Cooling system for hot parts of an aircraft engine, and aircraft engine equipped with such a cooling system

a technology for aircraft engines and cooling systems, which is applied in the direction of machines/engines, lighting and heating apparatus, and engine maintenance, etc., can solve the problems of inoperable heat exchangers, difficult access to engine maintenance parts, and difficulty in recirculating air in the heat exchangers, so as to eliminate the risk of recirculation of air increase the pressure loss in the heat exchanger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

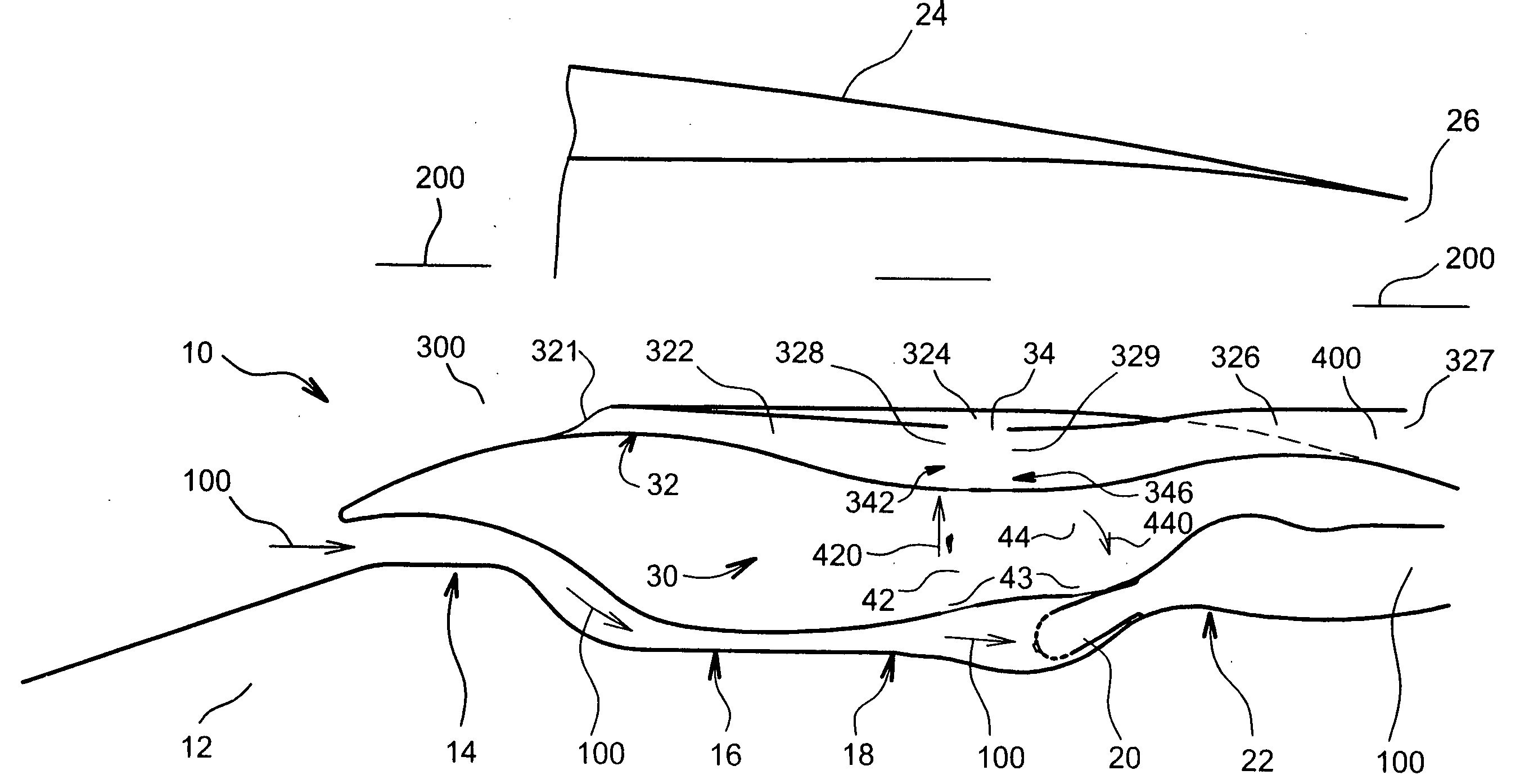

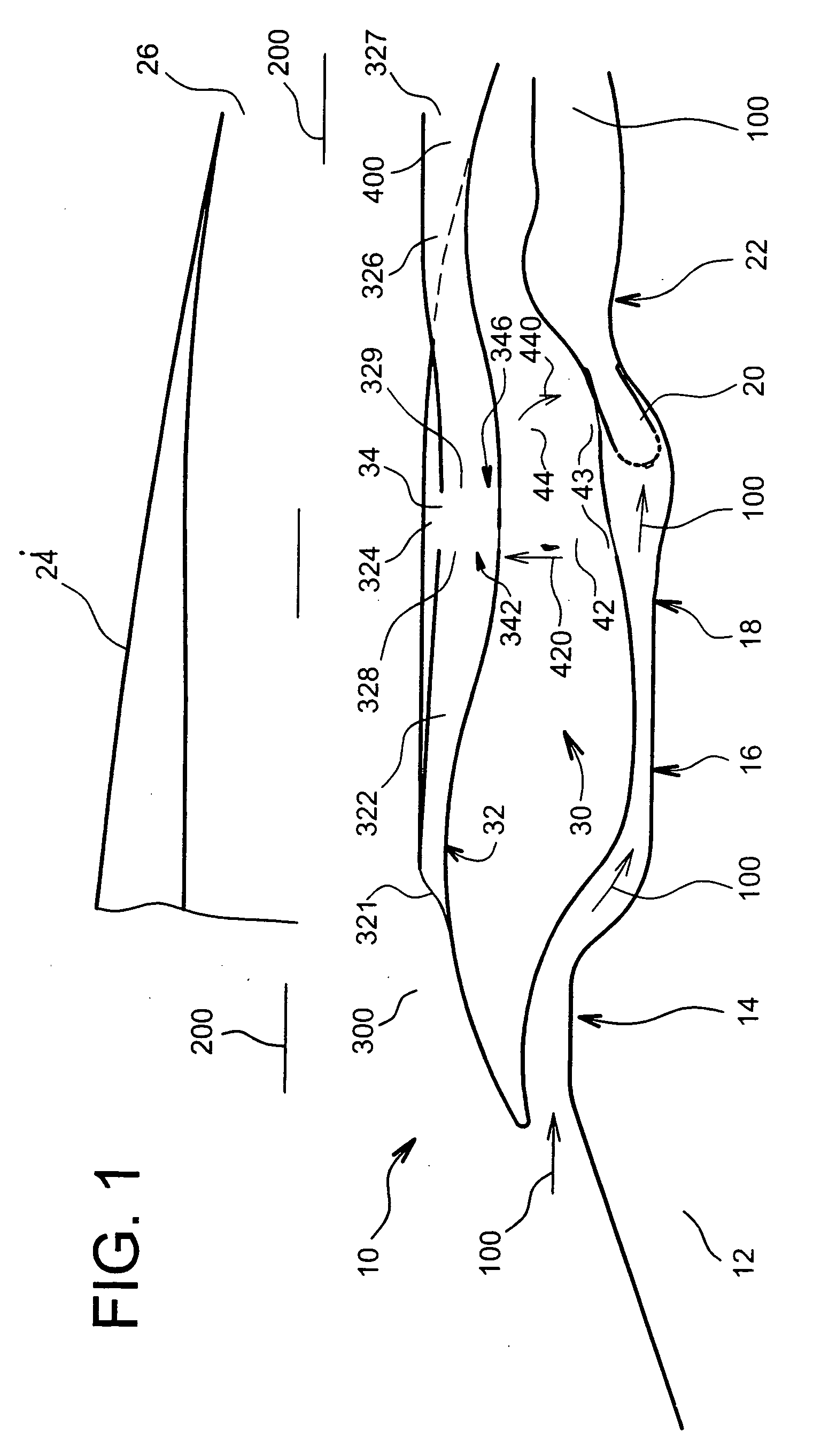

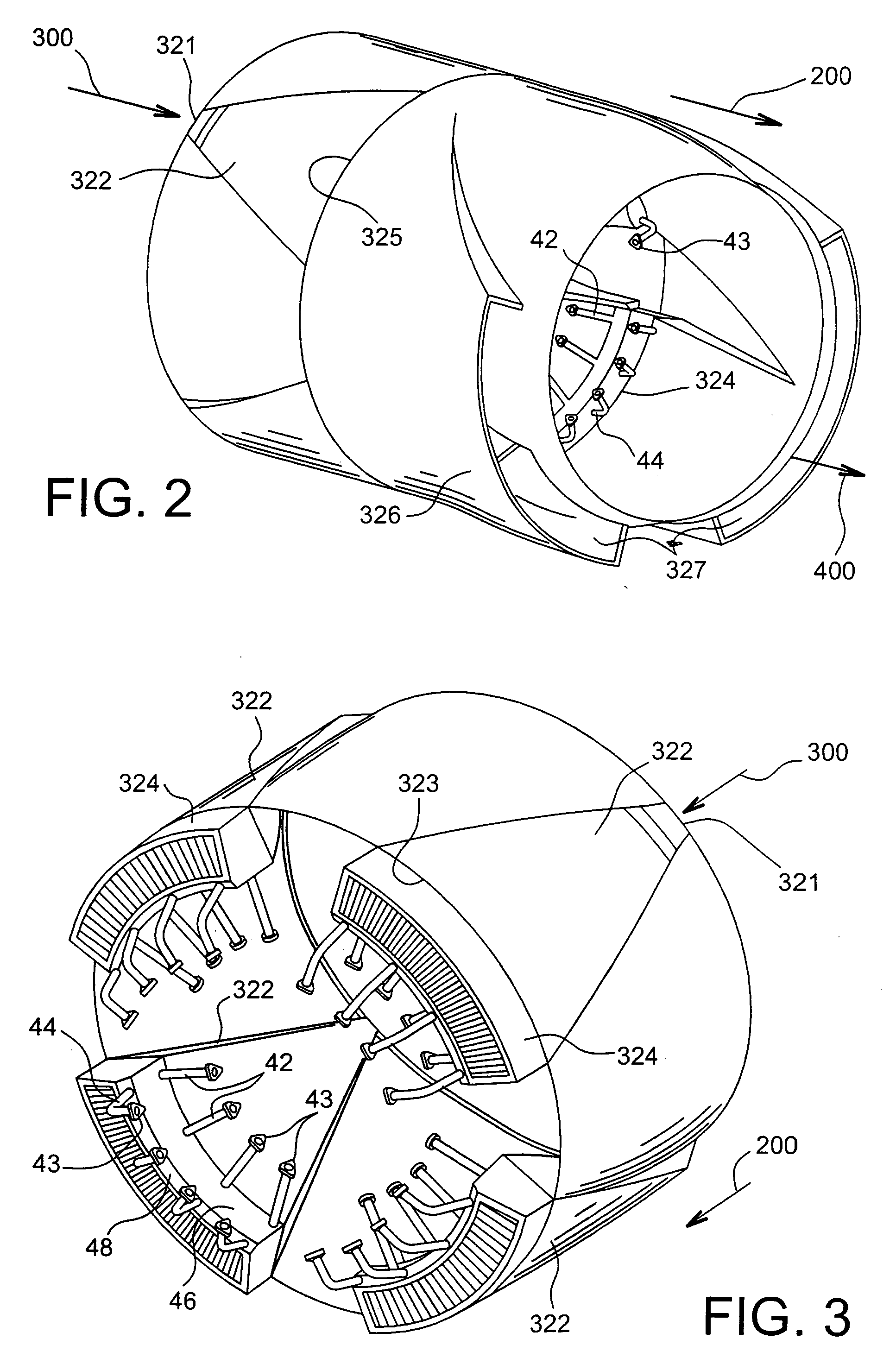

[0037]FIG. 1 diagrammatically shows an aircraft engine 10 with an axis of revolution 12.

[0038] In a manner known per se, the aircraft engine 10 comprises low pressure compressor stages 14, medium pressure compressor stages 16, high pressure compressor stages 18, a combustion chamber 20 and turbines 22. The aircraft engine 10 is surrounded by a nacelle 24 that terminates with an ejection nozzle 26.

[0039] In a manner known per se, a primary air flow represented by arrows 100 circulates inside the engine 10. It is heated as it passes through the compressor stages 14, 16 and 18 before arriving at the turbines 22.

[0040] In a manner known per se, a secondary air flow represented by the arrows 200 circulates in the nacelle 24 around the engine 10. This secondary air 200 external to the engine 10 is colder than the primary air 100 inside the engine 10.

[0041] According to the invention, the engine 10 comprises a cooling system 30 designed to cool hot parts of the engine 10, for example s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com