Method of extermination utilizing heated air

a technology of extermination and heated air, applied in the field of organism control, can solve the problems of proximal damage to equipment and/or facilities, excessive temperature stratification across the application zone, etc., and achieve the effect of improving pest control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

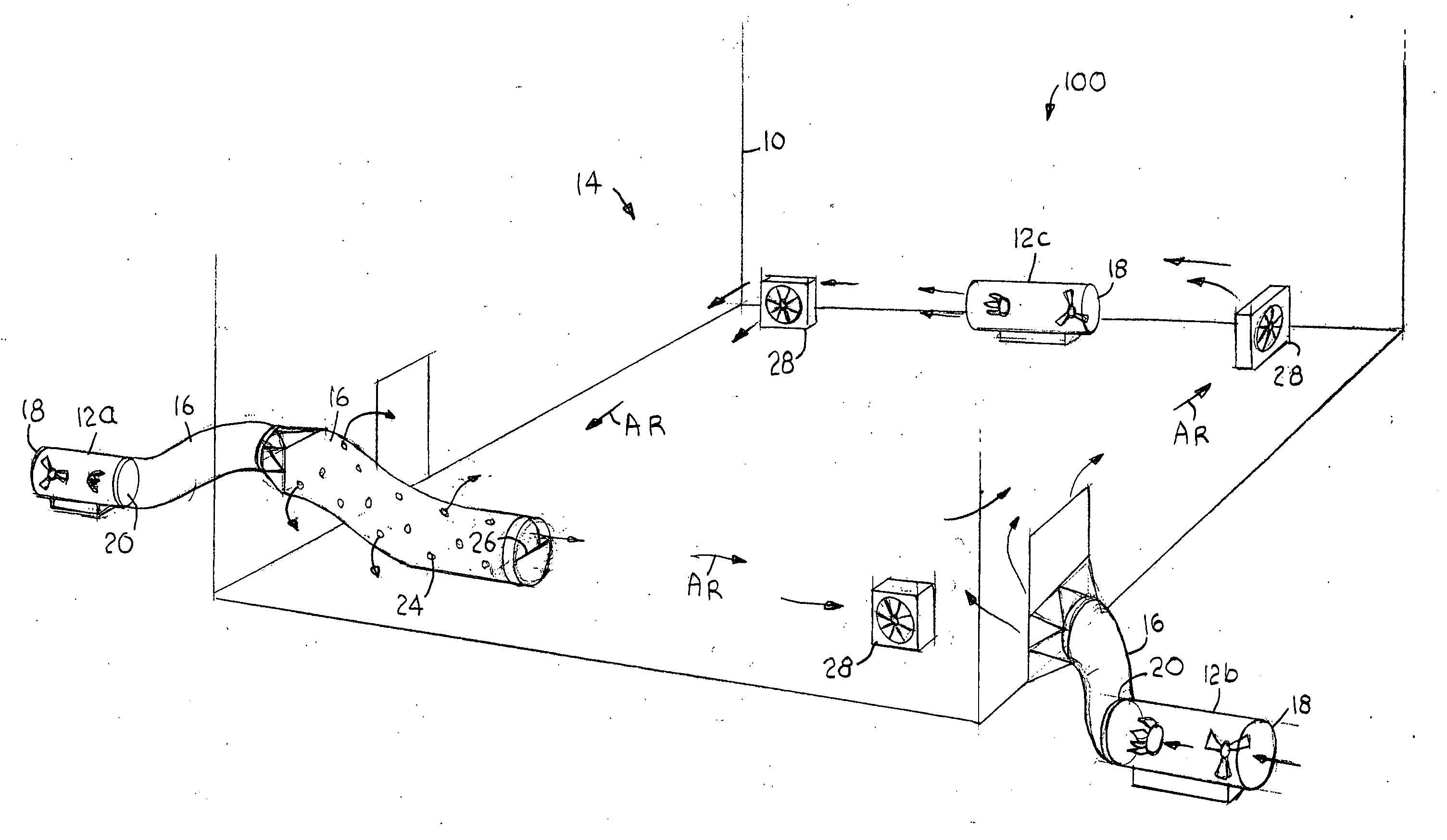

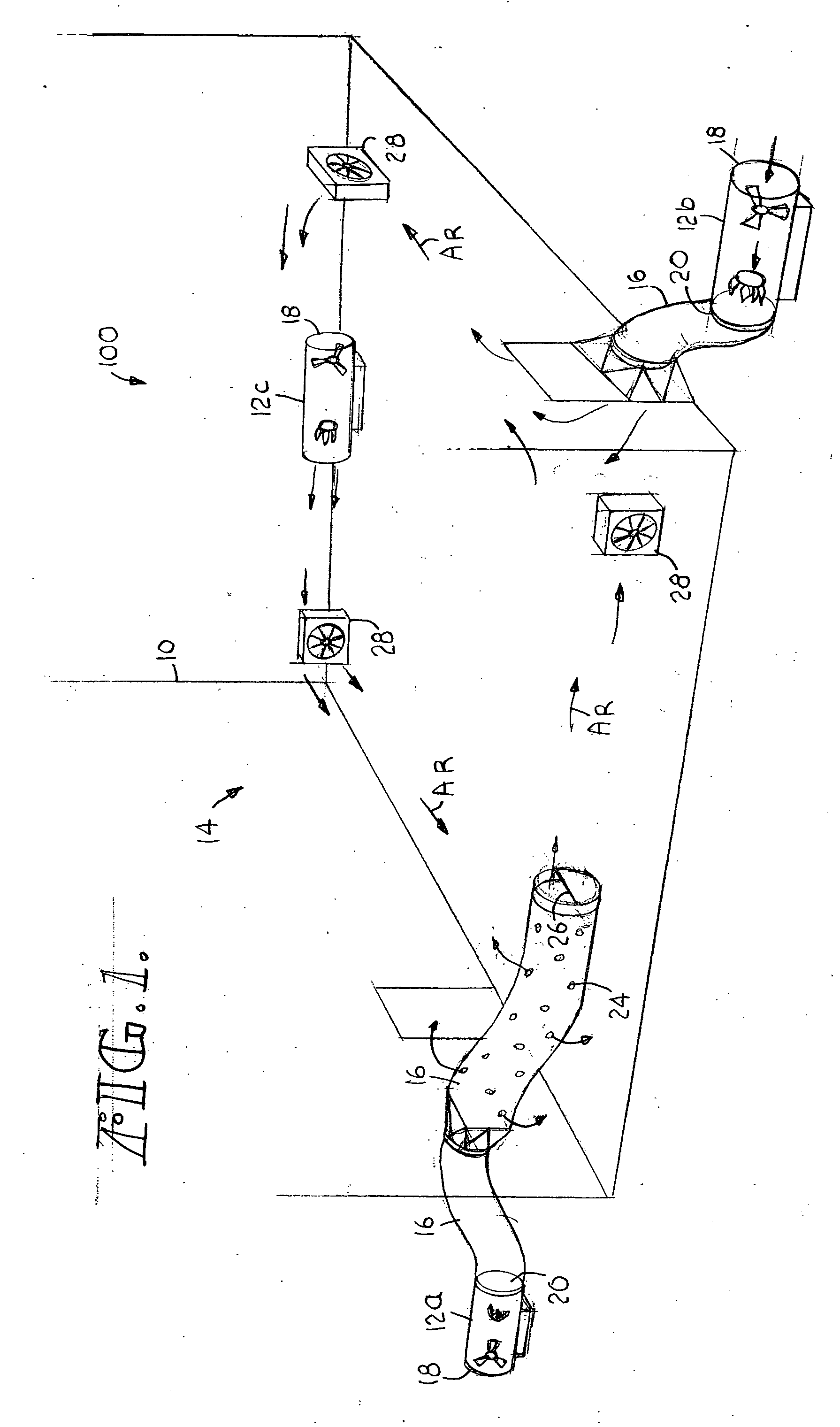

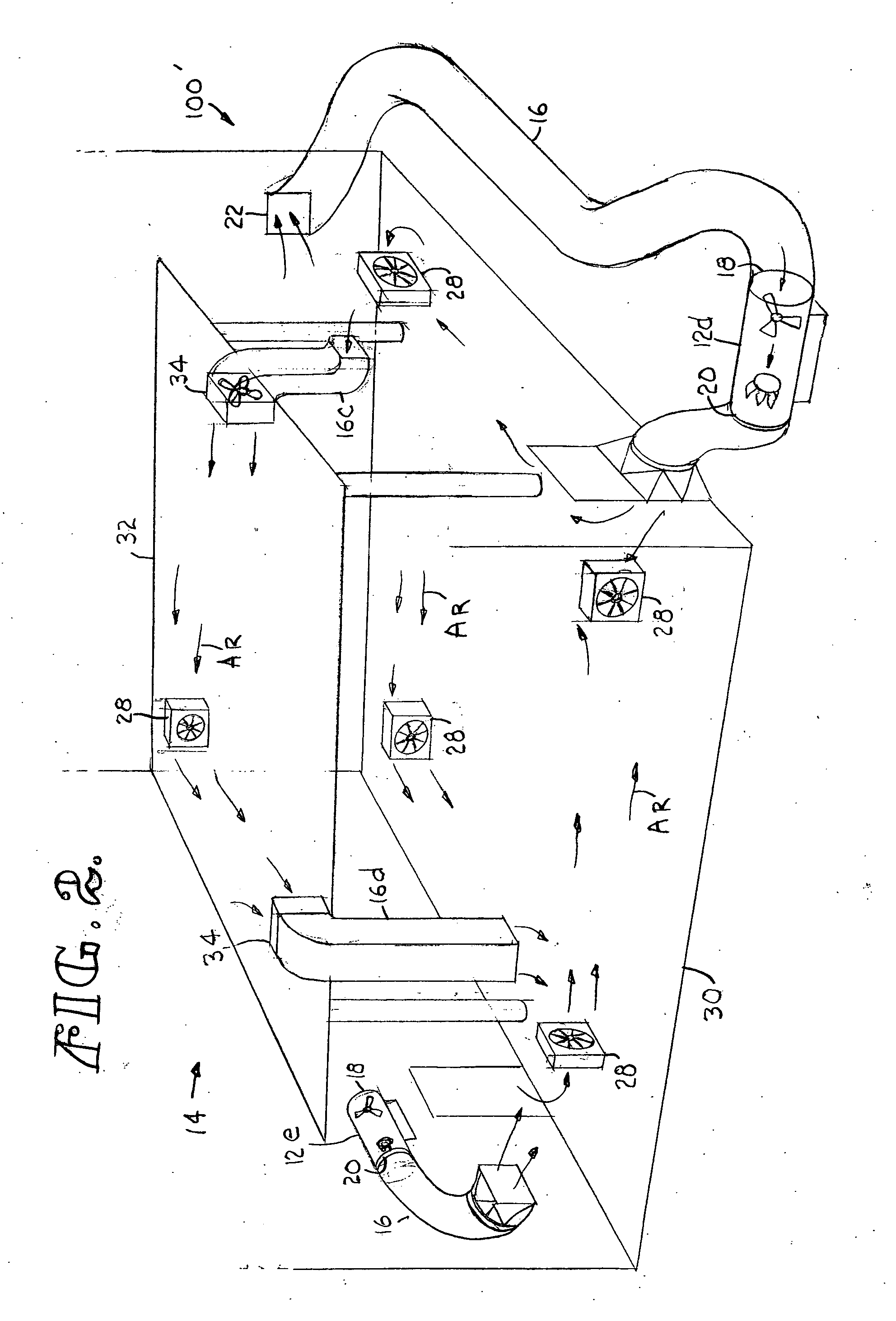

[0013] With reference to the several views of the drawing, and in particular FIG. 1, there is shown an enclosure, such as a building 10, where heated recirculated air (indicated by arrows AR) is utilized for pest extermination. Heaters 12a, 12b and 12 are depicted in FIG. 1, and may be referred to generically as heater(s) 12. However, any number of heaters 12 may be used according to calculated thermal energy needs for the building 10 to realize the necessary lethal temperature for pests. Heaters 12a-c may be, for example, direct or indirect gas-fired propane heaters that blow out a certain CFM of air at a certain elevated temperature; alternatively, heaters 12a-c may be any other kind of heater (e.g., natural gas, diesel, electric, steam, etc., or any heat source already available to the facilities operator, such as the HVAC system of the building 10), and may have a blower / fan included with the heater or located near the heater to move an amount of the heated air. One advantage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com