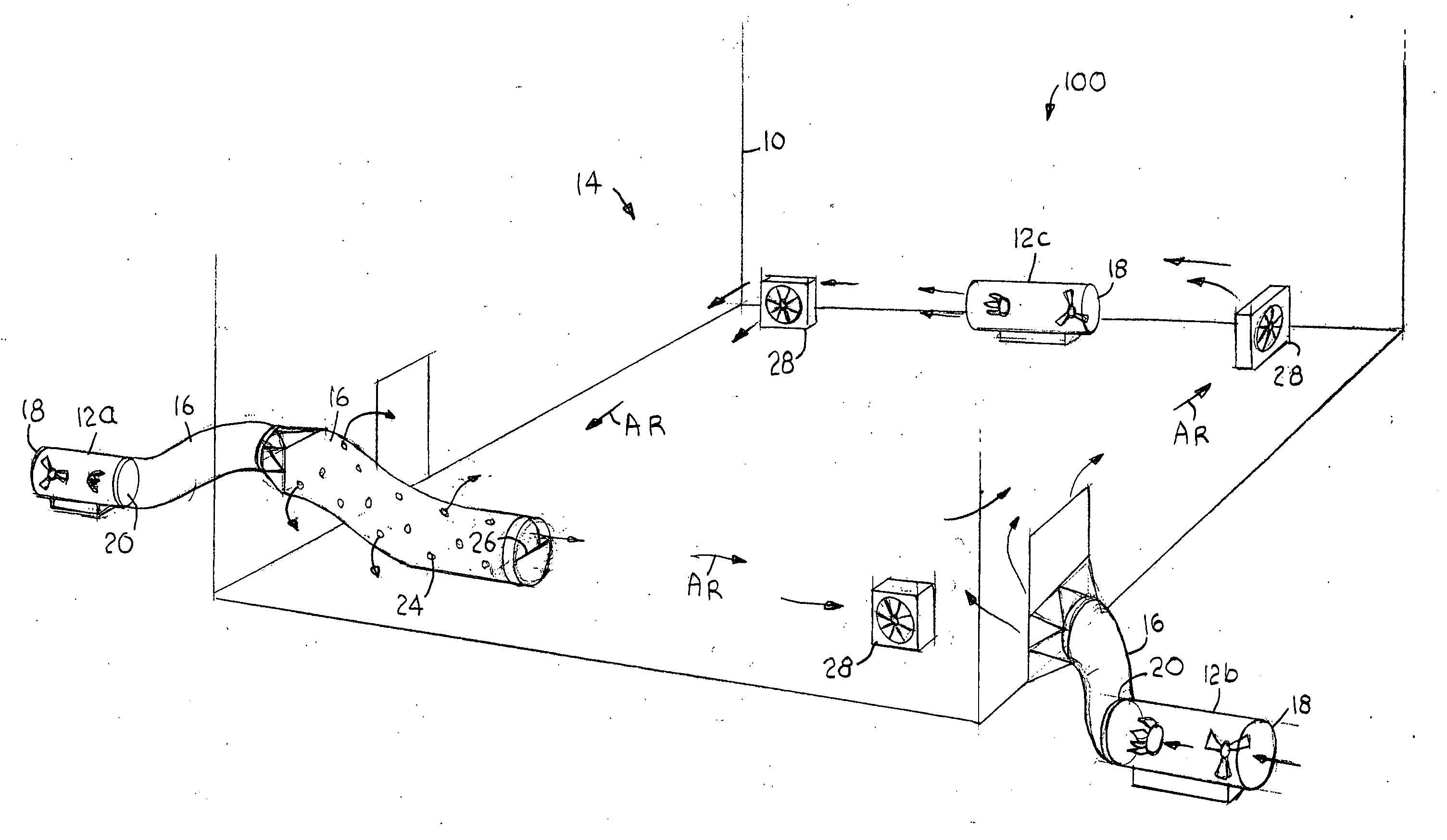

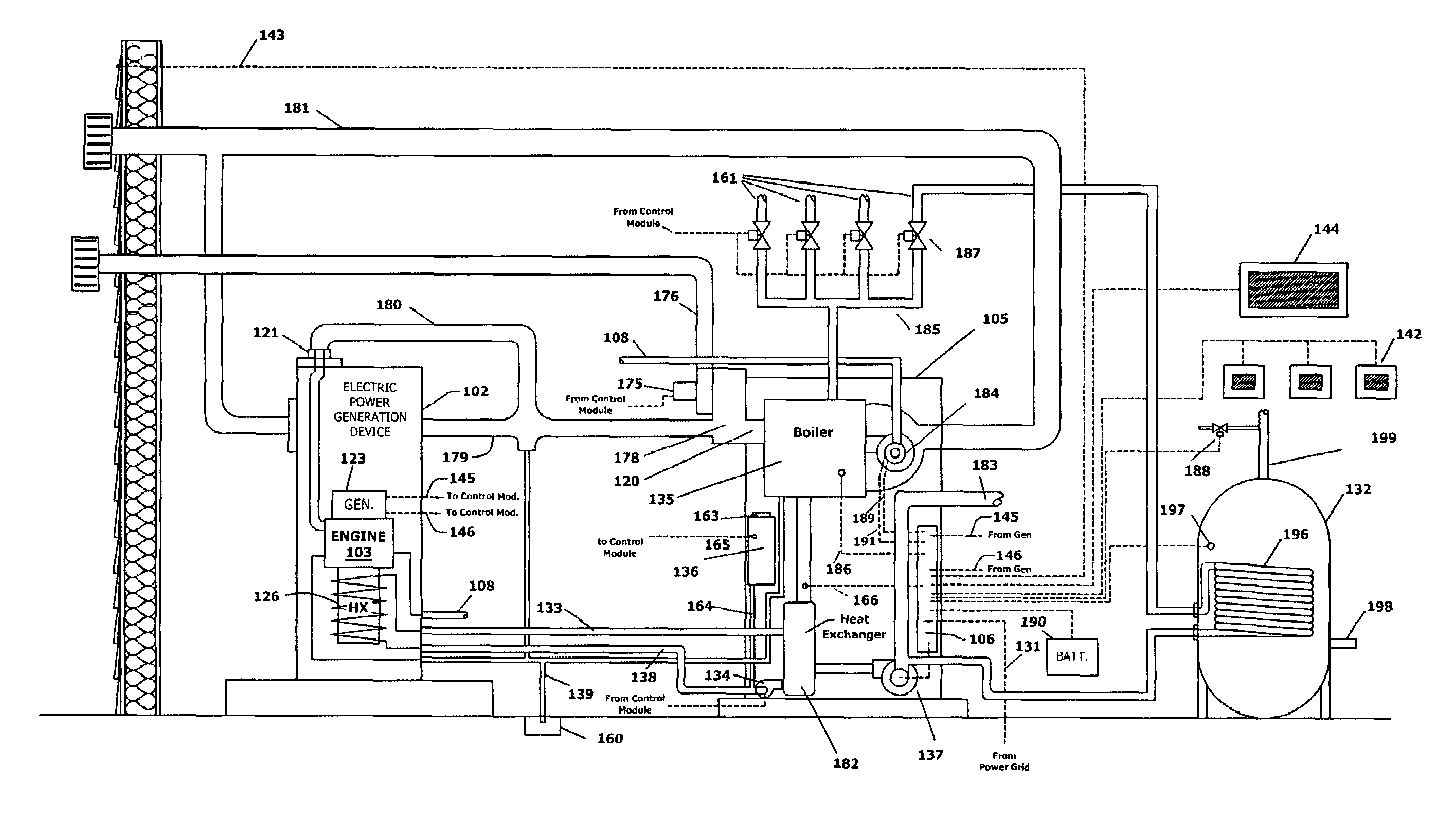

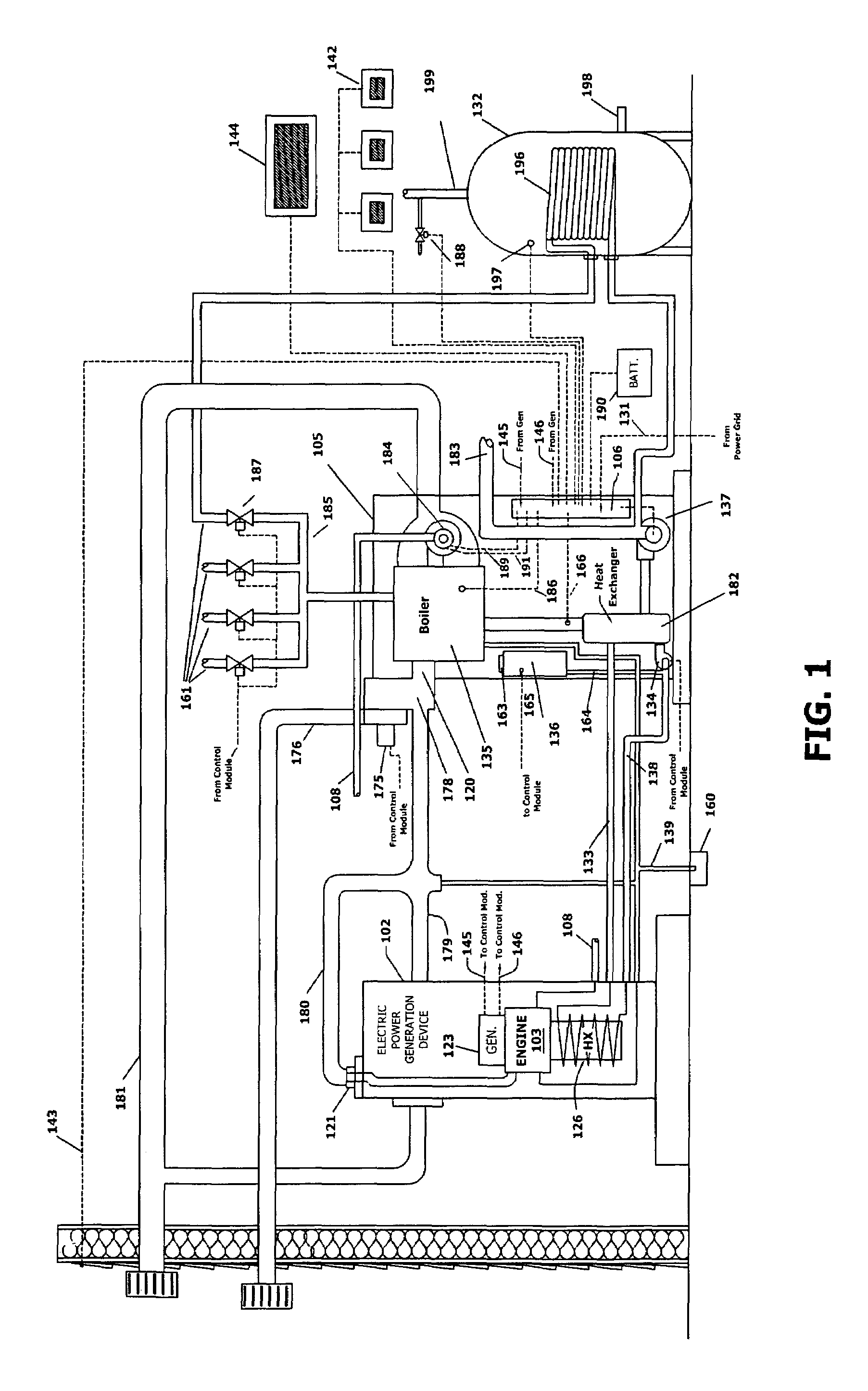

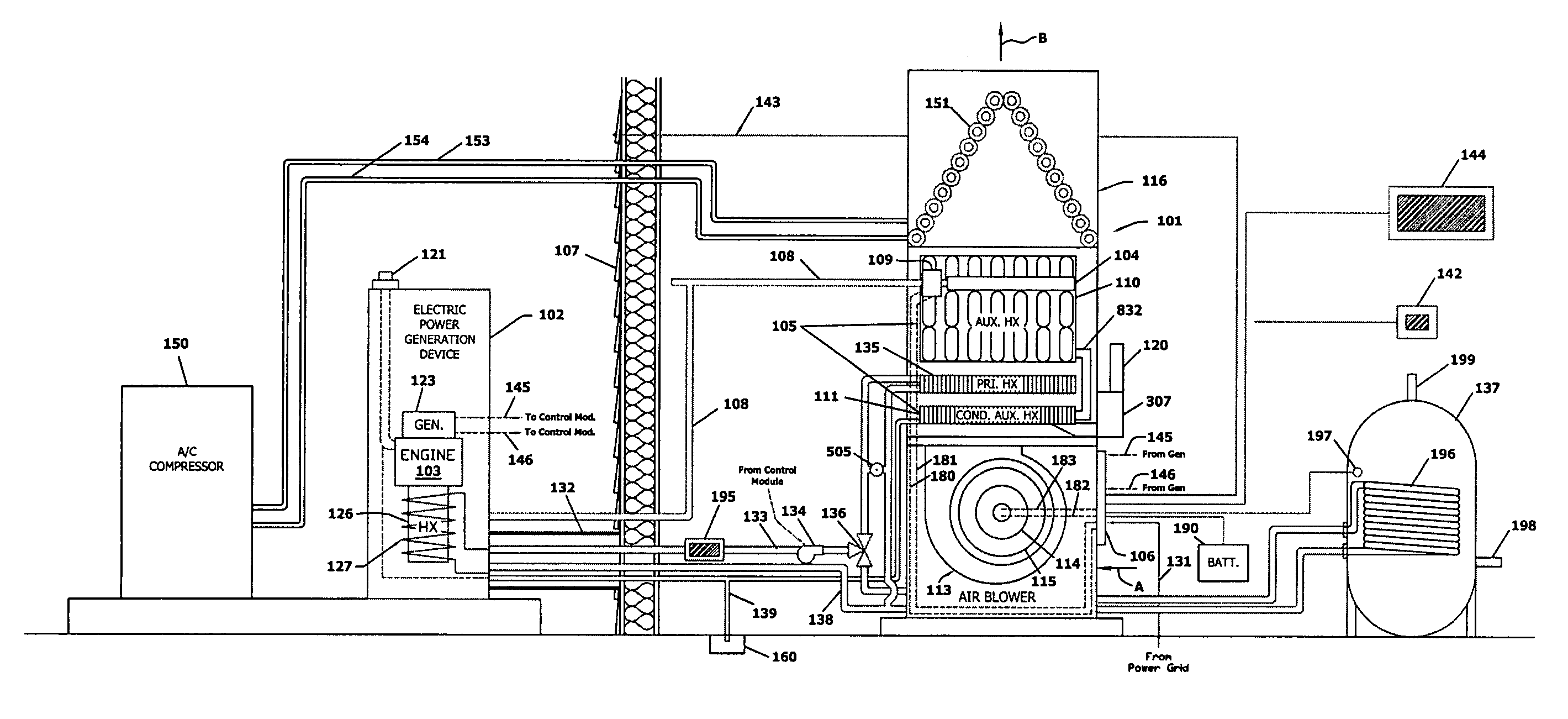

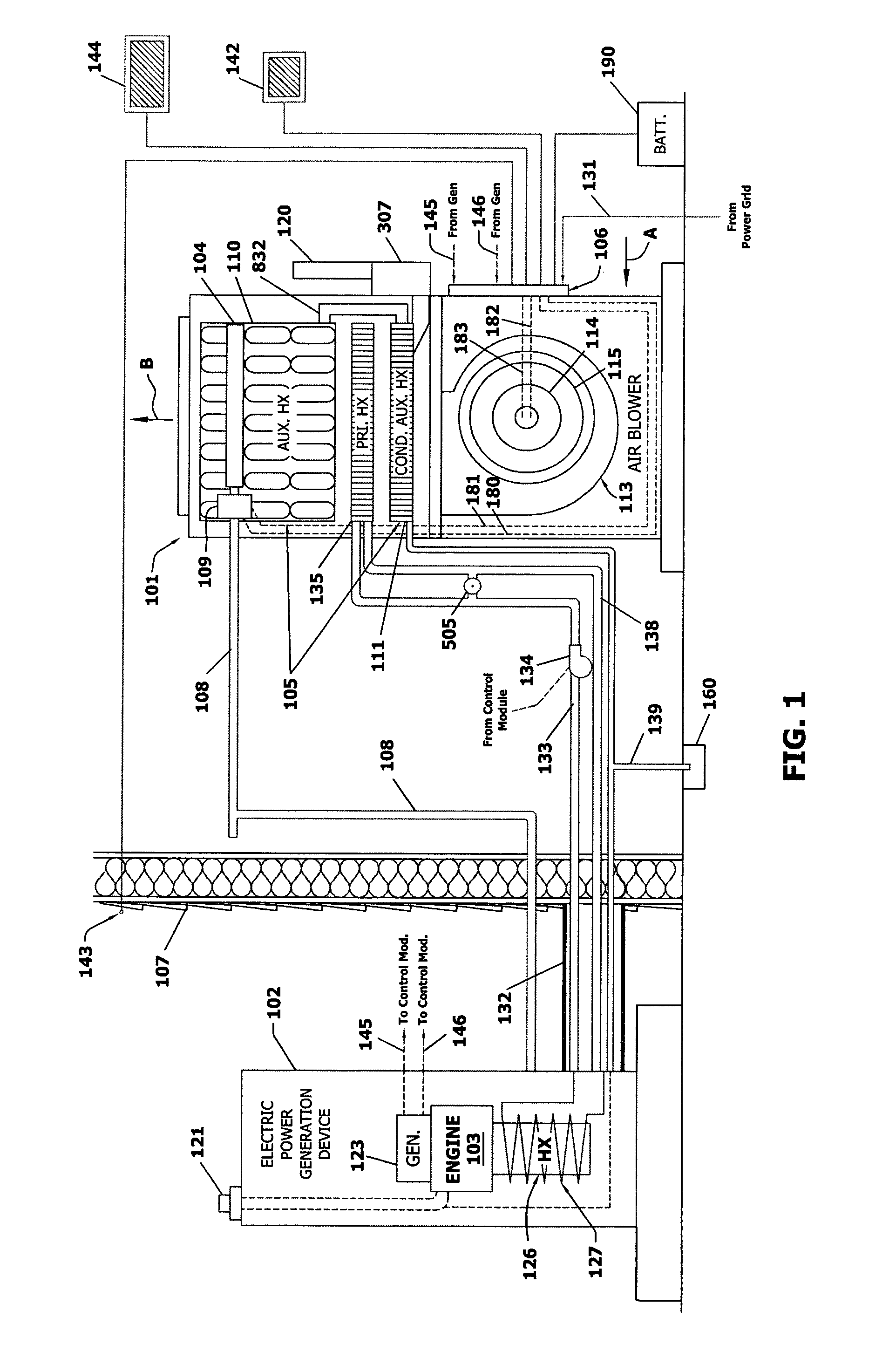

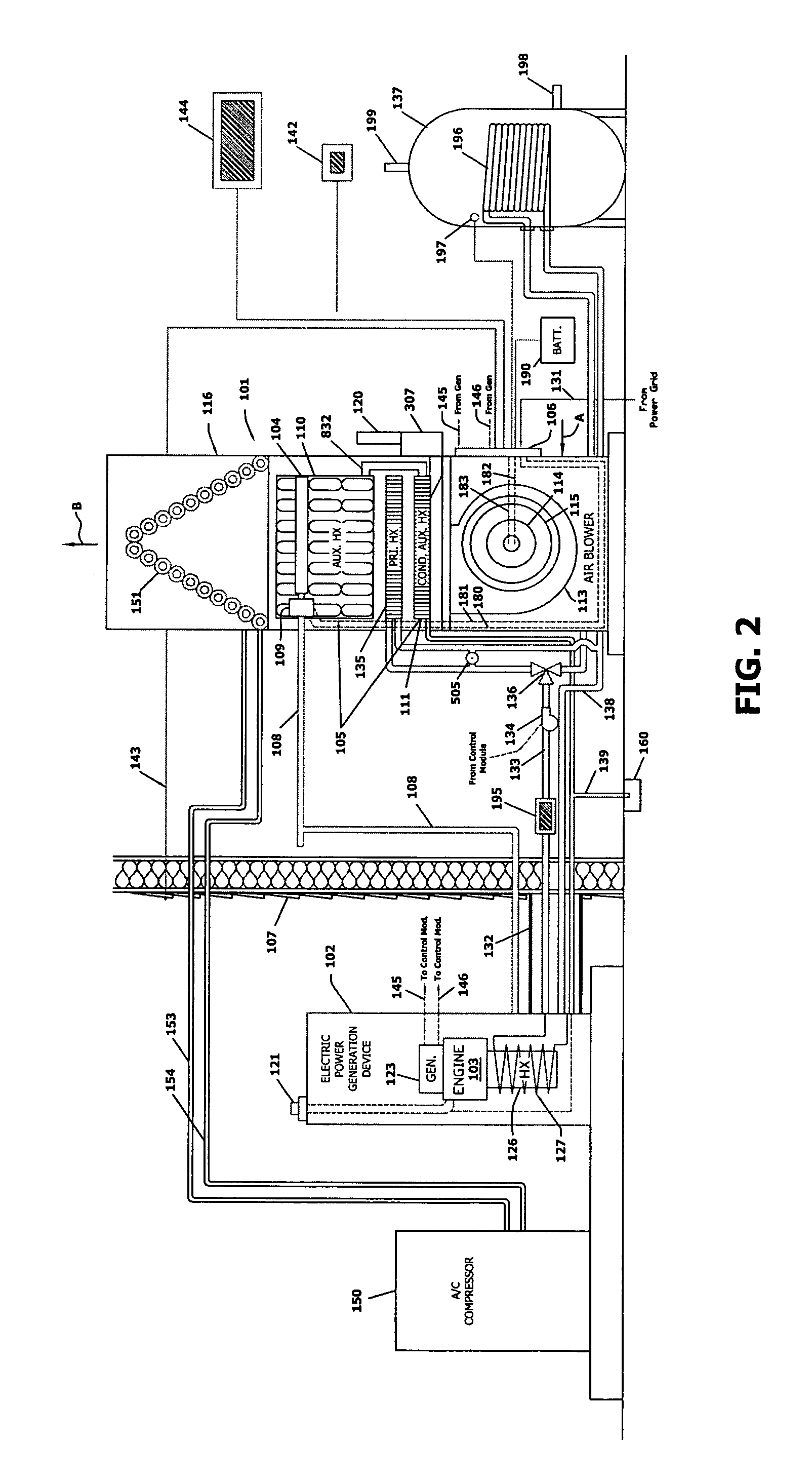

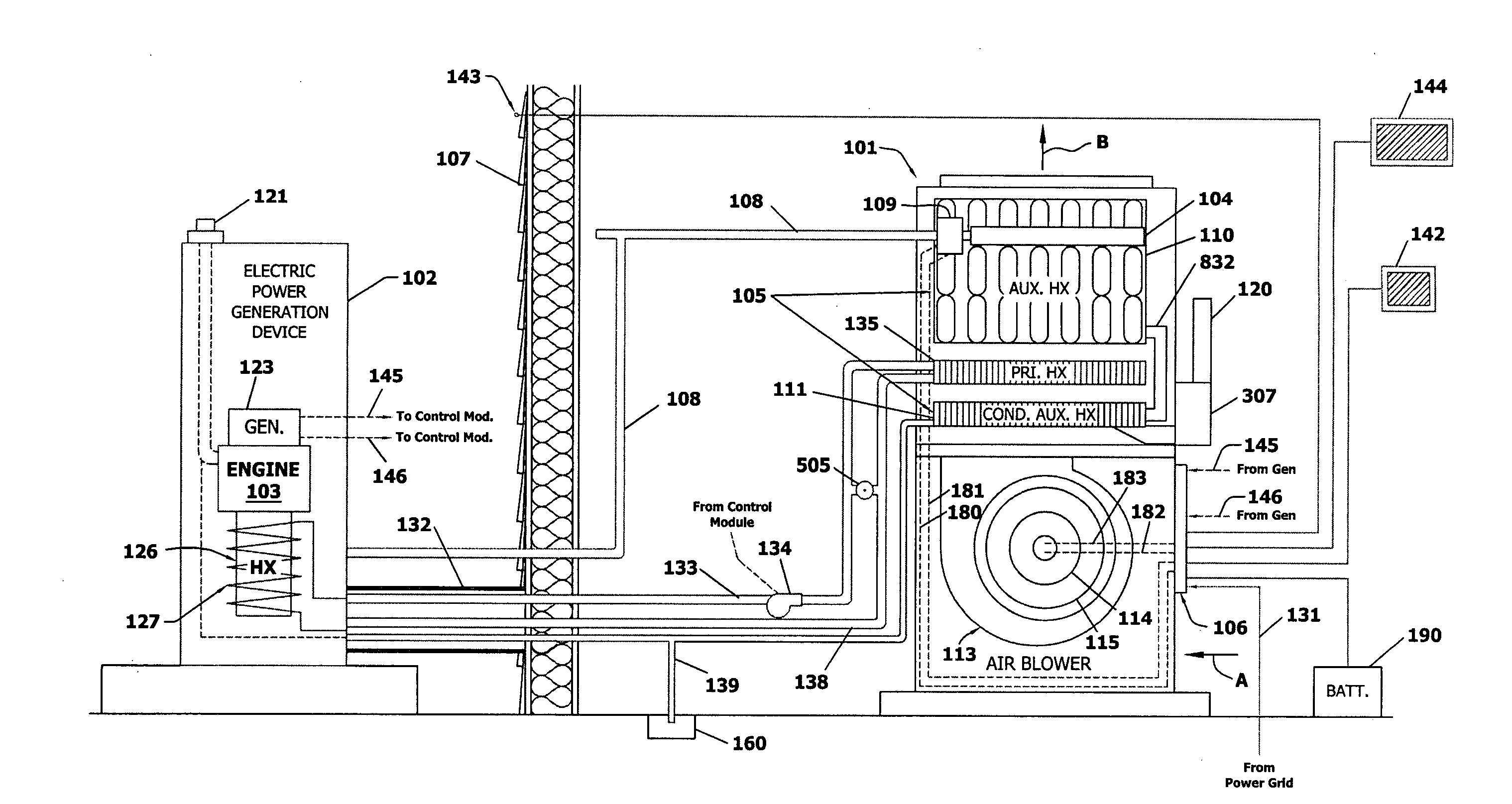

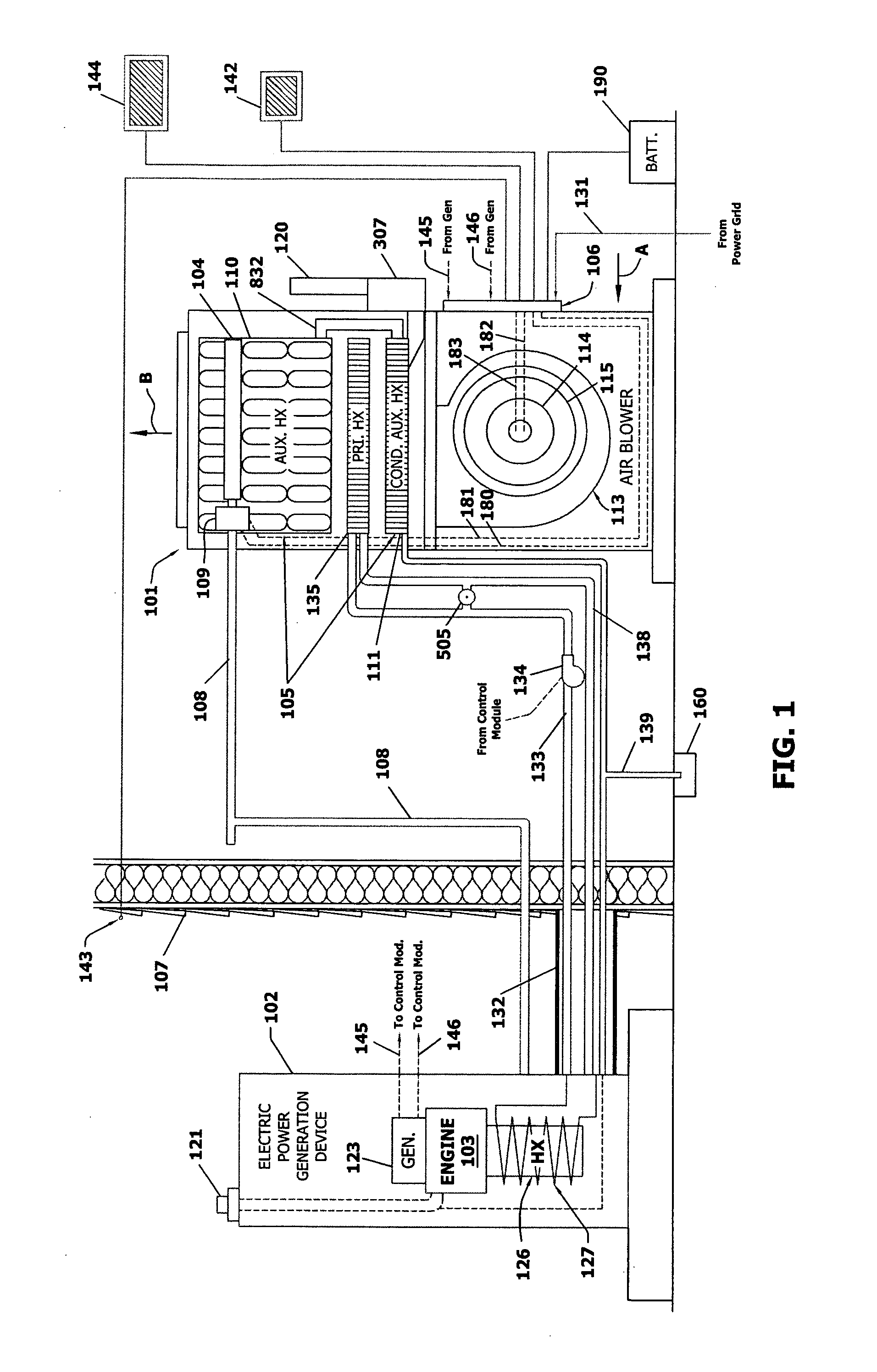

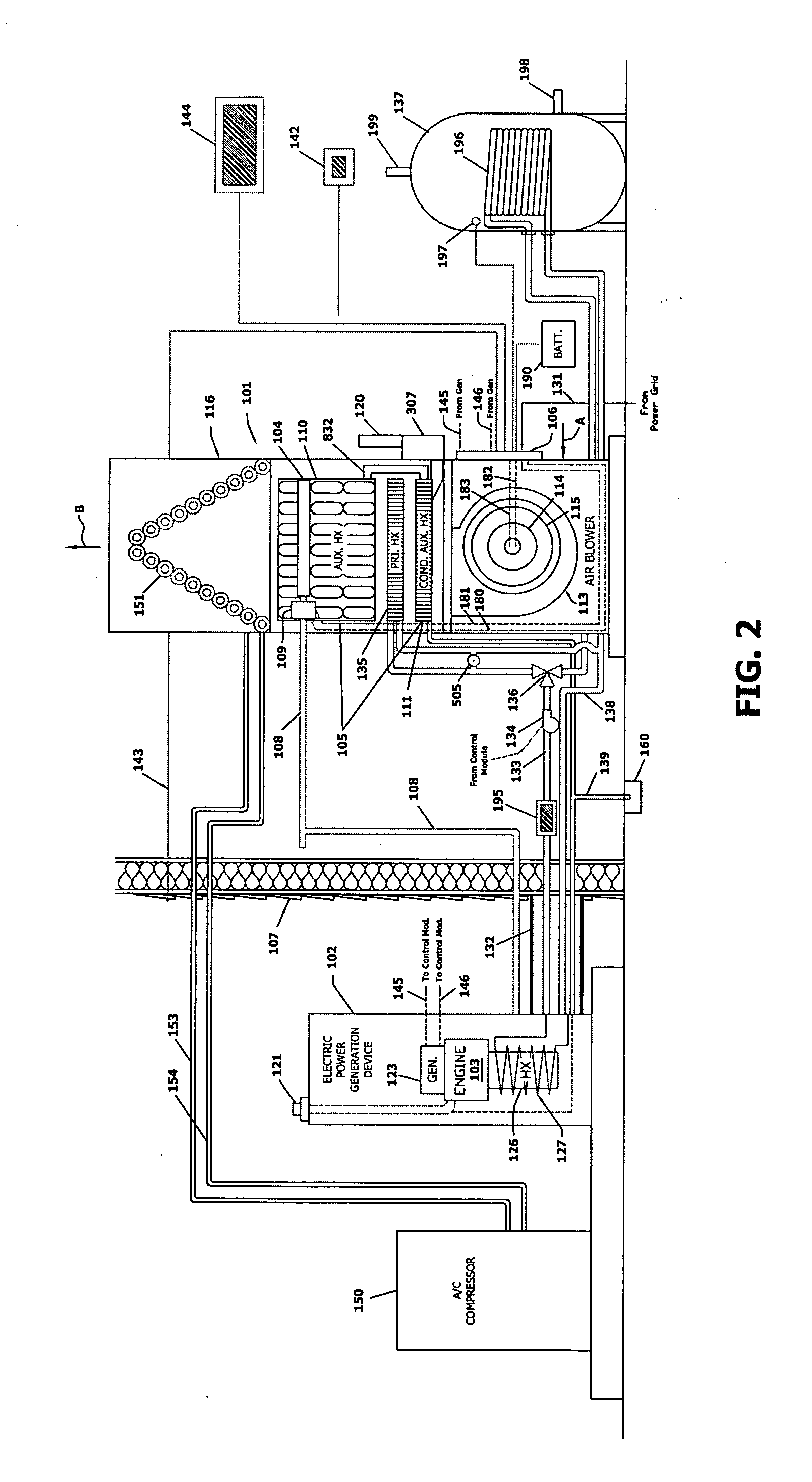

System and method for warm air space heating with electrical power generation

This invention provides a system and method for cogeneration of building heat and electric power and that efficiently interfaces a warm air heating system with a liquid-cooled electric power generator. The system and method utilizes an electric generator that is rated at near the time-averaged electric power consumption for the building. This generator is operated as the priority source of heat for the building, but normally only when there is a demand for heat in building. In this manner, the generator can run to generate a significant part of the building's electric power but in a manner that is typically supplemented in variable quantities by power from a public power grid. The heat output is directed via a liquid coolant circuit on the generator, as needed, to the warm air heating unit for the building. The warm air heating unit blows return air through a cabinet and out to the supply duct(s). The warm liquid coolant is directed through a primary heat exchanger in the cabinet. The air is passed over this primary heat exchanger to provide heat to the building. When heat from primary heat exchanger is insufficient to heat the building fully, an auxiliary heater, operated typically by burning fuel, supplements the heat through one or more auxiliary heat exchangers arranged in line along the airflow path with the primary heat exchanger. The blower that directs the airflow is controlled variably in speed to create the most efficient use of electric power by the blower and a desirable heated air delivery temperature.

Owner:CLIMATE ENERGY

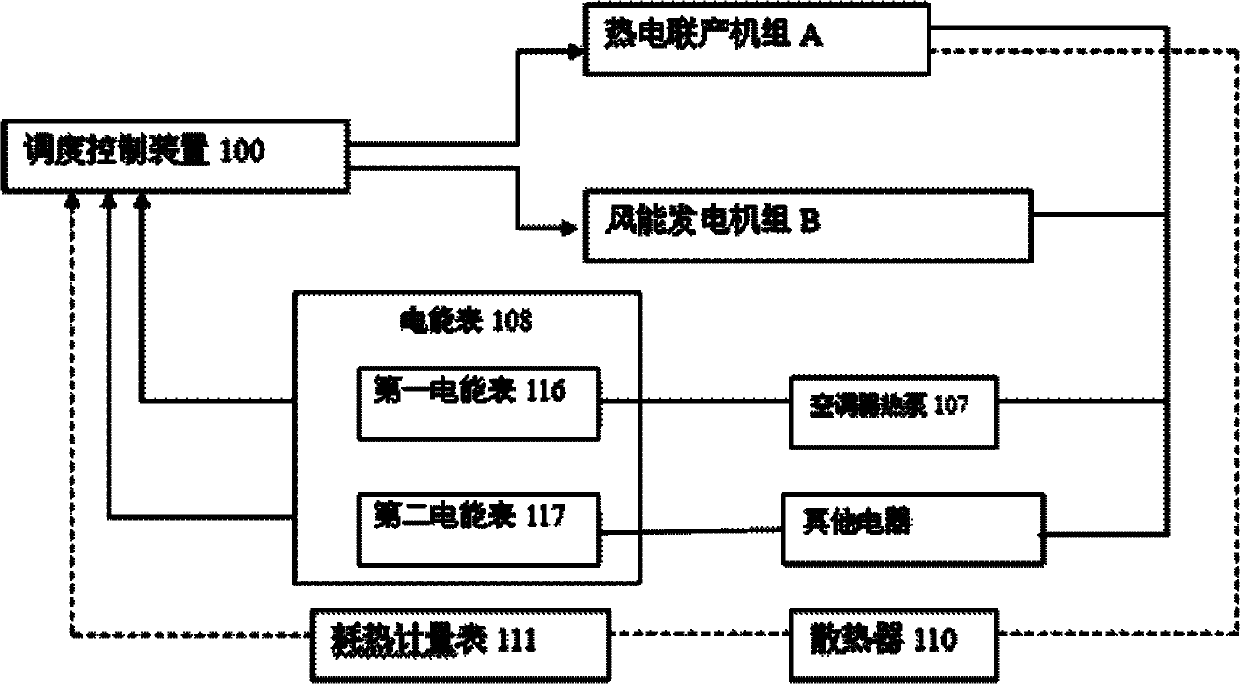

System and method for saving energy and shaving peak by coordinating cogeneration set and wind energy generator set

InactiveCN101950962AAvoid downtimeAvoid wastingLighting and heating apparatusSteam engine plantsControl signalCogeneration

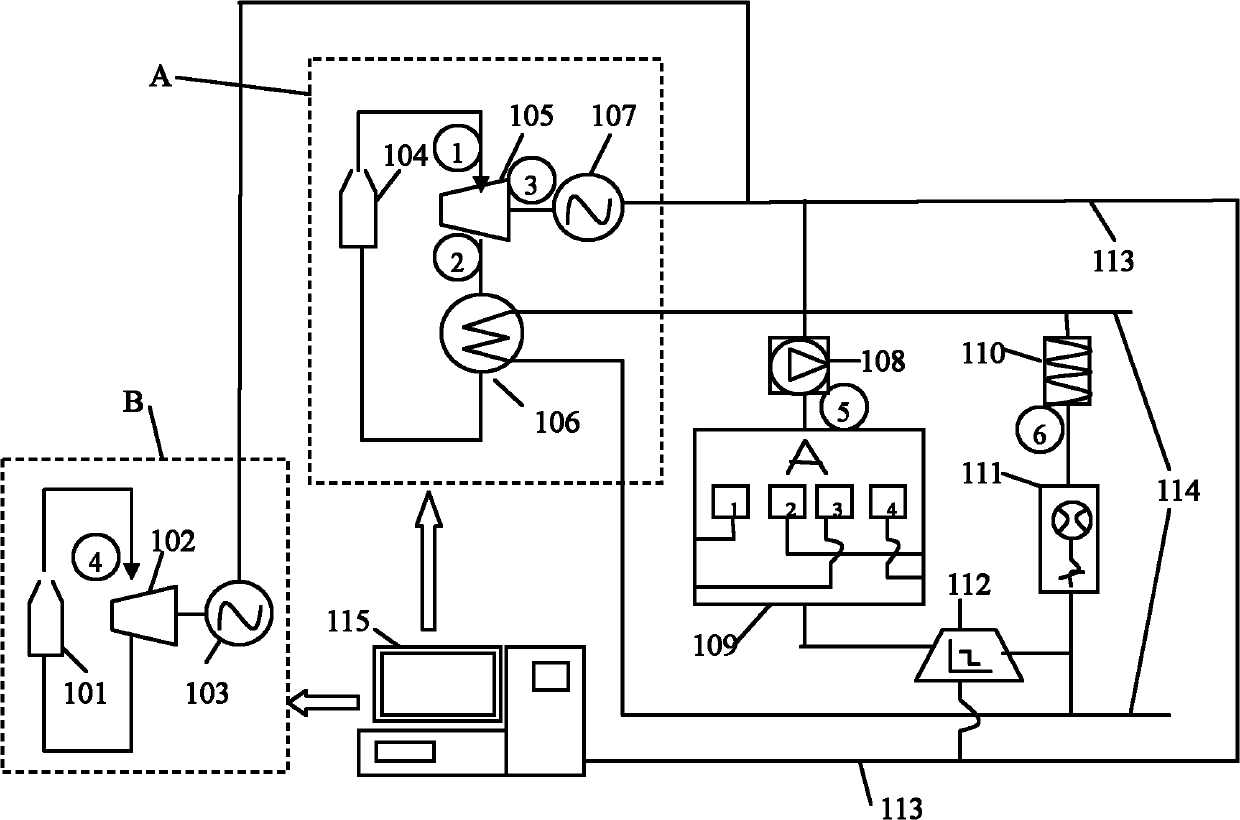

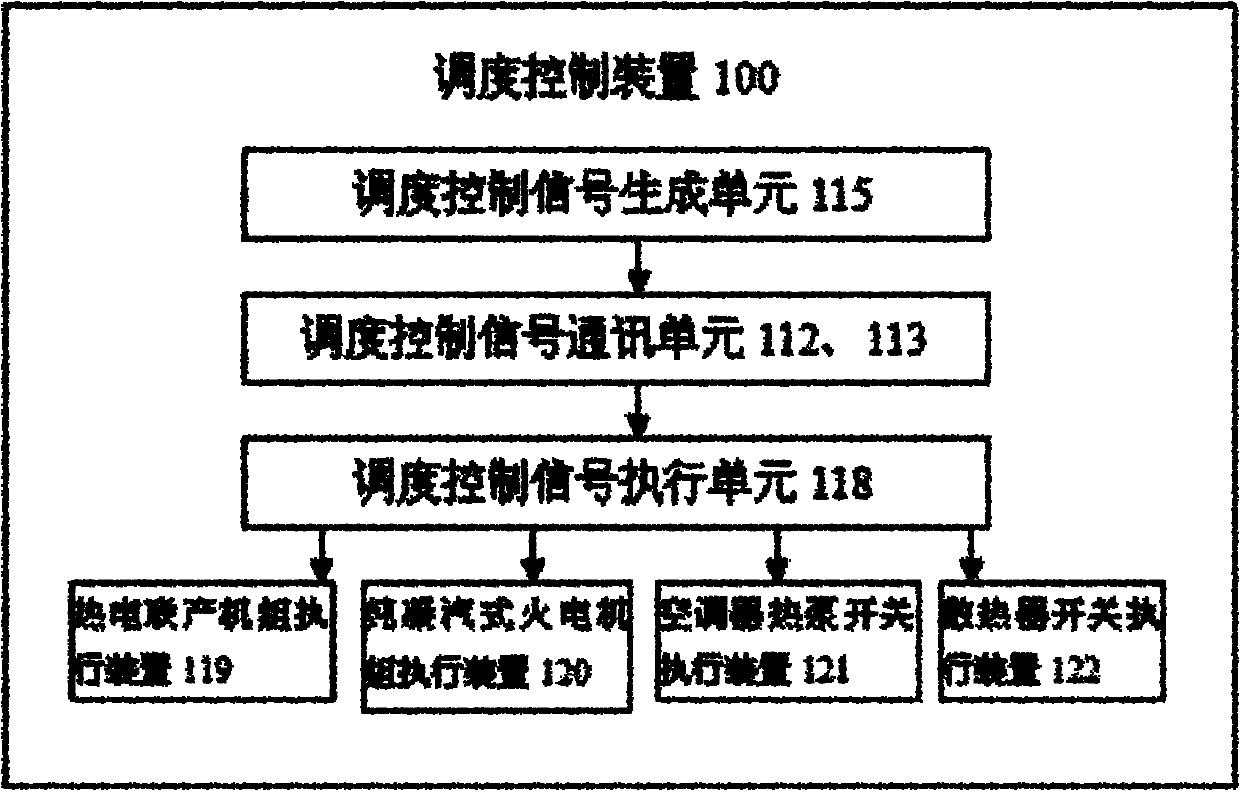

The invention relates to a system and a method for saving energy and shaving the peak by coordinating a cogeneration set and a wind energy generator set. The system comprises the cogeneration set, the wind energy generator set, a conditioner heat pump, an electric energy meter, a radiator, a heat consumption gauge, and a scheduling control device, wherein the scheduling control device is used for acquiring fuel consumption, generated output and heating output of the cogeneration set, generated output of the wind energy generator set, electric power consumption of heating of the conditioner heat pump, a scheduling control signal of the heating load of the radiator in the electric load trough period according to detected electivity consumption data and heating and heat consumption data, and controlling the cogeneration set, the wind energy generator set, the conditioner heat pump, and the radiator to run according to the scheduling control signal. Through the system and the method, the distribution of the generated output of each of the cogeneration set and the wind energy generator set is optimized so as to reduce the total energy consumption, save energy and solve the problems of the forced shutdown and the waste of abandoning electricity of the wind energy generator set in the electric load trough period of the power grid.

Owner:XI AN JIAOTONG UNIV

System and method for warm air space heating with electrical power generation

This invention provides a system and method for cogeneration of building heat and electric power and that efficiently interfaces a warm air heating system with a liquid-cooled electric power generator. The system and method utilizes an electric generator that is rated at near the time-averaged electric power consumption for the building. This generator is operated as the priority source of heat for the building, but normally only when there is a demand for heat in building. In this manner, the generator can run to generate a significant part of the building's electric power but in a manner that is typically supplemented in variable quantities by power from a public power grid. The heat output is directed via a liquid coolant circuit on the generator, as needed, to the warm air heating unit for the building. The warm air heating unit blows return air through a cabinet and out to the supply duct(s). The warm liquid coolant is directed through a primary heat exchanger in the cabinet. The air is passed over this primary heat exchanger to provide heat to the building. When heat from primary heat exchanger is insufficient to heat the building fully, an auxiliary heater, operated typically by burning fuel, supplements the heat through one or more auxiliary heat exchangers arranged in line along the airflow path with the primary heat exchanger. The blower that directs the airflow is controlled variably in speed to create the most efficient use of electric power by the blower and a desirable heated air delivery temperature.

Owner:CLIMATE ENERGY

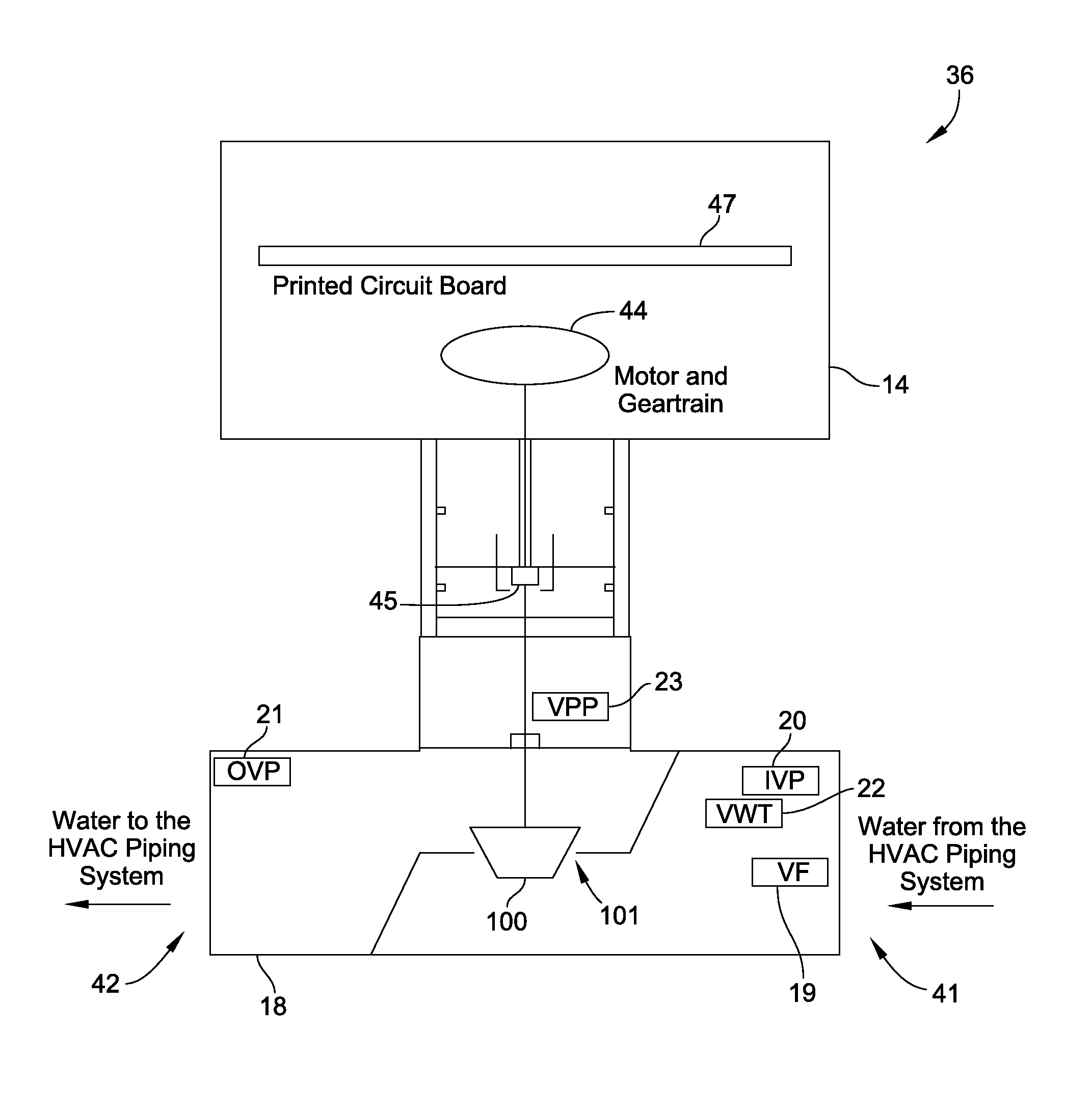

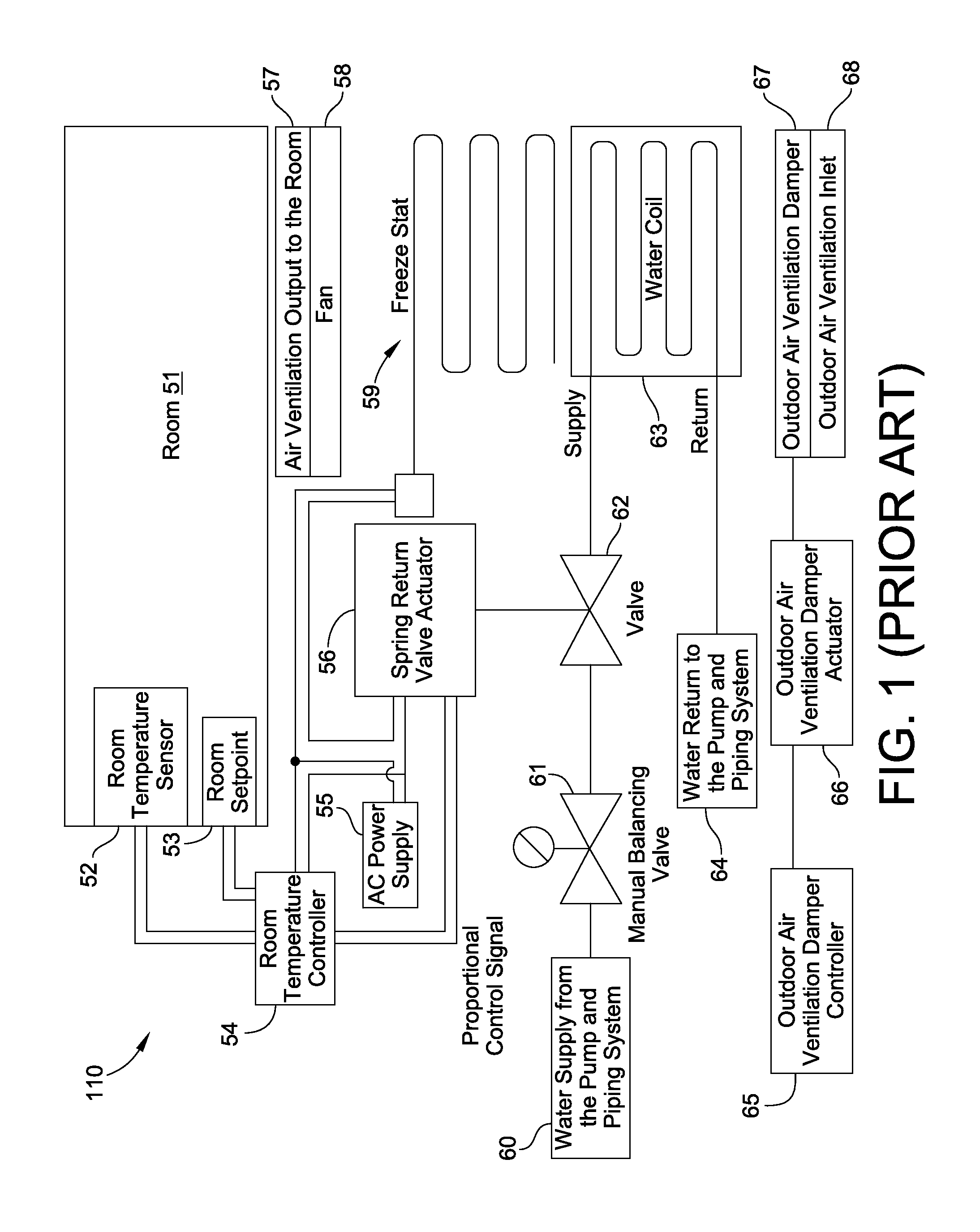

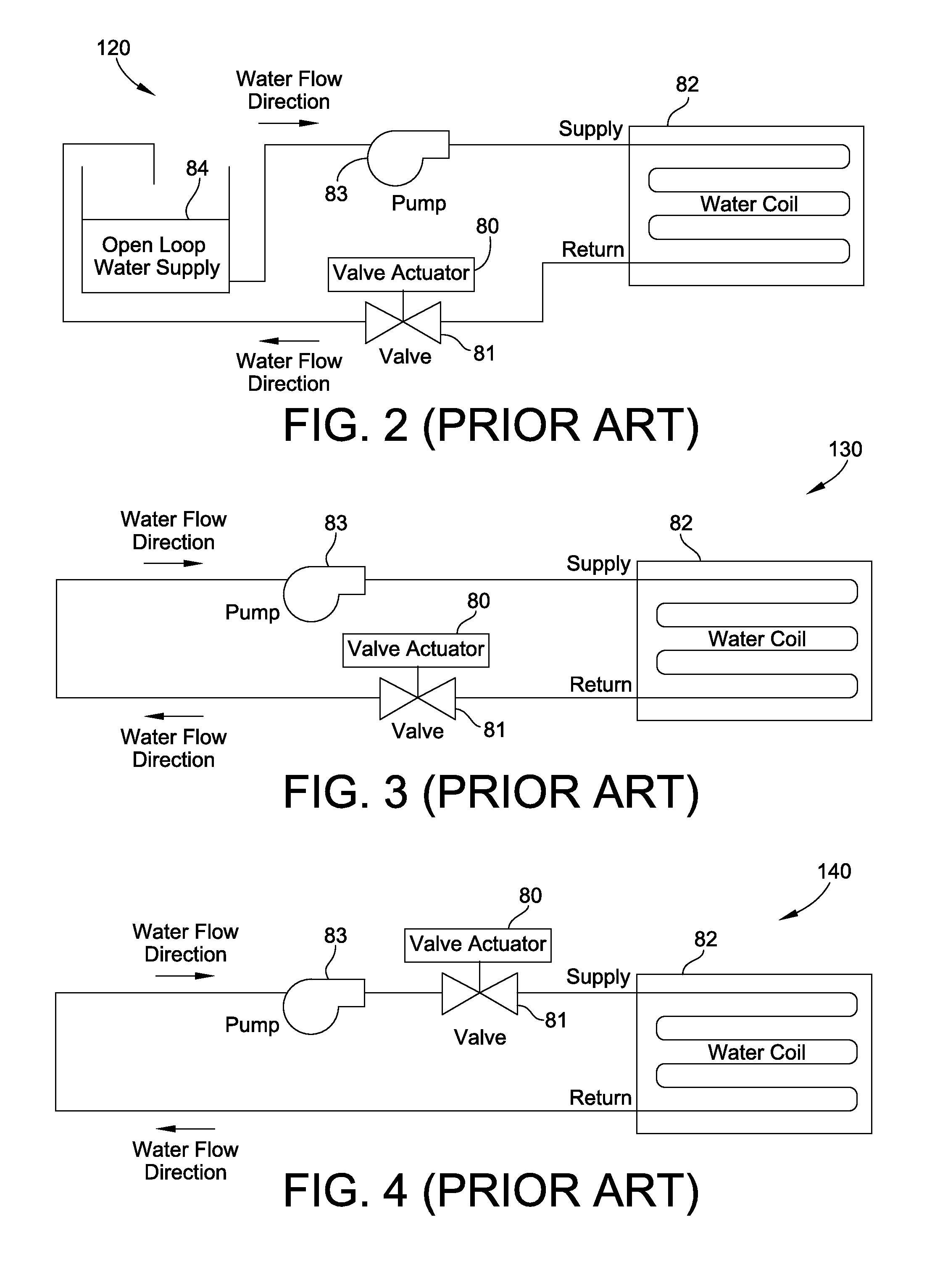

Advanced Valve Actuator With Remote Location Flow Reset

ActiveUS20140097367A1Improve energy efficiencyPrecise functionOperating means/releasing devices for valvesLighting and heating apparatusFluid controlValve actuator

An fluid control valve and actuator assembly includes a valve configured to control a flow of liquid, and a valve actuator configured to control opening and closing of the valve, and further configured to provide both a maximum flow rate and a minimum flow rate of the liquid through the valve. In a particular embodiment, the valve actuator has a communications module configured to facilitate communication with the valve actuator over a network, and further configured to allow both remote monitoring of the flow through the valve, and remote control of the valve actuator.

Owner:SCHNEIDER ELECTRIC BUILDINGS AMERICAS INC

Steam cooker

A steam cooker includes a first reservoir for receiving water, a second reservoir for receiving water, and a heating element. The water in the second reservoir is in fluid communication with the water in the first reservoir. The heating element is positioned proximate to the first reservoir and remote to the second reservoir.

Owner:GOODWAY ELECTRICAL CO LTD

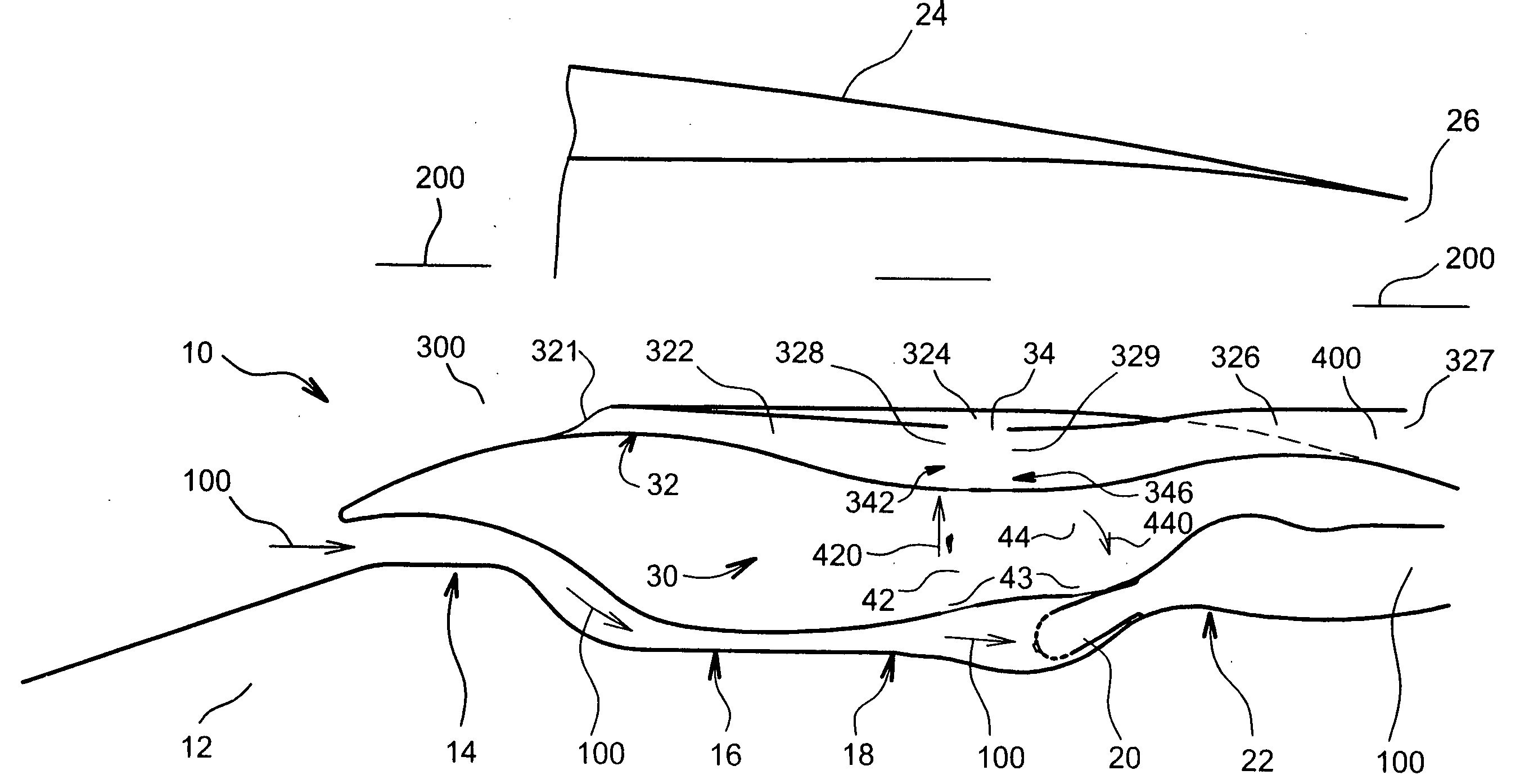

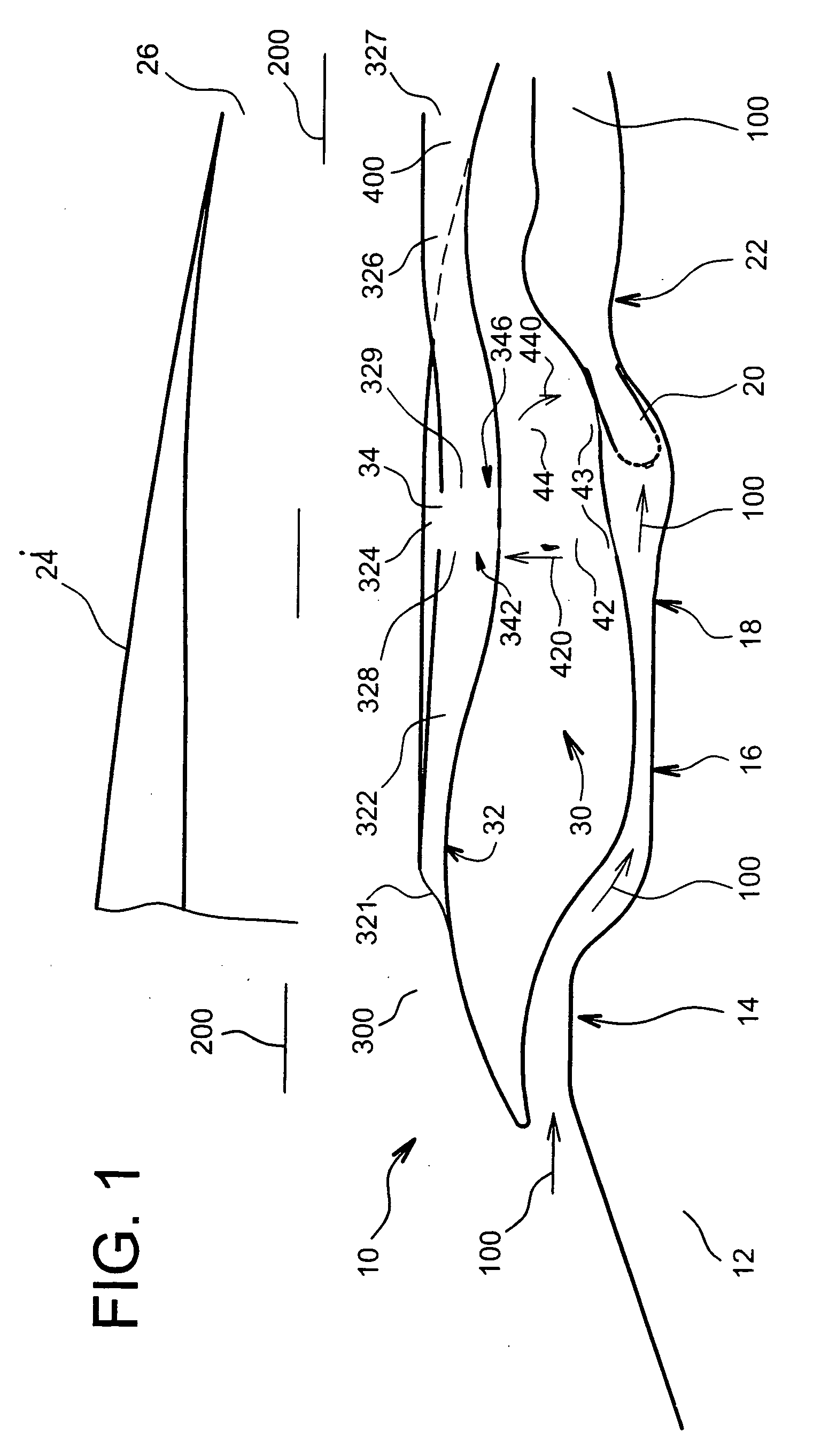

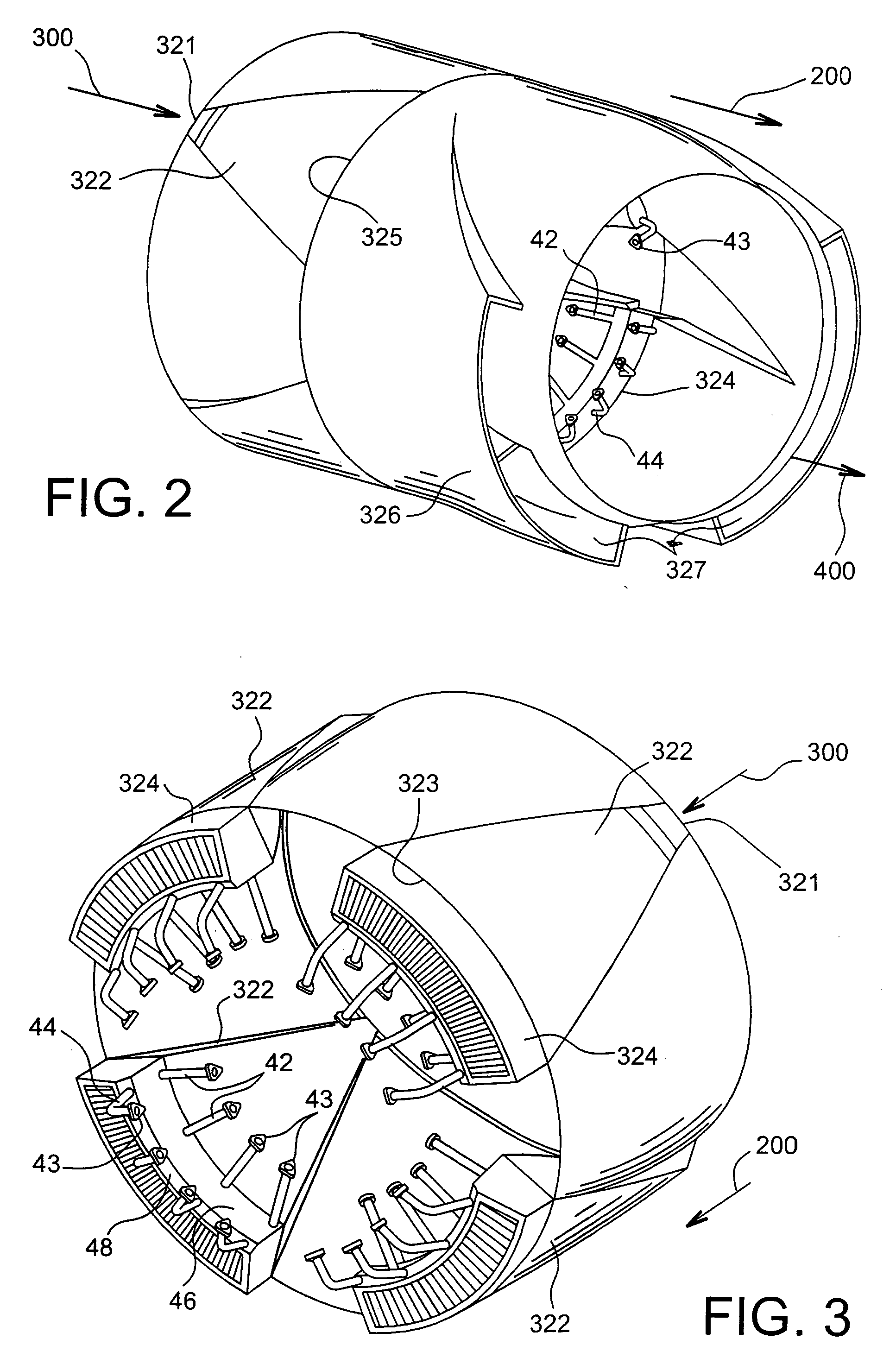

Cooling system for hot parts of an aircraft engine, and aircraft engine equipped with such a cooling system

InactiveUS20050150970A1Eliminate riskIncreased pressure lossRecuperative heat exchangersEngine fuctionsCold airNacelle

The cooling system (30) for an aircraft engine (10) comprises a channel (32) that draws off cold air in the secondary air flow (200), and a heat exchanger (34) located in the channel (32) and in which hot air circulates. The channel (32) comprises: a supply pipe (322) and an evacuation pipe (326) fixed to the nacelle (324), an intermediate box (324) located between the supply pipe (322) and the evacuation pipe (326), fixed to the engine (10), and in which the heat exchanger (34) is placed. Application to cooling of hot parts (22) in an aircraft engine (10).

Owner:SNECMA MOTEURS SA

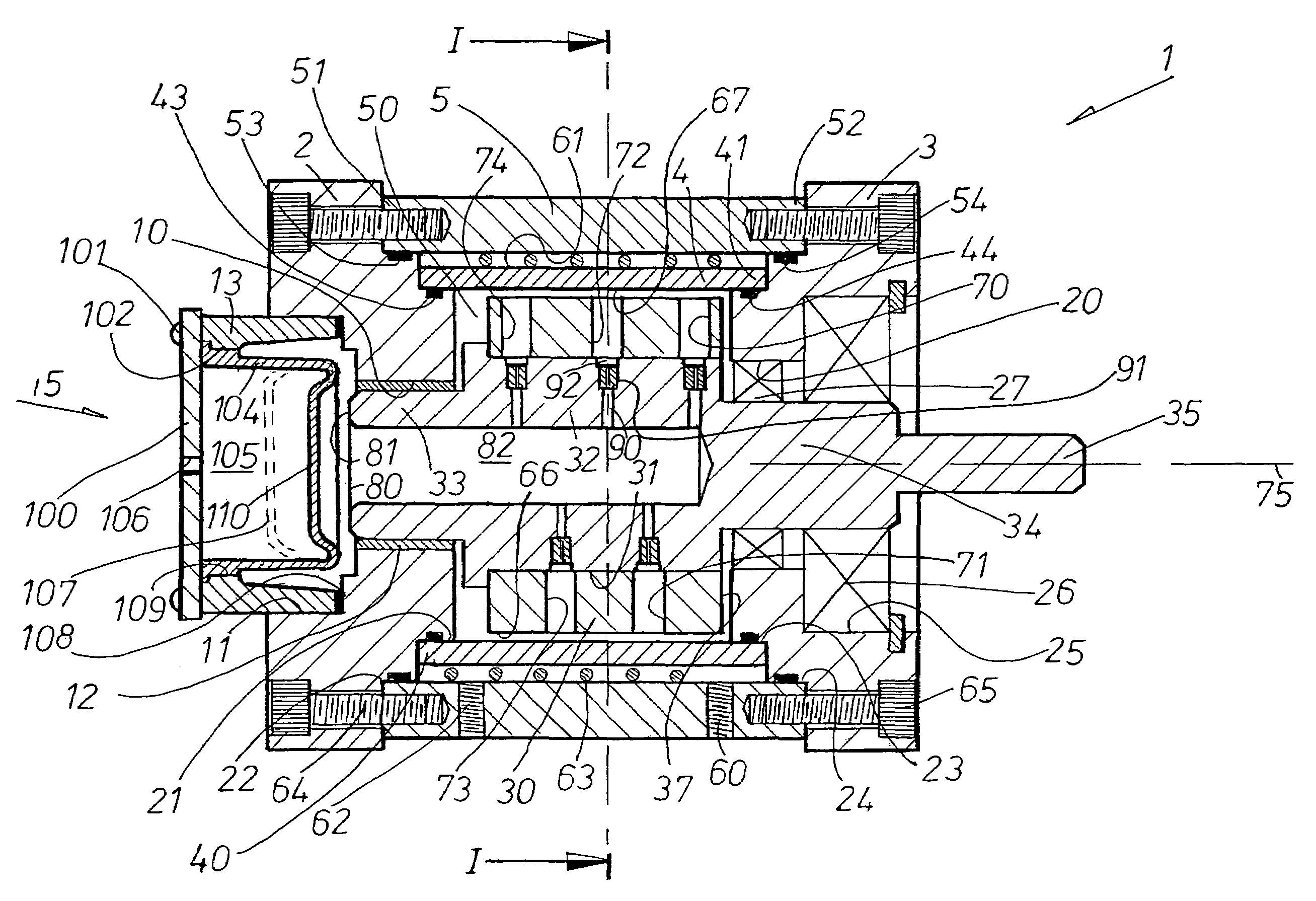

Heat generator

InactiveUS7387262B2Reduce equipment capacityPositive performanceAir-treating devicesOther heat production devicesInterior spaceViscous liquid

An apparatus for the heating of a viscous fluid contained in a heat generating chamber by a rotatable unit having a fluid shearing surface formed on a face thereof, the unit by shearing of the viscous fluid on that face induces the heating of said viscous fluid and where an external heat extracting surface is provided for this heat to be removed by a further fluid in contact with that surface. The two dissimilar fluids are kept apart by at least the housing acting as a fluid partition. The unit has an interior space as a storage location for viscous fluid with a deformable element for volume changes of the viscous fluid during the operation of the apparatus.

Owner:THOMA CHRISTIAN

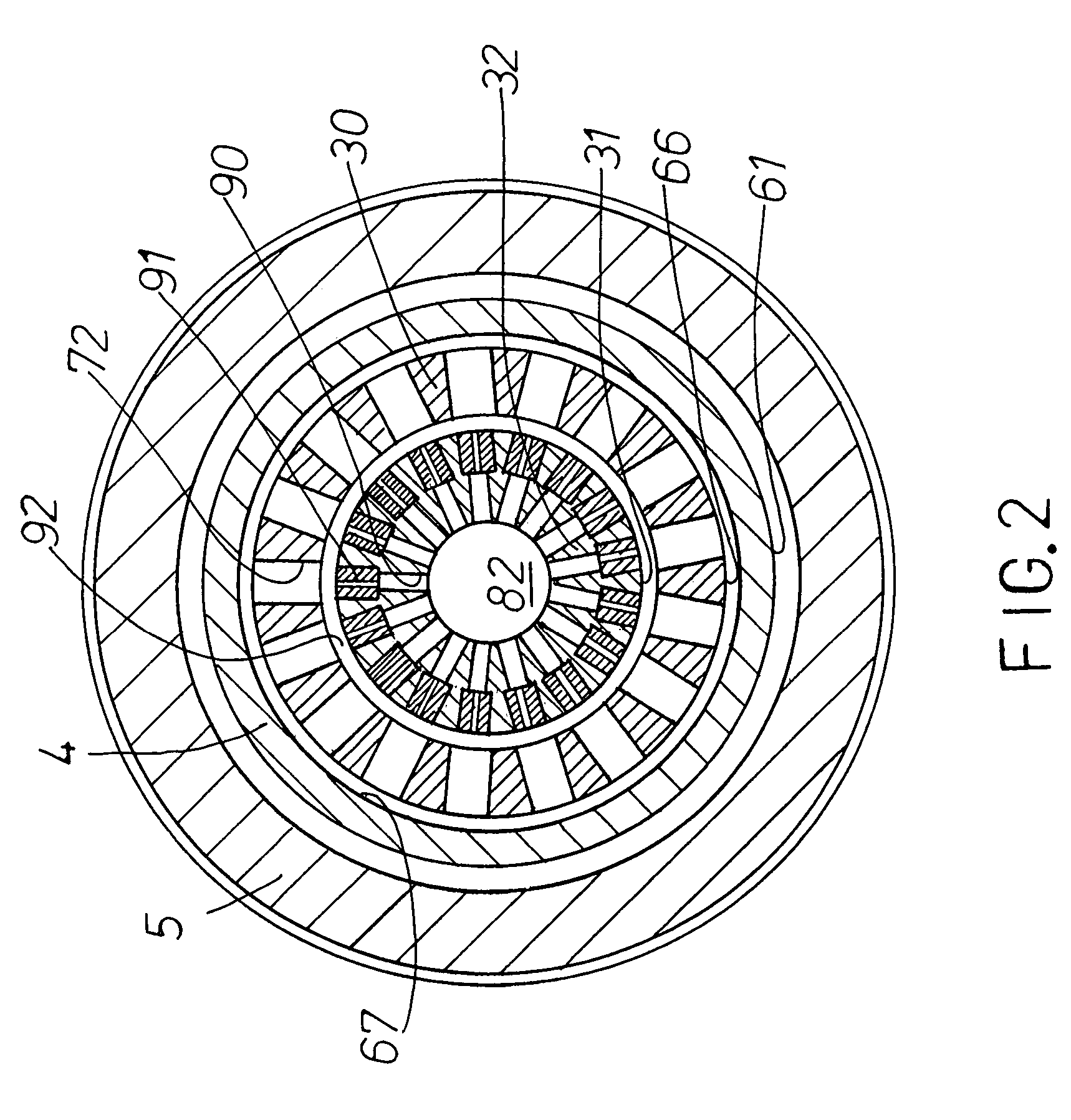

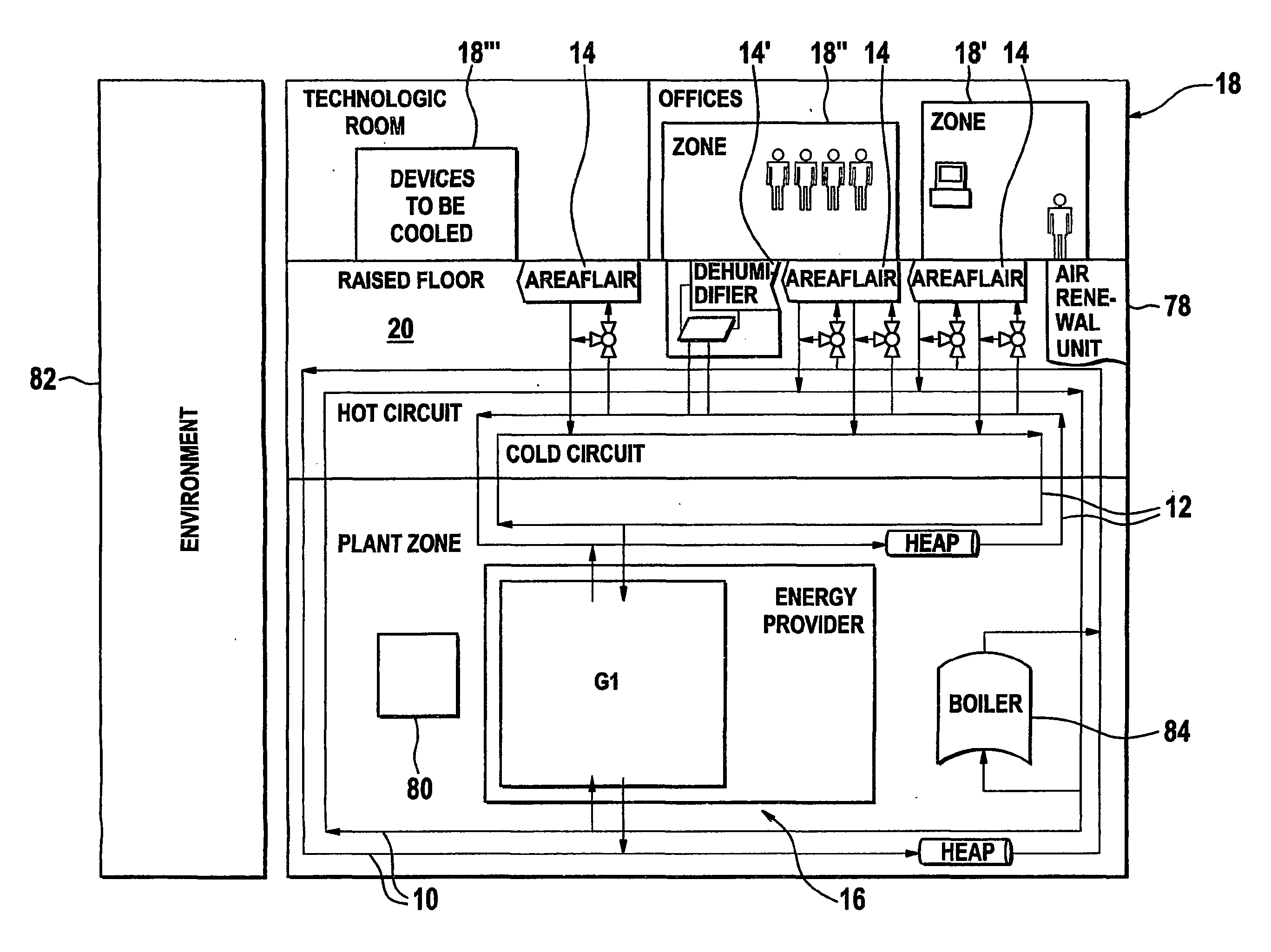

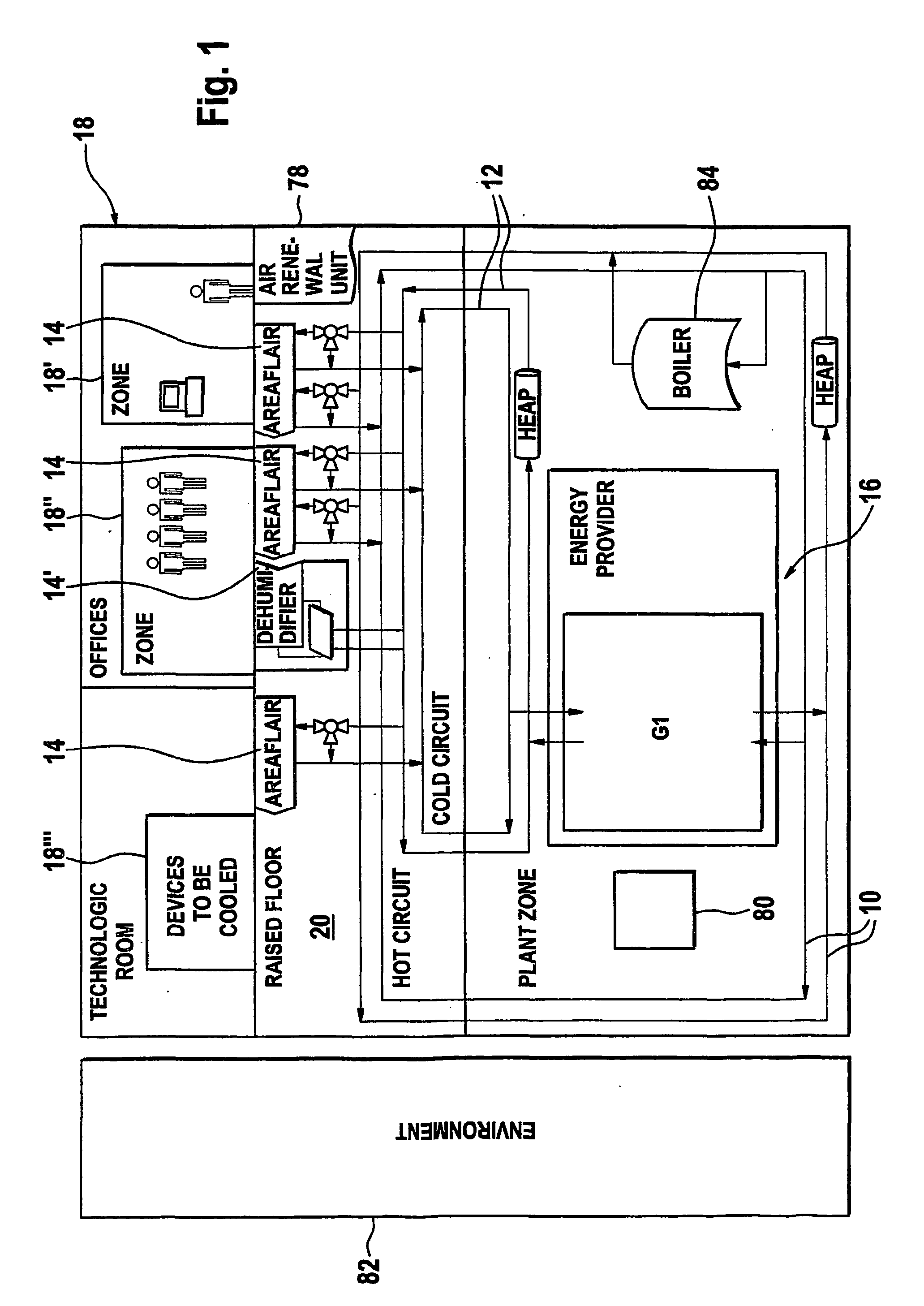

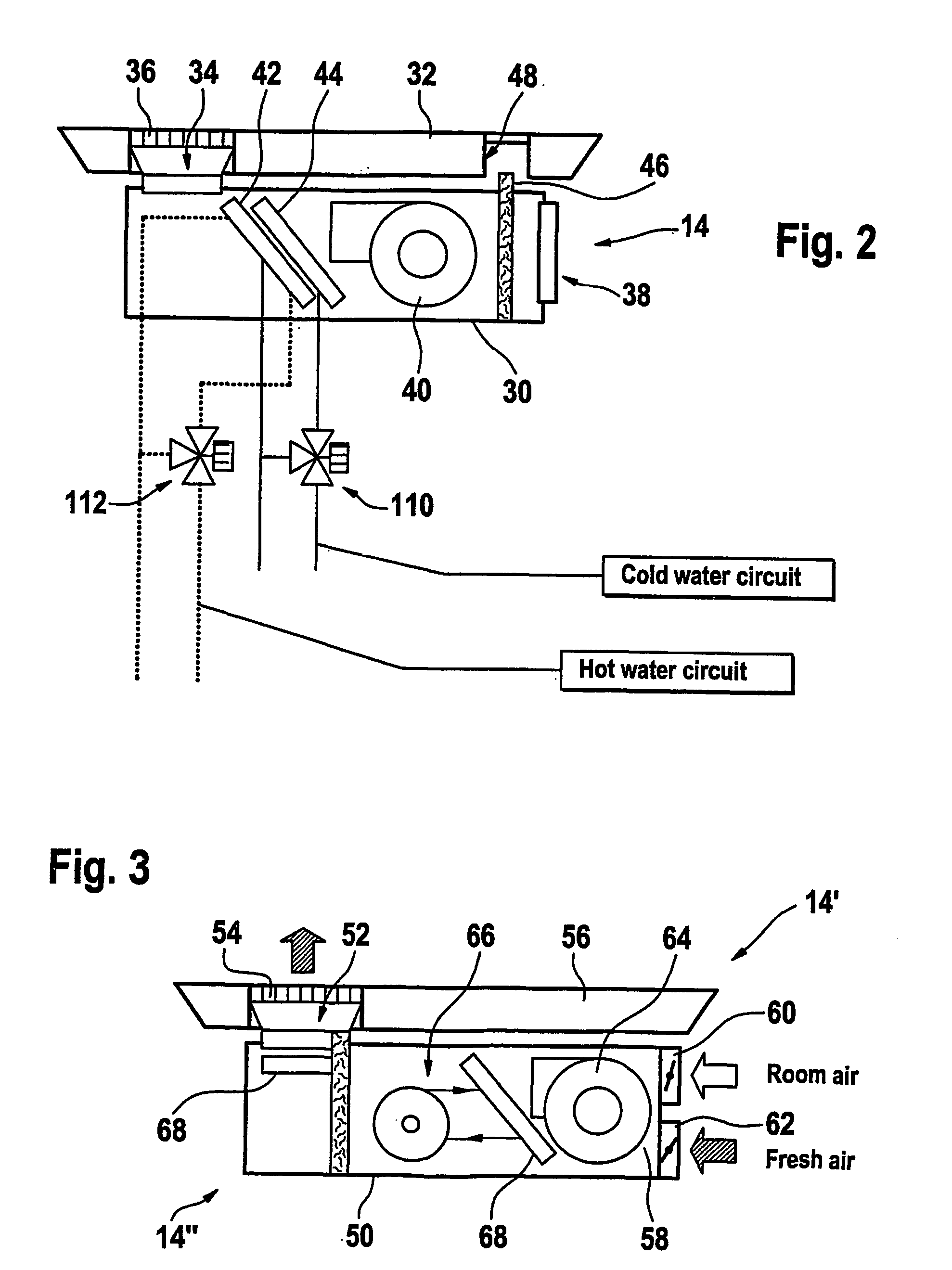

Air-conditioning system

ActiveUS20040148950A1Reduce energy consumptionReduce the space occupiedSpace heating and ventilation detailsHeating and refrigeration combinationsEngineeringAir conditioning

An air-conditioning system for a building comprises a hot water distribution circuit (10), a cold water distribution circuit (12) and several terminal air conditioning units (14). Each of these terminal air conditioning units (14) comprises a fan (40) for blowing air in a space of the building, a heating coil (42) connected to the hot water distribu-tion circuit (10) and / or a cooling coil (44) connected to the cold water distribution circuit (12). At least one ambient temperature control system allows to control heating power of the heating coils and cooling power of the cooling coils. The system further includes a calorific energy management system (80) with a heat pump for transferring calorific energy: a) from the cold water distribution system to the hot water distribution system; b) from the cold water distribution system to atmosphere; and c) from the atmosphere to the hot water distribution system. The calorific energy management system (80) is capable of managing the calorific energy transfers with a three level control system so as to optimise energy consumption.

Owner:UNIFLAIR IND SPA

Method of and apparatus for conveying molten metals while providing heat thereto

InactiveUS20080163999A1High heat conductivityPrevent oxidationHot-air central heatingLighting and heating apparatusCombustionEngineering

The invention relates to a method of and apparatus for providing heat to a molten metal flowing through metal-conveying apparatus. The apparatus includes a molten metal-conveying channel, an enclosure for receiving and circulating combustion gases while preventing entry of the gases into said channel, a heat-conductive body of material separating at least part of the channel from the enclosure; and a combustion device for generating combustion gases and delivering the gases to the enclosure. Heat from the combustion gases is used to heat molten metal held in the channel, while preventing contact between the combustion gases and the molten metal. The body of material may be a trough used to form the channel, a tube for conveying the molten metal, or a tube acting as the enclosure, or the like.

Owner:NOVELIS INC

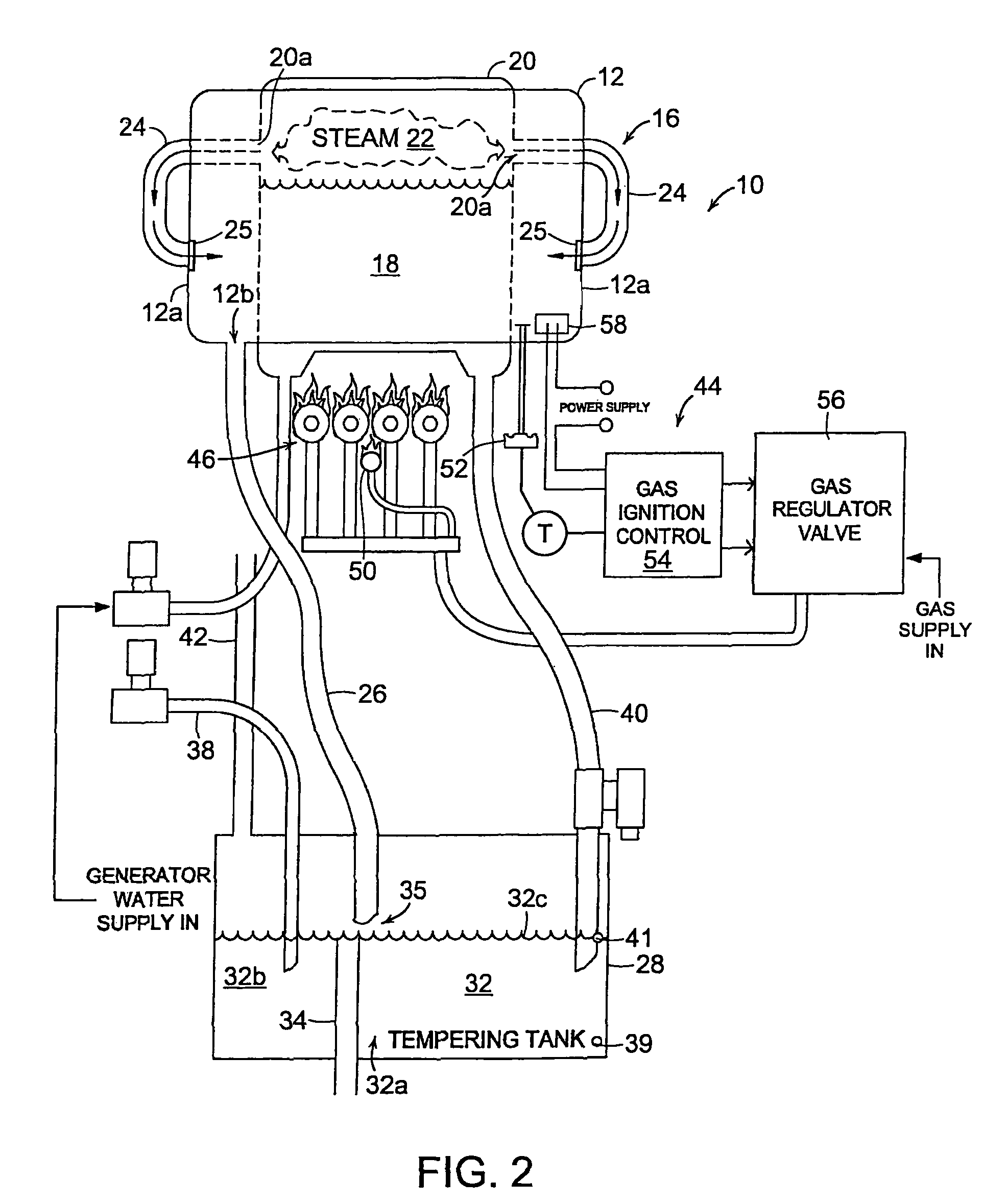

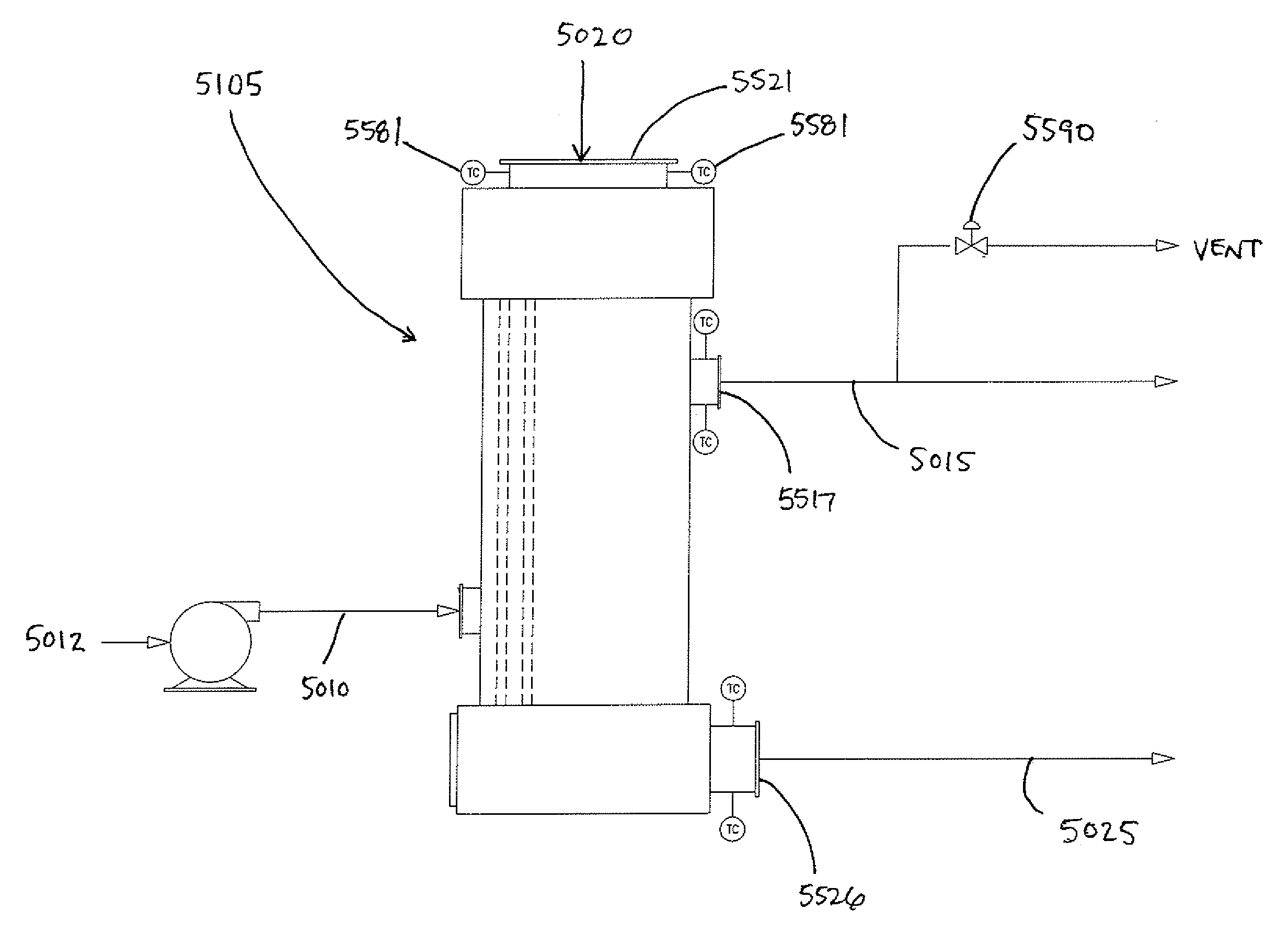

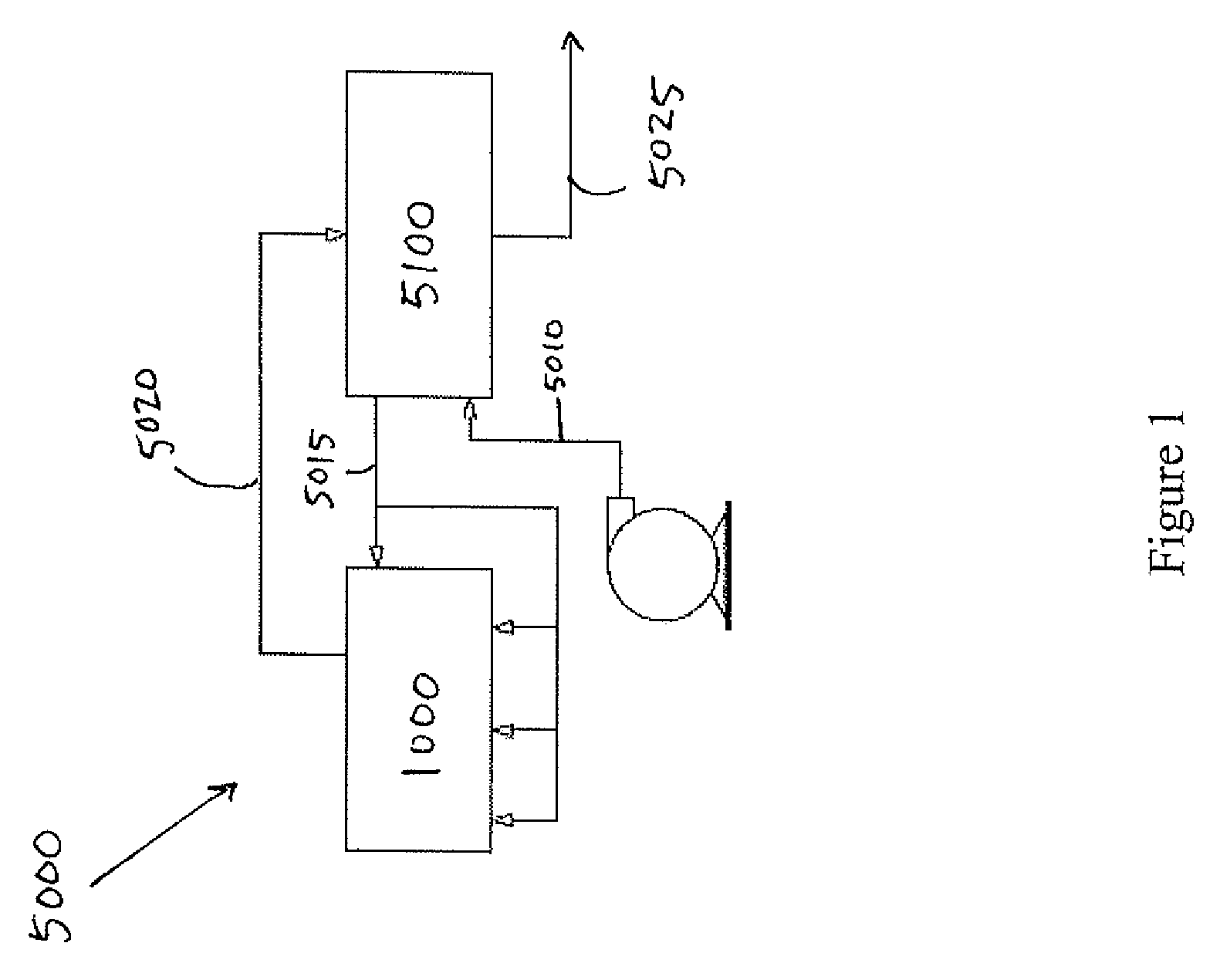

High efficiency atmospheric steamer

ActiveUS7810488B2Temperature control without auxillary powerDomestic stoves or rangesSteam pressureFiltration

A pressureless or atmospheric steamer for cooking food with a high cooking efficiency has a cooking compartment with an outlet for steam and condensate that feeds to a tempering tank via an outlet conduit. The outlet conduit is spaced closely from the controlled water level in the tempering tank, and is in fluid communication with the atmospheric vent to create an open steam cooker. A steam generator is adjacent the cooking compartment and has a water reservoir, a heat exchanger secured within the reservoir in a heat-transferring relationship at an exterior surface of the heat exchanger with the water held in the reservoir, and a heater that supplies heat to the interior of the heat exchanger. The tempering tank has a drain and level controls for a water supply held in the tempering tank. A pressure-sensitive device is disposed to measure the steam pressure in the cooking compartment and to generate electrical output signals indicative of minimum and maximum pressure values to control the operation of the heater to maintain the steam pressure in the cooking compartment within that operating range. The steamer has an in-built water filtration system for water supplied to the water reservoir.

Owner:MARKET FORGE INDS

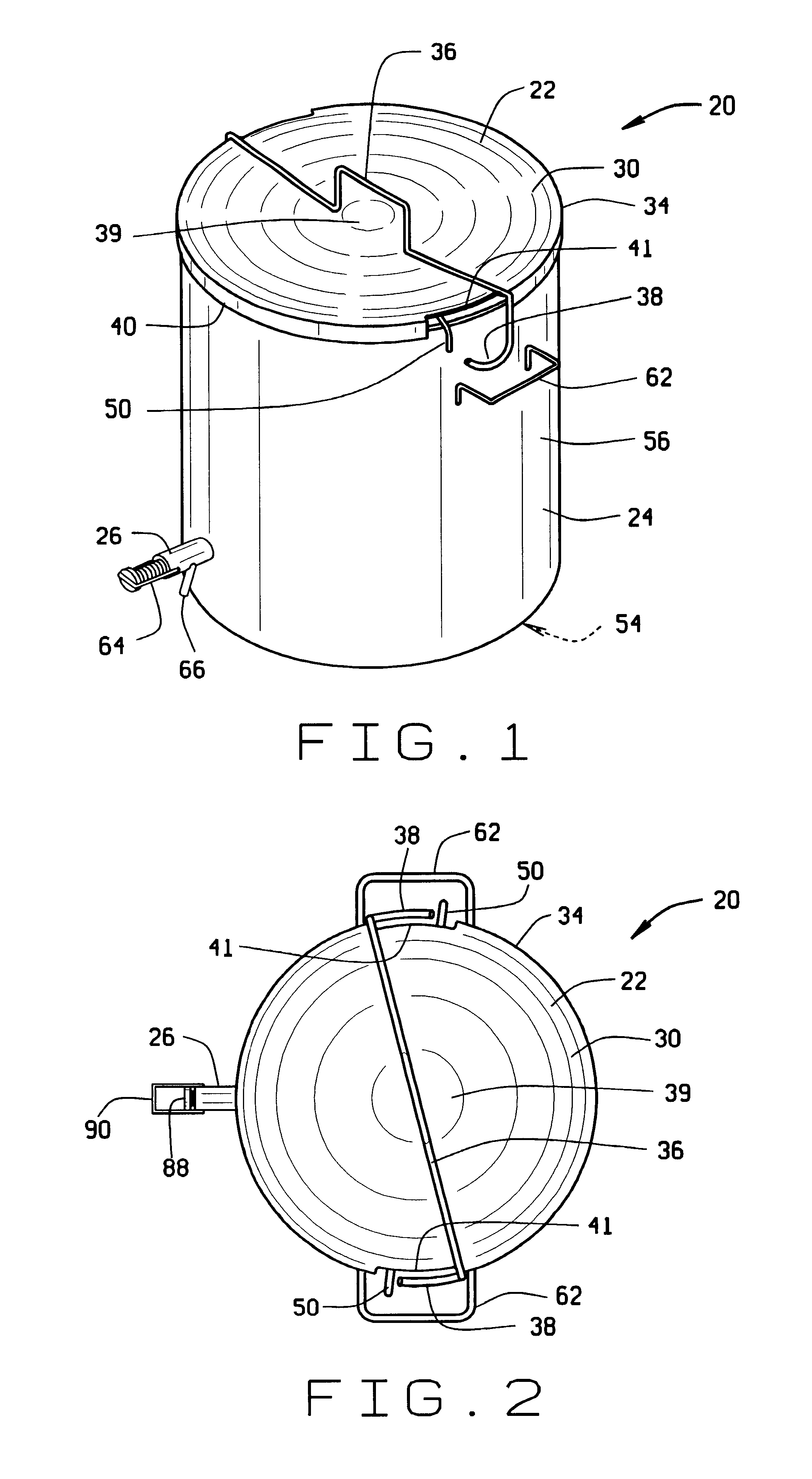

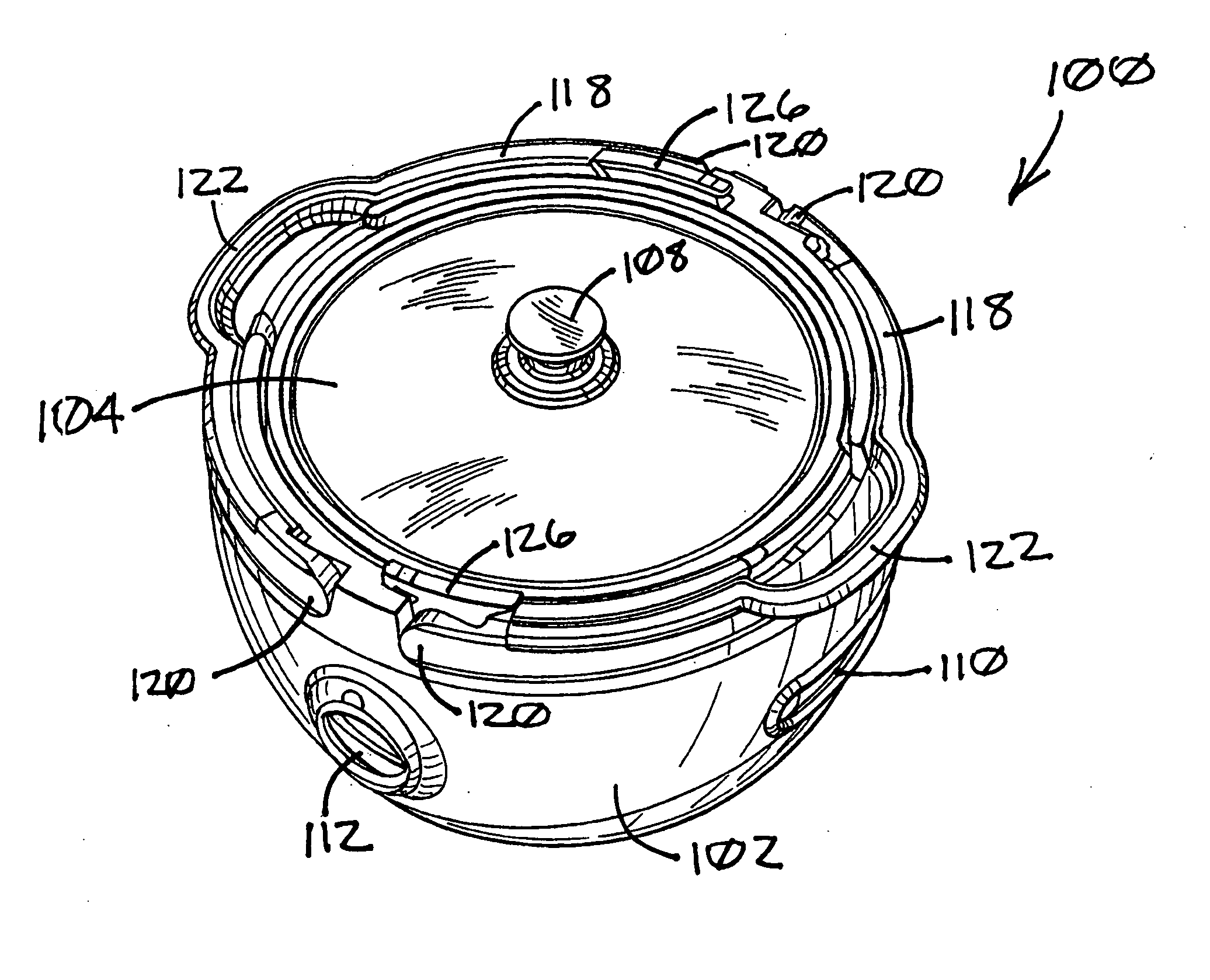

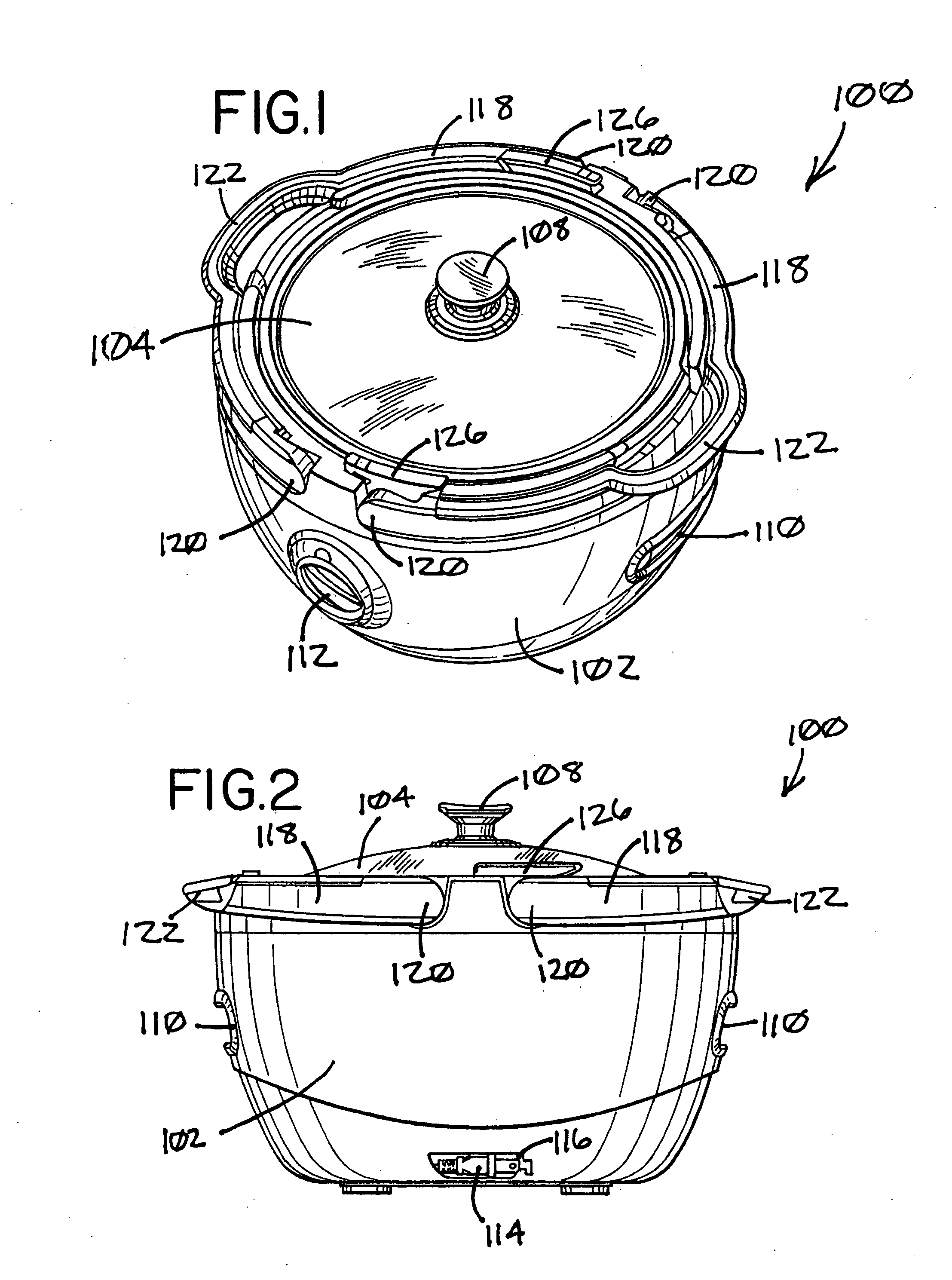

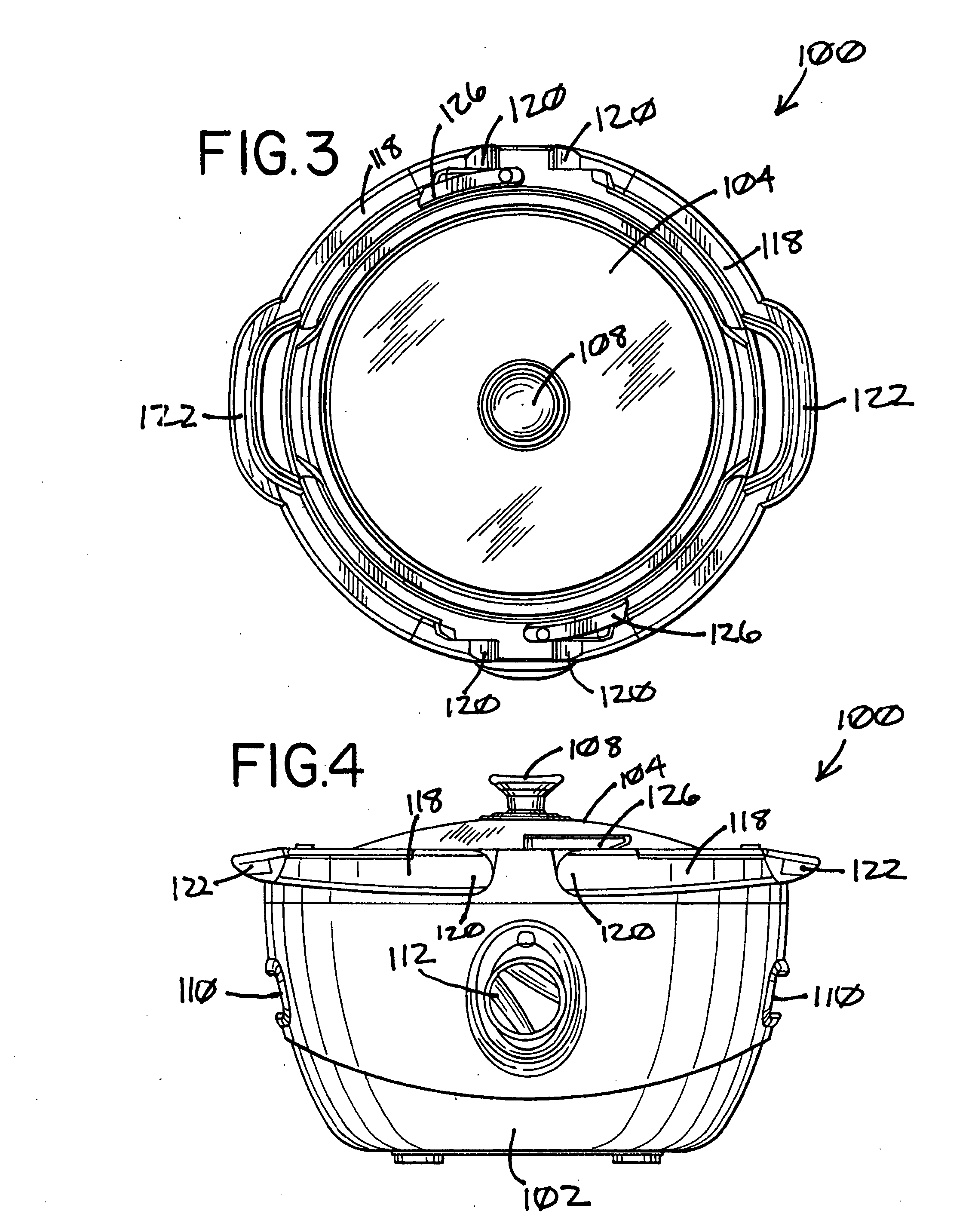

Portable slow cooker

The present invention relates to a sealing apparatus on a portable slow cooker. The sealing apparatus includes a handle, a latch and a gasket. The gasket is positioned between the lid and the heating vessel of the slow cooker. The handle is hingedly attached to the slow cooker and has a lowered position and a raised position. The latch is hingedly attached to the heating vessel, and has a locked position and an unlocked position. When the handle is in the lowered position, the latch is in the unlocked position and the lid is removable from the heating vessel. When the handle is in the raised position, the latch is in the locked position and the lid is sealed onto the heating vessel.

Owner:OLYMPIA GROUP +1

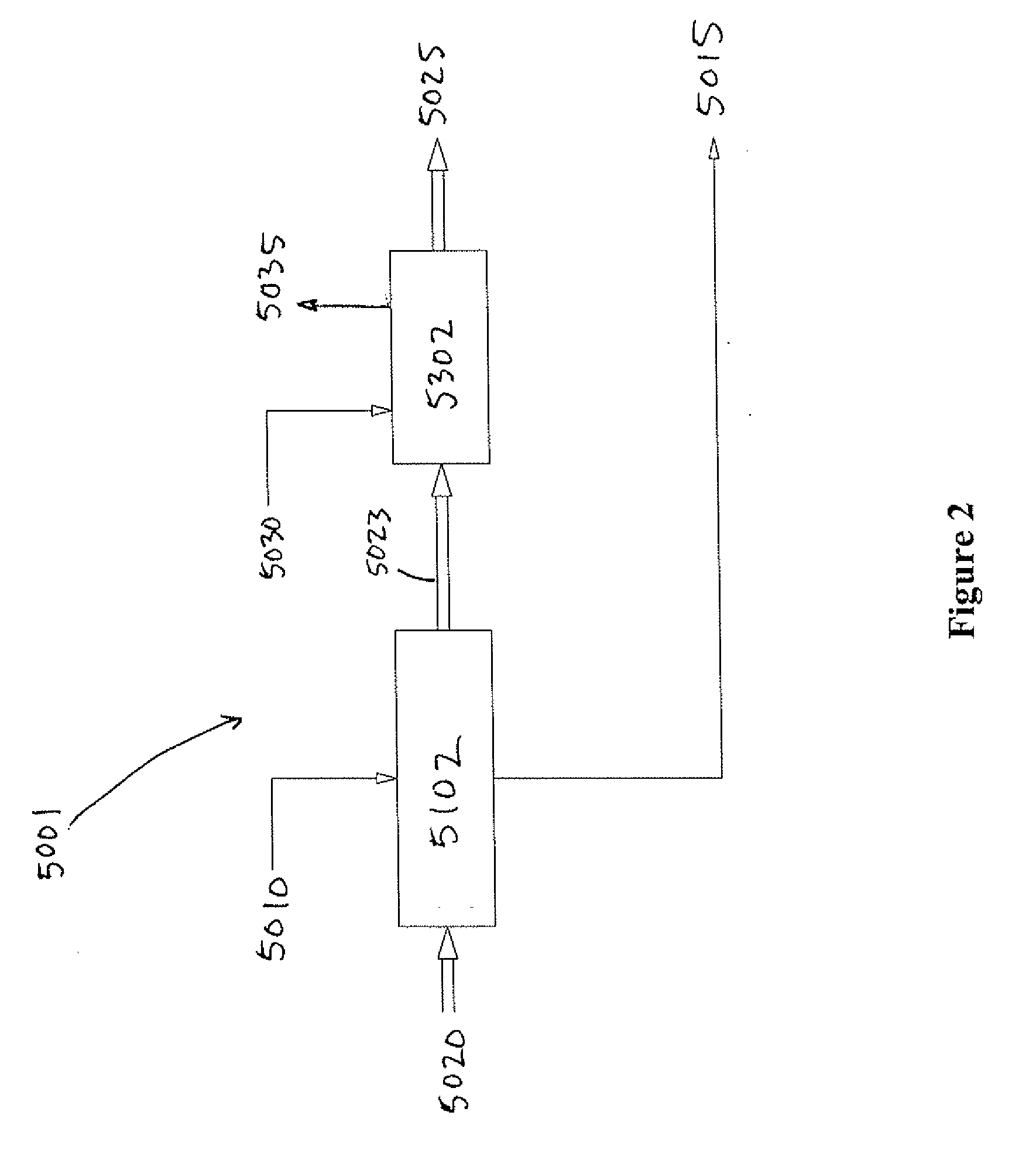

Heat Recycling System for Use with a Gasifier

InactiveUS20070284453A1Improve efficiencyMinimize energy consumptionGasifier mechanical detailsEnergy inputWorking fluidControl system

The present invention provides a system that recycles heat recovered from hot products of a carbonaceous feedstock gasification process back into the gasification process. The hot gaseous products are used to heat working fluids such as air and water to produce hot air, hot water or steam. The heated fluids are used to return heat back to the gasification process. The system also comprises a control system to optimize the efficiency of a gasification process by minimizing energy consumption of the process, while also maximizing energy production.

Owner:PLASCO ENERGY GROUP INC

System containing cogeneration unit and pure condensing steam thermal power unit as well as scheduling method

InactiveCN101950964AReduce consumptionAvoid wastingLighting and heating apparatusEnergy efficient heating/coolingElectricityCogeneration

The invention relates to a system containing a cogeneration unit and a pure condensing steam thermal power unit, comprising the cogeneration unit, the pure condensing steam thermal power unit, an air-conditioner heat pump, an electric energy meter, a radiator, a heat consumed meter and a scheduling control device, wherein the scheduling control device is used for collecting power consumption data detected by the electric energy meter and heating consumption data detected by the heat consumed meter to obtain a scheduling control signal and controlling the running of the cogeneration unit, the pure condensing steam thermal power unit, the air-conditioner heat pump and the radiator. Aiming at energy conservation scheduling during the off-peak period of electric load and energy conservation peak regulation during the low ebb period, the invention performs optimum allocation and control of heating demand and electricity output so as to reduce total energy consumption, thereby achieving the purpose of energy conversation.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com