Guide rail type ship shore power charging device

A charging device and rail-type technology, which is applied to battery circuit devices, circuit devices, collectors, etc., can solve the problems of increasing the work intensity of operators, slow interface installation speed, affecting the movement of personnel and vehicles, etc., to solve the problem of potential safety hazards And aesthetic problems, improve the degree of automation, improve the effect of charging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

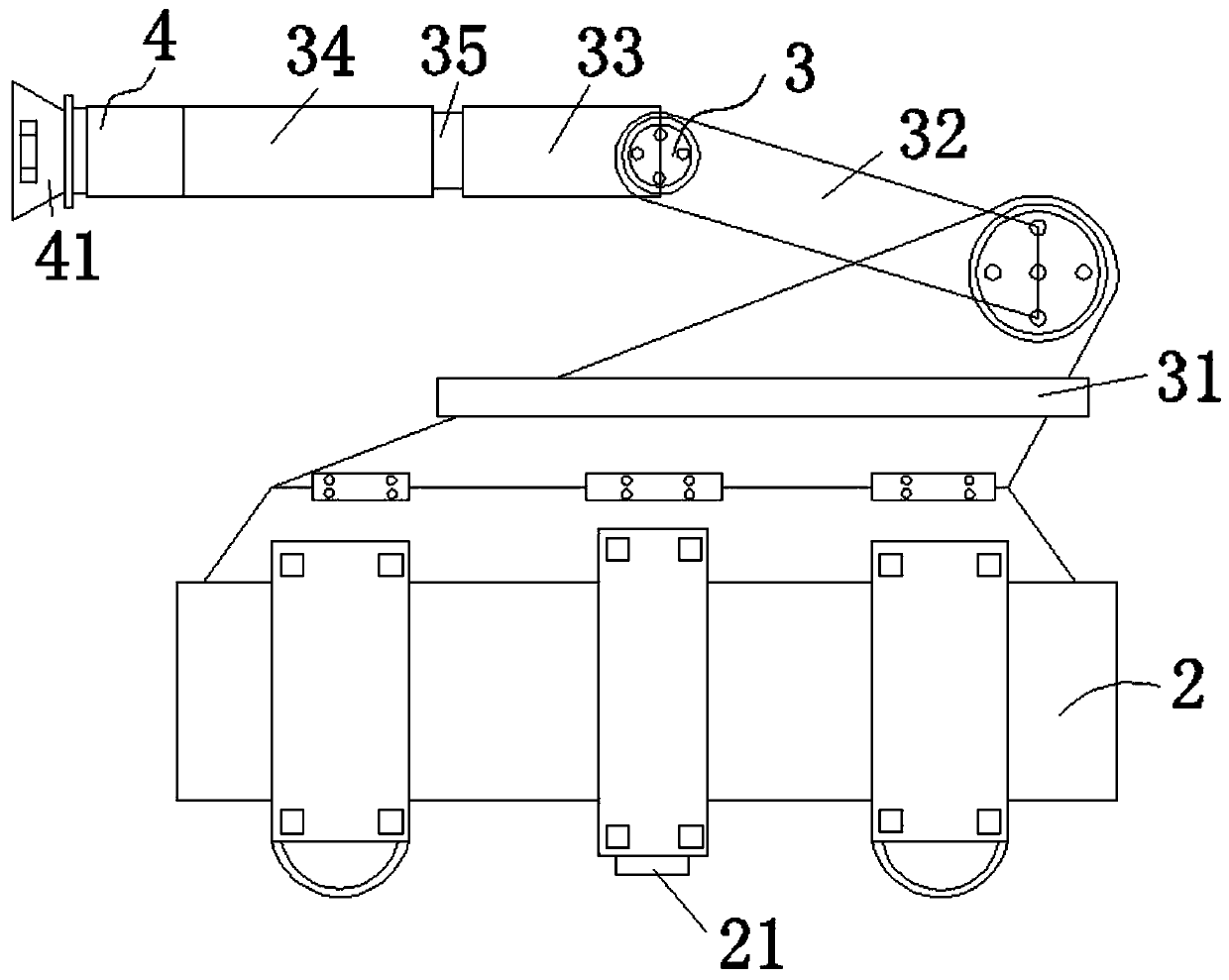

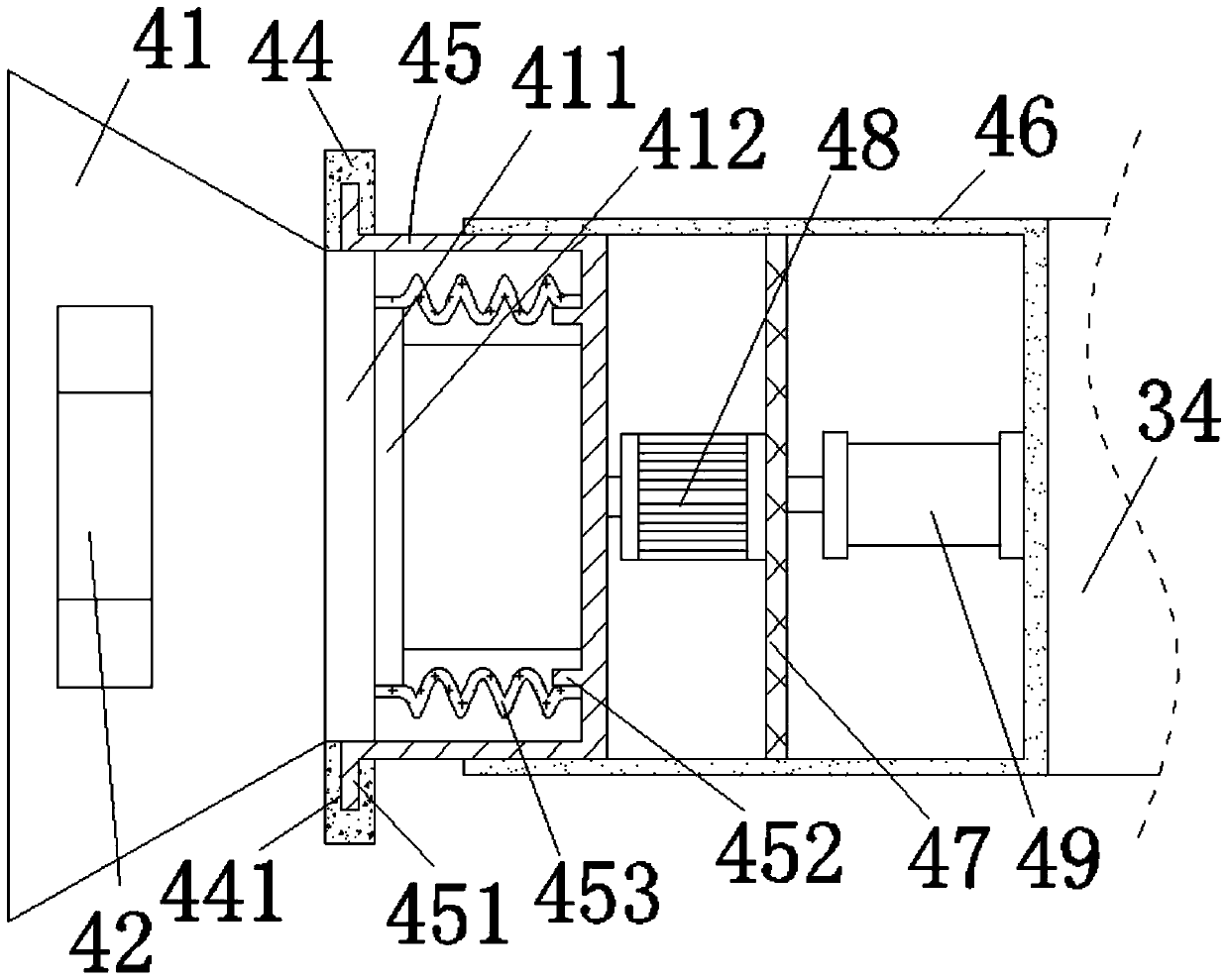

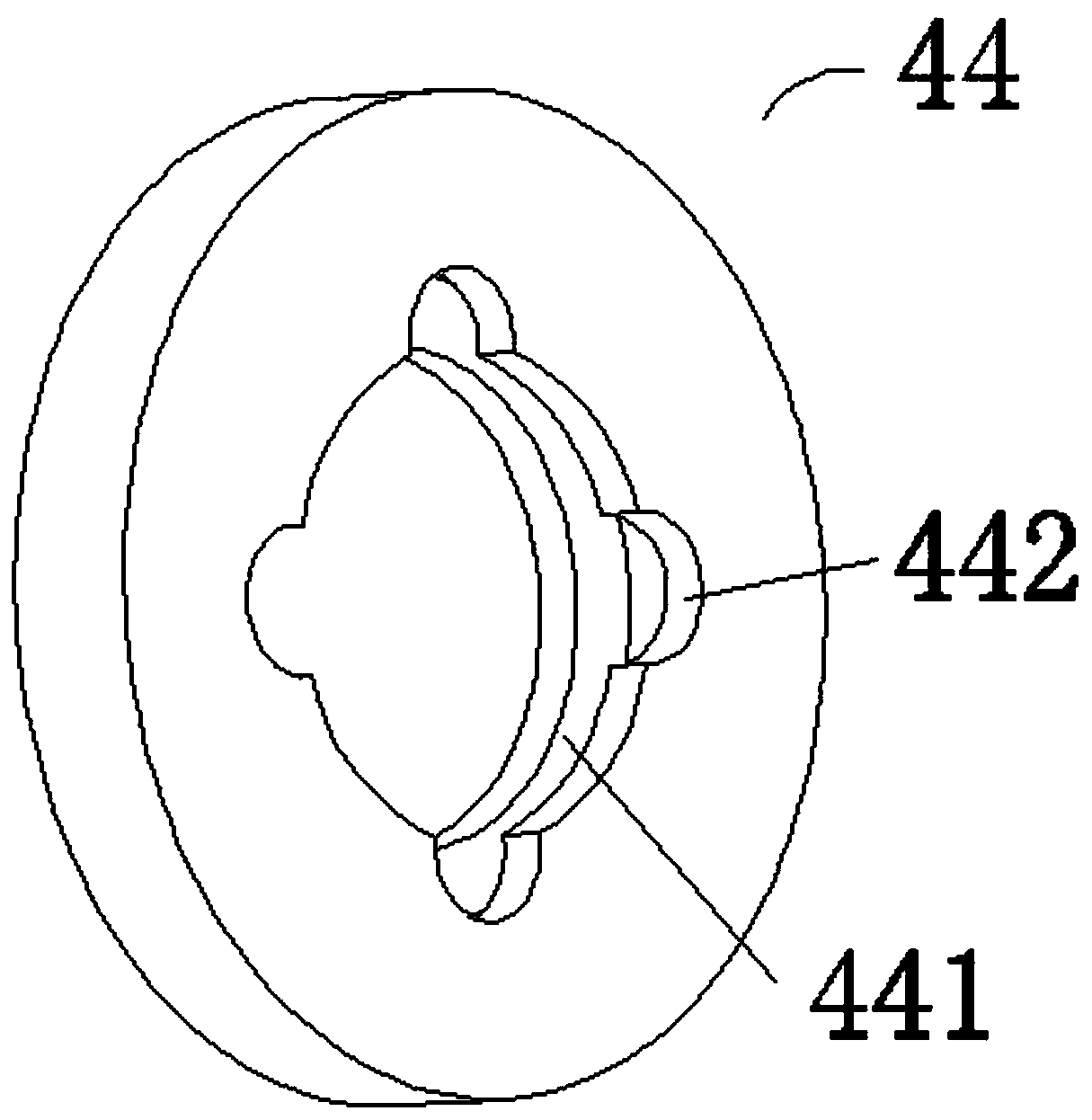

[0023] Such as Figure 1 to Figure 7 As shown, a guide rail type ship shore power charging device includes two parallel guide rails 1 and a vehicle 2 that can slide back and forth on the two guide rails 1, and a four-degree-of-freedom mechanical arm mechanism 3 is installed on the vehicle 2 The front end of the mechanical arm mechanism 3 is equipped with a charging structure 4, the charging structure 4 includes a plug 41, an infrared sensor 42 and an ultrasonic sensor 43 respectively installed on both sides of the front end of the plug 41 housing, fixed with the front end of the mechanical arm mechanism 3 The connected guide sleeve 46, the limit sleeve 45 that can be rotatably and slidably embedded in the annular inner wall of the guide sleeve 46, and the positioning sleeve 44 that is fixedly sleeved on the outer wall of the middle part of the plug 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com