Patents

Literature

210results about How to "Solve aesthetics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

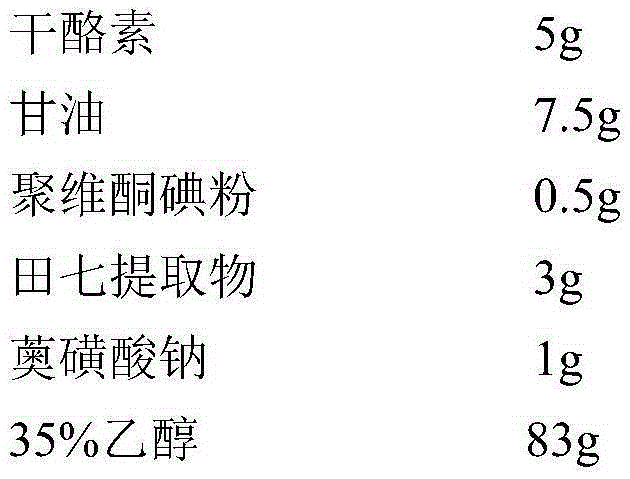

Liquid band-aid and preparation technology thereof

The invention relates to liquid band-aid and a preparation technology thereof. The liquid band-aid is prepared from the following components in percentage by weight: 5%-20% of a film-forming agent, 4%-12% of a softening agent, 0.1-8% of an antibacterial agent, 3%-10% of a haemostatic and analgetic agent, 1%-5% of a healing agent, and 53%-83% of a solvent. The preparation technology comprises the following steps: adding 5%-20% of the film-forming agent and 53-83% of the solvent into a reactor, and soaking for 1-2 h; heating to 65 DEG C to 70 DEG C so that the film-forming agent completely swells; and sequentially adding the softening agent, the antibacterial agent, the haemostatic and analgetic agent and the healing agent into the reactor under stirring, and uniformly stirring to prepare the liquid band-aid. The liquid band-aid overcomes the defects that the traditional band-aid is not attractive, and the wound can not move freely. The liquid band-aid has the characteristics of being rapid in hemostatic effect, strong in inflammation diminishing and bacteria killing properties, and low in cost, and the wound part can move freely.

Owner:天津顶硕药业股份有限公司

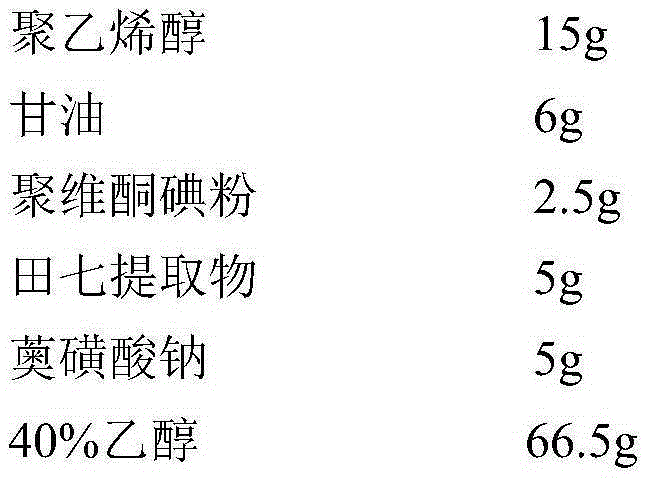

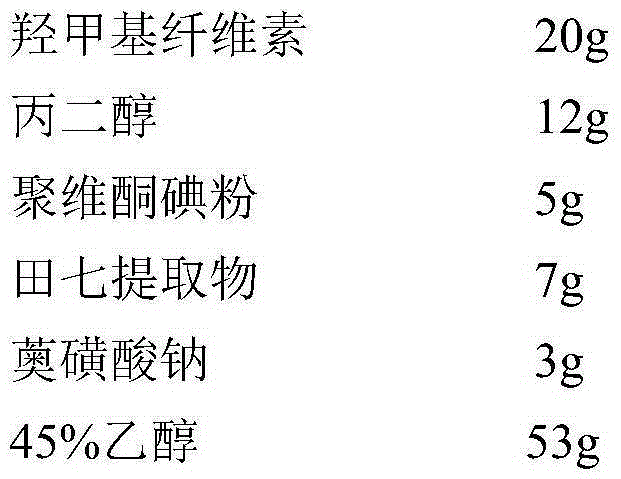

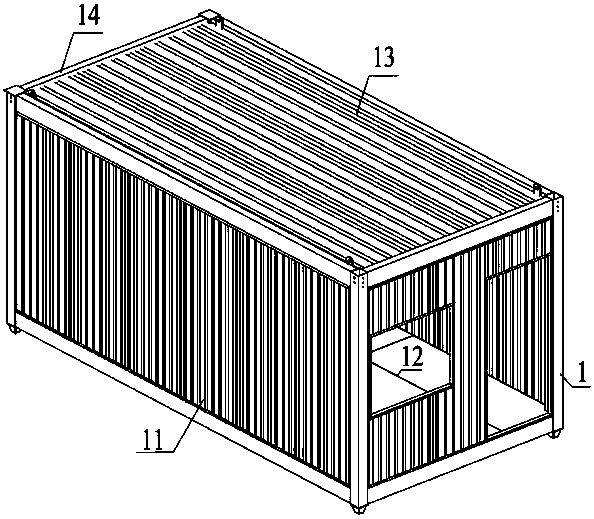

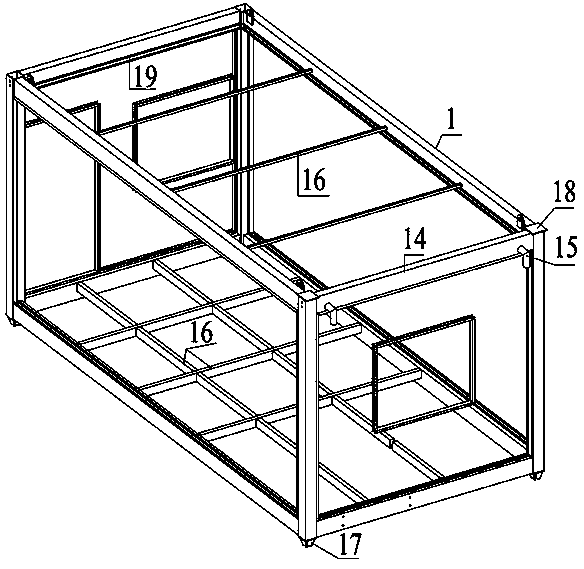

Combined type integrated box room

ActiveCN104018583AImprove carrying capacityImprove fire performanceBuilding constructionsFiberComputer engineering

The invention discloses a combined type integrated box room and belongs to the technical field of movable rooms. The combined type integrated box room comprises a standard box body room, a main frame of the standard box body room comprises stand columns and beams, and the main frame is formed by welding rectangular tubes. Peripheral wall plates embedded into the main frame are fireproof plates, and a bottom plate is a fiber cement pressure plate. A top plate comprises an inner-layer fireproof plate which is horizontally laid and an outer-layer waterproof plate which is obliquely laid. The top beam of at least one side of the standard box body room is a gutter beam. The combined type integrated box room has the better bearing capacity, the fireproof performance, the heat insulation property and the sound absorption and noise lowering effect, installation is convenient, the plate shape is beautiful, construction operation is simpler and faster, and working efficiency is improved.

Owner:广西源冠钢结构制品有限公司

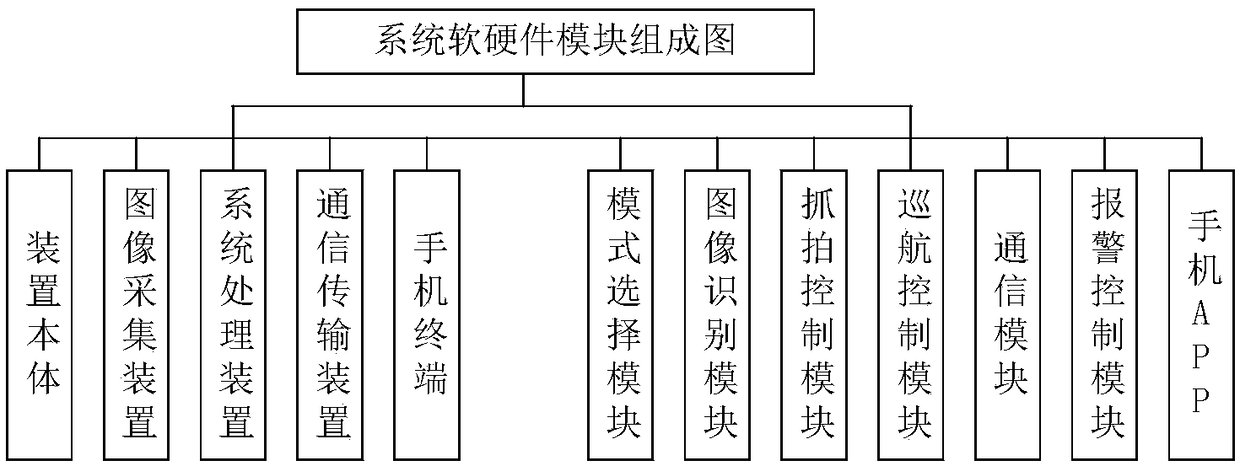

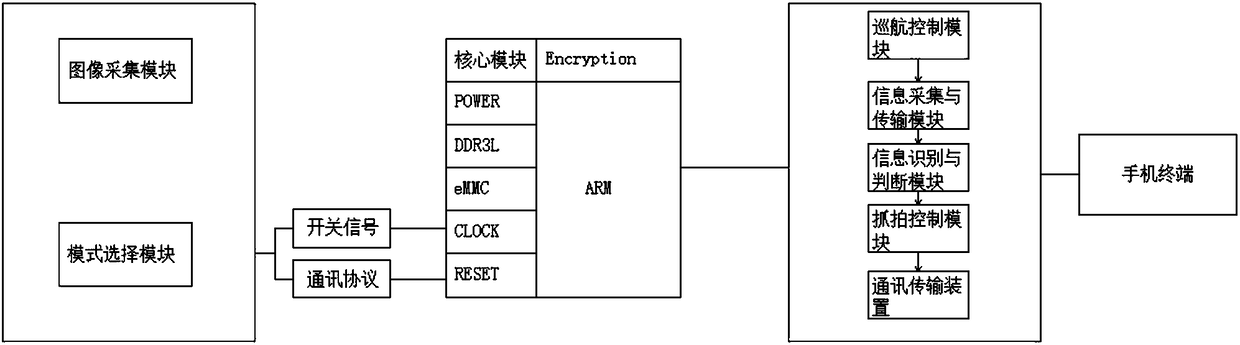

Intelligent mobile home monitoring system based on sweeping robot equipment

PendingCN108540780ARich product featuresMeet multiple needsCarpet cleanersFloor cleanersImaging processingMonitoring system

The invention discloses an intelligent mobile home monitoring system based on sweeping robot equipment, which comprises a sweeping robot body. An image acquisition device is arranged on the surface ofthe sweeping robot body; the image acquisition device is used for acquiring an image of a region above the sweeping robot body; the image acquisition device is connected with a processing module; theprocessing module is connected with an early warning device and a communication module; an image processing module is arranged in the processing module; and the processing module is used for carryingout real-time identification on the acquired image, identifying target person identity information by utilizing a human face identification algorithm when identifying a pedestrian target, and controlling the image acquisition device to carry out image snapshotting and carrying out early warning when identifying a doubtful target. By carrying out transformation on the structure of an existing sweeping robot and combining the sweeping robot with a safety monitoring device, in a case of not additionally installing redundant equipment, requirements for functions of home sweeping and safety burglary prevention of a user can be met.

Owner:SUZHOU TSINGTECH MICROVISION ELECTRONICS TECH

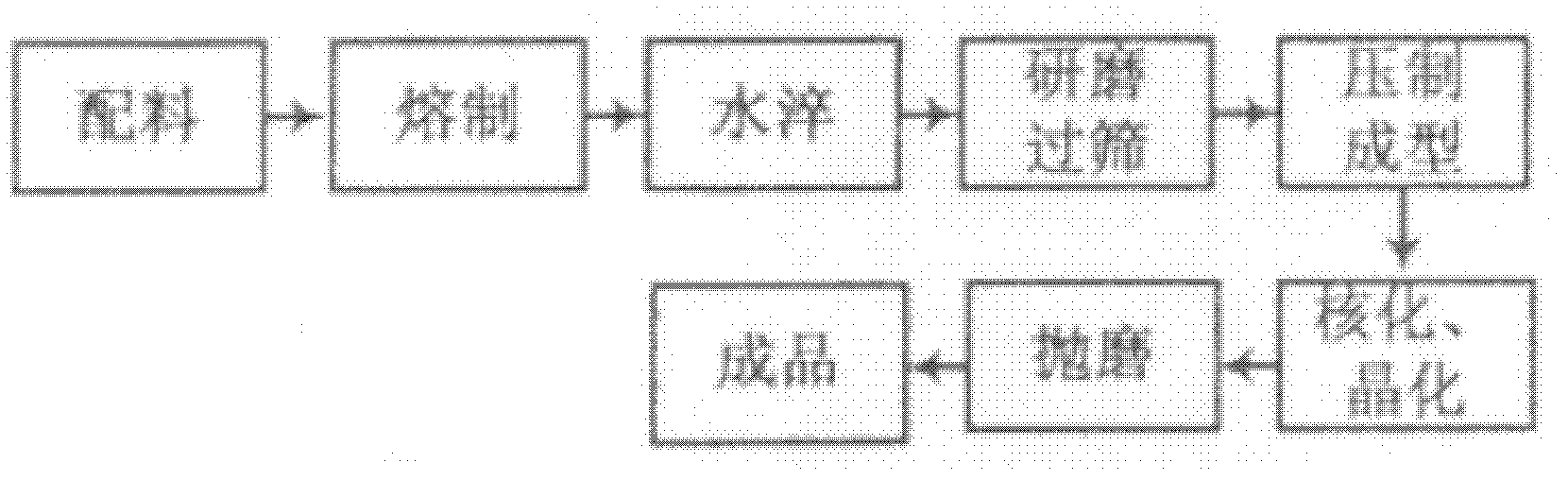

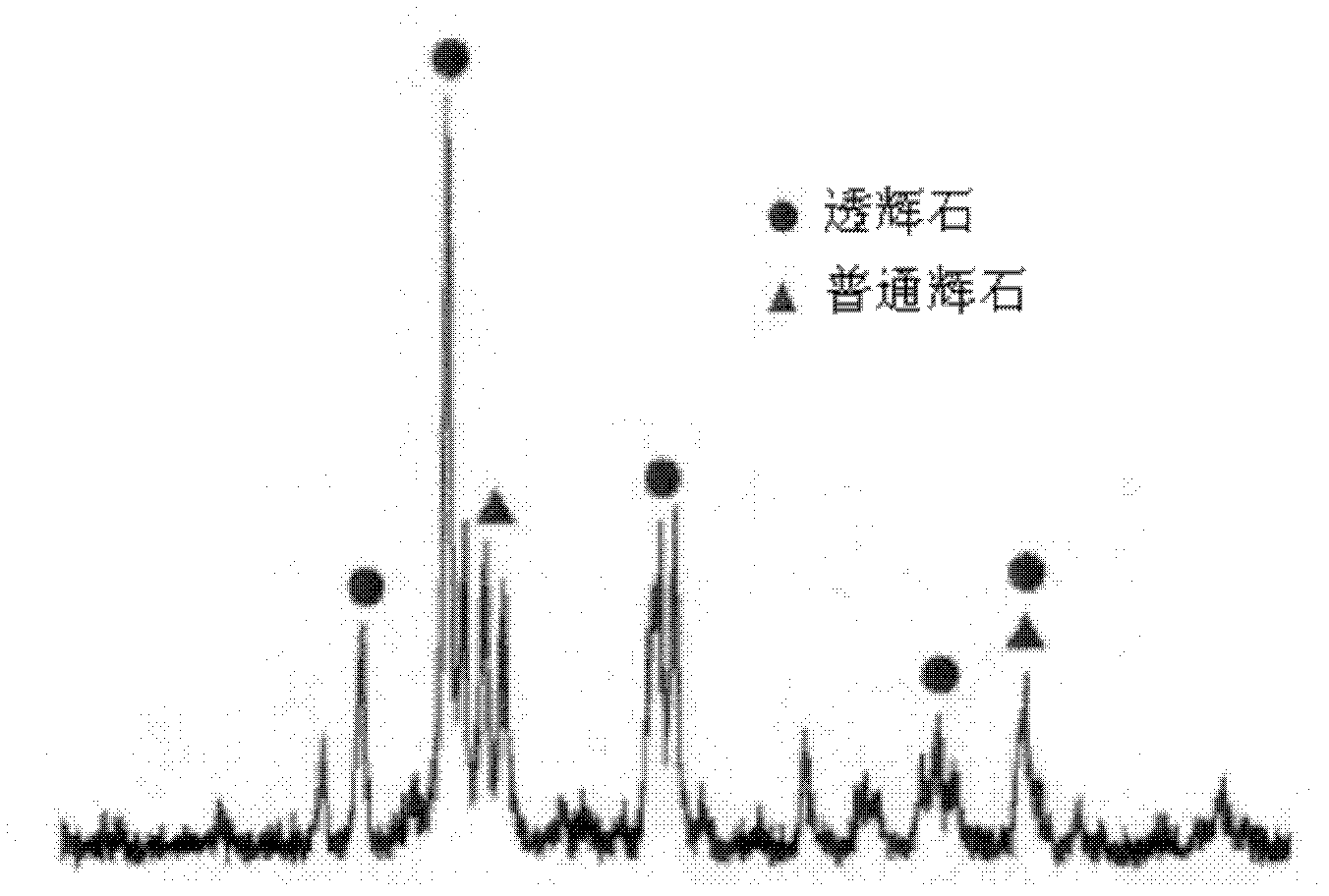

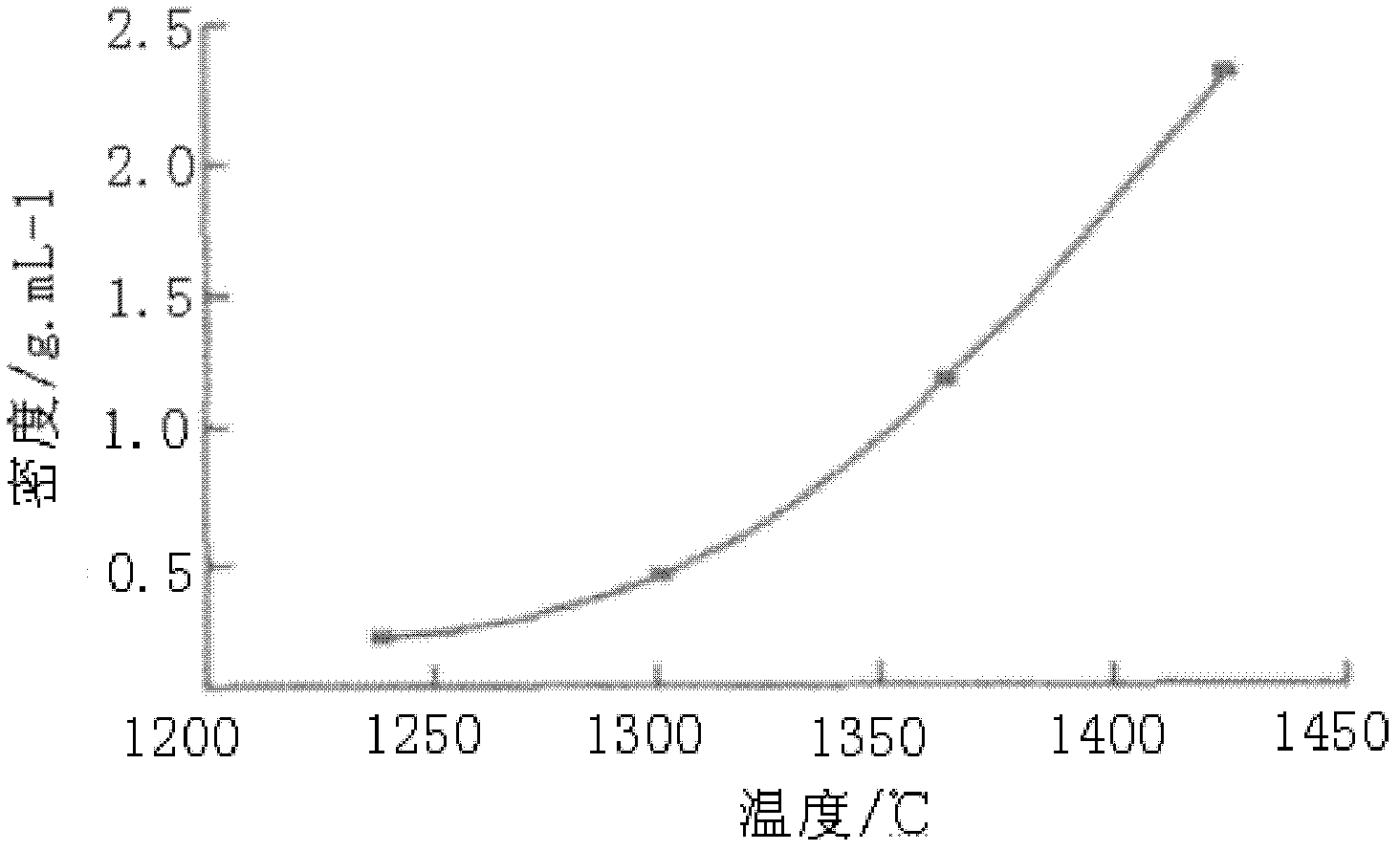

Wear-resistant crystallized glass plate and preparation method thereof

The invention discloses a wear-resistant crystallized glass plate and a preparation method thereof. The wear-resistant crystallized glass plate consists of the following components in parts by weight: 65-85 parts of steel and iron furnace slag, 20-30 parts of quartz sand, 6-10 parts of magnesium oxide, 5-10 parts of titanium dioxide and 1-3 parts of calcium fluoride, wherein the steel and iron furnace slag comprises the following components in percentage by weight: 13-20 percent of SiO2, 10-15 percent of FeO, 40-50 percent of CaO, 5-10 percent of MgO, 2-5 percent of Al2O3, 10-20 percent of TFe, 2-5 percent of MnO2, 0.1-0.5 percent of P2O3 and 0.5-1.5 percent of MFe. The method comprises burdening, melting, water quenching, grinding, sieving, press molding, nucleating, crystallizing and rubbing down, wherein melting is performed at the temperature of 1,380-1,450 DEG C for 1-3 hours; and crystallizing is performed at the temperature of 900-920 DEG C for 1-2 hours. Compared with the prior art, the wear-resistant crystallized glass plate has the advantages of low raw material cost, excellent melting performance, excellent crystallizabitity, high plate hardness, high bending strength, soft and bright surface gloss, denseness, immaculacy and wide product market prospect.

Owner:水经(上海)生物科技有限公司

Nano-silver mouldproof wallpaper coating and preparation method thereof

InactiveCN102839564AAddress spoilage riskIncrease productivityCoatings with pigmentsPaper/cardboardChemistryDioxide titanium

The invention belongs to the field of wallpaper auxiliary materials, and particularly relates to a nano-silver mouldproof wallpaper coating and a preparation method thereof. The nano-silver mouldproof wallpaper coating is prepared by stirring and mixing the following raw materials of, by weight, 100 parts of a polrvinyl chloride paste resin, 50-70 parts of dioctyl phthalate, 10-15 parts of titanium dioxide, 2-8 parts of a viscosity reduction agent, 6-10 parts of a foaming agent, 50-75 parts of calcium carbonate, 3-5 parts of a stabilizing agent and 2-3 parts of nano-silver. The invention also provides a preparation method of the nano-silver mouldproof wallpaper coating. Mouldy problems of mouldiness and bacterium generation which influence health of a user and beauty of the wallpaper after the wallpaper is pasted in previous decoration processes are solved.

Owner:杭州嘉力丰化工有限公司

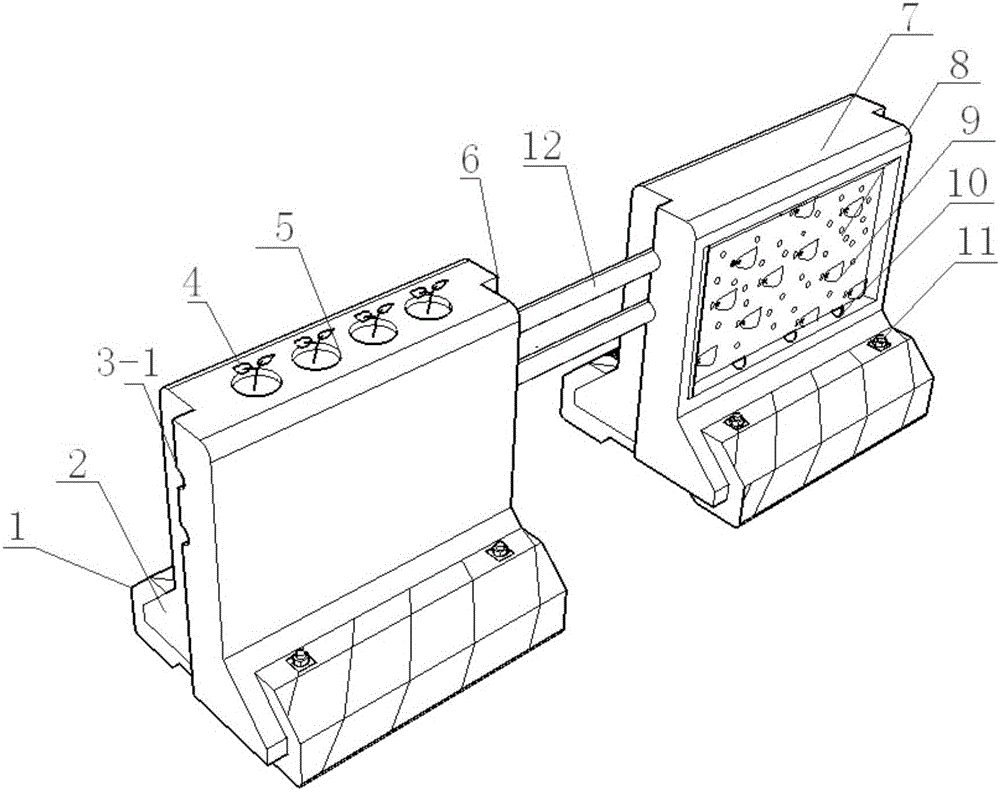

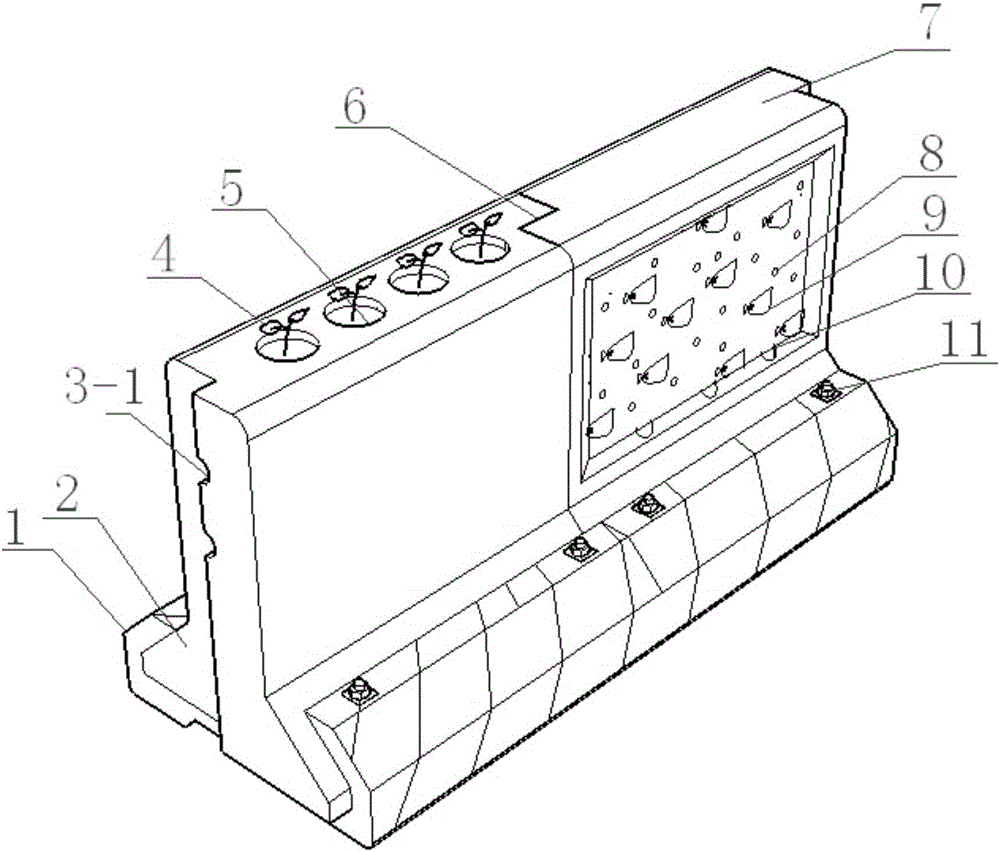

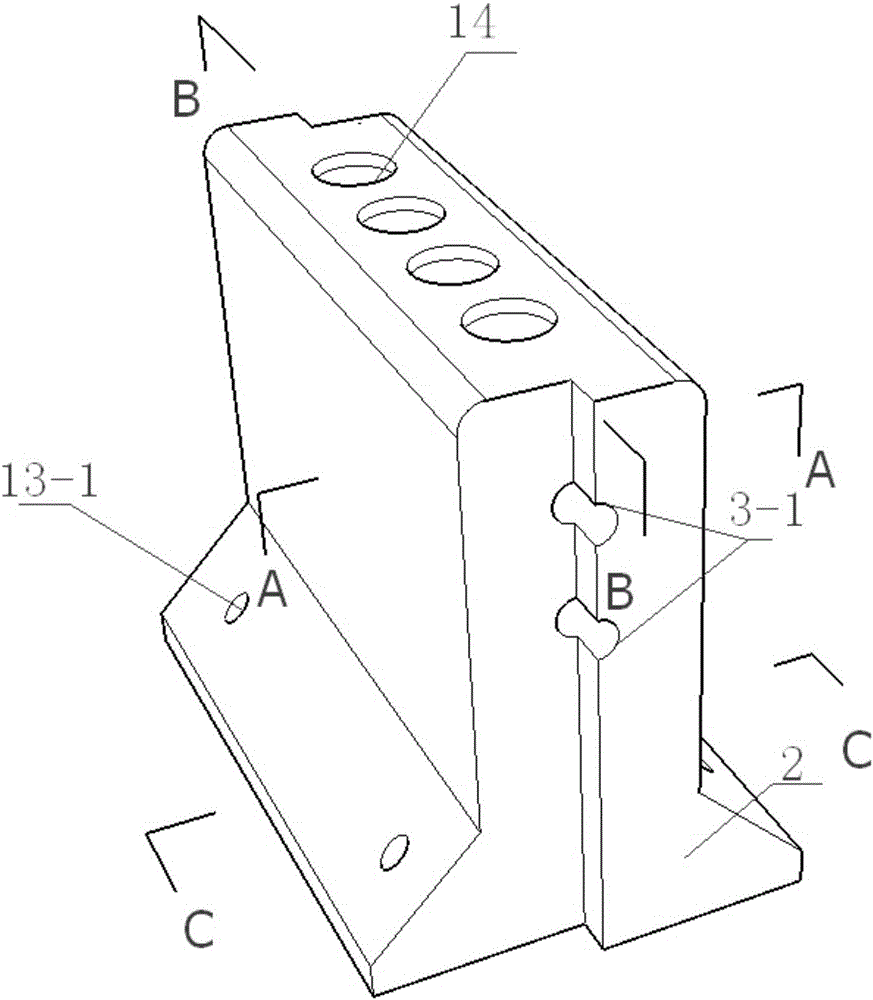

Multifunctional ecological isolation pier

The invention relates to a multifunctional ecological isolation pier which comprises a plant growing tank and a tail gas degradation tank base. Plant growing holes are formed in the plant growing tank. A cavity is formed inside the plant growing tank and filled with plant growing soil. The plant growing holes communicate with the cavity in the plant growing tank. Flowers are planted on the plant growing soil in the plant growing holes. Clamping grooves are formed in the two sides of a tail gas degradation tank. Transparent resin plates are embedded and inserted in the clamping grooves. A cavity is formed inside the tail gas degradation tank and filled with artificial noctilucent stone and a titanium dioxide package. The base is provided with water permeable holes and a bottom groove. The multifunctional ecological isolation pier has the beneficial effects that (1) the isolation pier is made from active powder concrete, thereby having high strength, high toughness and impact resistance; (2) through the assembled structure, the isolation pier is convenient to transport and install; (3) by adoption of the flowers, titanium dioxide powder, kieselguhr and ceramic grains, the isolation pier has the functions of impurity filtering-out, landscaping and tail gas degradation; and (4) by using the artificial noctilucent stone, the isolation pier can emit light at night, thereby achieving the traffic lighting effect.

Owner:YANGZHOU UNIV

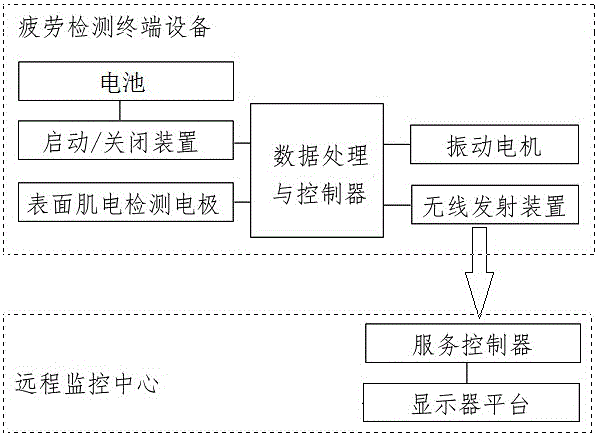

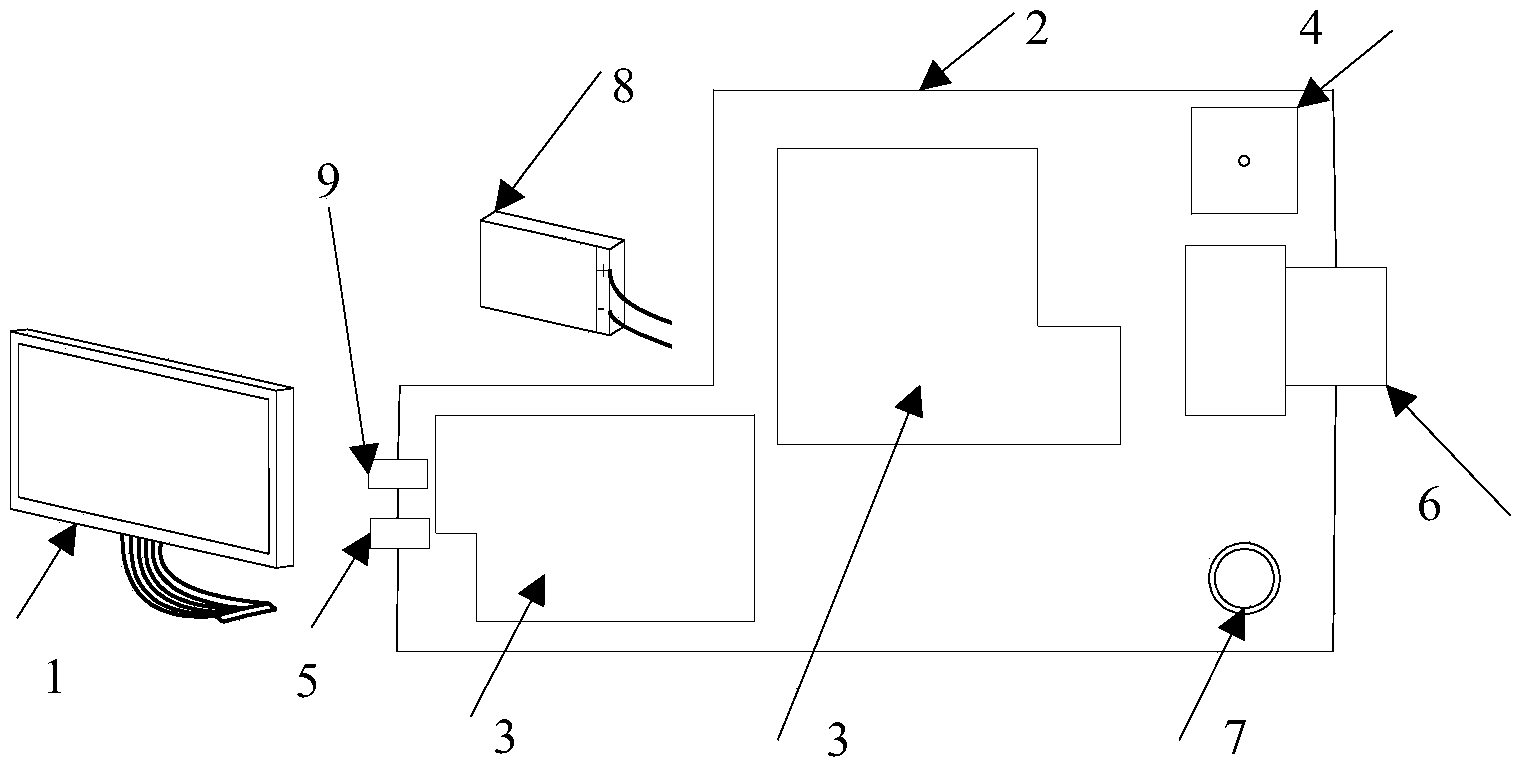

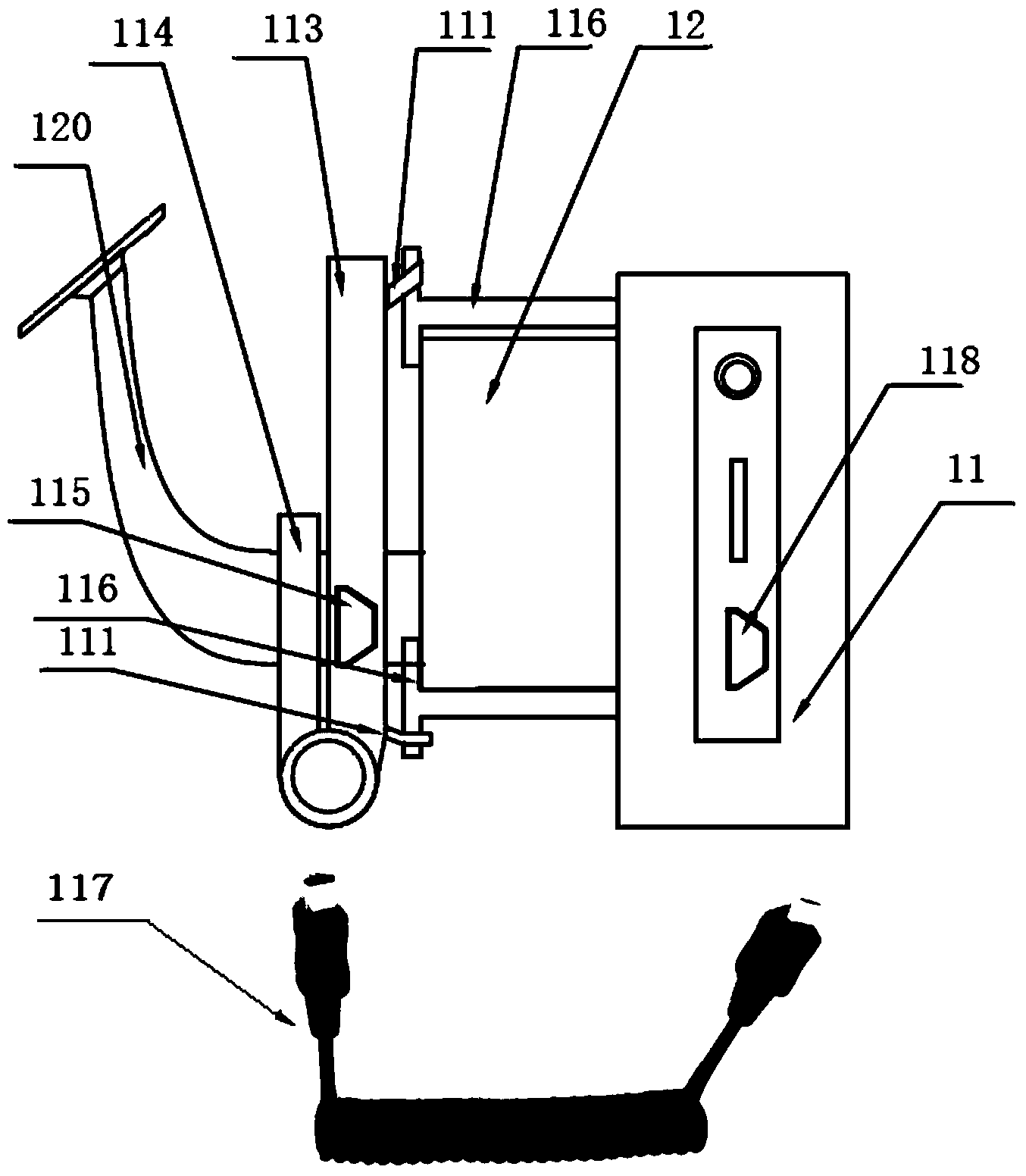

System for detecting driver fatigue based on surface myoelectricity technology

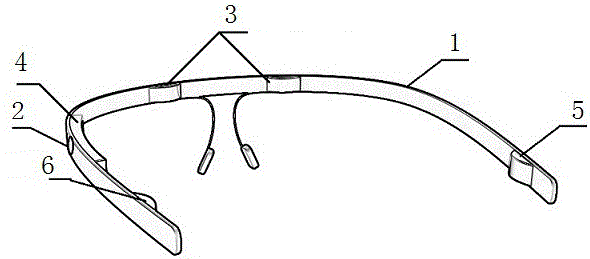

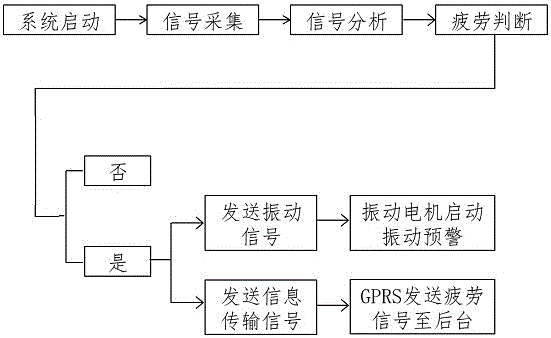

InactiveCN105662407AImprove accuracyThe principle is simpleDiagnostic recording/measuringSensorsEnvironment effectDriver/operator

The invention discloses a system for detecting driver fatigue based on surface myoelectricity technology. The system comprises two parts, a fatigue detecting terminal device and a remote monitoring center, wherein the fatigue detecting terminal device is designed to be a wearable headband which includes a turn on / off button, a surface myoelectricity detecting electrode, a data processing and controlling device, a vibration motor, and a wireless emitting device thereon. The detection of fatigue states can be realized through the detection of surface myoelectricity signals around eye part by employing the surface myoelectricity technology. The interaction between a local detection alert and a network backend alert enables operation entities to enhance real-time monitoring on driving states of drivers, which addresses the problems of great influence imposed by individual differences of the drivers and external environment, low relativity to fatigue features, and high difficulty of detecting technology of prior art mainstream detecting technology. The system of the invention provides a detecting system for detecting driver fatigue and is characterized by simple theory, comparatively low difficulty of realization, large parameter relativity, and high accuracy.

Owner:清华大学苏州汽车研究院(吴江)

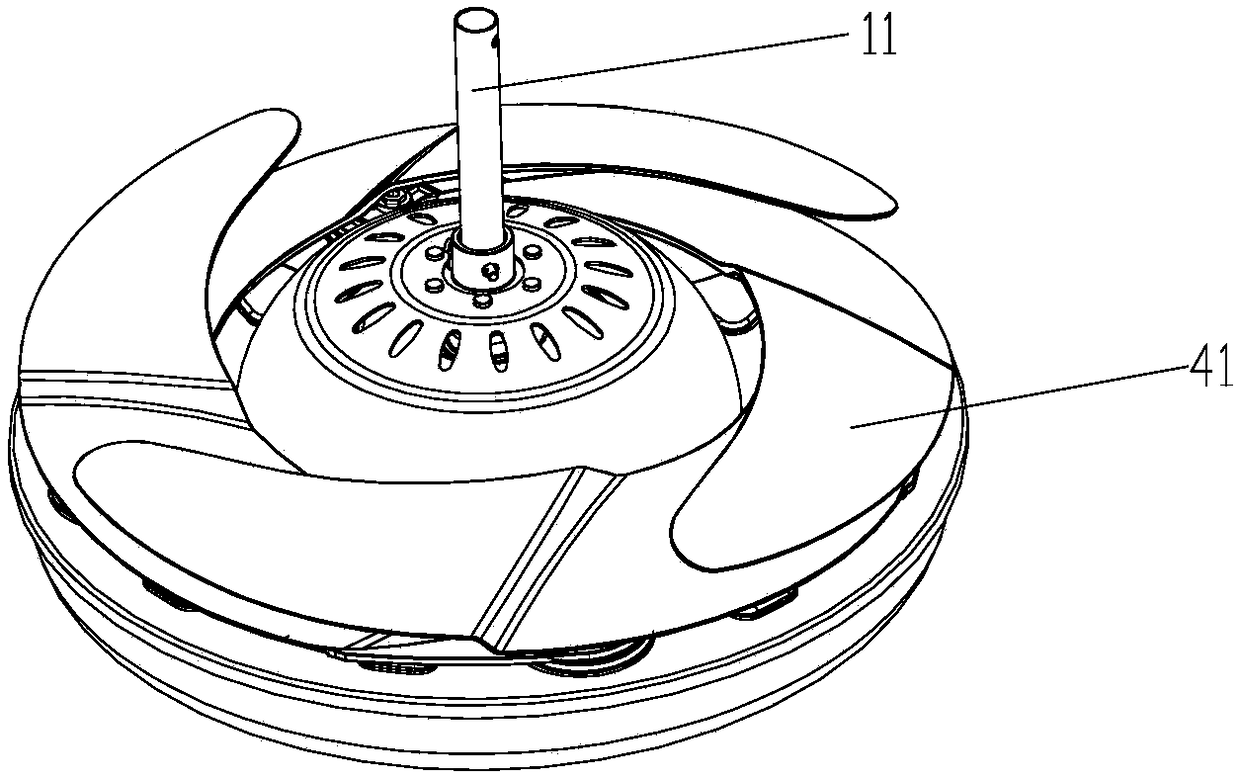

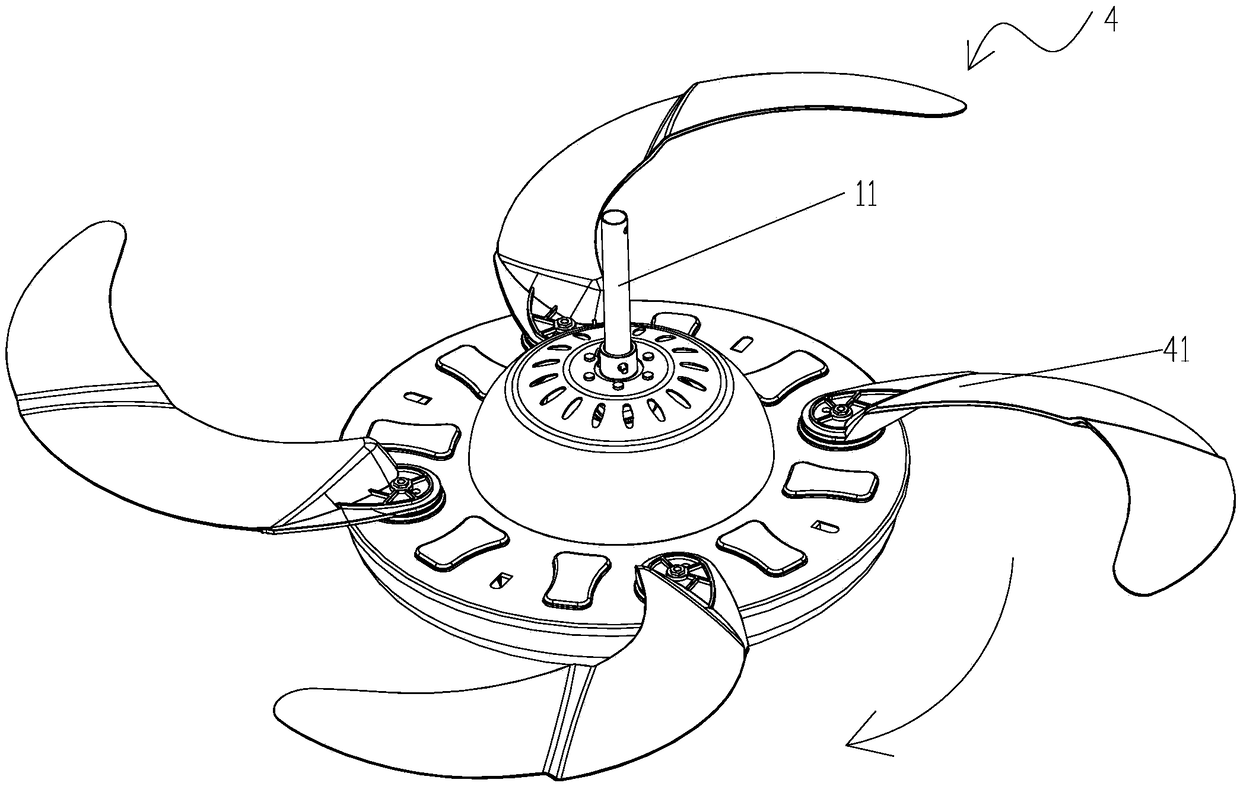

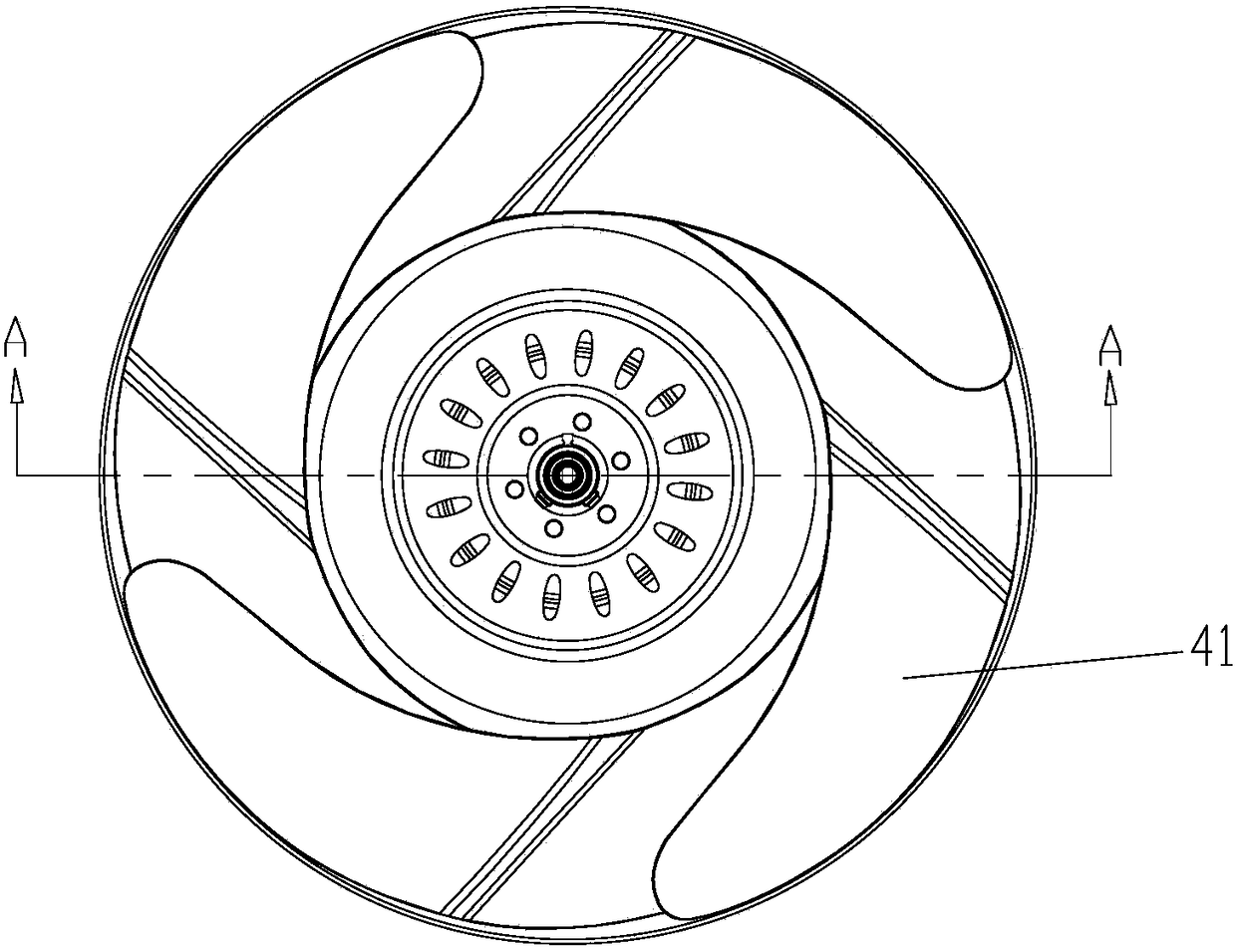

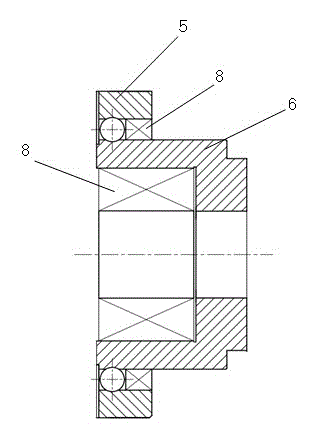

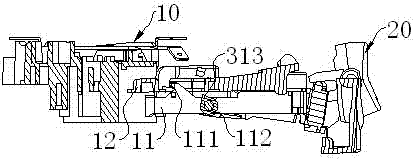

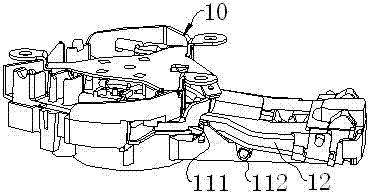

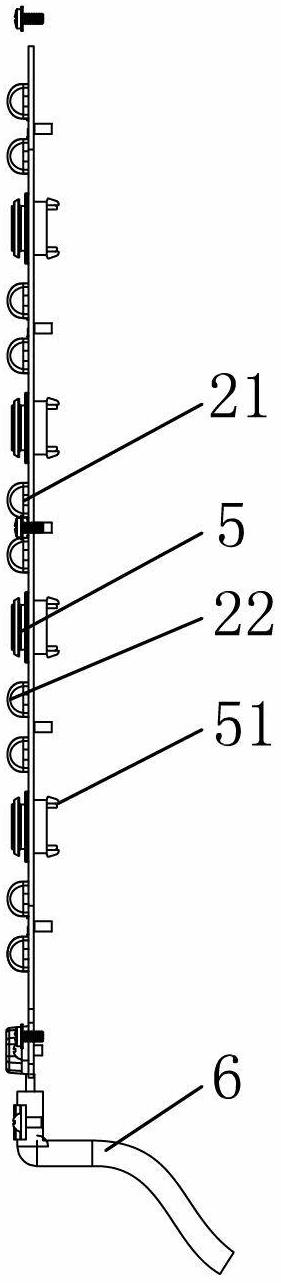

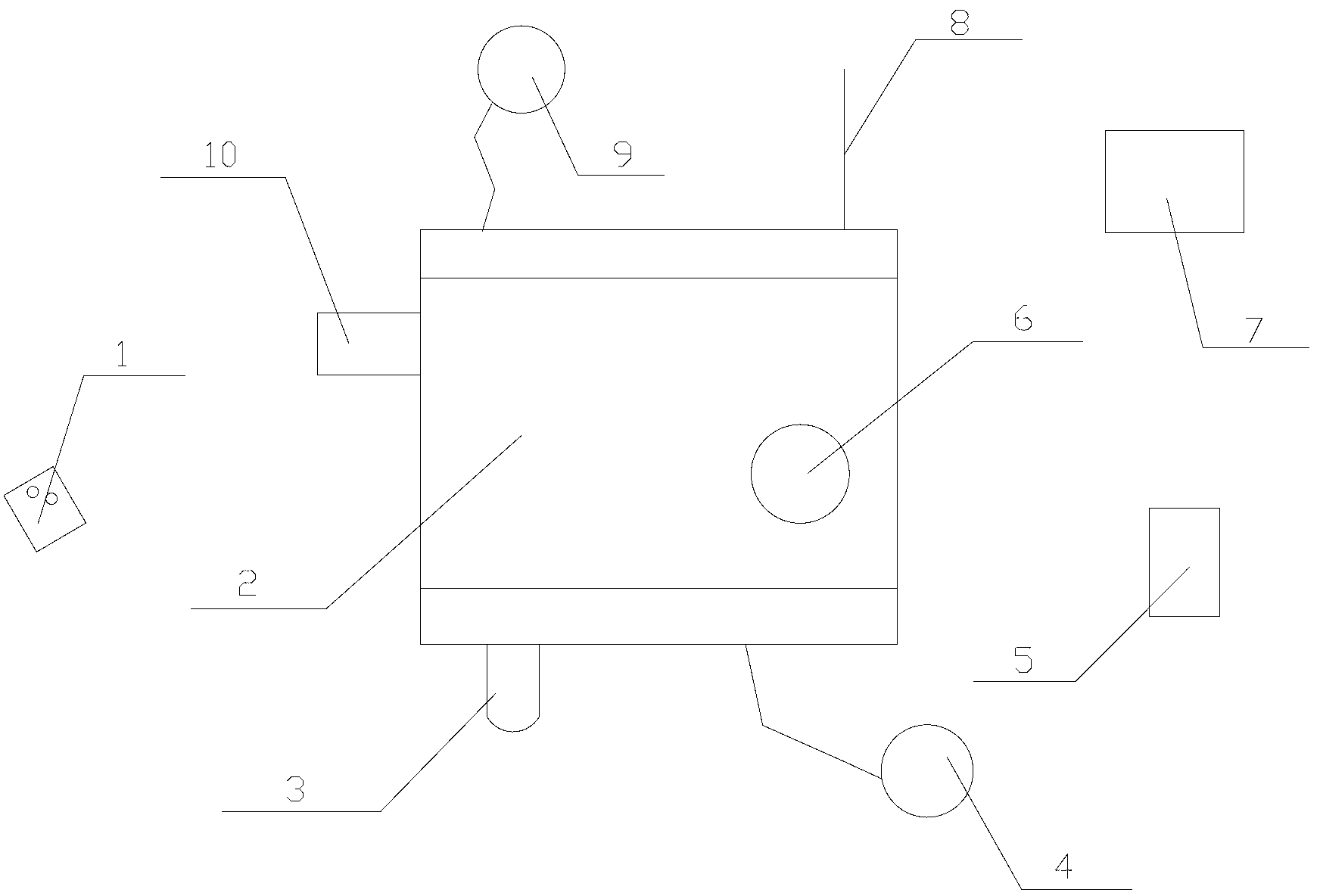

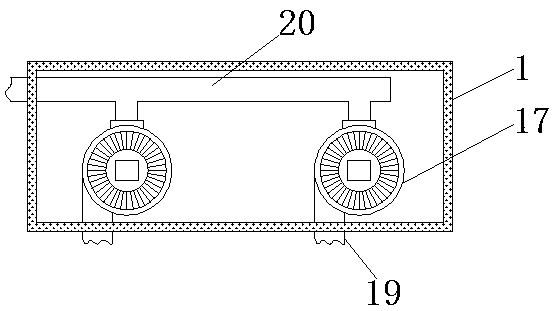

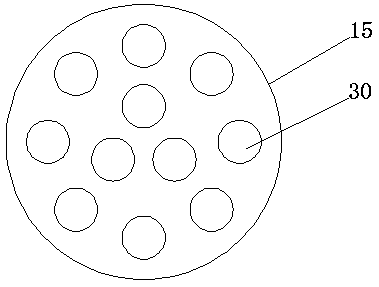

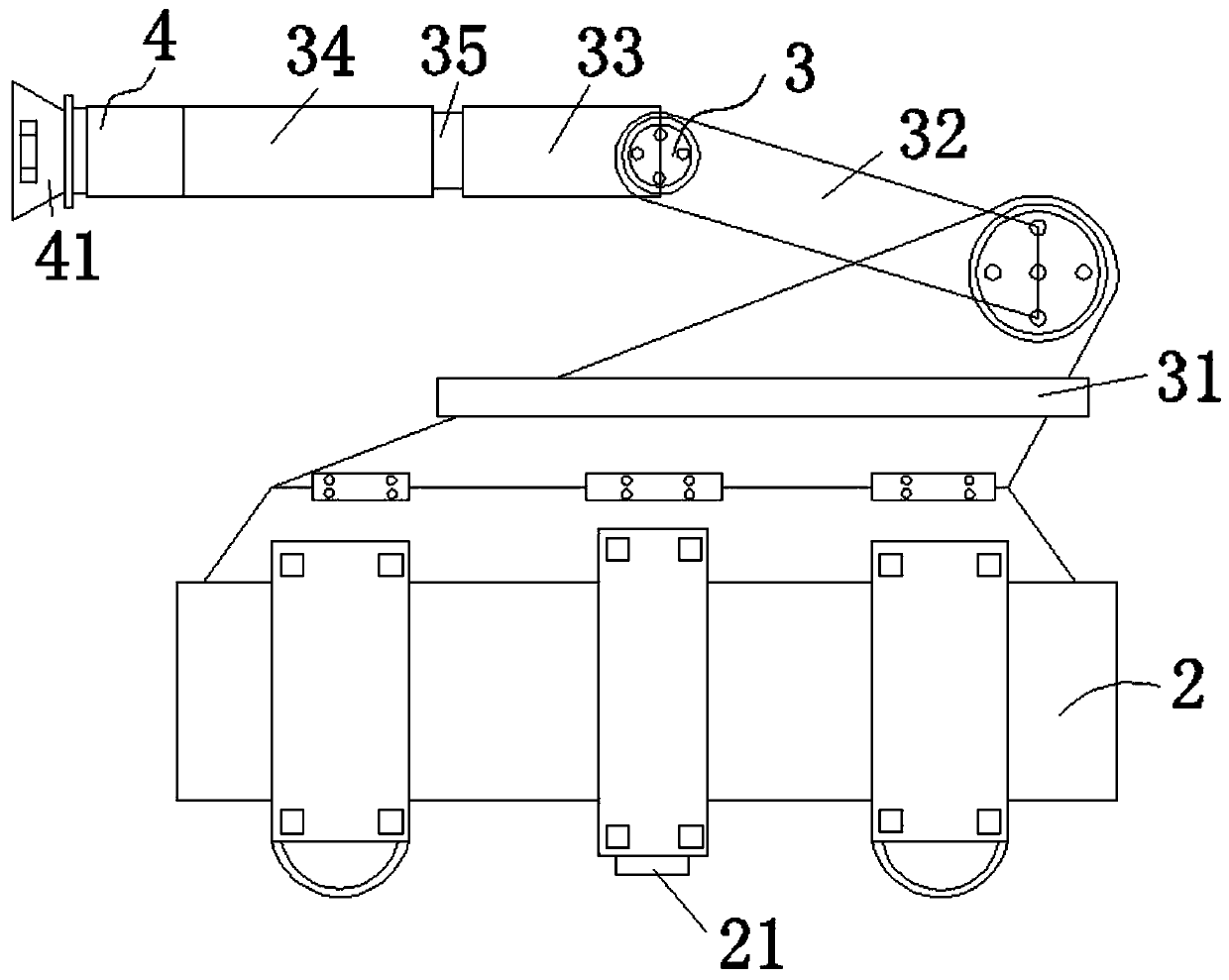

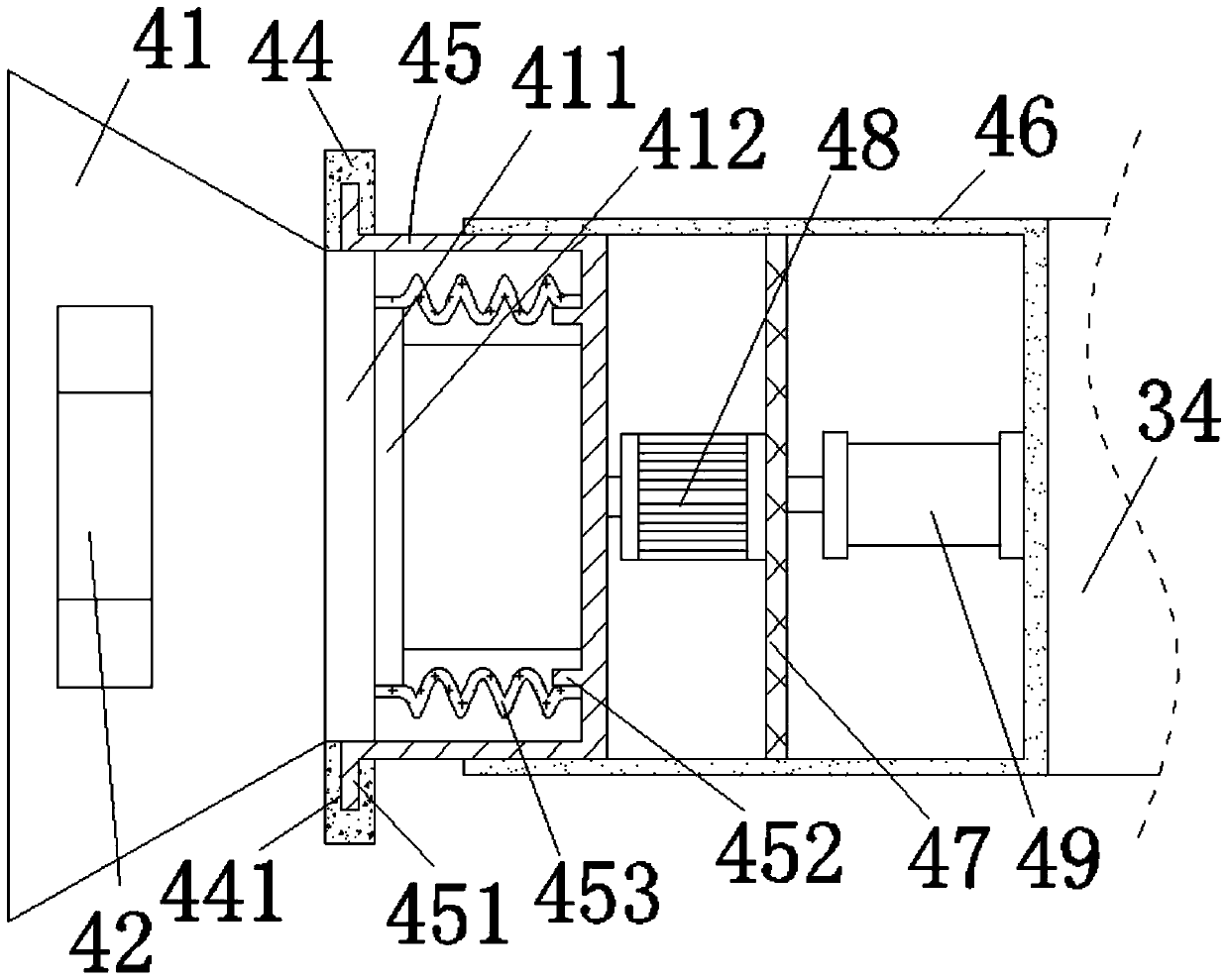

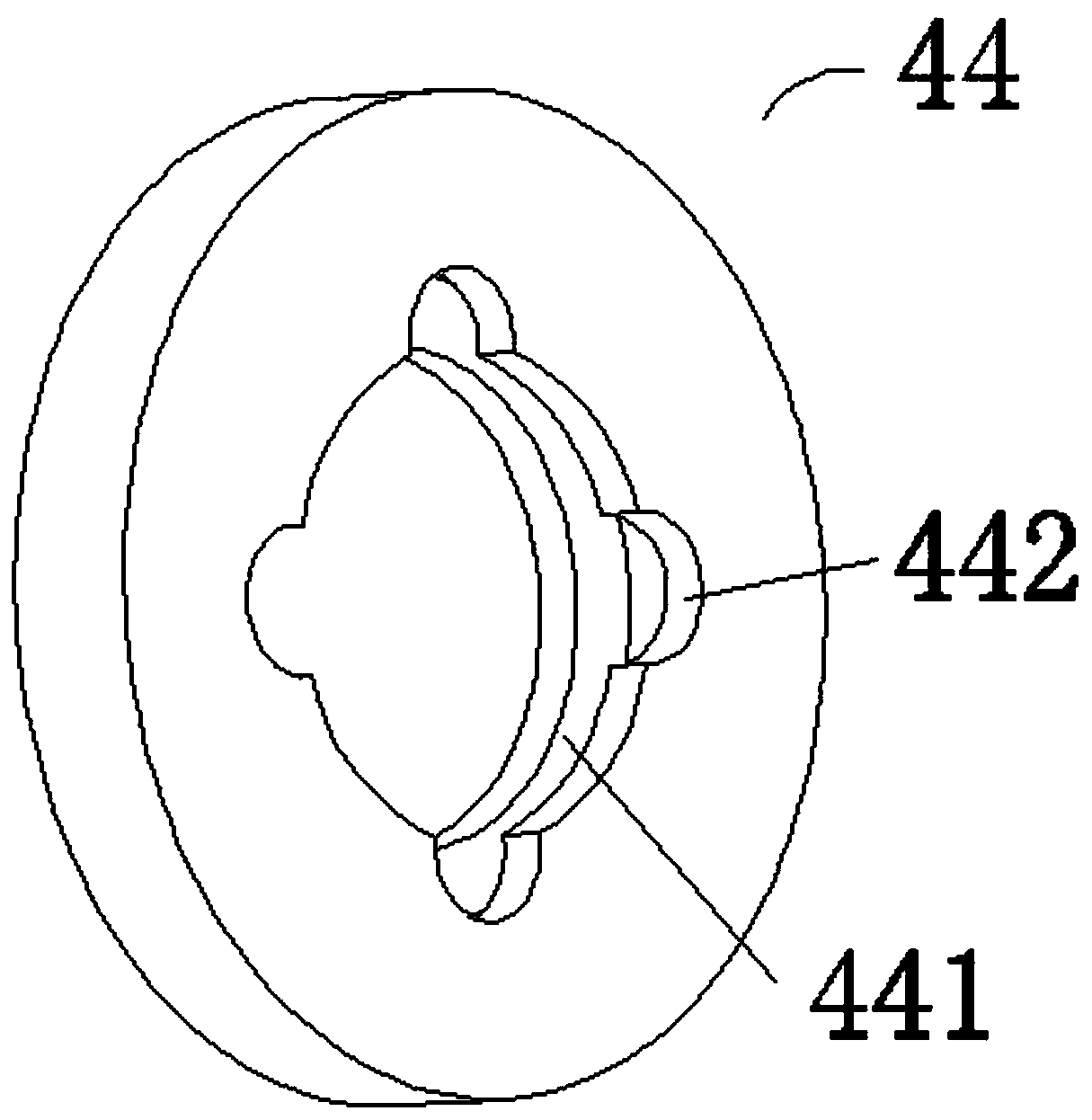

Hidden fan

PendingCN108150439ASolve space problemsSolve aestheticsPump componentsPump installationsGear wheelDrive motor

The invention provides a hidden fan. The hidden fan comprises a drive motor, a fixed shaft and an outer rotor. The hidden fan further comprises a rotary disc and a fan blade assembly. The fan blade assembly comprises fan blades and a fan blade gear. The fan blade gear is fixedly connected with the fan blades rotating along with rotation of the fan blade gear. The fan blades are unfolded or foldedrelative to the rotary disc. A position blocking mechanism is arranged between a drive gear and the rotary disc, and by means of the position blocking mechanism, when the drive gear rotates along withrotation of the outer rotor, the rotary disc and the drive gear are firstly staggered by a certain angle relatively and then synchronously rotate, and thus the fan blades are unfolded relative to therotary disc and then fixed relative to the rotary disc. A reset spring is further arranged between the drive gear and the rotary disc, and by means of the reset spring, when the drive gear stops rotating, the rotary disc is pulled to rotate relative to the drive gear to be reset, and thus the fan blades are folded relative to the rotary disc. The design structure is simple and compact, assembly is easy, space occupation can be reduced through folding of the fan blades, and the hidden fan looks attractive.

Owner:中山市聚达电器科技有限公司

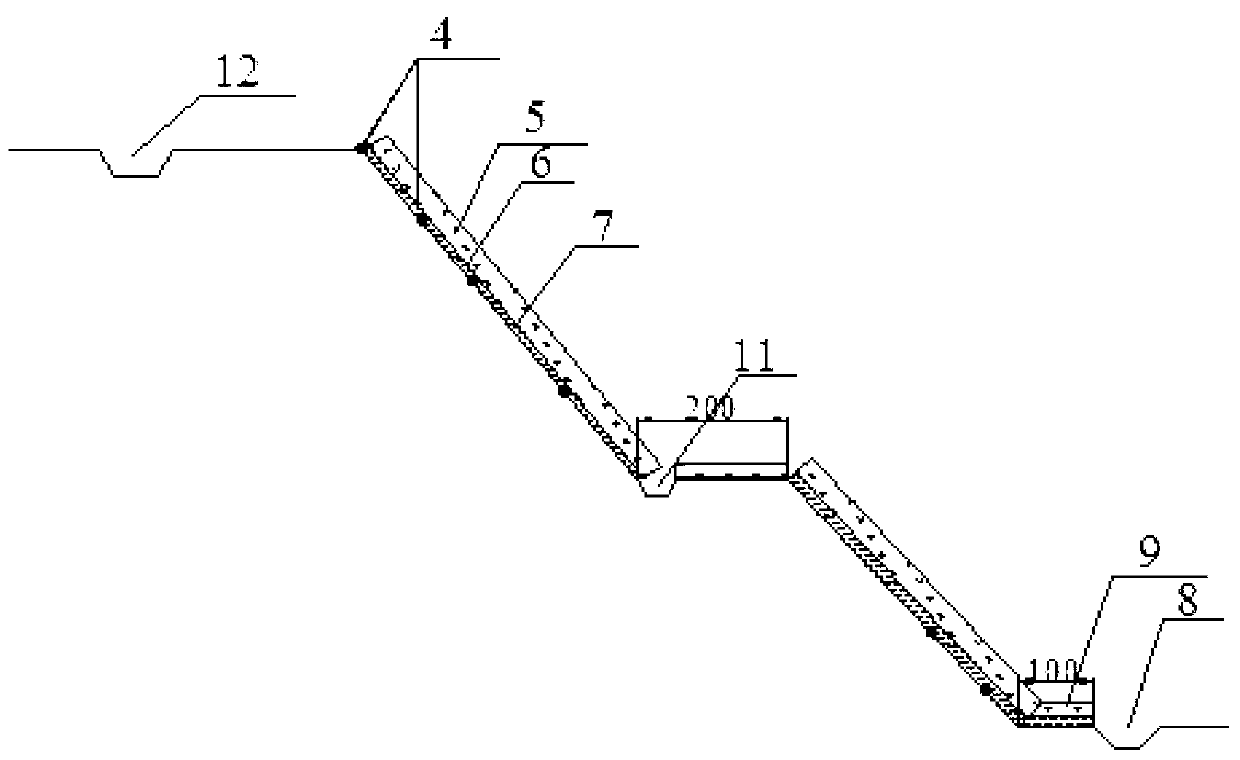

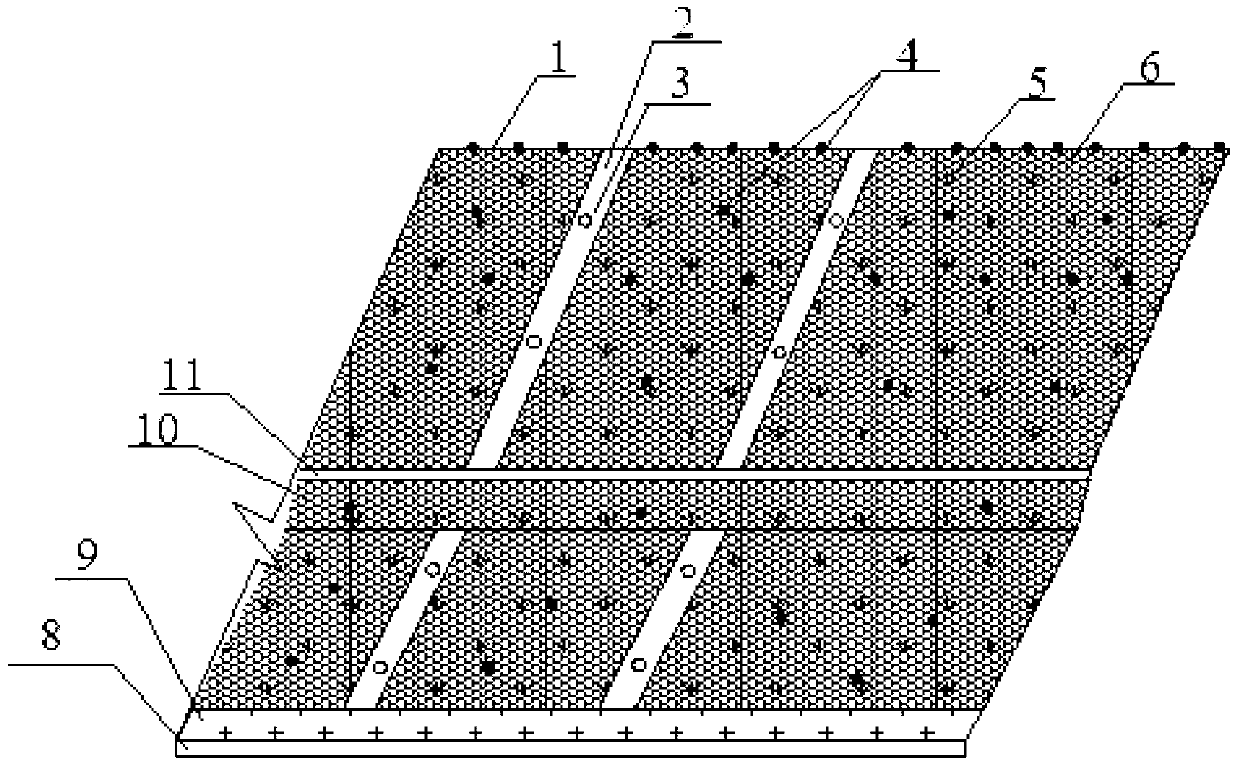

Reorganization and expansion highway slope protection system

InactiveCN103343542AFix stability issuesSolve aestheticsClimate change adaptationExcavationsEngineeringProtection system

The invention discloses a reorganization and expansion highway slope protection system which comprises a multistage slope body soil body (1), a thick-layer substrate (7), an anchor rod (4) and a coconut net (6). The reorganization and expansion highway slope protection system is safe and reliable and capable of reducing construction period, improves rain-washing-resisting capability and beautifies environment to solve the technical problems that a reorganization and expansion highway slope is poor in stability, not attractive, and prone to being washed by rain and damaged by falling rocks. The coconut net (6) is adopted to beautify the environment and can fix a slope toe, plants (5) on the thick-layer substrate (7) can improve the stability of the slope and improve the ecological protection effect of the slope, and the adopted anchor rod (4) can carry out reinforcing on the slope rope, and improves the stability of the slope.

Owner:广西桂海高速公路有限公司

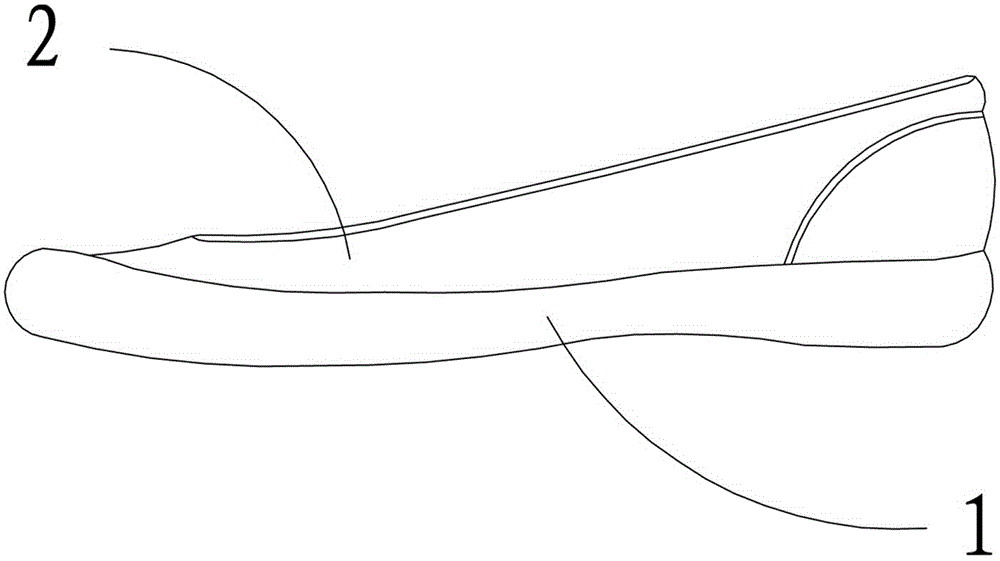

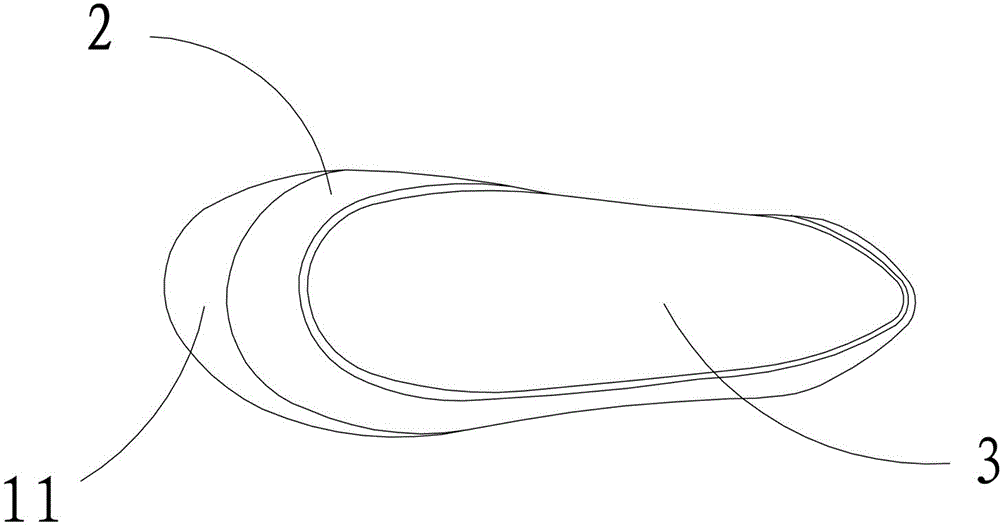

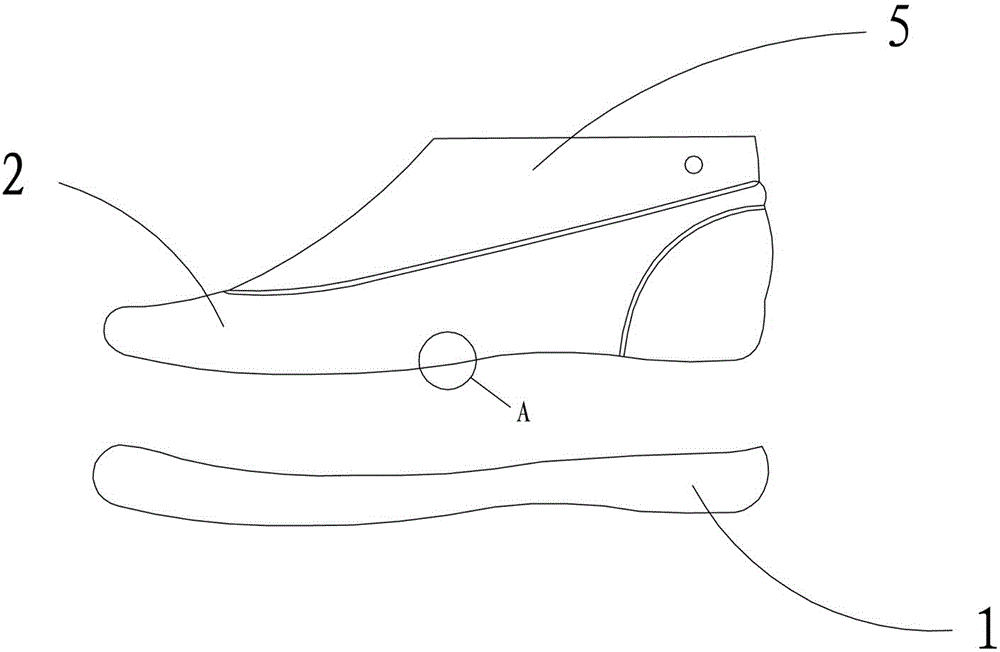

Structure of portable casual shoes and manufacturing process for portable casual shoes

ActiveCN102715696ASolve aestheticsEnough room to stretchShoe gluingAdhesive glueMechanical engineering

Owner:江西华景鞋业有限公司

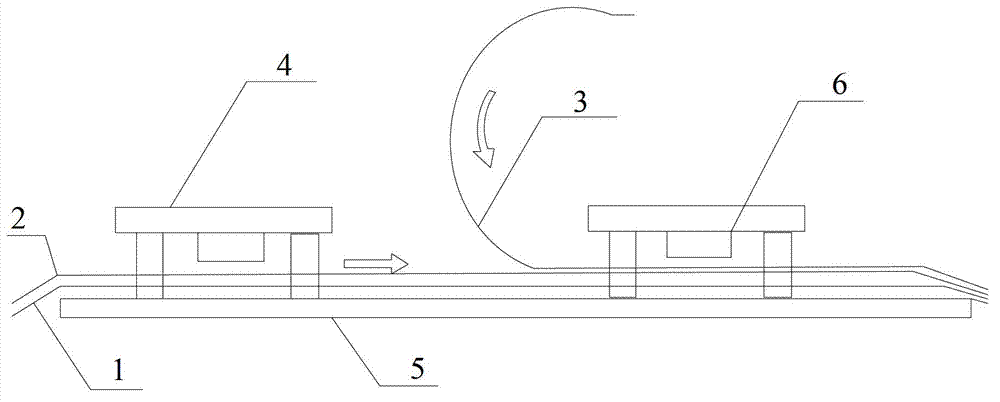

Processing device and processing technology for protective films with pull tapes

InactiveCN102765106ARealize continuous productionSolve the inconvenience of tearing offMetal working apparatusManipulatorElectrical and Electronics engineering

The invention discloses a processing device and a processing technology for protective films with pull tapes. The processing device for the protective films with the pull tapes comprises a die-cutting machine, a first die holder and a second die holder are sequentially arranged along the conveying direction of protective film raw materials on the die-cutting machine, a protective film die is placed in the first die holder, a pull tape die is placed in the second die holder, and manipulators of the die-cutting machine control the protective film die and the pull tape die to operate. The processing technology includes the steps of die-cutting kerfs on the protective films and die-cutting the pull tapes. The problems of inconvenience in tearing down and unattractiveness due to the fact that bonding areas of the pull tapes and the protective films cannot be well coincided resulting from manual bonding in a protective film production process in the prior art are solved.

Owner:罗华荣

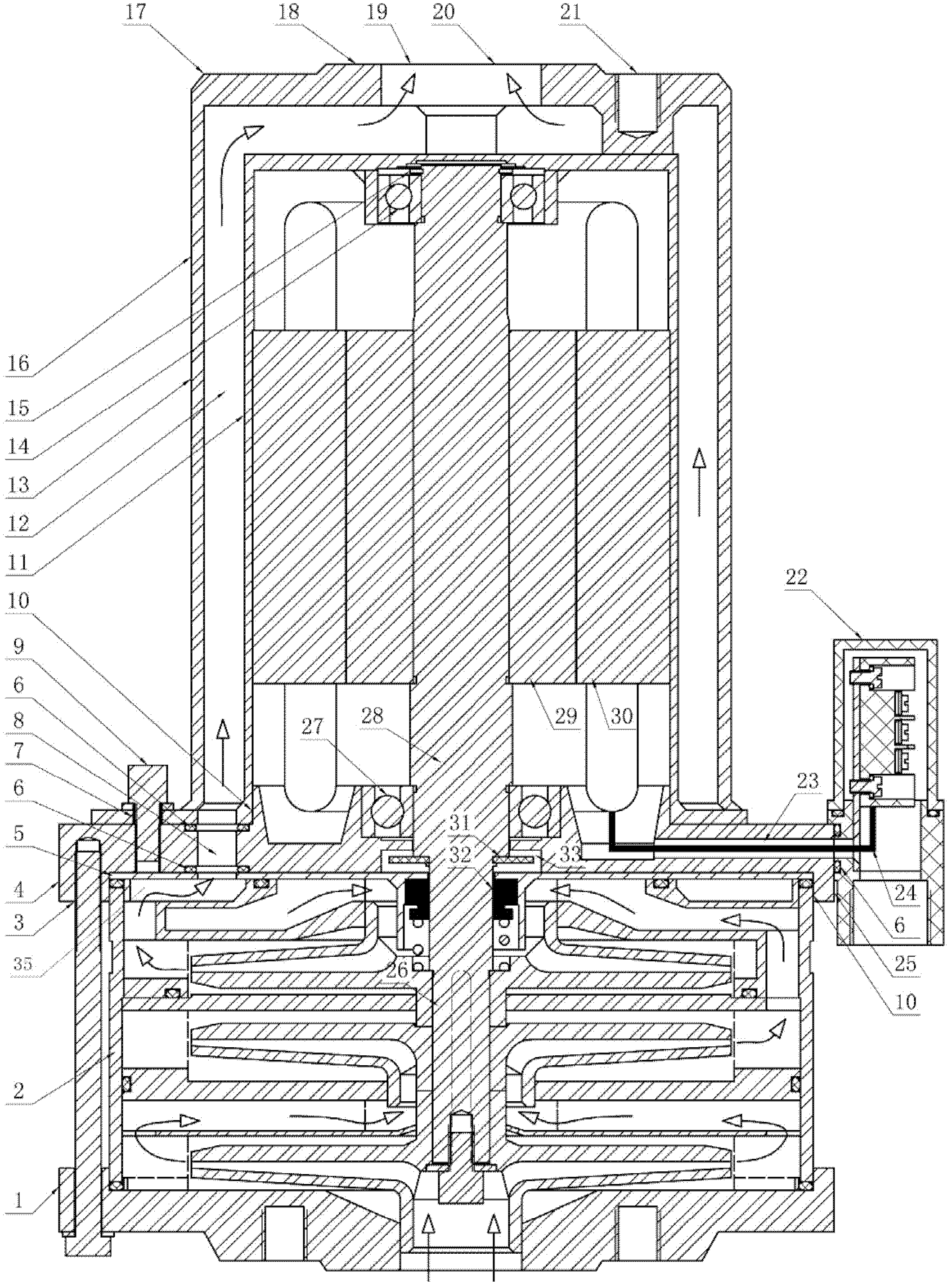

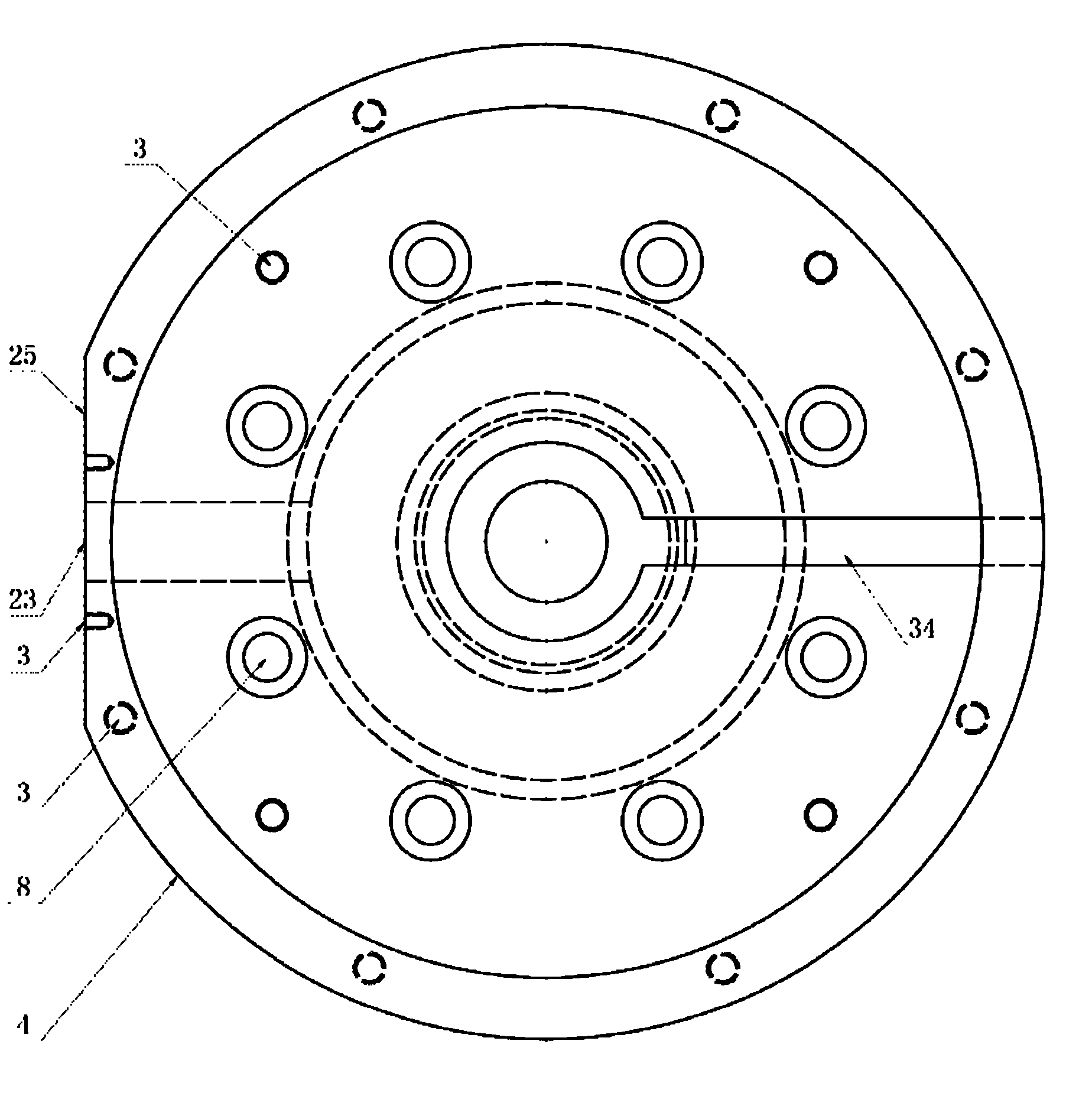

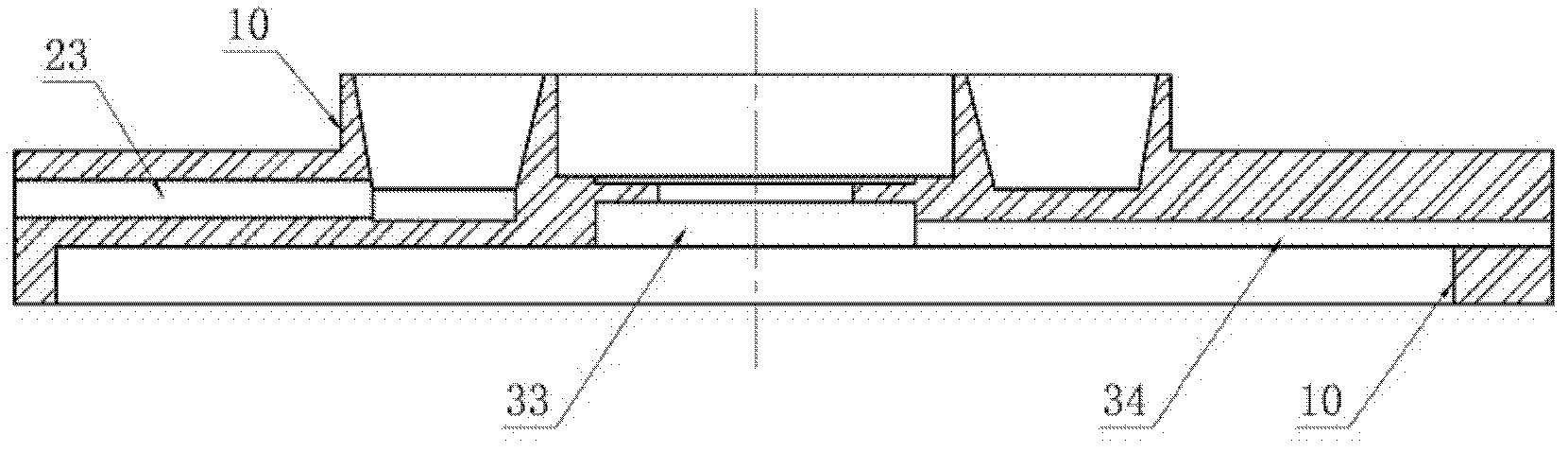

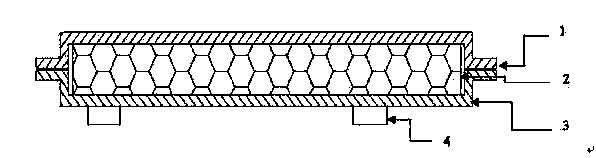

Pump water-cooled motor

InactiveCN102628445ACancel wind noiseRemove wind blade energy consumptionPump componentsPump installationsInsulation layerWater leakage

The invention discloses and relates to a pump water-cooled motor. a motor shellof the motor is provided with a cooling interlayer. The end of the inner shell is closed and the end of the outer shell is provided with a water outlet. The diversion outlets distributed on the ring cooling interlayer of the pump end of the motor shell are opposite to the diversion outlets of the cover end of the motor. Water from the pump passes through the diversion outlets and into the cooling interlayer of the motor shell, and is discharged from the water outlet. A motor shaft is led out from the pump end. If there is water leakage in mechanical seal, the leakage waterflows out of the pump through a draining chamber and a draining tank between the pump and the motor. A motor line is led out from a side hole of the cover end of the motor. The motor provided by the invention is characterized in that firstly the motor solves the problems of wind noiseand fan energy consumption of an air-cooled motor, greatly improves motor overload capacity, and effectively improves the disadvantages of quick motor bearing wear, fast lead insulation layer aging and burnout caused by super-large flow of a centrifugal pump; secondly the motor solves the disadvantages that water-cooled motor has high damage rate, has complex motor lead process, needs external diversion pipe, is not beautiful, has large size, and has high cost; thirdly the motor has characteristics of beautiful appearance, simple structure and easy production.

Owner:朱学斌

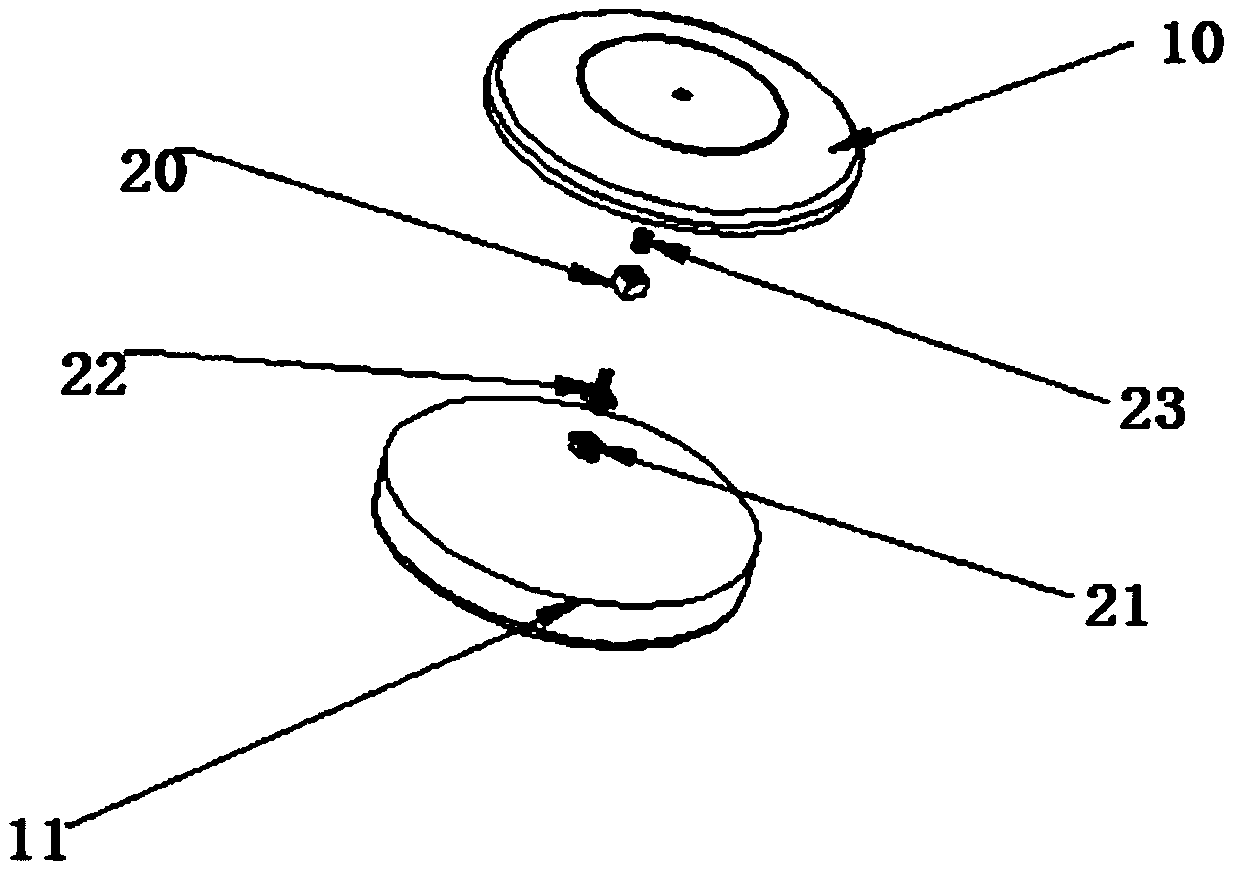

Centrally-mounted drive system of electric bicycle

ActiveCN102745298ALittle impact on appearanceIntensity effectWheel based transmissionChain/belt transmissionSingle stageVehicle frame

A centrally-mounted drive system of an electric bicycle comprises a chain wheel, a motor, a middle shaft and a reduction box, wherein the chain wheel has a disc-shaped structure; a concave circular mounting part is arranged in the middle position of the chain wheel; a housing of the reduction box is arranged in the concave mounting part and matched with the chain wheel; a reducing mechanism in the reduction box is a composite dual-overrun clutch, wherein the inner ring of an outer clutch and the outer ring of an inner clutch share the same component which serves as the output end of a hybrid power source; and the inner ring of the outer clutch is coaxially fixed to the chain wheel. The centrally-mounted drive system of the electric bicycle employs coaxial mounting, coaxial output and single-stage helical gear parallel transmission manners and successfully avoids great change of a frame caused by lift mounting; the single-stage reducing mechanism is employed to realize coaxial output; the volume of the motor is effectively reduced, which has little influence on the appearance of the entire bicycle; and viewed from the angle of the appearance of the entire bicycle, the similarity of the electric bicycle to the bicycle is very high.

Owner:广东广天机电工业研究院有限公司

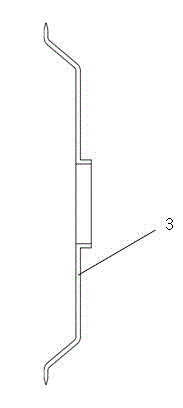

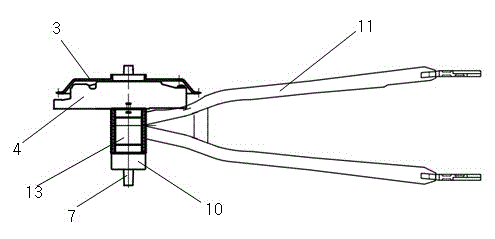

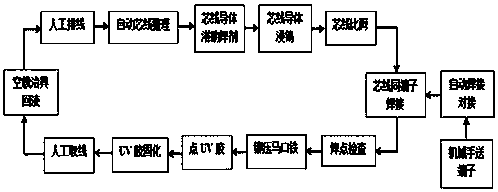

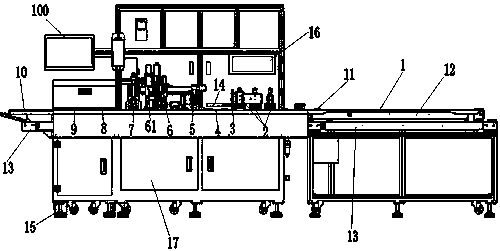

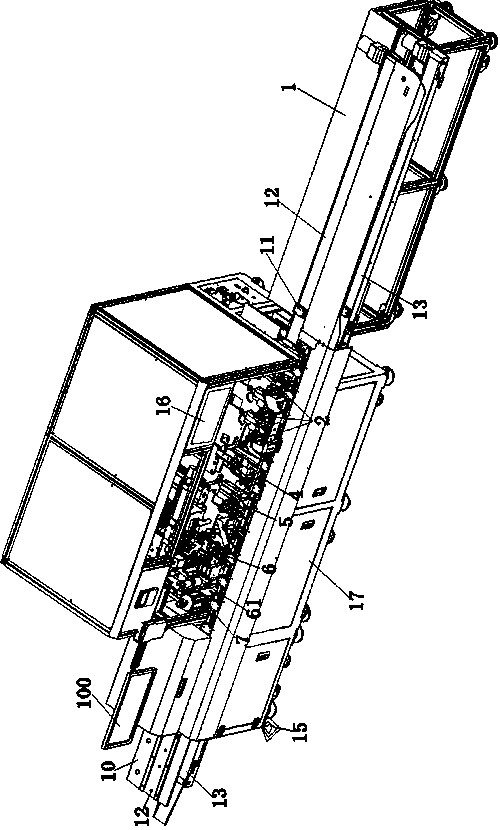

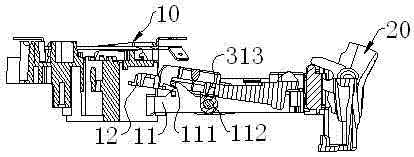

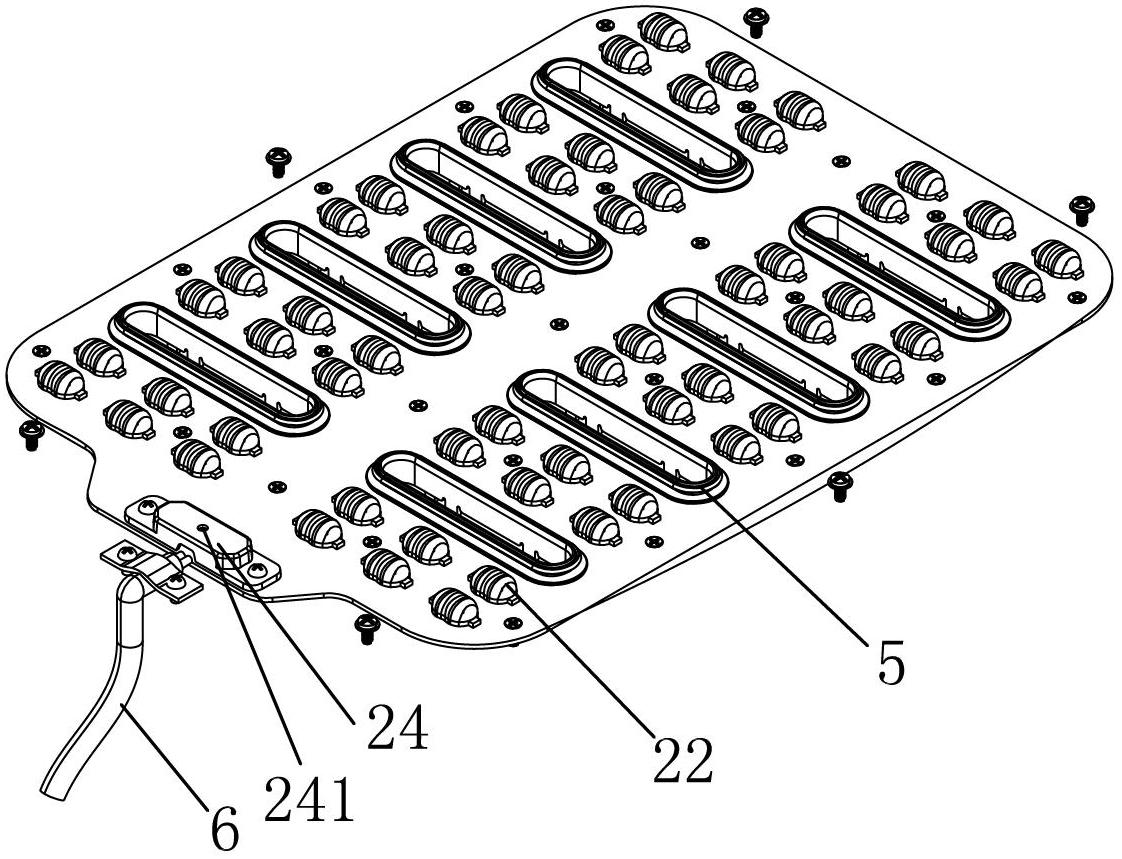

Assembly technique for data line and full-automatic production line for data line

PendingCN108063359AFlexible operationEasy maintenanceContact member cases/bases manufactureWire cuttingSoldering

The invention discloses an assembly technique for a data line, and the assembly technique comprises the following flow: manual line arranging-automatic core line arrangement-core line conductor coating of soldering flux-core line conductor tin immersing-core line proportional cutting-core line same terminal welding-welding spot checking-tinplate riveting and pressing-UV glue dispensing-UV glue solidification-manual line taking. The invention also discloses a full-automatic production line for the data line, and the production line comprises a machine platform, an output rail disposed on the machine platform, and a main controller. The main controller is electrically connected with an automatic stay wire cutting and peeling module group, a soldering flux dispensing module group, an automatic tin immersion module group, an automatic proportional cutting module group, an automatic tinning detection module group, an automatic riveting and pressing module group, an automatic glue dispensingmodule group, a point light source solidification module group and an output rail, wherein the automatic stay wire cutting and peeling module group, the soldering flux dispensing module group, the automatic tin immersion module group, the automatic proportional cutting module group, the automatic tinning detection module group, the automatic riveting and pressing module group, the automatic gluedispensing module group, the point light source solidification module group and the output rail are sequentially disposed beside the machine platform in a parallel manner. The production line enablesa plurality of processes to be effectively and seamlessly connected, improves the welding assembly efficiency by about three times, reduces the rejection ratio of products to zero, achieves the qualified rate of 100%, and is remarkable in effect.

Owner:HUIZHOU D&S CABLE

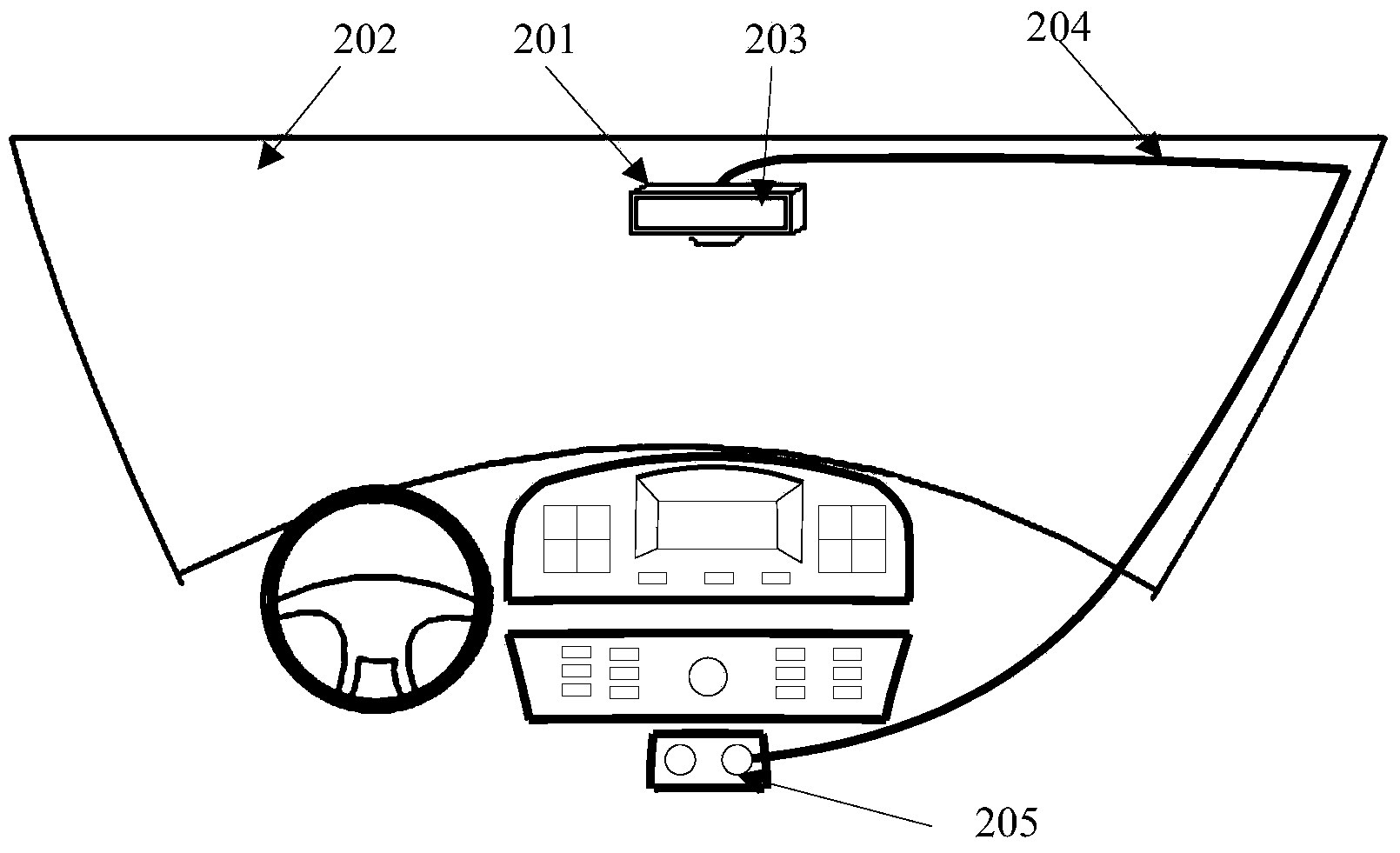

Charging device and charging method of vehicle-mounted navigator

InactiveCN103587483ASolve the inconvenience caused by the long-term need to plug in the power supply of the car cigarette lighterSolve aestheticsBatteries circuit arrangementsSecondary cells charging/dischargingUSBSatellite navigation

The invention discloses a charging device of a vehicle-mounted navigator. The charging device of the vehicle-mounted navigator comprises a plurality of buckles, a body, a first photovoltaic panel, a second photovoltaic panel and a first USB interface. An original rearview mirror is arranged between the charging device and the vehicle-mounted navigator. The buckles are arranged on the rear portion of the body and are matched with hooks on the rear portion of the vehicle-mounted navigator, so that the original rearview mirror is fixed between the charging device and the vehicle-mounted navigator. The first photovoltaic panel and the second photovoltaic panel are both in a foldable type and are arranged on the two sides of a fixed crank and a ball journal of the original rearview mirror respectively, the first photovoltaic panel and the second photovoltaic panel are in an L shape, and the first photovoltaic panel and the second photovoltaic panel are fixed on the body in a pivoted connection mode and can be unfolded to work in a rotating mode and can be packed up to be stored in a folding mode. The first USB interface is arranged on the body and is connected with a second USB interface arranged on the vehicle-mounted navigator through a USB connecting wire. The charging device of the vehicle-mounted navigator solves the technical problems of power line wiring and inconvenient mounting in the power supply process of an existing vehicle-mounted satellite navigation terminal.

Owner:HUBEI UNIV OF TECH

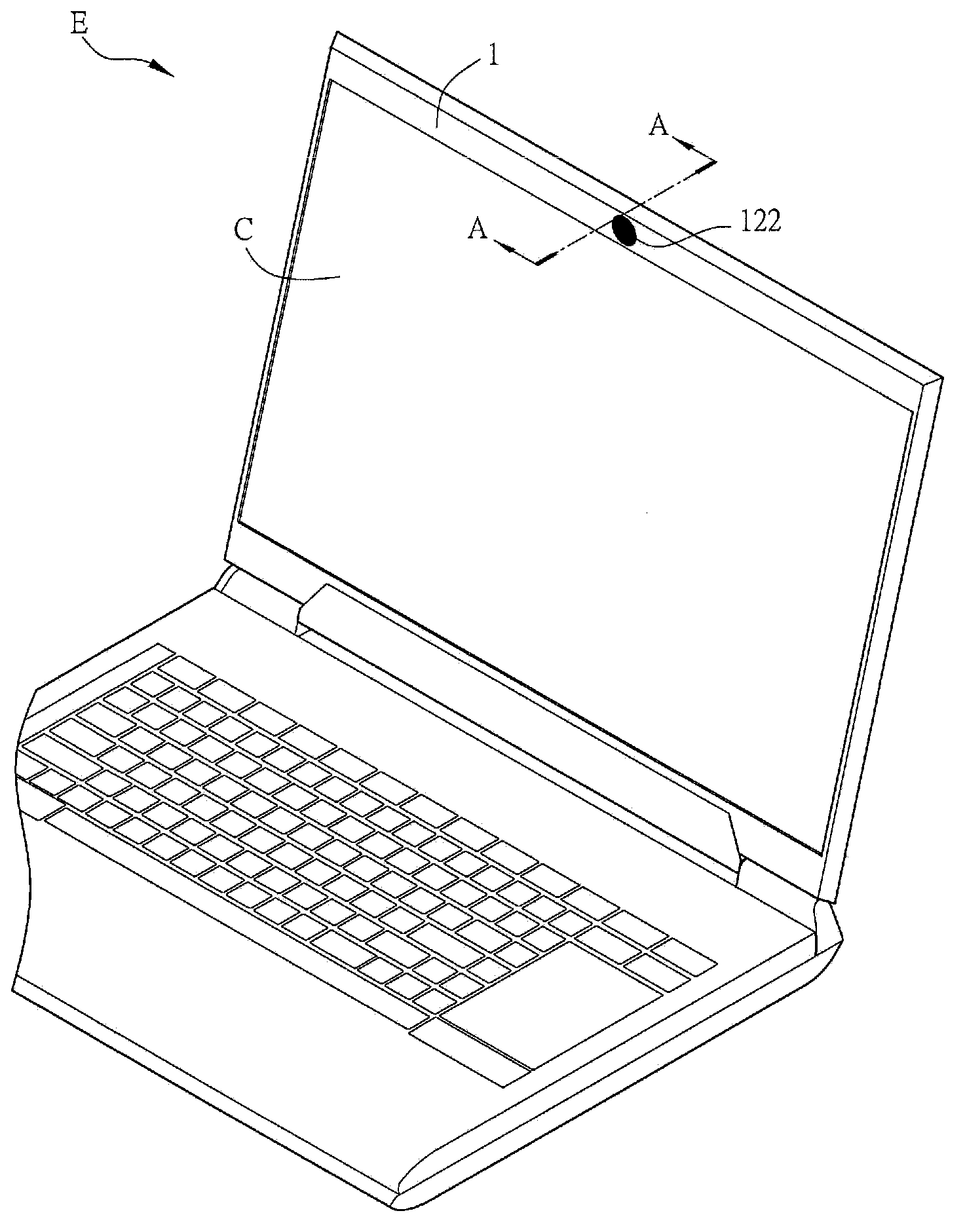

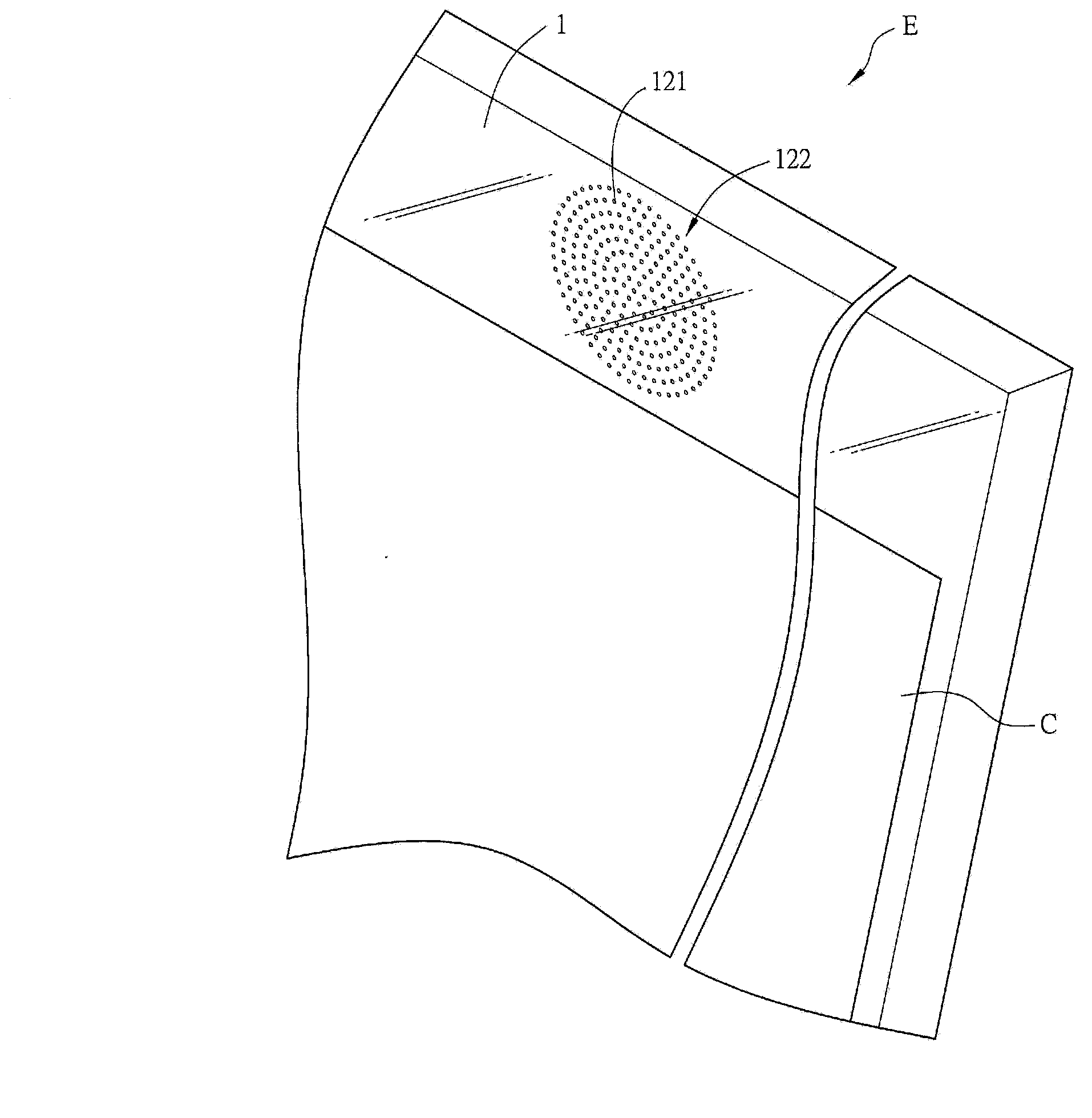

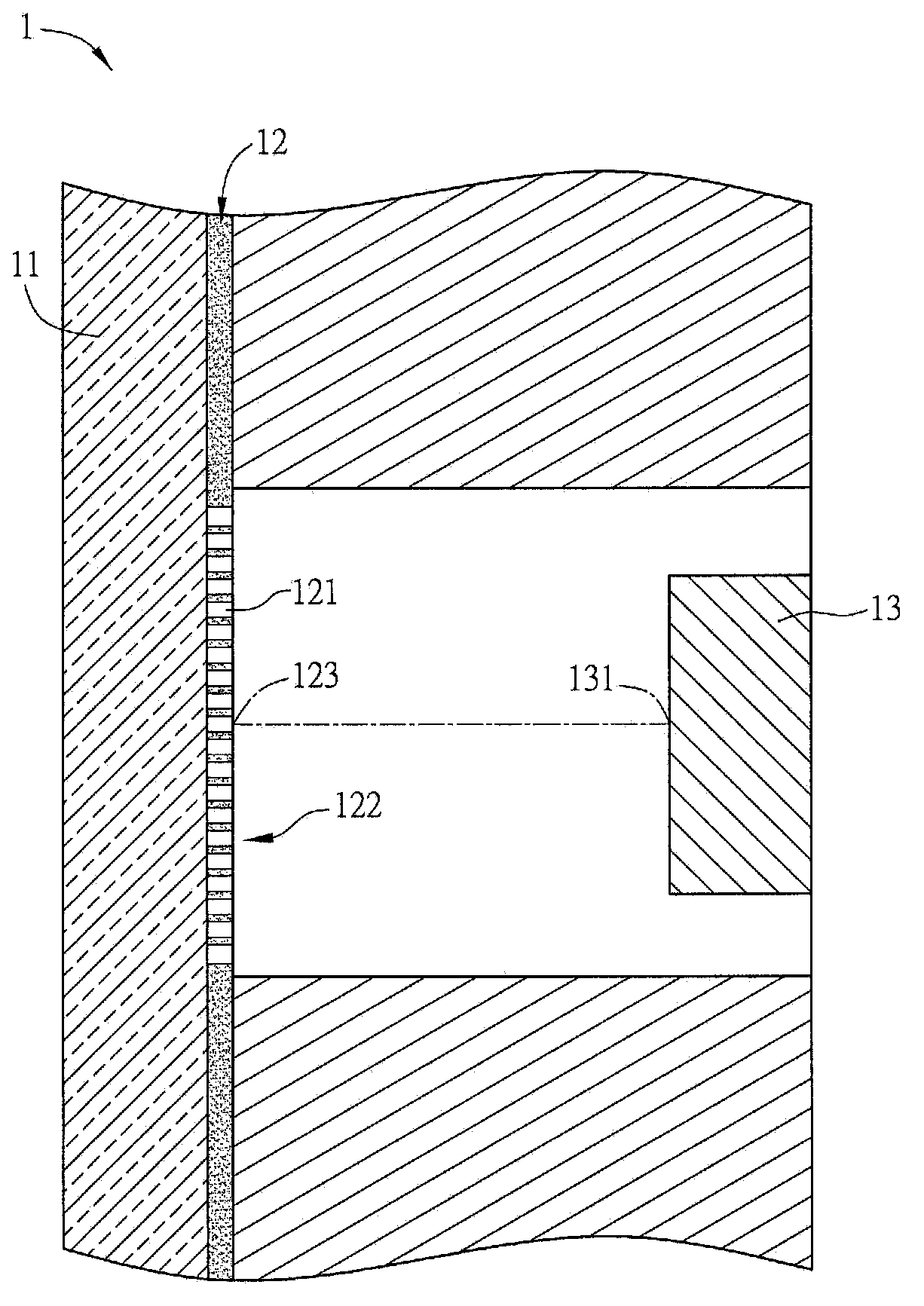

Optical panel and processing method thereof

InactiveCN103455099AGuaranteed aestheticsSolve aestheticsDigital data processing detailsPhotoresistElectron

A processing method of an optical panel used in an electronic device is disclosed. The processing method includes: selecting a light transparent panel and coating a photoresist on one surface of the light transparent panel; forming a plurality of light transmission hole patterns on a photomask; and forming a light shielding layer after the photoresist is exposed via the photomask and developing; and the light transmission hole patterns are transferred to the light shielding layer and a plurality of light transmission holes are formed on the light shielding layer.

Owner:ASUSTEK COMPUTER INC

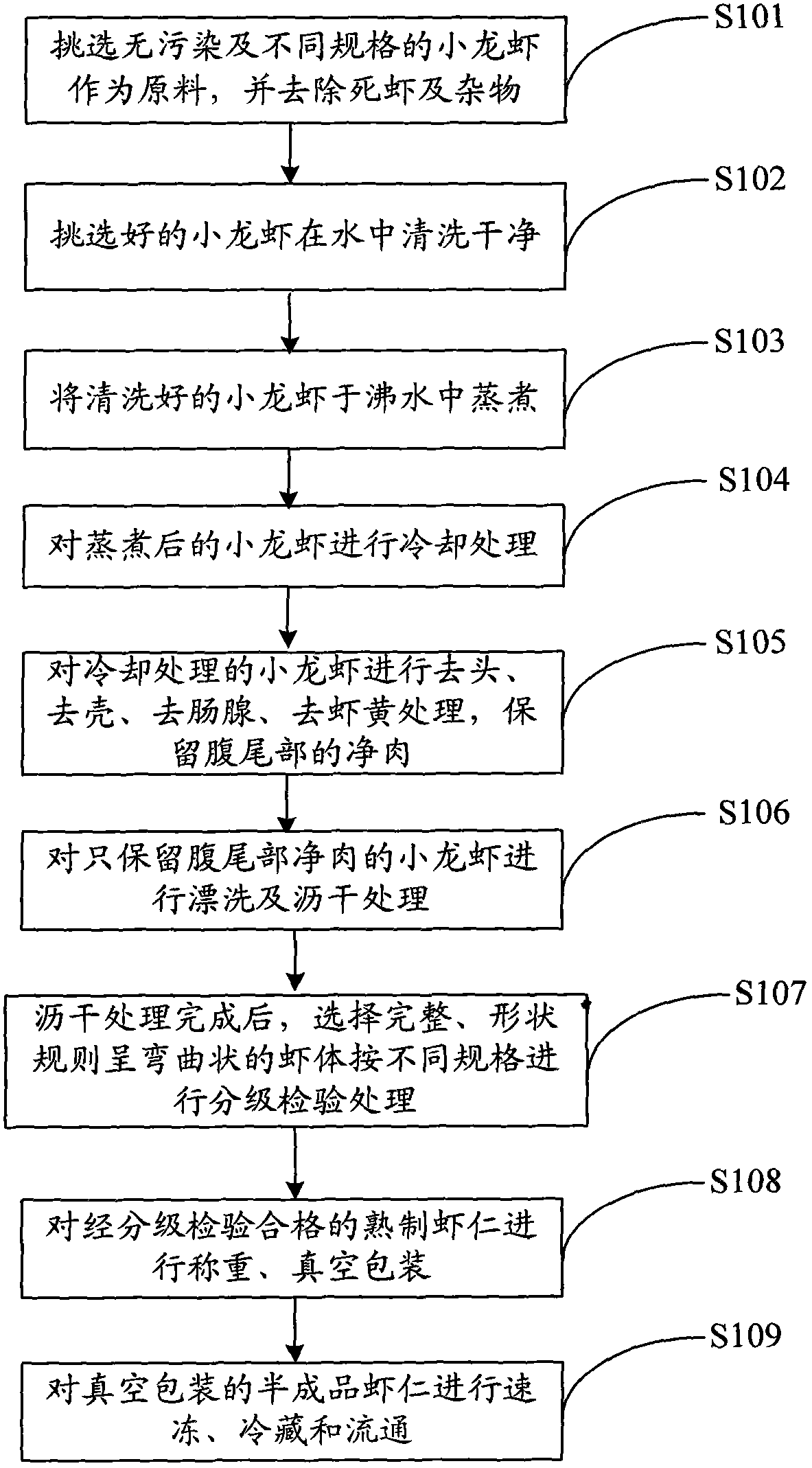

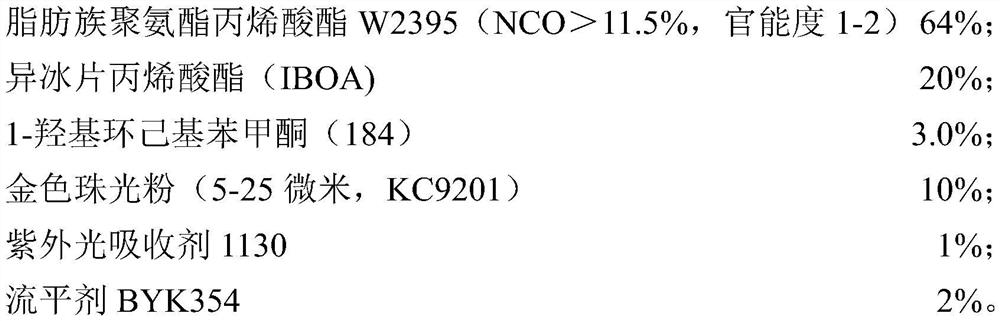

Method for quickly freezing cooked crayfish meat at low temperature

InactiveCN102640971AGuaranteed qualityNo significant difference in qualityFood preservationCold chainFlavor

The invention belongs to the technical field of food processing and provides a method for quickly freezing cooked crayfish meat at low temperature. The method has the following beneficial effects: under the condition of higher low temperature, the preservation time of the cooked crayfish meat can be lengthened to at least six months, thus the quality of the crayfish meat is assured; the crayfish meat at the moment does not obviously differ from the just cooked crayfish meat in quality, has unique flavor and strong delicate flavor, meets the requirement of people for crayfish all the year round, is quickly frozen at minus 20 DEC C and is stored and circulated under the condition of cold chain at minus 18 DEG C, thus not only lowering the freezing treatment costs of enterprises but also solving the problems that the raw crayfish meat is difficult to strip off the crayfish and is easy to pollute and the whole structure and beauty of the crayfish meat are easier to damage in the processing process; meanwhile, the crayfish is not easy to pollute and the product is not easy to perish; and the method has extensive prospect and advantages in the crayfish industry and has stronger popularization and application values.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

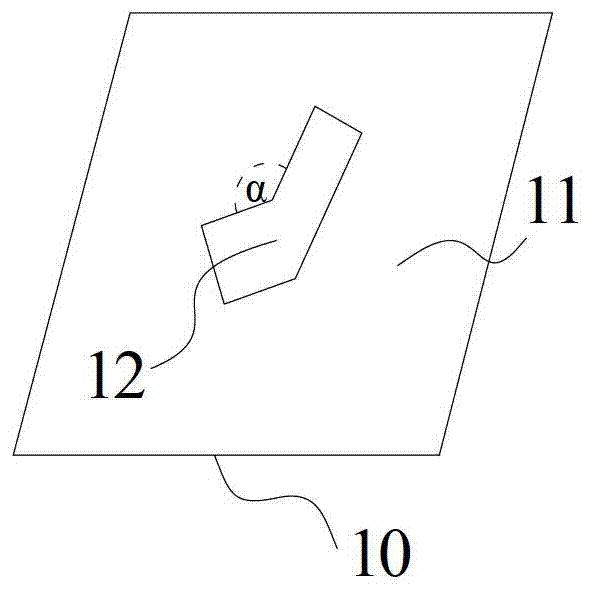

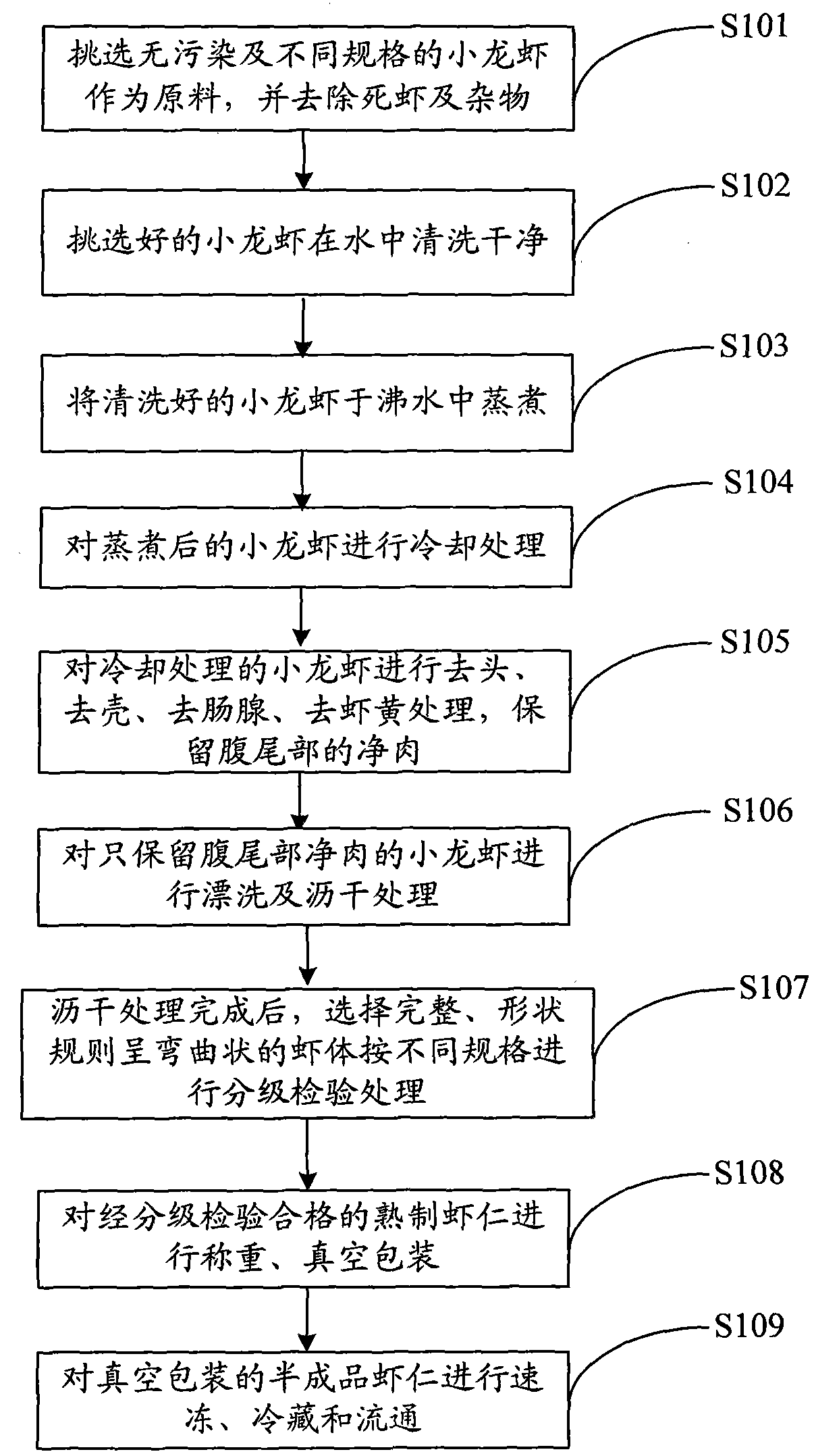

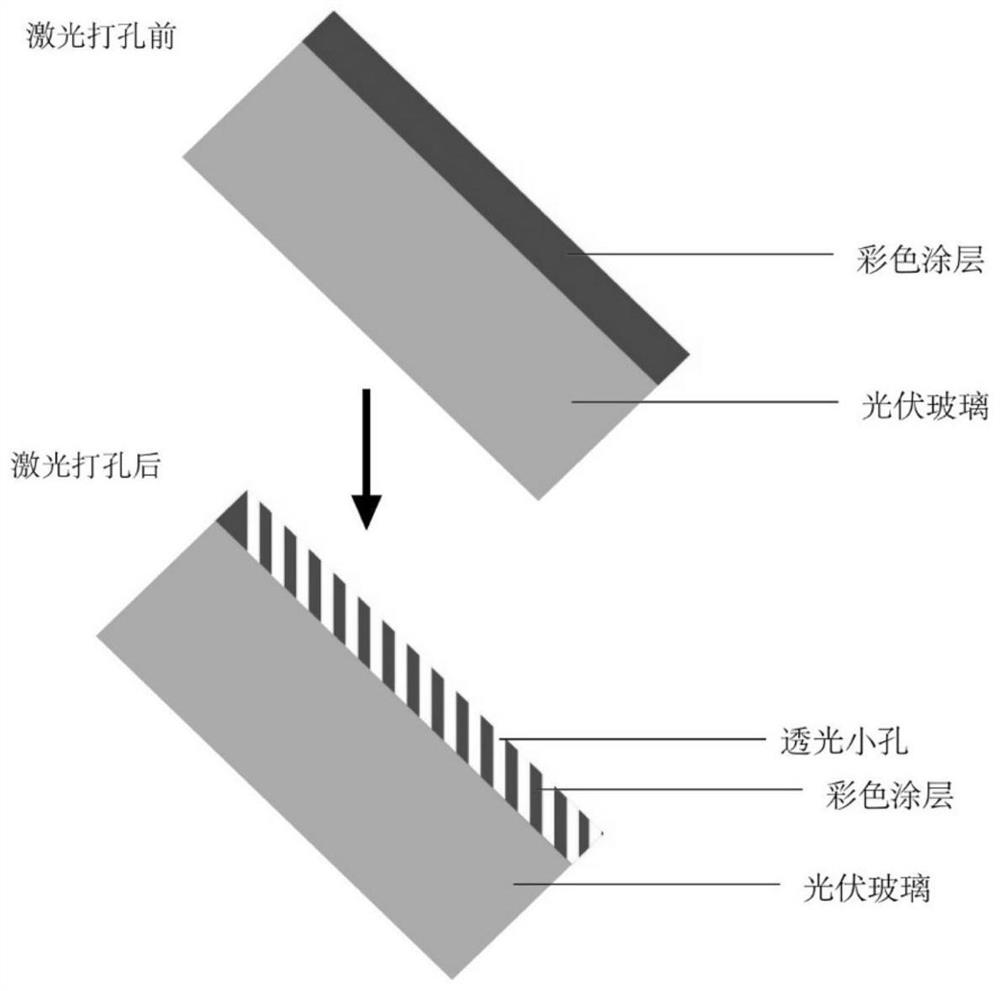

Solar panel with honeycomb-shaped colored coating, production method of solar panel and colored solar photovoltaic module

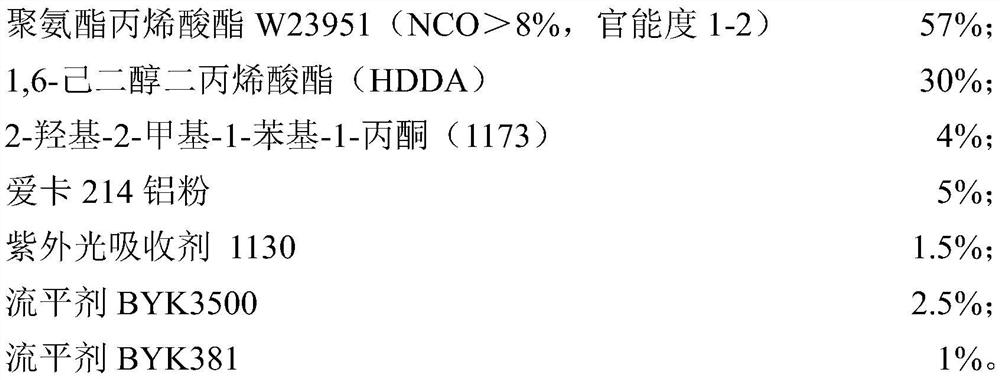

ActiveCN113097340AImprove photoelectric conversion efficiencySolve aestheticsPhotovoltaic energy generationSemiconductor devicesPhotosensPhoto irradiation

The invention discloses a solar panel with a honeycomb color coating, a production method of the solar panel and a color solar photovoltaic module, and the production method comprises the following steps: coating a transparent substrate with a UV color coating, and preheating the transparent substrate; after preheating, adopting ultraviolet light to irradiate the UV colored coating, and enabling the UV colored coating to be subjected to preliminary curing; obliquely punching or scribing the preliminarily cured UV colored coating by adopting a laser beam to form light holes or grooves, so that the UV colored coating forms a honeycomb structure; and performing post-curing on the perforated UV colored coating to form a solar panel with a honeycomb colored coating. The UV colored paint comprises the following raw materials in percentage by mass: 50-70% of a photosensitive polymer; 10-25% of a low-viscosity photoactive diluent; 1-5% of a photosensitizer; 1-15% of a pigment; 0.5-2% of an ultraviolet light absorber; and 0.01-3% of a leveling agent. The UV colored coating has a honeycomb structure, so that the light transmittance of the solar panel is obviously improved.

Owner:HANGZHOU KEWANG SPECIAL INK CO LTD

Double-flanged PP honeycomb plate luggage case spare cover plate and its production method

ActiveCN104385764AGuaranteed firmnessReduce the number of operatorsSynthetic resin layered productsLaminationFlangingWork in process

The invention discloses a double-flanged PP honeycomb plate luggage case spare cover plate and its production method. The spare cover plate is formed through compounding and flanging bonding of a skeleton layer (2), and a surface layer nonwoven fabric (1) and a back layer nonwoven fabric (3) which are compounded to the surfaces of the skeleton layer, the surface layer nonwoven fabric (1) and the back layer nonwoven fabric (3) are bonded in a double flanging compounding manner, the skeleton layer (2) is a PP honeycomb plate, and the surface layer nonwoven fabric (1) and the back layer nonwoven fabric (3) are nonwoven fabrics compounded with hot melt adhesive powder which can be easily bonded with a PP material respectively; and the back layer nonwoven fabric (3) at the back of the skeleton layer (2) is provided with a shock pad (4). The production method sequentially comprises the following steps: skeleton layer punching, heating compounding flanging, cooling fixing, semi-finished product punching and finished product production. The nonwoven fabric is compounded with back layer of the PP honeycomb plate and is bonded with the surface layer nonwoven fabric in a double flanging manner, so the strength and the rigidity of the cover plate are increased, the weight of the cover plate and the whole car noises are reduced, and the requirements of the car industry on light weight, environmental protection and beauty are met.

Owner:YANTAI ZHENGHAI HIGH TECH

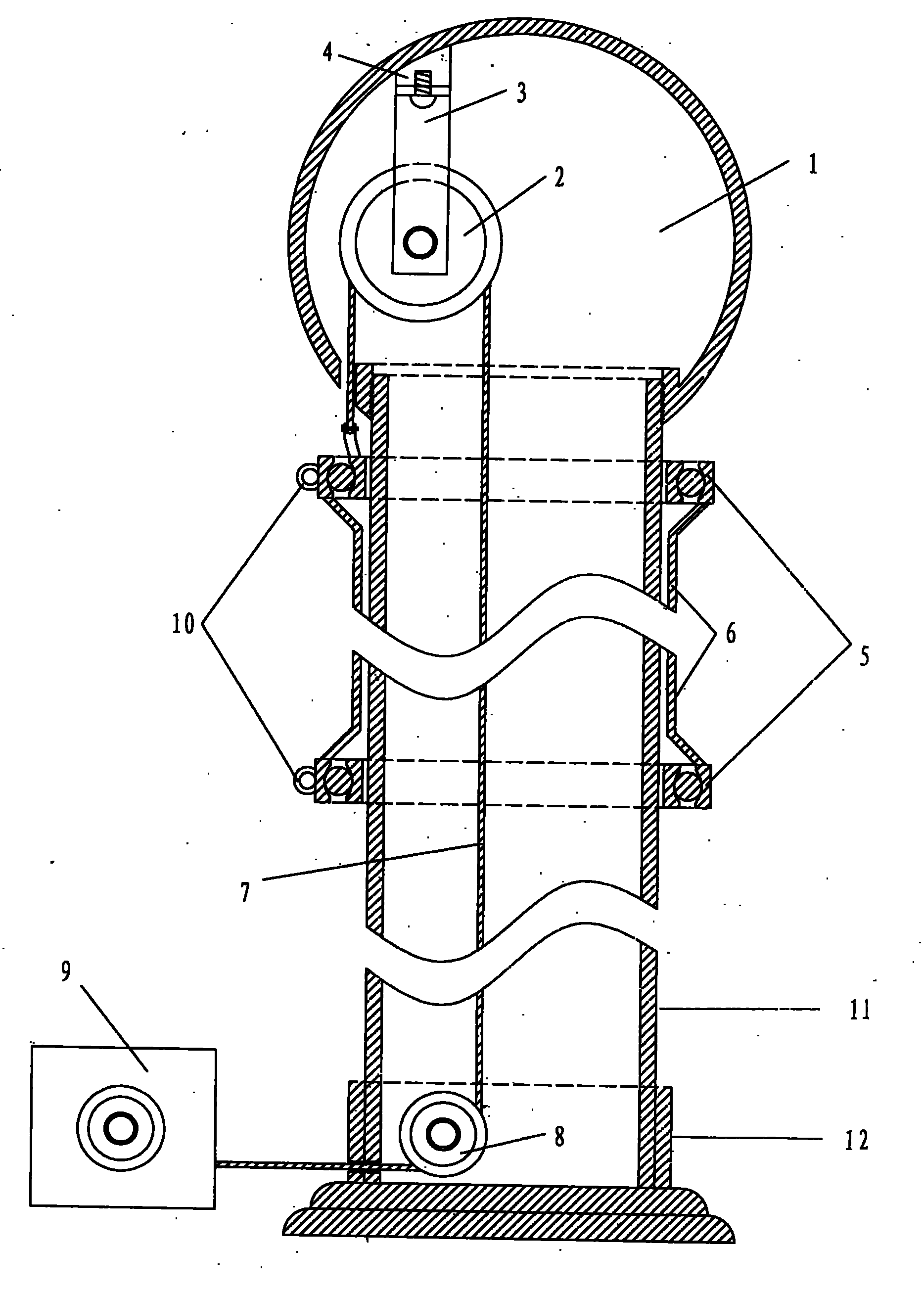

Lifting anti-winding flag pole

Commonly used flag poles are divided into two classes according to using methods, namely a lifting flag pole of which the upper end is provided with a fixed pulley and on which a flag is usually lifted by using a rope, and a fixed flag pole on which the flag is not easy to replace after the flag is directly hung on the flag pole. The invention discloses the lifting flag pole. The invention relates to the technical field of flag poles which do not wind the flags in any wind direction. Moreover, after the flag is lifted, the rope for lifting the flag cannot be seen from the outside. The technical background comprises that in most current lifting flag poles, the fixed pulley is placed at the tail end of the flag pole, and the flag is lifted and suspended through the rope hung on the fixed pulley. The invention solves the problem that the flag pole is unaesthetic and undignified because the flag is wound and the lifting rope is naked outside the flag pole due to the change of the wind direction. The total design comprises that a fixed pulley is arranged in a spherical crown body at the top end of the flag pole, and the spherical crown body opposite to the lower part of a pulley groove is provided with a rope passage so that one end of the rope can pass to get the outside of the flag pole. A flag anti-winding device is linked under the rope. The upper and lower end parts of the anti-winding device are provided with two special-shaped bearings which are sleeved outside the flag pole (inner sleeves of the bearings are slightly thicker than the flag pole, and have certain clearance so that the device slides on the flag pole). Outer shaft sleeves of the two bearings are connected by two symmetrical connecting plates, and the outer shaft sleeves and the connecting plates can rotate freely and horizontally. The problem that the flag is wound on the flag pole is solved by using tension of wind and free rotation.

Owner:宋铁芳

Temperature controller switching component

InactiveCN102376492ASimple structureSolve health problemsBoiling over preventionThermal switch detailsControl theoryWater bottle

The invention relates to the technical field of switching mechanisms, in particular to a temperature controller switching component which can be used for an electric kettle. The component comprises a temperature controller and a switching button, wherein the temperature controller comprises a main body component and a moving component; the moving component is arranged on the main body component and can rotate around a rotating shaft; the moving component rotates to close or open a circuit contact of the main body component; the component also comprises a bracket; the bracket is provided with a connecting rod capable of driving the moving component to act and is clamped with the main body component through the connecting rod; the switching button is clamped on the bracket; and through mutual linkage action between the switching button and the bracket and between the bracket and the temperature controller, the switching button drives the bracket to move, the connecting rod of the bracket pushes the moving component of the temperature controller to realize on and off of the temperature controller circuit when the switching button acts. Through the temperature controller switching component, the problems of sanitation and beautification finally caused by over-large holes due to a large switching path on a kettle body are solved, and meanwhile, the technical problems of large space occupied by the switch and limitation in size design of the kettle body are solved.

Owner:MIDEA GRP CO LTD

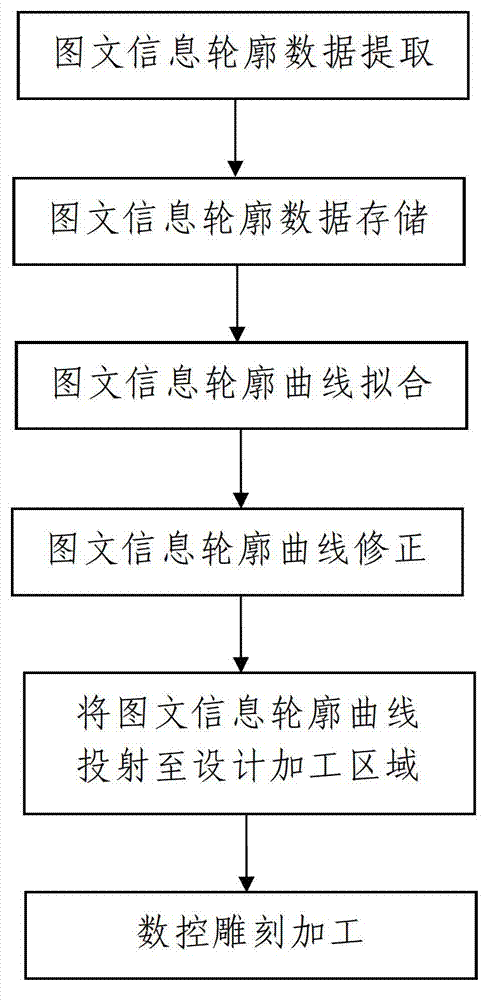

Engraving method for image-text information outline

ActiveCN102819238AThe method steps are simpleEasy to operateComputer controlSimulator controlNumerical controlData ingestion

The invention discloses an engraving method for an image-text information outline, wherein image-text information required to be engraved is a manually drawn image or a manually written text. The method comprises the following steps of: 1, image-text information outline data extraction, namely extracting outline data of the image-text information required to be engraved by adopting a manual extraction or automatic extraction method; 2, image-text information outline data storage, namely storing the extracted outline data of the image-text information required to be engraved and generating a data storage file; and 3, digital control engraving, namely respectively engraving all external outline lines and all internal outline lines in the image-text information required to be engraved by utilizing a numerically-controlled machine according to the information stored in the data storage file. The method provided by the invention has simple steps, is convenient to realize, requires less manpower and material resources, is high in processing efficiency and engraving accuracy, and can be used for solving the problems such as low processing efficiency, difficulty in ensuring the neatness and tidiness of processed images or texts and poor appearance of the processed images or texts in an existing steel matrix manual printing method.

Owner:XIAN COAL MINING MACHINERY

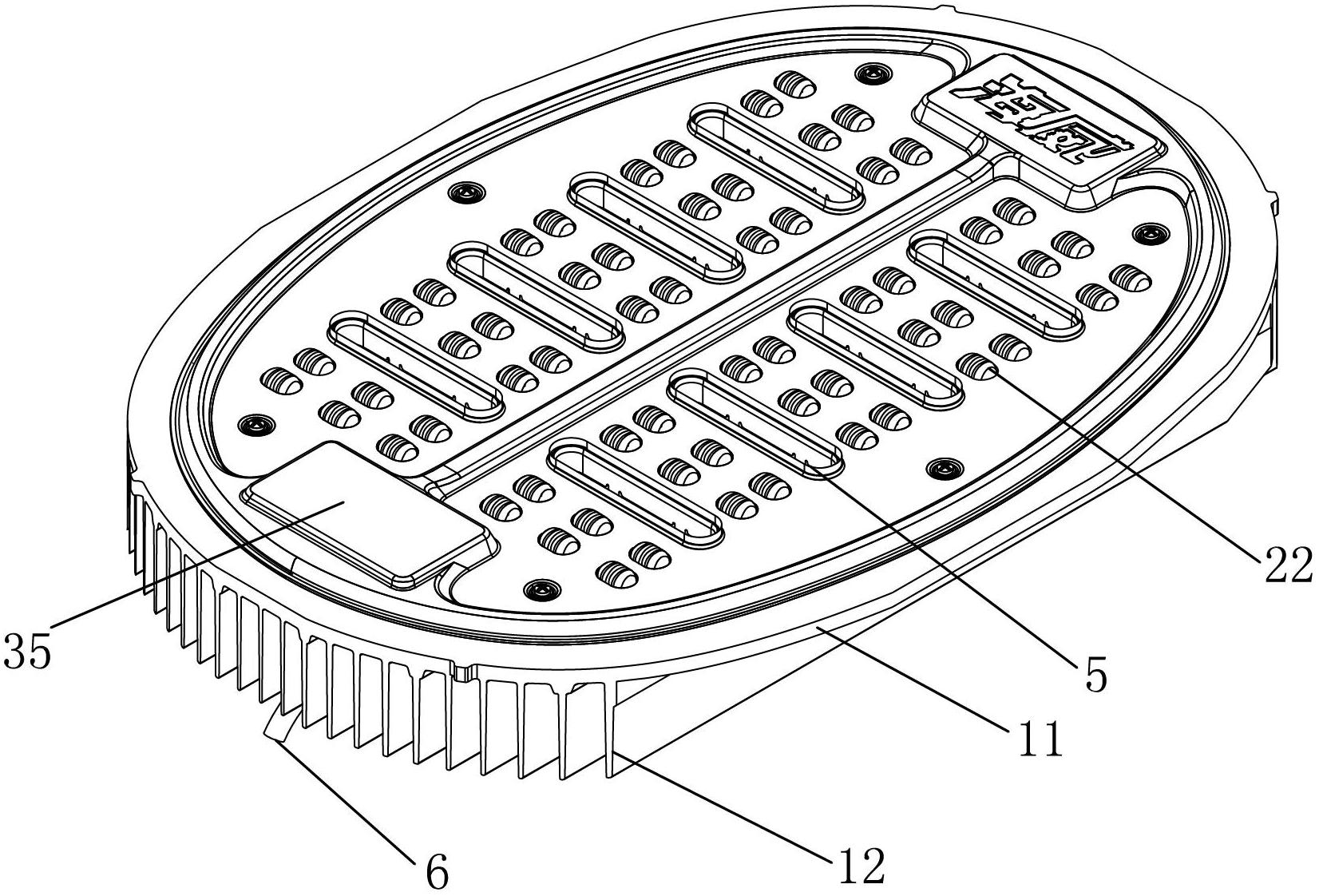

Integral light-emitting diode (LED) street lamp module

InactiveCN102661552AOutstanding and Beneficial Technical EffectsDawn has the same effectPoint-like light sourceLighting heating/cooling arrangementsEngineeringAluminum substrate

The invention belongs to the technical field of light-emitting diode (LED) street lamps, and in particular discloses an integral LED street lamp module. The integral LED street lamp module comprises a radiator, an aluminum substrate and a panel which are connected in sequence, wherein the aluminum substrate is provided with LEDs and lamp shades; radiating fins are arranged on a radiator bottom board; and a plurality of air vents are formed at corresponding positions on the radiator bottom board, the aluminum substrate and the panel. The integral LED street lamp module has high radiating performance and long service life, can be matched with a street lamp bracket as an integral penetration type LED street lamp module, and is rapidly mounted and dismounted and convenient to maintain.

Owner:浙江海威照明科技有限公司

Intelligent anti-theft door lock

InactiveCN103321491ASolve aestheticsImprove anti-theft performanceNon-mechanical controlsLock casingsElectricityMotor drive

The invention provides an intelligent anti-theft door lock and relates to the technical field of safety and protection. The intelligent anti-theft door lock is used for solving the problems that the existing anti-theft door lock is unattractive in appearance, poor in anti-theft performance and inconvenient to disassemble. The intelligent anti-theft door lock comprises a lock body, an integrated circuit board and a plurality of sensors; the lock body comprises a lock casing, a transmission rod and a motor; a lock cylinder is fixed at one end of the transmission rod; the motor drives the transmission rod to move; the integrated circuit board is provided with a remote controller, an inductor and an alarm controller; the remote controller is connected with a key; the inductor is electrically connected with the alarm controller; the alarm controller controls an alarm which is connected with the alarm controller to give alarms; the sensors are arranged on doors and windows. The intelligent anti-theft door lock has the advantages of being simple in structure and convenient to install, being capable of simultaneously protecting the windows and doors, being automatic in alarming and being capable of automatically switching on illuminating lamps, automatically dialing communication tools and accordingly performing on-site and remote monitoring, alarming and crime evidence collection in real time.

Owner:青岛良赢建设工程有限公司

Preparation method of jun porcelain heat preservation cup with metal luster and anti-bacterial function

InactiveCN107879718ASolve aestheticsSolve insulation problemsDrinking vesselsClaywaresCalcitePotassium

The invention discloses a preparation method of a jun porcelain heat preservation cup with metal luster and an anti-bacterial function. According to the method, 25-30 parts of kaolin soil, 15-20 partsof potassium feldspar, 5-10 parts of quartz, 5-10 parts of chinastone, 5-8 parts of tourmaline and 3-5 parts of bentonite are obtained, sealing rods and a blank body with an interlayer and reserved holes are prepared, and presintering is carried out; 5-8 parts of tourmaline, 12-15 parts of Muyu stone, 25-35 parts of albite, 45-50 parts of quartz, 10-15 parts of calcite, 15-20 parts of sintered kaolin soil, 12-15 parts of chinastone, 5-10 parts of zirconium silicate and 2-3 parts of stannic oxide are adopted for preparing glaze materials to be applied to the outer and inner walls of the presintered blank body and the surfaces of the sealing rods; the sealing rods are inserted into the reserved holes of the blank body, then the blank body is placed into a vacuum sintering oven, a vacuum pump is switched on to pump air in the interlayer, and the glaze materials on the sealing rods and the interlayer are melted to achieve sealing between the sealing rods and the blank body; then the outerwall of the densified ceramic heat preservation cup body after glaze firing is plated with a metal membrane and an anti-bacterial nanometer coating. The prepared jun porcelain heat preservation cup has not only the metal texture but also the anti-bacterial function.

Owner:张自军

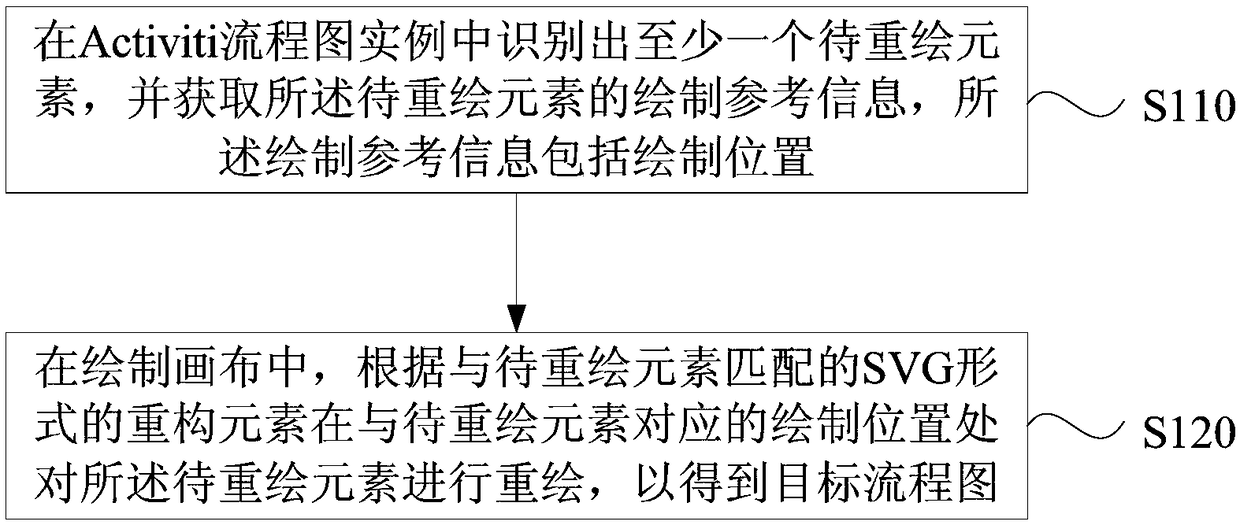

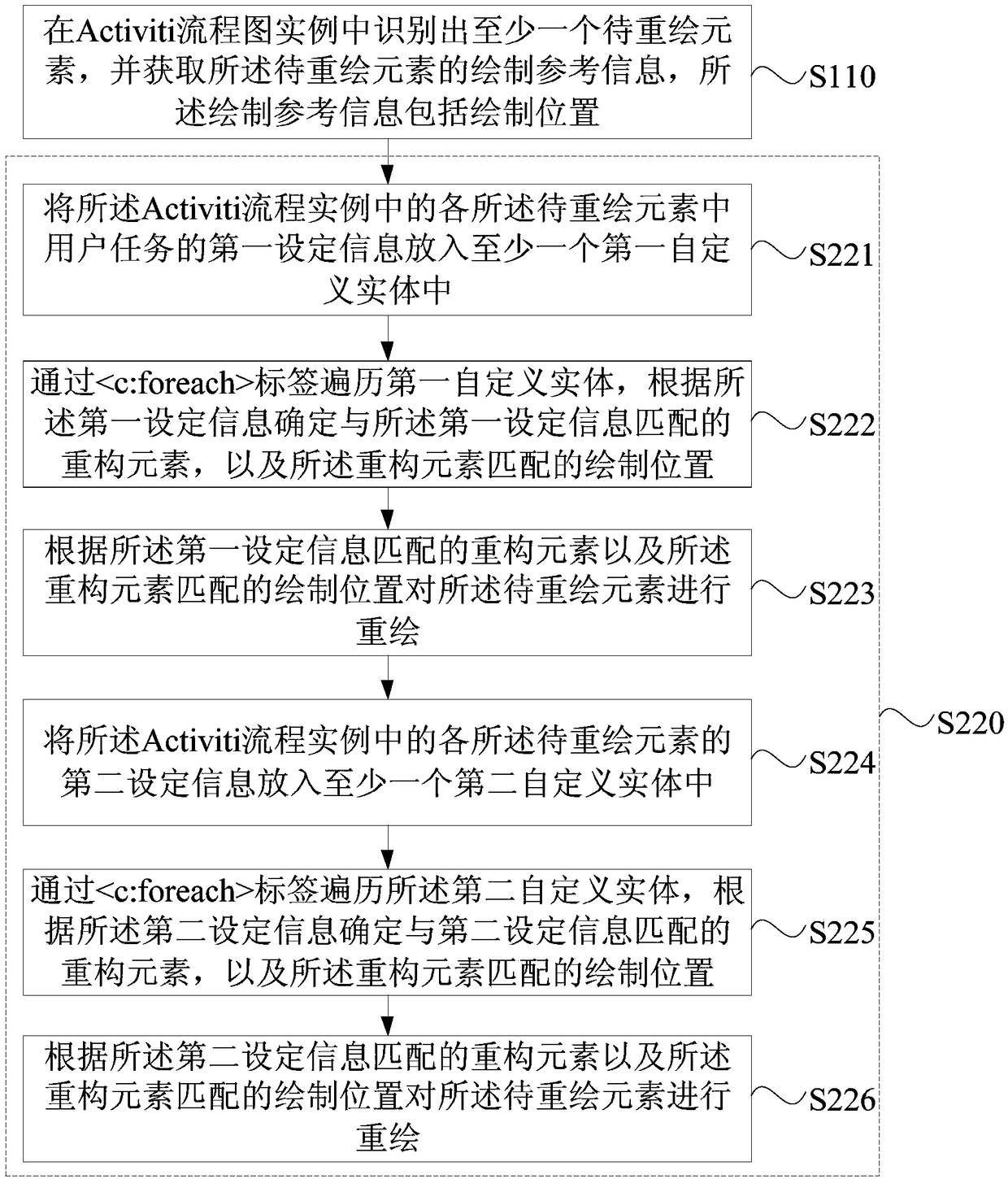

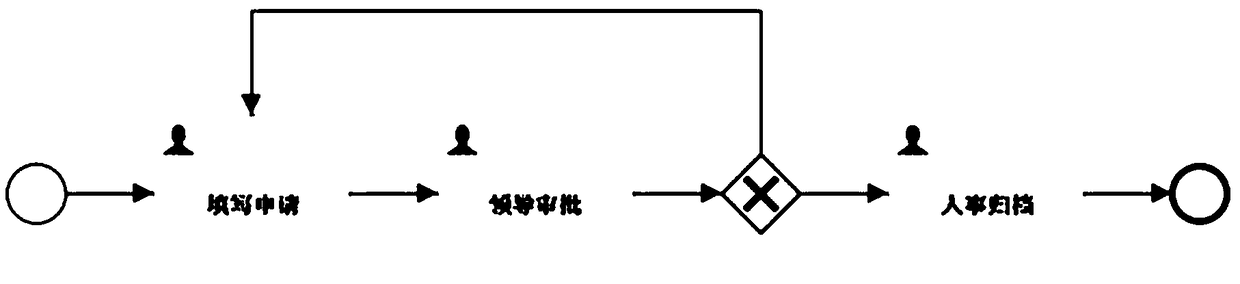

Activiti flowchart redrawing method, apparatus, computer device and storage medium

InactiveCN109343924AImplement refactoringSolve functionOffice automationExecution for user interfacesComputer science

The embodiment of the invention discloses a redrawing method of an Activiti flowchart, The method comprises the following steps: identifying at least one element to be redrawn in an Activiti flowchartexample, and obtaining drawing reference information of the element to be redrawn, wherein the drawing reference information comprises a drawing position; In the drawing canvas, the element to be redrawn is redrawn at a drawing position corresponding to the element to be redrawn according to a reconstructed element in the SVG form matching the element to be redrawn to obtain a target flowchart. The technical proposal of the embodiment of the invention realizes the reconstruction of the Activiti flowchart, so as to enrich the function of the task node in the Activiti flowchart and improve theaesthetics of the Activiti flowchart.

Owner:RUN TECH CO LTD BEIJING

Preparation method for colored foamed ceramic sheet material by utilizing polished waste slag

InactiveCN105732078AGood weather resistanceSolve the hazardCeramic materials productionCeramicwareFoaming agentMold filling

The invention relates to a preparation method for a colored foamed ceramic sheet material by utilizing polished waste slag. The method mainly solves the problem of hazard to the environment due to waste material discharge of ceramic production enterprises which mainly produce polished tiles. The method prepares the colored foamed ceramic sheet material capable of being used as a decorative material for interior and exterior walls by using the polished waste slag as a raw material through addition of a certain amount of auxiliary materials like purple clay, ceramic pigment and a foaming agent, ball milling and mixing treatment, mold filling and shaping, and high-temperature sintering at about 1200 DEG C, wherein the material has stable and adjustable color, a volume weight of 0.3 to 0.45 g / cm3 and a thermal conductivity of 0.06 to 0.12 w / (m / k). The preparation method provided by the invention has characteristics like low cost, high additional value, good durability, convenient construction and good fireproof performance, realizes integration of environmental friendliness and beautiful appearance of a decorative sheet material used for building, greatly simplifies construction process, and can be extensively applied in the field of decorative materials for interior and exterior walls.

Owner:LIAONING LIMENG HI TECH NEW MATERIAL

Process method for coating molding of metal sheet

ActiveCN104985392AExtended service lifeAvoid deforestationLaminationLamination apparatusCorrosion resistantMetallic materials

The invention relates to a process method for coating molding of a metal sheet. The method includes following steps: A. the metal sheet is cut, and a sheet metal member provided with bending edges is machined; B. the surface of the sheet metal member is bonded with a PVC decoration film, and the PVC decoration film at the bending edges is inwardly folded; C. secondary bending forming is performed, the PVC decoration film at the connecting positions of adjacent bending edges is pressed into slits formed by bending, and a bending member is formed; D. a metal plate matched with the bending member is machined, and the surface of the metal plate is bonded with the PVC decoration film; and E. the metal plate is bonded to the bending member, and the metal plate by coating molding is obtained. Compared with the prior art, according to the method, the cost is lowered, the problems of the ugly product surface made of metal materials and the exposure of cross sections can be solved, the method is more environmentally-friendly and safer, the machined metal plate are corrosion-resistant, moisture-resistant, and deformation-resistant, the service lifetime of the product is extended, timber products in various fields can be replaced and recycled, and the method is in accordance with the national calls of energy saving and emission reduction and environment protection.

Owner:成都翱岳钣金制造有限公司

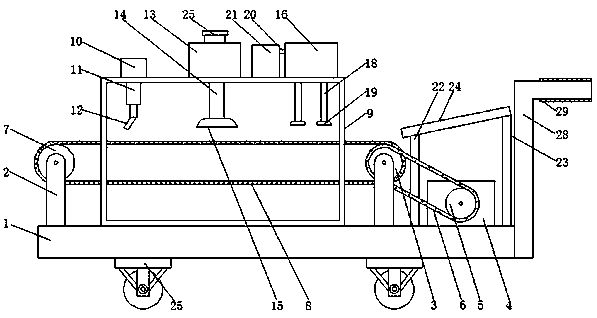

Spraying device for coating

The invention discloses a spraying device for a coating. The device comprises a base, wherein supporting columns are fixedly connected to the left and right sides of the top of the base; a first driven wheel is hinged to the top end of the supporting column on the right side of the top of the base; a motor is fixedly connected to the right side of the top of the base; a driving wheel is fixedly connected to the motor in a sleeving manner through a rotary shaft at one end of the motor; the driving wheel is in transmission connection to the first driven wheel through a first conveyor; a second driven wheel is hinged to the top end of the supporting column on the left side of the top of the base; and a second conveyor belt is in transmission connection to the surface of the second driven wheel. According to the spraying device for the coating, the coating on the surface of a coated product is brushed flatly uniformly by arranging an electric push rod and a brush plate, so that the problemthat the spraying device sprays the coating unevenly is solved. By arranging a material storage room, a first connecting pipe, a nozzle and a through hole, the coating can be more uniformly sprayed to the surface of the product, so that the spraying device sprays the coating more uniformly.

Owner:佘峰

Guide rail type ship shore power charging device

ActiveCN111064255ARealize automatic dockingImprove charging efficiencyBatteries circuit arrangementsElectric powerUltrasonic sensorElectric machine

The invention discloses a guide rail type ship shore power charging device. The device comprises guide rails and a vehicle capable of sliding back and forth on the two guide rails, a mechanical arm mechanism is mounted on the vehicle, and a charging structure is mounted at the front end of the mechanical arm mechanism. The charging structure comprises a plug, an infrared sensor, an ultrasonic sensor, a guide sleeve, a limiting sleeve and a positioning sleeve. The limiting sleeve is connected with the plug through a hose. The positioning sleeve and the limiting sleeve realize rotary clamping connection or separation through the matching effect of a motor and an air cylinder. An embedded hole for a cable for supplying power to the charging structure to penetrate through is embedded between the two guide rails, a cable winch for winding and unwinding the cable is installed at the end point of one end of each guide rail, and limiting pieces for preventing the vehicle from rushing out of the guide rails are installed at the end points of the two ends of each guide rail respectively. Automatic butt joint of the charging plug and the charging interface on the ship is achieved, the automation degree of port operation is improved, and damage to the charging plug and the charging interface of the ship due to violent fluctuation of the water surface during charging is prevented.

Owner:ZHEJIANG TUNA ENVIRONMENTAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com