Solar panel with honeycomb-shaped colored coating, production method of solar panel and colored solar photovoltaic module

A solar panel and color coating technology, applied in the field of solar photovoltaics, can solve the problems of the coating being unable to cover the black matrix of the cells, burning the solar modules, and the difference in light transmittance, and reducing the probability and process of burning the photovoltaic modules. Simple, ensure the effect of light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

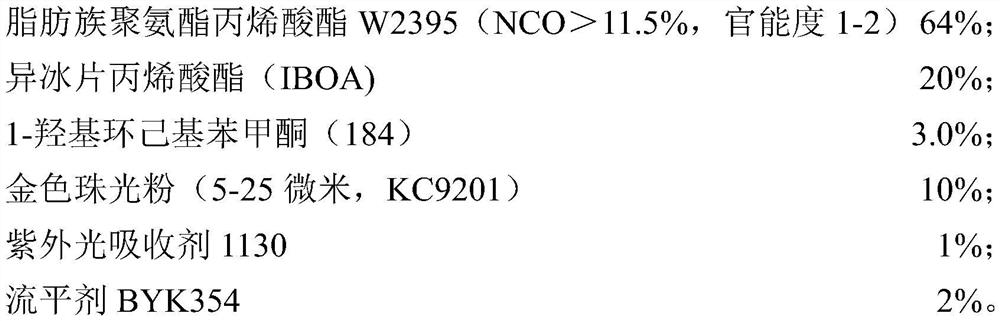

[0058] Honeycomb golden UV coating formula (mass percentage of raw materials):

[0059]

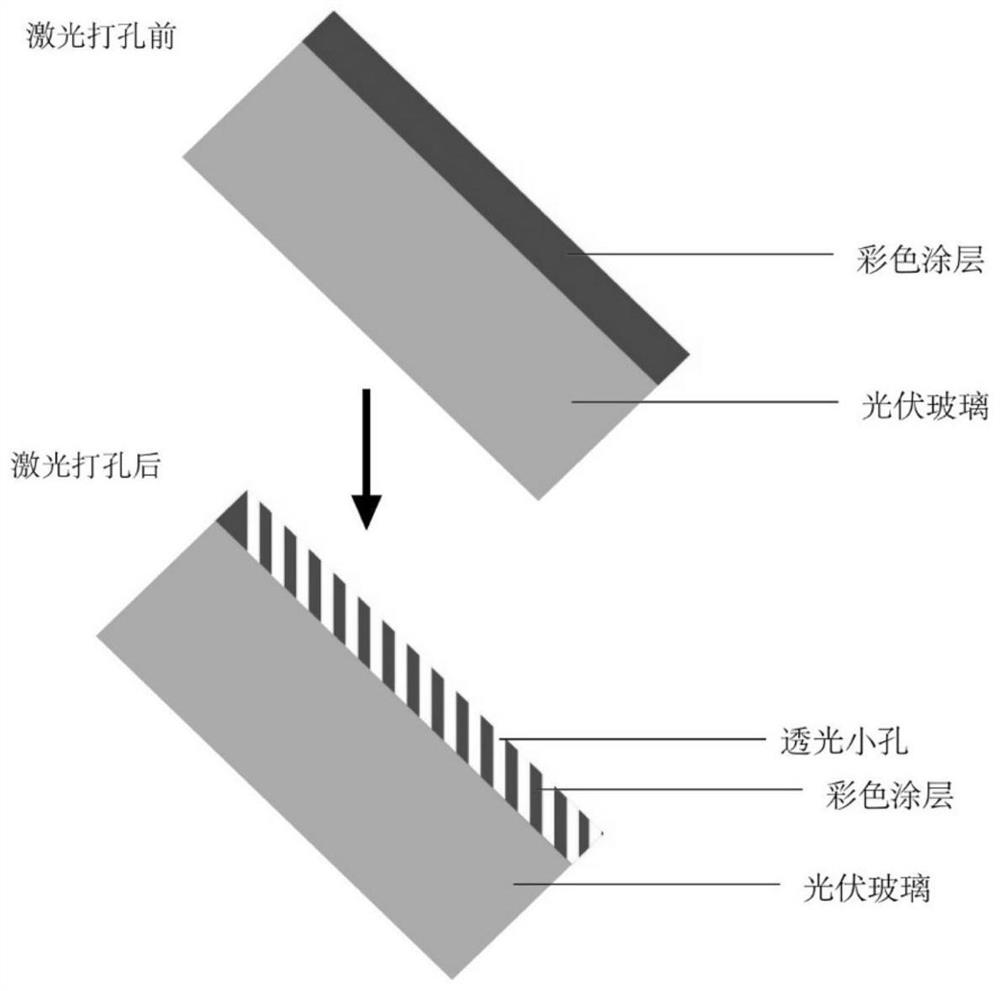

[0060] Stir the components in the above formula evenly, and print the above color coating on the surface of photovoltaic glass with a 200-mesh screen to obtain a color coating with a thickness of 25 microns; preheat at 50°C for 30 seconds to fully defoam and level the coating; UV light curing, the irradiation energy is 800 mJ / cm2; use a green laser with a wavelength of 532 nm and a power of 10 watts to drill holes at an angle of 45 degrees to the glass, with a diameter of 15 microns and a ratio of hole to coating area of 10%; The glass after the hole was placed at room temperature for 18 hours to dry naturally, and a honeycomb golden solar glass panel was obtained. When viewed from a distance, it is golden glass with uniform color, and physical and chemical indicators such as light transmittance are measured, see attached table 1.

Embodiment 2

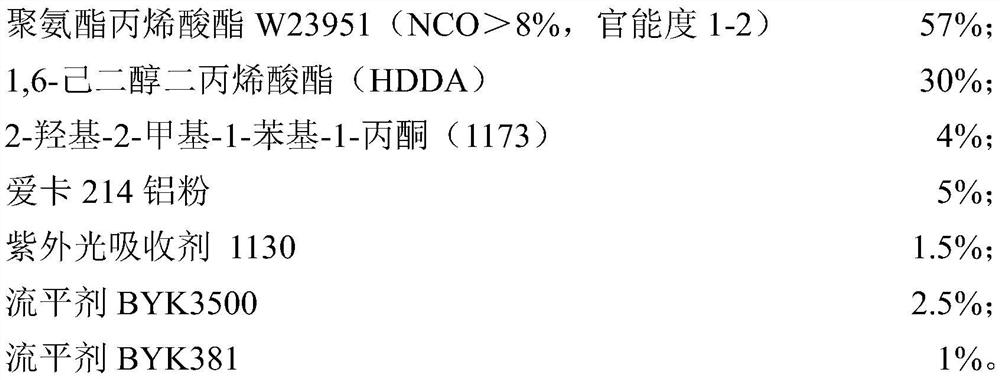

[0062] Honeycomb silver UV coating formula (mass percentage of raw materials):

[0063]

[0064] Stir the components in the above formula evenly, and apply a color coating with a thickness of 18 microns on the surface of photovoltaic glass by roller coating method; preheat at 50°C for 30 seconds to fully defoam and level the coating; UV light curing, irradiation energy 600 Millijoules / square centimeter; After photocuring, the glass is drilled with a green laser with a wavelength of 532 nm and a power of 10 watts at an angle of 45 degrees to the glass. The hole diameter is 15 microns, and the ratio of the hole to the coating area is 20%; The glass was placed at room temperature for 24 hours to further dry and solidify the coating, and a honeycomb silver solar glass panel was obtained. From a long distance, it is a uniform silver coating. From a close view, there are many oblique light-transmitting small holes on the surface of the coating. The physical and chemical indicator...

Embodiment 3

[0066] Honeycomb white UV coating formula (mass percentage of raw materials):

[0067]

[0068] Stir the components in the above formula evenly, and print the above color coating on the surface of photovoltaic glass with a 200-mesh screen plate to obtain a color coating with a thickness of 22 microns; preheat at 50°C for 30 seconds to fully defoam and level the coating; UV light curing, irradiation energy 1000 mJ / cm2. Use a green laser with a wavelength of 532 nm and a power of 10 watts to drill holes at an angle of 45 degrees to the glass. The hole diameter is 15 microns, and the ratio of the hole to the coating area is 25%. After the hole is placed at room temperature for 36 hours, it is naturally dried and cured. The white honeycomb glass coating is prepared, and it is white glass with uniform color when viewed from a long distance. There are many oblique light-transmitting small holes distributed on the surface of the coating when viewed from a close distance. The physi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com