Patents

Literature

382results about "Egg-cookers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

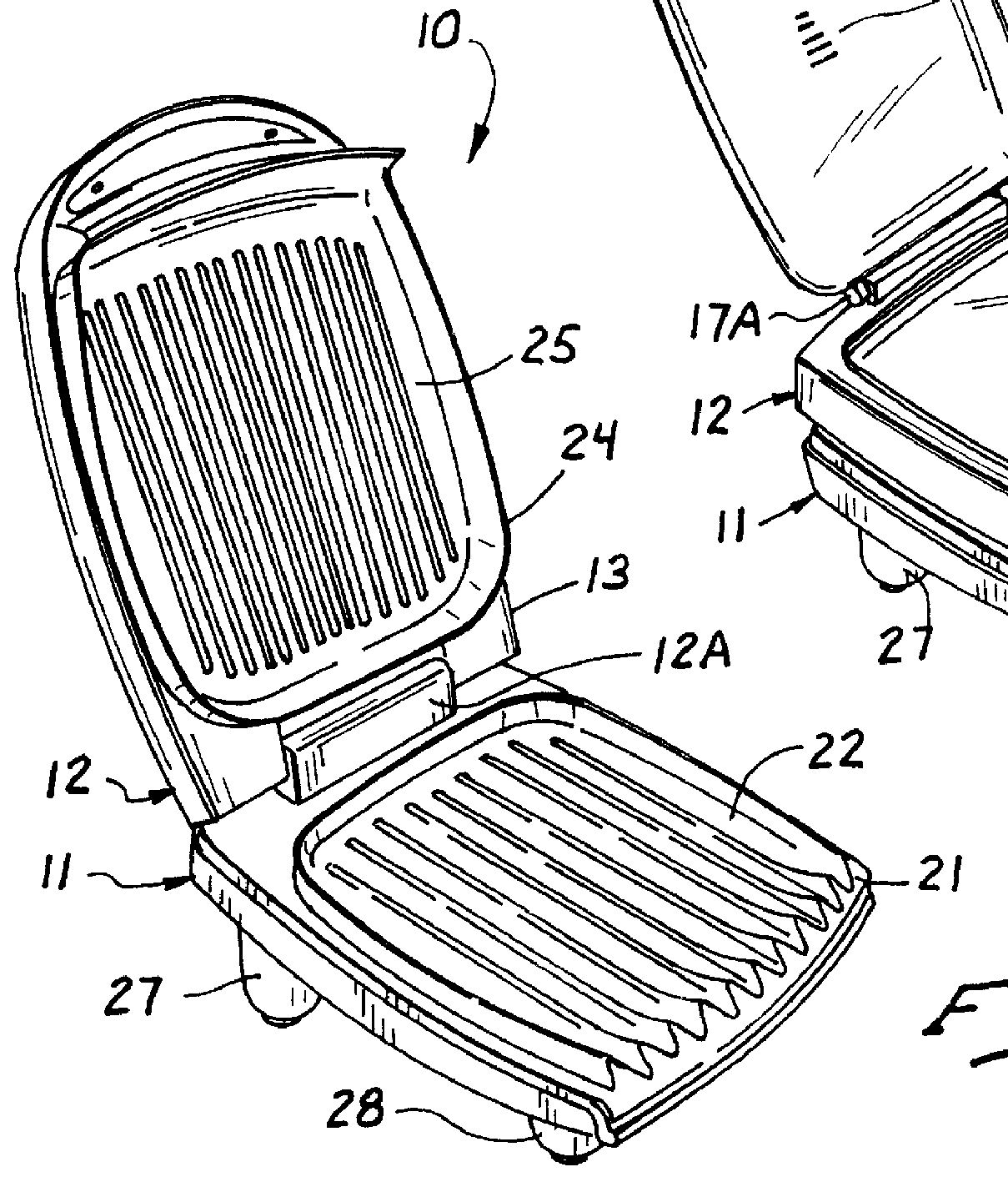

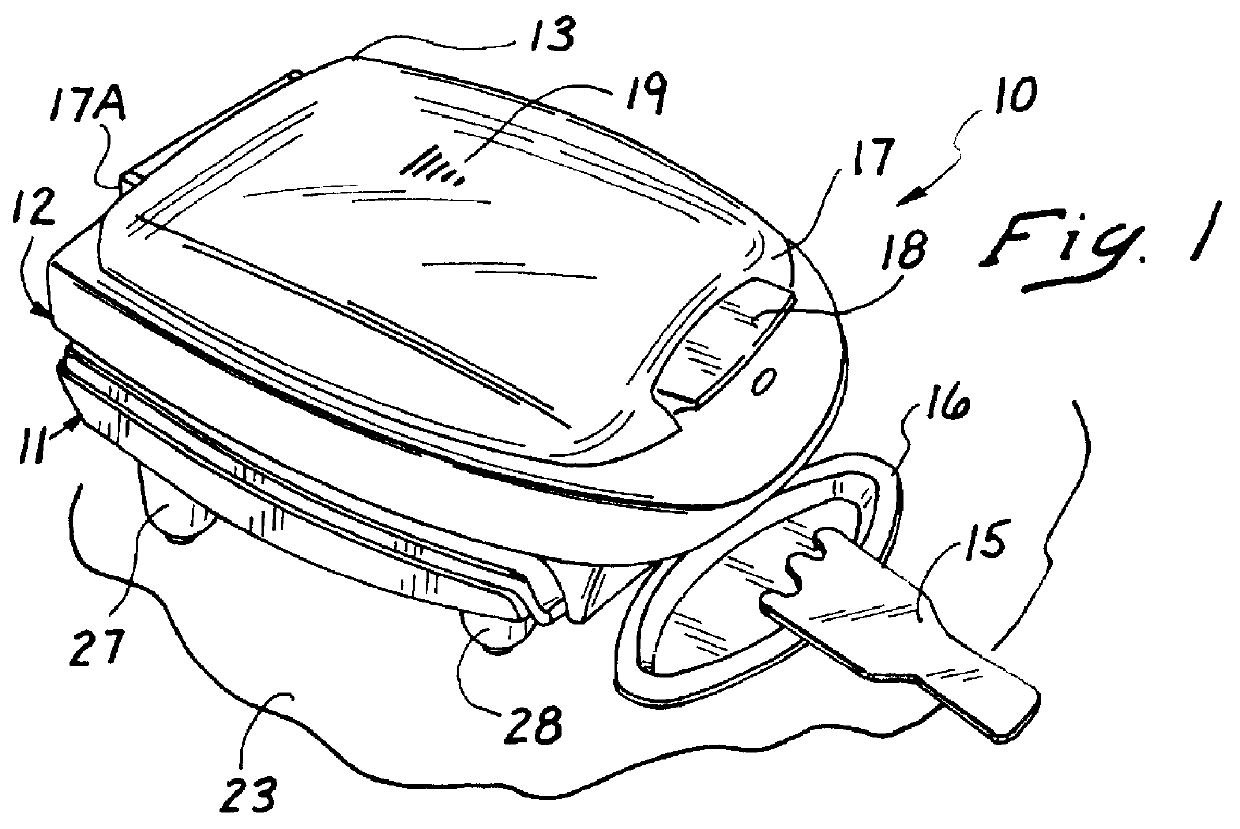

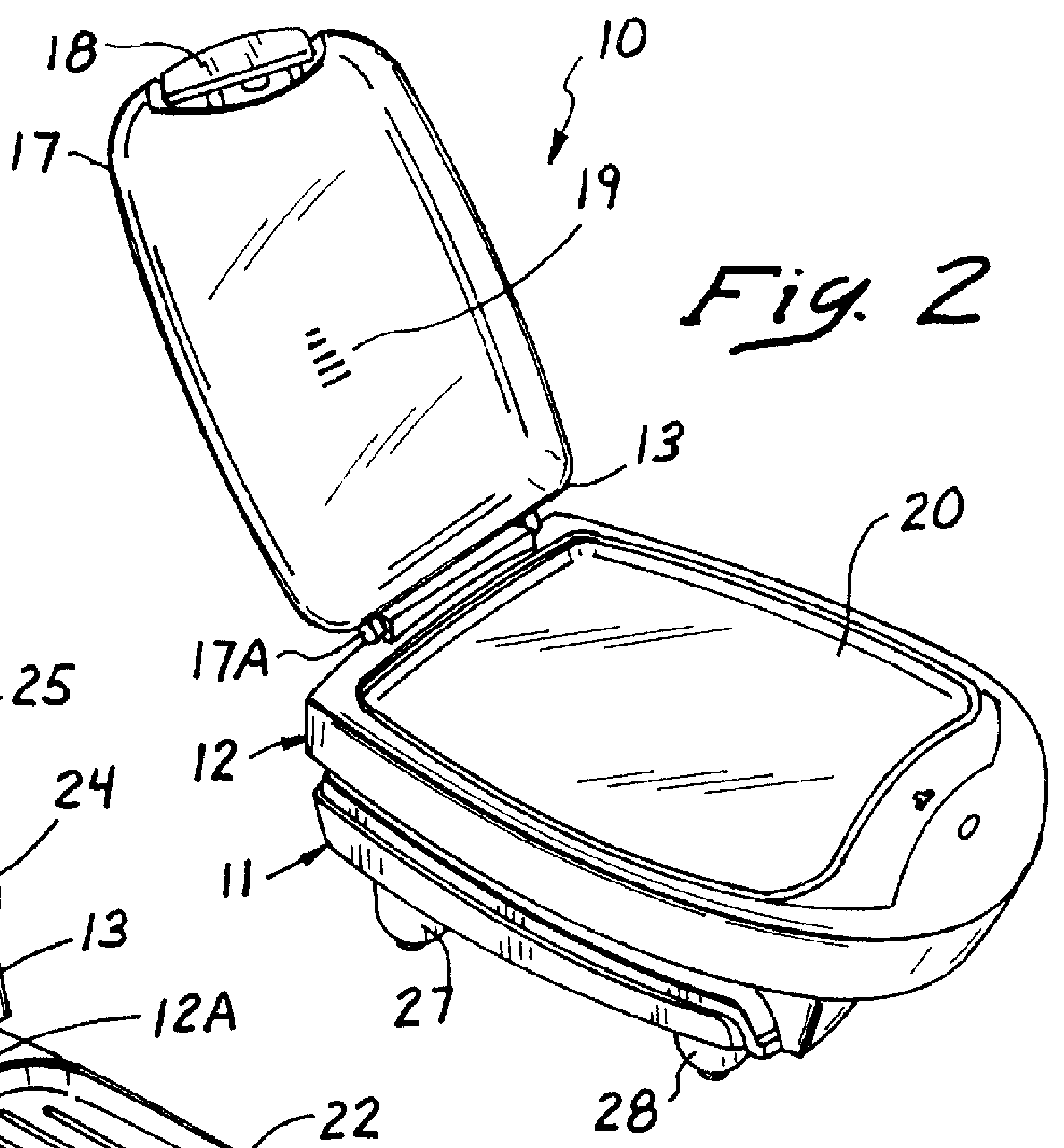

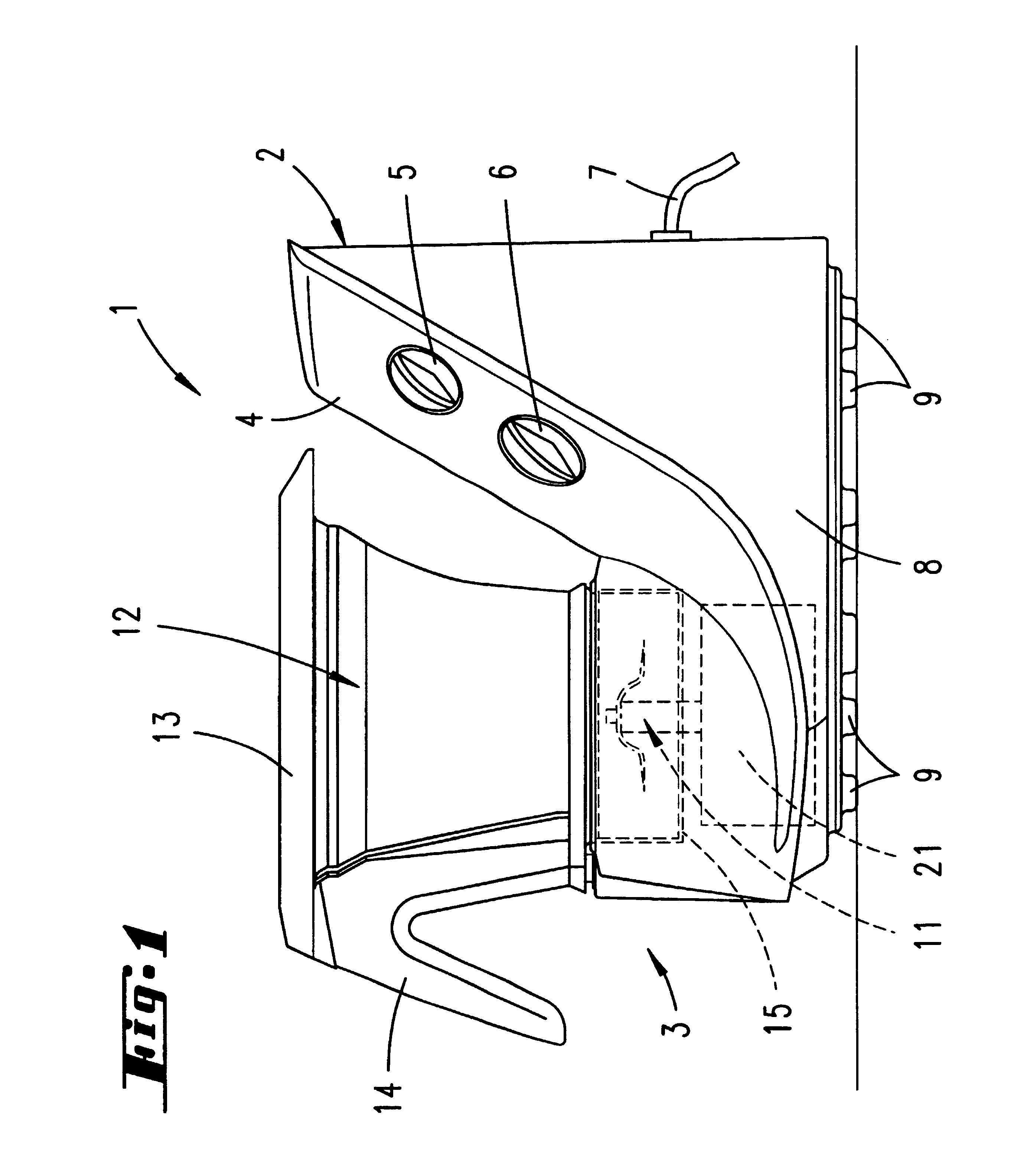

Electric countertop grill

An electric grill for cooking hamburgers and other foodstuffs includes a first grill plate assembly adapted for use atop a kitchen countertop, table top, or other horizontal support surface, a second grill plate assembly connected by a hinge arrangement to the first grill plate assembly in a clamshell arrangement, and a bun warmer portion of the second grill plate assembly that defines a compartment adapted to hold at least one bun (e.g., a hamburger bun) in order to warm the bun. In one embodiment, the bun warmer portion of the second grill plate assembly includes a metal plate adapted to support the bun, and a vented transparent lid over the plate. The first grill plate assembly may include an electric grill plate with an inclined cooking surface that slopes to facilitate grease runoff to a drip tray, and components in the form of leg extensions for adjusting the height of the first cooking surface above the horizontal support surface.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

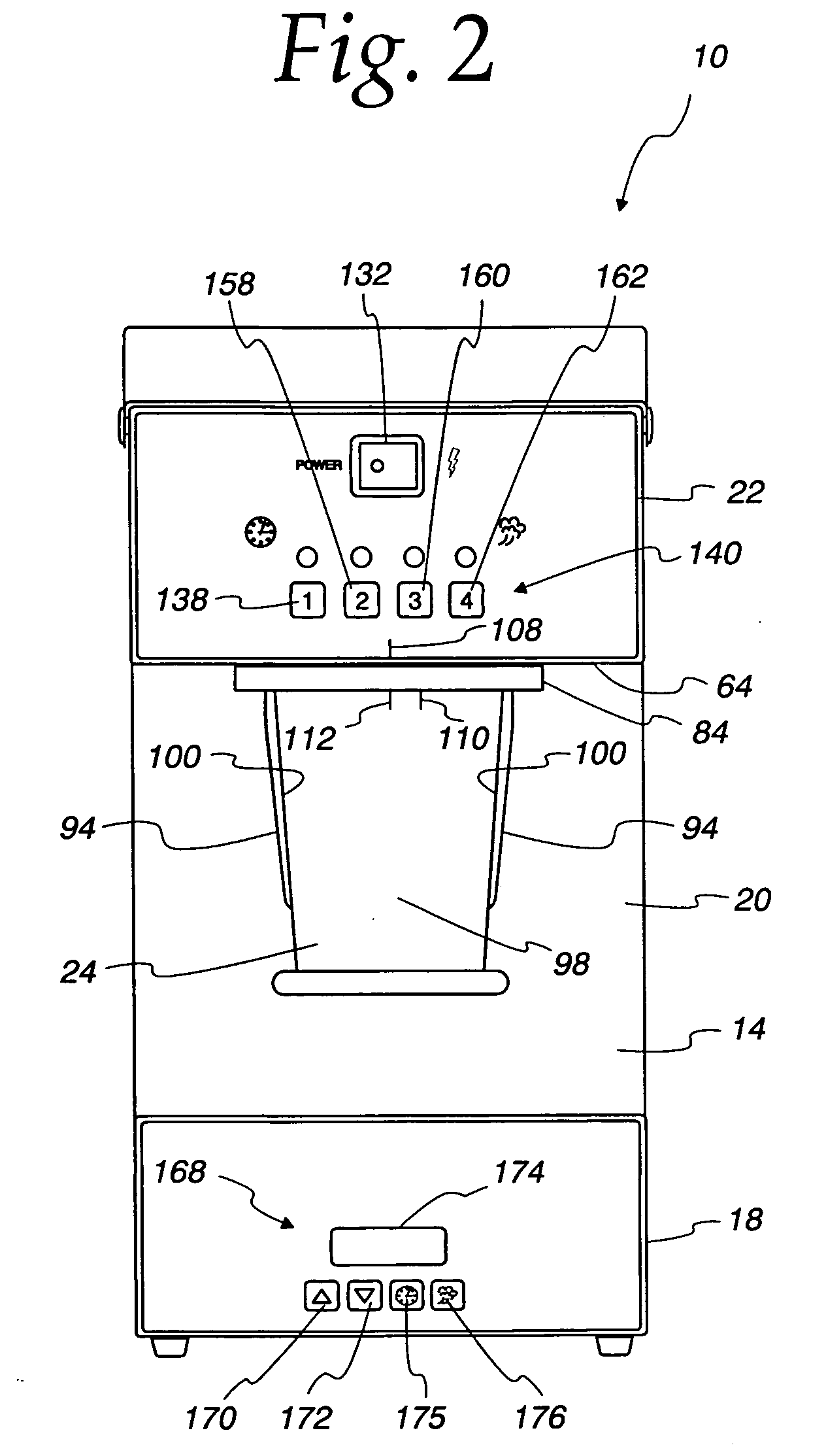

Food cooking apparatus

InactiveUS6269737B1Lighting and heating apparatusWater-bath cooking vesselsMechanical engineeringLiquid content

Owner:EMPIRE COMFORT SYST

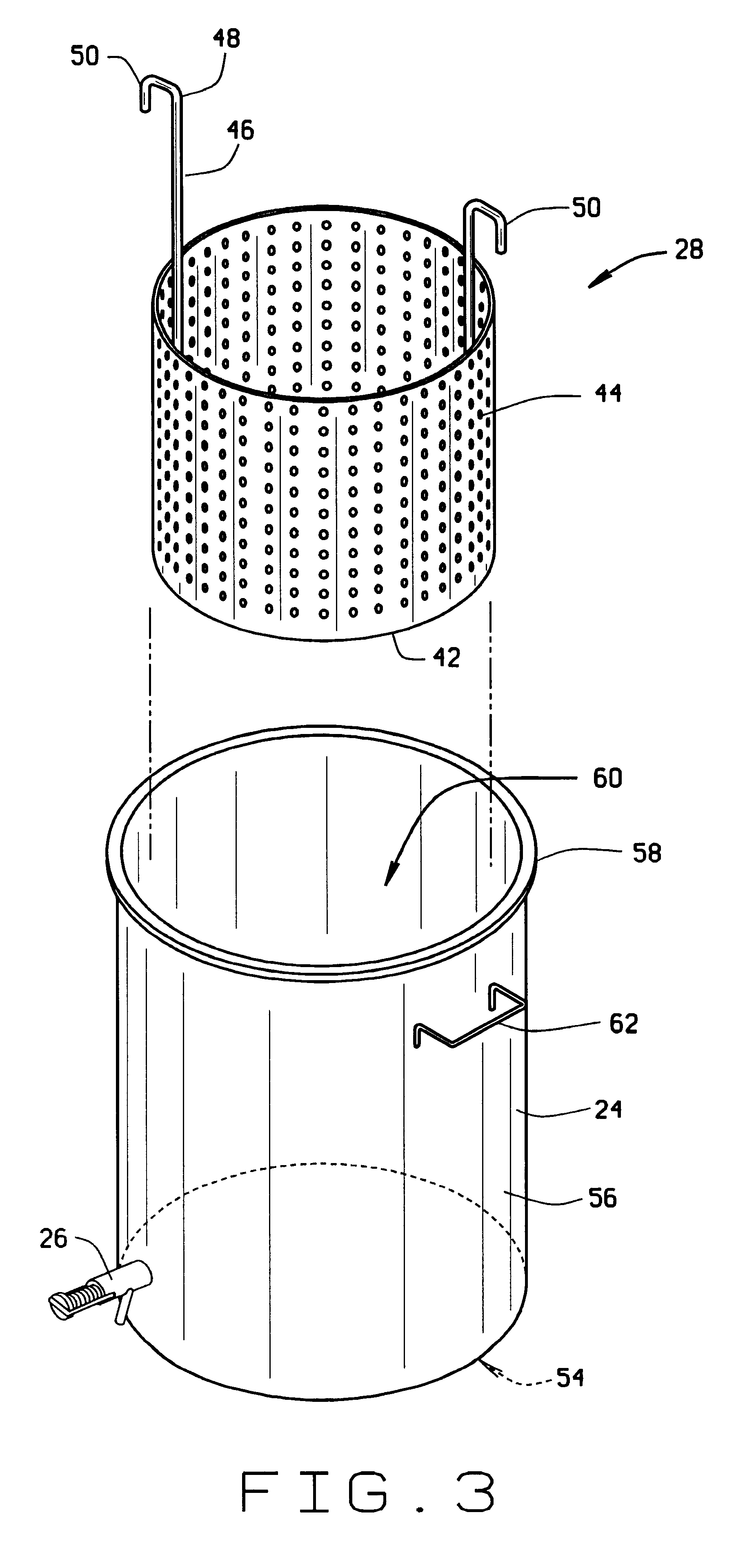

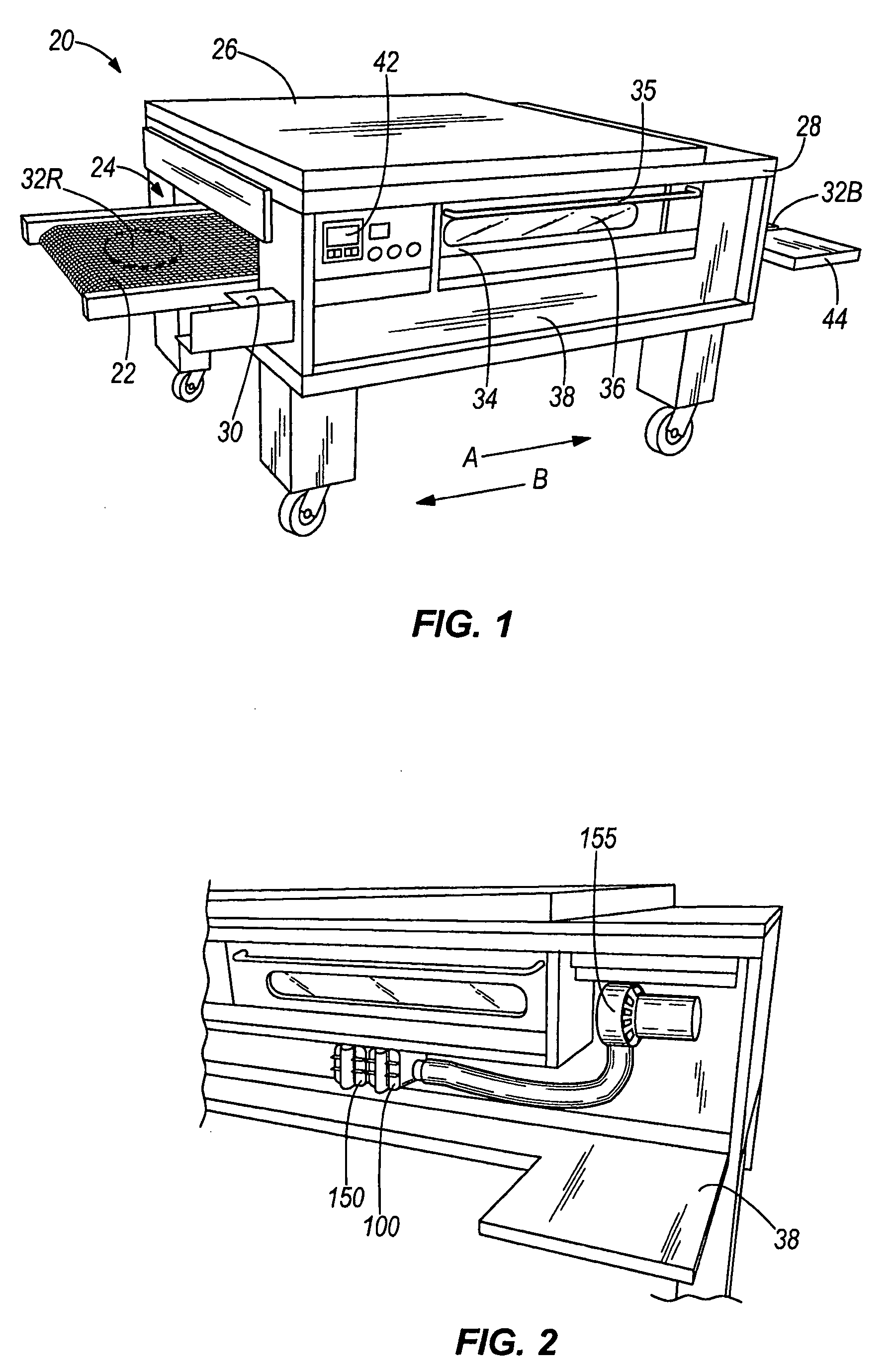

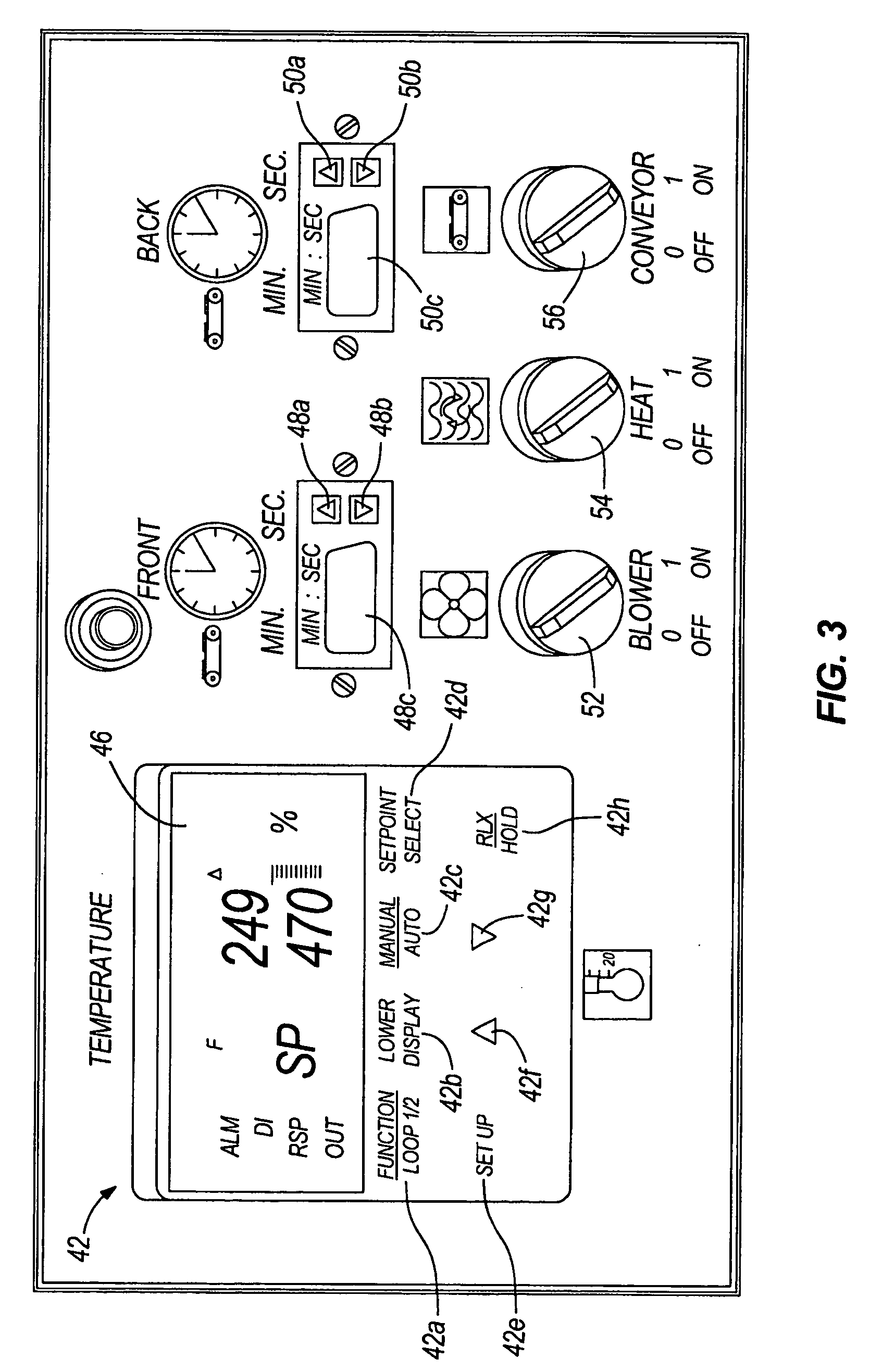

Conveyor oven apparatus and method

ActiveUS20070012307A1Easy accessDomestic stoves or rangesElectrical heating fuelEngineeringIngested food

An oven according to some embodiments includes an oven chamber in which food is cooked, a heating element, a fan, a sensor for sensing the temperature of the oven chamber, a remote input device, and a controller configured to receive a signal from the remote input device and to change the fan or heating element based at least in part upon the signal received from the remote input device. In a method of operating the oven according to some embodiments, the oven enters an operating mode from an energy-savings mode responsive to receiving an signal from a remote device.

Owner:MIDDLEBY CORPORATION

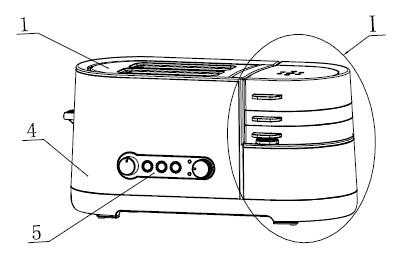

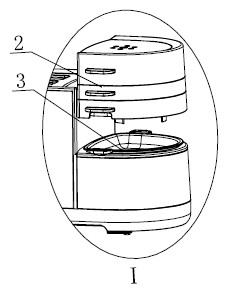

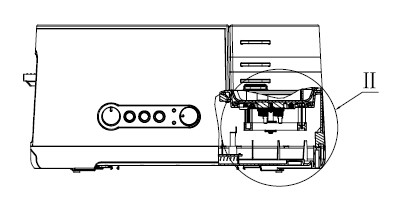

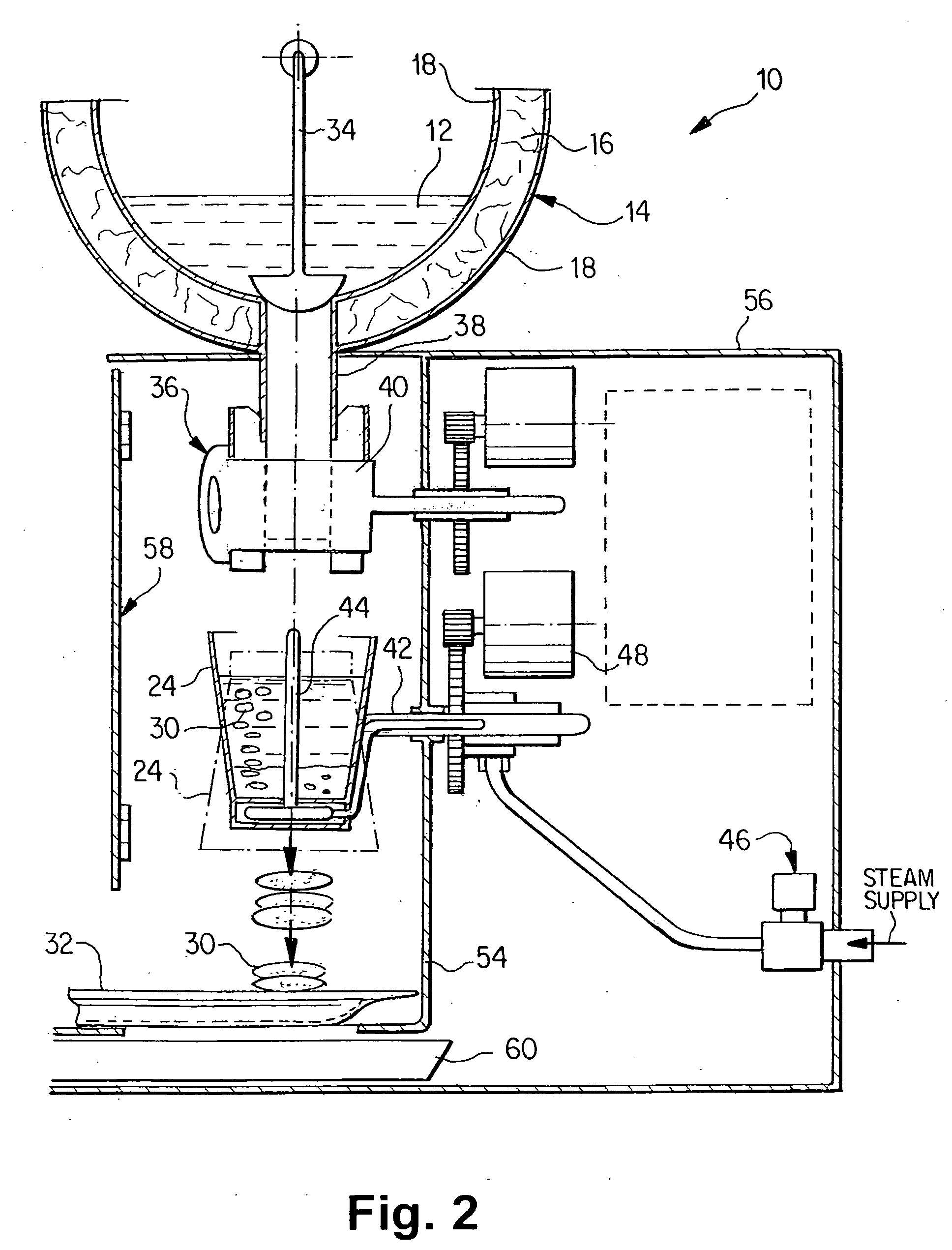

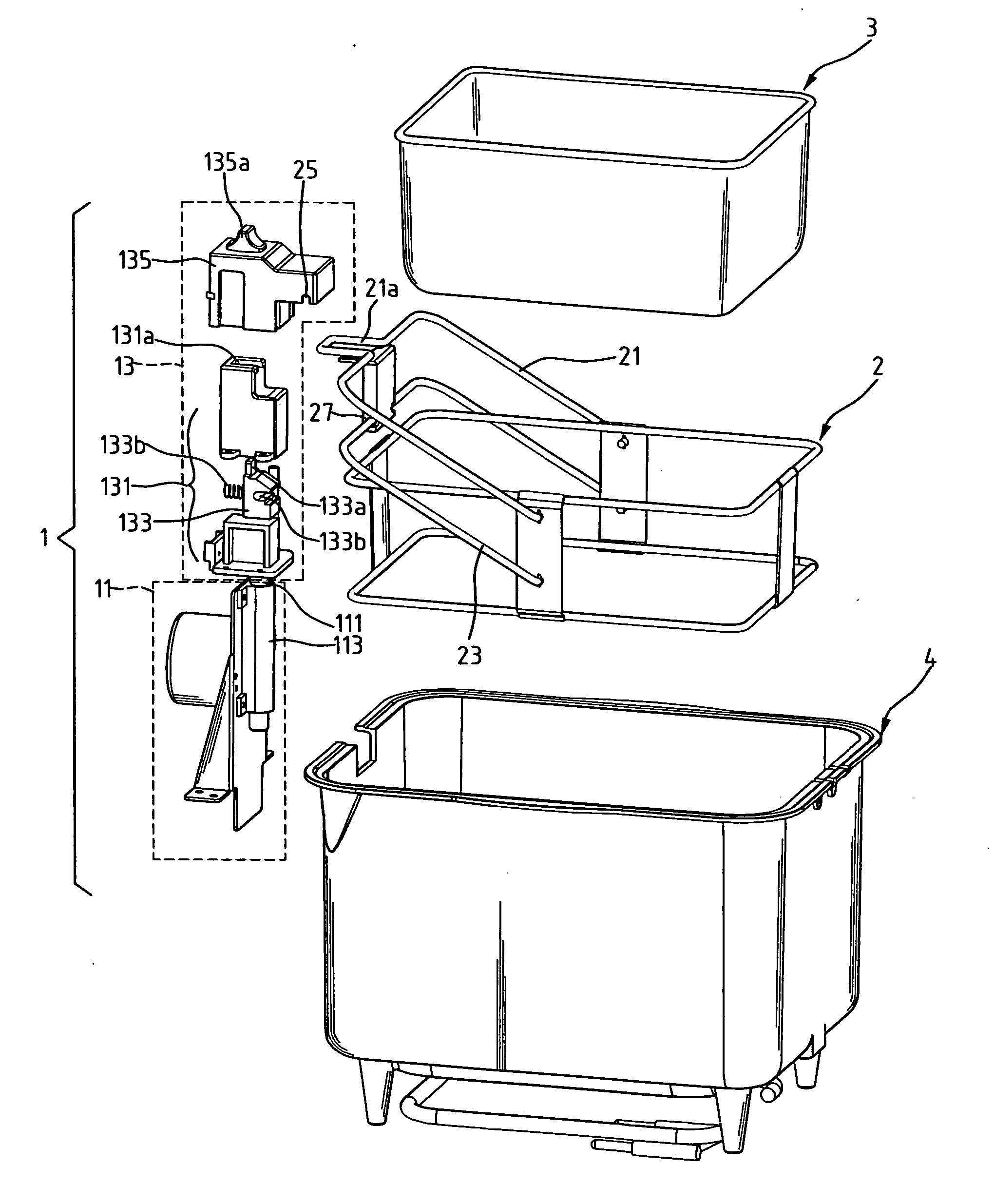

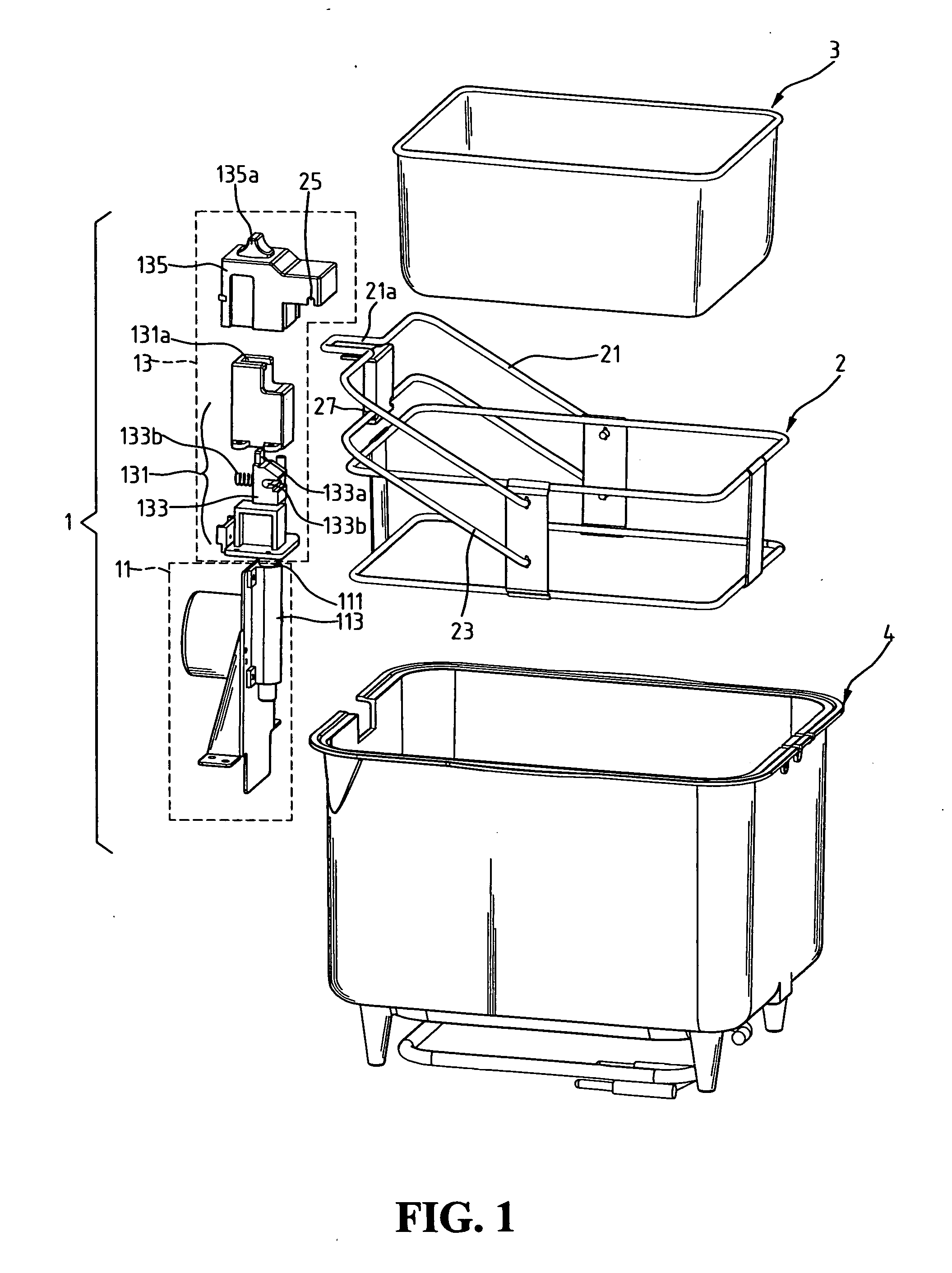

Multifunctional breakfast making machine

InactiveCN102551518AReduce occupancyReduce household expensesMultiple-unit cooking vesselsEgg-cookersElectrical controlEngineering

The invention discloses a multifunctional breakfast making machine, which comprises a base, a bread roaster, an egg cooker, a frying device and an electrical control unit. The bread roaster, the egg cooker, the frying device and the electrical control unit are placed on the base, the bread roaster is located in a first base area of the base, the egg cooker and the frying device are located in a second base area of the base, the second base area is provided with a heating plate, the frying device is located above the heating plate, the egg cooker is located above the frying device and comprises an egg tray, the frying device comprises a frying pan capable of containing liquid, the egg tray is provided with grooves which can hold eggs and are communicated with the frying pan, and the electrical control unit is used for controlling operations of the bread roaster, the egg cooker and the frying device. The multifunctional breakfast making machine can integrally complete cooking of various types of food, not only saves household expense, but also greatly reduces occupation of appliances in spaces of kitchens.

Owner:YONG AN ELECTRICAL IND

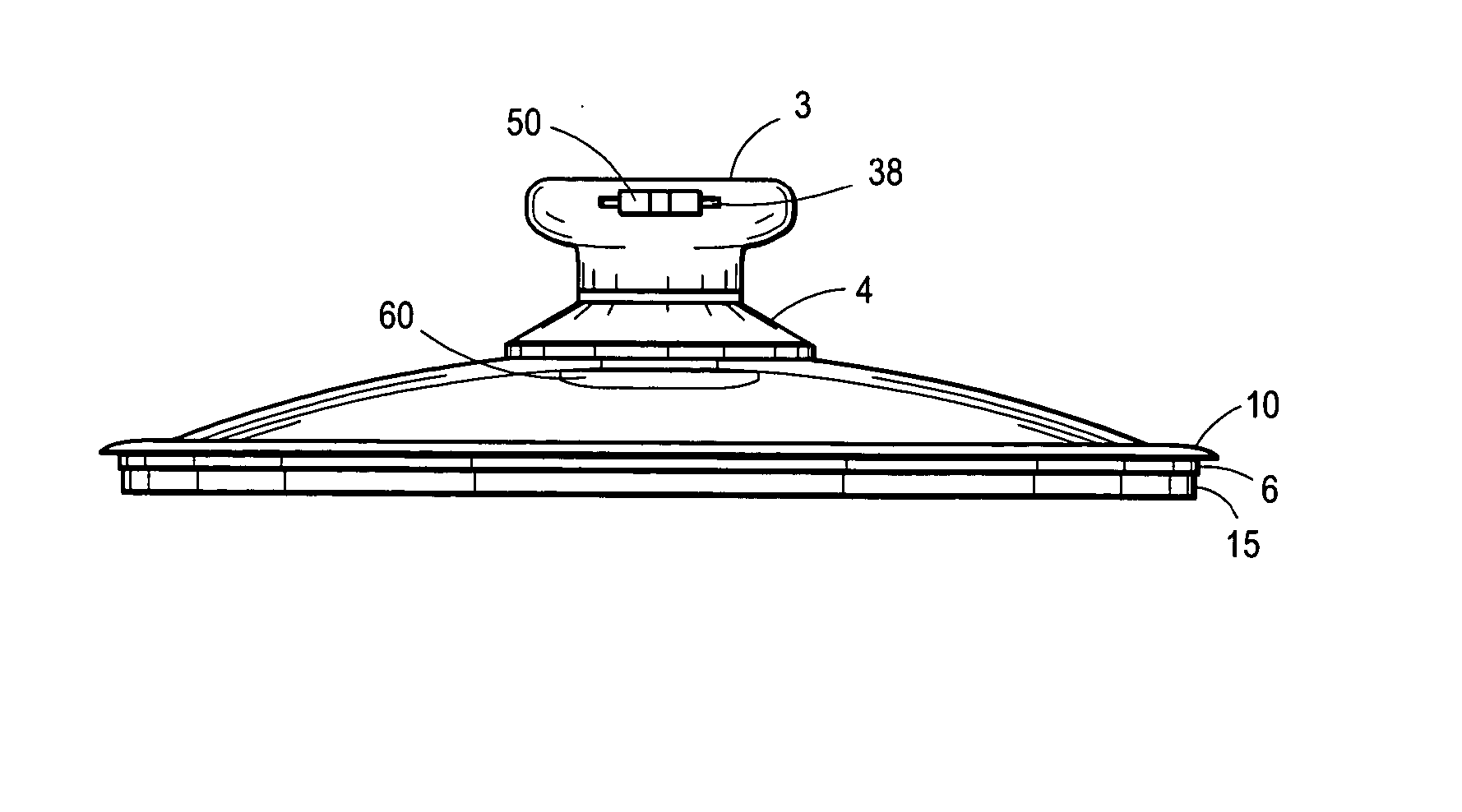

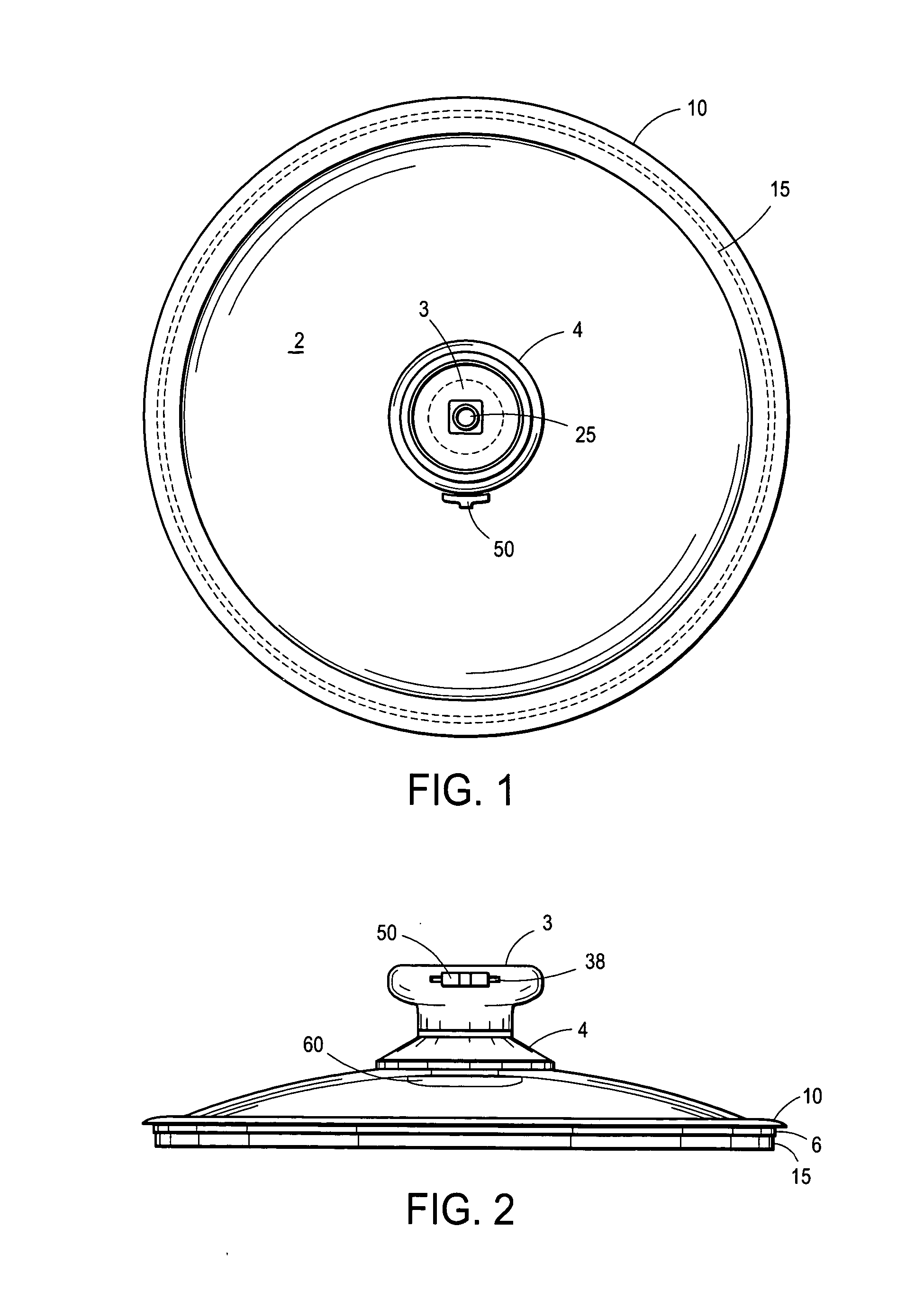

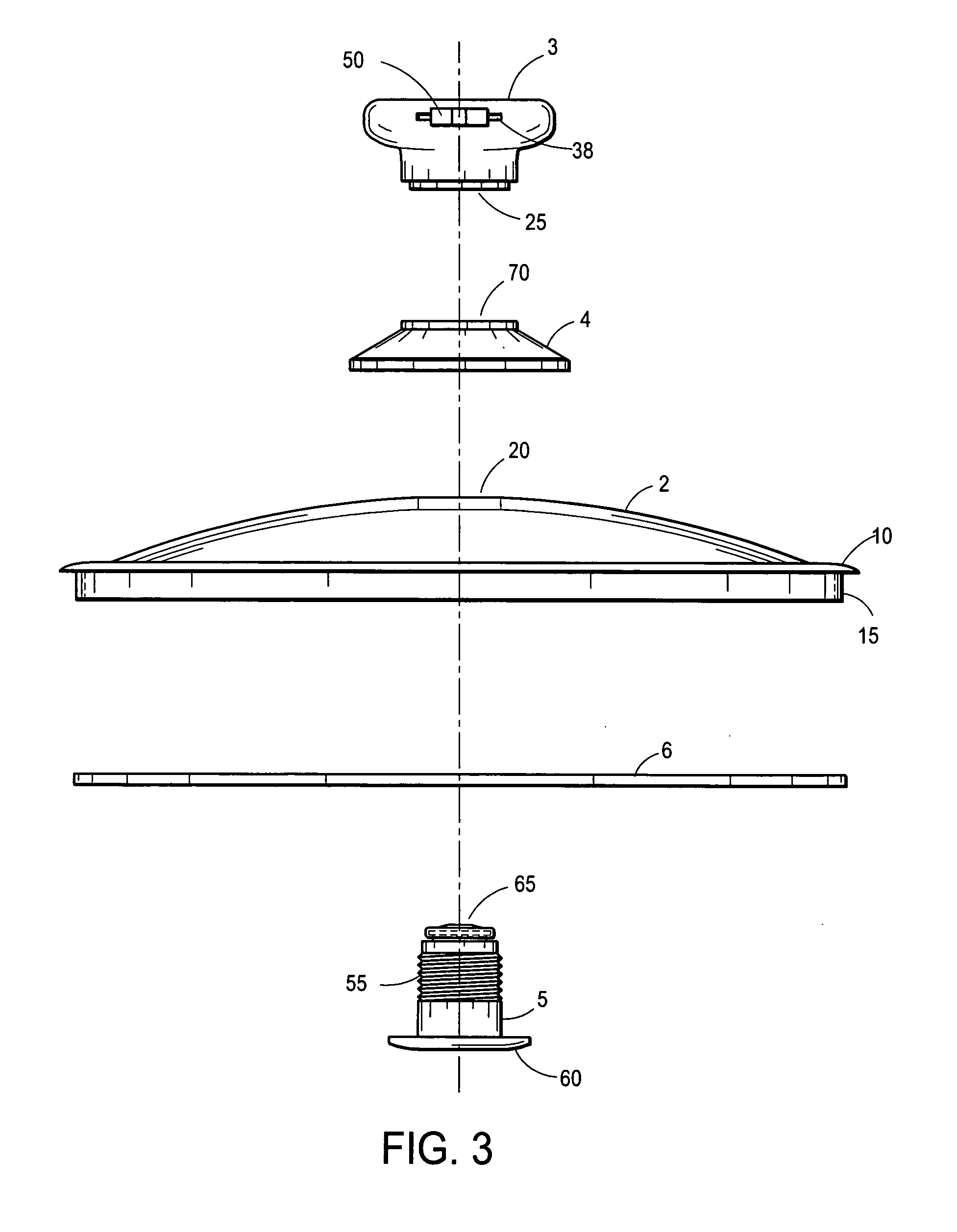

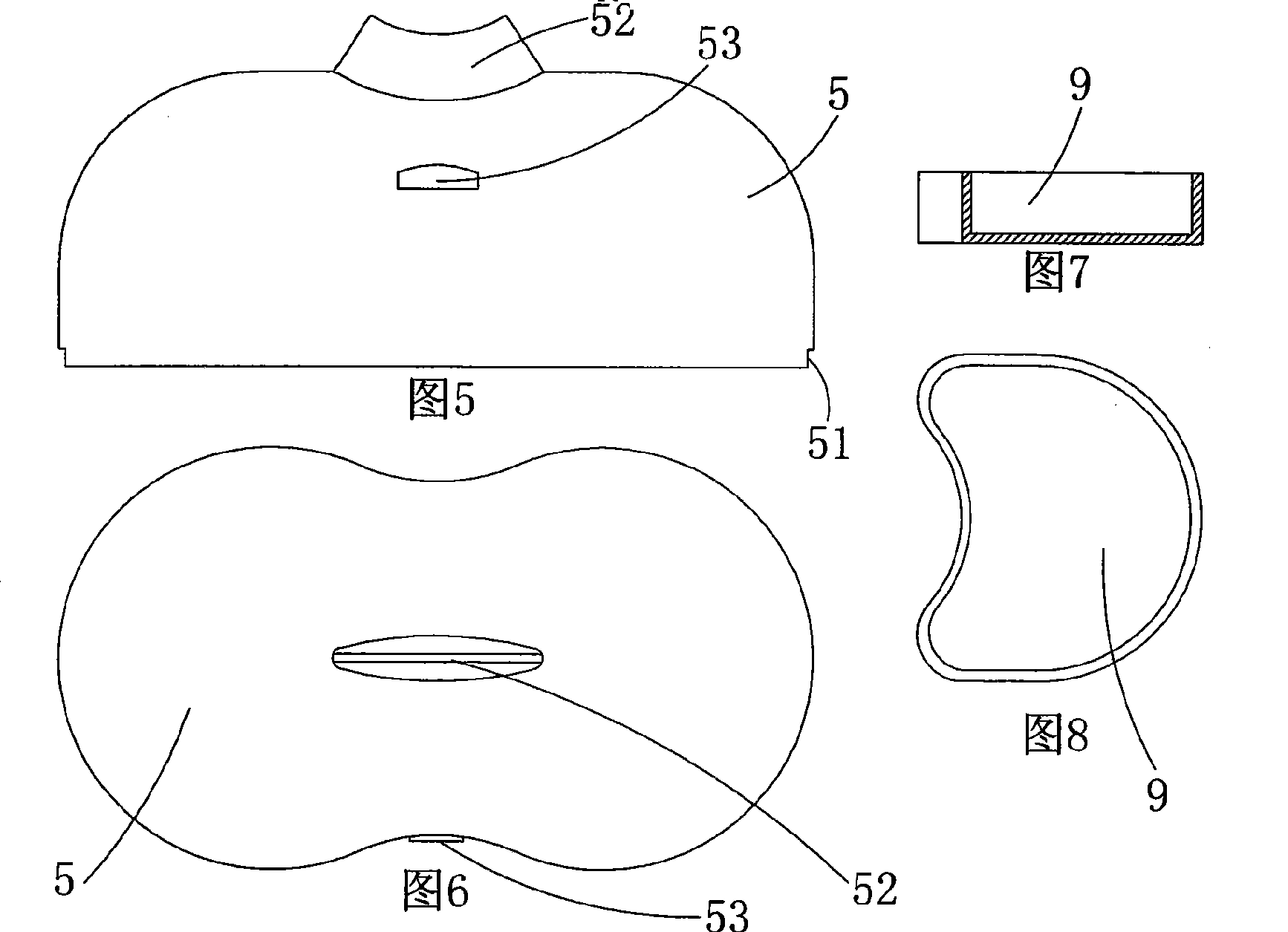

Cookware lid assembly with sealing band and whistling handle

InactiveUS20050205577A1Reduce heatEasy to disassembleBoiling over preventionCooking-vessel lids/coversEngineeringFlange

A cookware lid assembly having a whistling handle and a removable flexible sealing band that extends around a flange on the lid. The sealing band secures the lid to the cookware to prevent the lid from being dislodged from the cookware as pressure inside the cookware increases or as water in the cookware comes to a boil. The handle has a hole in it that generates as whistling noise when the pressure in the cookware increases. A movable slide in the handle allows the hole in the lid to be closed or remain fully or partly open. The slide also allows the volume and pitch of the whistle to be adjusted.

Owner:INNOVATION IP HLDG

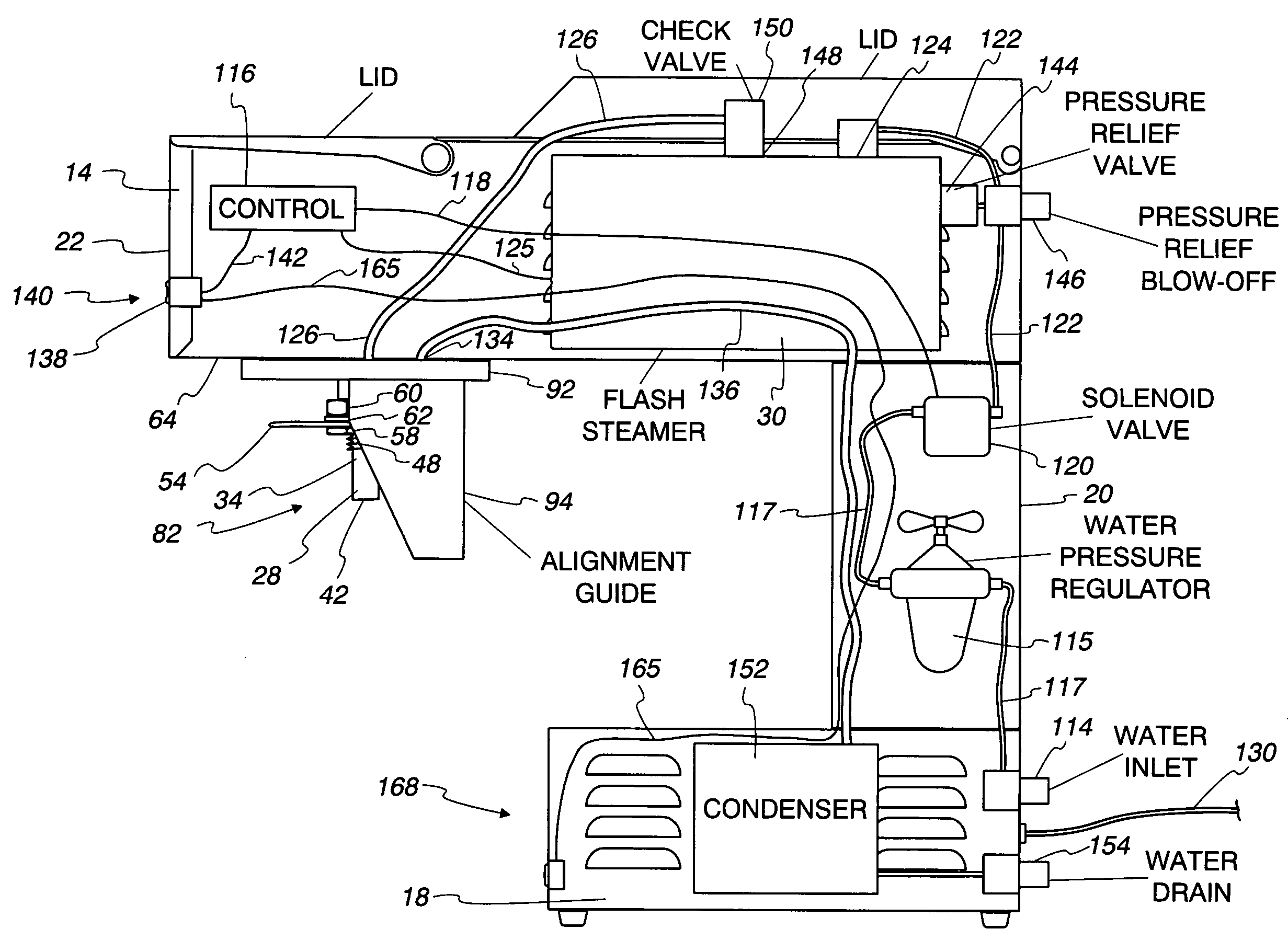

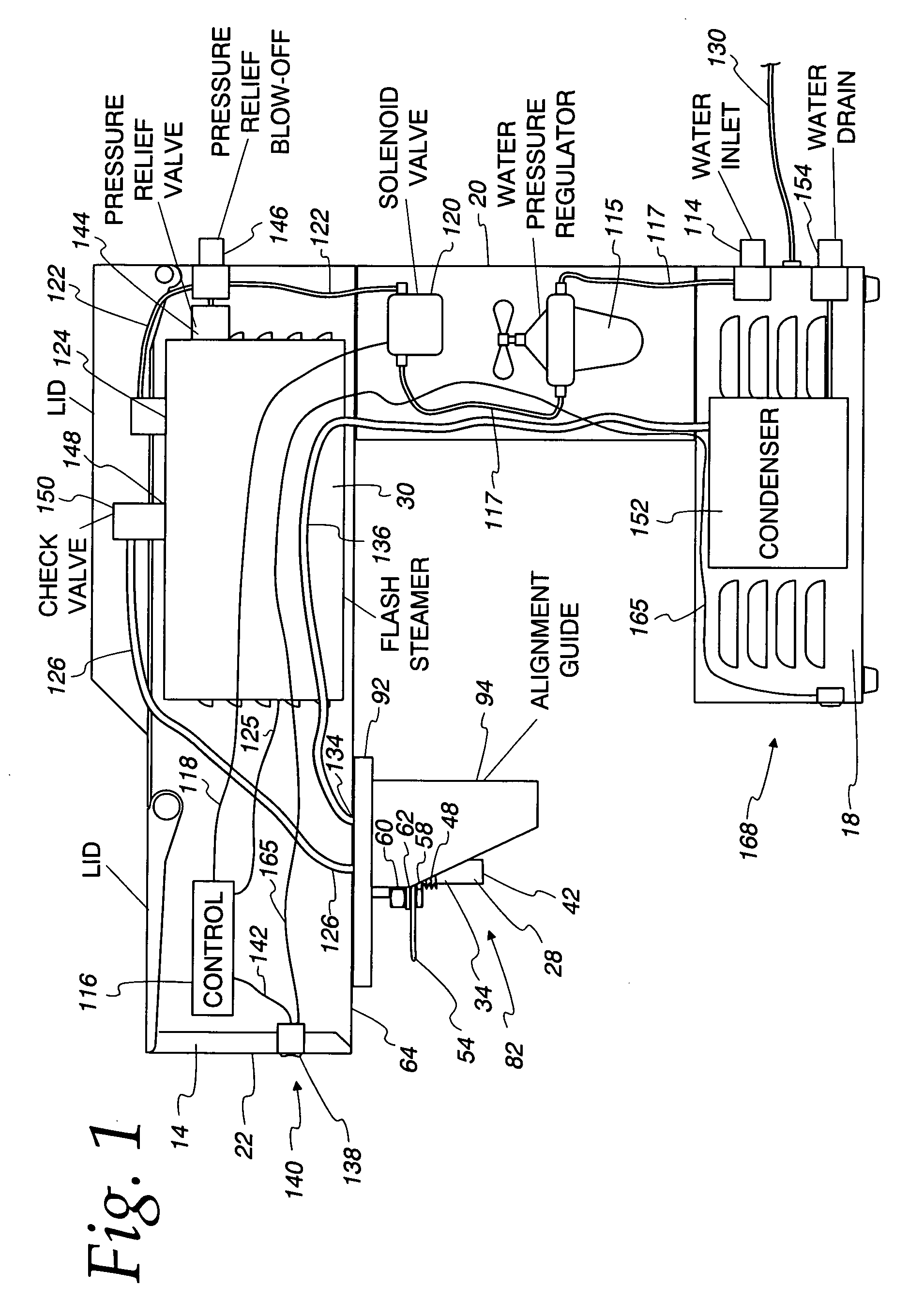

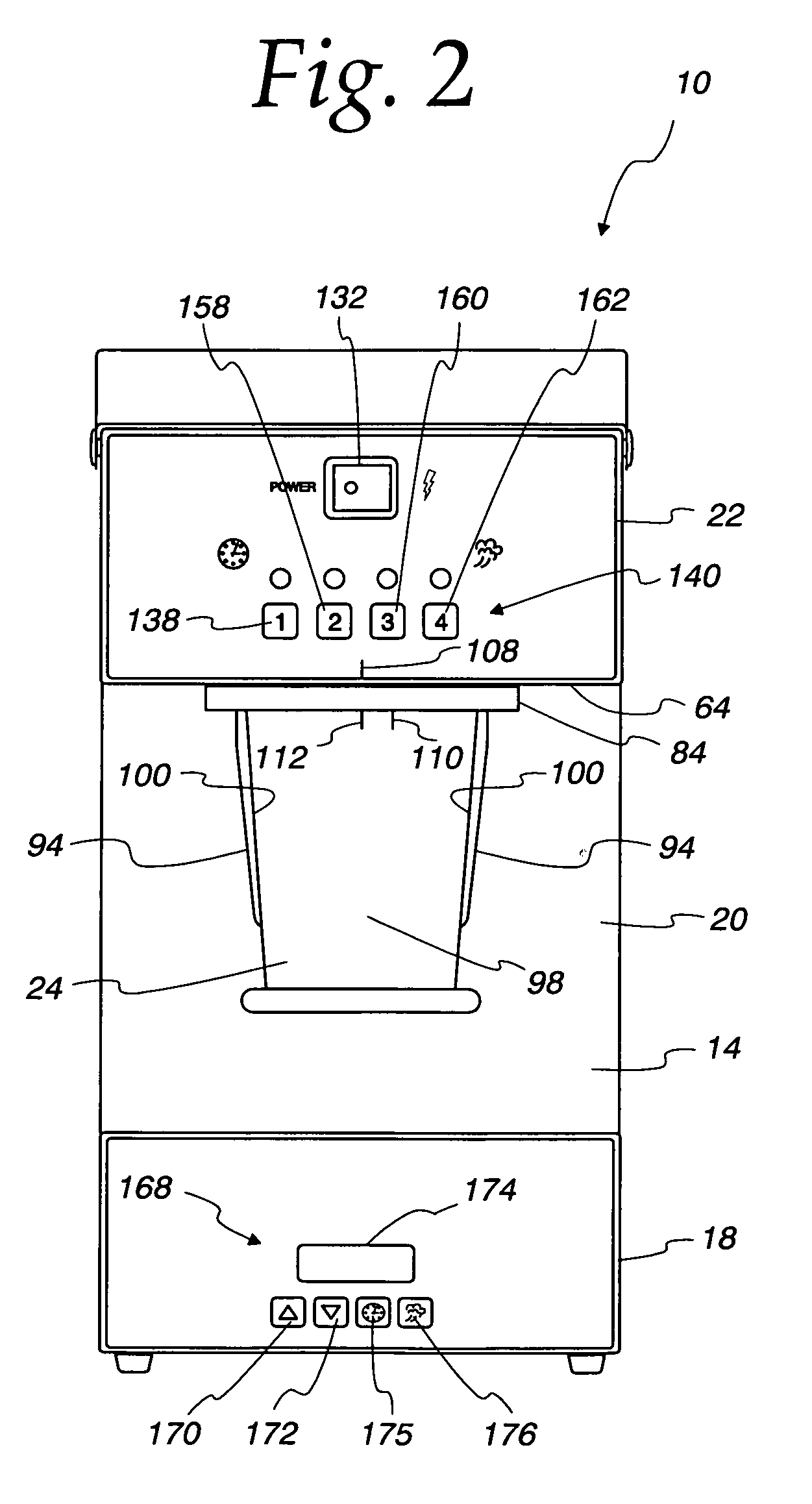

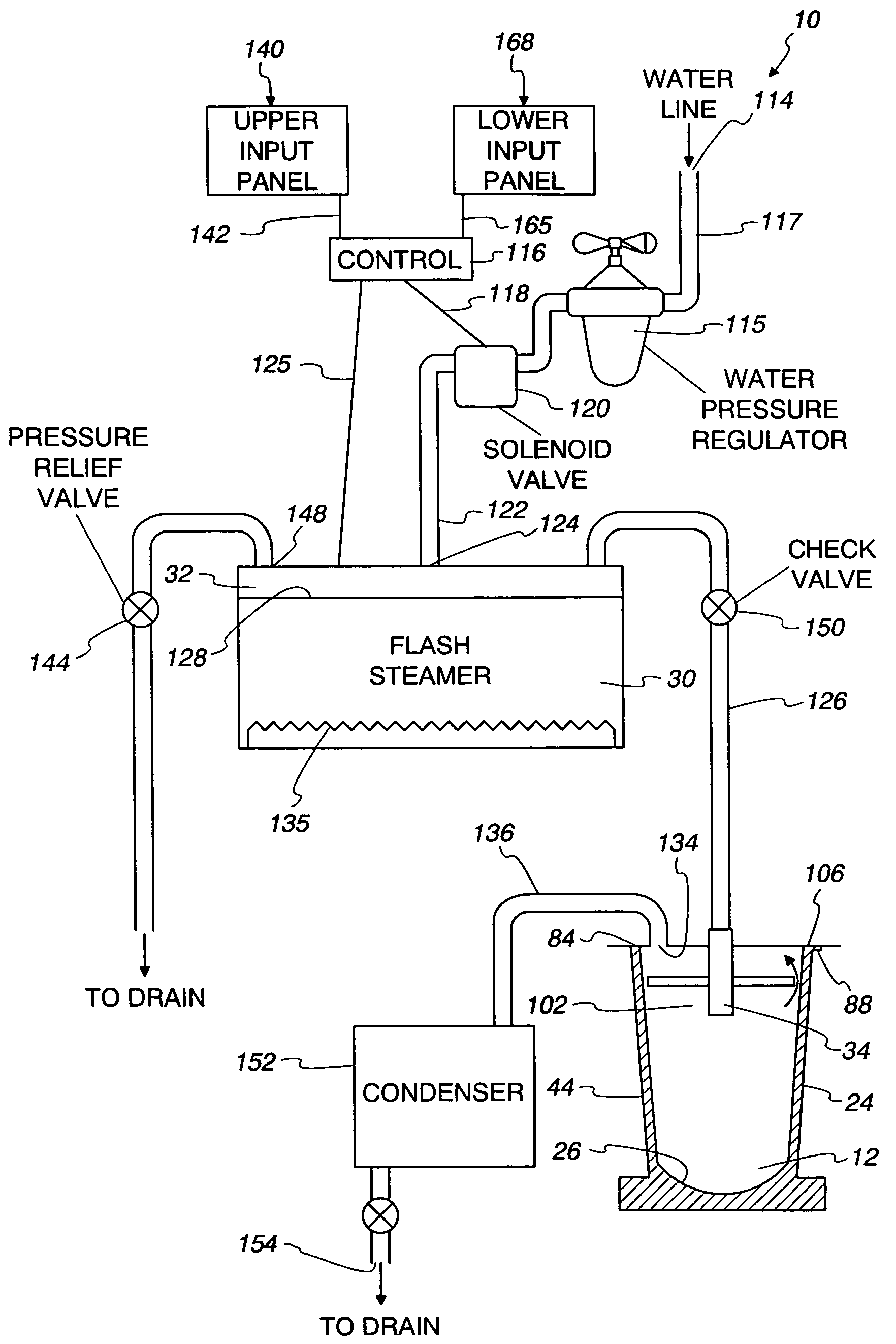

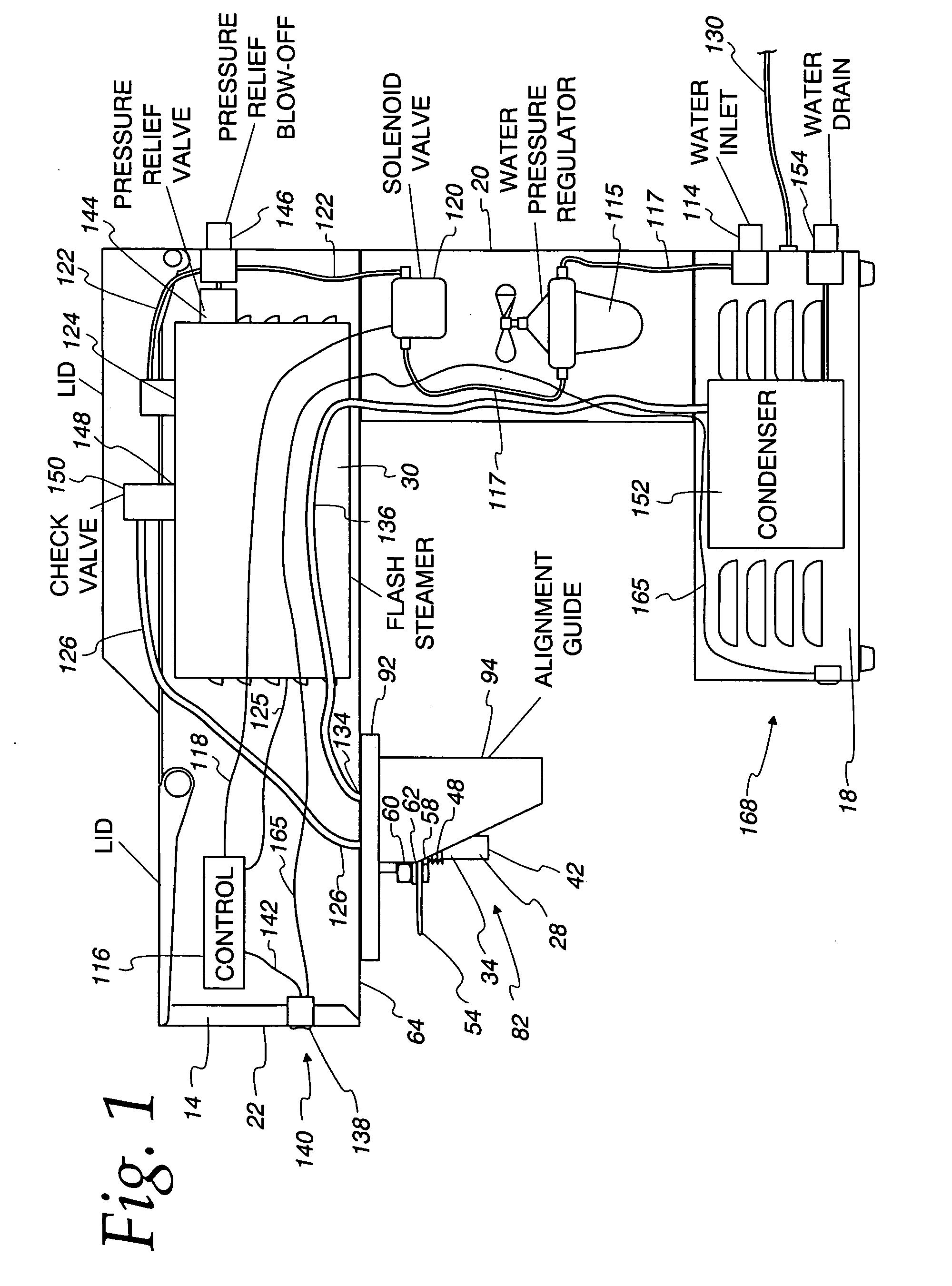

Steam injection cooking device and method

An apparatus and method are provided for steam injection heating of a liquid or solid edible material. When cooking, the method includes providing a predetermined amount of edible material. A predetermined amount of water supplied from a water tank is injected into a heated cavity to form a quantity of steam that is sufficient to cook the predetermined quantity of edible material when injected therein. The predetermined amount of water is provided by a liquid water injector. The predetermined amount of the edible material may be a single serving, or integer multiples thereof. When heating a serving amount that is an integer multiple of at least two times the amount of a single serving, the predetermined quantity of water is injected in pulses. The number of pulses is the same as the integer multiple of servings being heated, and each pulse contains substantially equal amounts of liquid water.

Owner:RESTAURANT TECH

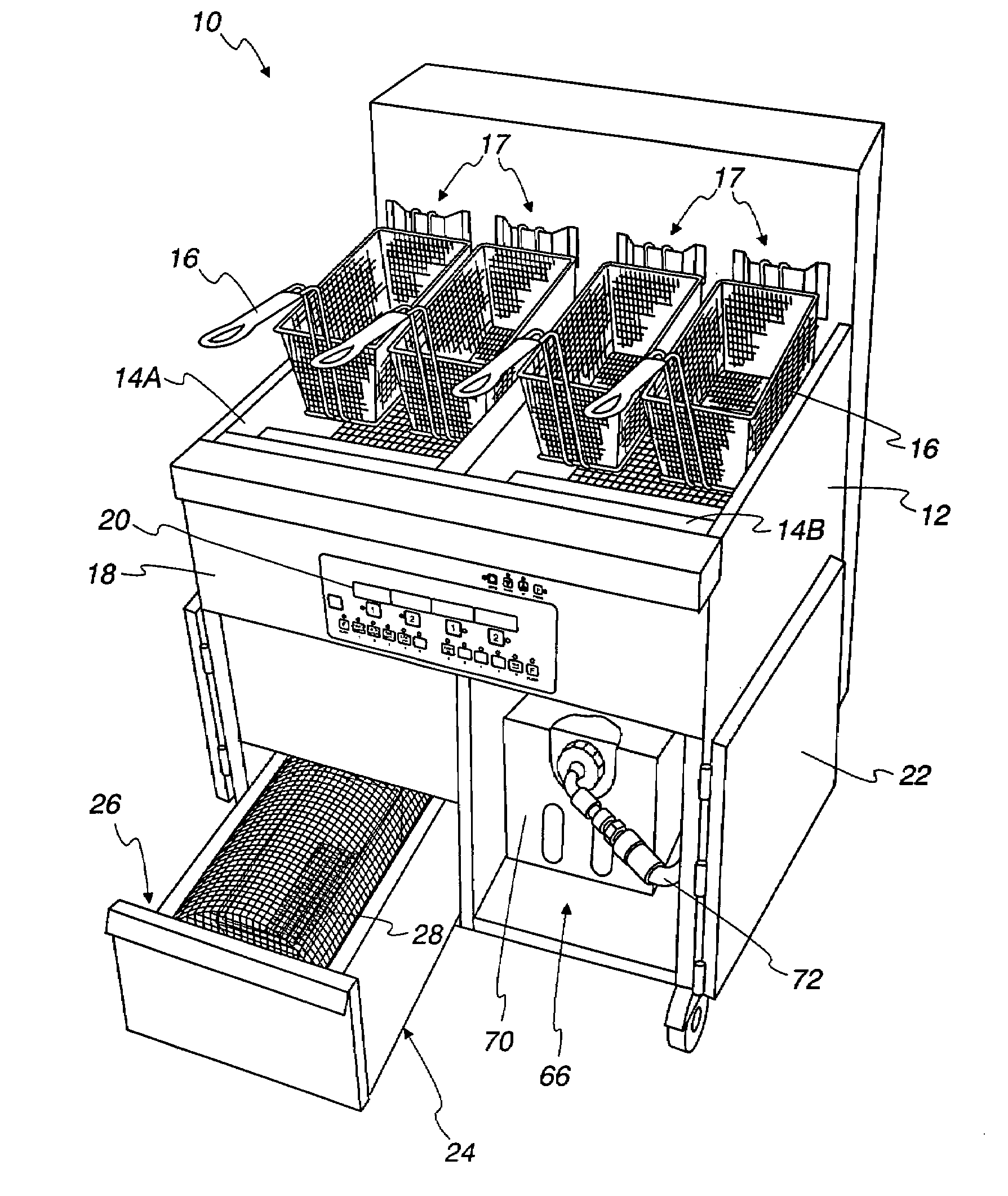

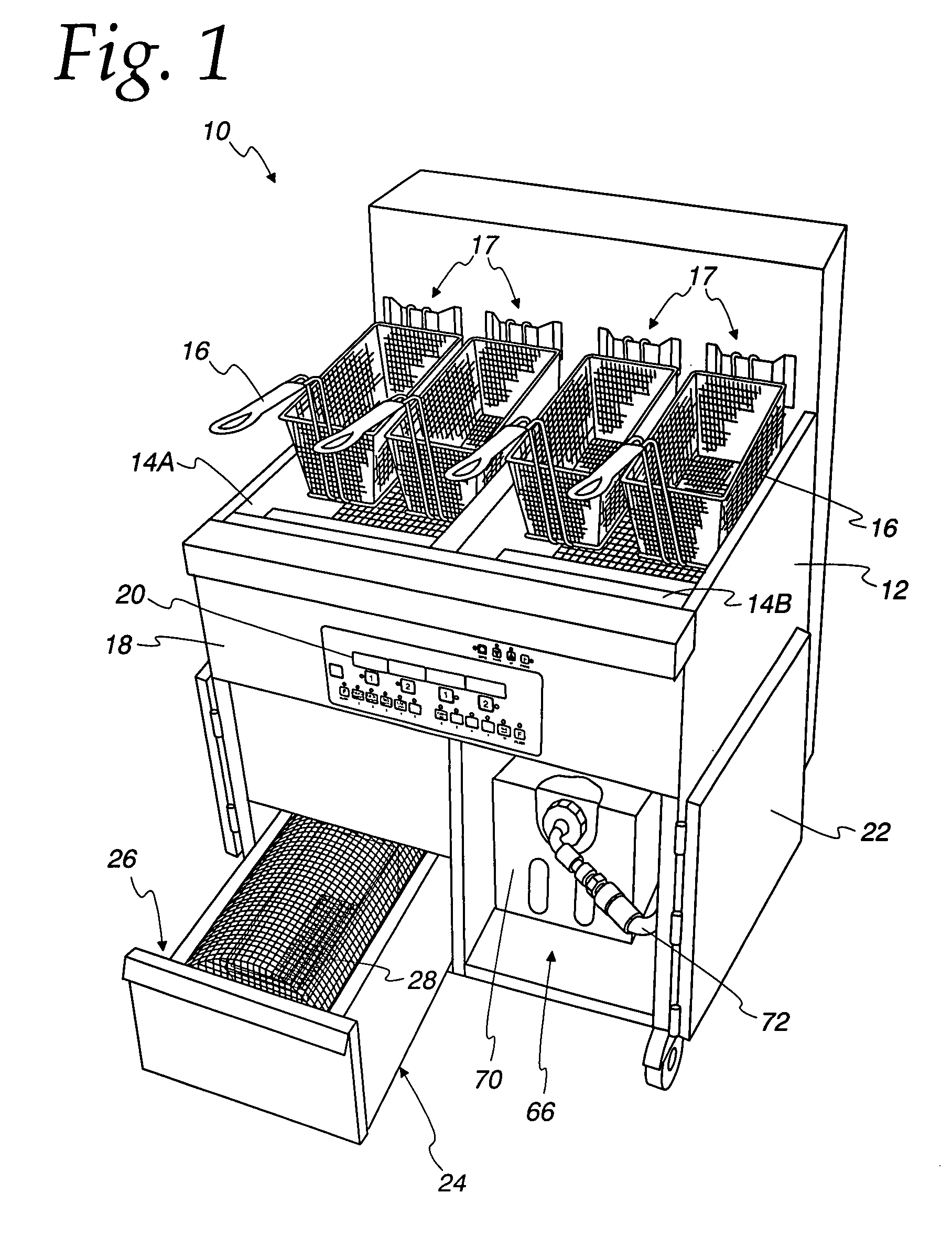

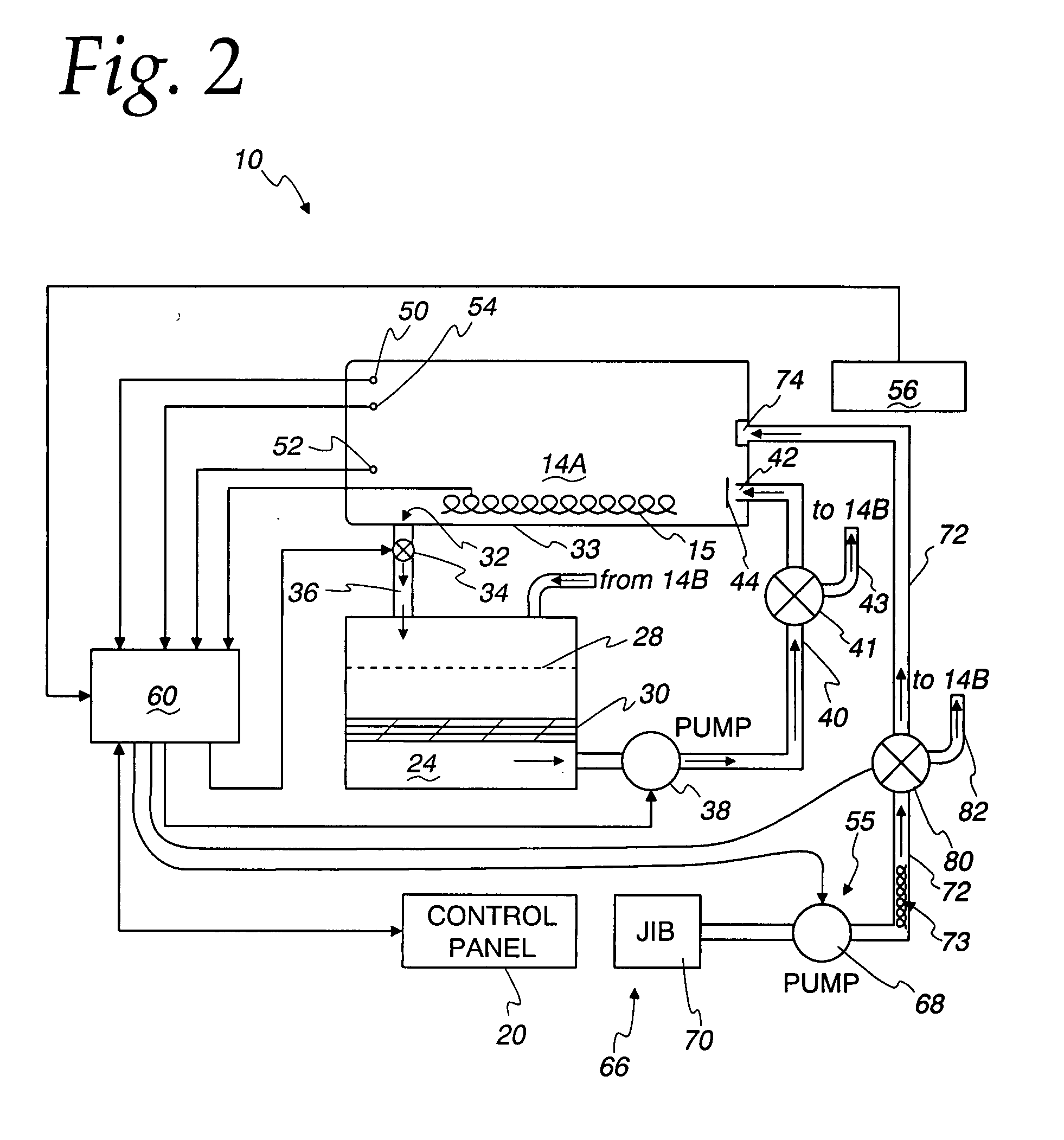

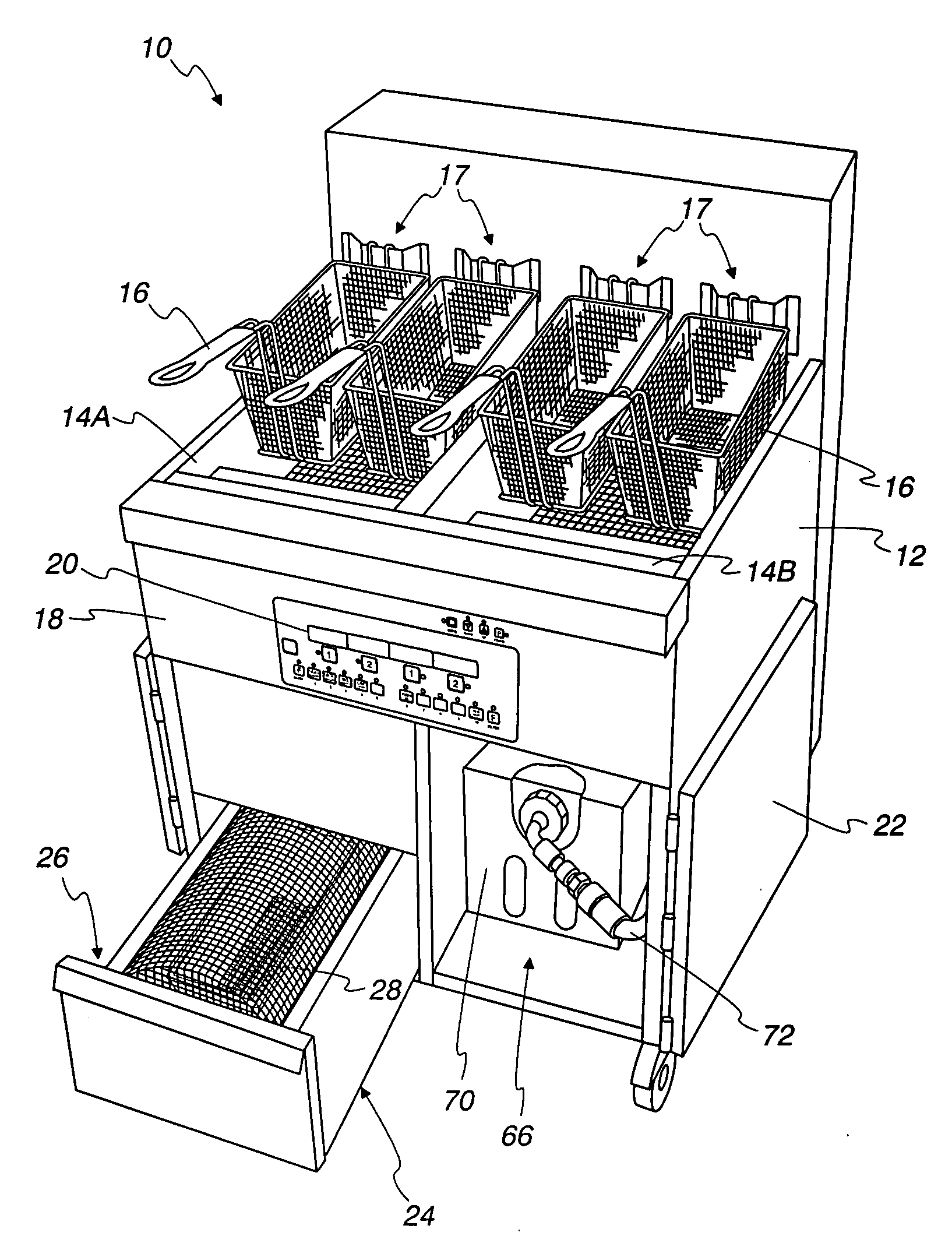

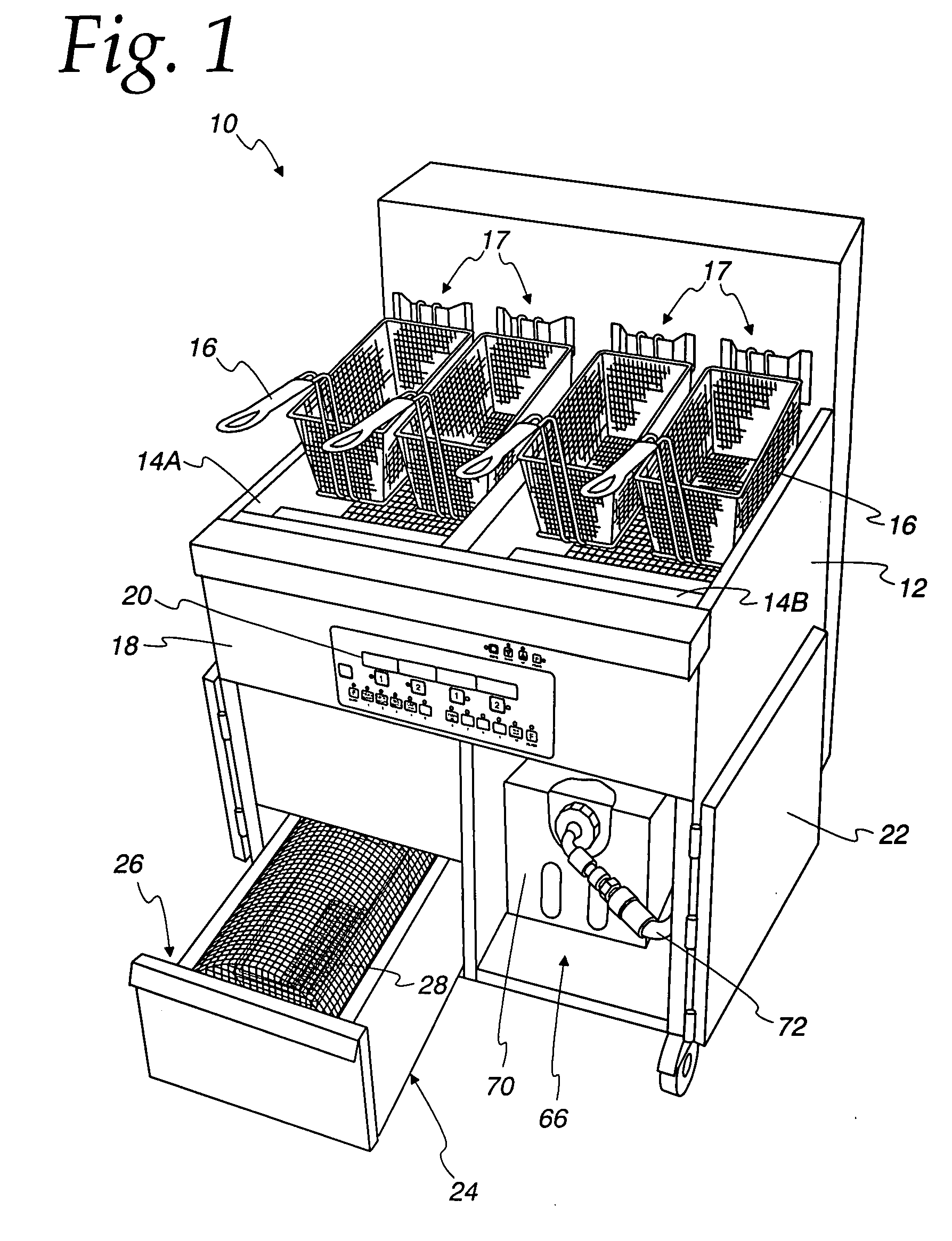

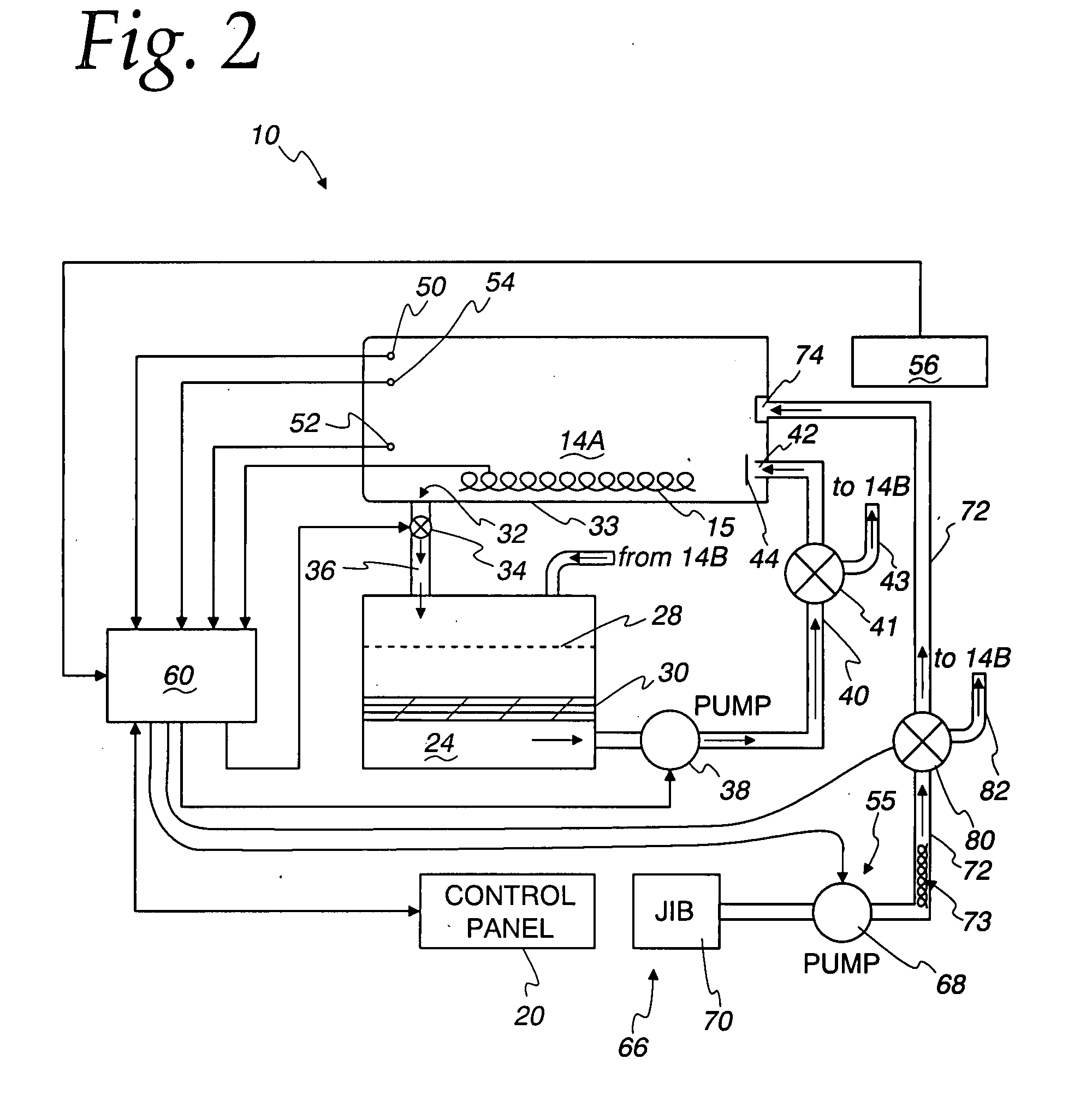

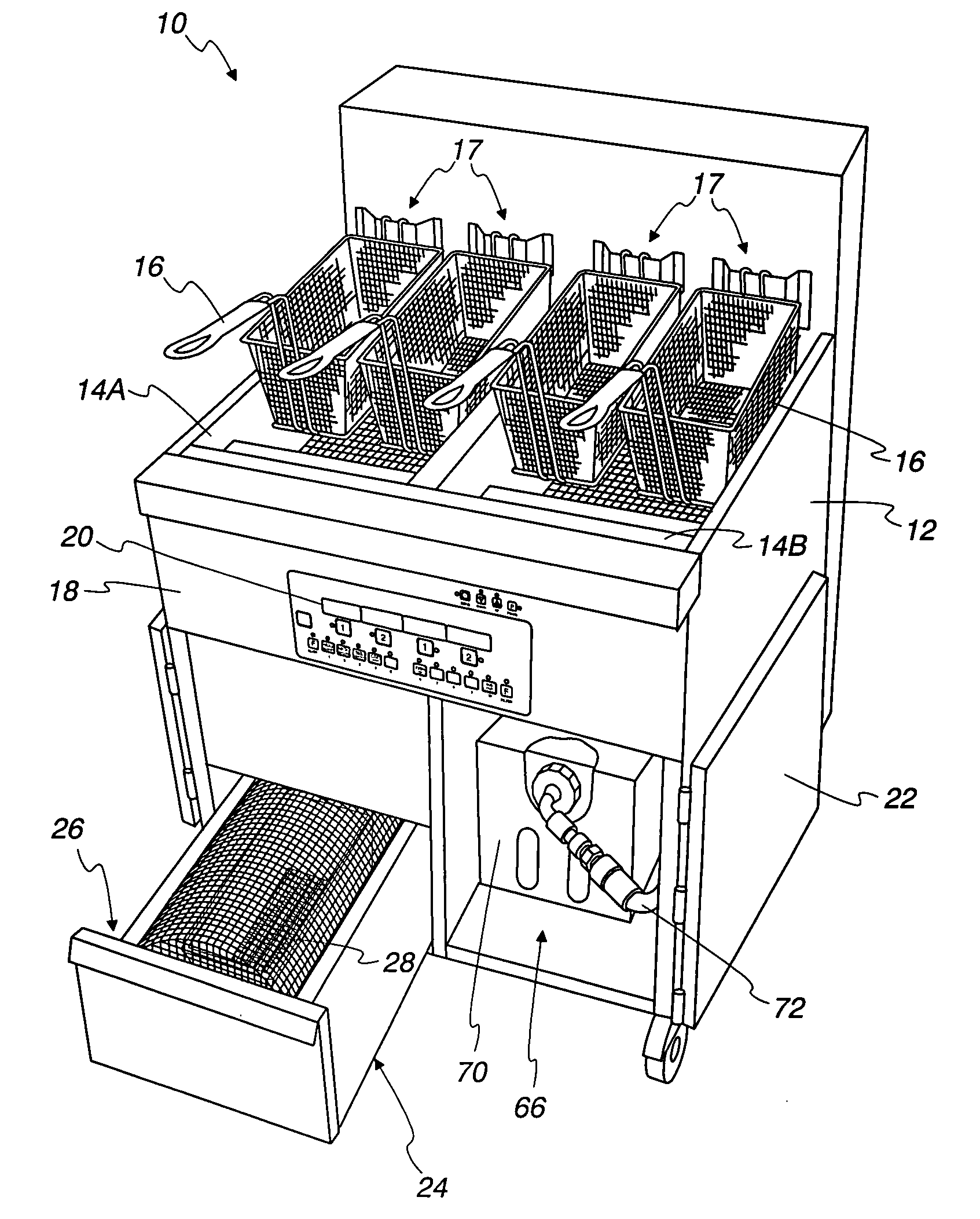

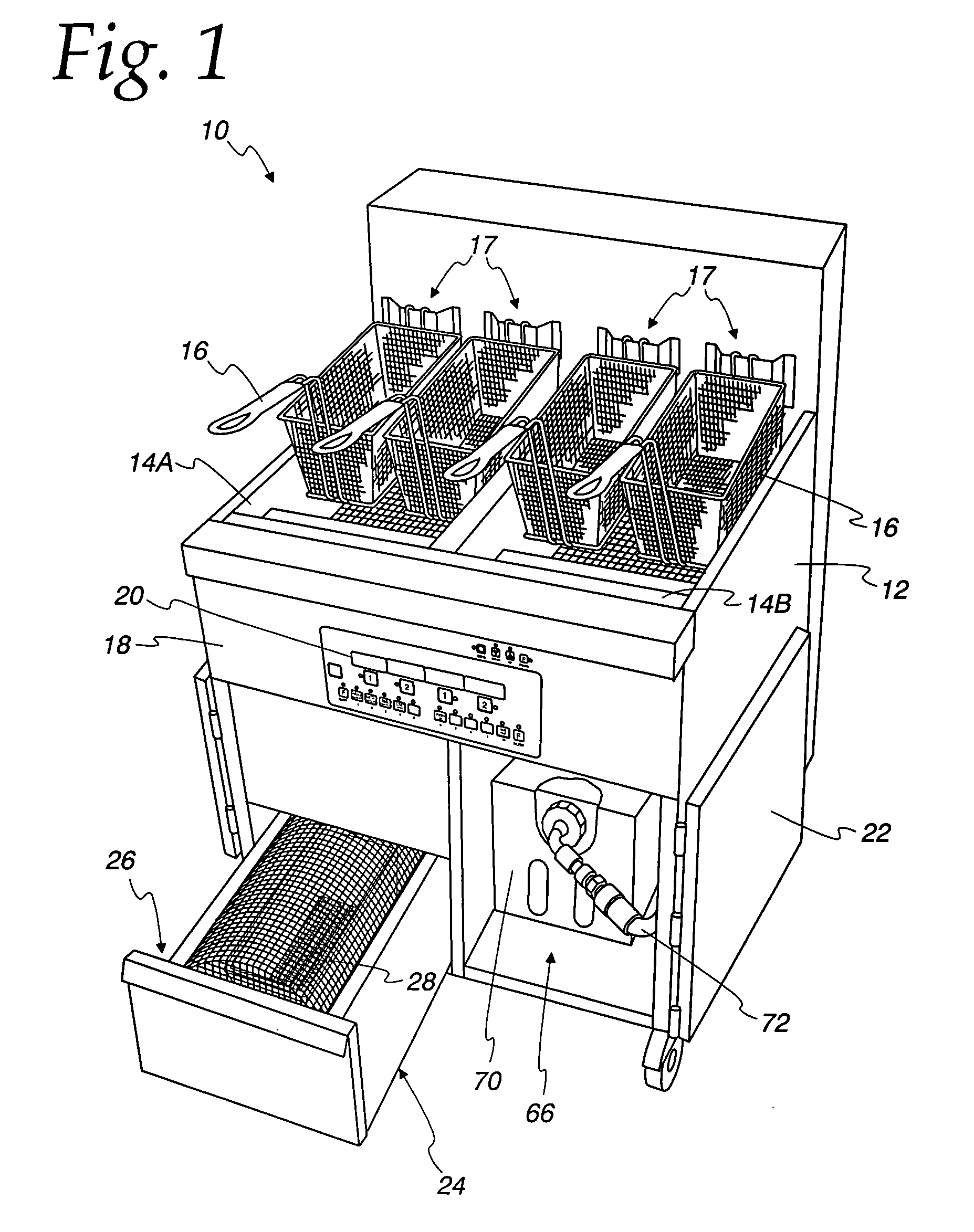

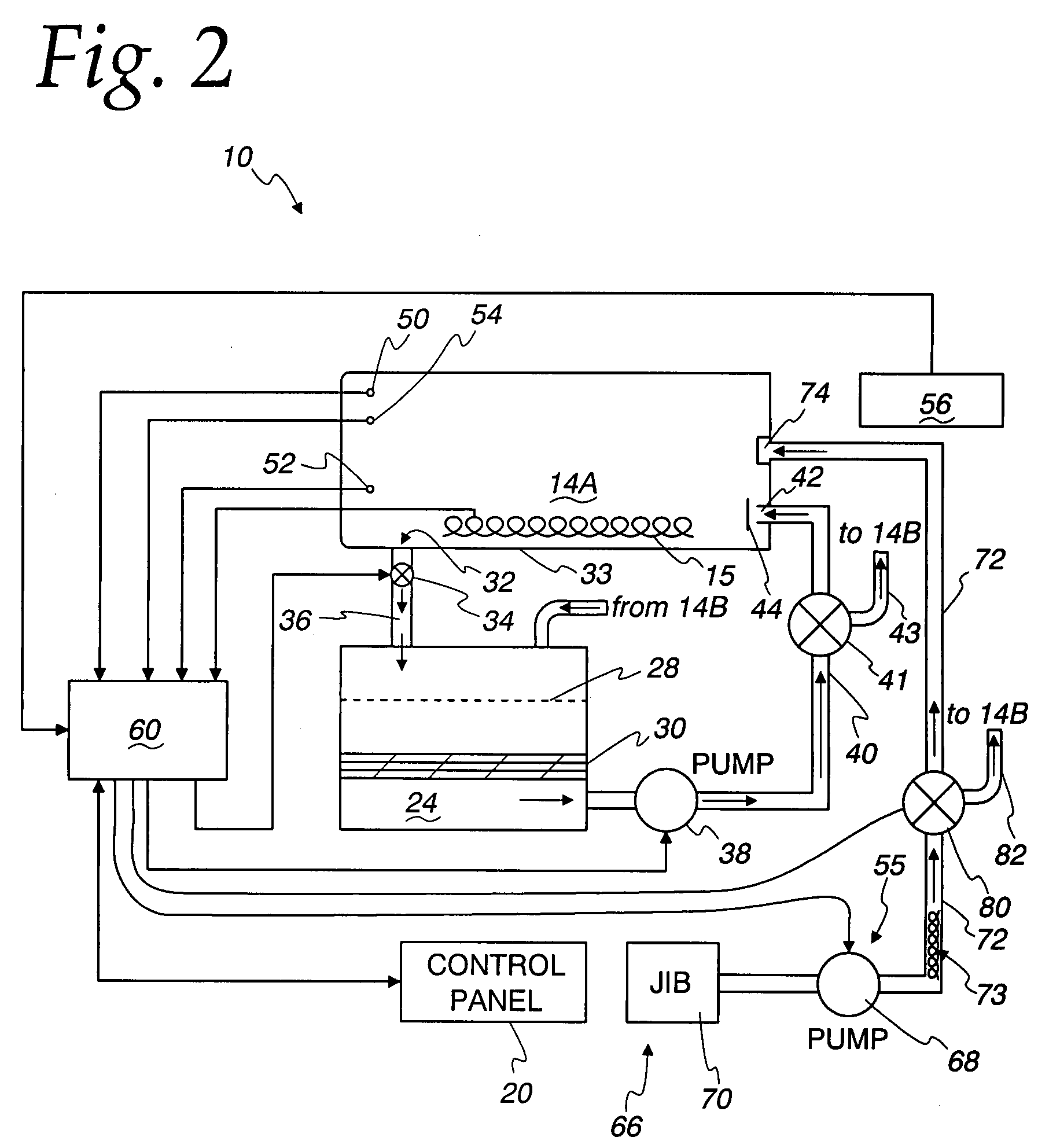

Automated fryer refilling device and method

InactiveUS20080213446A1Quality improvementOil consumption is minimizedFatty oils/acids recovery from wasteCooking vesselsUncooked FoodsFiltration

A commercial device and method for cooking food product in cooking oil includes a fry vat containing an amount of cooking oil used to cook discrete batches of uncooked food in discrete batches of a weight relative to the amount of cooking oil in the range of from about 0.0375 to about 0.1, with the total amount of food being cooked at any one time relative to the amount of oil in the fry vat being about 0.1 or less. Cooking the food results in an uptake of oil by the food in an amount of from about 5.5% to about 13% by weight of the uncooked food, and an oil turnover ratio of from about 0.0026 to about 0.007 per discrete batch. Replacement oil is periodically added, and a sufficient number of batches are cooked over 60 hours of operation to achieve at least one vat oil turnover.Automated intermittent filtration is employed in the device and method that can include monitoring the elapsed time since the last filtration of the cooking oil, monitoring the amount of food by number of batches or by weight of food product cooked in the oil since the last filtration, and filtering the oil when a predetermined threshold value is reached based on the elapsed time since the last filtration and the amount of food cooked.An automated device and method for maintaining a level of oil in a fry vat having a volume includes sensing the level of oil in the vat. When the sensed level of oil in the vat is less than or equal to a first predetermined level, replacement oil is automatically added to the fry vat, typically when at ambient temperature at a low average flow rate in the range of about 0.008 to about 0.08 gallons per minute per gallon of the oil present in the vat at the first predetermined level. The low average flow rate of added oil avoids a temperature drop of more than 15° F., 10° F. or 5° F. in the bulk oil present in the fry vat as result of adding the oil as desired.

Owner:RESTAURANT TECH

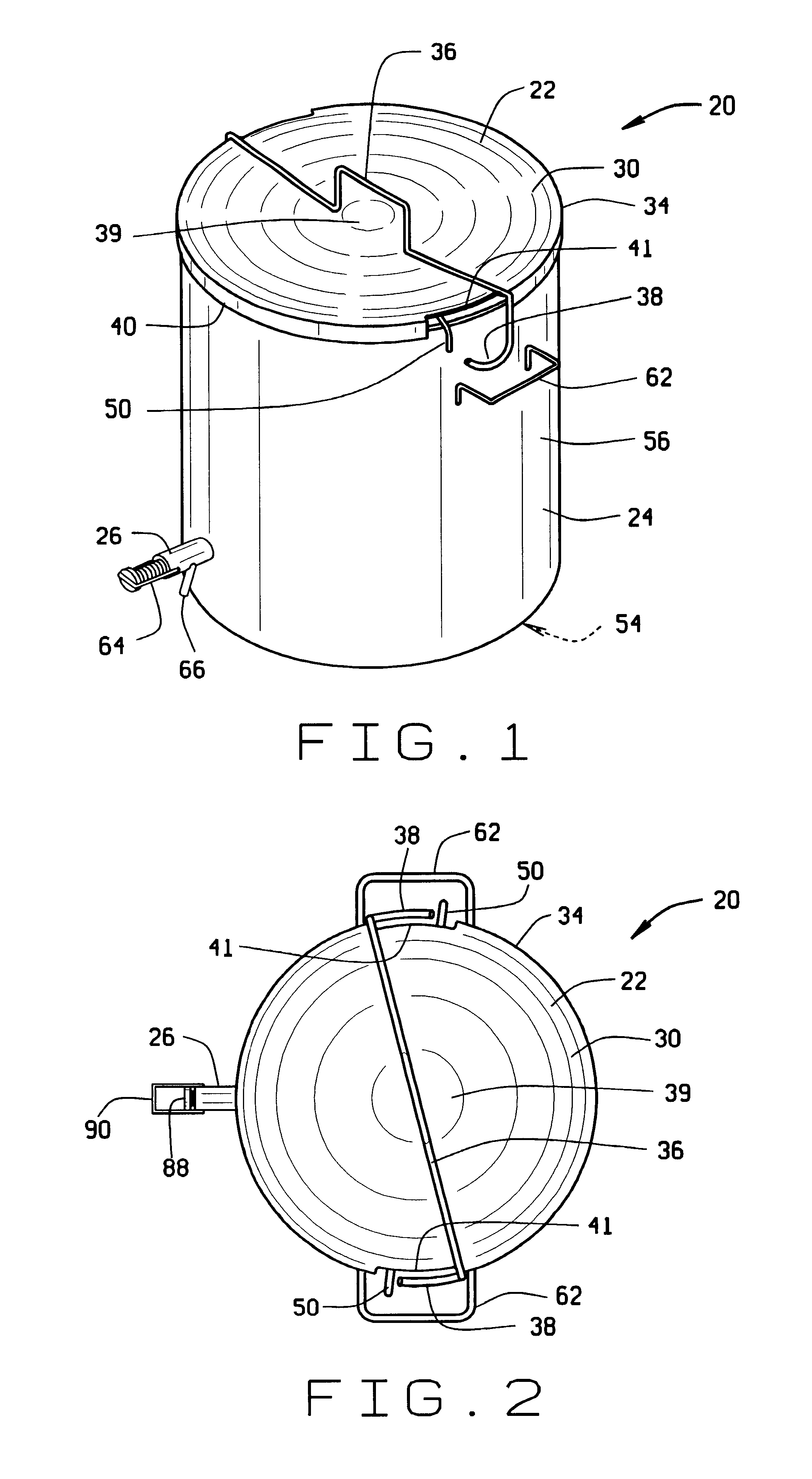

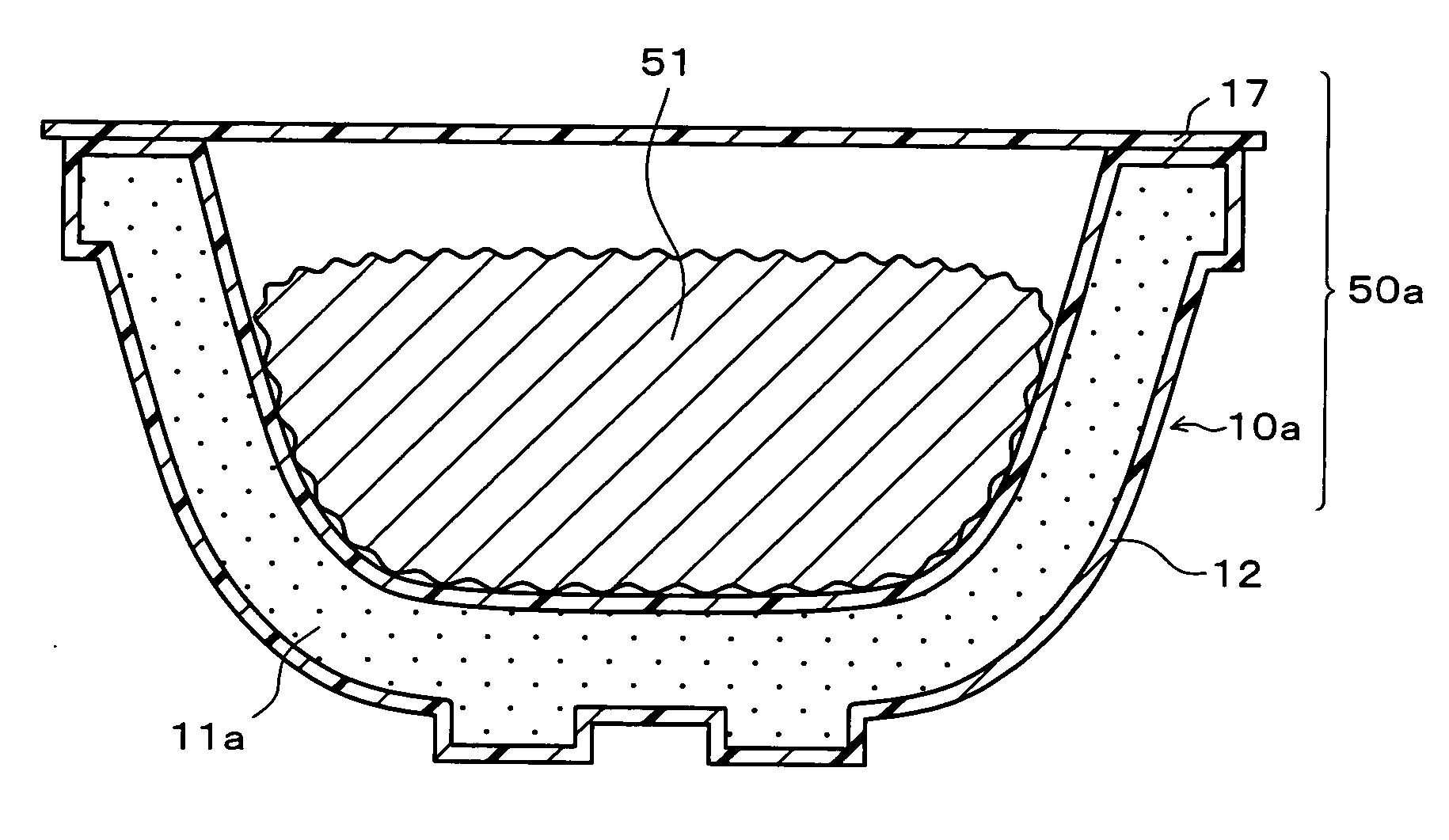

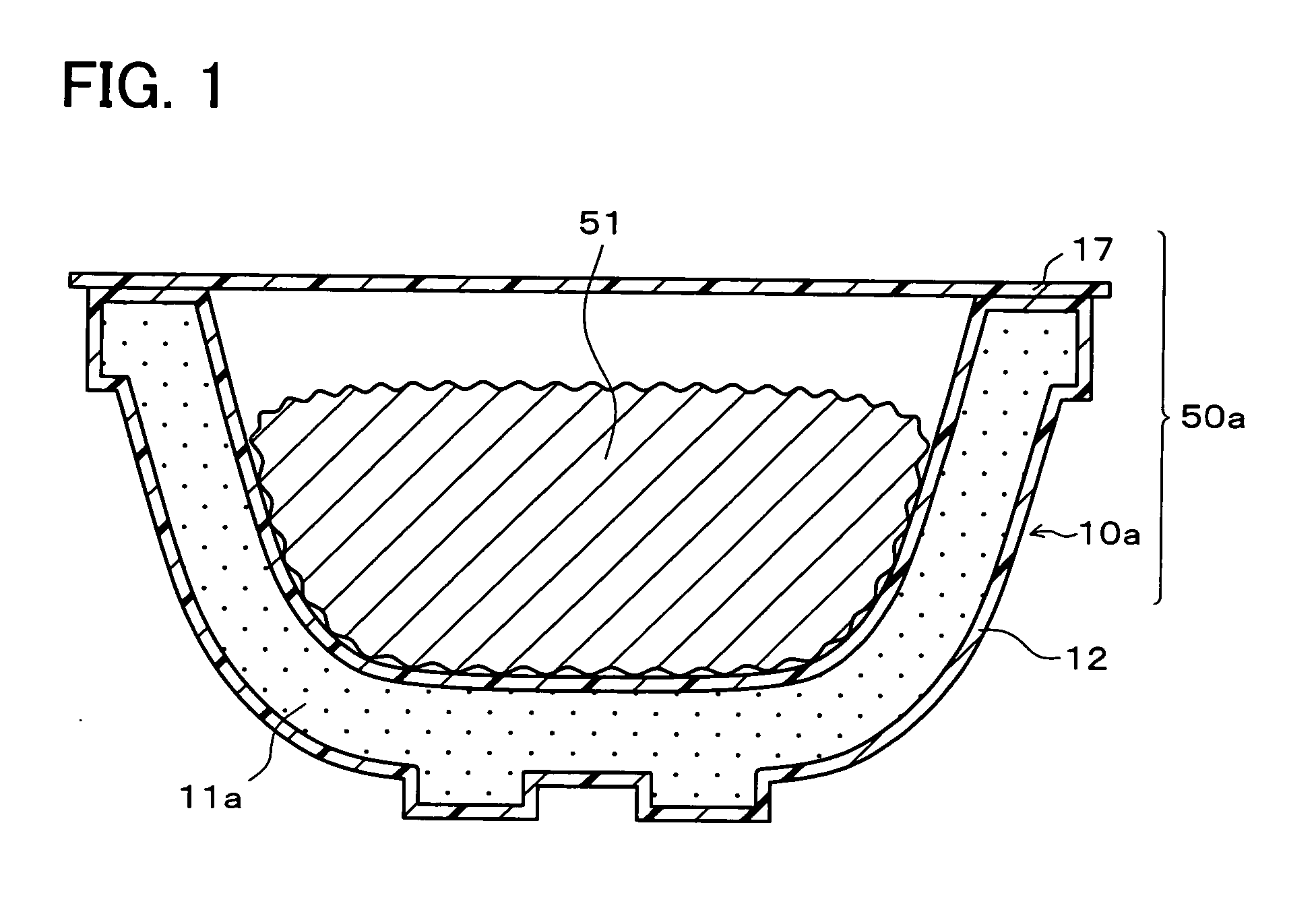

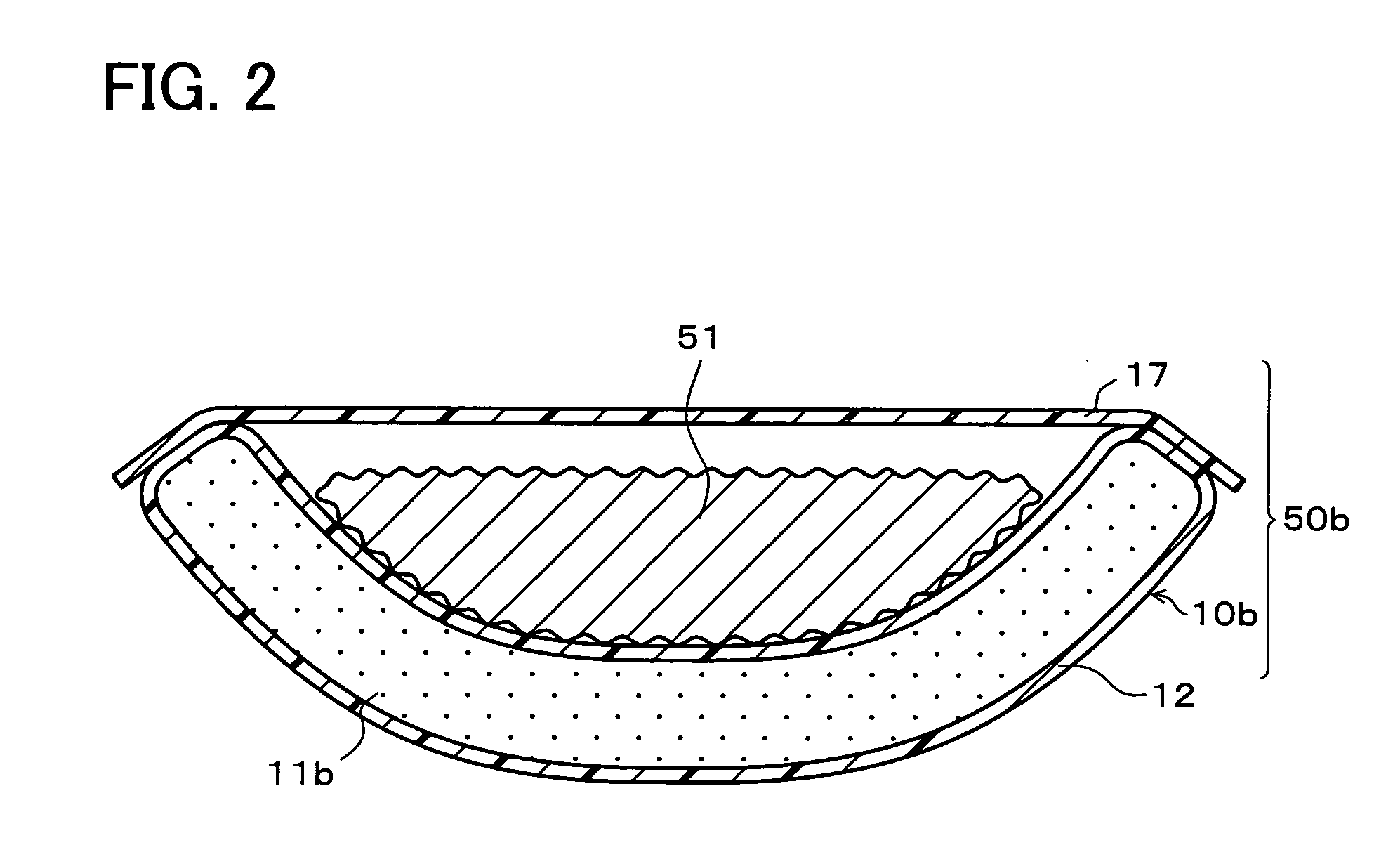

Hermetically sealed container

InactiveUS20050236415A1High strengthPromote biodegradationFlexible coversWrappersShell moldingEngineering

A bowl-shaped container (10a) which is as a hermetically sealed container includes a bowl-shaped container (10a) having a space to contain contents (51) at the inside and an opening to take in and out the contents (51), and a lid (17) mainly made of plastic to seal the opening of the bowl-shaped container (10a), which is heat-sealed to a rim of the opening of the bowl-shaped container (10a). The bowl-shaped container (10a) adheres a coating film (12) mainly made of biodegradable plastic and having at least hydrophobicity to the surface of the main body (11a) of the container mainly made of starch. The main body (11a) is molded through steam expansion of a slurry or dough molding material containing starch and water. For these reasons, it is possible to provide a hermetically sealed container mainly made of starch having sufficient strength and at least sufficient water resistance, and a very excellent biodegradability.

Owner:NISSEI CO LTD

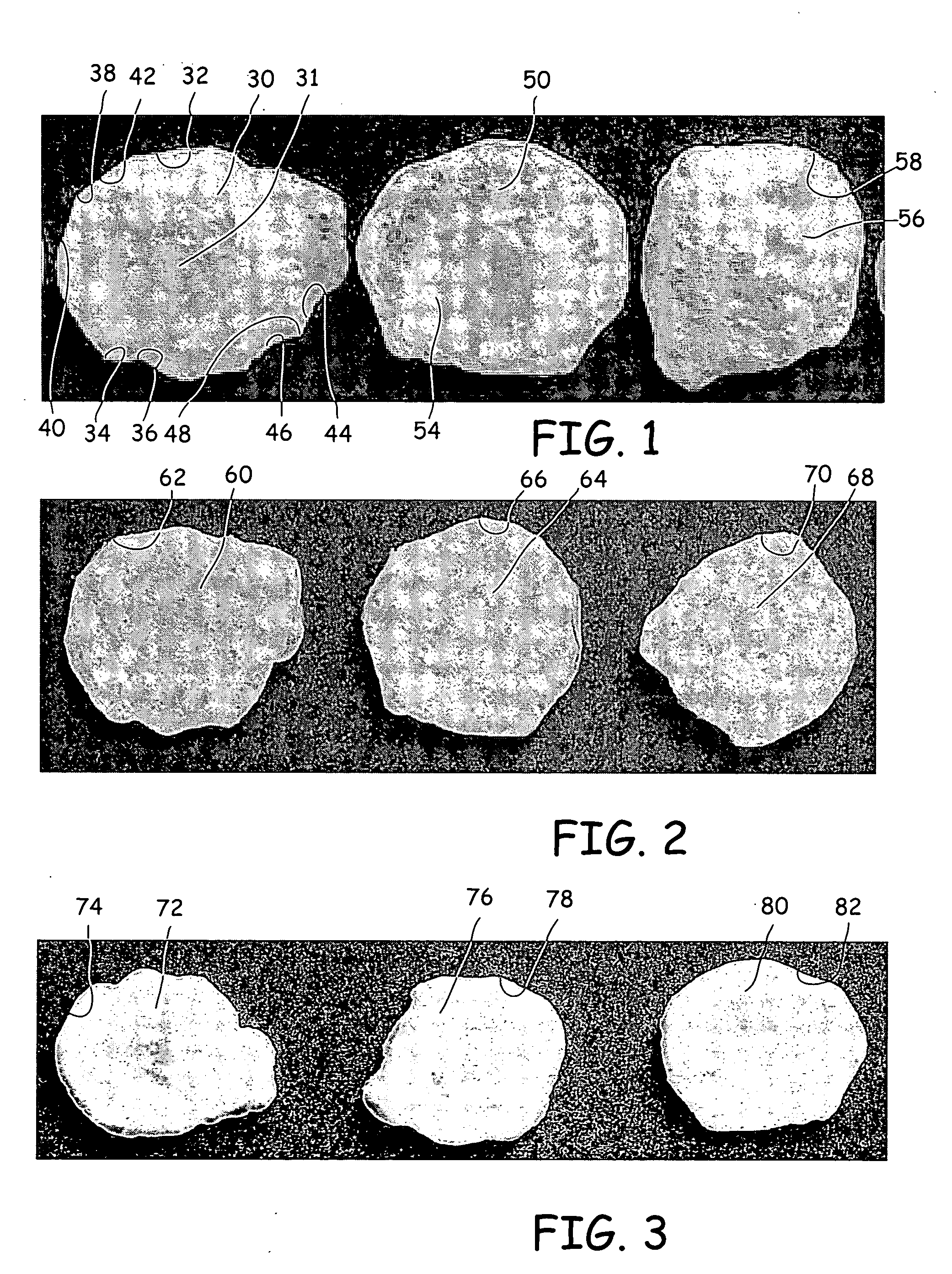

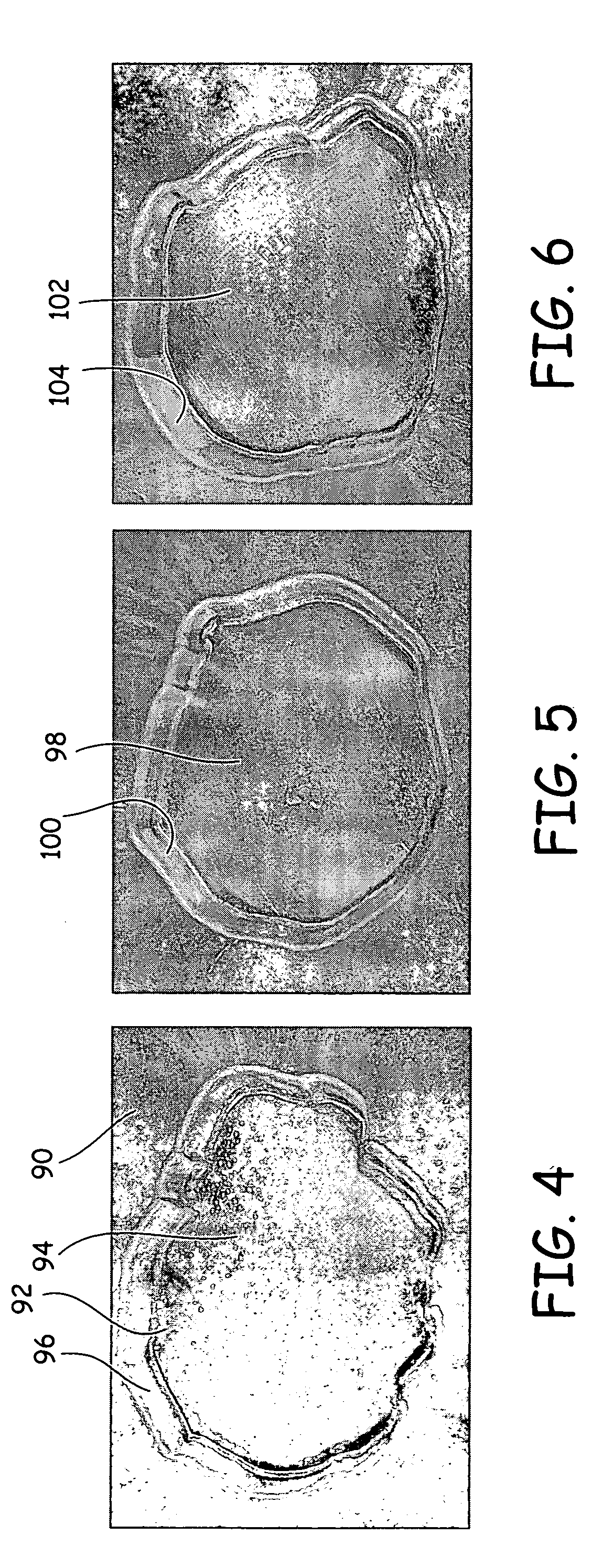

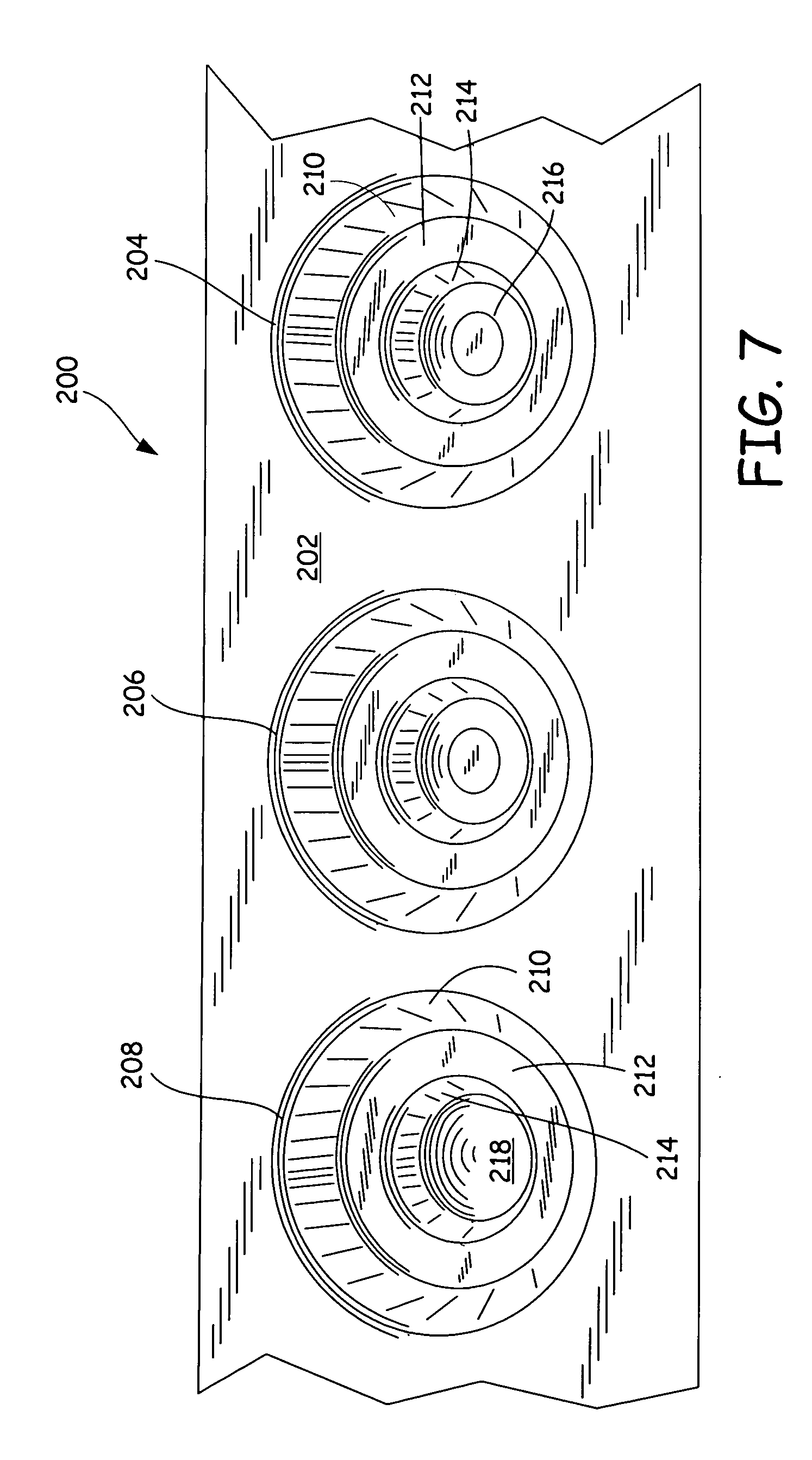

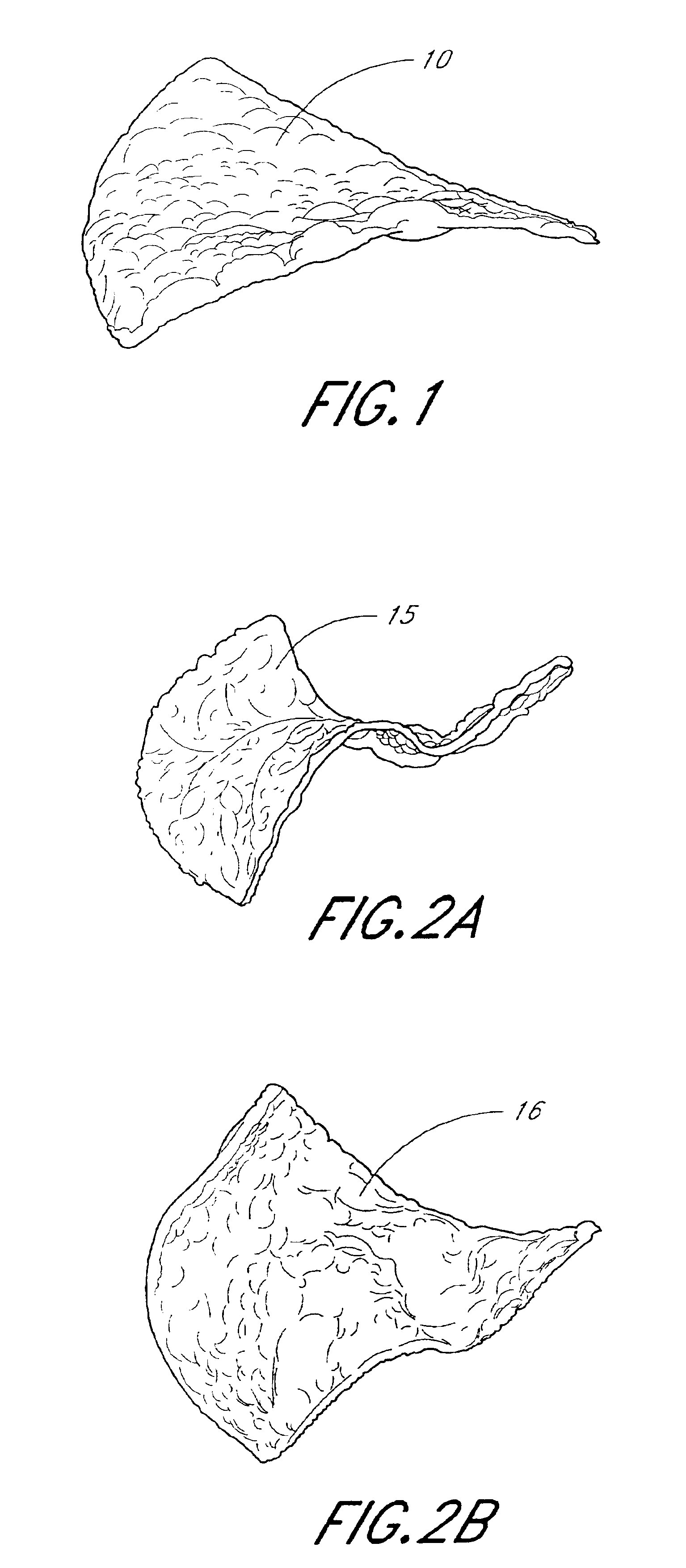

Methods and devices for automatically making large quantities of pre-cooked eggs having a natural appearance

The present invention includes methods and devices for mass producing cooked, cooled egg products having a grill fried egg appearance. One device includes a portion for positioning whole, intact, shelled eggs positioned laterally across and above a cooking mold conveyor, and a portion for cracking the eggshells and depositing the eggs into cooking molds on the conveyor. Some devices and methods include an egg yolk splitter for rupturing the egg yolk sac to deposit a whole egg having a ruptured egg yolk into each mold. Other devices and methods include irregular shaped egg molds for providing a mass produced cooked egg having a natural, irregular shaped outlines and / or surfaces. Devices and methods according to the present invention can be used to produce irregular, outlined shaped cooked egg products including whole eggs, formulated eggs, or eggs made from scrambled egg mixes. The pre-cooked eggs can be delivered pathogen free to fast food establishments and reheated for consumers in less time than required to cook the egg.

Owner:MICHAEL FOODS INC

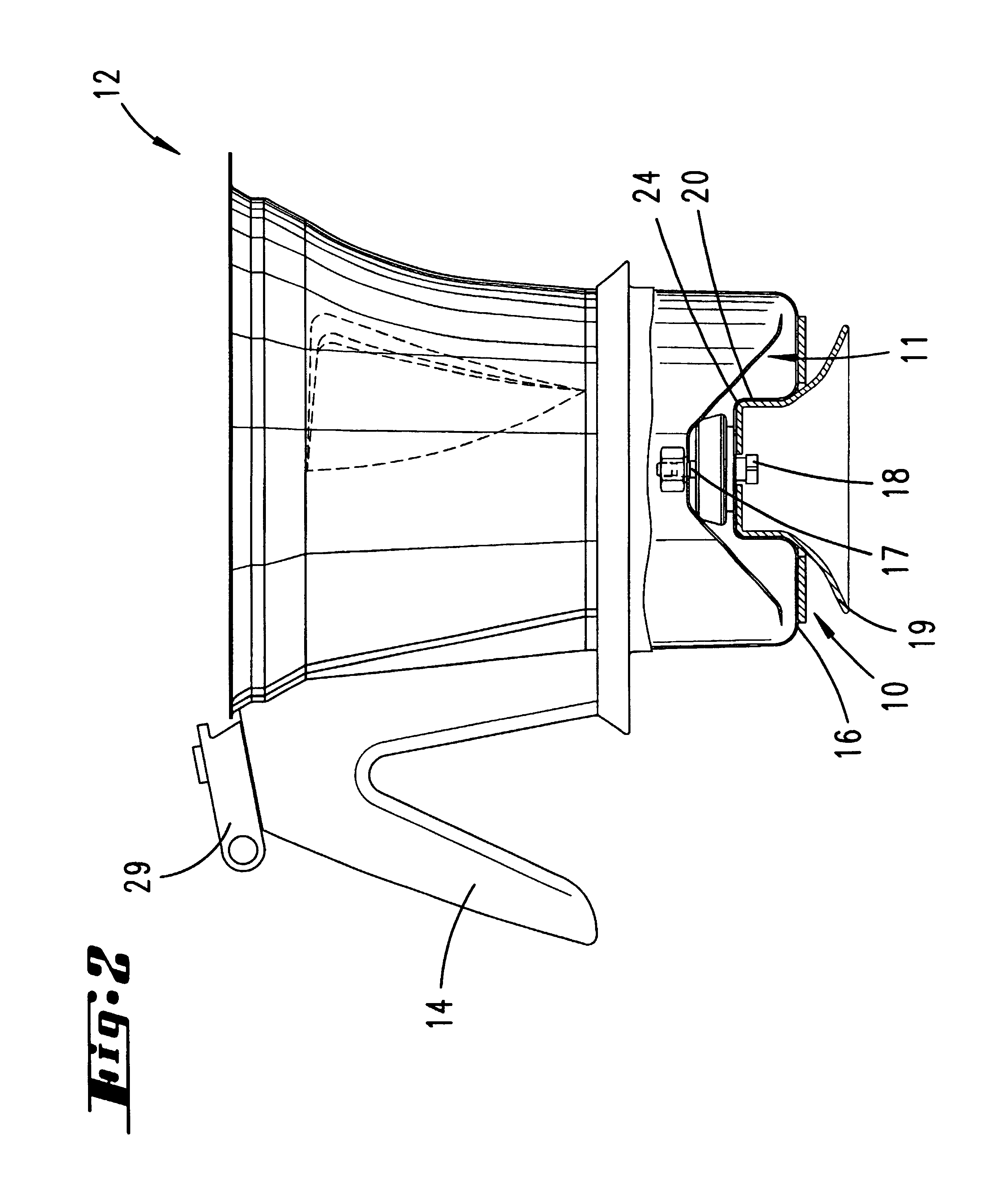

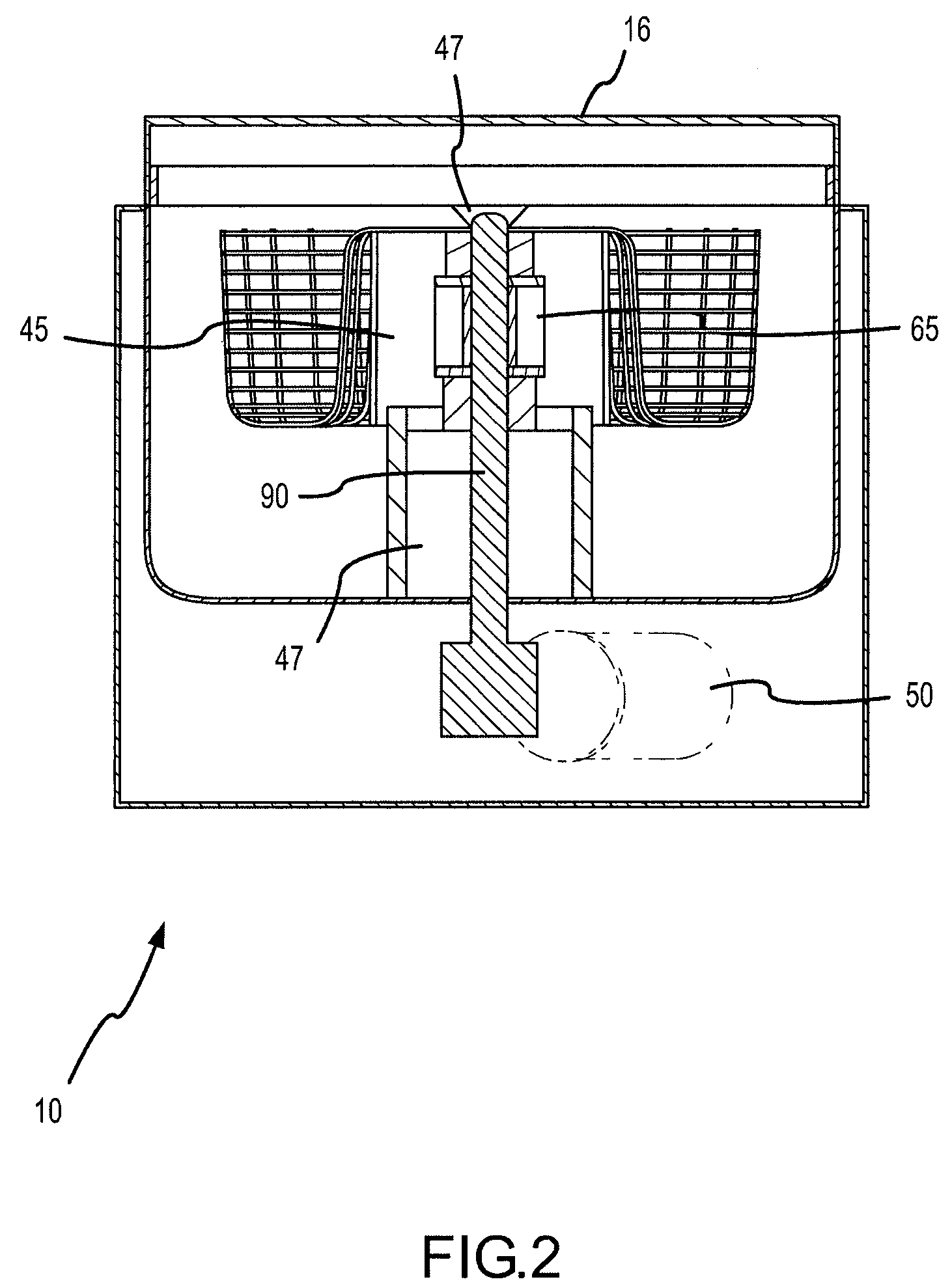

Kitchen machine with a stirrer vessel

InactiveUS6640692B1Improve controllabilityIncrease ratingsJuice extractionOther chemical processesDielectricElectrical conductor

A food processor (1) with a mixing vessel (12) and a drive (21) for an agitator (11) in the mixing vessel (12), the mixing vessel (12) being heatable in its lower region and having on a bottom a dome (24) which has a securing mount for the agitator, wherein a resistance heating element (10) with printed conductors (23) applied to a dielectric (22) is fitted on a base (16) of the mixing vessel (12), the heating element (10) having a central recess (25) which is adapted to the dome (24), said heating element (10) being generally circular and disk-shaped.

Owner:VORWERK & CO INTERHOLDING GMBH

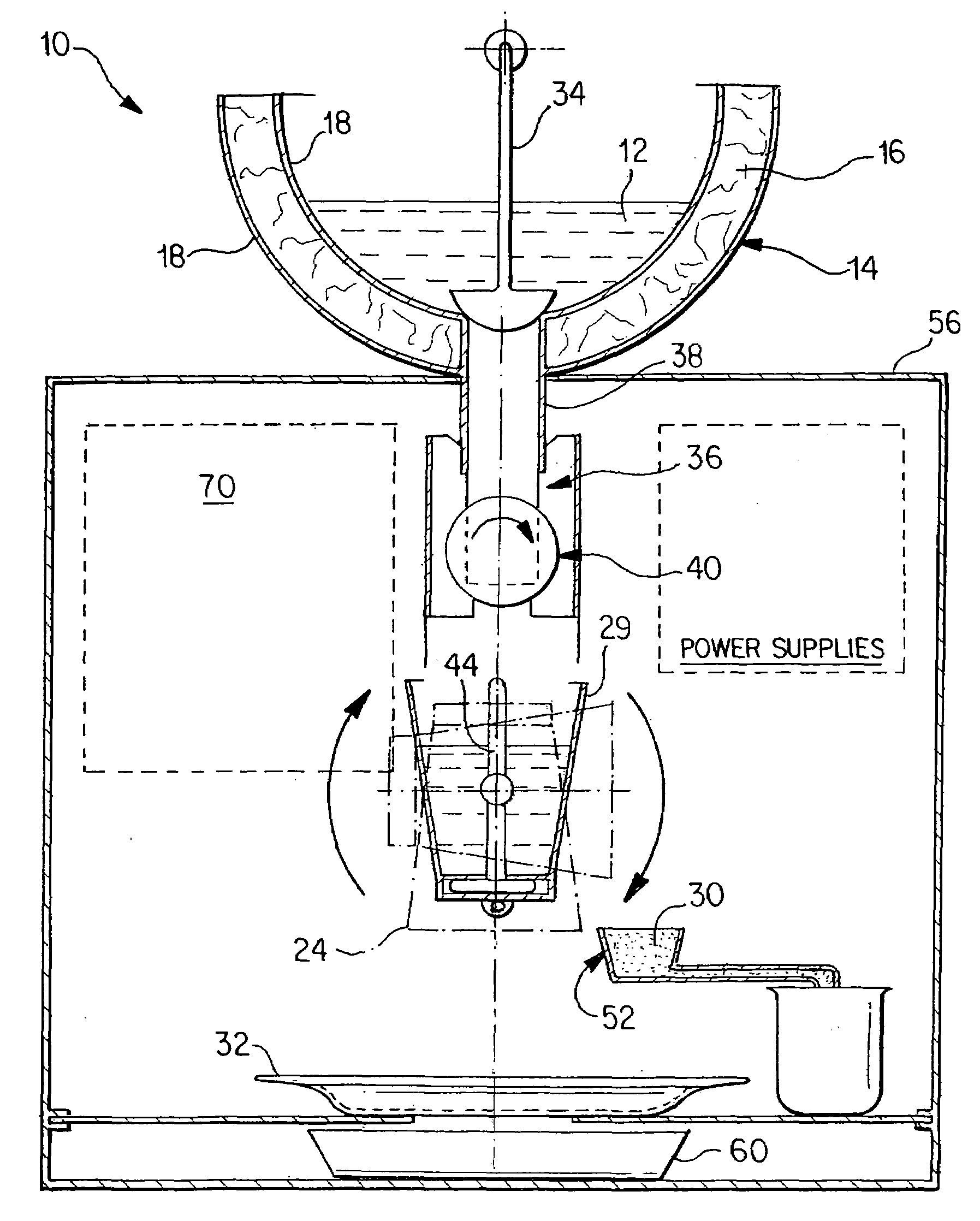

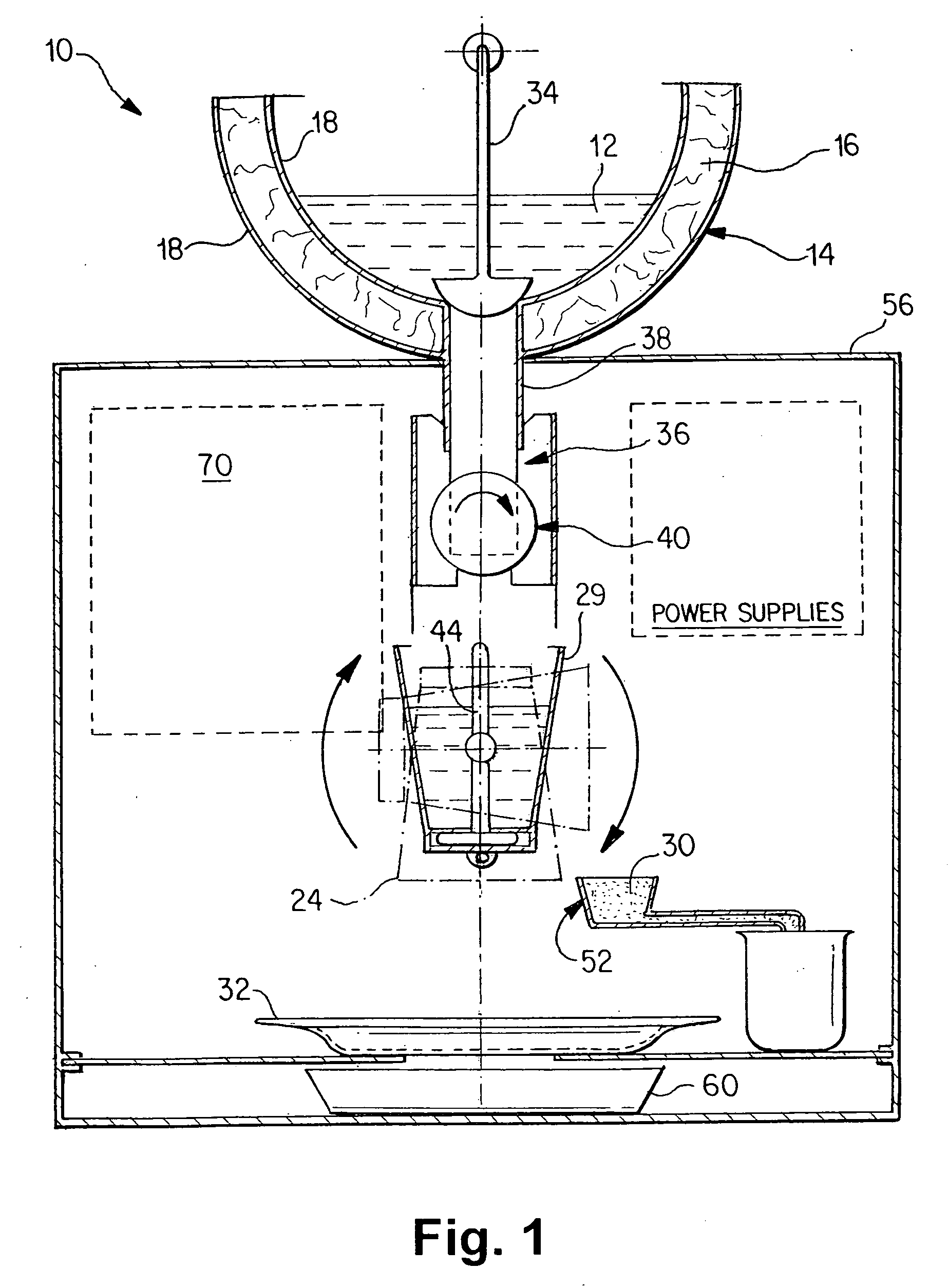

Steam injection cooking device and method

InactiveUS20090252855A1Boiling over preventionMeat/fish preservation by heatingPortion sizeLiquid water

An apparatus and method are provided for steam injection heating of a bulk food product. When cooking scrambled eggs, the method includes providing a predetermined amount of liquid uncooked egg. A predetermined amount of water is injected into a heated cavity to form a quantity of steam that is sufficient to cook the predetermined quantity of liquid uncooked egg when injected therein. The liquid egg may be liquid pasteurized whole egg. The predetermined amount of the food product may be a single serving, or integer multiples thereof. When heating a serving amount that is an integer multiple of at least two times the amount of a single serving, the predetermined quantity of water is injected in pulses. The number of pulses is the same as the integer multiple of servings being heated, and each pulse contains substantially equal amounts of liquid water.

Owner:RESTAURANT TECH

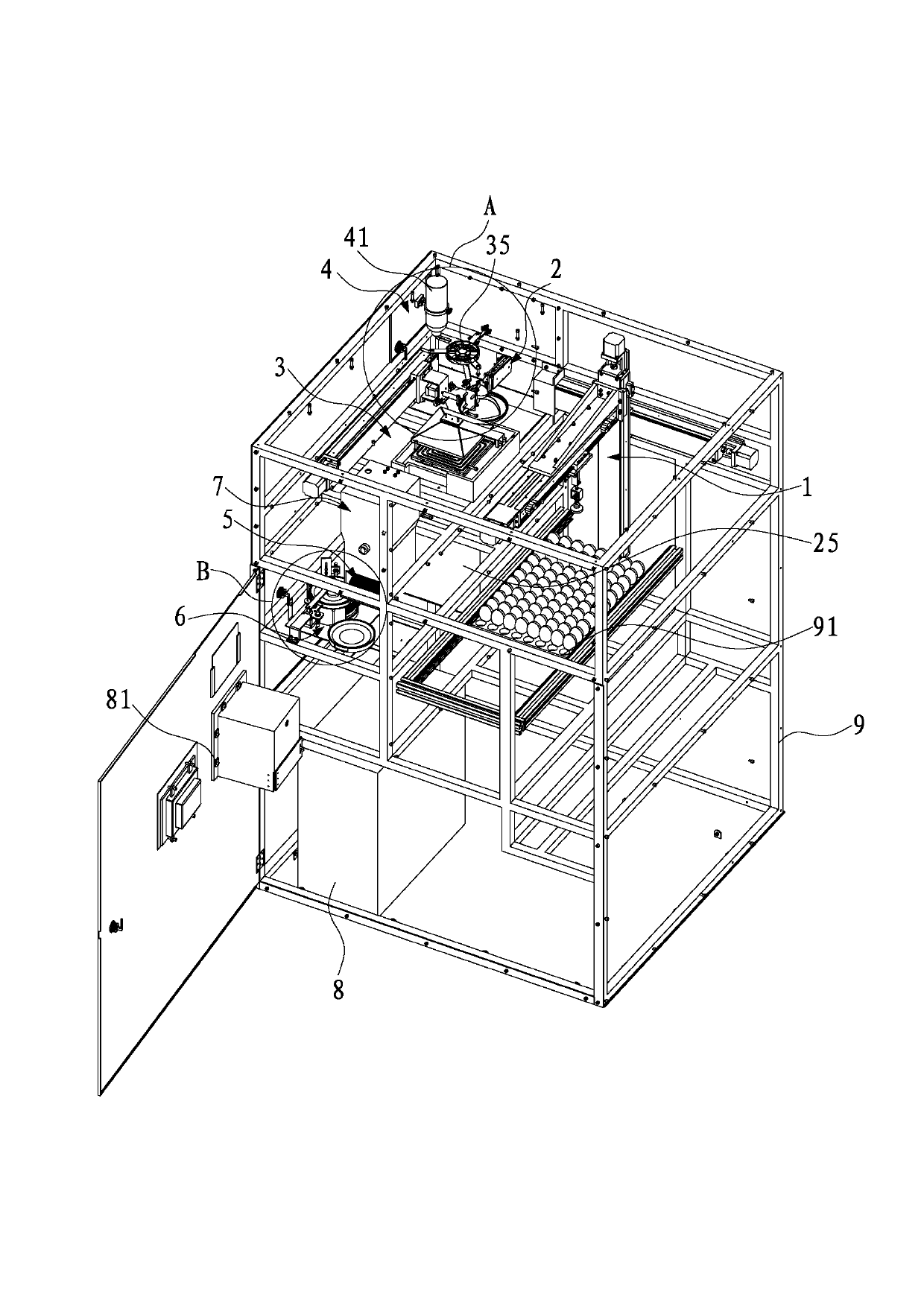

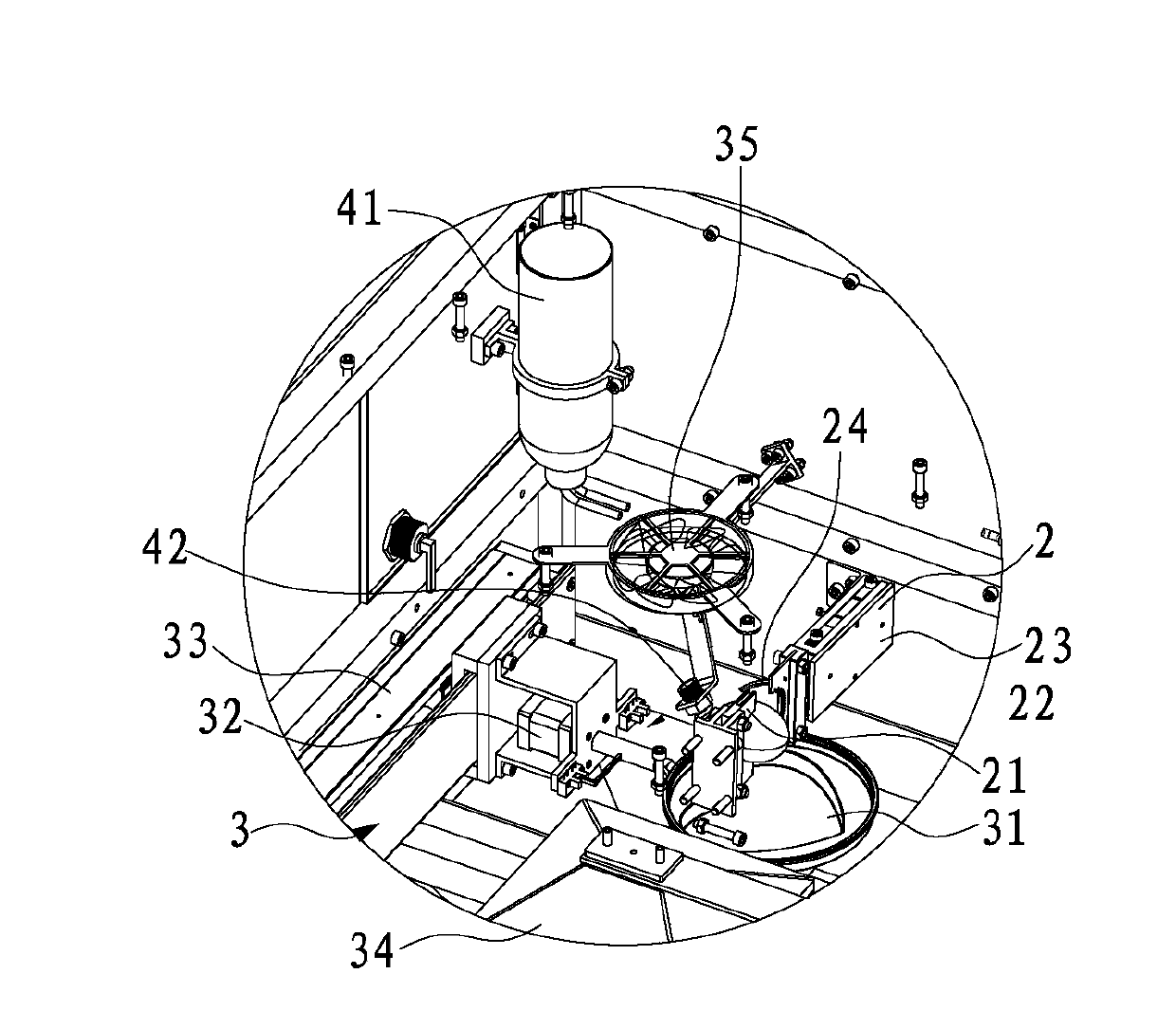

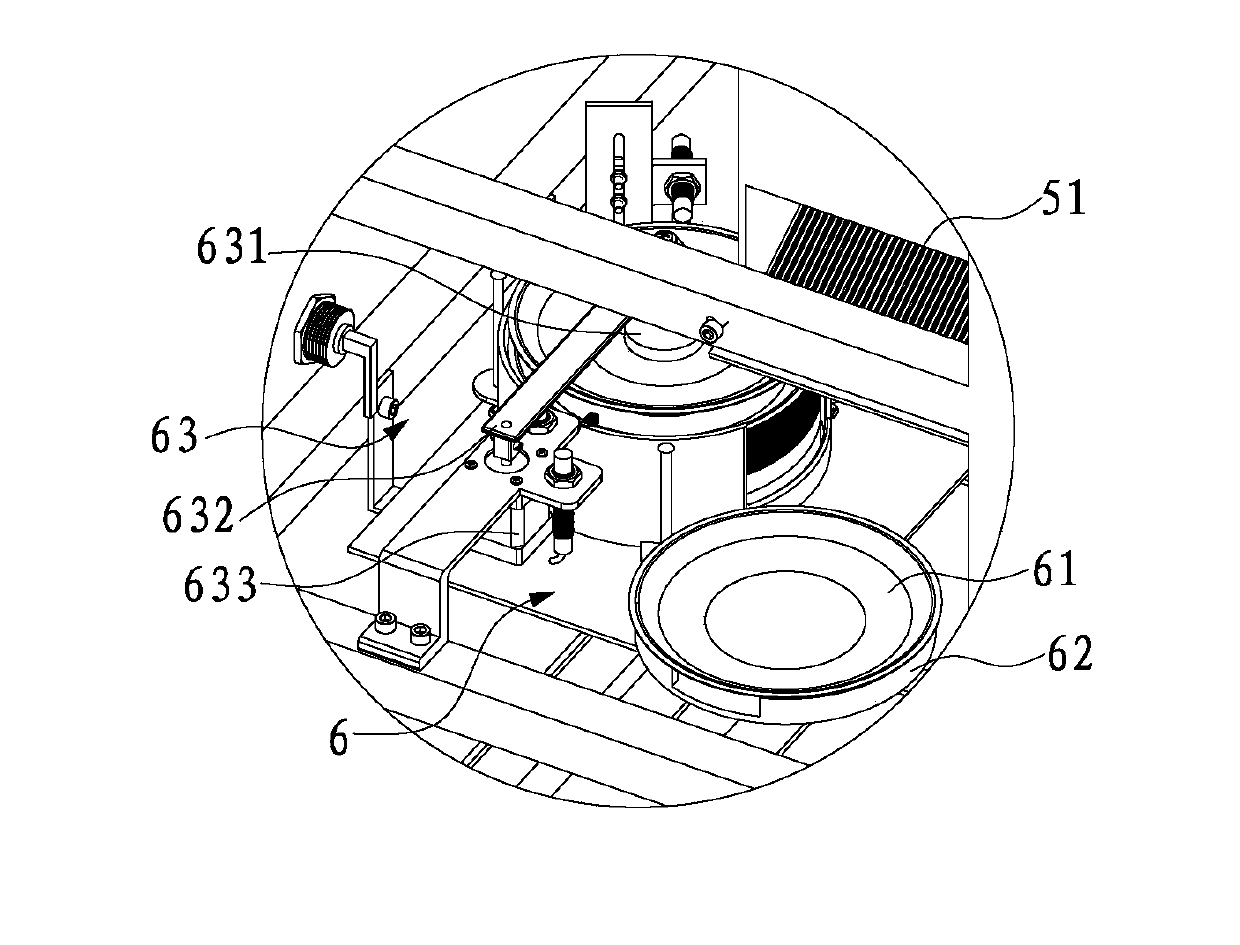

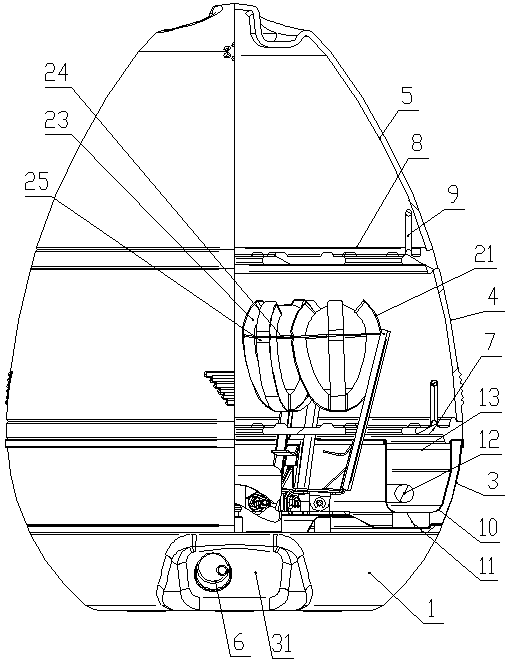

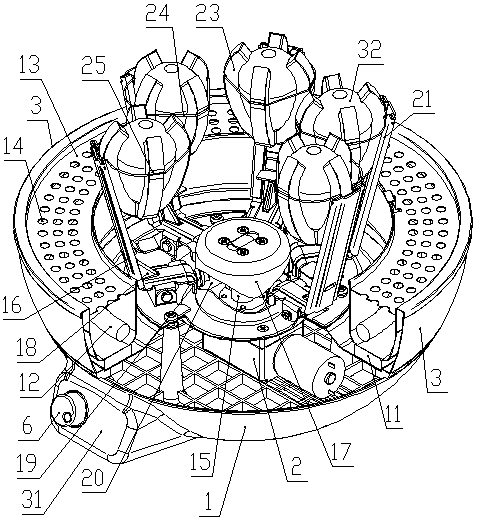

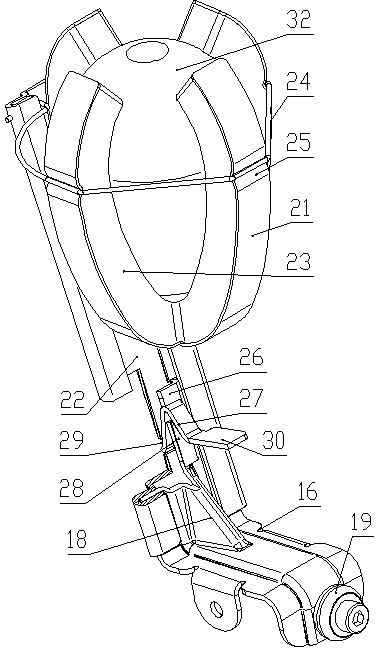

Full-automatic egg frying and vending machine

The invention discloses a full-automatic egg frying and vending machine. The full-automatic egg frying and vending machine comprises an egg taking mechanism, an egg liquid separation mechanism, an egg frying and conveying mechanism, an oil addition mechanism and a control mechanism, wherein the egg liquid separation mechanism is used for cracking an eggshell in a clamping mode to enable egg liquid to flow out, the mechanisms are fixedly installed on a rack, and the rack is provided with an egg rack; the egg taking mechanism comprises an egg taking device and a moving device, wherein the egg taking device is used for taking raw eggs down from the egg rack, and the moving device is used for moving the egg taking device to the egg liquid separation mechanism; the egg frying and conveying mechanism comprises a frying pan, a horizontal movement device and a heating and egg frying device, wherein the horizontal movement device can drive the frying pan to move; the oil addition mechanism is used for adding oil to the frying pan. According to the full-automatic egg frying and vending machine, the process from raw egg taking operation, egg cracking operation, processing to vending operation can be automatically accomplished, manual intervention is not needed, the defect that in the traditional egg frying process, a worker needs to be on site is overcome, convenience and rapidness are achieved, the cost is low, the eggs can be fried immediately, it is ensured that fried eggs are fresh and delicious, the market prospect is wide, and the full-automatic egg frying and vending machine has quite high investment value.

Owner:XIAMEN UNIV OF TECH

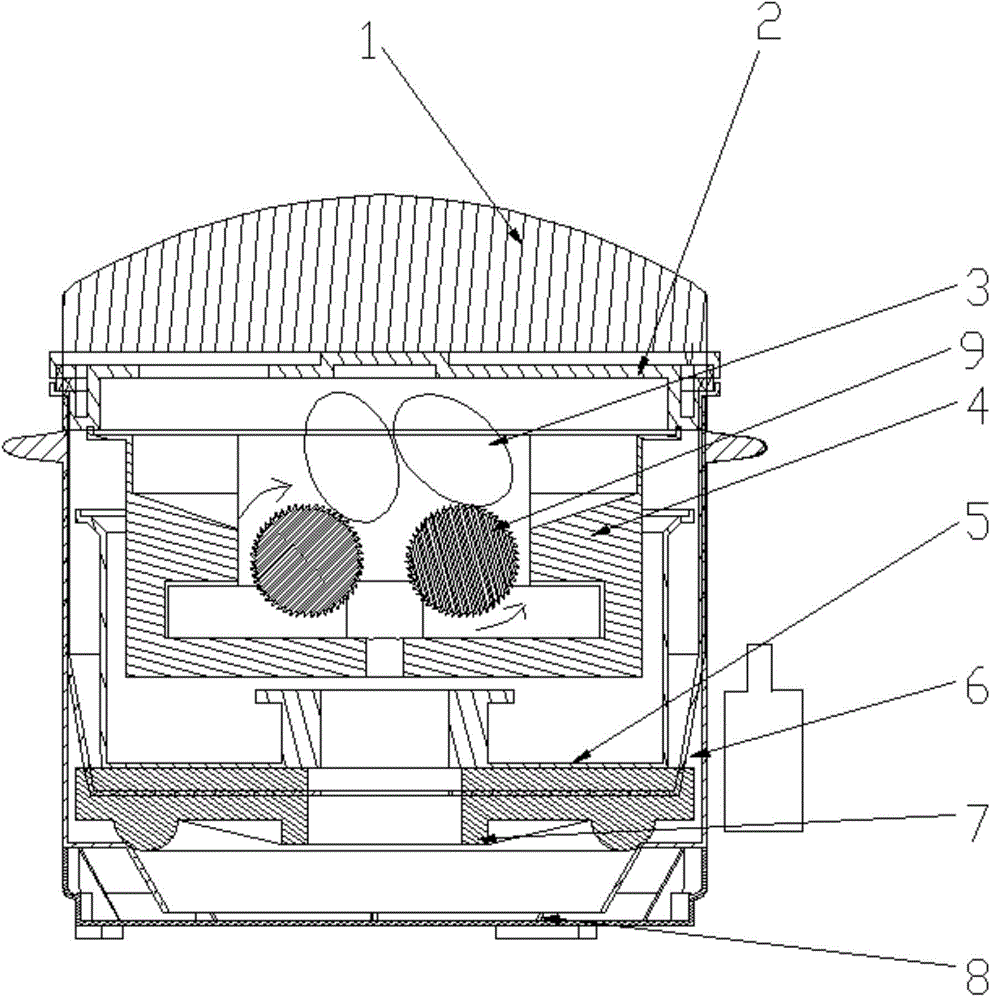

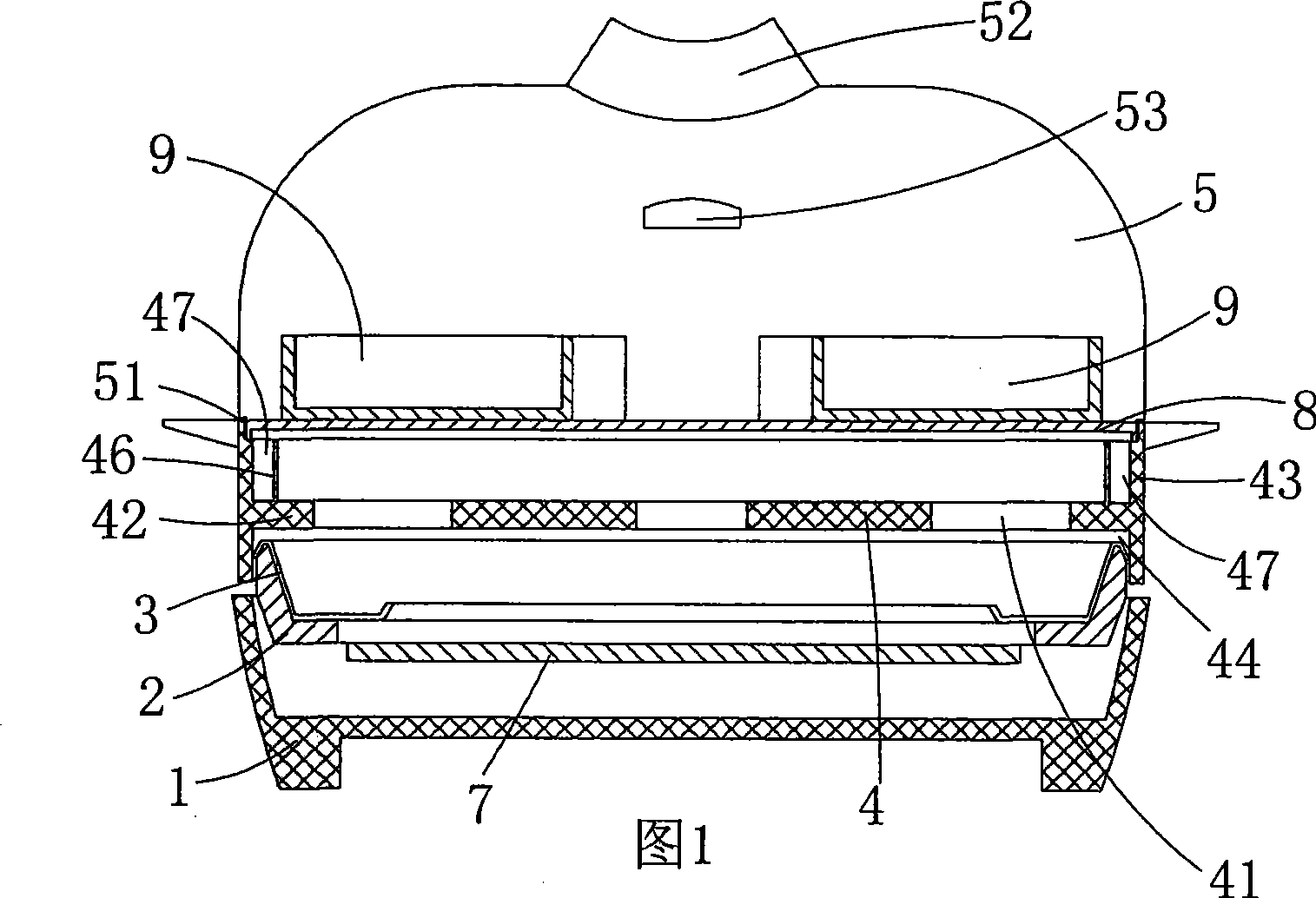

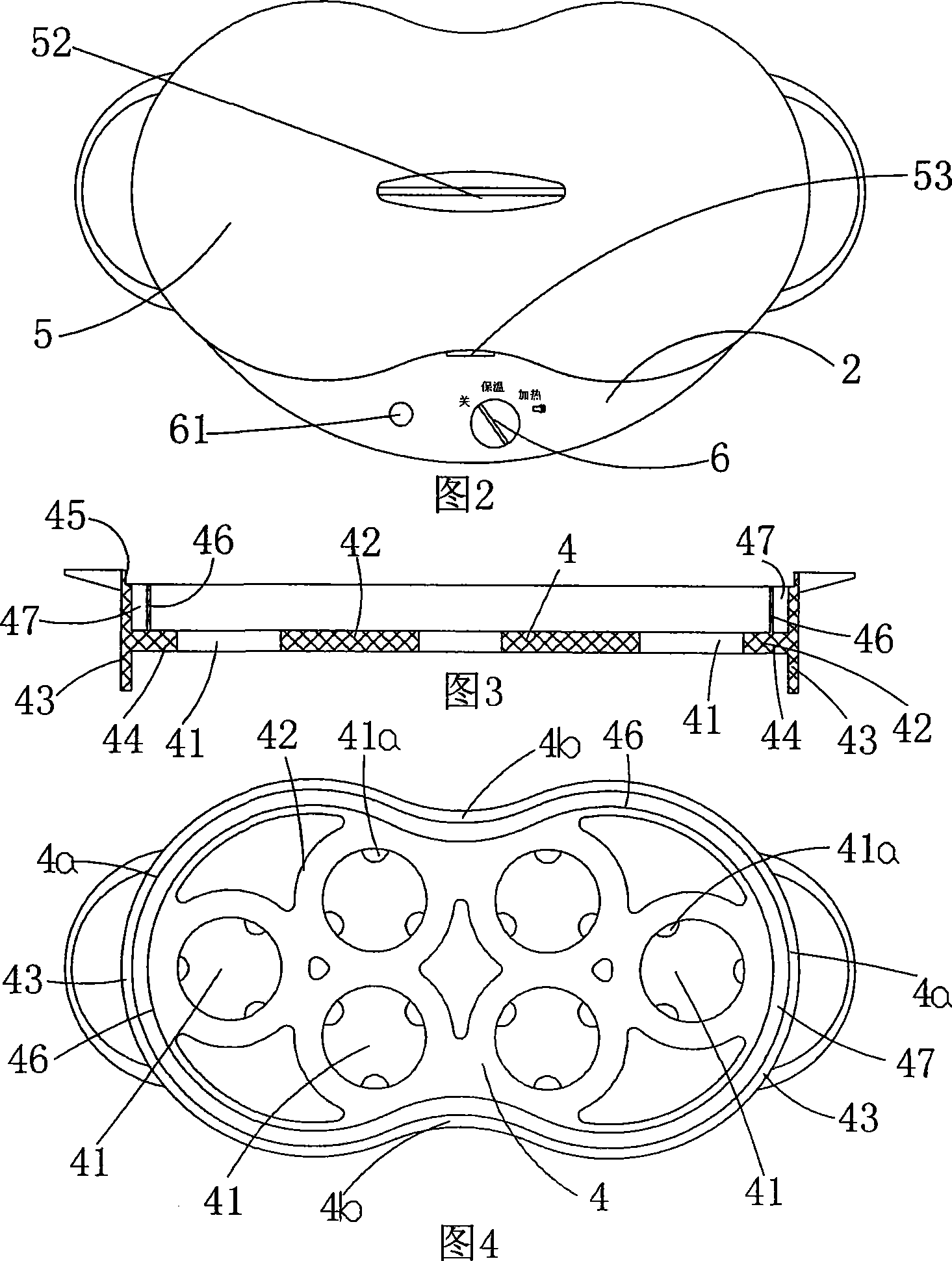

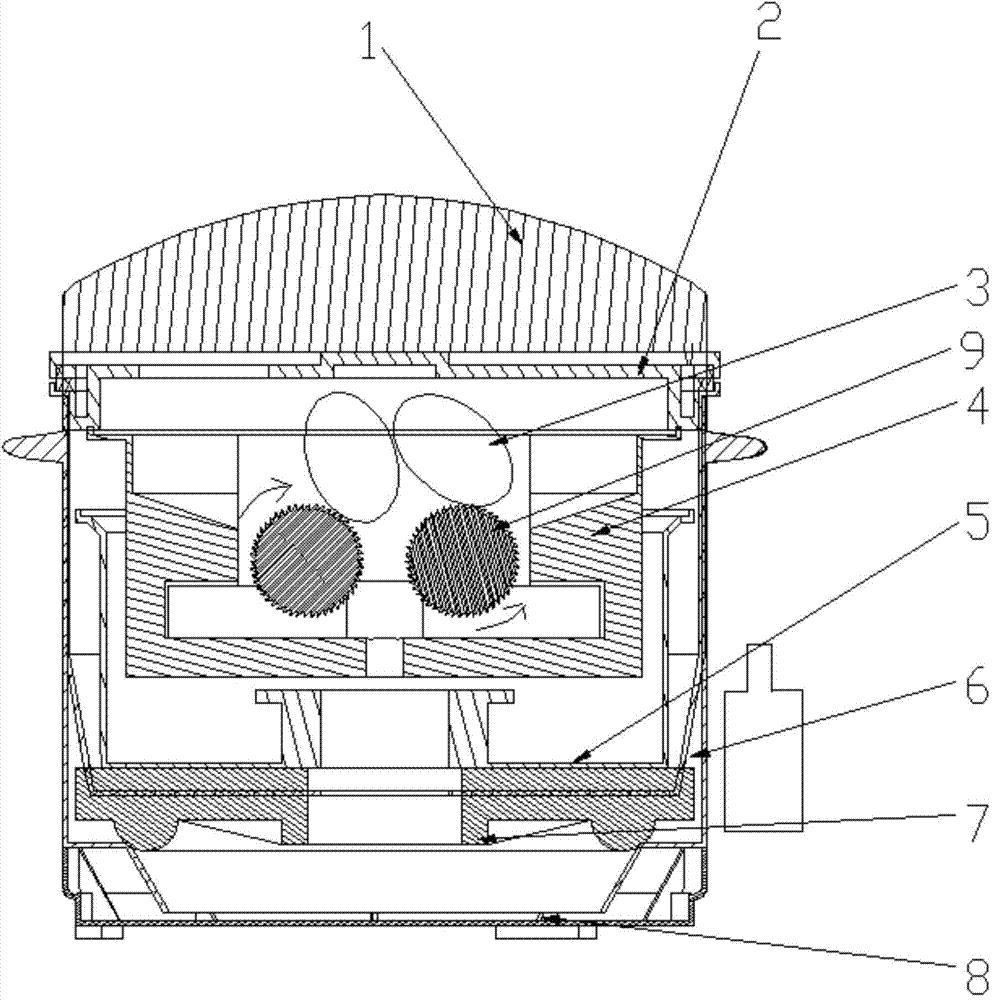

Multifunctional gold egg steamer

A multifunctional gold egg steamer comprises a base, wherein a housing is arranged on the edge of the base; a heating device located on the inner side of the housing is arranged on the base; a reducer motor is arranged in the middle of the base; a power output end of the reducer motor is connected with a shaking mechanism; and a dismountable egg loading mechanism is arranged on the shaking mechanism. The steamer is unique in design, compact in structure, high in automation degree and high in egg steaming efficiency, greatly reduces the unsuccessful labor intensity during manual egg shaking, particularly meets fast-paced living needs of office workers, is a brand-new small home appliance capable of mixing egg white and yolk of an egg uniformly and steaming the egg automatically, gives consideration to an ordinary steaming task, and is multifunctional, strong in practicability and easy to popularize and apply.

Owner:HUANGHE S & T COLLEGE

Automated fryer filtration device and method

ActiveUS20080213445A1Quality improvementOil consumption is minimizedFatty oils/acids recovery from wasteElectric heatingUncooked FoodsFiltration

A commercial device and method for cooking food product in cooking oil includes a fry vat containing an amount of cooking oil used to cook discrete batches of uncooked food in discrete batches of a weight relative to the amount of cooking oil in the range of from about 0.0375 to about 0.1, with the total amount of food being cooked at any one time relative to the amount of oil in the fry vat being about 0.1 or less. Cooking the food results in an uptake of oil by the food in an amount of from about 5.5% to about 13% by weight of the uncooked food, and an oil turnover ratio of from about 0.0026 to about 0.007 per discrete batch. Replacement oil is periodically added, and a sufficient number of batches are cooked over 60 hours of operation to achieve at least one vat oil turnover.Automated intermittent filtration is employed in the device and method that can include monitoring the elapsed time since the last filtration of the cooking oil, monitoring the amount of food by number of batches or by weight of food product cooked in the oil since the last filtration, and filtering the oil when a predetermined threshold value is reached based on the elapsed time since the last filtration and the amount of food cooked.An automated device and method for maintaining a level of oil in a fry vat having a volume includes sensing the level of oil in the vat. When the sensed level of oil in the vat is less than or equal to a first predetermined level, replacement oil is automatically added to the fry vat, typically when at ambient temperature at a low average flow rate in the range of about 0.008 to about 0.08 gallons per minute per gallon of the oil present in the vat at the first predetermined level. The low average flow rate of added oil avoids a temperature drop of more than 15° F., 10° F. or 5° F. in the bulk oil present in the fry vat as result of adding the oil as desired.

Owner:RESTAURANT TECH

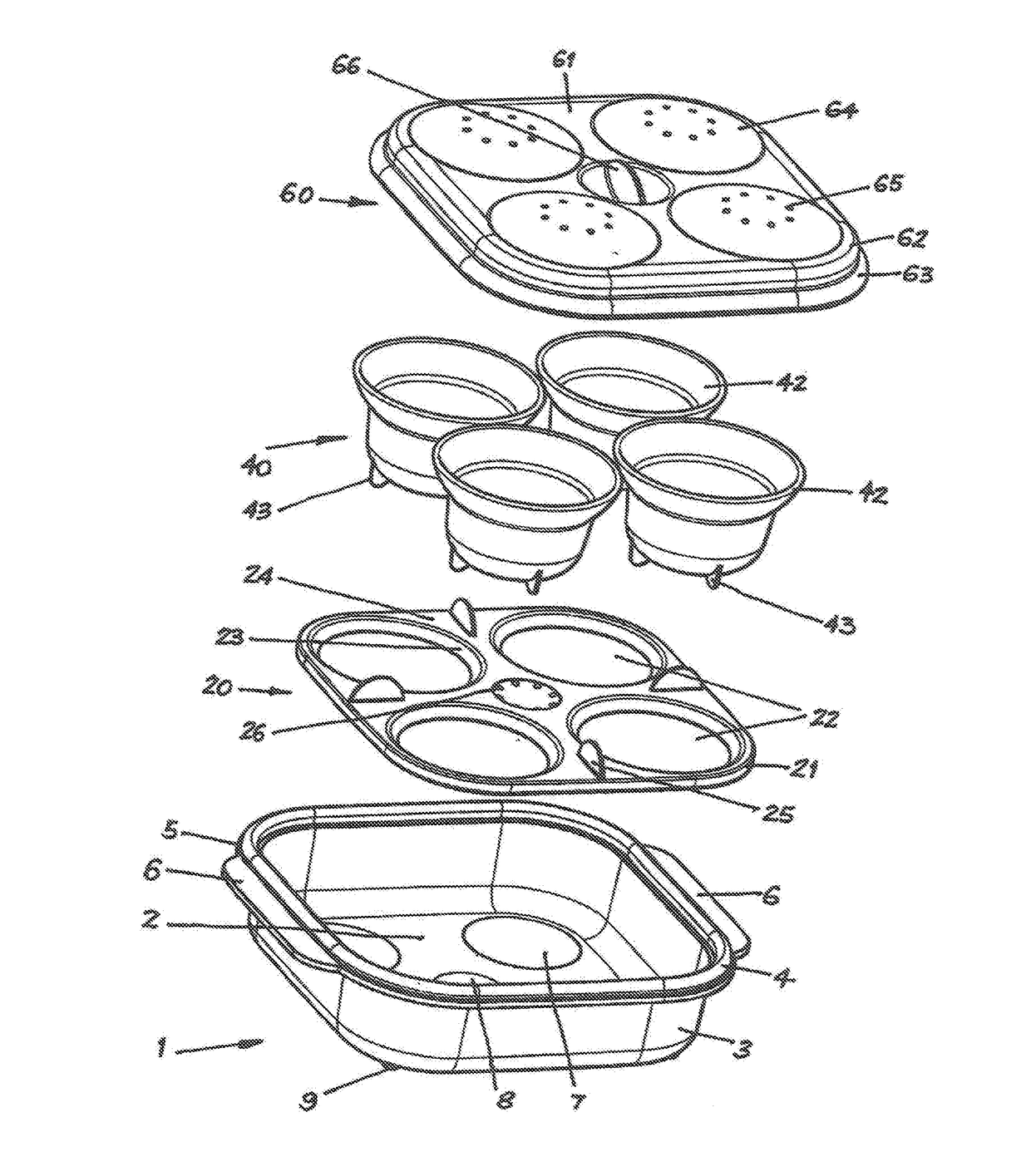

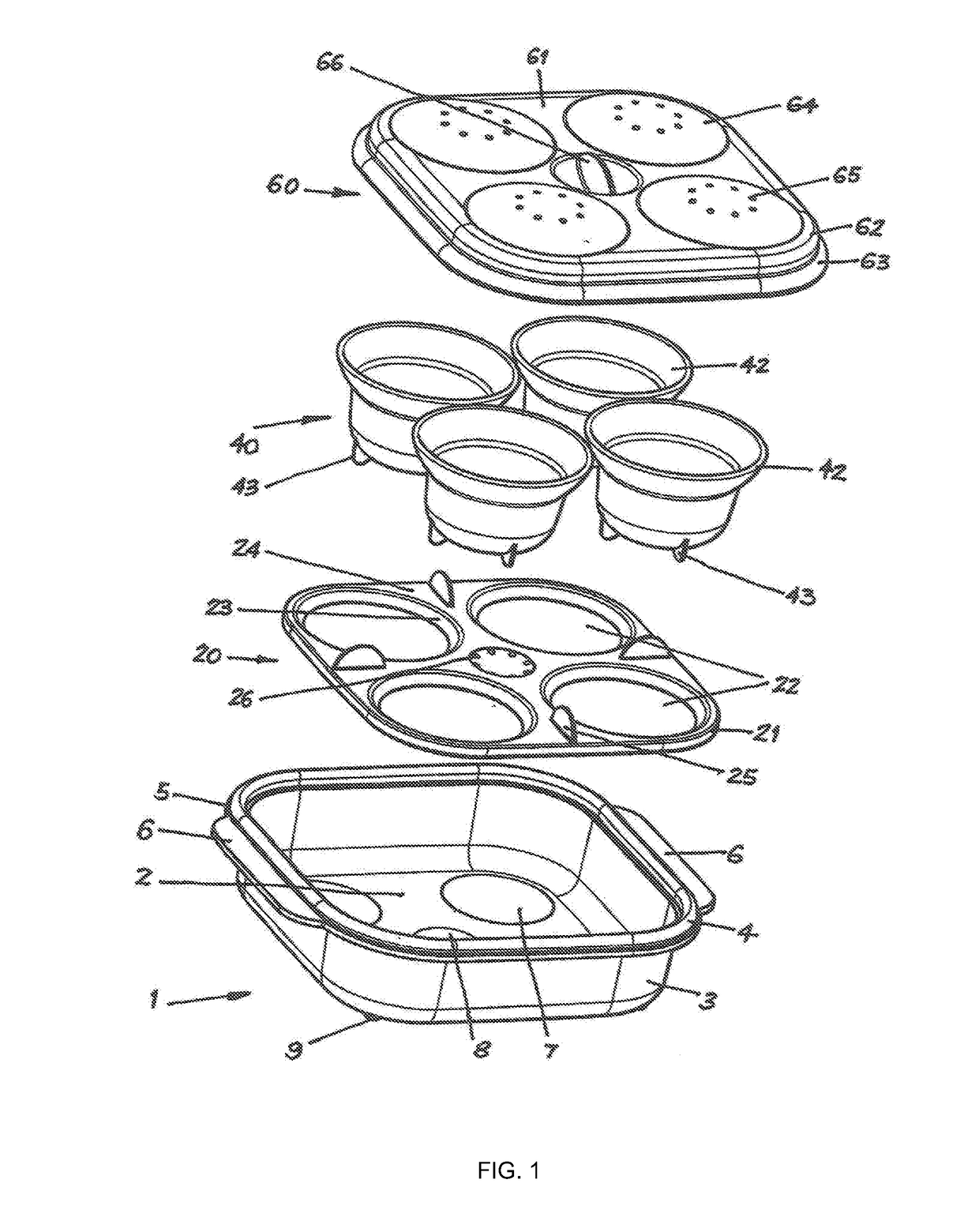

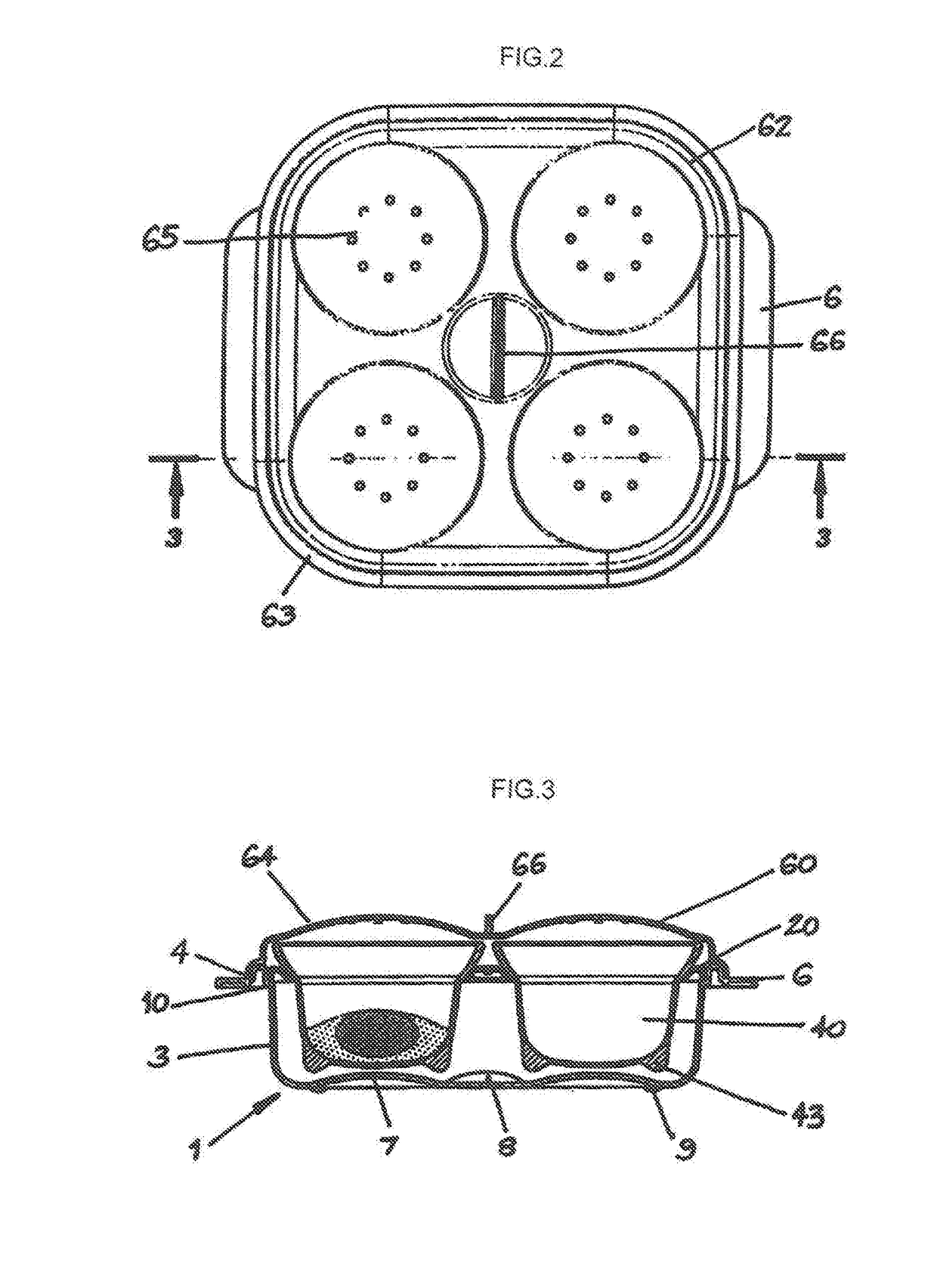

Egg poacher

An egg poacher for poaching one or more eggs in a microwave oven. The egg poacher includes a base member for holding water and an egg cup for holding a raw egg covered by water. The egg cup is removably supported by an upper portion of the base member so that the egg cup, in use, is partially submerged in the water in the base member. The egg cup is configured to be spaced from an adjacent wall of the base member so as to provide a gap between a side of the egg cup and the adjacent side of the base member so that, in use, water in the base, in combination with water covering the raw egg, creates a water shield that surrounds the raw egg.

Owner:THE DECOR

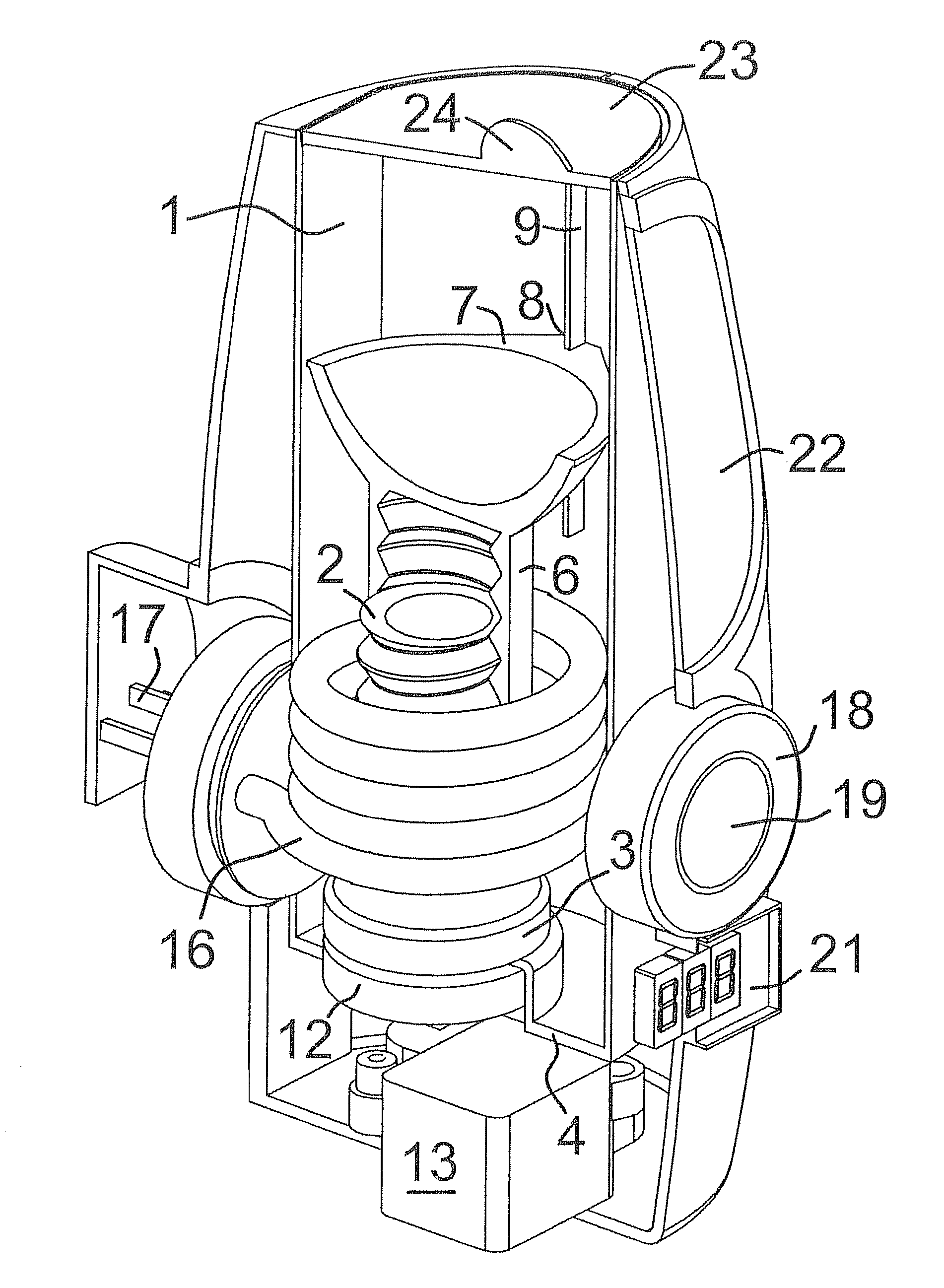

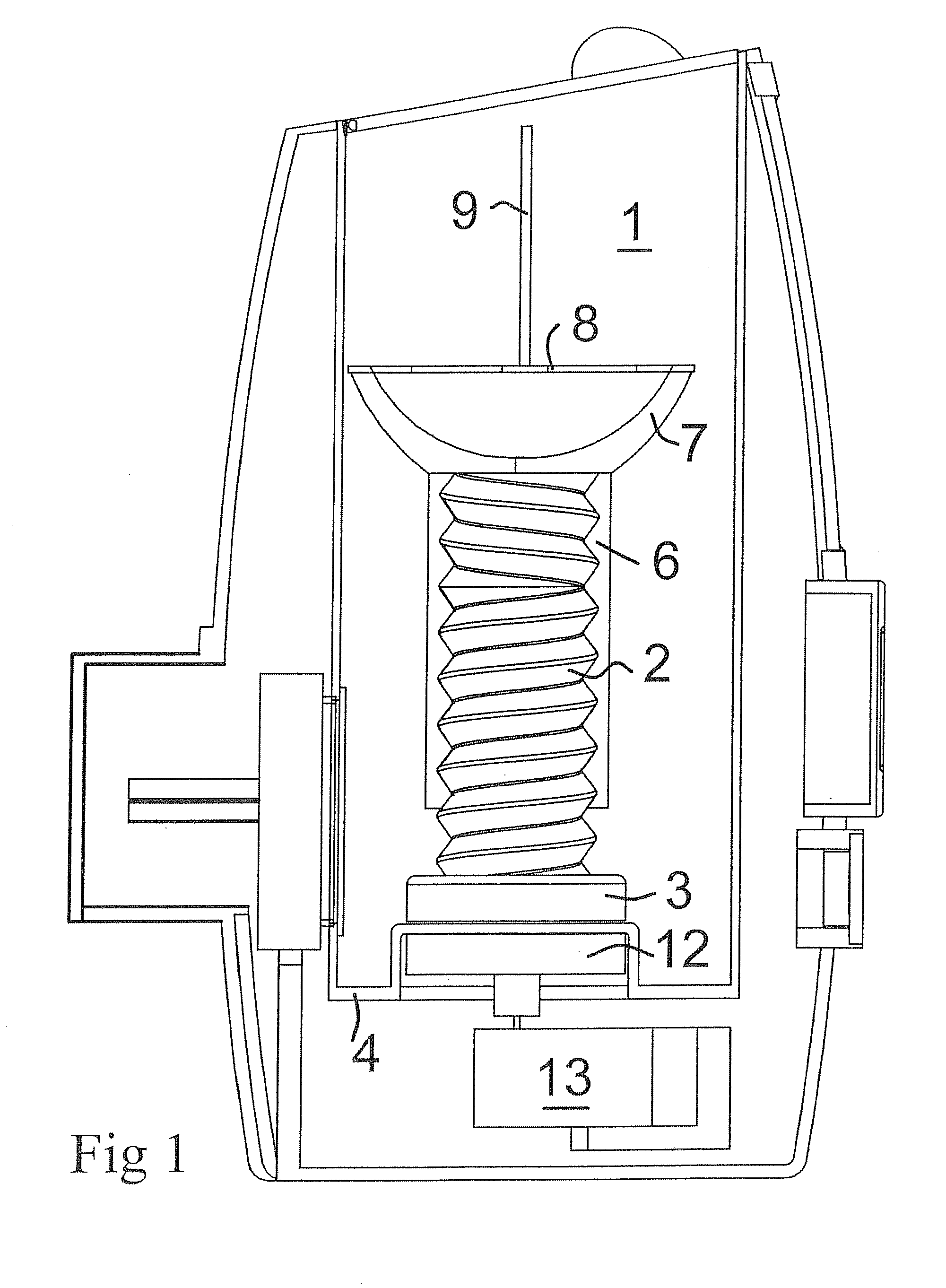

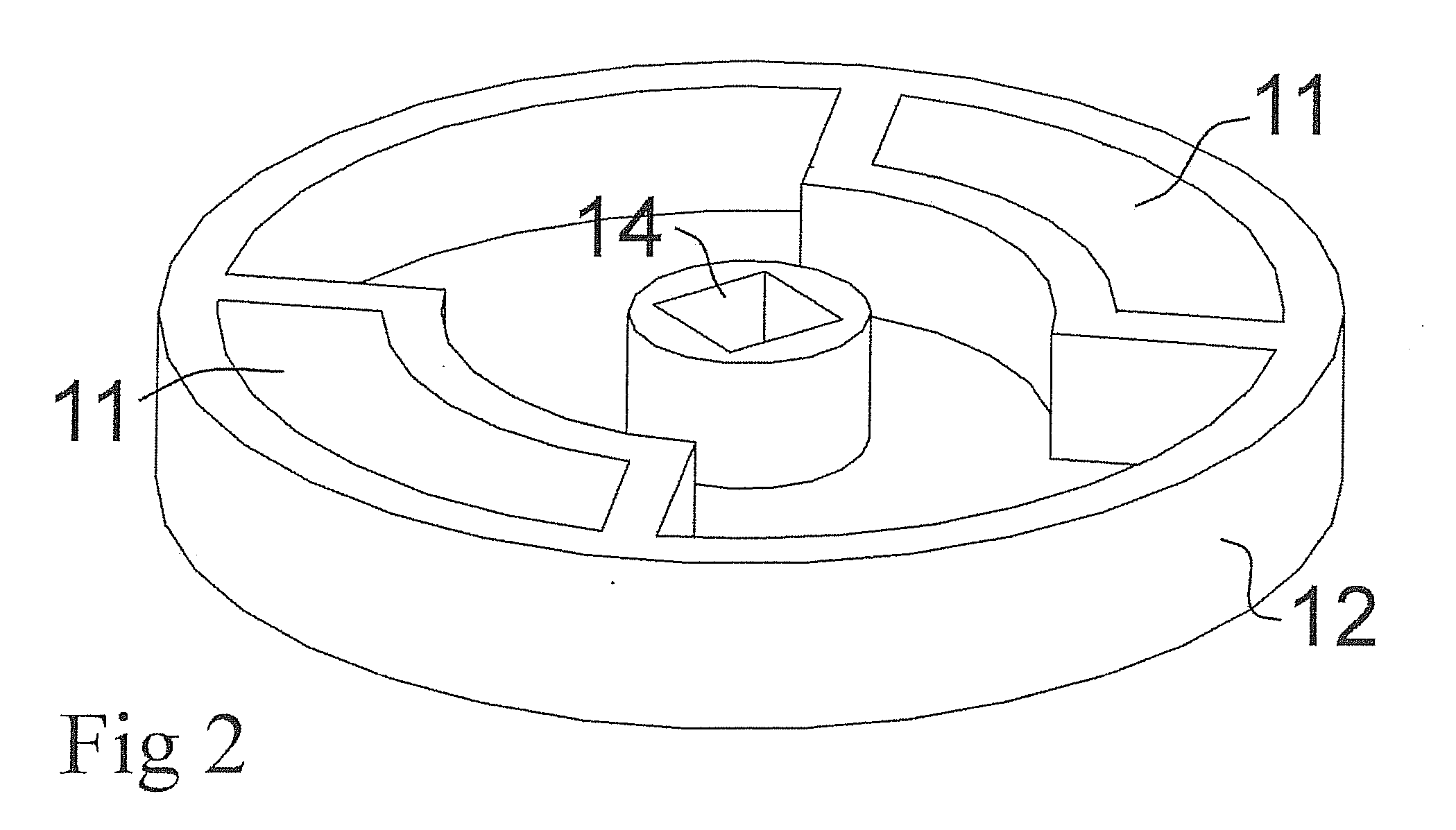

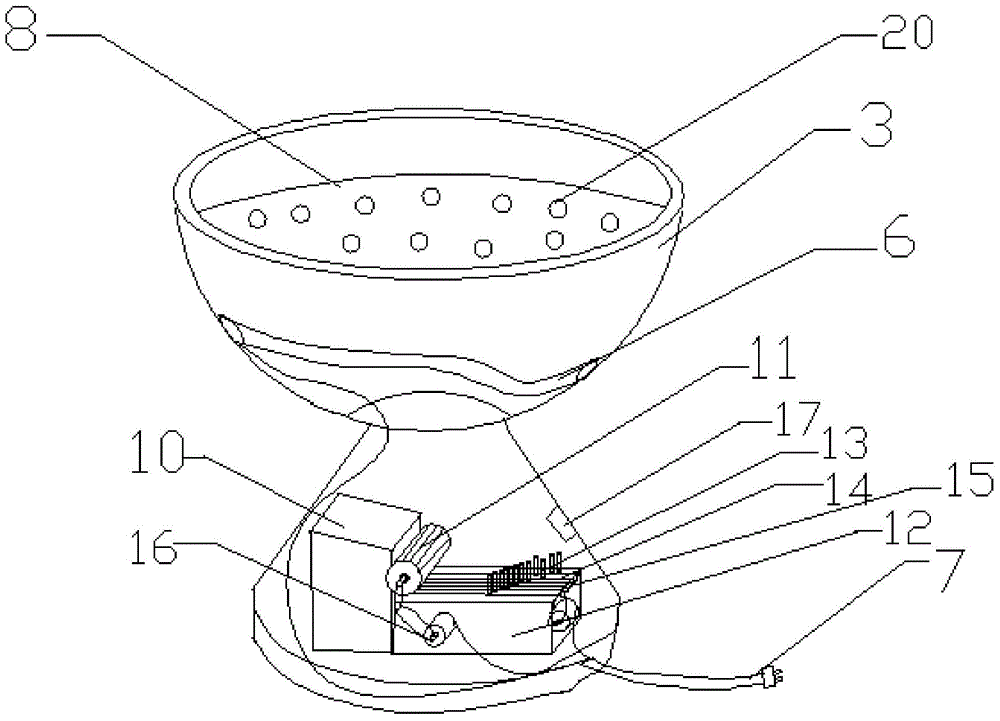

Egg Cooker Device

InactiveUS20110088564A1Without impairing water sealing effectivenessPrevent rotationEgg-cookersBeverage vesselsRest positionCoupling

An egg cooker device comprises a water container 1 and an electric heating element, the container including a support platform 7 capable of lowering an egg into a body of water in the container 1, an electric motor 13 arranged for moving the platform 7 from a rest position at an open top of the container to an egg heating position within the container, a timer device connected to the motor such that the platform will remain in the egg heating position for a predetermined time interval, in which the support platform 7 includes a drive means 3 linked by a magnetic coupling to a drive source 12 located outside the container 1. This construction uses a magnetic coupling to get a drive from the motor 13 shaft through the wall of the container, it thus avoids a need to provide a water sealed opening for the shaft in the container 1 wall.

Owner:BONSELL STUART

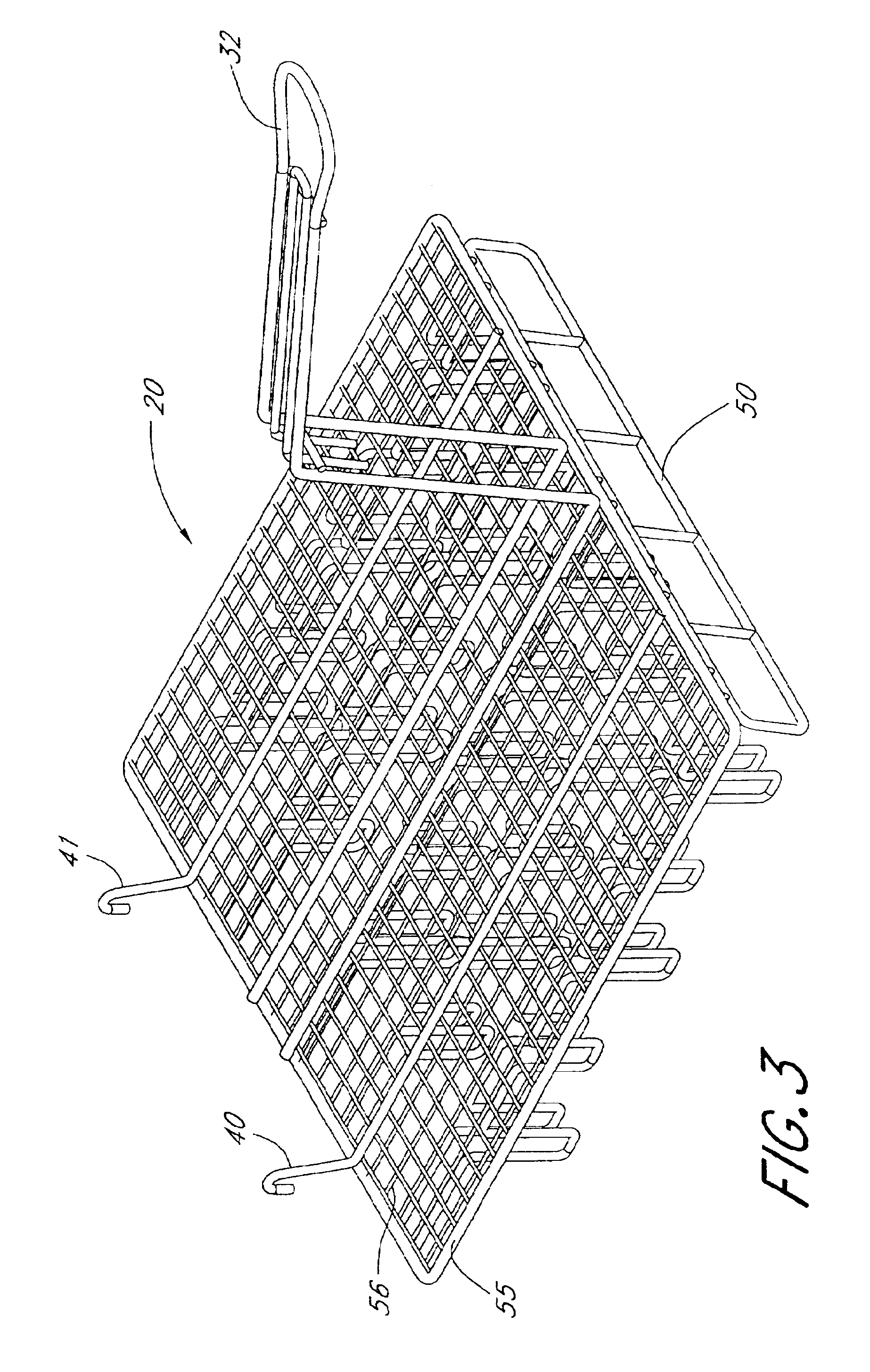

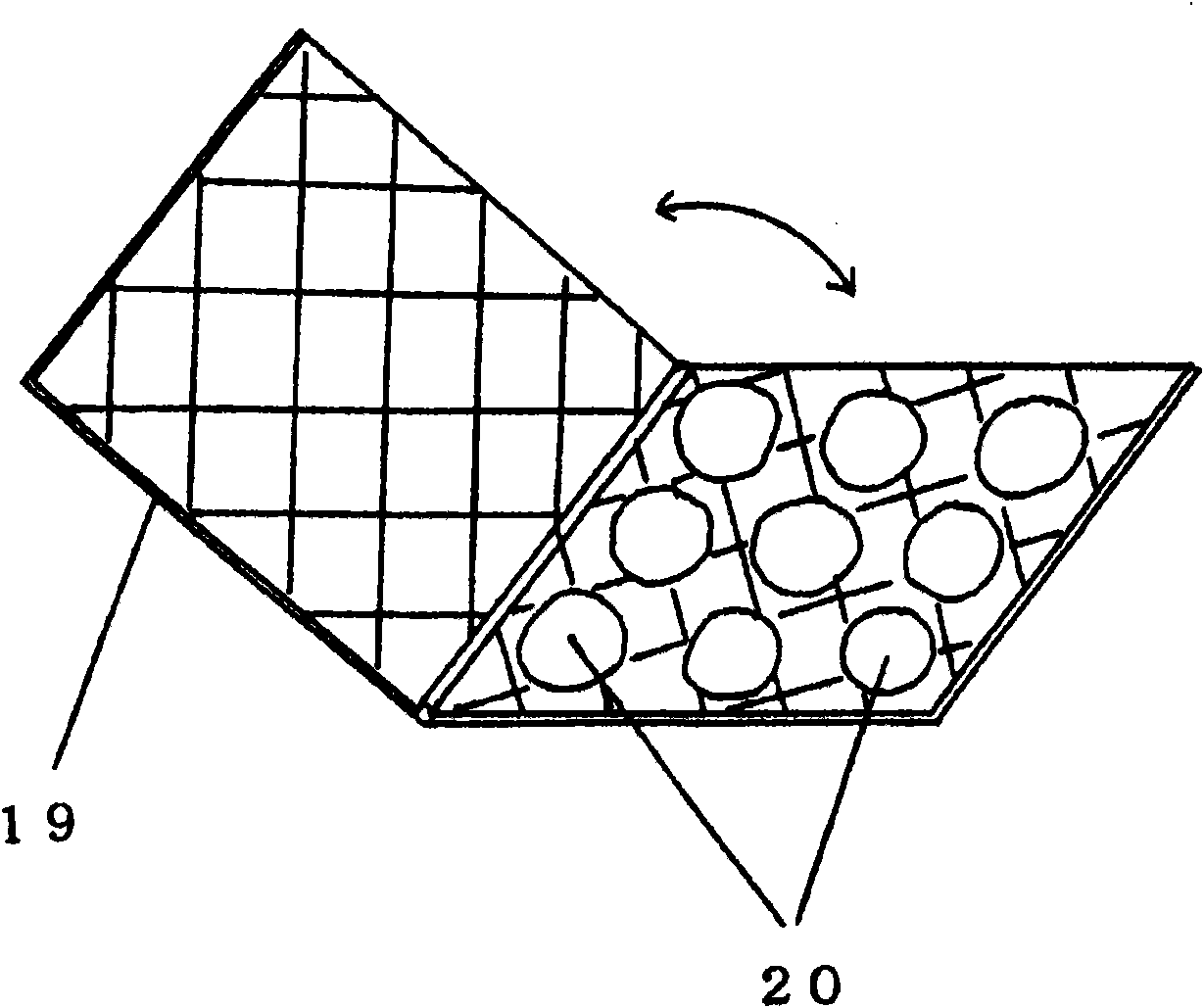

Method and apparatus for deep-frying a chip food product

InactiveUS6868776B2Easy swivel movementPrevent escapeCooking vesselsMeat processingDeep fryingEngineering

The apparatus is a chip fry lid having an array of long and short posts for contacting and agitating the chips during the deep frying process. In the preferred embodiment of the invention, each of the posts is formed by proximate sets of wire bent to form a series of long and short generally U-shaped prongs. A hinge at the front of the lid and a handle at the opposite end facilitate manual oscillation of the lid during the deep frying process to achieve a high percentage of chips of uniform high quality, both in terms of uniform cooking and chips having sufficient curls to form a chip functionally useful for holding dipped food and also aesthetically pleasing.

Owner:TACO BELL IP HOLDER LLC

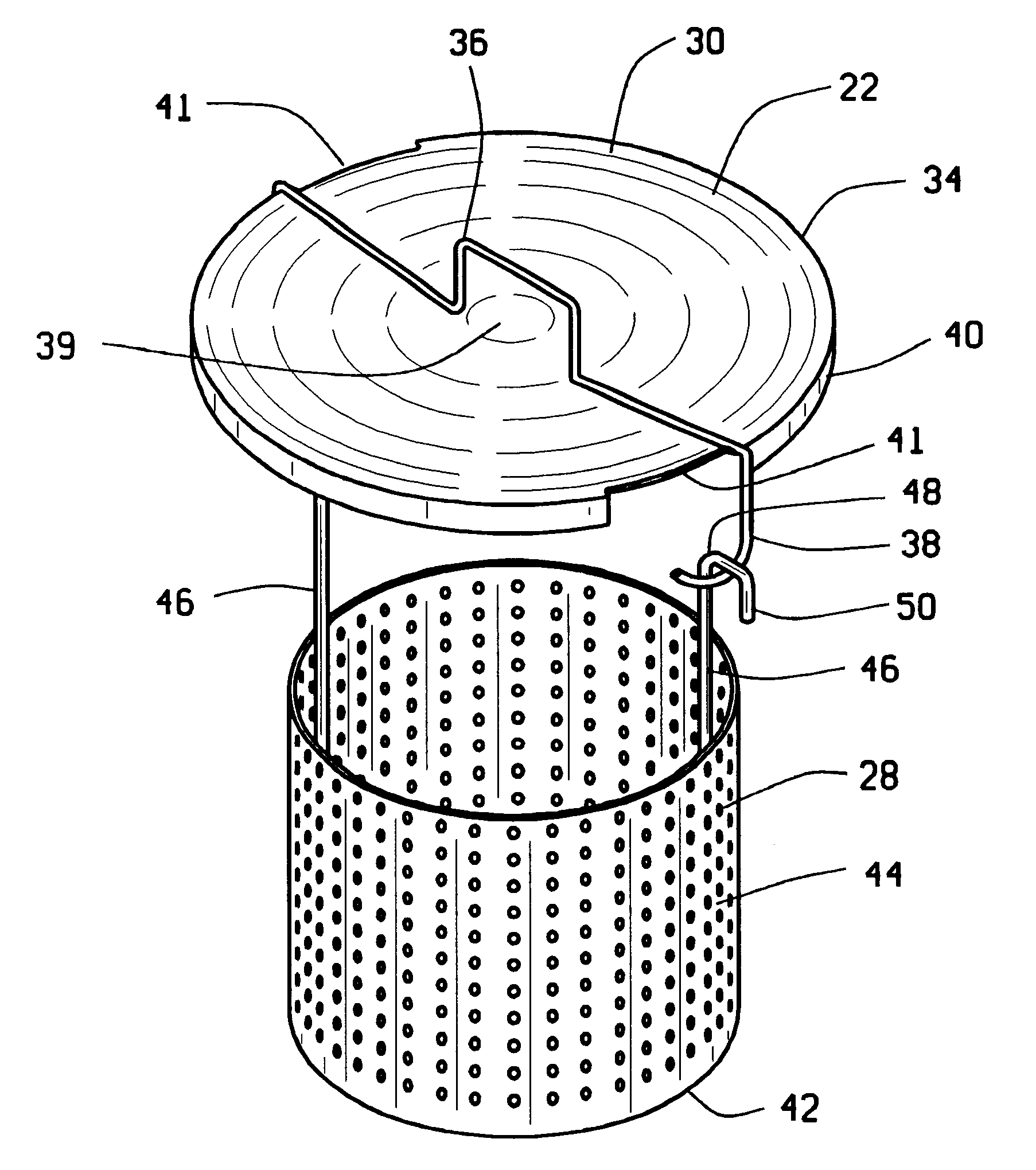

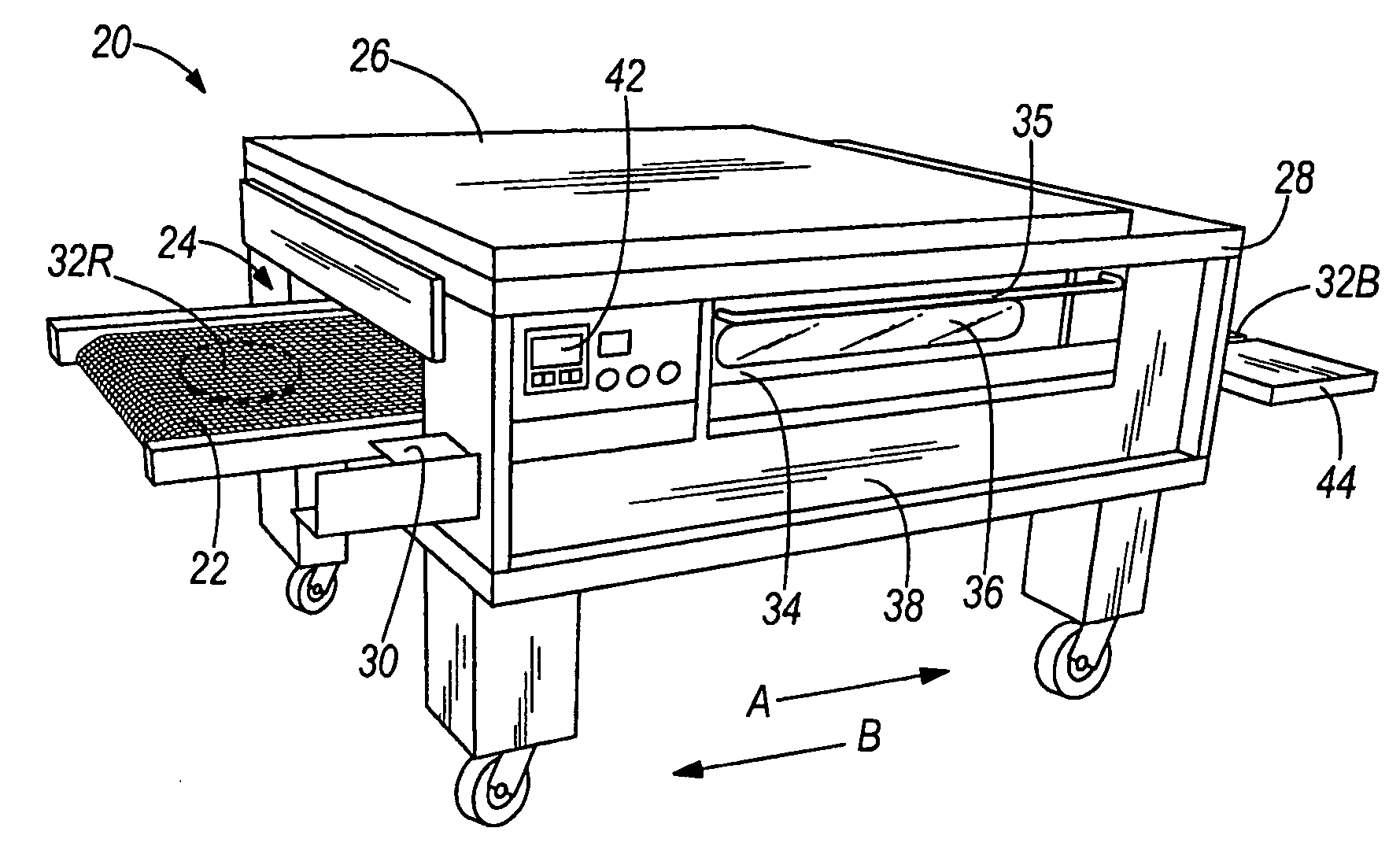

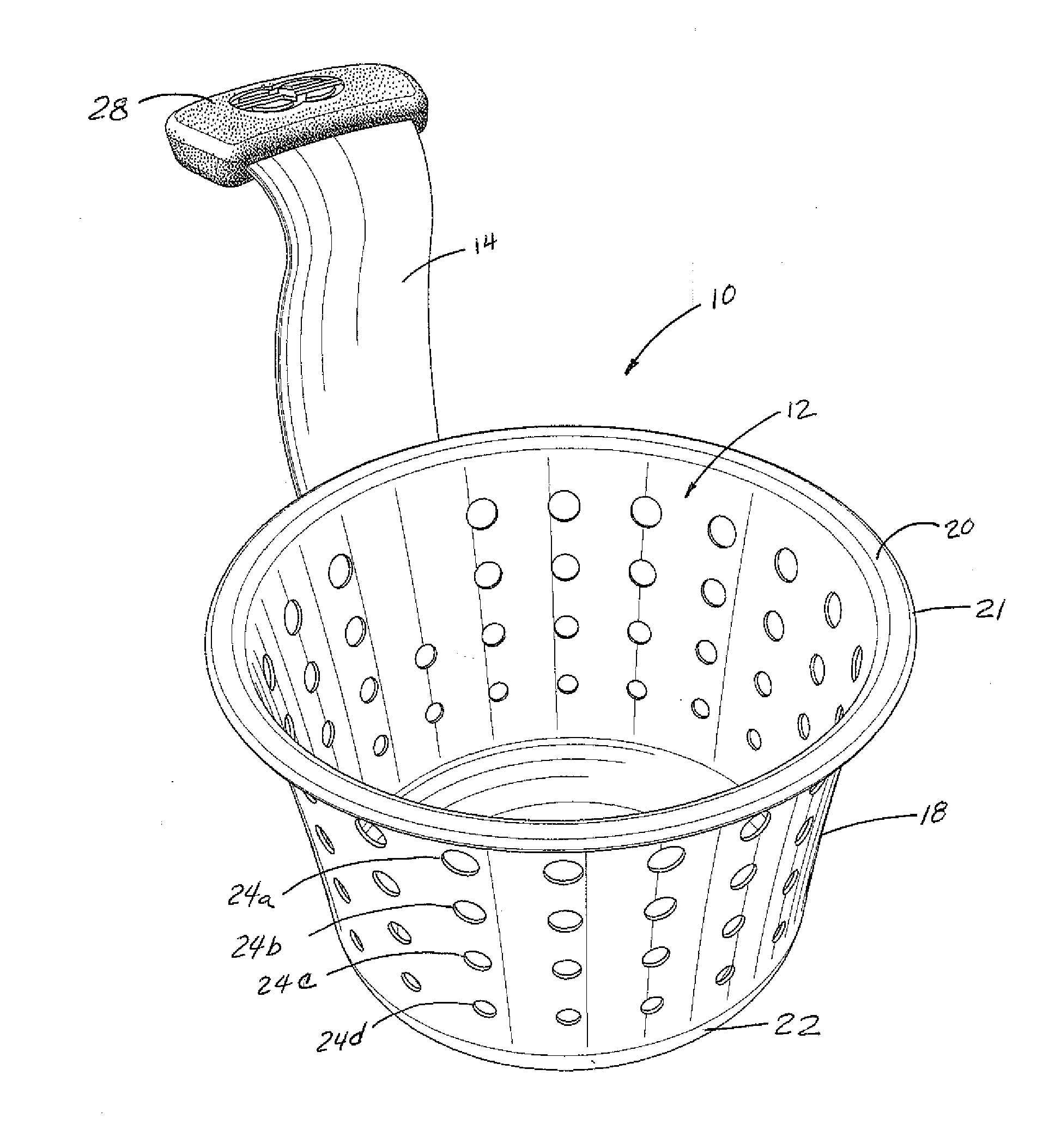

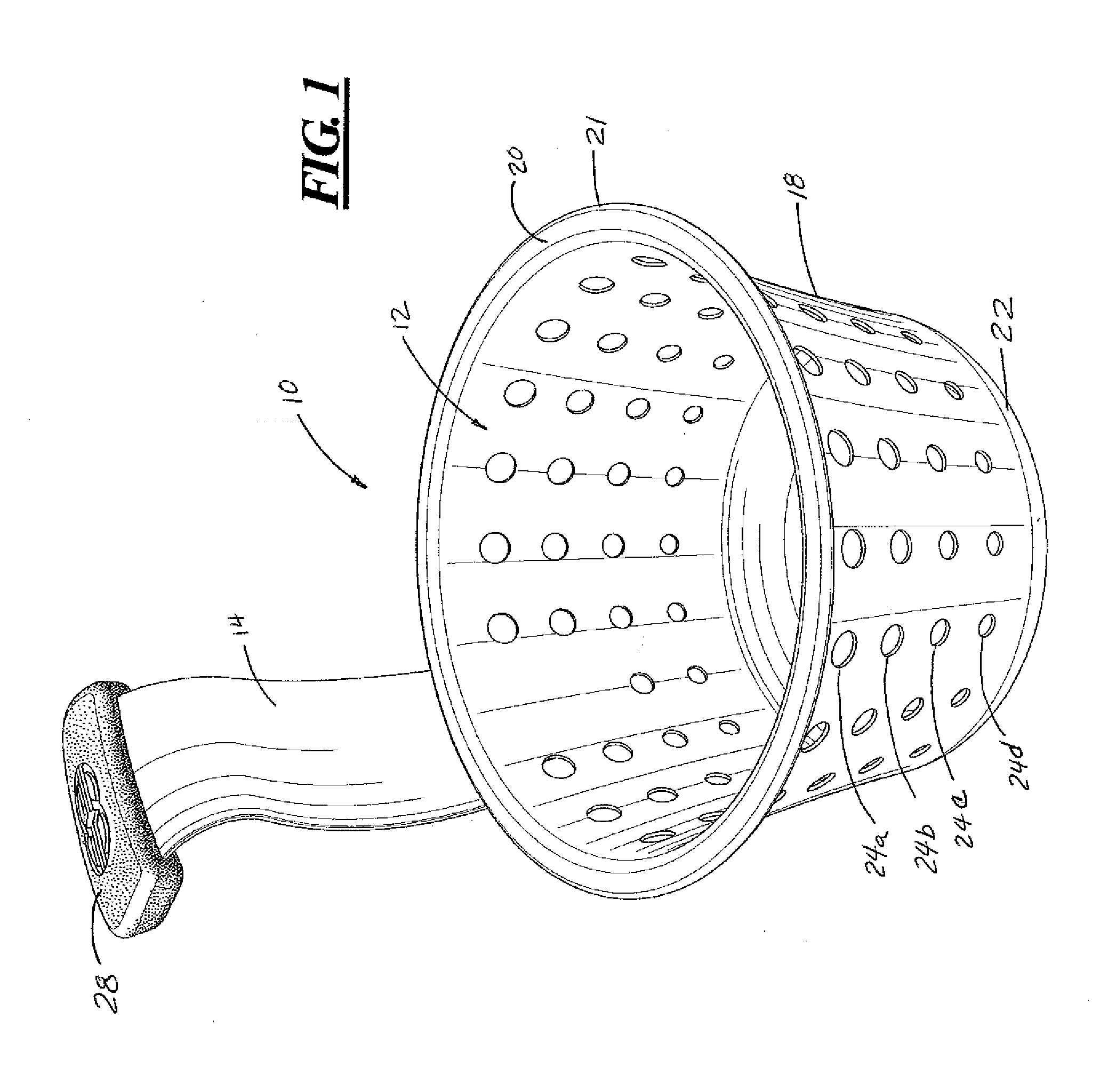

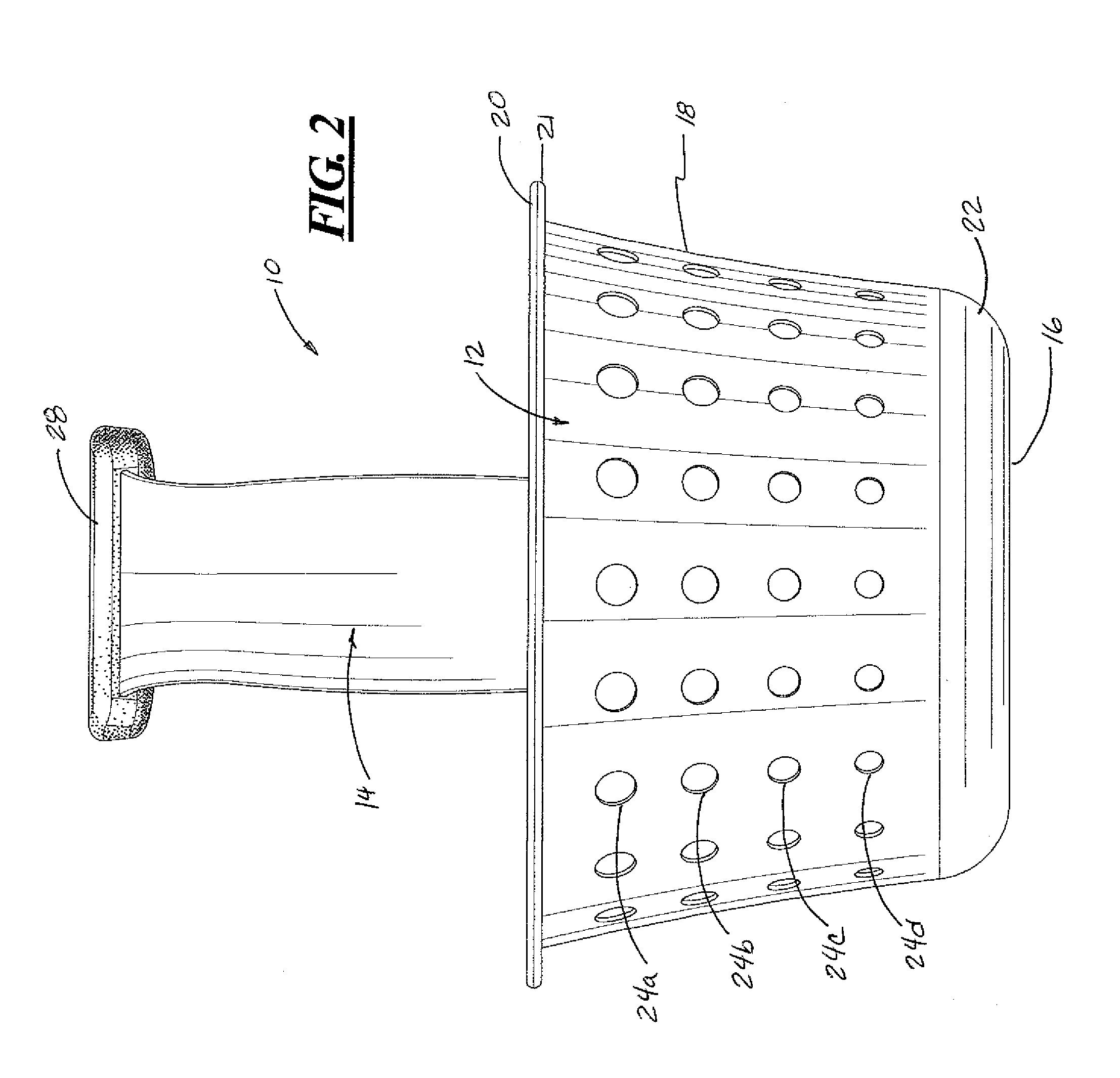

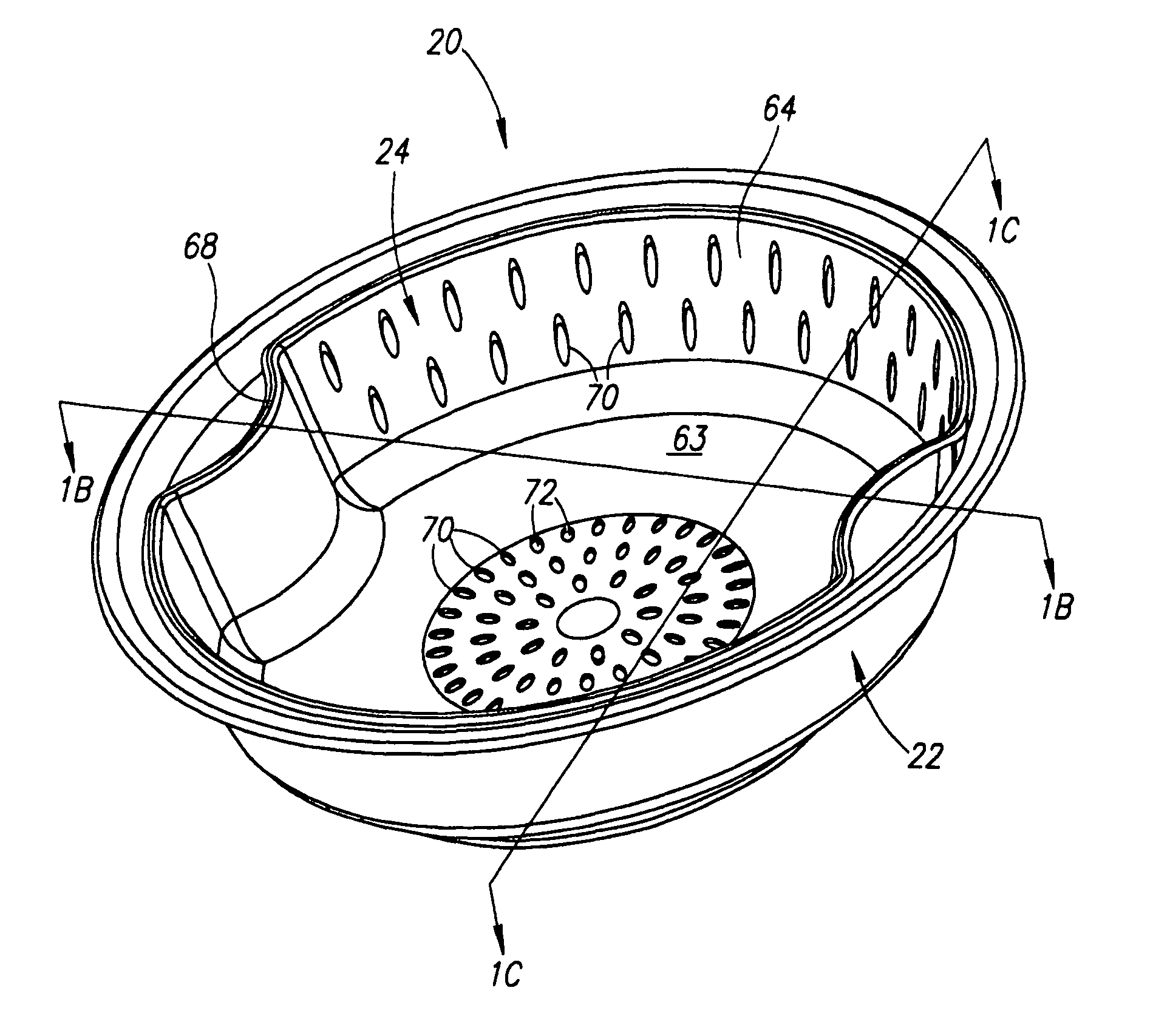

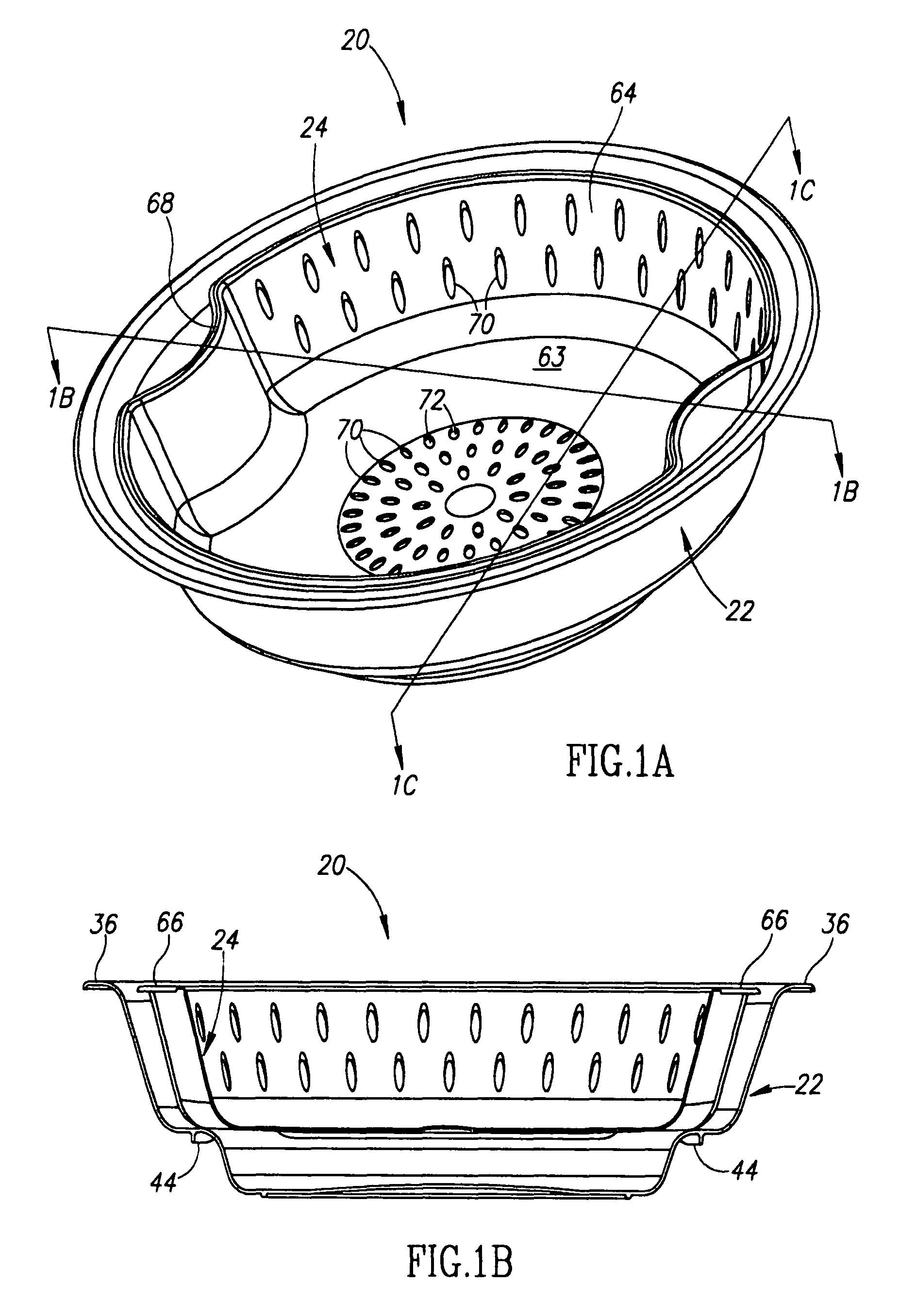

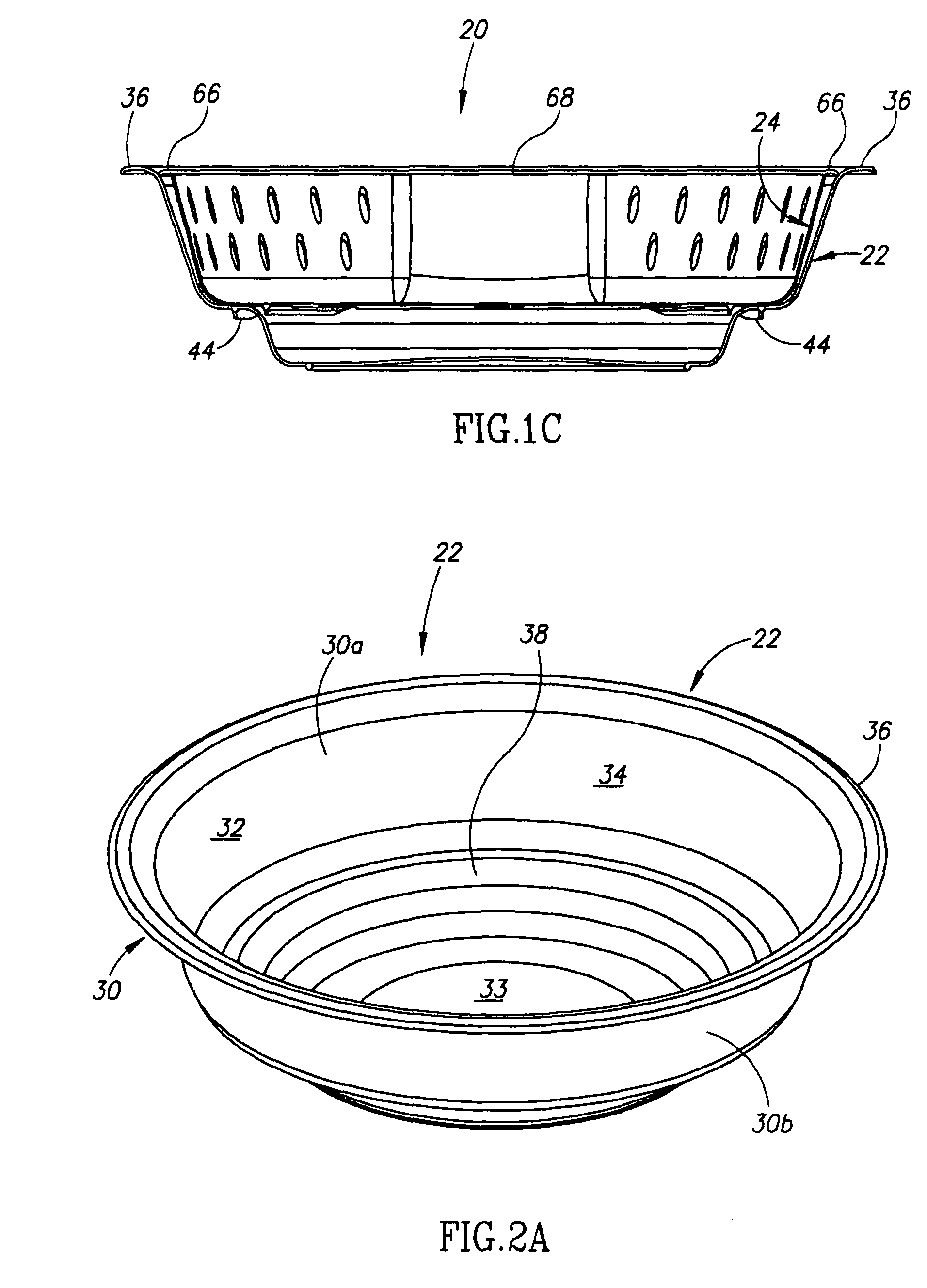

Egg Poacher and Method for Poaching

An egg poacher includes a cup having a bottom, a side wall extending upward from a perimeter of the bottom, an open top at a top edge of the side wall, and a plurality of perforations formed through the side wall but not through the bottom. The egg poacher may have a handle connected to a part of the side wall. The handle may be curved. A method of poaching an egg includes the steps of selecting an egg poacher, placing the egg poacher in a pan of simmering water, cracking open and placing a raw egg contents in the cup, cooking the egg contents, lifting and draining water from the cup, and releasing the cooked egg.

Owner:CALPHALON

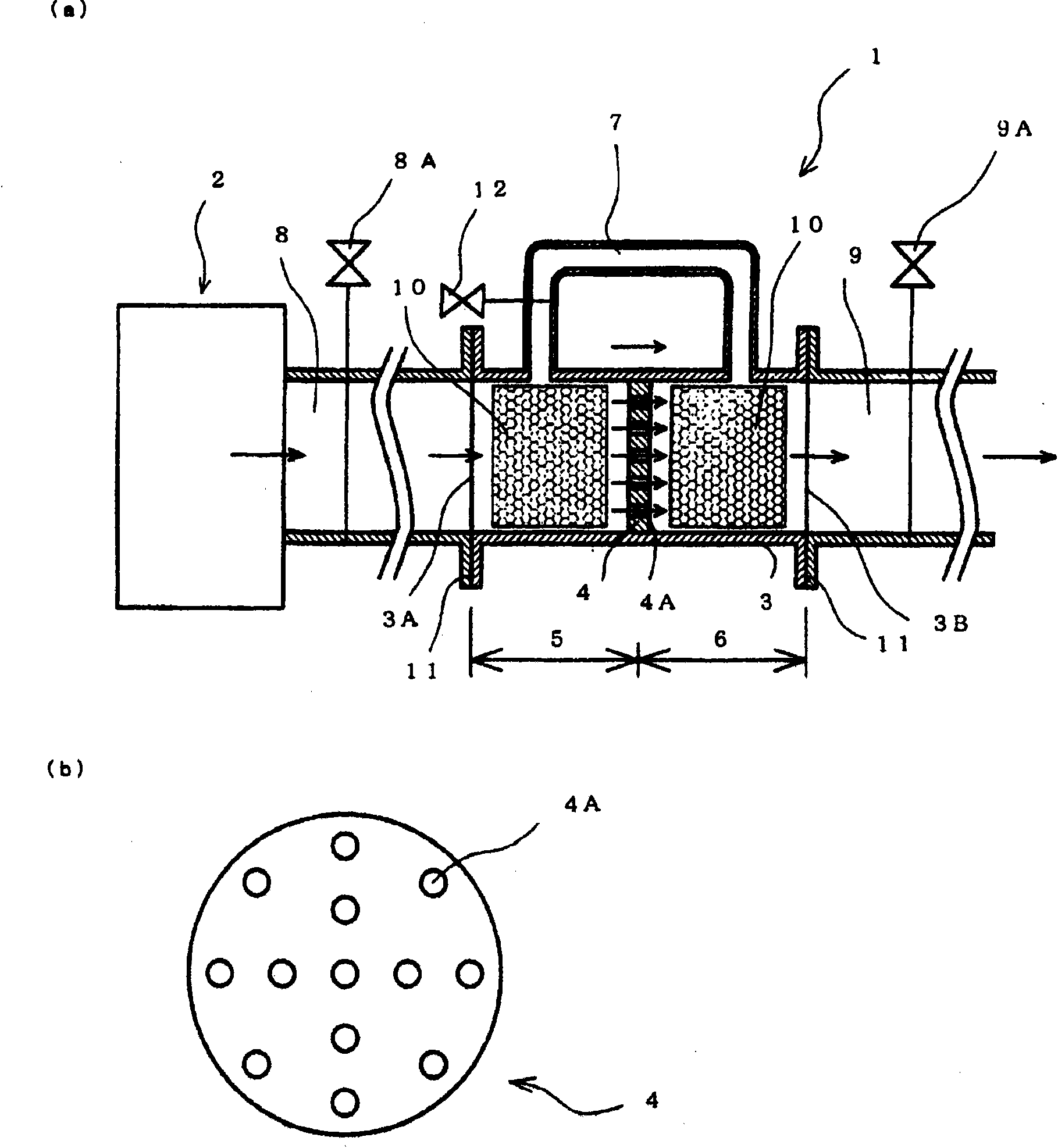

Overheated compressed hot air stream producing method and device, object processed by overheated compressed hot air stream, processing method, and processing apparatus

InactiveCN101910748ADry evenlyEven drying effectLiquid fuel feeder/distributionDrying solid materials with heatWater qualityEngineering

A method and device for producing a minus-ion air similar to a heated compressed hot air stream, electromagnetic waves in the far-infrared and submilimeter region (hereinafter referred to as ''terahertz wave'') by regulating the discharge pressure and the discharge temperature. The device is excellent in versatility, small in size, and low in cost. An object processed by using the method and device, a processing method, and a processing apparatus are also provided. Air is sent from a blower or an air compressor (2) through an air pipe (8) to a heated compressed air regulator (vessel (3)). The air sealed in the heated compressed airregulator (1) regulated under a predetermined discharge pressure (for example, 30 kPa to 150 kPa) and at a temperature (40 DEG C to 250 DEG C) is passed through a through hole (4A) of a circular plate (4) to produce a heated compressed air. In the produced hot air stream, a resonance electromagnetic wave resonating with the natural frequency of the water molecule is generated by a terahertz wave and a generated thermal shock wave, thereby the hydrogen bond of the water molecules in the air is cut, and electrons are released from hydrogen atoms, thus also producing a minus-ion air stream. A processed object, a processing method, and a processing apparatus are so constituted that the produced hot air stream is used for drying, production of a functional water by exposing water to the hot air stream, production of an aqueous fuel, beauty / health appliances, air / water quality improvement devices, combustion efficiency enhancement devices for internal combustion engines, and so forth.

Owner:SUZUYAELECTRIC SERVICE

Cooking method and apparatus

ActiveUS8850964B2Not degradeNot discolorContainer filling methodsMeat processingFood ComponentEngineering

Owner:CONAGRA FOODS RDM INC

A kind of household boiled egg peeling machine

InactiveCN103494538BChange the defect of a single functionEasy to useEgg-cookersEggshellElectric heating

The invention relates to a domestic egg stewing and peeling machine and belongs to the technical field of small domestic appliances. The domestic egg stewing and peeling machine is characterized by comprising a shell crushing device (4) which is a container and in a cylinder shape. The bottom face of the shell crushing device is provided with a middle shaft hole which is connected with a power device. The power device drives the shell crushing device to rotate. A pair of peeling shafts (9) is arranged in the shell crushing device (4). Peeling teeth are arranged on the peeling shafts (9). The pair of peeling shafts (9) rotates in the same direction or opposite directions. A water containing device (5) is arranged below the shell crushing device (4). The lower portion of the water containing device (5) adheres to an electric heating plate (7). The functions of stewing eggs, crushing eggshells and removing the eggshells are integrated in the domestic egg stewing and peeling machine, the defect that an existing domestic egg stewing device is single in function is overcome and a gap in the field of domestic egg stewing and peeling machines is filled.

Owner:SHANGHAI UNIV OF ENG SCI

Egg boiling machine with automatic shelling function

InactiveCN104873101AEasy dischargeSave manpower and material resourcesEgg-cookersGear wheelMaterial resources

The invention relates to the field of food mechanism, in particular to an egg boiling machine with an automatic shelling function. The egg boiling machine with the automatic shelling function comprises a pedestal, a bracket, a tray and an upper cover, the tray is spherical crown-shaped, the bottom of the tray is separable, and the bottom is connected with a handle; a heating pipe and a draw plate are arranged in the tray, the draw plate runs through two ends of the tray, the draw plate is connected with a pull handle, an egg storage platform is arranged in the bracket, the egg storage platform is connected with a feed roller, the feed roller is connected with a shelling mechanism, the shelling mechanism comprises a plurality of shell crushing rubber rods and a plurality of roller posts, gears are arranged at the head faces of the roller posts, each egg shelling passage comprises at least one group of shell crushing rubber rods, and each group comprises two shell crushing rubber rods correspondingly arranged at two sides of the transmission direction of the corresponding egg shelling passage. The egg boiling machine with the automatic shelling function is capable of automatically shelling after boiling the egg thoroughly, a user does not need to take out the egg to shell specially, a lot of manpower and material resources are saved, the time is saved, the cost is lowered, and the production is facilitated.

Owner:高金建

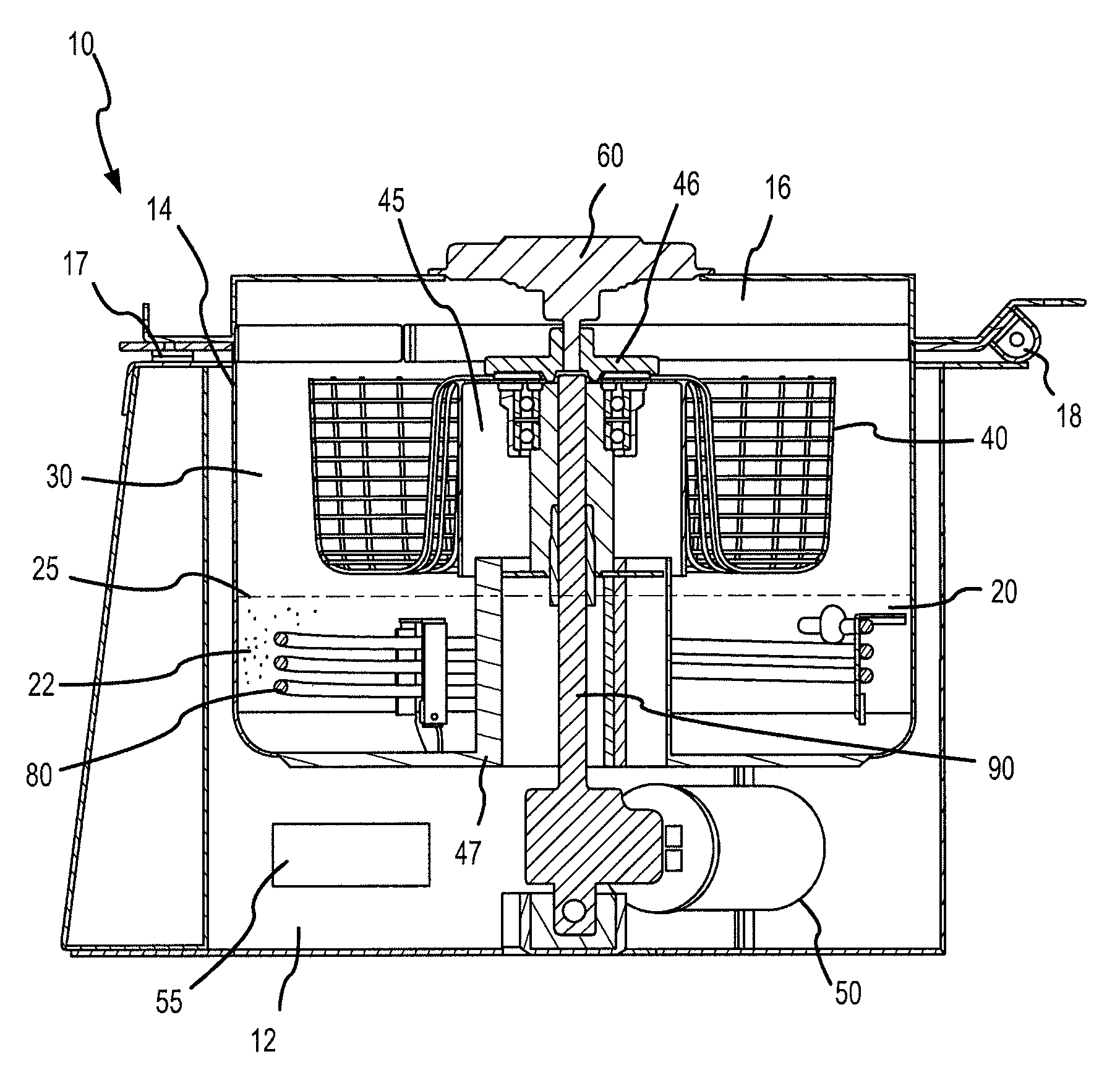

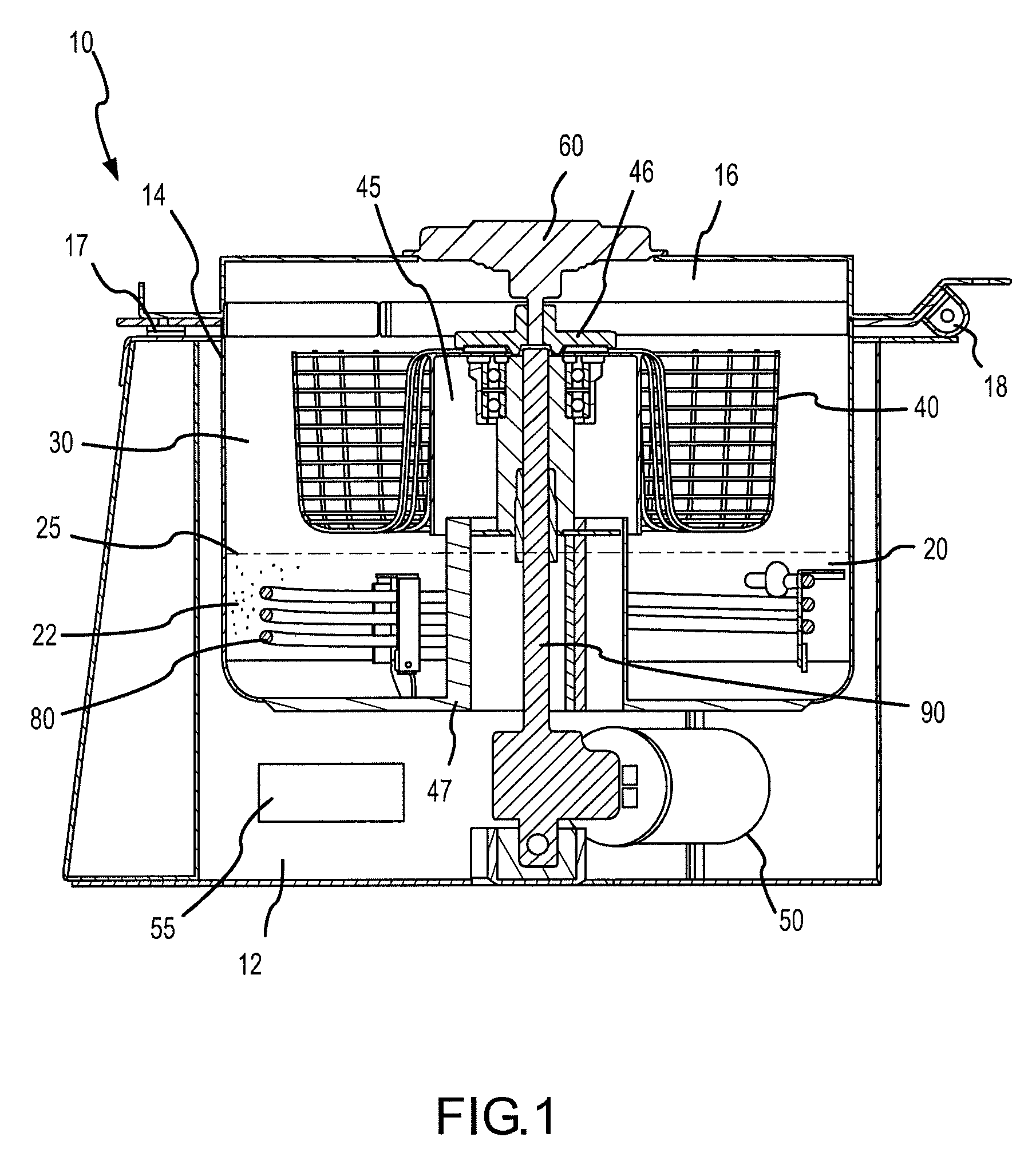

Low oil volume frying device and method

ActiveUS20080213448A1Quality improvementOil consumption is minimizedEgg-cookersBeverage vesselsUncooked FoodsFiltration

A commercial device and method for cooking food product in cooking oil includes a fry vat containing an amount of cooking oil used to cook discrete batches of uncooked food in discrete batches of a weight relative to the amount of cooking oil in the range of from about 0.0375 to about 0.1, with the total amount of food being cooked at any one time relative to the amount of oil in the fry vat being about 0.1 or less. Cooking the food results in an uptake of oil by the food in an amount of from about 5.5% to about 13% by weight of the uncooked food, and an oil turnover ratio of from about 0.0026 to about 0.007 per discrete batch. Replacement oil is periodically added, and a sufficient number of batches are cooked over 60 hours of operation to achieve at least one vat oil turnover.Automated intermittent filtration is employed in the device and method that can include monitoring the elapsed time since the last filtration of the cooking oil, monitoring the amount of food by number of batches or by weight of food product cooked in the oil since the last filtration, and filtering the oil when a predetermined threshold value is reached based on the elapsed time since the last filtration and the amount of food cooked.An automated device and method for maintaining a level of oil in a fry vat having a volume includes sensing the level of oil in the vat. When the sensed level of oil in the vat is less than or equal to a first predetermined level, replacement oil is automatically added to the fry vat, typically when at ambient temperature at a low average flow rate in the range of about 0.008 to about 0.08 gallons per minute per gallon of the oil present in the vat at the first predetermined level. The low average flow rate of added oil avoids a temperature drop of more than 15° F., 10° F. or 5° F. in the bulk oil present in the fry vat as result of adding the oil as desired.

Owner:RESTAURANT TECH

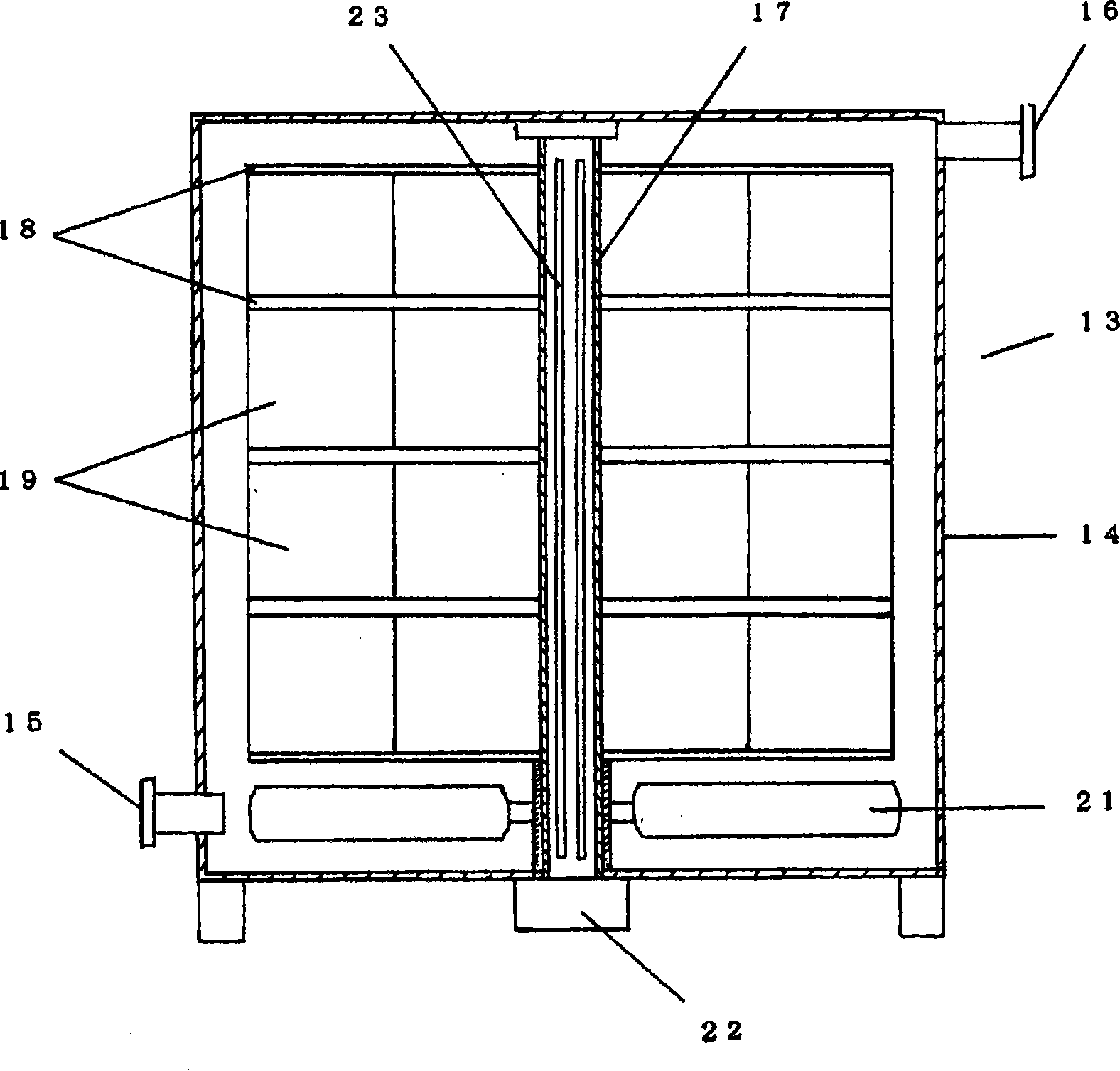

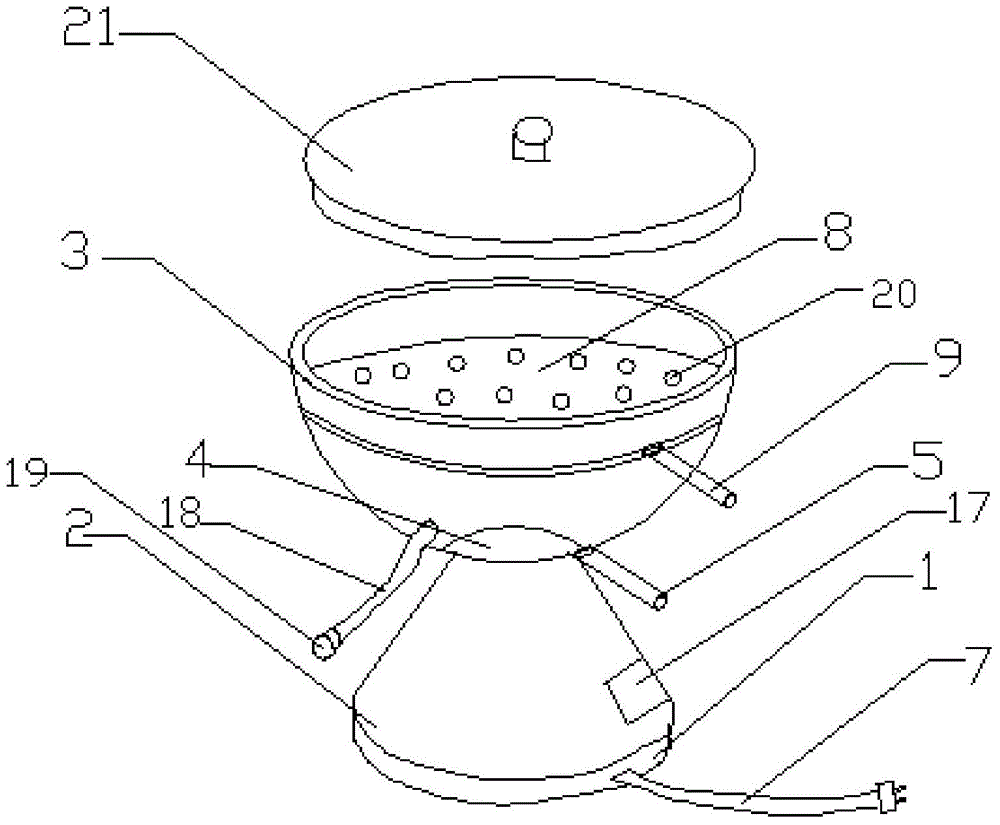

Egg boiling equipment

InactiveCN101390708AImprove efficiencyReduce the temperatureEgg-cookersWater storage tankDistilled water

The invention discloses an egg braiser, comprising a base. A tray base is fixed at the upper part of the base, and a concave liquid container tray is arranged at the upper edge of the tray base. An egg separator layer is buckled at the upper edge of the liquid container tray and at least three egg holder holes are arranged on the egg separator layer. A cover is arranged on the egg separator layer. At least one control switch is arranged at one side face of the tray base, a heater is arranged inside the tray base, and the heater is arranged at the bottom of the liquid container tray. The heater is connected with the control switch, and the egg separator layer is directly spliced above the liquid container tray. The liquid container tray generates steam after being heated and the steam directly acts on the eggs which are put on the egg separator layer and ensures that the temperature of the eggs rises quickly, thus improving the using efficiency of the egg braiser. A water storage tank is added at the internal circumference of the egg separator layer and can prevent distilled water after being cooled on the cover from returning to be mixed with the boiling water of the liquid container tray, thus reducing the temperature of the original boiling water in the liquid container tray, namely improving the efficiency of the effective steam.

Owner:吴金潮

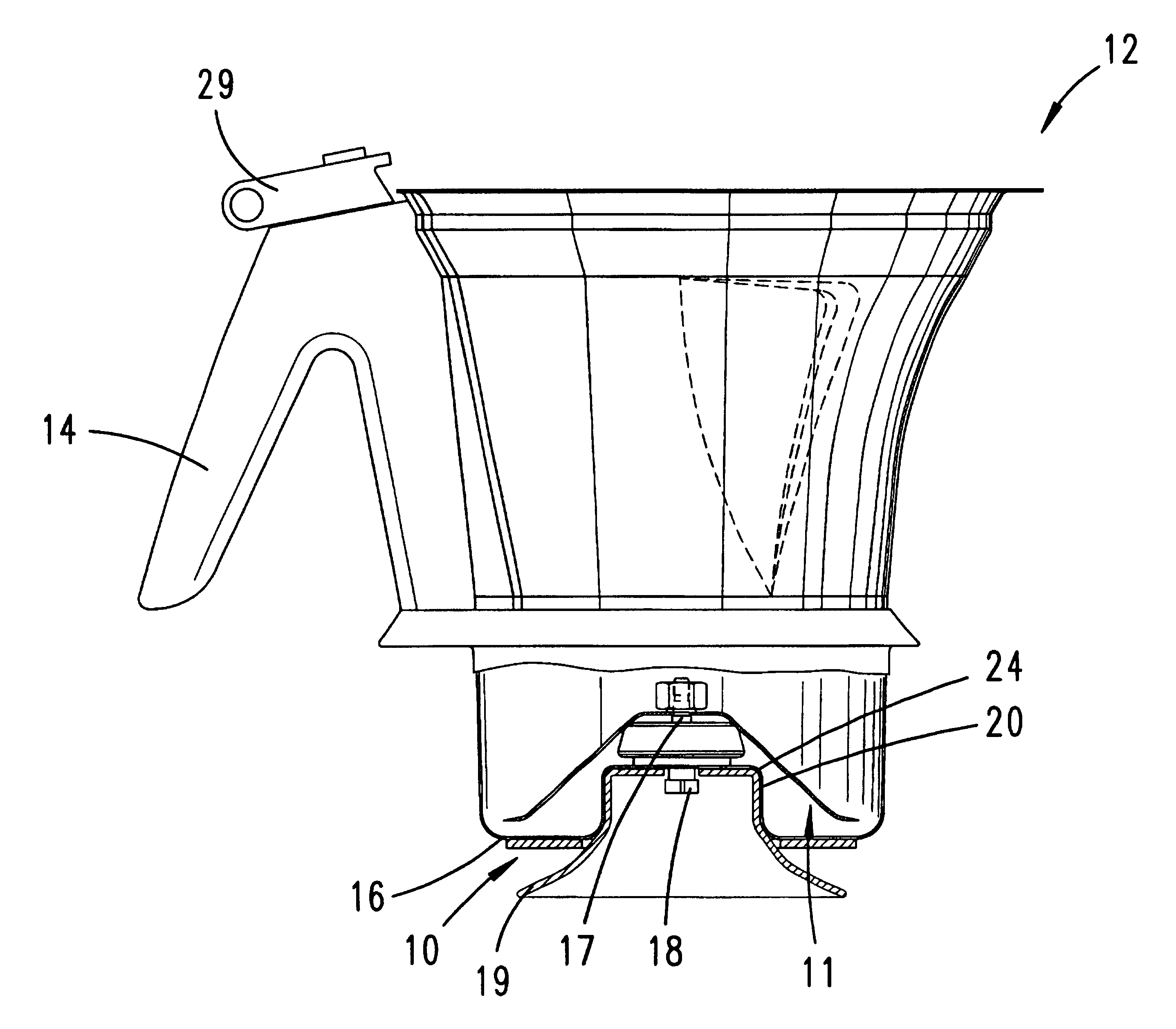

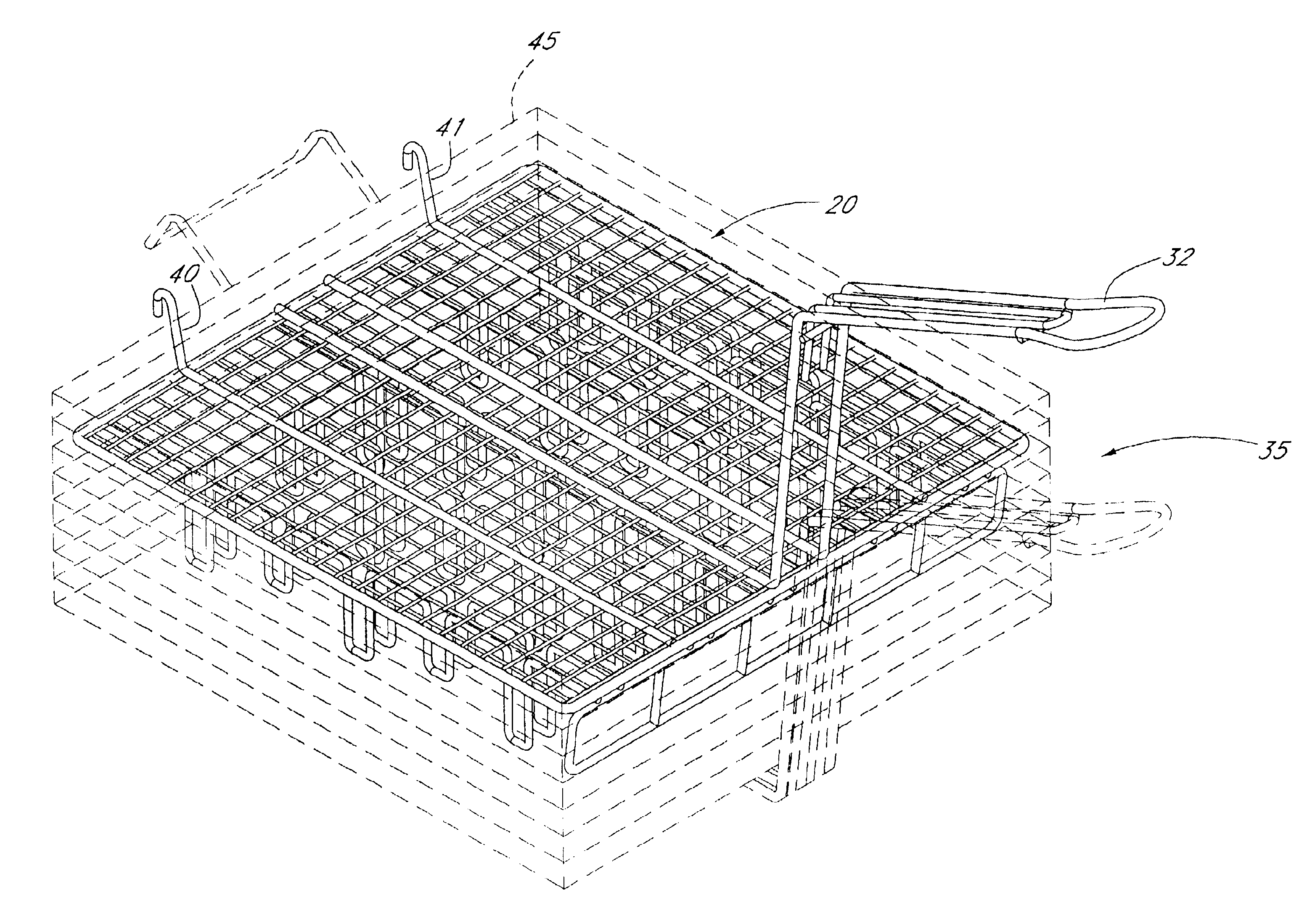

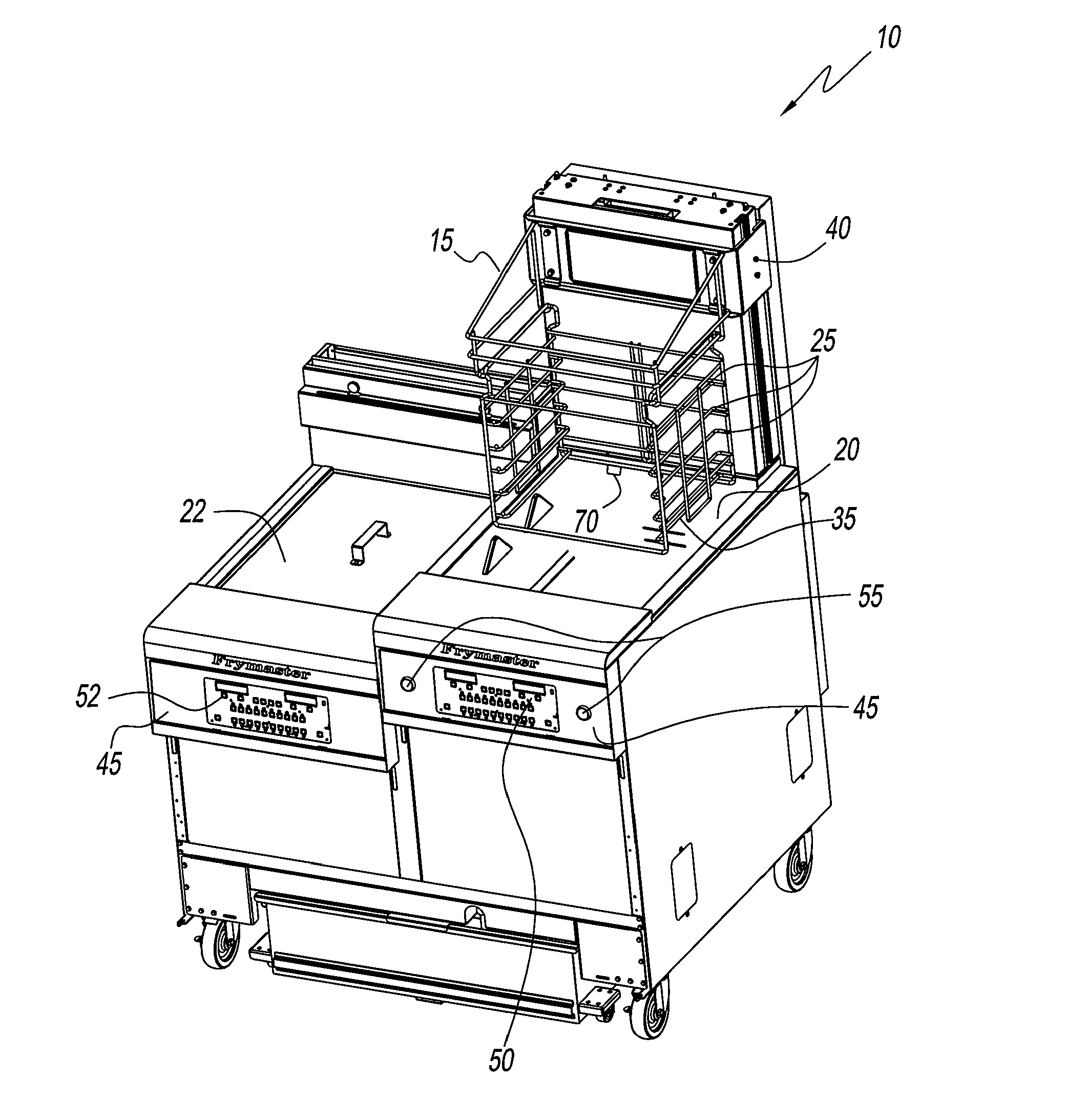

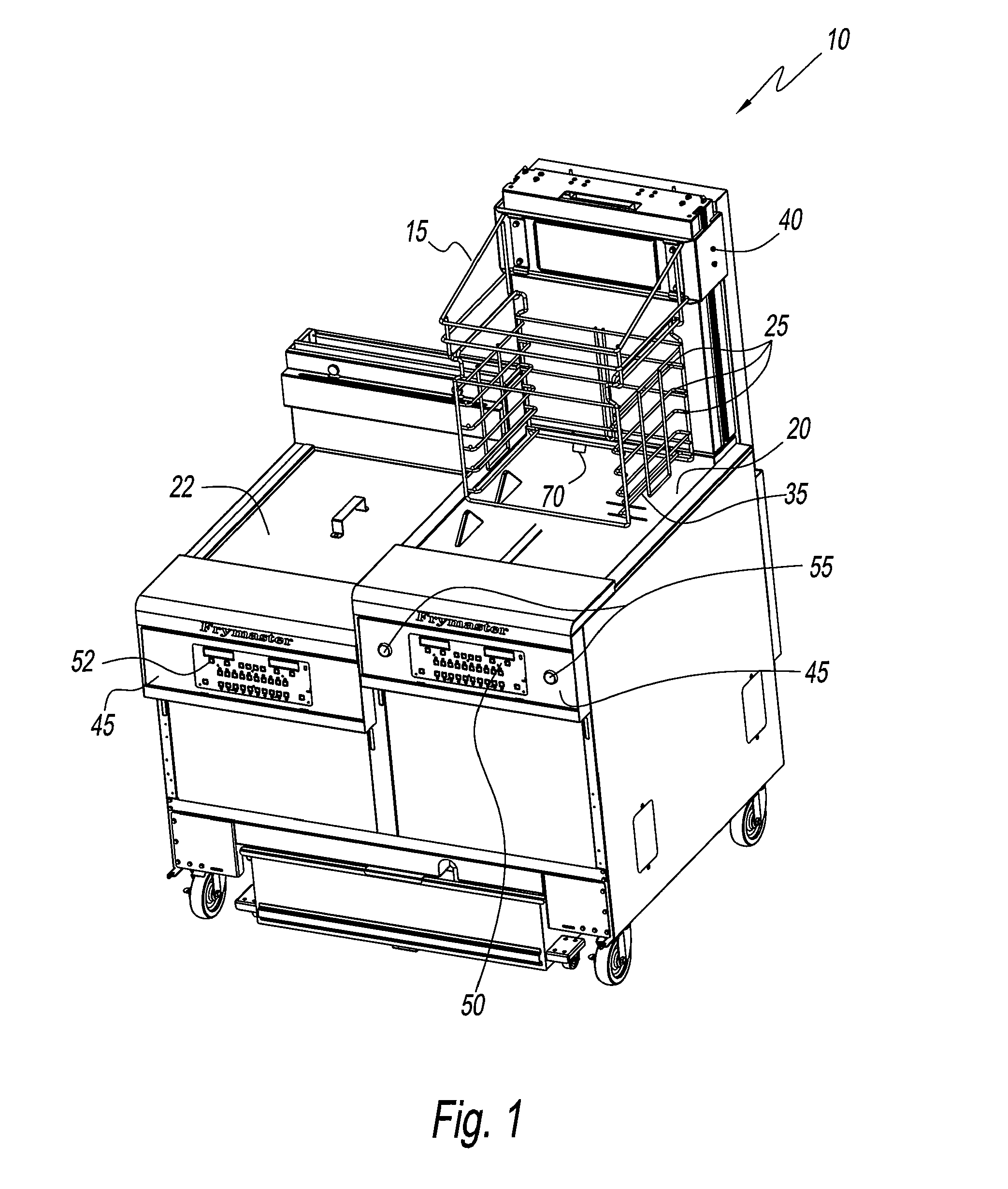

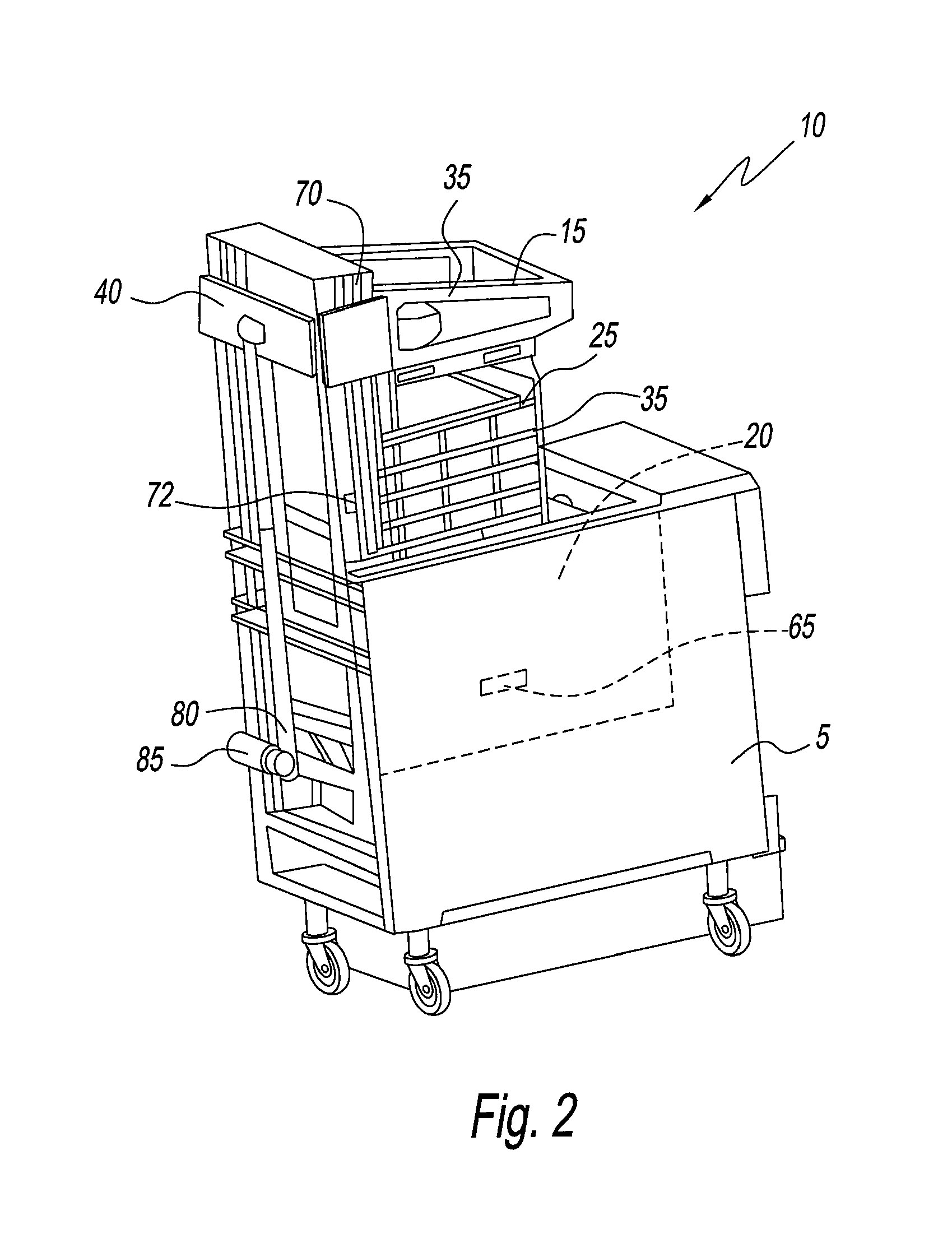

Racking system for deep fryer

A system for a deep fryer having a frypot containing a cooking Medium including a holder that carries a food product to be cooked in the cooking medium and a motor operatively connected to the holder that lowers the holder into the cooking medium. The system further includes a sensor that detects contact of the holder when the holder is immersed in the cooking medium; and a controller including a timer that commences cooking the food product when the sensor contacts holder.

Owner:THE FRYMASTER CORP LLC

Egg making device

An egg making assembly, comprising: a refrigerating container holding chilled eggs at a predetermined temperature; a cooking container; a portioning mechanism structured and arranged to supply a predetermined measured amount of egg from the refrigerating container to the cooking container; a controller coupled to the portioning mechanism to selectively activate the portioning mechanism; a steam supplying device contacting the egg in the cooking container to cook the egg; and a dispensing mechanism coupled to the cooking container to move the cooking container between a cooking position and an dispensing position to permit a consumer to access the cooked egg, and a method of making eggs, comprising: positioning eggs within a chilled container at a predetermined temperature; selectively activating a controller to supply a predetermined portion of egg to a cooking container; cooking the predetermined portion of egg with steam; moving the cooking container between a cooking position and an dispensing position to permit a consumer to access the cooked egg.

Owner:DAVID J B WALLIS

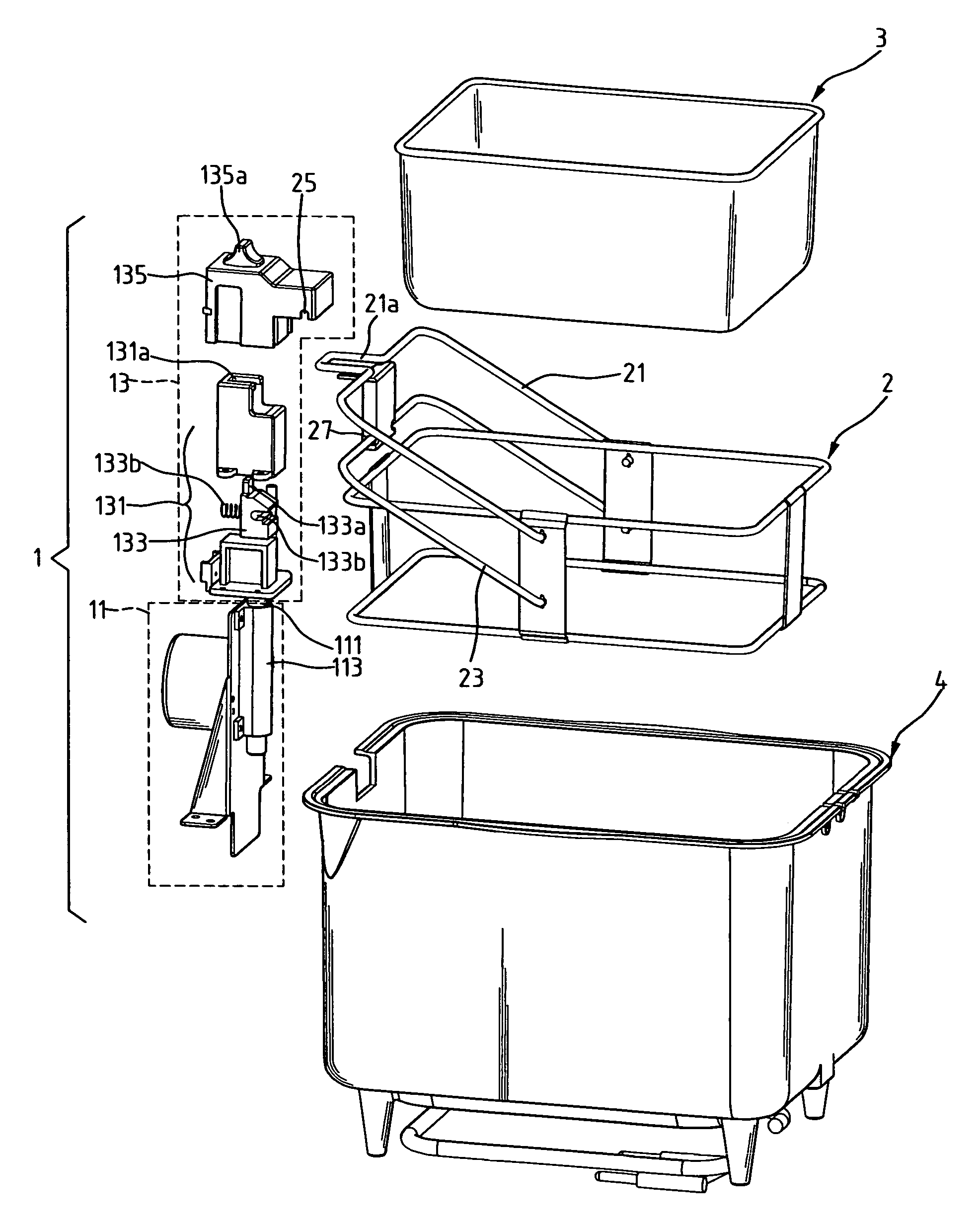

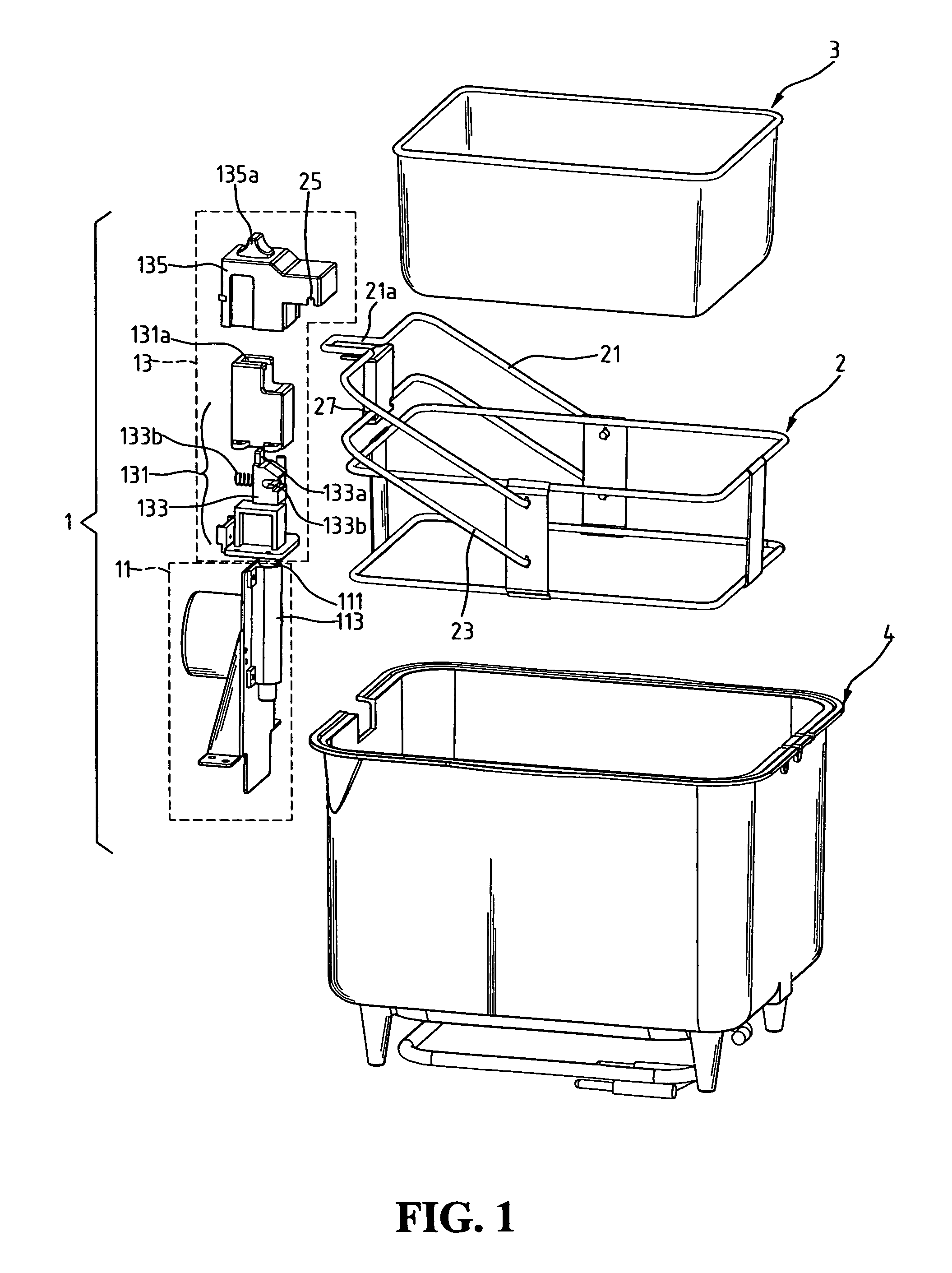

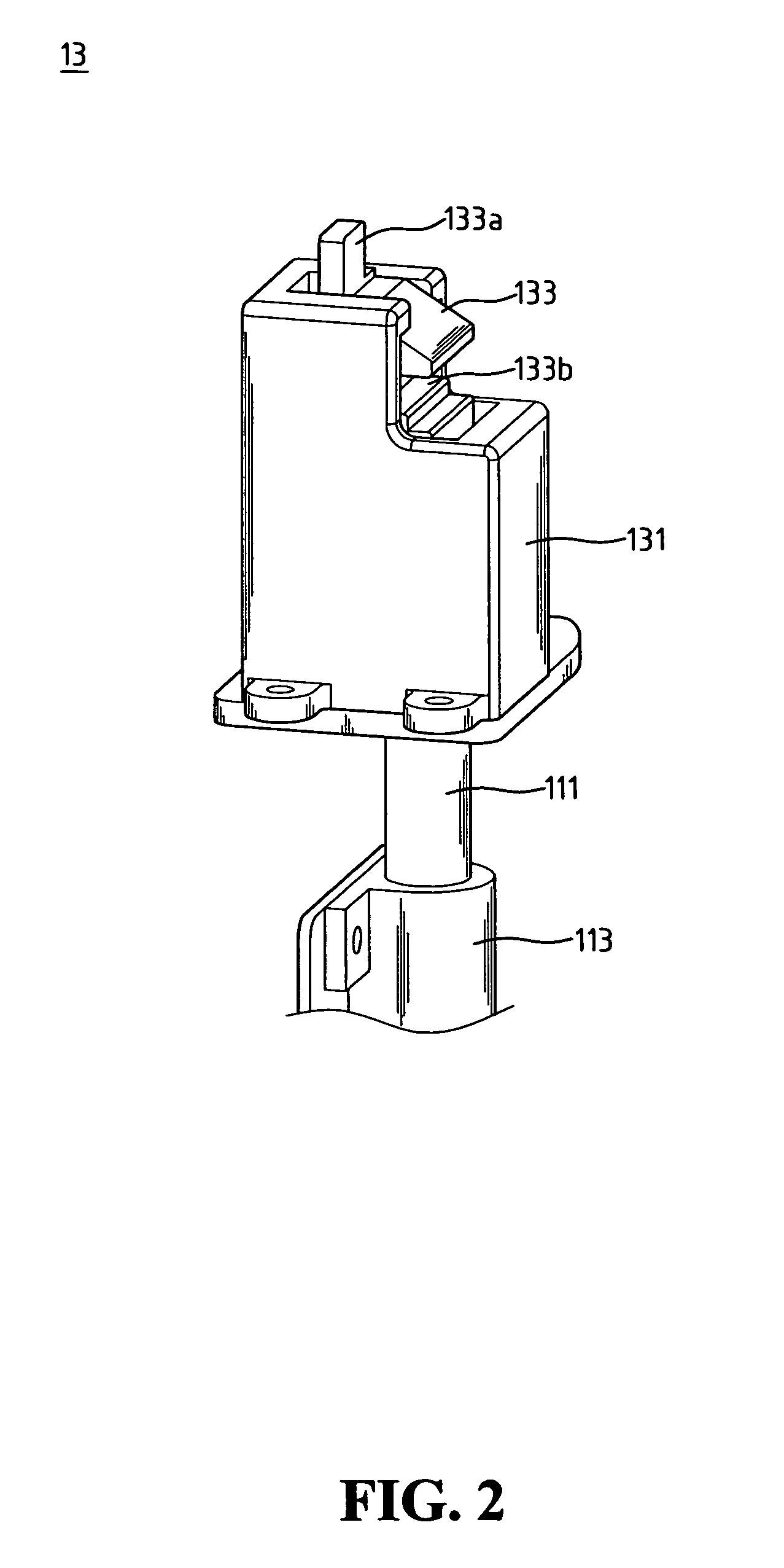

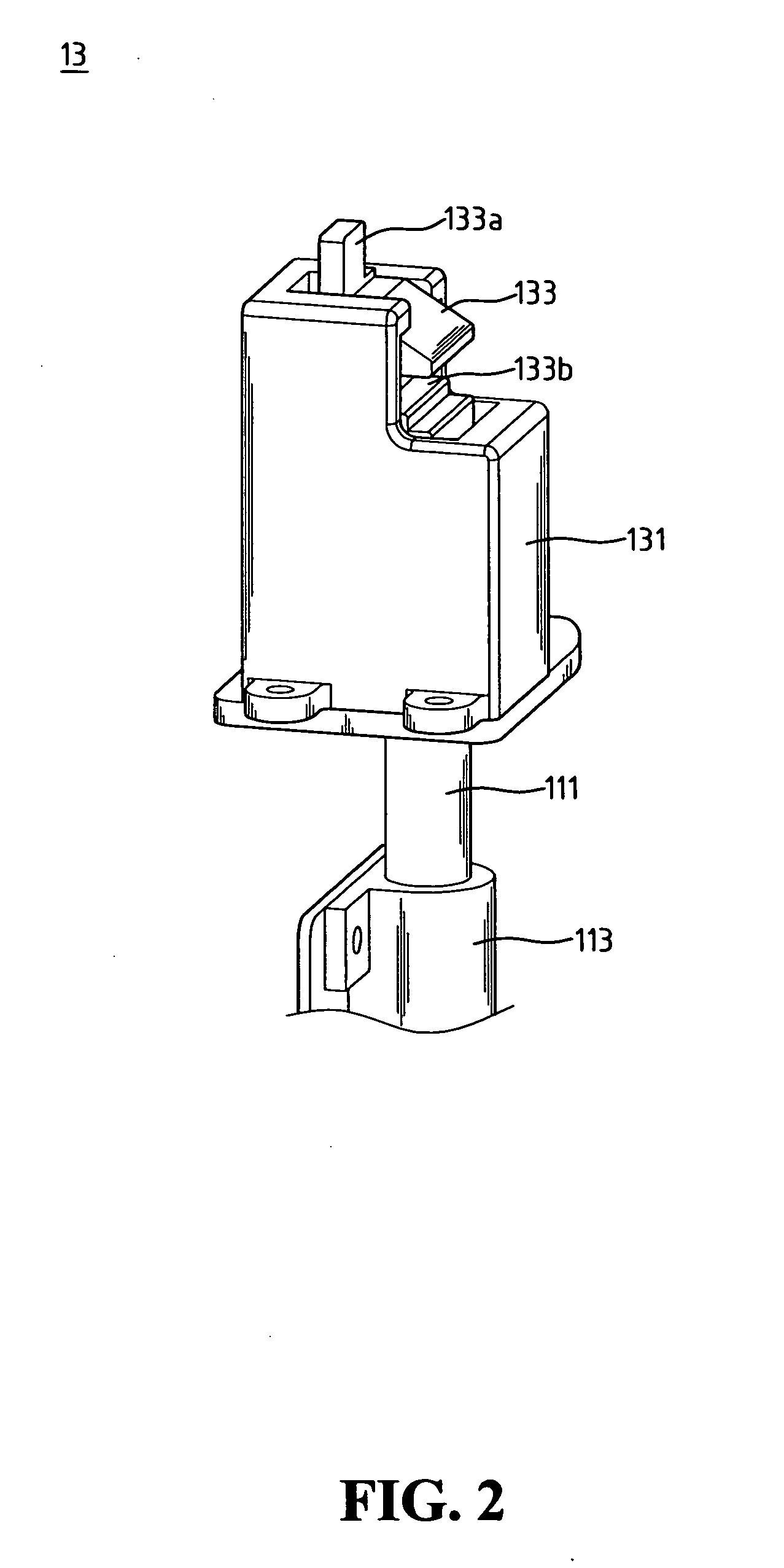

Control mechanism for deep fryer to control elevation of basket received in the deep fryer

InactiveUS7036425B2Reduce riskImprove motion stabilityEgg-cookersBeverage vesselsEngineeringMechanical engineering

A control mechanism includes a driving device and a driven device coupling a bracket that is movably arranged in the deep fryer to the driving device. The driving device drives the basket upward / downward relative to the deep fryer. The driven device has a seat, a guiding slot, a limit having a guiding shaft extending upward to correspond to and be received in the guiding slot and an enclosure enclosing the seat and fixed to a portion of the driving device. A recoil spring is arranged at a rear side of the limit and the pushbutton. The bracket includes a first U-shaped arm and a second U-shaped arm pivotally received in a first pivot cutout and a second pivot cutout in the enclosure respectively.

Owner:LYU JAN

Domestic egg stewing and peeling machine

The invention relates to a domestic egg stewing and peeling machine and belongs to the technical field of small domestic appliances. The domestic egg stewing and peeling machine is characterized by comprising a shell crushing device (4) which is a container and in a cylinder shape. The bottom face of the shell crushing device is provided with a middle shaft hole which is connected with a power device. The power device drives the shell crushing device to rotate. A pair of peeling shafts (9) is arranged in the shell crushing device (4). Peeling teeth are arranged on the peeling shafts (9). The pair of peeling shafts (9) rotates in the same direction or opposite directions. A water containing device (5) is arranged below the shell crushing device (4). The lower portion of the water containing device (5) adheres to an electric heating plate (7). The functions of stewing eggs, crushing eggshells and removing the eggshells are integrated in the domestic egg stewing and peeling machine, the defect that an existing domestic egg stewing device is single in function is overcome and a gap in the field of domestic egg stewing and peeling machines is filled.

Owner:SHANGHAI UNIV OF ENG SCI

Control mechanism for deep fryer to control elevation of basket received in the deep fryer

InactiveUS20050268792A1Reduce riskImprove motion stabilityEgg-cookersBeverage vesselsEngineeringMechanical engineering

A control mechanism includes a driving device and a driven device coupling a bracket that is movably arranged in the deep fryer to the driving device. The driving device drives the basket upward / downward relative to the deep fryer. The driven device has a seat, a guiding slot, a limit having a guiding shaft extending upward to correspond to and be received in the guiding slot and an enclosure enclosing the seat and fixed to a portion of the driving device. A recoil spring is arranged at a rear side of the limit and the pushbutton. The bracket includes a first U-shaped arm and a second U-shaped arm pivotally received in a first pivot cutout and a second pivot cutout in the enclosure respectively.

Owner:LYU JAN

Cooking device

The present invention relates to a food fryer. The food frying apparatus generally comprises two sections: a frying section and an oil removal section. The frying section houses and / or heats oil for frying the food, and the oil removal section is operable to reduce the oil content of the food. Exemplary embodiments of the invention comprise a basket well that is configured to be movable between a cooking section and a spinning section. The basket well may be configured to comprise a bearing surface and a basket well gear. The fryer device may further comprise a frame that comprise a bearing configured to interface with the bearing surface. Further, the fryer device may comprise a rotational motor that comprises a spinning gear configured to interface with the basket well gear. The fryer device may also comprise a drawer configured to be slidably removable from the fryer device. The fryer device may also comprise a retrofit fryer device configured to be adaptable to pre-existing fryer devices. In other embodiments, the fryer device may be configured to be operated at least in part by a processor, and the processor may receive instructions from a storage medium. Various aspects of the fryer device are configured to be automatically controlled.

Owner:SPINFRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com