Heat Recycling System for Use with a Gasifier

a gasifier and heat recycling technology, applied in the details of gasification processes, combustion processes, combustible gas production, etc., can solve the problems of insufficient attention of prior systems and processes, less desirable disposal of waste materials by incineration, etc., to maximize energy production, minimize process energy consumption, and optimize gasification process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

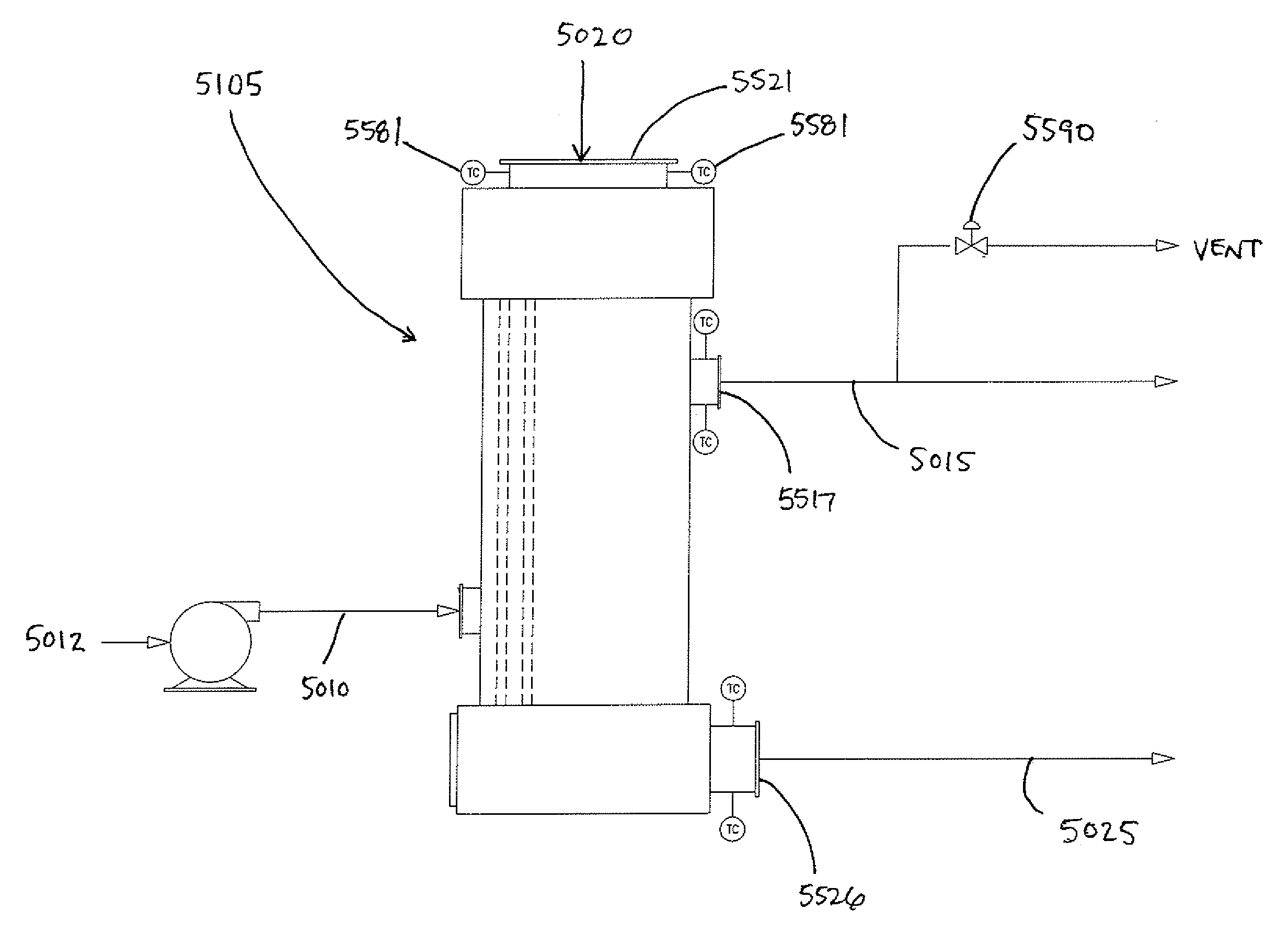

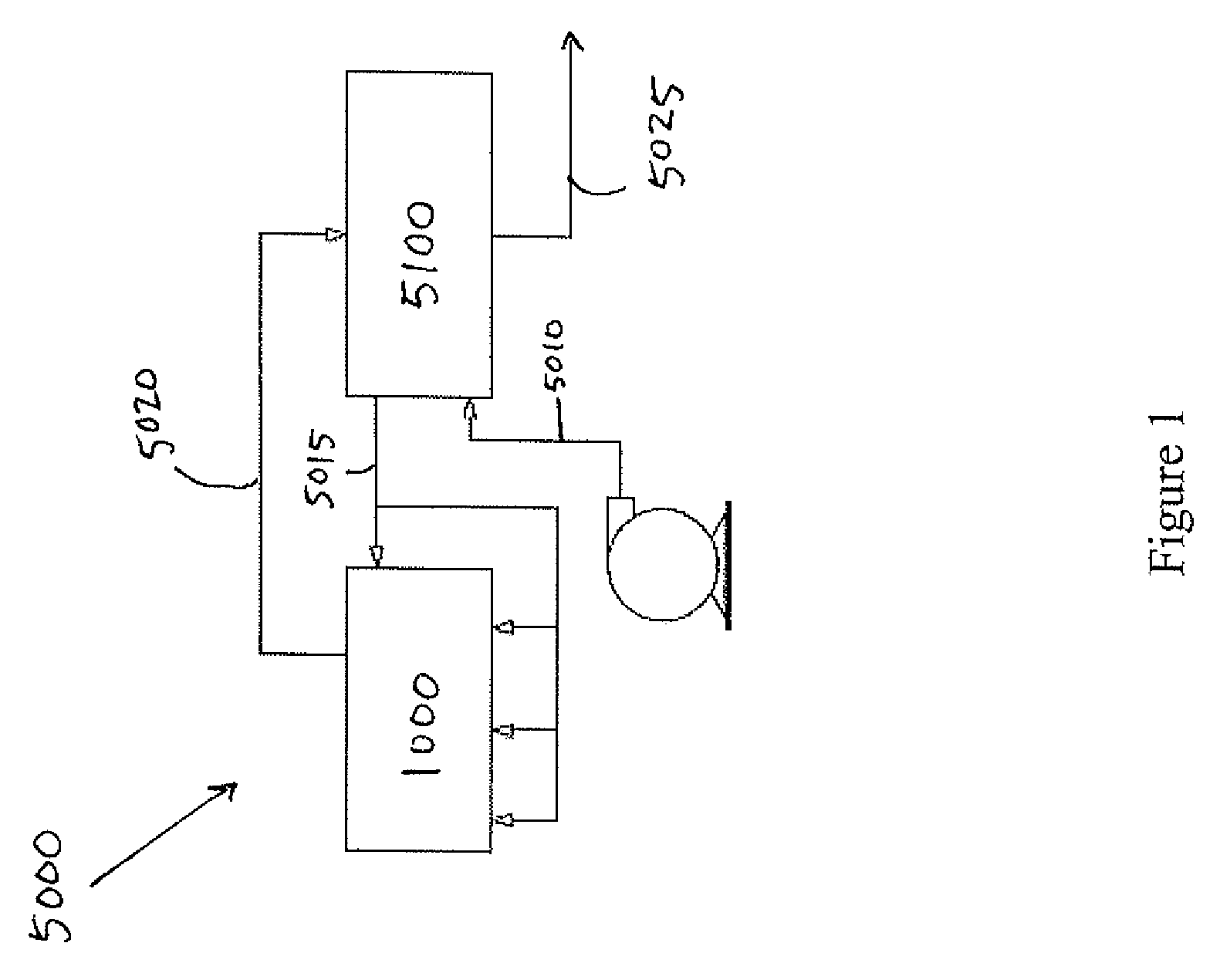

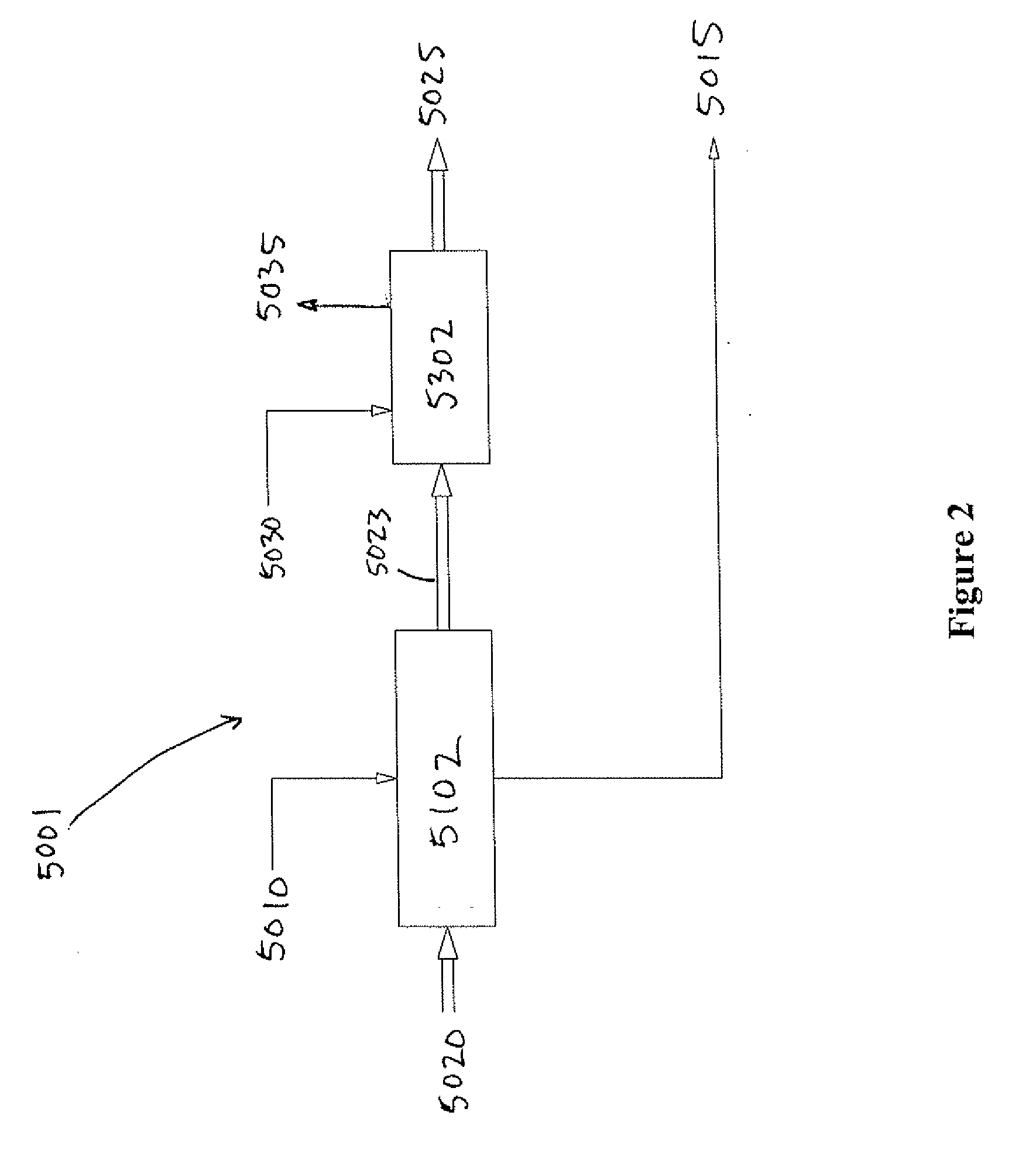

[0209] In general, the system of the present invention is used by feeding exchange-air into a converter where feedstock is subjected to sufficient heat to allow the gasification reaction to take place.

[0210] In the exemplary embodiments depicted in FIG. 12 and 13, the gasifiers 2100 and 2200 each have stepped floors having three floor levels, or steps. Optionally, each floor level is sloped between about 5 and about 10 degrees. In a step-floor gasifier, the individual steps (floor levels) provide conditions appropriate for the respective drying, volatilization and char-to-ash conversion stages of the gasification process, to thereby allowing for the optimization of the gasification process.

[0211] In each of these exemplary gasifiers, the feedstock is fed onto the first step, where the conditions are provided such that the major process here is that of drying, with some volatilization and char-to-ash conversion. The normal temperature range for this step (as measured at the bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com