Egg boiling equipment

An egg steamer and egg hole technology, which is applied in the field of egg steamers, can solve the problems of single structure, unfavorable and convenient maintenance, complicated electrical control structure, etc., and achieves the effects of improving steam efficiency, facilitating convenient observation, and improving the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

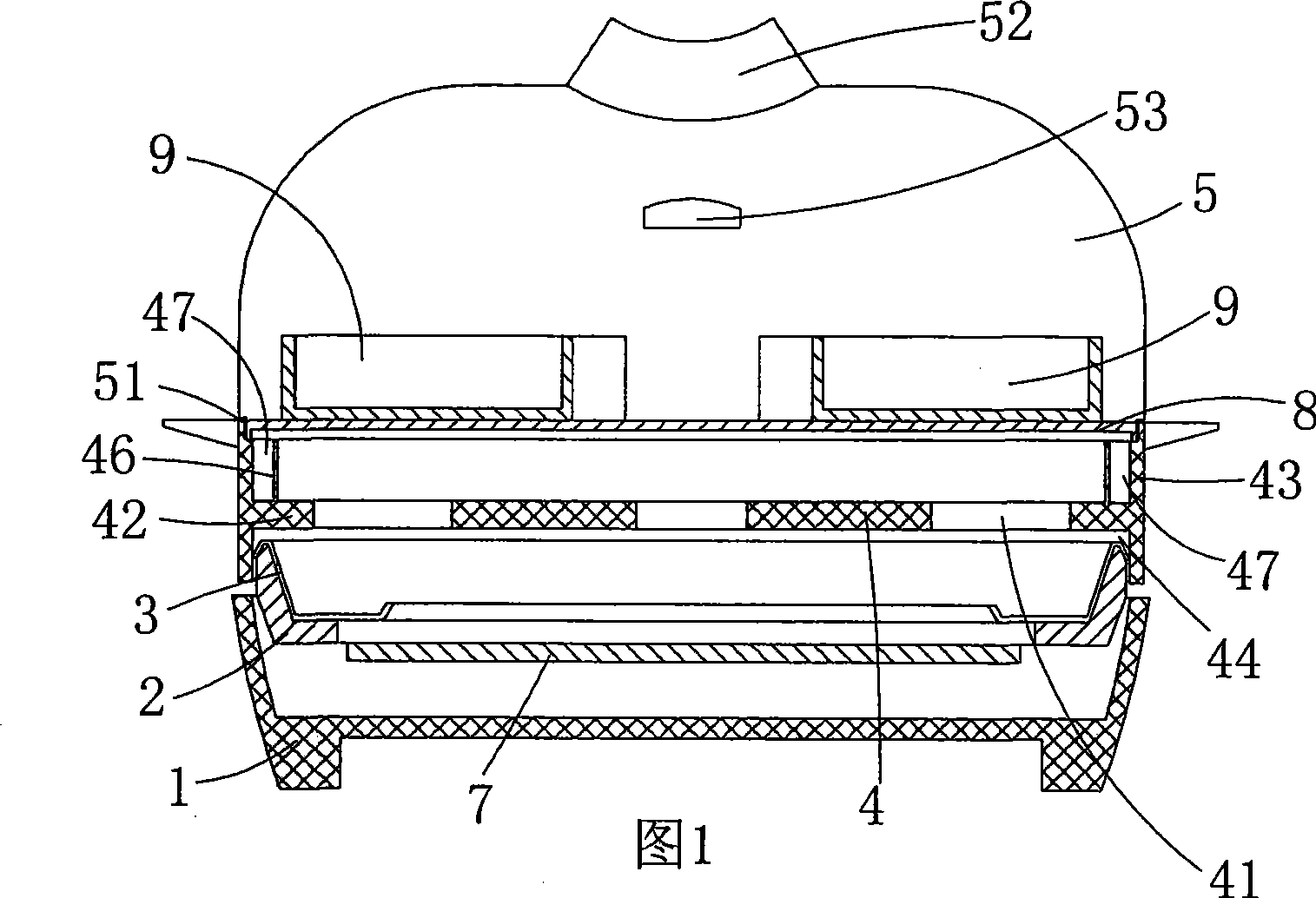

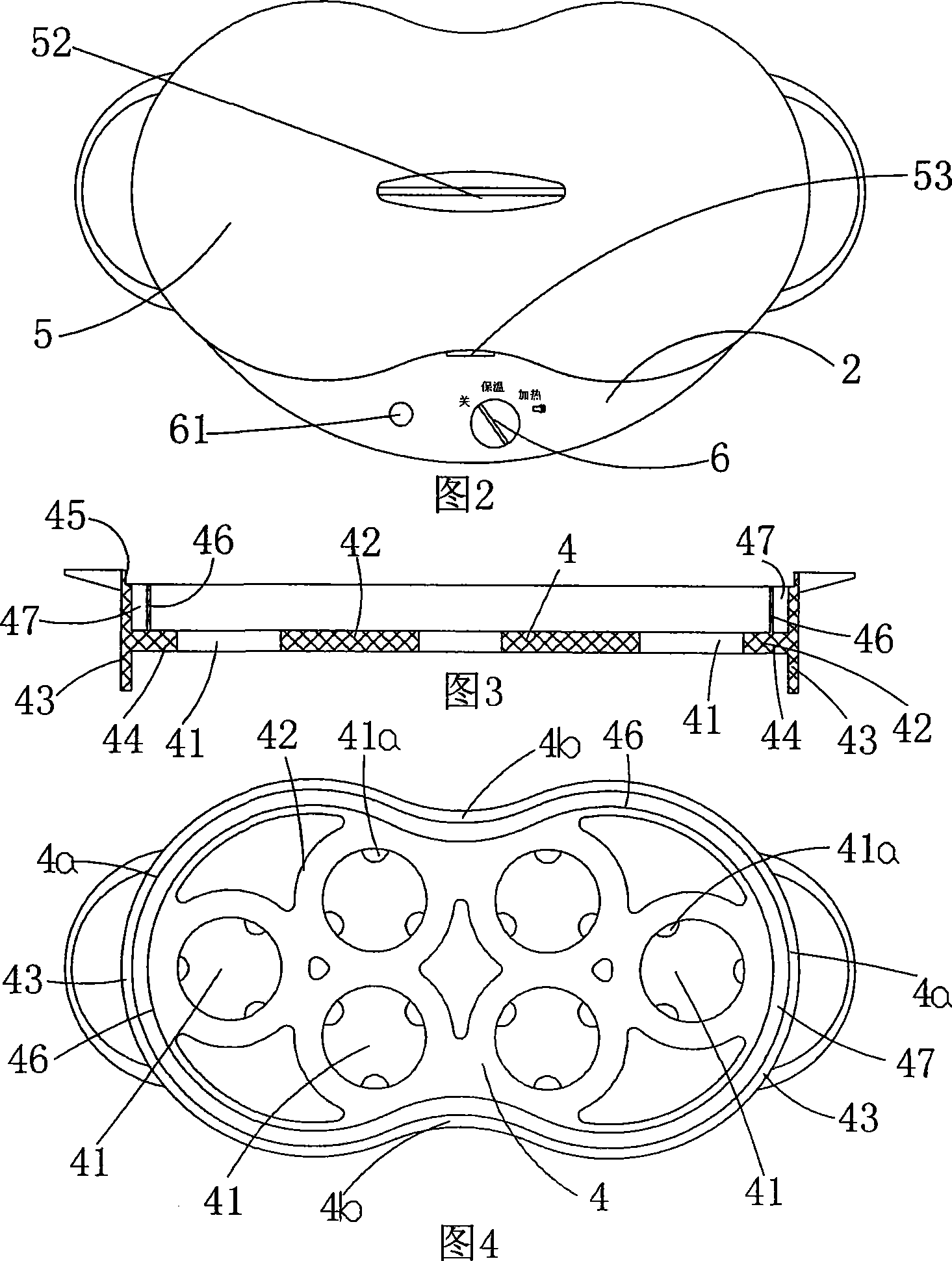

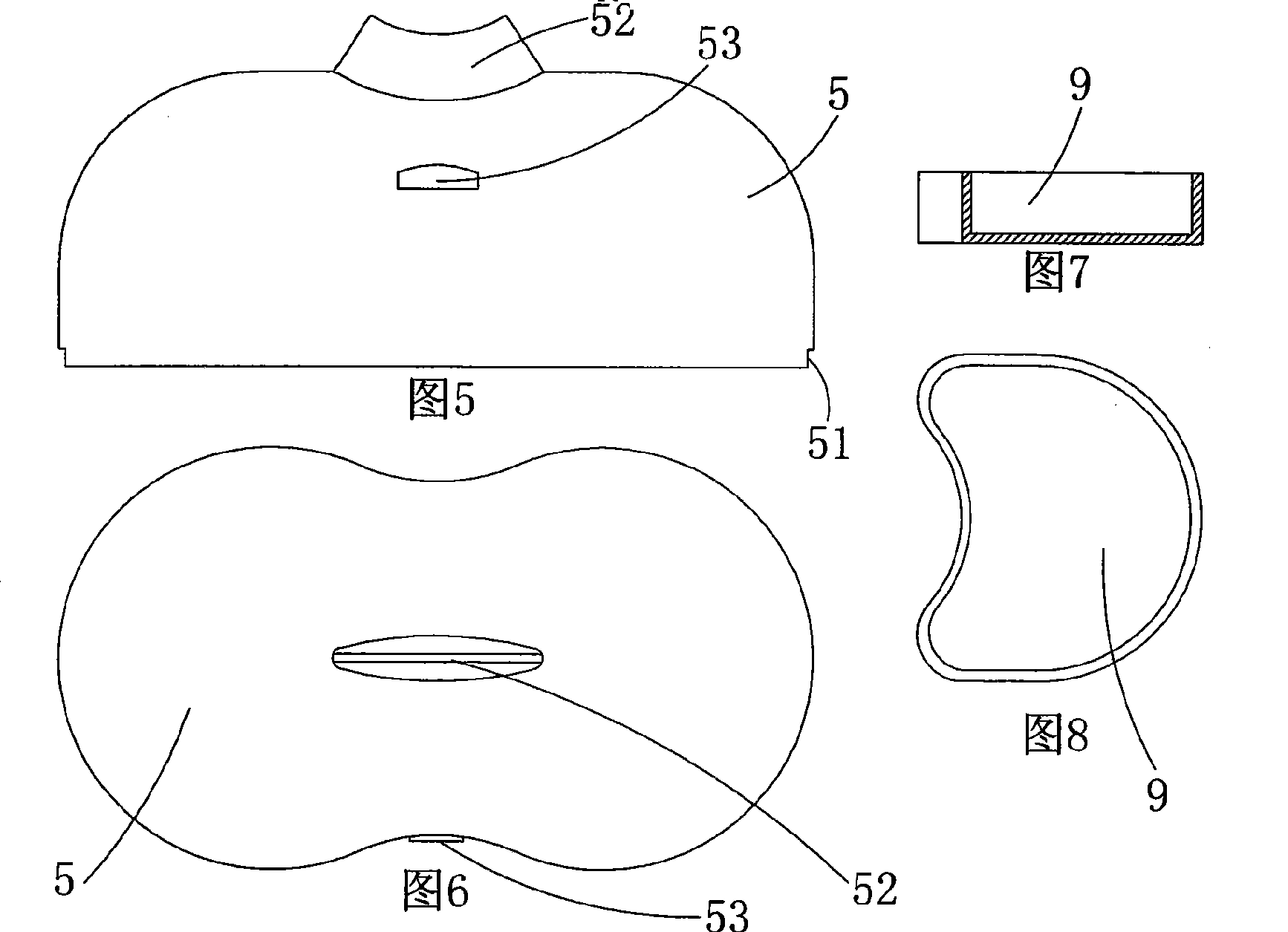

[0027] Figure 1 to Figure 11 As shown, the icon numbers are explained as follows: base 1, tray seat 2, liquid pan 3, egg compartment 4, first arc body 4a, first concave arc 4b, egg hole 41, support block 41a, separation layer Plate 42, vertical edge 43, concave cavity 44, fastening inner edge 45, water retaining vertical edge 46, water storage tank 47, cover body 5, fastening outer edge 51, handle 52, vent hole 53, control switch 6, Power supply indicator light 61, heater 7, movable partition 8, ventilation groove 8a, second arc body 8b, second inner concave arc 8c, box 9.

[0028] In the embodiment of the present invention, the egg steamer includes a base 1, a tray seat 2 is fixed on the upper part of the base 1, and a concave liquid tray 3 is arranged on the upper edge of the tray seat 2, and the upper edge of the liquid tray 3 is buckled. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com