Structure of portable casual shoes and manufacturing process for portable casual shoes

A casual shoe, lightweight technology, applied in the direction of shoe-making machinery, footwear, adhesive shoe parts, etc., can solve the problems of wrinkling, degumming midsole, etc., to avoid damage, solve the bond firmness and smoothness and beauty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

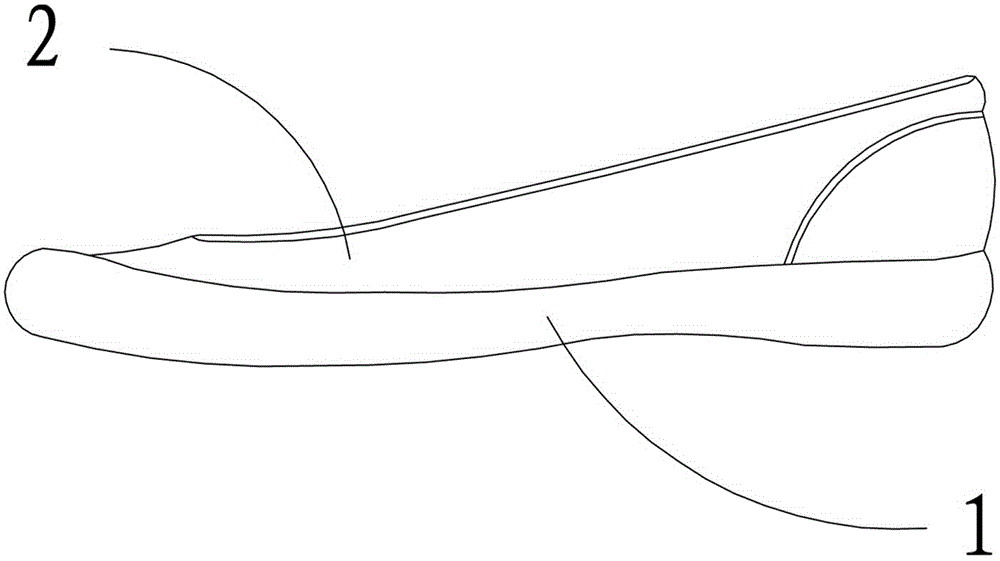

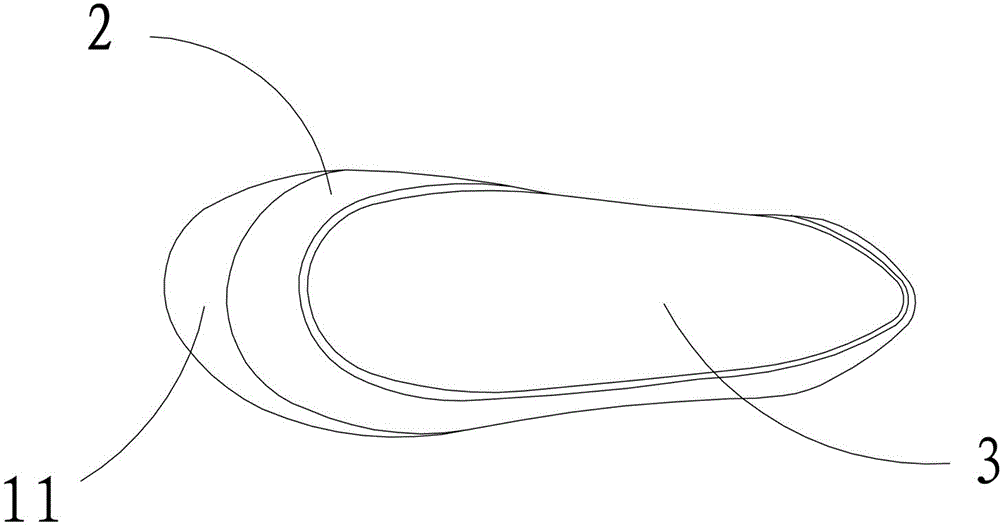

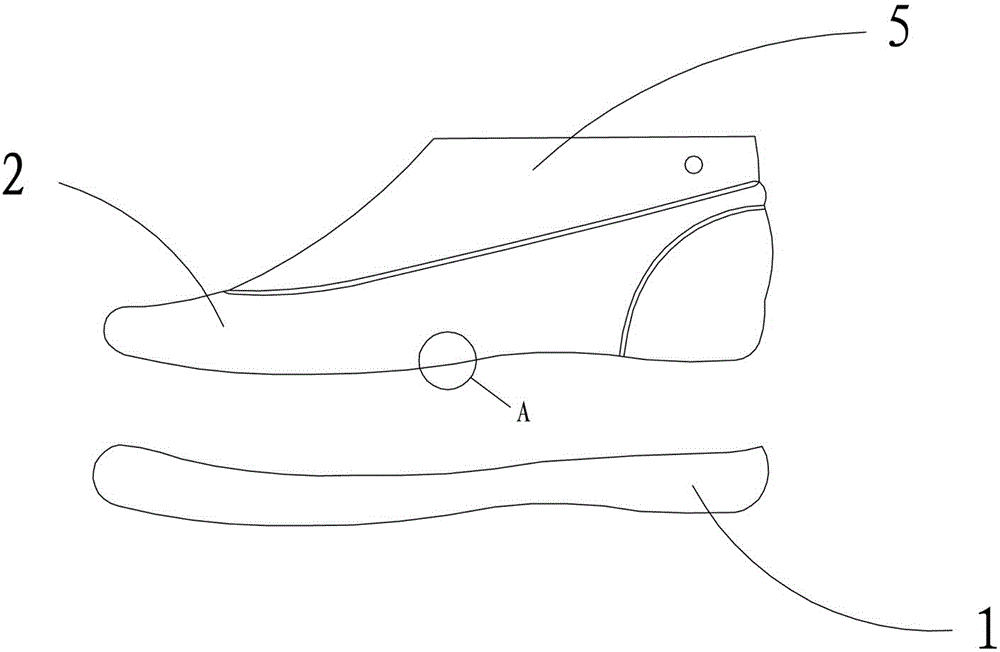

[0023] See Figure 1 to Figure 6 , Is a light casual shoe, including a sole 1, an upper 2 and a midsole 3. The lower edge of the upper 1 and the side edges of the midsole 3 are stitched into one body. The sole 1 is made of lightweight EVA sole The upper 2 and the midsole 3 are made of Lycra elastic fabric, wherein the upper 2 is made of a single-layer thickened fabric, and can be heat-transferred various patterns on the upper to make The upper is more beautiful, the midsole 3 is made of lycra and canvas double-layer fabric. The sole 1 is glued to the lower surface of the midsole and the outer lower edge of the upper by glue. When the lower edge of the upper 2 and the edge of the midsole 3 are stitched, the outer margin 4 has a width h of approximately 1-1.5 mm, the front end of the sole 1 is provided with a rearward flanging structure 11 for wrapping the toes.

[0024] The above-mentioned manufacturing process of casual shoes includes the following steps:

[0025] a. First make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com